3.1. Tractor Stability Parameters

Considering the technical parameters of the experimental tractor, the coordinates of COG and the static overturning angle were calculated according to standard [

12], as listed in

Table 2. The lateral positions of COG

z of 0.0038 m and 0.0043 m were calculated in case of the standard and extended overall width on tyres. The value of this parameter is relatively low in regarding to other tractor dimensions, but it was used for next calculations by the reason of systematic errors elimination.

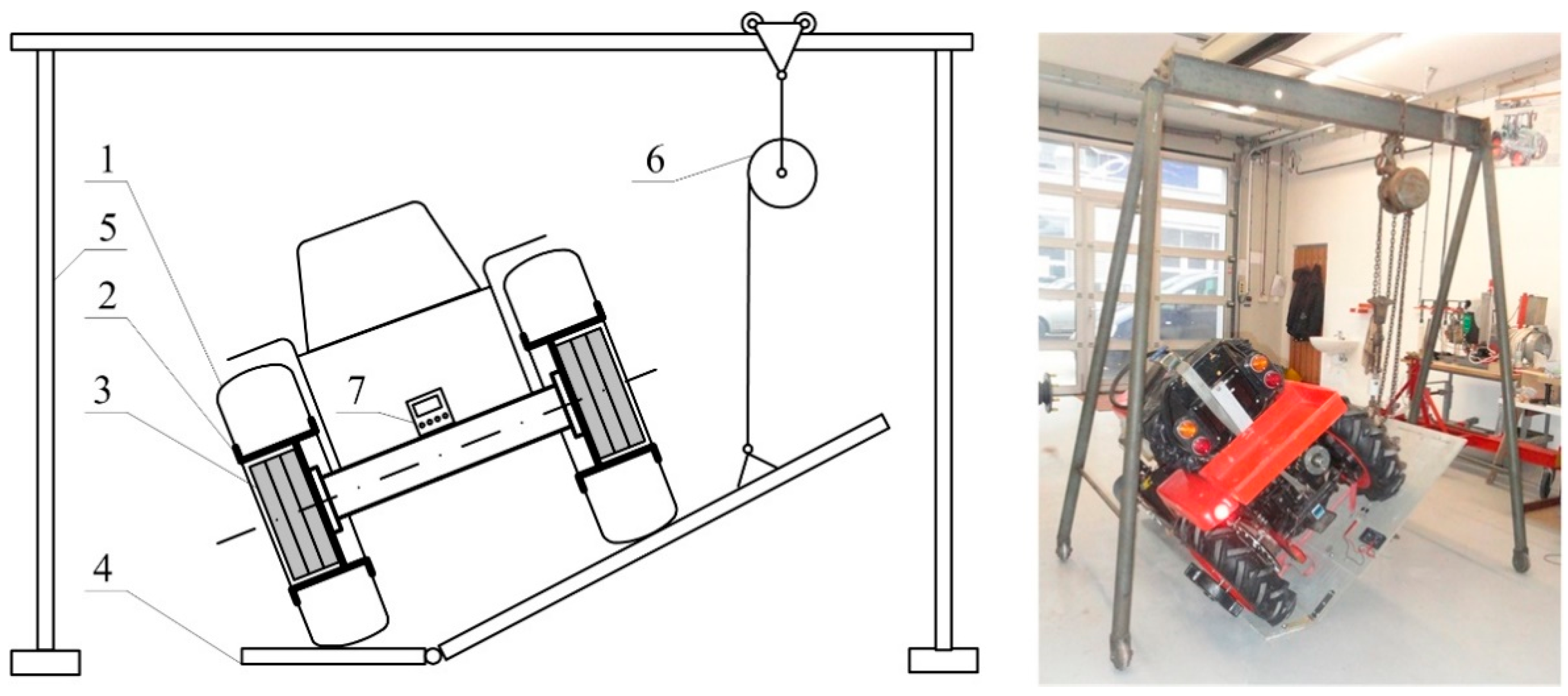

The static overturning angle was measured under experimental conditions. Using the tilting platform and the portal crane, the experimental tractor with right wheels touching the ground was tilted. When the tractor was inclined at the moment when it is resting in a state of unstable equilibrium, the experimental static overturning angle (

Table 3) was measured by the digital protractor. Experiments were carried out with various rear wheel ballast weights at two overall widths on tyres. An increase in load causes an increase in tyre deformation characterized by the vertical distance of tyre section height

i and distance

v, as listed in

Table 3.

The effect of rear wheel ballast weight on the stability parameters, namely the vertical and longitudinal coordinates of COG and static overturning angle, was statistically analysed at standard and extended overall width on tyres. [

23] confirmed the fact that the choice of selection of the rear track width in the stability of vehicles working on side sloping terrains is indeed a very important one. The rear wheel ballast weight was selected as an independent variable for regression analysis. Considering the 95% confidence interval, a statistically significant relationship between the variables was stated because the

p-values of fitting a linear regression model (

Figure 8) were lower than 0.05. The regression coefficients

R2 of linear regressions were higher than 0.99. The statistical significance demonstrated the effect of the rear wheel ballast weight on the static overturning angle. This relationship allows predicting the tractor lateral stability at various rear wheel ballast weights. [

24] statistically analysed the effect of the weight of tractor protective structures on the vertical coordinate of the COG regarding the tractor lateral stability. Regression analysis showed a significant relationship between the protective structure weight and tractor stability. [

25] presented similar results in the paper aimed at the influence of the tractor weight on lateral stability. [

26] also verified that the ballast weight can substantially change the lateral and longitudinal stability angles.

3.2. Comparison of ISO 16231-2 (2015) with Experimental Data and Tyre Deformation Analysis

Differences between the static overturning angles calculated according to standard [

12] (

Table 2) and experimental data (

Table 3) at various rear wheel ballast weights are presented in

Figure 8. The difference reached the highest value in case of the highest rear wheel ballast weight. The lowest difference was observed in case of the tractor without any ballast weight. Considering different slopes of linear regression models, the influence of rear wheel ballast weight on the difference between the data calculated according to [

12] and experimental data are expressed by different constants of regression equations.

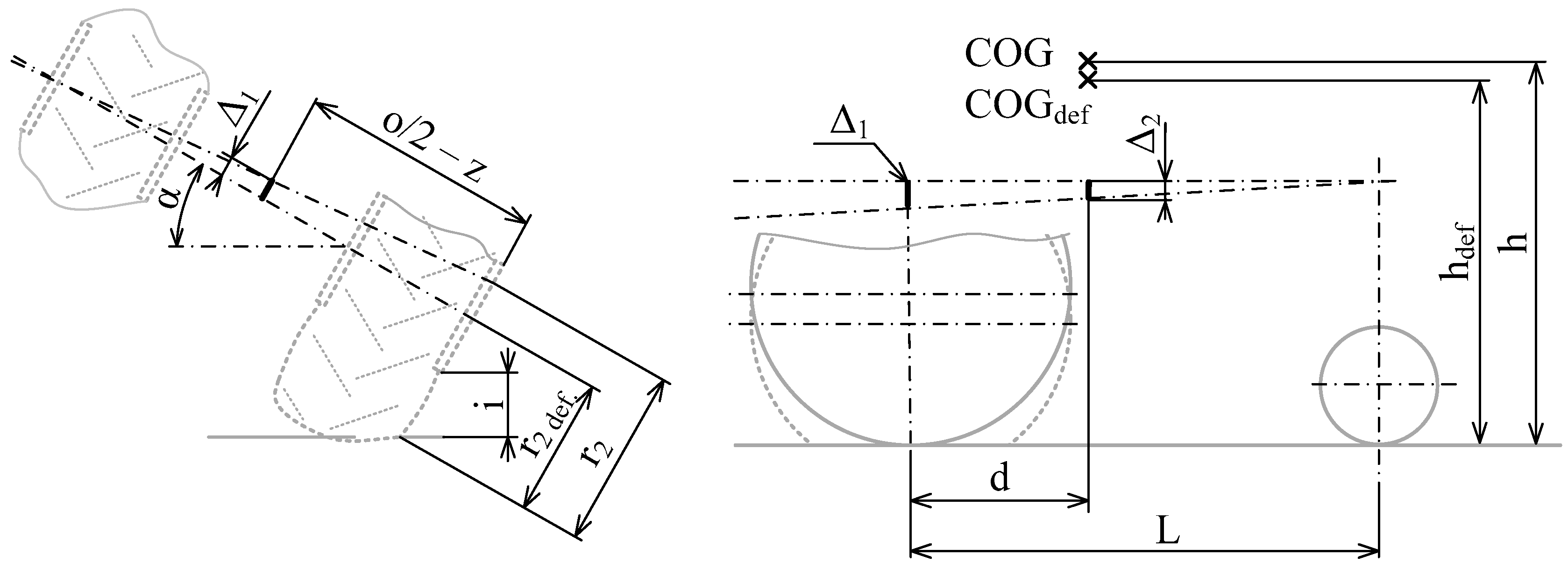

Practical experiments showed that the increase in rear wheel ballast weight affects the tyre deformation. When the tractor was tilted at the static overturning angle, the weight on the wheel touching the ground reached the maximal value. Therefore, the tyre deformation was measured in the state of unstable equilibrium. Using vertical distance of tyre section height

i (

Table 3), the parameters Δ

1 and Δ

2 were stated to calculate the vertical coordinate of COG and the static overturning angle considering the vertical tyre deformation (

Table 4). The vertical tyre deformation decreases the vertical coordinate of COG and increases the static overturning angle

α, as shown in

Figure 9. The experiments showed that this parameter improves the tractor lateral stability.

When the tractor was tilted at the experimental static overturning angle, the parameter

v (

Table 3) needed for calculation of the tyre shift due to the lateral tyre deformation, was measured. The tyre shift

m was calculated according to Equation (4), and the base line of the stability triangle

AA′ was calculated according to Equation (5), as listed in

Table 5. Considering the tyre shift, the base line of the stability triangle and the static overturning angle were decreased. The tyre shifts due to lateral tyre deformation negatively affected the tractor lateral stability,

Figure 10.

Considering both effects of tyre deformation, namely the vertical tyre deformation and the tyre shift, the calculation methodology according to standard [

12] was modified. The static overturning angles calculated in this way are presented in

Figure 11 and

Table 6 in case of the tractor with the standard and the extended overall width on tyres. The experiments presented a minimal decrease in the static overturning angle due to the tyre shift in comparison with an increase in it due to the vertical tyre deformation. The summary effect of the tyre deformation increased the static overturning angle.

Comparison of the experimental data with the data calculated according to [

12] considering the vertical tyre deformation and tyre shift showed lower difference than in case of [

12] ignoring the tyre deformation (

Table 7). Besides the measuring errors, the difference between data calculated according to [

12] and experimental data depends on the tyre deformation, regarding the results of experiments.

Considering the decrease in vertical coordinate of COG due to the vertical tyre deformation and the overall width on tyres due to tyre shift, the calculation method according to [

12] was improved because the difference between calculated and experimental data was decreased. The constants of the regression equations (

Figure 11) showed the different slope of the linear models of the calculated and experimental data. The difference between calculated and experimental data increases when the rear wheel ballast weight increases. The tyre deformation is a complex problem defined by various parameters ([

27,

28]). To detailly describe the tyre deformation and eliminate the increase in difference between the calculated and the experimental data due to the increase in the rear wheel ballast weight, complex measurements are needed. Regarding small absolute values of the percentage difference, there is no point in next complex measurements.

The results showed the difference between the experimental data and calculated according to [

12] due to tyre deformation. In practice, this difference is not dangerous because the tyre deformation decreases the vertical coordinate of COG, increases the static overturning angle and therefore improves the tractor’s lateral stability. [

19] studied the changes in lateral overturning angle by movement of the centre of gravity coordinates due to asymmetric connection of the harvest system to the tractor. The study of these authors presented a positive and negative change in static overturning angle at a decrease and increase in the vertical coordinate of COG.

The tyre contact patch was analysed according to the length of rubber lug

n and length of contact patch

u,

Figure 7c. The tyre footprints on the paper sheet showed the tyre contact patches of the tractor with various rear wheel ballast weights when the tractor was inclined at the static overturning angle. An example of the tyre contact patch of the tractor equipped with 122 kg of the rear wheel ballast weight (standard overall width on tyres

o = 0.795 m) is shown in

Figure 12.

Experimental measurements confirmed the fact that the rear wheel ballast weight affects the tyre deformation. Inclining the tractor at the experimental static overturning angle, the length of the tyre contact patch

u (

Table 8) depended on the rear wheel ballast weight due to the tyre deformation. The increase in the rear wheel ballast weight caused an increase in the length of contact patch (

Figure 13a). Nonlinear regression equations pointed out that the tyre deformation is a complex problem. The coefficients of determination

R2 higher than 0.98 and

p-values lower than the significance level of 0.05 present a significant effect of tyre deformation due to the rear wheel ballast weight on the length of the contact patch.

On the other hand, the results of experiments showed that the length of rubber lug

n (

Table 8) did not change at various rear wheel ballast weights,

Figure 13b). The coefficients of determination

R2 lower than 0.1 and

p-value higher than 0.05 express a statistically insignificant relationship between the rear wheel ballast weight and the length of the rubber lug. The increase in the rear wheel ballast weight causes an increase in the static overturning angle which compensates the increase in the length of the tyre rubber lug due to tyre deformation. Considering the experimental results, the dimensions of the tyre contact patch did not affect the calculation of the static overturning angle because the length of the contact patch

u did not affect the distance

AA′ and the length of rubber lug

n did not change.

The tractor overturns around the rolling point when it reaches the limit value of the static overturning angle and loses stability (equilibrium). [

6] present that the standard is intended for the calculation of static overturning angle in case of different tractor types with different agricultural tyres. Agricultural tyres are different in dimensions and elastic properties affecting the forces between the ground and tyre. The standard [

12] defines the position of the force below the tyre in the rolling point of the fixed axle as three quarters (0.75) of the tyre width (

Figure 4). If higher or lower value than 0.75 of tyre width

p is considered, the calculated value of static overturning angle is higher or lower because the length of the base line of the stability triangle

AA′ is changed. In the case of experimental tractor equipped with standard tyres, the higher inclination of the tractor (better lateral stability) due to higher wheel weight compensates the higher tyre deformation.