A Vehicle Guidance Model with a Close-to-Reality Driver Model and Different Levels of Vehicle Automation

Abstract

1. Introduction

2. Methodology

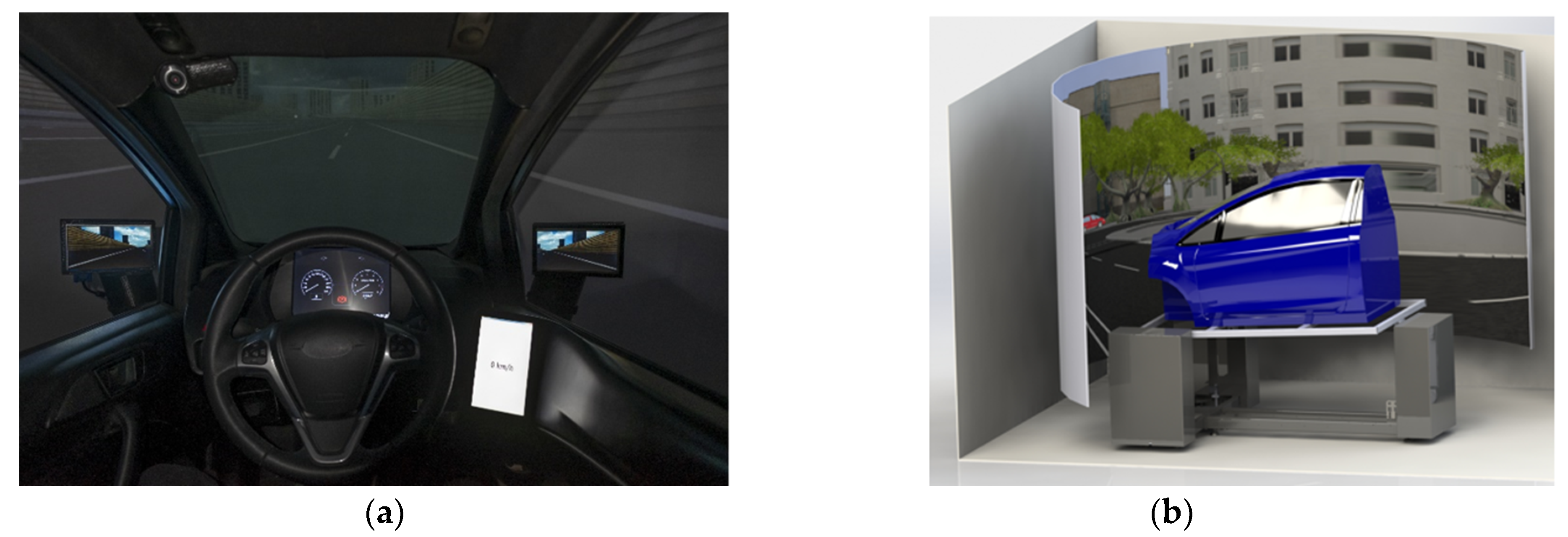

2.1. Participants and Driving Simulator

2.2. Experimental Arrangement

2.3. Data Analysis

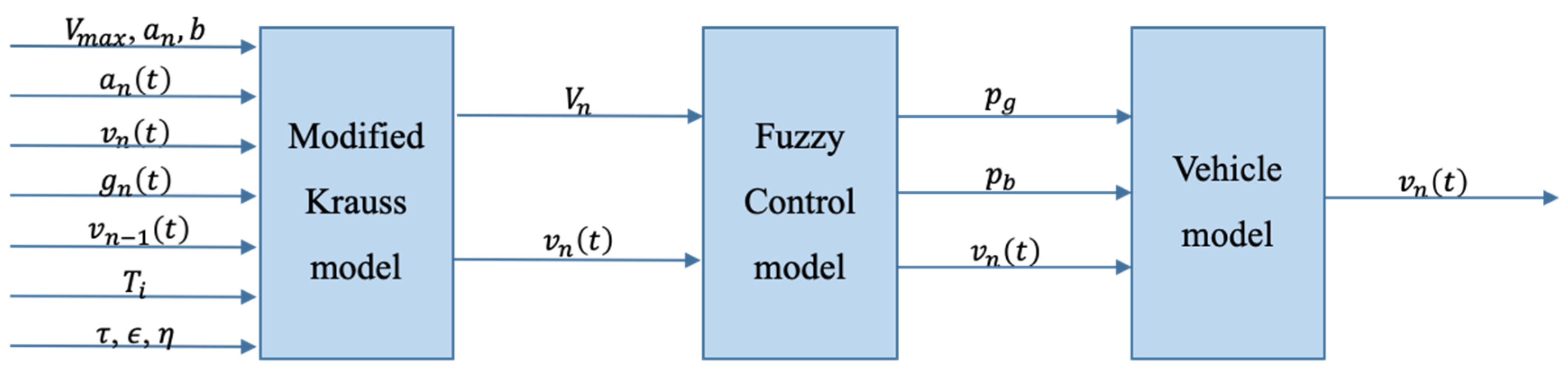

3. Driver Model

3.1. Modified Krauß Model

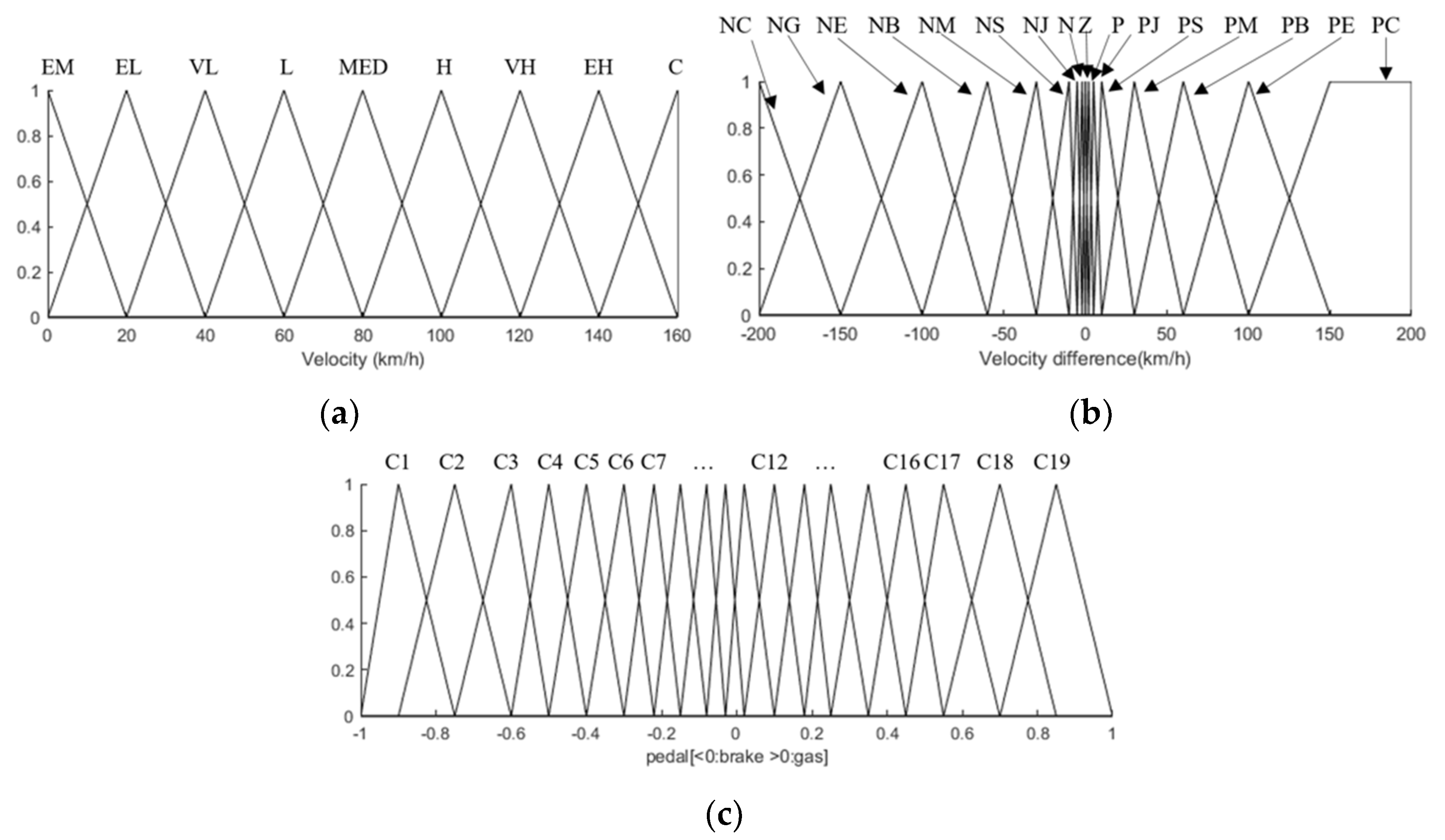

3.2. Fuzzy Model

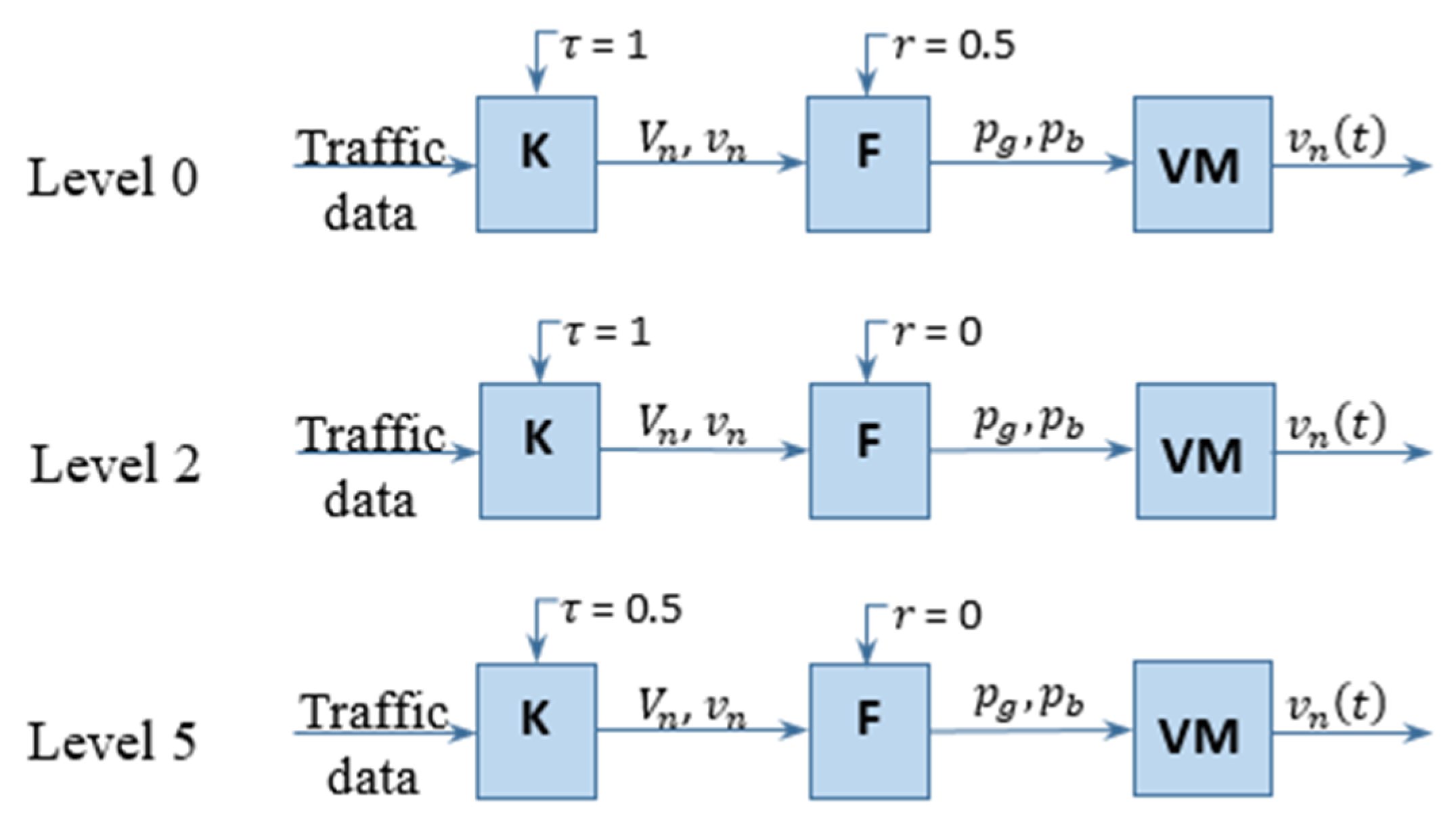

3.3. Vehicle Guidance Model with Different Degrees of Automation

4. Verification and Simulation

4.1. Simulation Scenario and Software

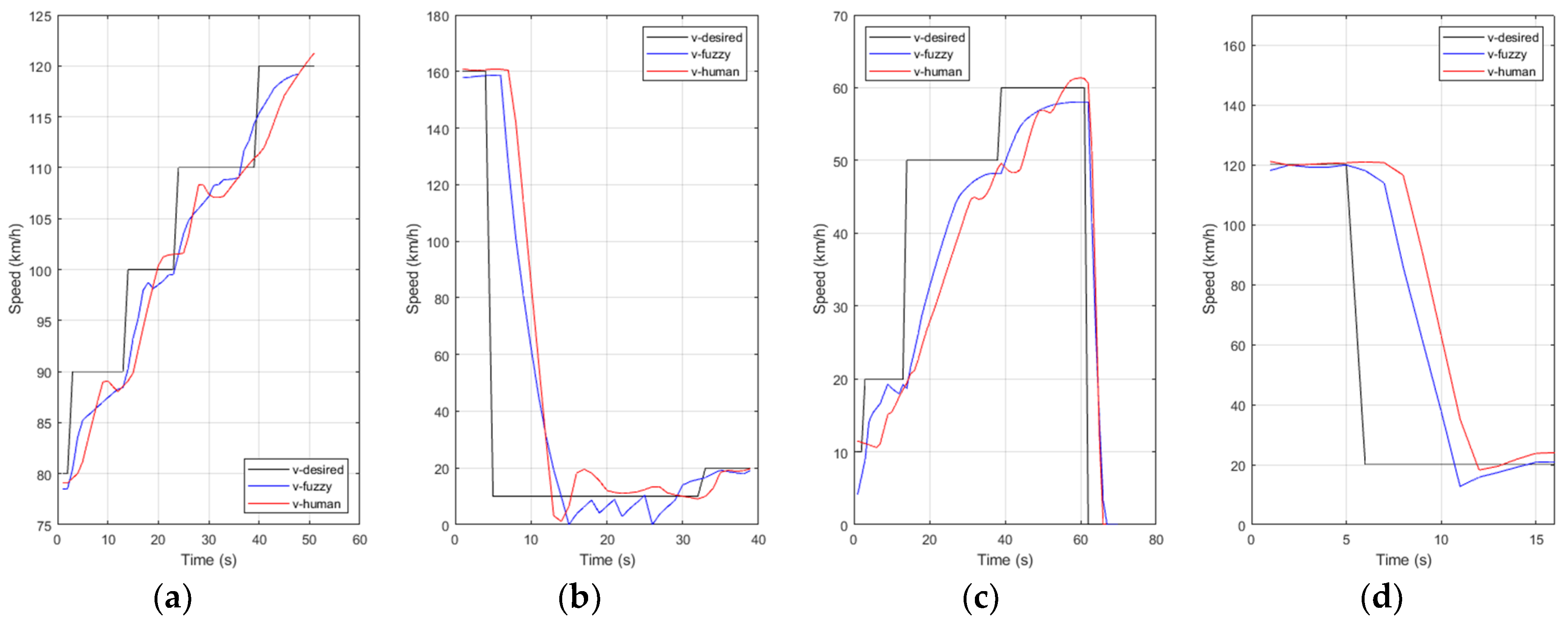

4.2. Comparison of Fuzzy Model and Human Driver Data

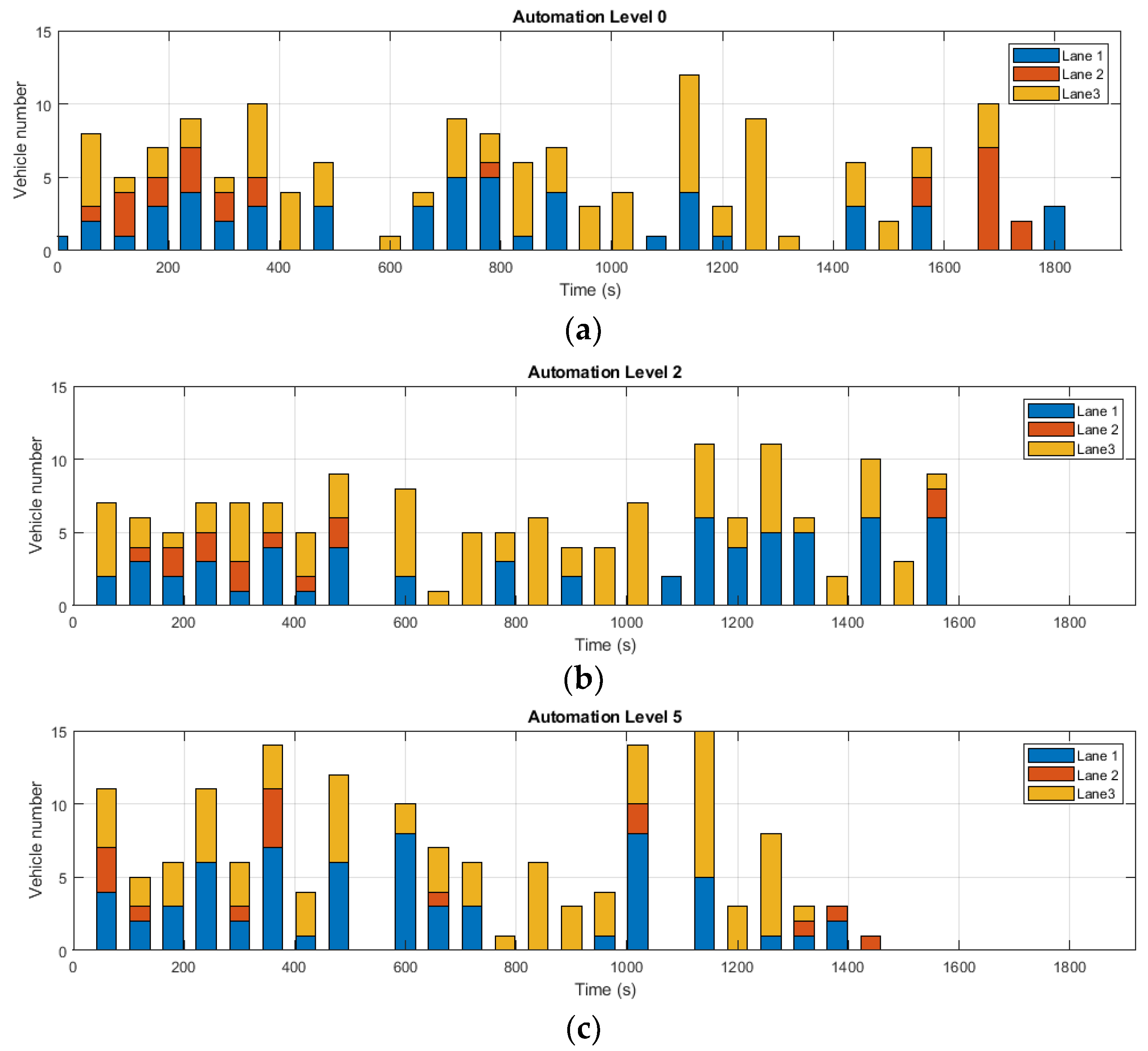

4.3. Comparison of Different Levels of Automation

5. Discussion and Future Scope

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gipps, P.G. A behavioural car-following model for computer simulation. Transp. Res. Part B: Methodol. 1981, 15, 105–111. [Google Scholar] [CrossRef]

- Krauß, S. Microscopic Modeling of Traffic Flow. Investigation of Collision Free Vehicle Dynamics; Als, G., Ed.; Zentrum für Luft- und Raumfahrt e.V., Abt. Unternehmensorganisation und -Information: Köln, Germany, 1998. [Google Scholar]

- Treiber, M.; Kesting, A. Traffic Flow Dynamics. Data, Models and Simulation; Springer: Berlin/Heidelberg, Germany, 2013; ISBN 978-3-642-32460-4. [Google Scholar]

- Chandler, R.E.; Herman, R.; Montroll, E.W. Traffic dynamics: Studies in car following. Oper. Res. 1958, 6, 165–184. [Google Scholar] [CrossRef]

- Pipes, L.A. An operational analysis of traffic dynamics. J. Appl. Phys. 1953, 24, 274–281. [Google Scholar] [CrossRef]

- Gazis, D.C.; Herman, R.; Rothery, R.W. Nonlinear follow-the-leader models of traffic flow. Oper. Res. 1961, 9, 545–567. [Google Scholar] [CrossRef]

- Wiedemann, R. Simulation des Strassenverkehrsflusses. 1974. Available online: https://trid.trb.org/view/596235 (accessed on 2 January 2021).

- Lu, Z.; Fu, T.; Fu, L.; Shiravi, S.; Jiang, C. A video-based approach to calibrating car-following parameters in VISSIM for urban traffic. Int. J. Transp. Sci. Technol. 2016, 5, 1–9. [Google Scholar] [CrossRef]

- Fabianova, J.; Michalik, P.; Janekova, J.; Fabian, M. Design and evaluation of a new intersection model to minimize congestions using VISSIM software. Open Eng. 2020, 10, 48–56. [Google Scholar] [CrossRef]

- Hayashi, K.; Shimizu, Y.; Dote, Y.; Takayama, A.; Hirako, A. Neuro fuzzy transmission control for automobile with variable loads. IEEE Trans. Control Syst. Technol. 1995, 3, 49–53. [Google Scholar] [CrossRef]

- Holve, R.; Protzel, P.; Naab, K. (Eds.) Generating Fuzzy Rules for the Acceleration Control of an Adaptive Cruise Control System. In Proceedings of the North American Fuzzy Information Processing, Berkeley, CA, USA, 19–22 June 1996; IEEE: Piscataway, NJ, USA, 1996. [Google Scholar]

- Naranjo, J.E.; González, C.; García, R.; de Pedro, T. ACC+ Stop&go maneuvers with throttle and brake fuzzy control. IEEE Trans. Intell. Trans. Syst. 2006, 7, 213–225. [Google Scholar]

- Pananurak, W.; Thanok, S.; Parnichkun, M. (Eds.) Adaptive cruise control for an intelligent vehicle. In Proceedings of the 2008 IEEE International Conference on Robotics and Biomimetics, Bangkok, Thailand, 22–25 February 2009; IEEE: Piscataway, NJ, USA, 2009. [Google Scholar]

- Chen, G.; Zhang, W.; Li, X.; Yu, B. Adaptive speed control method for electromagnetic direct drive vehicle robot driver based on fuzzy logic. Meas. Control 2019, 52, 1344–1353. [Google Scholar] [CrossRef]

- Maas, N.; Benjamin, H.; Martin, K.; Schramm, D. (Eds.) Simulator Setup According to Use Case Scenarios-A Human-Oriented Method for Virtual Development. In Proceedings of the 2014 IEEE/ASME 10th International Conference on Mechatronic and Embedded Systems and Applications (MESA), Senigallia, Italy, 10–12 September 2014; IEEE: Piscataway, NJ, USA, 2014. [Google Scholar]

- Maas, N. Konzeptionierung, Auslegung und Umsetzung von Assistenzfunktionen für die Übergabe der Fahraufgabe aus Hochautomatisiertem Fahrbetrieb. Ph.D. Thesis, Universitätsbibliothek Duisburg-Essen, Duisburg, Germany, 2017. [Google Scholar]

- Schweig, S.; Liebherr, M.; Schramm, D.; Brand, M.; Mass, N. (Eds.) The impact of psychological and demographic parameters on simulator sickness. In Proceedings of the SIMULTECH, Porto, Portugal, 29–31 July 2018. [Google Scholar]

- Lopez, P.A.; Behrisch, M.; Bieker-Walz, L.; Erdmann, J.; Flötteröd, Y.-P. (Eds.) Microscopic traffic simulation using sumo. In Proceedings of the 2018 21st International Conference on Intelligent Transportation Systems (ITSC), Maui, HI, USA, 4–7 November 2018; IEEE: Piscataway, NJ, USA, 2018. [Google Scholar]

- Wagner, P. Steuerung und Management in Einem Verkehrssystem mit Autonomen Fahrzeugen; Autonomes Fahren; Springer: Berlin/Heidelberg, Germany, 2015; pp. 313–330. [Google Scholar]

- Teichner, W.H. Recent studies of simple reaction time. Psychol. Bull. 1954, 51, 128. [Google Scholar] [CrossRef] [PubMed]

- Johansson, G.; Rumar, K. Drivers’ brake reaction times. Hum. Fact. 1971, 13, 23–27. [Google Scholar] [CrossRef] [PubMed]

- Orosz, G.; Wilson, R.E.; Krauskopf, B. Global bifurcation investigation of an optimal velocity traffic model with driver reaction time. Phys. Rev. E 2004, 70, 26207. [Google Scholar] [CrossRef] [PubMed]

| Vn | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NC | NG | NE | NB | NM | NS | NJ | N | Z | P | PJ | PS | PM | PB | PE | PC | ||

| vn | EM | C0 | C1 | C1 | C1 | C2 | C3 | C8 | C10 | C10 | C11 | C12 | C14 | C17 | C17 | C18 | C18 |

| EL | C0 | C1 | C1 | C1 | C2 | C3 | C8 | C10 | C10 | C11 | C13 | C14 | C14 | C17 | C18 | C18 | |

| VL | C0 | C1 | C1 | C1 | C3 | C3 | C10 | C10 | C11 | C11 | C13 | C14 | C15 | C17 | C18 | C18 | |

| L | C0 | C1 | C1 | C1 | C2 | C3 | C10 | C10 | C11 | C11 | C13 | C14 | C16 | C16 | C18 | C19 | |

| MED | C0 | C1 | C1 | C2 | C2 | C3 | C10 | C10 | C11 | C12 | C13 | C14 | C16 | C17 | C18 | C19 | |

| H | C0 | C1 | C1 | C2 | C2 | C4 | C11 | C11 | C11 | C12 | C13 | C14 | C16 | C17 | C18 | C19 | |

| VH | C0 | C1 | C1 | C2 | C3 | C4 | C11 | C12 | C13 | C13 | C14 | C15 | C16 | C17 | C18 | C19 | |

| EH | C0 | C1 | C2 | C2 | C3 | C4 | C11 | C12 | C13 | C13 | C14 | C15 | C16 | C17 | C18 | C19 | |

| C | C0 | C1 | C1 | C2 | C3 | C5 | C11 | C12 | C14 | C13 | C14 | C15 | C16 | C17 | C18 | C19 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, X.; Hu, X.; Schweig, S.; Pragalathan, J.; Schramm, D. A Vehicle Guidance Model with a Close-to-Reality Driver Model and Different Levels of Vehicle Automation. Appl. Sci. 2021, 11, 380. https://doi.org/10.3390/app11010380

Ma X, Hu X, Schweig S, Pragalathan J, Schramm D. A Vehicle Guidance Model with a Close-to-Reality Driver Model and Different Levels of Vehicle Automation. Applied Sciences. 2021; 11(1):380. https://doi.org/10.3390/app11010380

Chicago/Turabian StyleMa, Xiaoyi, Xiaowei Hu, Stephan Schweig, Jenitta Pragalathan, and Dieter Schramm. 2021. "A Vehicle Guidance Model with a Close-to-Reality Driver Model and Different Levels of Vehicle Automation" Applied Sciences 11, no. 1: 380. https://doi.org/10.3390/app11010380

APA StyleMa, X., Hu, X., Schweig, S., Pragalathan, J., & Schramm, D. (2021). A Vehicle Guidance Model with a Close-to-Reality Driver Model and Different Levels of Vehicle Automation. Applied Sciences, 11(1), 380. https://doi.org/10.3390/app11010380