A Review on the Importance of Microbial Biopolymers Such as Xanthan Gum to Improve Soil Properties

Abstract

1. Introduction

2. Biological Processes in Geotechnical Engineering

2.1. Application of Biopolymers in Soil Treatment

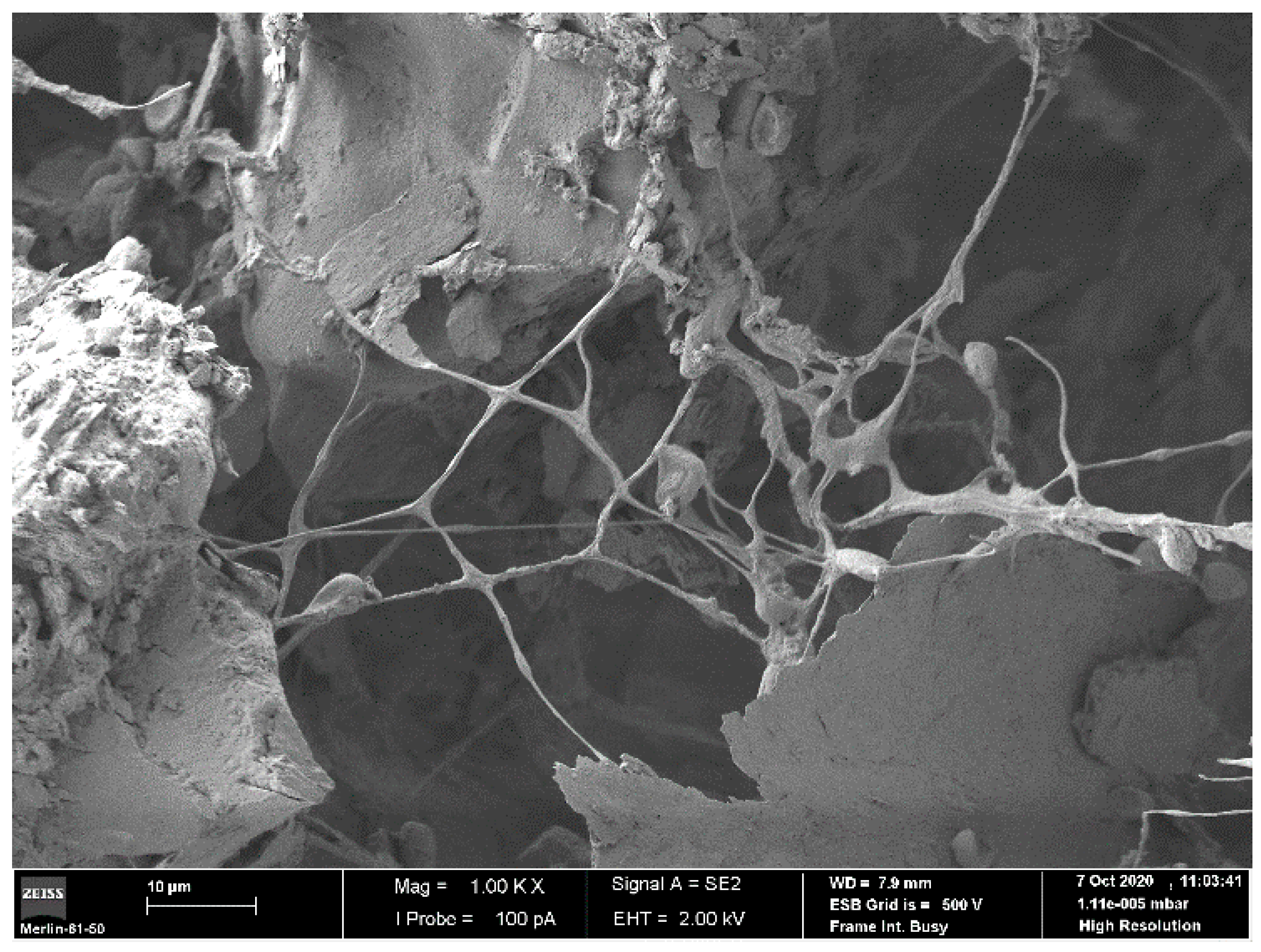

2.2. Soil–Biopolymer Interaction

3. Bioclogging Technique

3.1. Bioclogging as Solution in Geotechnical Engineering

3.2. Bioclogging Application: Benefits and Limitations

4. Xanthan Gum Biopolymer

4.1. Xanthomonas Campestris Species

4.2. General Features

4.3. Effects of Xanthan Gum on Soil Properties for Geotechnical Engineering

4.3.1. Mechanical Properties

4.3.2. Permeability

4.3.3. Stability and Durability

4.3.4. Other Properties

5. Conclusions and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chang, I.; Im, J.; Cho, G.-C. Introduction of microbial biopolymers in soil treatment for future environmentally friendly and sustainable geotechnical engineering. Sustainability 2016, 8, 251. [Google Scholar] [CrossRef]

- Ivanov, V.; Chu, J. Applications of microorganisms to geotechnical engineering for bioclogging and biocementation of soil in situ. Rev. Environ. Sci. Biotechnol. 2008, 7, 139–153. [Google Scholar] [CrossRef]

- Murphy, E.M.; Ginn, T.R. Modeling microbial processes in porous media. Hydrogeol. J. 2000, 8, 142–158. [Google Scholar] [CrossRef]

- Basu, D.; Misra, A. Sustainability in Geotechnical Engineering. In Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering, Paris, France, 2–6 September 2013. [Google Scholar] [CrossRef]

- Narjary, B.; Aggarwal, P.; Singh, A.; Chakraborty, D.; Singh, R. Water availability in different soils in relation to hydrogel application. Geoderma 2012, 187–188, 94–101. [Google Scholar] [CrossRef]

- Murthy, V.N.S. Geotechnical Engineering: Principles and Pratices of Soil Mechanics and Foudation Engineering; Marcel Dekker, Inc.: New York, NY, USA, 2016. [Google Scholar]

- Baveye, P.; Vandevivere, P.; Blythe, L.H.; DeLeo, P.; Sanchez, L.D. Environmental Impact and Mechanisms of the Biological Clogging of Saturated Soils and Aquifer Materials. Crit. Rev. Environ. Sci. Technol. 2010, 28, 123–191. [Google Scholar] [CrossRef]

- Velde, K.V.D.; Kiekens, P. Biopolymers: Overview of several properties and consequences on their applications. Polym. Test. 2002, 21, 433–442. [Google Scholar] [CrossRef]

- Choi, S.; Chang, I.; Lee, M.; Lee, J.; Han, J.; Kwon, T. Review on geotechnical engineering properties of sands treated by microbially induced calcium carbonate precipitation (MICP) and biopolymers. Constr. Build. Mater. 2020, 246, 118415. [Google Scholar] [CrossRef]

- Jose, A.; Carvalho, F. Starch as Source of Polymeric Materials. In Biopolymers: Biomedical and Environmental Applications; Wiley: Salem, MA, USA, 2011. [Google Scholar]

- Khachatoorian, R.; Petrisor, I.G.; Khan, C.C.; Yen, T.F. Biopolymer plugging effect: Laboratory-pressurized pumping flow studies. J. Petroleum. Sci. Eng. 2013, 38, 13–21. [Google Scholar] [CrossRef]

- Smitha, S.; Sachan, A. Use of agar biopolymer to improve the shear strength behavior of sabarmati sand. Int. J. Geotech. Eng. 2016, 10, 387–400. [Google Scholar] [CrossRef]

- Mataix-Solera, J.; Guerrero, C.; Hernandez, M.T.; Garcıa-Orenes, F.; Mataix-Beneyto, J.; Gomez, I.; Escalante, B. Improving soil physical properties related to hydrological behaviour by inducing microbiological changes after organic amendments. Geophys. Res. 2005, 7, 00341. [Google Scholar] [CrossRef]

- Chang, I.; Prasidhi, A.K.; Im, J.; Shin, H.D.; Cho, G.C. Soil treatment using microbial biopolymers for anti-desertification purposes. Geoderma 2016, 44, 253–254. [Google Scholar] [CrossRef]

- Chang, I.; Prasidhi, A.K.; Im, J.; Cho, G.C. Soil strengthening using thermo-gelation biopolymers. Const. Build. Mat. 2015, 77, 430–438. [Google Scholar] [CrossRef]

- Mitchell, J.K.; Santamarina, J.C. Biological considerations in geotechnical engineering. J. Geotech. Geoenviron. Eng. 2005, 131, 1222–1233. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Prasidhi, A.K.; Cho, G.C. Effects of Xanthan gum biopolymer on soil strengthening. Constr. Build. Mater. 2015, 74, 65–72. [Google Scholar] [CrossRef]

- Yakimets, I.; Paes, S.S.; Wellner, N.; Smith, A.C.; Wilson, R.H.; Mitchell, J.R. Effect of Water Content on the Structural Reorganization and Elastic Properties of Biopolymer Films: A Comparative Study. Biomacromolecules 2007, 8, 1710–1722. [Google Scholar] [CrossRef]

- Stewart, T.L.; Fogler, H.S. Biomass plug development and propagation in porous media. Biotechnol. Bioeng. 2001, 72, 353–363. [Google Scholar] [CrossRef]

- Garcia-Ochoa, F.; Santos, V.E.; Casas, J.A.; Gomez, E. Xanthan gum: Production, recovery, and properties. Biotechnol. Adv. 2000, 18, 549–579. [Google Scholar] [CrossRef]

- Bouazza, A.; Gates, P.W.; Ranjith, P.G. Hydraulic conductivity of biopolymer-treated silty sand. Geotechnique 2009, 59, 71–72. [Google Scholar] [CrossRef]

- Mendonça, A.C.S. Use of Microbial Biopolymer to Decrease Soil Permeability by Bioclogging. Master’s Thesis, University of Coimbra, Coimbra, Portugal, 2020. [Google Scholar]

- Pansu, M.; Gautheyrou, J. Handbook of Soil Analysis—Mineralogical, Organic and Inorganic Methods; Springer-Verlag: Berlin, Germany, 2006. [Google Scholar]

- Kwon, Y.M.; Chang, I.; Lee, M.; Cho, G.C. Geotechnical engineering behavior of biopolymer-treated soft marine soil. Geomech. Eng. 2019, 17, 453–464. [Google Scholar] [CrossRef]

- Chang, I.; Kwon, Y.-M.; Im, J.; Cho, G.C. Soil consistency and interparticle characteristics of Xanthan gum biopolymer–containing soils with pore-fluid variation. Can. Geotech. J. 2019, 56, 1206–1213. [Google Scholar] [CrossRef]

- Kucharski, E.S.; Winchester, W.; Leeming, W.A.; Cord-Ruwisch, R.; Muir, C.; Banjup, W.A.; Whiffin, V.S.; Al-Thawadi, S.; Mutlaq, J. Microbial Biocementation. International Patent Application No.PCT/AU2005/001927, 29 June 2006. [Google Scholar]

- Krishna Leela, J.; Sharma, G. Studies on xanthan production from Xanthomonas campestris. Bioprocess. Eng. 2000, 23, 687–689. [Google Scholar] [CrossRef]

- Jang, J. A Review of the Application of Biopolymers on Geotechnical Engineering and the Strengthening Mechanisms between Typical Biopolymers and Soils. Adv. Mater. Sci. Eng. Hindawi 2020, 2020, 1–16. [Google Scholar] [CrossRef]

- Ayeldeen, K.M.; Abdelazim, M.N.; Mostafa, A.E.S. Evaluating the physical characteristics of biopolymer/soil mixtures. Arab. J. Geosci. 2016, 9, 371. [Google Scholar] [CrossRef]

- Lee, S.; Chang, I.; Chung, M.K.; Kim, Y.; Kee, J. Geotechnical shear behavior of xanthan gum biopolymer treated sand from direct shear testing. Geomech. Eng. 2017, 12, 831–847. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Wiszniewski, M.; Skutnik, Z. Effects of Xanthan Gum Biopolymer on the Permeability, Odometer, Unconfined Compressive and Triaxial Shear Behavior of a Sand. Soil Mech. Found. Eng. 2017, 54, 356–361. [Google Scholar] [CrossRef]

- Cabral, D.J.R. Stabilization of a Soil through the Use of Biopolymers: Effect of the Content and Curing Time. Master’s Thesis, University of Coimbra, Coimbra, Portugal, 2020. (In Portuguese). [Google Scholar]

- Qureshi, M.U.; Chang, I.; Al-Sadarani, K. Strength and durability characteristics of biopolymer-treated desert sand. Geomech. Eng. 2017, 12, 785–801. [Google Scholar] [CrossRef]

- Lee, S.; Chung, M.; Park, H.M.; Song, K.-I.; Chang, I. Xanthan gum Biopolymer as Soil-Stabilization Binder for Road Construction Using Local Soil in Sri Lanka. J. Mater. Civ. Eng. 2019, 31, 06019012. [Google Scholar] [CrossRef]

- Joga, J.R.; Varaprasad, B.J.S. Sustainable Improvement of Expansive Clays Using Xanthan Gum as a Biopolymer. Civ. Eng. J. 2019, 5, 1863–1903. [Google Scholar] [CrossRef]

- Chang, I.; Jeon, M.; Cho, G.C. Application of microbial biopolymers as an alternative construction binder for earth buildings in underdeveloped countries. Int. J. Polym. Sci. 2015. [Google Scholar] [CrossRef]

- Fatehi, H.; Abtahi, S.M.; Hashemolhosseini, H.; Hejazi, S.M. A novel study on using protein based biopolymers in soil strengthening. Constr. Build. Mater. 2018, 167, 813–821. [Google Scholar] [CrossRef]

- Chen, R.; Zhang, L.; Budhu, M. Biopolymer Stabilization of Mine Tailings. J. Geotech. Geoenviron. Eng. 2013, 139, 1802–1807. [Google Scholar] [CrossRef]

- Latifi, N.; Horpibulsuk, S.; Meehan, C.L.; Abd Majid, M.Z.; Tahir, M.M.; Mohamad, E.T. Improvement of Problematic Soils with Biopolymer—An Environmentally Friendly Soil Stabilizer. J. Mater. Civ. Eng. 2017, 29, 04016204. [Google Scholar] [CrossRef]

- Soldo, A.; Miletić, M.; Auad, M.L. Biopolymers as a sustainable solution for the enhancement of soil mechanical properties. Sci. Rep. 2020, 10, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Muguda, S.; Booth, S.J.; Hughes, P.N.; Augarde, C.E.; Perlot, C.; Bruno, A.W.; Gallipoli, D. Mechanical properties of biopolymer-stabilised soil-based construction materials. Géotech. Lett. 2017, 7, 309–314. [Google Scholar] [CrossRef]

- Chen, C.; Wu, L.; Perdjon, M.; Huang, X.; Peng, Y. The drying effect on xanthan gum biopolymer treated sandy soil shear strength. Constr. Build. Mater. 2019, 197, 271–279. [Google Scholar] [CrossRef]

- Czarnes, S.; Hallett, P.D. Root and microbial-derived mucilages affect soil structure and water transport. Eur. J. Soil Sci. 2000, 51, 435–443. [Google Scholar] [CrossRef]

- Khatami, H.; O’Kelly, B. Improving mechanical properties of sand using biopolymers. J. Geotech. Geoenviron. 2013, 139, 1402–1406. [Google Scholar] [CrossRef]

- Dehghan, H.; Tabarsa, A.; Latifi, N.; Bagheri, Y. Use of Xanthan and guar gums in soil strengthening. Clean Technol. Environ. Policy 2019, 21, 155–165. [Google Scholar] [CrossRef]

- Biju, M.S.; Arnepalli, D.N. Effect of biopolymers on permeability of sand-bentonite mixtures. J. Rock Mech. Geotech. Eng. 2020, 12, 1093–1102. [Google Scholar] [CrossRef]

- Nugent, R.; Zhang, G.; Gambrell, R. Effect of exopolymers on the liquid limit of clays and its engineering implications. Transp. Res. Rec. 2010, 2101, 34–43. [Google Scholar] [CrossRef]

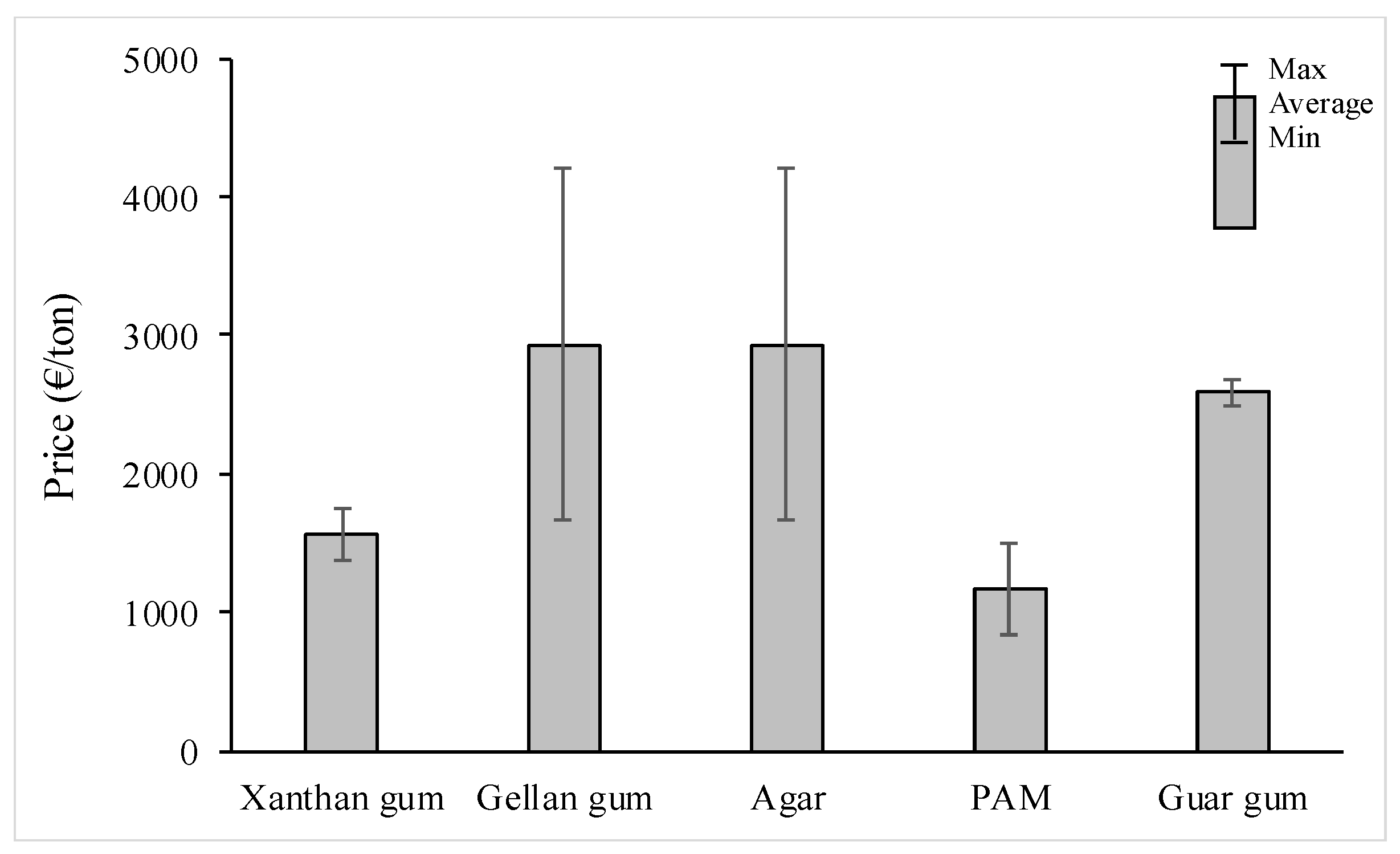

| Biopolymer | Effect |

|---|---|

| Casein and Sodium Caseinate salt | Stabilize sand dunes [1]. |

| Curdlan | Clogs the soil [2]. |

| Chitosan gum | Decreases hydraulic conductivity [11]; Remediates wastewater and contaminated soil [1,5]. |

| Xanthan gum | Decreases permeability; Retains water due to strong hydrogen bonding [1,12,13]. |

| β-Glucan | Increases the resistance to soil erosion and promotes the growth of vegetation [1,14]. |

| Gellan Gum | Improves mechanical properties [1,4,14,15]. |

| Polyacrylamide (PAM) | Decreases soil erosion due to PAM hydrogels [1,15]. |

| Agar Gum | Rapid gelation and increases water infiltration [16]. |

| Guar Gum | Increases mechanical properties [1,4,17,18,19]; Reduces the collapsible potential of plastic soil [13]; Decreases the hydraulic conductivity of silty sand [20]; Increases the liquid limit of kaolinite clay [21]. |

| Group of Microorganisms | Bioclogging’s Mechanism | Essential Conditions | Potential Geotechnical Applications |

|---|---|---|---|

| Algae and cyanobacteria | Formation of impermeable biomass layer | Penetration of light and presence of nutrients | Reduction in water infiltration |

| Aerobic and facultative anaerobic slime-production bacteria | Production of slime in soil | Presence of oxygen and medium with ratio of C:N > 20 | Avoidance of cover for soil erosion control and slope protection |

| Nitrifying bacteria | Production of slime in soil | Presence of ammonium and oxygen in soil | Reduction in drain channel erosion |

| Sulphate-reducing bacteria | Production of undissolved sulfides of metals | Anaerobic conditions, presence of sulfate and a source of carbon in the soil | Formation of grout curtains to reduce the migration of heavy metals. |

| Ammonifying bacteria | Formation of undissolved metals carbonates in the soil due to an increase in pH and release of CO2 | Presence of urea and dissolved metal salt | Prevention of piping of earth dams and dikes. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mendonça, A.; Morais, P.V.; Pires, A.C.; Chung, A.P.; Oliveira, P.V. A Review on the Importance of Microbial Biopolymers Such as Xanthan Gum to Improve Soil Properties. Appl. Sci. 2021, 11, 170. https://doi.org/10.3390/app11010170

Mendonça A, Morais PV, Pires AC, Chung AP, Oliveira PV. A Review on the Importance of Microbial Biopolymers Such as Xanthan Gum to Improve Soil Properties. Applied Sciences. 2021; 11(1):170. https://doi.org/10.3390/app11010170

Chicago/Turabian StyleMendonça, Amanda, Paula V. Morais, Ana Cecília Pires, Ana Paula Chung, and Paulo Venda Oliveira. 2021. "A Review on the Importance of Microbial Biopolymers Such as Xanthan Gum to Improve Soil Properties" Applied Sciences 11, no. 1: 170. https://doi.org/10.3390/app11010170

APA StyleMendonça, A., Morais, P. V., Pires, A. C., Chung, A. P., & Oliveira, P. V. (2021). A Review on the Importance of Microbial Biopolymers Such as Xanthan Gum to Improve Soil Properties. Applied Sciences, 11(1), 170. https://doi.org/10.3390/app11010170