1. Introduction

Industrial control systems (ICS) comprise heterogeneous hardware and software components for control, sensing, and actuation, that are interconnected with specialized industrial networks. These are typically employed in environments for industrial control and automation. Owing to the remarkable advances in technology, ICS has expanded to various application domains including energy and power systems, transportation, avionics, and robotics [

1,

2,

3,

4]. Although traditional ICS main controllers are based on high-end powerful computers, in the last decade, the rapid development of embedded systems and their consistent increase in performance has made them valid as strong alternatives. Indeed, embedded systems are able to provide better solutions, especially in practical applications, owing to their portability, low power requirements, and relatively inexpensive costs compared to their high-end counterparts. This paradigm shift enables the smaller and low-cost design of control systems while remaining competitive in terms of performance. Embedded systems as the main controllers in various cyber-physical systems for industrial automation are also considered as one of the backbones of the fourth industrial revolution [

5]. ICSs are “safety-critical” systems, which means that any task failure can lead to catastrophic results that can damage properties, infrastructures, or even people. Thus, ICSs should be bounded with stringent temporal constraints and should guarantee hard real-time performance [

6] to avoid such accidents or malfunction.

Due to the complex combination of numerous hardware devices and control algorithms, the underlying software should be robust to any changes. Thus, the traditional super-loop concept [

7] or single task software development is not advisable. Operating systems were introduced, offering standard application programming interfaces (API) to ensure easier interaction with different devices in various application domains. They also provide a multi-tasking environment, separating functions into self-contained processes, executed depending on the governing scheduler. Operating systems are divided into two major classifications. General purpose operating systems (GPOS) are more concerned on the best-effort performance of the system with more relaxed timing. In contrast, real-time operating systems (RTOS) conserve strict timing in executing tasks, which are scheduled based on priorities. Simply put, tasks with lower priorities can run only if there are no available high-priority tasks. This behavior guarantees the determinism and predictability of executing real-time tasks, which are critical requirements in satisfying the safety of ICSs.

Android is gaining huge popularity as the leading operating system of embedded systems owing to its open source nature. Android was developed as a software stack on top of the Linux kernel. As Android is a GPOS, its ability as the main controller of an ICS is still in question. Currently, there is a huge effort from various researchers to evaluate the viability of Android and its utilization in real-time embedded and industrial applications [

8,

9,

10]. According to these studies, the feasibility of Android-based industrial controllers is still an open problem due to two major drawbacks: safety (real-time characteristics) and security. Several studies have addressed the timeliness and real-time constraints of Android. Yan et al. [

11] proposed RTDroid, a real-time variant of Android with most of the internal components redesigned. This provides a deterministic response of Android applications by replacing both the kernel and runtime with their respective real-time alternatives. RTDroid was tested mainly for real-time sound processing, and the measured sound latency performance is presented in their extended work [

12]. However, its extendibility to industrial applications is moot as most industrial software tools and libraries are designed for the standard Linux kernel. Porting these libraries to Android requires significant amount of development costs and time. In this regard, the most common approach is running Android on a remote guest system connected to a host controller with an RTOS. Truong et al. [

13] presented the remote monitoring and control of an industrial CNC machine via a wireless network on an Android platform. This is remarkably similar to the solution of Mateo et al. [

14], called Hammer, an Android-based teach pendant application, to control industrial robotic arms. These approaches can cause performance bottleneck on the host system, depending on the governing communication protocol. Manufacturing cost is also an issue because these solutions require more than a single hardware platform. To this end, we aim to address the safety issues of Android by developing a single-board embedded system which can guarantee hard real-time constraints and integrate Android applications to real-time tasks.

Security is another issue that affects safety due to the increased connectivity in industrial systems, which causes a higher risk of cyber and hardware attacks. In an ICS, attacks are divided into three major categories: physical, communication, and software attacks. Physical attacks refer to any change in the hardware that includes physical contact, such as the removal of a chip package or tampering with any devices. In communication attacks, the attacker can manipulate, intercept, or spoof any message coming from a device within a network. Software attacks are mostly executed by accessing restricted resources through malware, system bugs, or any unexpected call sequences. For embedded systems based on the ARM architecture, ARM TrustZone [

15] has been widely available on selected platforms that provides protection for the software that executes within the platform. It also provides a secure boot sequence that only loads authenticated kernel images. Aside from the limited availability of supported hardware, the developers of the technology do not disclose technical details, resulting in difficulties in its implementation. Its application on Android is also questionable due to it being inaccessible directly from Android processes or applications. For Android applications, security is handled in the software stack or in the ecosystem [

16]. Attacks on the software stack result in the direct acquisition of root privileges, giving the attacker complete access to and control of the entire system. In contrast, the ecosystem form of attacks refers to the attackers tricking naive users into downloading and installing bogus applications to gain control of the device. To prevent any intrusion and corruption to the software stack (specifically the kernel), Samsung Knox offers Real-time Kernel Protection (RKP) [

17]. However, RKP is highly dependent on the ARM TrustZone, along with its flaws, and the system is still vulnerable to ecosystem attacks [

18]. Several researchers have addressed this issue, focusing on the different forms of ecosystem attacks, namely privilege escalation [

19], advertisements [

20], and application repackaging [

21,

22]. Although most of these studies increase the security of Android, they require changes to the native code and could exhibit additional performance overheads to the end users. In this sense, we aim to enforce security schemes ensuring that the embedded system is protected from physical tampering, and also ensure that attackers could not run unauthorized Android applications.

In this paper, we develop a safe and secure Android-based embedded system applicable as a main controller of industrial control systems. To address the safety and real-time issues of Android, the real-time characteristics of Xenomai [

23], a dual-kernel approach of real-time Linux, were explored and implemented on our own developed NXP i.MX6-based embedded platform, namely JECS-600ITX. Although the Linux kernel and Android sources are provided as board support packages (BSP) by NXP, compatibility with Xenomai and other patches is trivial. Thus, we provide complete development details on developing a real-time environment, considering the version compatibility of Linux, Android and Xenomai for easier reproduction. In a dual-kernel configuration, running the Linux system calls in the Xenomai domain result to mode switching. This causes the real-time tasks to be non-deterministic, resulting in a system freeze or a kernel panic. To deal with this issue, we developed a communication interface between Android applications and Xenomai, utilizing the shared memory mechanism of Android Interface Definition Language (AIDL) and a variant of our previous work in [

24]. This interface ensures integration and smooth communication between Android applications and Xenomai real-time tasks. An open source EtherCAT master was implemented on top of Xenomai [

25] to connect with actual ICS networks.

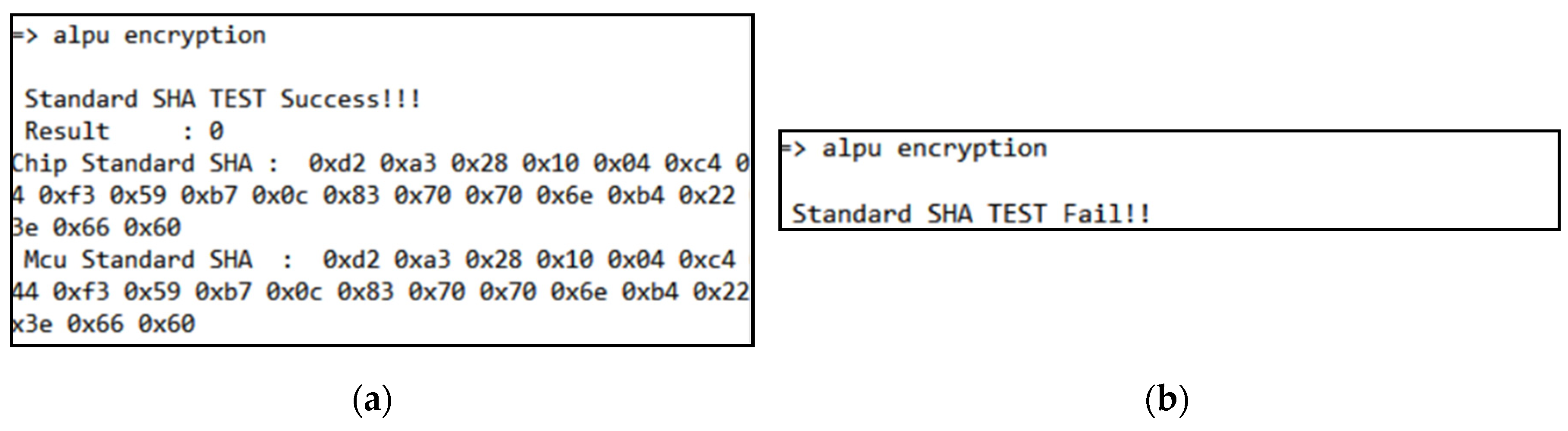

Dealing with the security issues of Android, we have adopted a hardware copy protection chip called Algorithm License Permmituition Unit (ALPU) by Neowine [

26]. As the chip only comes with a library supporting Linux, encryption APIs were developed for both the bootloader and Android to enforce four administrative policies. To prevent hardware breaches, such as tampering with the ALPU, the following policies are implemented in the booting process: (1) the booting process is initiated only in the presence of the ALPU, and (2) the booting process is initiated only if the stored encryption key in the embedded platform matches the ALPU. With the ultimate goal of protecting the embedded system from running unauthorized applications in Android, the following policies are enforced in the Android application layer: (3) third party software, which should include the developed authentication library, and (4) only applications with the encryption key are executable. These policies ensure that the embedded platform is protected from any physical breaches such as modifications to the firmware of the embedded system and avoids any form of unwanted software intrusion in the Android software stack. Experiments were conducted to demonstrate the articulacy of the administrative policies and the JECS-600ITX is connected to a series of industrial motion devices (EtherCAT servo drives) to show operability in an actual working environment. The real-time performance of the embedded platform is evaluated in terms of schedulability and responsiveness, which are extremely critical to determine the safety and reliability of the entire ICS.

The remainder of this paper is organized as follows.

Section 2 introduces the software architecture and the details of the development environment of the Android-based industrial presented in this work. This section also includes the communication interface integrating Android applications and Xenomai real-time tasks. In

Section 3, an overview of the policy-oriented security scheme and the ALPU is provided.

Section 4 presents the experiments and results, demonstrating the practicality of the developed embedded system in terms of the articulacy of the administrative policies, operability on an actual industrial network, and real-time performance. The last section summarizes the concluding remarks of the paper.

2. Android-based Industrial Controller for Safety-Critical Applications

Safety is an essential requirement for ICSs to avoid system malfunction or accidents in a working environment. In this paper, we define “safety” from a functional point of view, such that all functions must be executde correctly at the correct time or within a specific temporal deadline to be safe. This means that ICSs should adhere to hard real-time constraints to avoid system failure. To meet such requirements, the main controllers of ICSs were traditionally developed based on powerful computers with high-performance RTOSs. As the current trend of developing main controllers based on embedded systems becomes a paradigm, there is an increasing demand for Android in industrial applications. Researchers have evaluated and proposed various solutions to enable its use as a platform for safety-critical and real-time applications [

11,

12,

13,

14,

27,

28,

29]. In this section, we provide the complete development details of a real-time environment employing Xenomai as the dual-kernel approach of real-time Linux and the implementation of an open-source EtherCAT master for our own developed embedded platform, namely JECS-600ITX. Due to mode switching [

23,

24], a communication interface integrating Android applications with Xenomai real-time tasks is also introduced.

2.1. Software Architercture

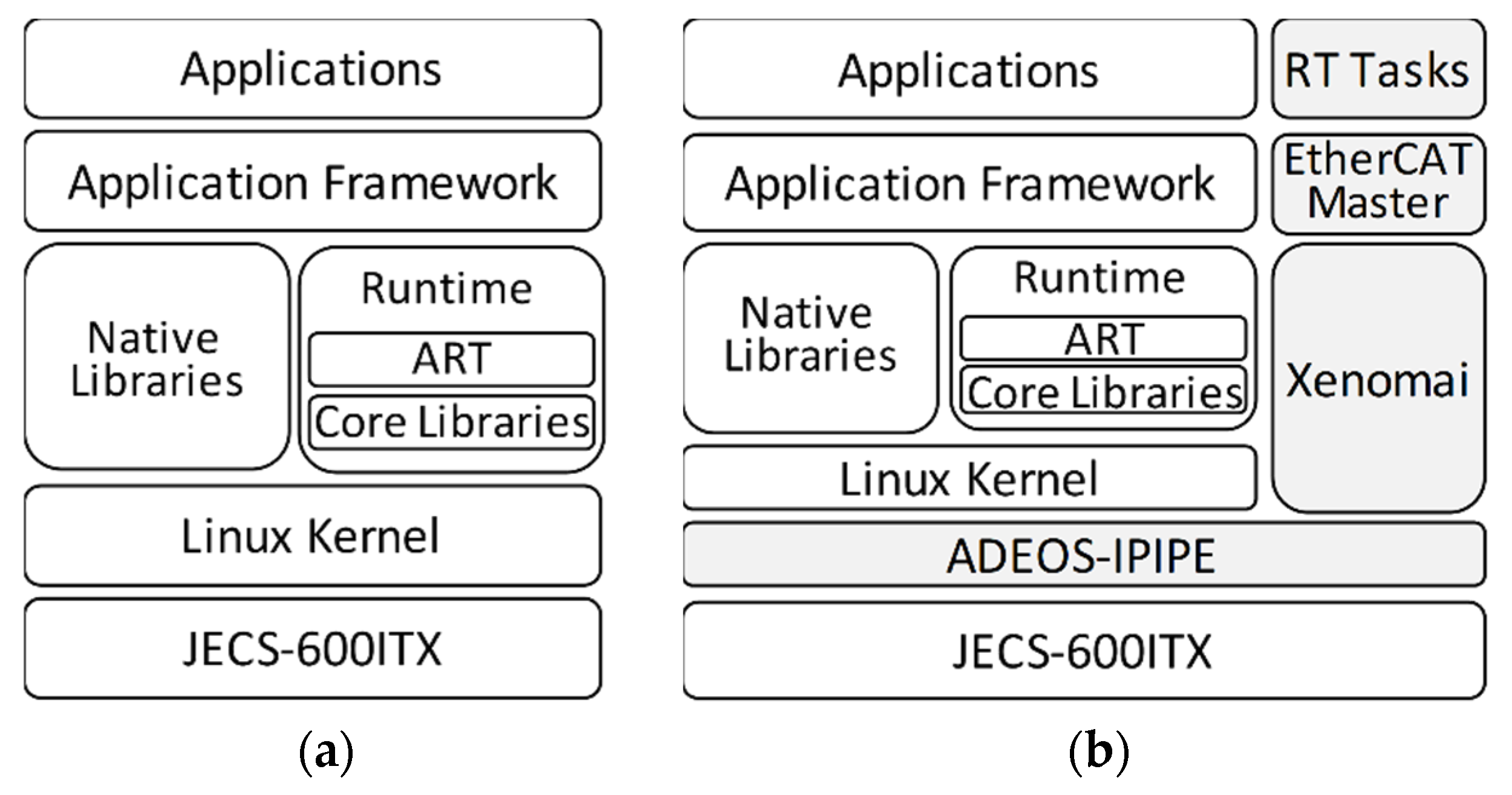

Figure 1 shows the simplified software architecture of the Android operating system for our own developed embedded system, namely JECS-600ITX. As depicted in

Figure 1a, the standard Android software consists of the runtime and libraries, the application framework, and the application layers and the Linux kernel. For the Android with versions later than 5.0, the runtime consists of the core libraries and the Android Runtime (ART). Each Android application runs its own ART and runs multiple virtual machines optimized for a minimal memory footprint. Core libraries provide support for the Java programming language. Developing Android applications requires system components and services provided by the native libraries, which are written in C and C++. The Android framework layer exposes these native libraries to be used in applications. The standard Linux kernel was modified to handle the rest of the Android layers and does not support any real-time features, as the scheduler values “fairness” over priorities of processes [

30].

The issues of real-time for Android attract various researchers. Maia et al., in [

27], evaluated the real-time capabilities of Android and presented different architectural models including the usage of an RTOS kernel instead of the Linux kernel and the possibility of developing a real-time hypervisor or a real-time Java machine. In this regard, RTDroid was developed by Yan et al. [

11]. However, its extendibility to industrial applications is an open problem considering that industrial software tools and libraries are mostly designed for compatibility with Linux. Porting these to Android requires a significant amount of development time and manpower. To address this issue, various researches implemented a host–guest approach, where an RTOS is running on the host and Android on the guest system, respectively [

13,

14]. This would result to an increase in manufacturing costs due to the requirement of multiple hardware platforms. Thus, we present a unique solution integrating Android applications to real-time Xenomai tasks for a single hardware, as shown in

Figure 1b. Modifications to the standard Android architecture are represented by the shaded blocks.

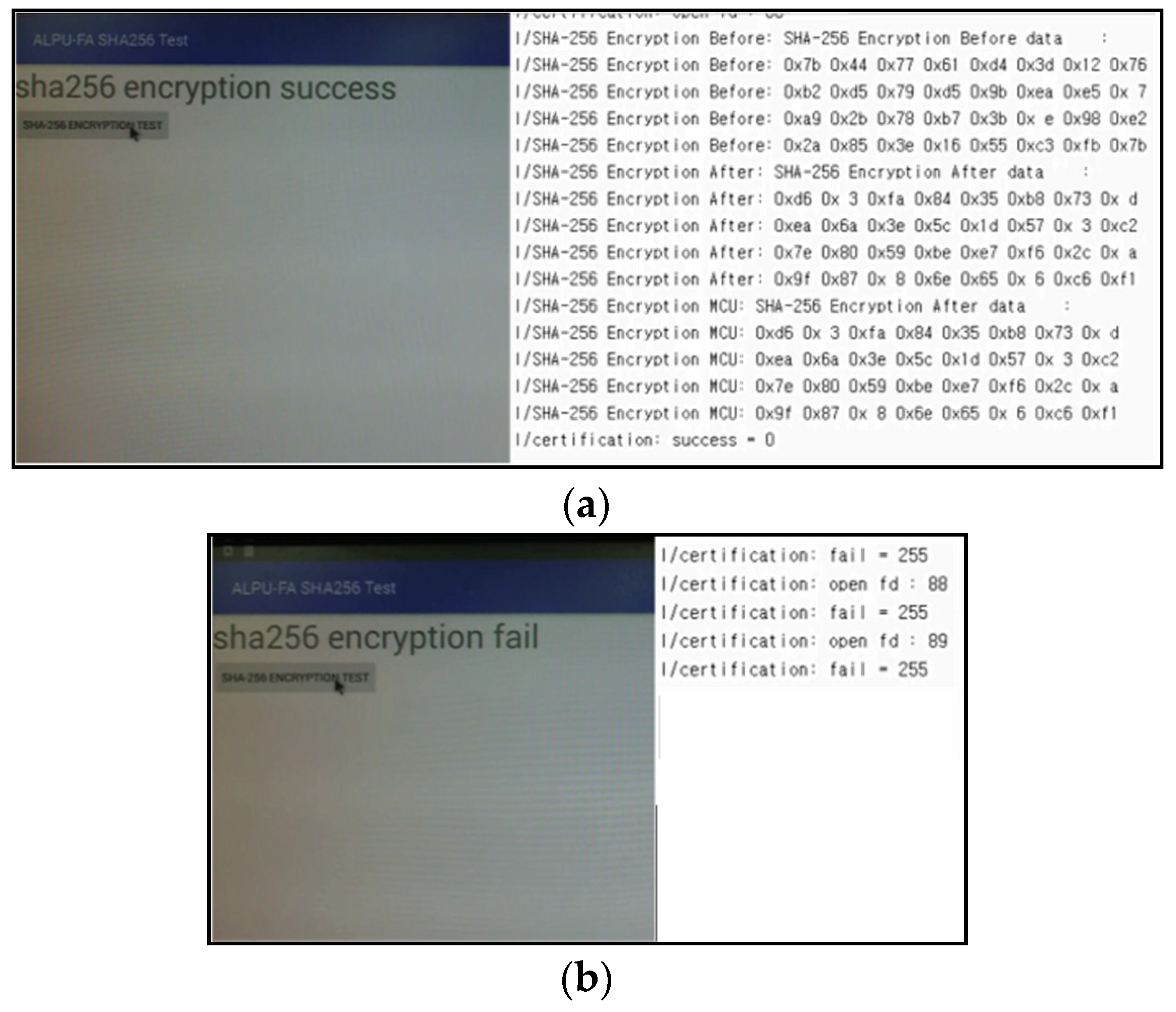

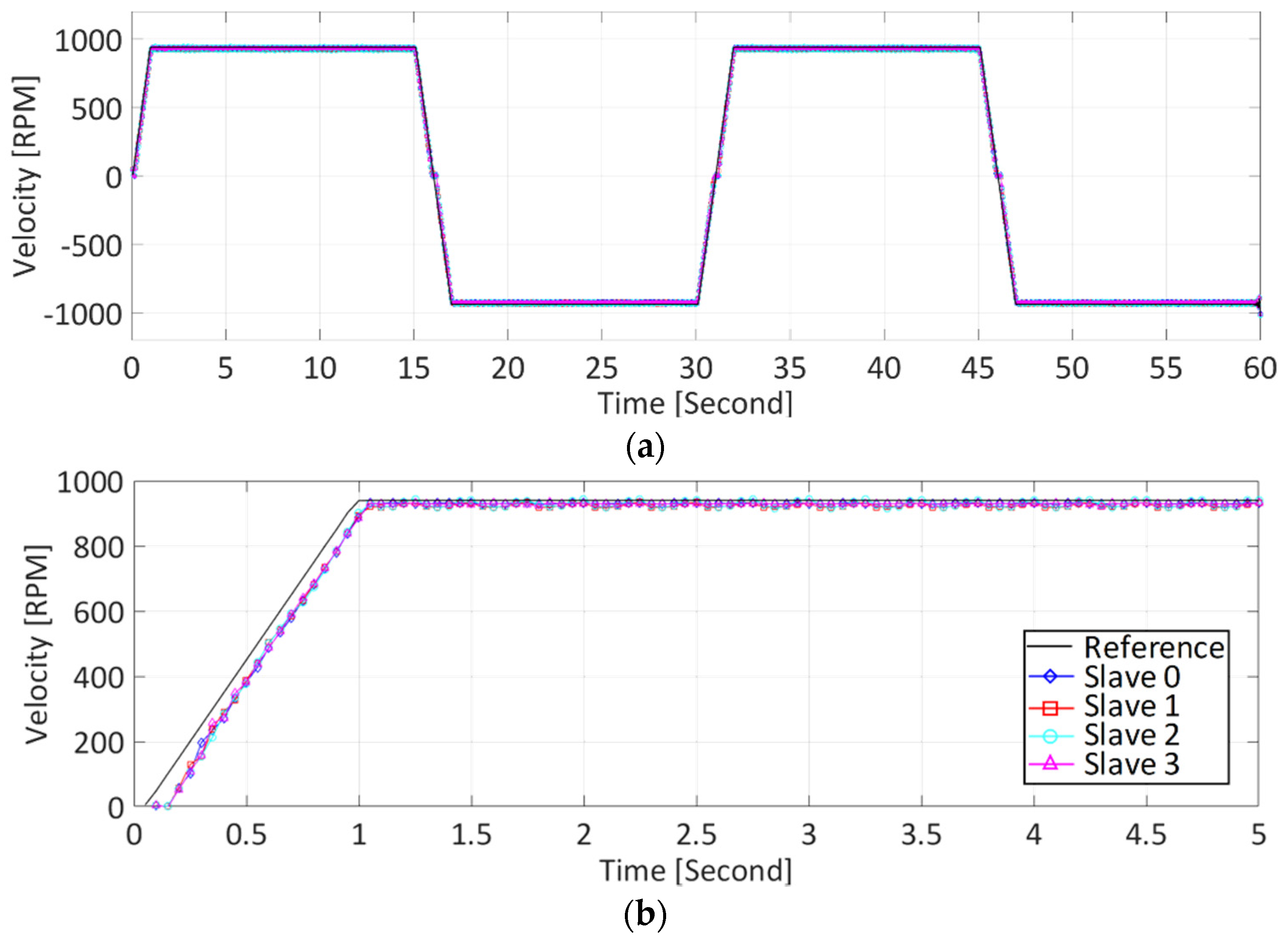

Xenomai is an RTOS implemented as a dual-kernel approach of real-time Linux. It provides a multi-tasking environment for real-time tasks (RT Tasks) with a priority-based preemptive scheduler and inter-task synchronization mechanisms. Adaptive domain environment for operating systems (ADEOS-IPIPE) abstracts hardware interrupts and other operations enabling the existence of both Xenomai and Linux on a single hardware. ADEOS-IPIPE ensures that Xenomai holds the highest priority and should preempt any non-real-time Linux processes. Meaning, Linux only runs if there are no pending Xenomai processes. The performance of Xenomai on an i.MX6-based embedded platform similar to JECS-600ITX is presented in our previous work [

31]. As EtherCAT is becoming the standard network protocol in ICSs, an open source EtherCAT master, IgH Etherlab, was stacked on top of Xenomai to establish a connection with an actual industrial network. In the literature, numerous studies are present related to the implementation and performance of EtherCAT on different variations of real-time Linux [

25,

32,

33]. To our knowledge, this work is the first attempt on implementing EtherCAT on an Android-based embedded system. The complete details of the real-time software environment for the JECS-600ITX are organized in

Table 1. As the board was developed based on the reference platform, i.MX6 SABRE-SD, the same board support package (BSP), which includes the bootloader, Linux kernel and Android, is implemented. In case of the kernel, the device tree binaries were modified, considering the physical address of the onboard random-access memory. The BSP was cross-compiled on a host machine complying with the Android open-source project requirements. The resulting Android image was flashed to the internal embedded multimedia controller (eMMC) memory of the JECS-600ITX. To implement Xenomai, an ADEOS-IPIPE patch compatible with both the Linux kernel and Xenomai itself is required, however, the patch for Linux 4.1.15 is not available in the Xenomai repository. Thus, we have modified the closest available patch source namely, ipipe-core-4.1.18-arm9, ensuring that all patch hunks are successful. After patching the Linux kernel with ADEOS-IPIPE, kernel options related to power management, kernel debugging, memory page migration, and CPU frequency scaling were disabled to ensure that the unwanted voltage and frequency scaling that can affect the real-time performance of Xenomai will not occur [

31]. Thereafter, the Xenomai-enabled kernel is flashed to the JECS-600ITX.

The latest official distribution of IgH Etherlab is only compatible with the earlier versions of both Linux kernel and Xenomai (earlier than 4.0 and 3.0, respectively). One advantage of open software is that the source code is available to all developers and everyone can contribute to the improvement of the project. An unofficial patch set for the IgH Etherlab is available, solving the compatibility issues with our development environment, and is currently awaiting approval for mainline merge available at [

34]. IgH Etherlab was compiled, enabling the generic device driver, as the real-time device drivers for i.MX6 platforms are not currently available. The user space libraries of both IgH Etherlab and Xenomai were compiled and copied to the filesystem of the Android environment. As Android does not support typical Linux operating system commands, the IgH Etherlab scripts for loading the EtherCAT master module and device drivers were modified. Instead of using modprobe, we employed the insmod and rmmod commands to load and unload kernel modules, respectively. Although we have successfully leveraged a real-time environment for the JECS-600ITX, Android should be able to communicate with Xenomai tasks to be applicable in safety-critical industrial applications. The next section offers a solution, integrating Android applications with Xenomai RT tasks.

2.2. Integration of Android Applications and Real-Time Xenomai Tasks

In the dual-kernel configuration presented in the previous section, the entire system consists of two parts. The non-real-time part includes Android running on top of the Linux kernel and the real-time part, which is Xenomai. Accordingly, user space tasks can be divided into non-real-time Android applications, standard Linux tasks, and the Xenomai RT tasks. Each part has its own private memory address space and software abstractions, due to the hardware abstraction of the ADEOS-IPIPE. This means that direct communication between Android applications and Xenomai real-time Xenomai tasks is restricted. Moreover, using non real-time libraries or system calls within RT tasks results to an event called mode switching. This results in a chaotic scenario where RT tasks lose their hard real-time capabilities, causing the entire system to become unstable and non-deterministic. In our previous work, we implemented a cross-domain datagram protocol (XDDP) to address the communication issue between standard Linux and Xenomai [

23].

Although XDDP provides communication between non real-time and real-time tasks, the same approach cannot be applied to Android due to its architecture, which does not allow direct device access to regular applications. However, Android provides an interface definition language that allows users to define a programming interface between applications to communicate through inter-process communication mechanisms. In this work, we have selected the anonymous shared memory mechanism (ashmem) as the communication channel between Android applications and standard Linux tasks.

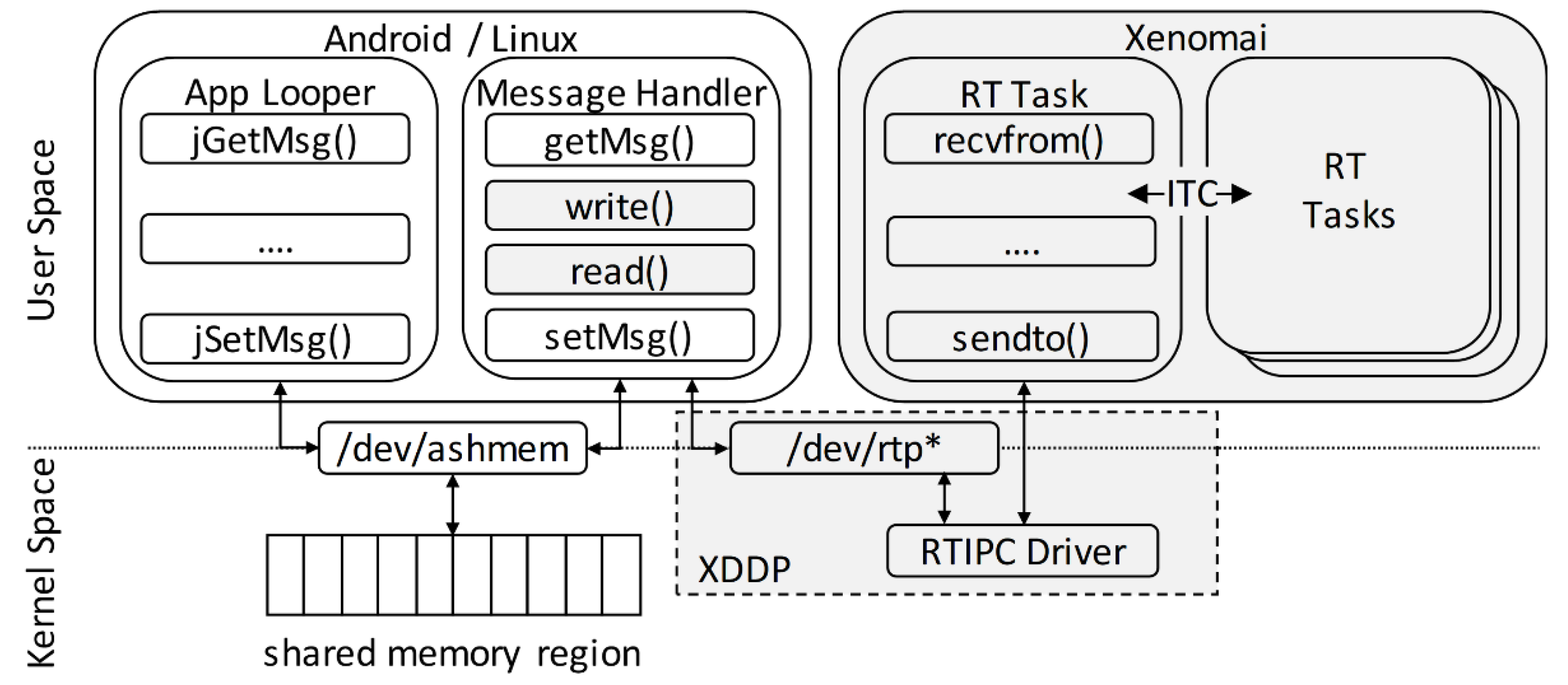

Figure 2 shows the thread model of integrating Android applications with Xenomai RT tasks, leveraging both XDDP and ashmem mechanisms. All the operations and components of the non-real-time part are represented by the white blocks, while the shaded blocks represent the real-time ones.

For the purpose of simplification, we assume a single connection between an Android application (App Looper) and a standard Linux task (Message Handler) via ashmem. The App Looper acts as a server, which creates a file descriptor for the shared memory and includes the message-passing activity. Implementing the interface requires the developer to create a user-defined Android library to map the ashmem and pass file objects between processes through the Java native interface. We have created an Android library consisting of two message-passing functions to access the shared memory called jGetMsg() and jSetMsg(), which are responsible for reading and writing messages, respectively. The processing logic for these message passing functions is highly dependent on the application, which is specifically defined by the developer. In our case, we have developed the library to pass the string datatype of messages.

For the Linux side, the Message Handler is a non-real-time task that accesses the shared memory through the device file, /dev/ashmem, using the standard Linux open() function. Accordingly, we have developed getMsg() and setMsg() functions as the respective counterparts of jGetMsg() and jSetMsg() in the Linux domain. To date, communication between the App Looper and the Message Handler is successfully realized. Given that the Message Handler task should act as a bridge between Android applications and Xenomai real-time tasks, we employ the XDDP mechanism [

23]. XDDP serves as the communication interface between Linux and Xenomai tasks. Herein, the Message Handler is linked to an XDDP port by accessing the real-time inter-process communication (RTIPC) driver through the /dev/rtp* character device (* represents the minor number of the device file). XDDP ports are identified by this minor number and, by default, there are 32 useable XDDP ports. After opening the respective device file, the standard Linux read() and write() functions are used to access the stored message in the XDDP port. Note that the Message Handler is a cyclic task, therefore the opening of both ashmem and XDDP device files is executed before entering the infinite loop. Inside the loop, the Message Handler waits for messages from the App Looper with the getMsg() function and sends it directly to the Xenomai domain using write(). Feedback from the real-time task, acquired using read(), is sent back to the App Looper with setMsg().

On the other hand, a Xenomai RT task accesses XDDP through socket operation. The RT task is bound to a socket with the port number, depending on the minor number of the character device accessed by the Message Handler task. This means that port 0 in the RT task is connected to the device file /dev/rtp0. AF_RTIPC and IPCPROT_XDDP switches are also enabled for the socket domain and protocol, respectively. To access the stored messages, socket recvfrom() and sendto() are called to acquire and set messages, respectively. In case of the recvfrom() function, we have enabled the MSG_DONTWAIT flag to enable non-blocking operation and ensure that messages from the App Looper would not affect the real-time performance of the Xenomai task. Note that this approach can be implemented in a multitasking environment, where multiple Android applications are interfaced to their respective Message Handler task in the Linux domain and RT tasks in the Xenomai domain. Xenomai also offers inter-task communication (ITC) mechanisms for synchronization and communication between RT tasks.

This method opens up possibilities for industrial applications that require the integration of Android with hard RT tasks. For example, safety-critical application with hard real-time constraints such as feedback control with sensors and actuators can be implemented in the Xenomai domain, while being monitored and manipulated by graphical user interface monitoring and control software in the Android domain.

3. Policy Oriented Security Scheme

Security is another issue that affects the safety of an ICS due to the increased connectivity in industrial systems causing a higher risk of cyber and hardware attacks. In this section, we introduce a policy-oriented security scheme employing a hardware copy protection chip called the Algorithm License Permmituition Unit (ALPU) developed by Neowine [

26]. Administrative policies were implemented in the bootloader and Android user space level to protect the developed embedded system from any form of hardware and cyber-attacks.

3.1. Algorithm License Permmituition Unit (ALPU)

The ALPU is a high-performance illegal copy protection chip applied in different electronic systems such as dashboard cameras, navigation systems, and industrial controllers. It is very suitable for embedded systems, considering its small size and low power requirements. The encryption module is based on a Rijndeal AES-128 standard with 192-bits programmable parameters. The module consists of several blocks which are the AES-128 encryption module, the encryption parameters, feedback buffers, and the hash generator.

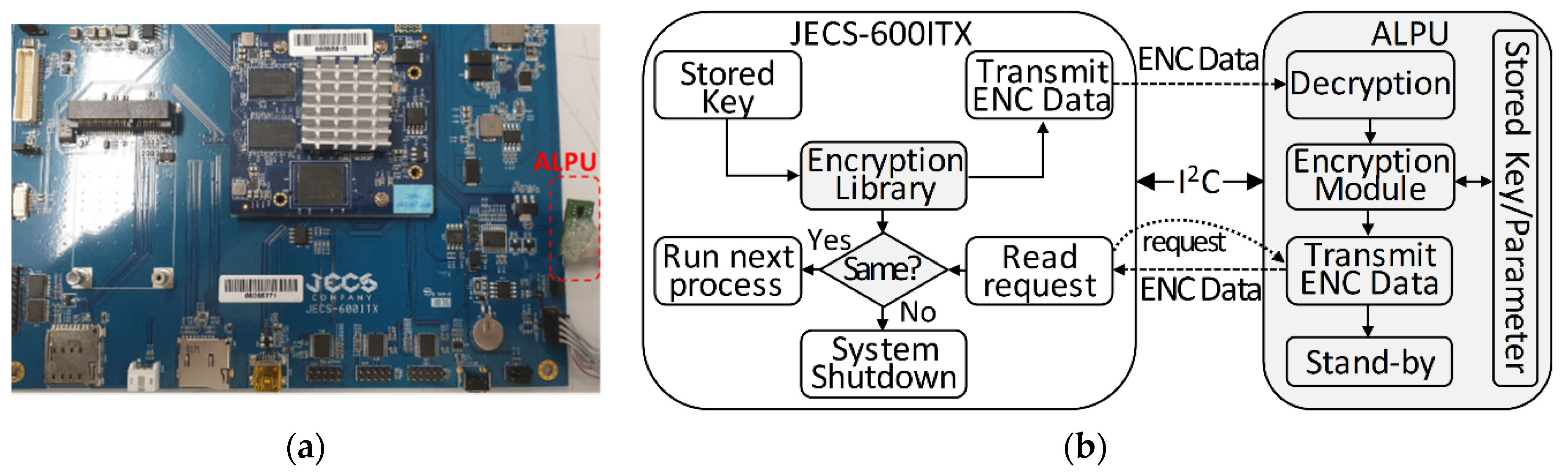

Figure 3a shows our own developed embedded system, namely JECS-600ITX, attached with an ALPU.

The ALPU offers three modes of authentication: bypass mode, feedback encryption mode, and hash generator mode. The bypass mode is only used in testing the communication between the ALPU and the main controller—in this case, the JECS-600ITX. The ALPU will perform exclusive or (XOR) operation with 0x01 on the received data and return it back to the JECS-600ITX. On the other hand, feedback encryption and hash generator are encryption methods developed by Neowine. In this paper, we focus on the hash generator mode, which is a variation of SHA-256 and is the strongest encryption algorithm available within the ALPU. Aside from the ones stored in the ALPU itself, these algorithms are distributed as a library, and used for encrypting the authentication key stored in the main controller. The authentication key is only known to the user and is unique for every ALPU chip, ensuring that the authentication process fails in cases where a different ALPU chip is attached.

Figure 3b illustrates the authentication process of the ALPU. The stored authentication key in the JECS-600ITX is encrypted depending on the selected mode of encryption. Together with the mode of encryption, the encrypted data (ENC Data) are transmitted to the ALPU through I

2C protocol. Users can set the number of passes to apply the encryption algorithm, which makes the key more difficult to analyze, thereby increasing security.

The complete steps of the authentication process are as follows:

The stored authentication key in the JECS-600ITX is encrypted using the encryption library depending on the selected mode. The encrypted data are then transmitted to the ALPU;

Upon receipt, the ALPU decrypts the data and process them with the encryption module based on the stored key value and parameters. The results are transmitted back to the JECS-600ITX;

Back in the JECS-600ITX, the encrypted authentication key is compared with the response from the ALPU. The authentication process is successful when both are the same;

In contrast, the authentication fails if one of the keys is different from the other, which can invoke a system halt or shutdown depending on the procedure implemented by the developer.

Due to the encryption library being specifically made compatible only with the Linux operating system, we have ported it to be compatible with both the bootloader and Android. In the case of the bootloader, we have created a new bootloader command including the ported encryption library and the I2C interface files to implement the authentication process as explained above. The new command is added to the list of bootloader commands and the board initiation process.

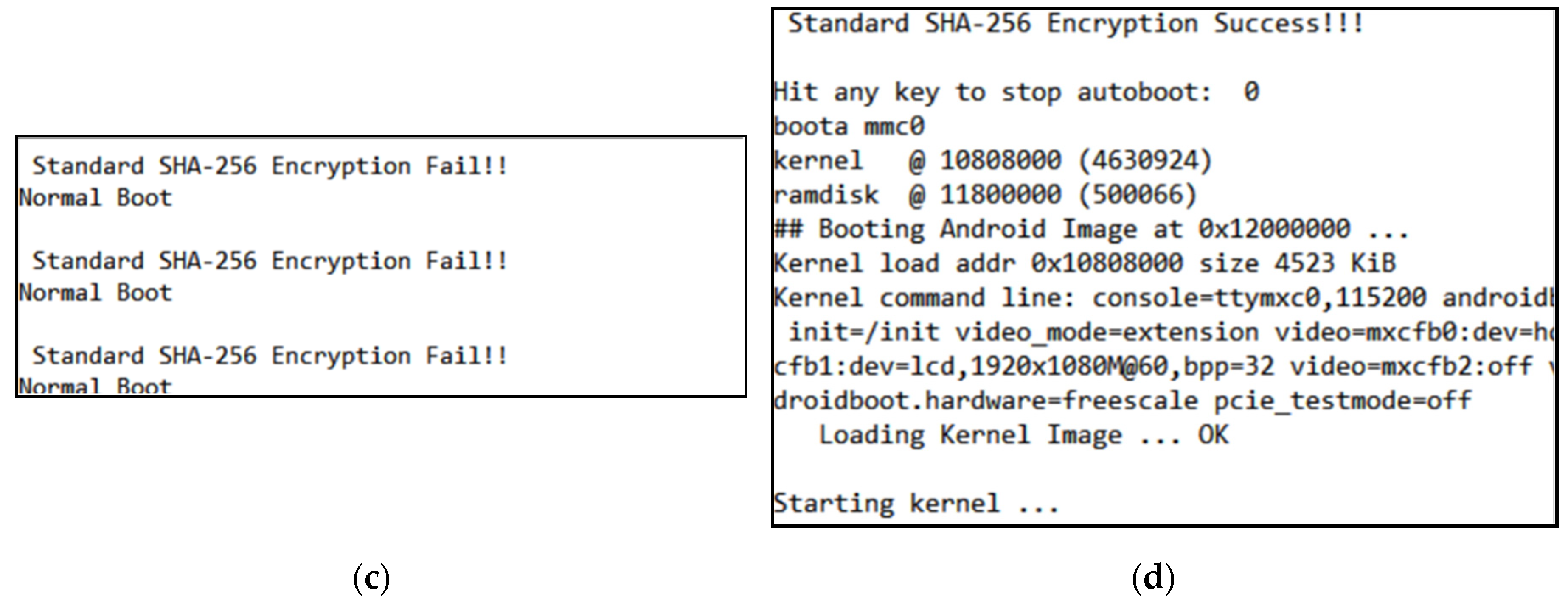

With the ultimate goal of protecting the embedded system from running unauthorized applications, we have developed an Android API including the encryption library that can be added to user-authorized applications. Note that the encryption key is compiled within the developed encryption library to prevent numerous developers from accessing it. This means that a unique library should be compiled for each ALPU. To distinguish between unauthorized and authorized applications, we have developed a security manager daemon that continuously checks whether an application contains the developed encryption API. An application without the encryption API is forcibly terminated. By implementing the encryption library ported in both bootloader and Android, we enforce administrative policies to protect the embedded system presented in the next subsection.

3.2. Administrative Policies

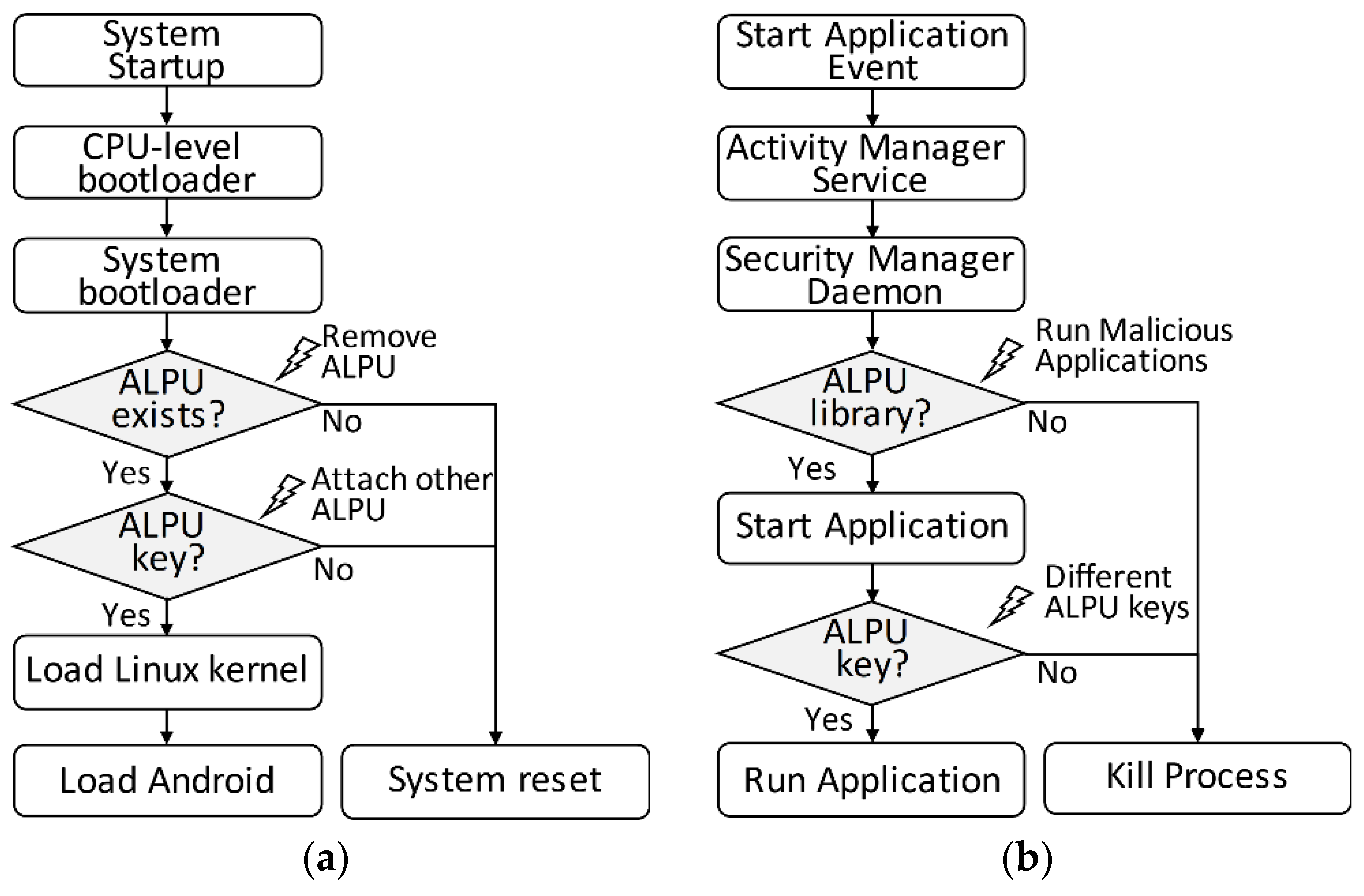

In this section, we discuss the administrative policies implemented on the JECS-600ITX attached with an ALPU. The policies were enforced with the aim of protecting the developed system from distinct types of attacks including hardware tampering, unwanted access to the device filesystem, and the execution of unauthorized applications, which are critical in operating industrial automation and control systems. These policies are implemented either before the booting process or in the Android application layer. For the booting process:

The booting process of the JECS-600ITX starts when the board is connected to a power supply invoking a system startup. The first level bootloader is loaded from the CPU read-only memory to the internal memory. This initiates the CPU and the board level memory. The system bootloader stored in the eMMC is loaded in the random-access memory, which initializes the entire system. The enforced booting process policies ensure that the system checks the I²C bus for the existence of an ALPU chip. (1) If the ALPU is not present, the booting process fails invoking a system restart. If the ALPU is properly recognized, on the other hand, (2) the ALPU encryption key is compared with the one stored in the bootloader environment by implementing the authentication process through the encryption library. If the ALPU chip’s credentials do not match with the one stored in the embedded system, the booting process will fail. For the Android application layer:

- 3.

Android software and applications should include the developed encryption API;

- 4.

Only applications with the correct encryption key are executable.

Only if the booting processes succeed will the system load the kernel and the Android operating system. The developed security manager daemon, which is responsible for checking whether applications contain the encryption API, will run as soon as Android finishes loading all essential drivers and processes. When a new Android application is opened by the user, the activity manager service performs a fork system call to the security manager daemon to run a new process. (3) If the daemon detects applications without the developed authentication library, the whole process will be killed, and the application will be terminated. Otherwise, (4) the application will start and run the authentication process with the ALPU chip. The authentication process checks whether the encryption key compiled in the Android application matches with the one stored inside the ALPU. The authentication process will fail, and the application will be terminated if the ALPU does not recognize the encryption key. This prevents execution of the application in case a different ALPU is connected to the JECS-600ITX.

In the next section, we will discuss the behavior of these policies in the presence of various threats in both the system level and the Android application layer.

3.3. Adversary Model

Here, we consider an adversary model where the attacker tries to physically tamper an embedded system connected to an industrial control network in order to bypass the booting process and obtain access to the Android operating system. Once the adversary has access to the operating system, all the connected devices can easily be manipulated, and confidential data such as control algorithms and machine specifications can be modified or downloaded. To achieve this goal, the adversary can either remove the ALPU chip or attach a similar one. In our developed system, we have enforced two bootloader policies, explained in the previous section, in order to prevent the adversary from booting to the Android operating system.

To restrict the adversary from tampering with any of the bootloader environment variables, we have disabled the command line interface, which results in an infinite system reset procedure. The flow diagram and the adversary model of the booting process policies are shown in

Figure 4a. The standard boot procedures are depicted by the white blocks, while the shaded blocks represent the implemented booting process policies using the ALPU.

In the figure, the adversary can try to bypass the authentication process by removing the ALPU from the embedded system. However, with the first bootloader policy enforced, the entire system will fall into an unlimited reset procedure unless it is powered off. In case the adversary can get hold of a similar ALPU chip and attach it to the embedded system, the second policy ensures that the system is protected by executing the ALPU authentication process. This means that the system will boot only if the encryption key in the ALPU is the same as the one stored inside the embedded system.

If, by any chance, the adversary is able to bypass the bootloader policies, the system is also enforced with administrative policies in the Android layer. Here, we assume an adversary trying to indirectly access the embedded system by executing unauthorized and malicious applications, as shown in

Figure 4b. Through the developed security manager, the Android application is checked to ensure that it was developed with the encryption API in compliance with the third policy. If not, the security manager kills the entire process and prevents the execution of the application. If the adversary develops an application by reverse engineering the encryption API, the entire system will still be secured by the fourth security policy. The malicious application will not be executed as long as the correct encryption key is not compensated.