Glass-Ceramics Processed by Spark Plasma Sintering (SPS) for Optical Applications

Abstract

1. Introduction

- It reduces the sintering temperature and time through applying pressure, also inhibiting crystal growth.

- It reduces flaws, voids, and microcracks, and thus favors to improve properties, such as mechanical and optical.

- It enhances the homogeneity of material characteristics, which is very important to get high transmittance magnitudes and more luminescence intensity in the case of optical materials.

- It’s possible to retain the initial shape (near net shape) after SPS.

2. History of Spark Plasma Sintering

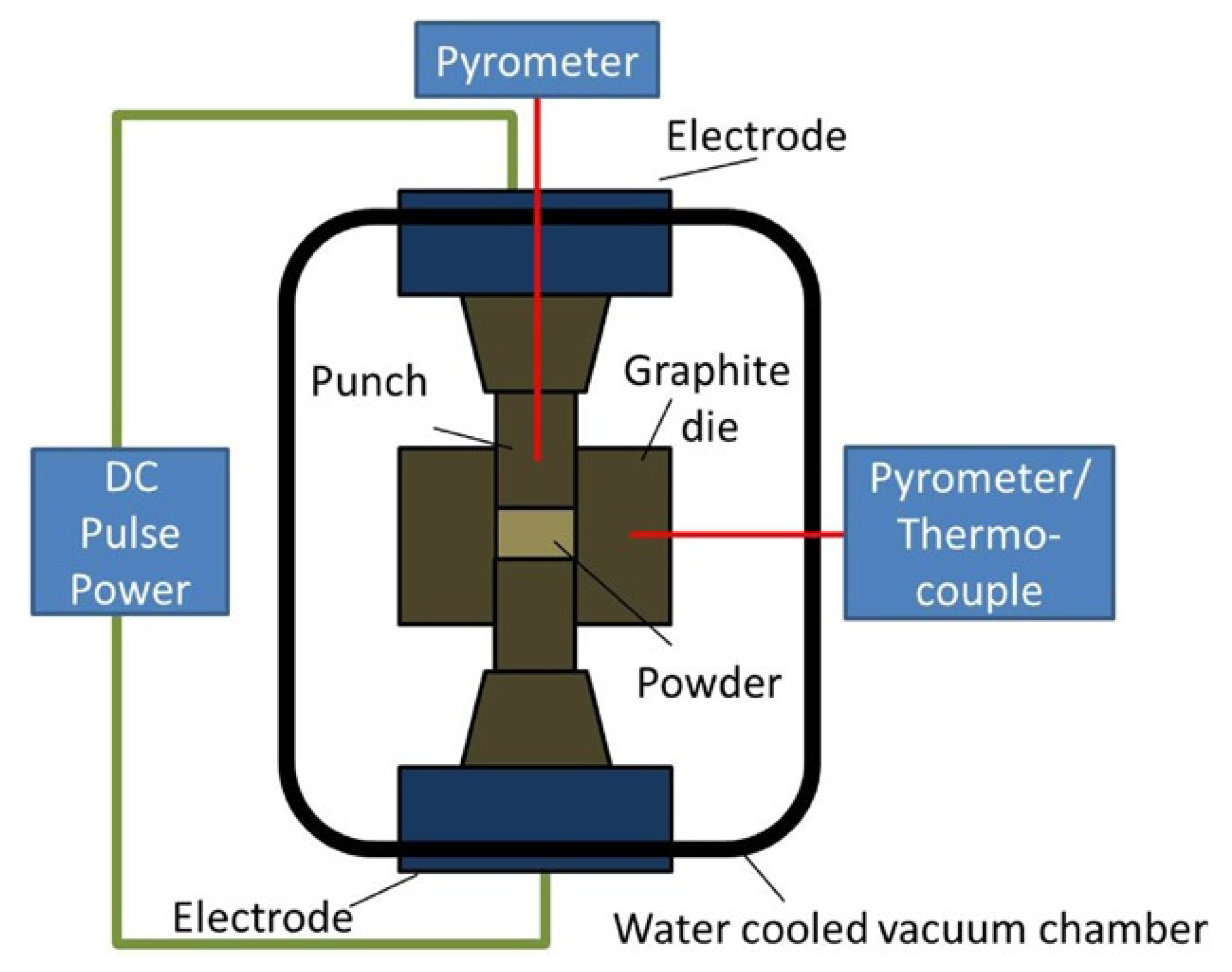

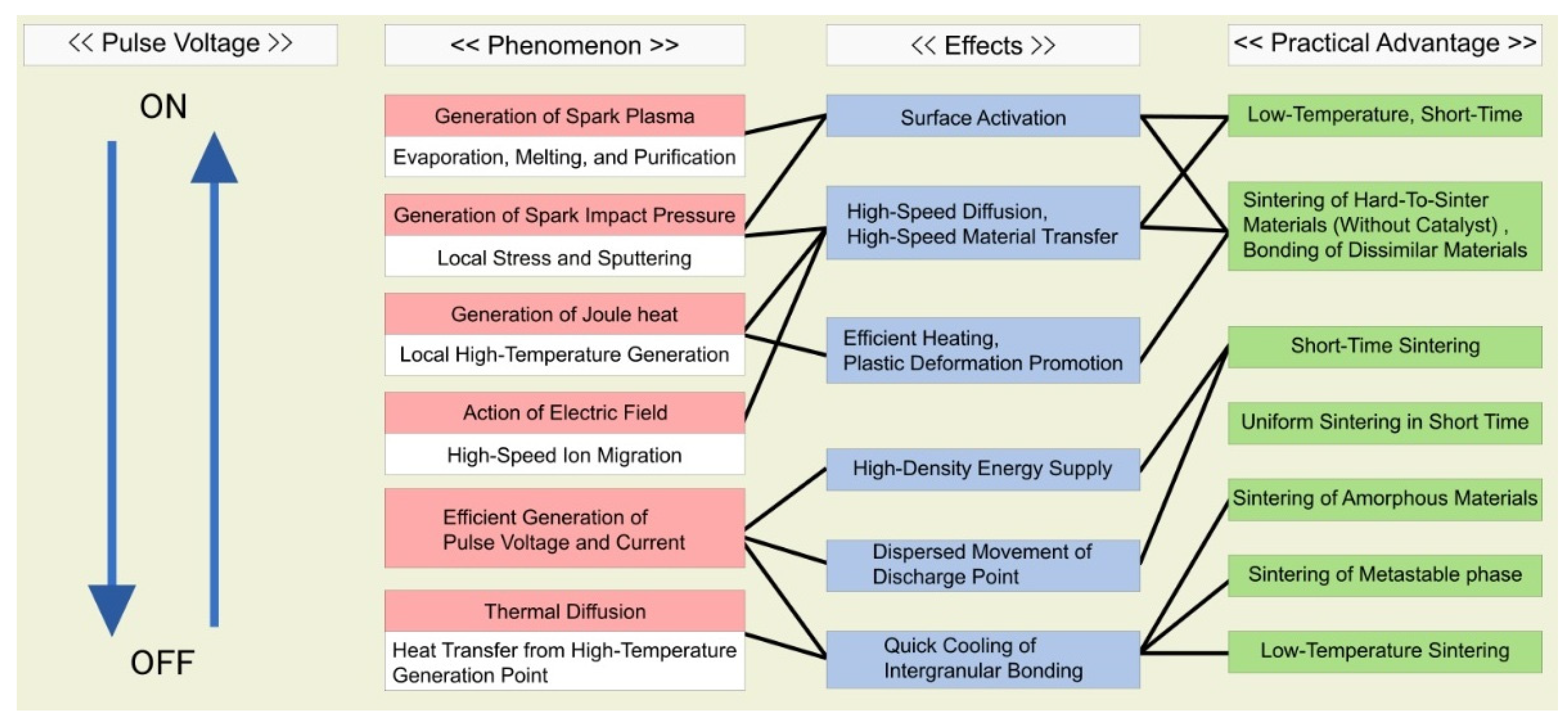

3. Mechanism of Spark Plasma Sintering

4. Transparent Ceramics

5. Transparent Glass-Ceramics

5.1. Silicate GCs

5.2. Chalcogenide GCs

5.3. OxyfluorideGCs

6. Conclusions and Future Prospects

Author Contributions

Funding

Conflicts of Interest

References

- Torralba, J.M. Improvement of mechanical and physical properties in powder metallurgy. Compr. Mater. Process. 2014, 3, 281–294. [Google Scholar]

- Tokita, M. Spark plasma sintering (SPS) method, systems, and applications. In Handbook of Advanced Ceramics, 2nd ed.; Somiya, S., Ed.; Elsevier Inc.: London, UK, 2013; pp. 1149–1175. [Google Scholar]

- Nygren, M.; Shen, Z. Ceramics Science and Technology, 1st ed.; Synthesis and Processing; WILEY-VCH Verlag Gmbh & Co. KGaA: Weinheim, Germany, 2012; Volume 3, p. 189. [Google Scholar]

- Kang, S.J.L. Sintering: Densification, Grain Growth and Microstructure; Heinemann, B., Ed.; Elsevier: London, UK, 2005. [Google Scholar]

- Ghosh, N.C.; Harimkar, S.P. Consolidation and synthesis of MAX phases by Spark Plasma Sintering (SPS): A review. In Advances in Science and Technology of Mn+1AXn Phases; Woodhead: London, UK, 2012; pp. 47–80. [Google Scholar]

- Huang, J.L.; Din, L.M.; Lu, H.H.; Chan, W.H. Effects of Two-Step Sintering on the Microstructure of Si3N4. Ceram. Int. 1996, 22, 131–136. [Google Scholar] [CrossRef]

- Chen, I.W.; Wang, X.H. Sintering dense nanocrystalline ceramics without final stage grain growth. Nature 2000, 404, 168–171. [Google Scholar] [CrossRef] [PubMed]

- Lukianova, O.; Novikov, V.Y.; Parkhomenko, A.A.; Sirota, V.; Krasil’Nikov, V.V. Microstructure of Spark Plasma-Sintered Silicon Nitride Ceramics. Nanoscale Res. Lett. 2017, 12, 293. [Google Scholar] [CrossRef]

- Belmonte, M.; González-Julián, J.; Miranzo, P.; Osendi, M.I. Spark plasma sintering: A powerful tool to develop new silicon nitride-based materials. J. Eur. Ceram. Soc. 2010, 30, 2937–2946. [Google Scholar] [CrossRef]

- Tamari, N.; Tanaka, T.; Tanaka, K.; Kondoh, I.; Kawahara, M.; Tokita, M. Effect of Spark Plasma Sintering on Densification and Mechanical Properties of Silicon Carbide. J. Ceram. Soc. Jpn. 1995, 103, 740–742. [Google Scholar] [CrossRef]

- Nygren, M. SPS Processing of Nano-Structured Ceramics. J. Iron Steel Res. Int. 2007, 14, 99–103. [Google Scholar] [CrossRef]

- Kim, H.C.; Shon, I.J.; Jeong, I.K.; Ko, I.Y.; Yoon, J.K.; Doh, J.M. Rapid sintering of ultrafine WC and WC-Co hard materials by high-frequency induction heated sintering and their mechanical properties. Met. Mater. Int. 2007, 13, 39–45. [Google Scholar] [CrossRef]

- Stookey, S.D. Catalyzed crystallization of glass in theory and practice. Ind. Eng. Chem. 1959, 51, 805–808. [Google Scholar] [CrossRef]

- Beall, G.H. Dr. S. Donald (Don) Stookey (1915–2014): Pioneering Researcher and Adventurer. Front. Mater. 2016, 3, 37. [Google Scholar] [CrossRef]

- Vaney, J.B.; Carreaud, J.; Piarristeguy, A.; Morin, C.; Delaizir, G.; Viennois, R.; Colas, M.; Cornette, J.; Alleno, E.; Monnier, J.; et al. Stabilization of metastable thermoelectric crystalline phases by tuning the glass composition in the Cu-As-Te system. Inorg. Chem. 2018, 57, 754–767. [Google Scholar] [CrossRef] [PubMed]

- Smiljanić, S.; Karamanova, E.; Grujić, S. Sintering, crystallization and foaming ofLa2O3·SrO·5B2O3 glass powders–effect of the holding temperature and the heatingrate. J. Non-Cryst. Solids 2018, 481, 375–382. [Google Scholar] [CrossRef]

- Siligardi, C.; Wu, J.P.; Boccaccini, A.R. Sintering and crystallisation of vanadium doped CaO–ZrO2–SiO2 glass-ceramics. Mater. Lett. 2006, 60, 1607–1612. [Google Scholar] [CrossRef]

- Anselmi-Tamburini, U.; Woolman, J.N.; Munir, Z.A. Transparent nanometric cubic and tetragonal zirconia obtained by high-pressure pulsed electric current sintering. Adv. Funct. Mater. 2007, 17, 3267–3273. [Google Scholar] [CrossRef]

- Suarez, M.; Fernandez, A.; Menendez, J.L.; Torrecillas, R. Grain growth control and transparency in spark plasma sintered self-doped alumina materials. Scr. Mater. 2009, 61, 931–934. [Google Scholar] [CrossRef]

- Meng, F.C.; Fu, Z.Y.; Zhang, J.Y.; Wang, H.; Wang, W.M.; Wang, Y.C. Rapid densification of nano-grained alumina by high temperature and pressure with a very high heating rate. J. Am. Ceram. Soc. 2007, 90, 1262–1264. [Google Scholar] [CrossRef]

- Chaim, R.; Shen, Z.J.; Nygren, M. Transparent nanocrystalline MgO by rapid and low-temperature spark plasma sintering. Mater. Sci. 2004, 19, 2527–2531. [Google Scholar] [CrossRef]

- Xiong, Y.; Fu, Z.Y.; Wang, Y.C.; Quan, F. Fabrication of transparent AIN ceramics. J. Mater. Sci. 2006, 41, 2537–2539. [Google Scholar] [CrossRef]

- Chaim, R.; Marder-Jaeckel, R.; Shen, J.Z. Transparent YAG ceramics by surface softening of nanoparticles in spark plasma sintering. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2006, 429, 74–78. [Google Scholar] [CrossRef]

- Frage, N.; Kalabukhov, S.; Sverdlov, N.; Ezersky, V.; Dariel, M.P. Densification of transparent yttrium aluminum garnet (YAG) by SPS processing. J. Eur. Ceram. Soc. 2010, 30, 3331–3337. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, Z. Transparent MgAl2O4 ceramic produced by spark plasma sintering. Scr. Mater. 2009, 61, 193–196. [Google Scholar] [CrossRef]

- Bernard-Granger, G.; Benameur, N.; Guizard, C.; Nygren, M. Influence of graphite contamination on the optical properties of transparent spinel obtained by spark plasma sintering. Scr. Mater. 2009, 60, 164–167. [Google Scholar] [CrossRef]

- Fedorov, P.P.; Luginina, A.A.; Popov, A.I. Transparent oxyfluoride glass ceramics. J. Fluor. Chem. 2015, 172, 22–50. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, J.; Zhou, S.; Yue, Y.; Qiu, J. Transparent glass-ceramics functionalizedby dispersed crystals. Prog. Mater. Sci. 2018, 97, 38–96. [Google Scholar] [CrossRef]

- De Pablos-Martín, A.; Mendez-Ramos, J.; del-Castillo, J.; Duran, A.; Rodríguez, V.D.; Pascual, M.J. Crystallization and up-conversion luminescence properties of Er3+/Yb3+-doped NaYF4-based nano-glass-ceramics. J. Eur. Ceram. Soc. 2015, 35, 1831–1840. [Google Scholar] [CrossRef]

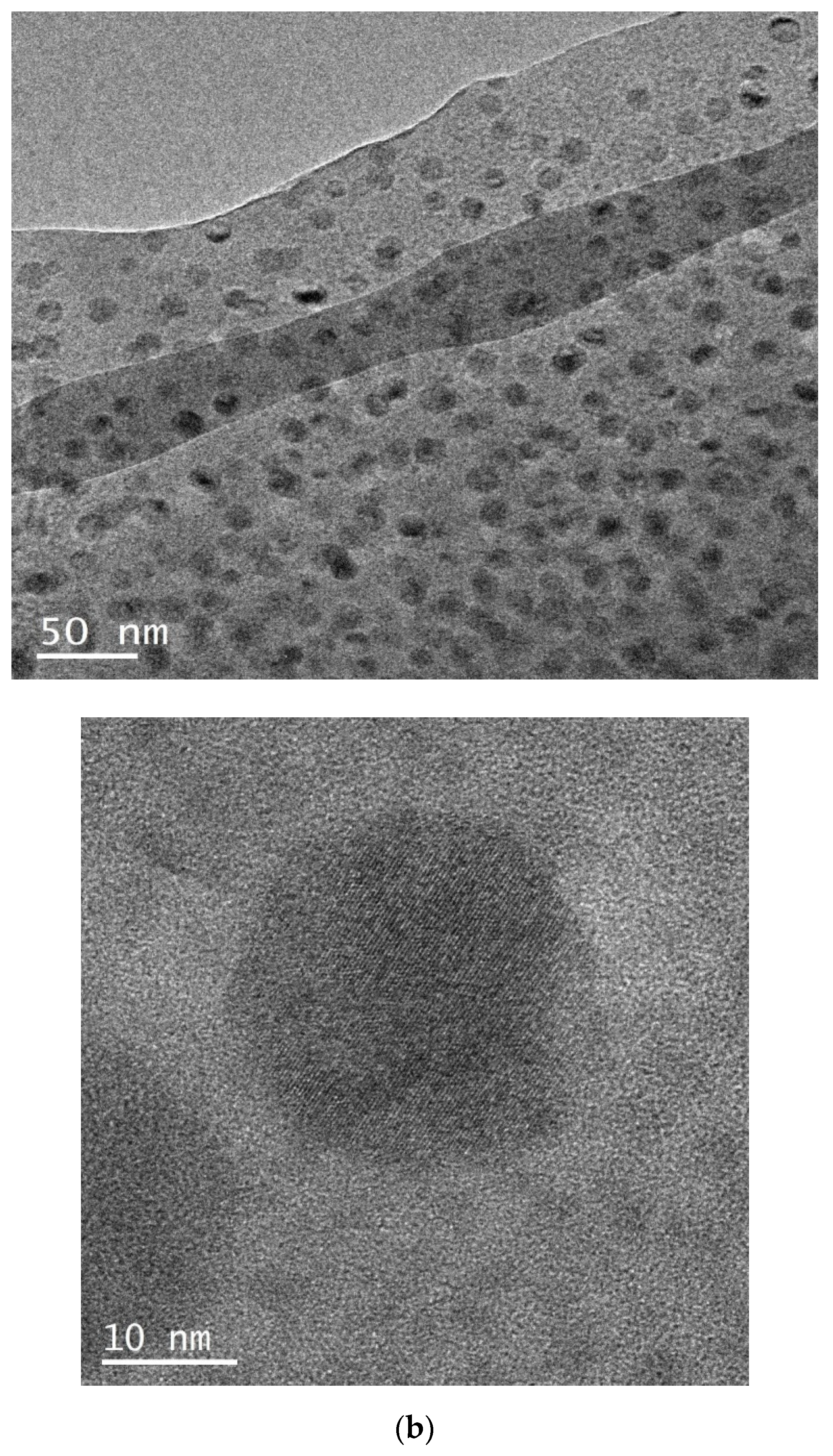

- De Pablos-Martín, A.; Mather, G.C.; Muñoz, F.; Bhattacharyya, S.; Höche, T.; Jinschek, J.R.; Heil, T.; Durán, A.; Pascual, M.J. Design of oxy-fluoride glass-ceramicscontaining NaLaF4nano-crystals. J. Non-Cryst. Solids 2010, 356, 3071–3079. [Google Scholar] [CrossRef]

- Guillon, O.; Gonzalez-Julian, J.; Dargatz, B.; Kessel, T.; Schierning, G.; Räthel, J.; Herrmann, M. Field-assisted sintering technology/spark plasma sintering: Mechanisms, materials, and technology developments. Adv. Eng. Mater. 2014, 16, 830–849. [Google Scholar] [CrossRef]

- Taylor, G.F. Apparatus for Making Hard Metal Compositions. U.S. Patent 1,896,854, 7 February 1993. [Google Scholar]

- Cremer, G.D. Sintering Together Powders Metals Such as Bronze, Brass or Aluminum. U.S. Patent 2,355,954, 15 August 1944. [Google Scholar]

- Inoue, K. Electric Discharge Sintering. U.S. Patent 3,241,956 (Ser.No.247,387 filed 1962), 22 March 1966. [Google Scholar]

- Inoue, K. Apparatus for Electrically Sintering Discrete Bodies. U.S. Patent 3,250,892, 10 May 1966. [Google Scholar]

- Saheb, N.; Iqbal, Z.; Khalil, A.; Hakeem, A.S.; Al-Aqeeli, N.; Laoui, T.; Al-Qutub, A.; Kirchner, R. Spark plasma sintering of metals and metal matrix nanocomposites: A review. J. Nanomater. 2012, 2012, 1–13. [Google Scholar] [CrossRef]

- Grasso, S.; Sakka, Y.; Maizza, G. Electric current activated/assisted sintering (ECAS): A review of patents 1906–2008. Sci. Technol. Adv. Mat. 2009, 10, 053001. [Google Scholar] [CrossRef]

- Suárez, M.; Fernández, A.; Menéndez, J.L.; Torrecillas, R.; Kessel, H.U.; Hennicke, J.; Kirchner, R.; Kessel, T. Challenges and Opportunities for Spark Plasma Sintering: A Key Technology for a New Generation of Materials. Intech. 2013, 319–338, Chapter 13. [Google Scholar] [CrossRef]

- Wang, H.; Qi, J.; Lu, Z.; Lu, T.; Wang, Q. On the densification mechanism of nanograined Yttrium aluminum garnet transparent ceramic during high pressure sintering process. Scr. Mater. 2018, 142, 126–128. [Google Scholar] [CrossRef]

- Frenkel, J. Viscous flow of crystalline bodies under the action of surface tension. J. Phys. (USSR) 1945, 9, 385–391. [Google Scholar]

- Bordia, R.K.; Kang, S.-J.L.; Olevsky, E.A. Current understanding and future research directions at the onset of the next century of sintering science and technology. J. Am. Ceram. Soc. 2017, 100, 2314–2352. [Google Scholar] [CrossRef]

- Weinberg, M.C. Nucleation and crystallization in glasses andliquids. J. Am. Ceram. Soc. 1993, 30, 127–133. [Google Scholar]

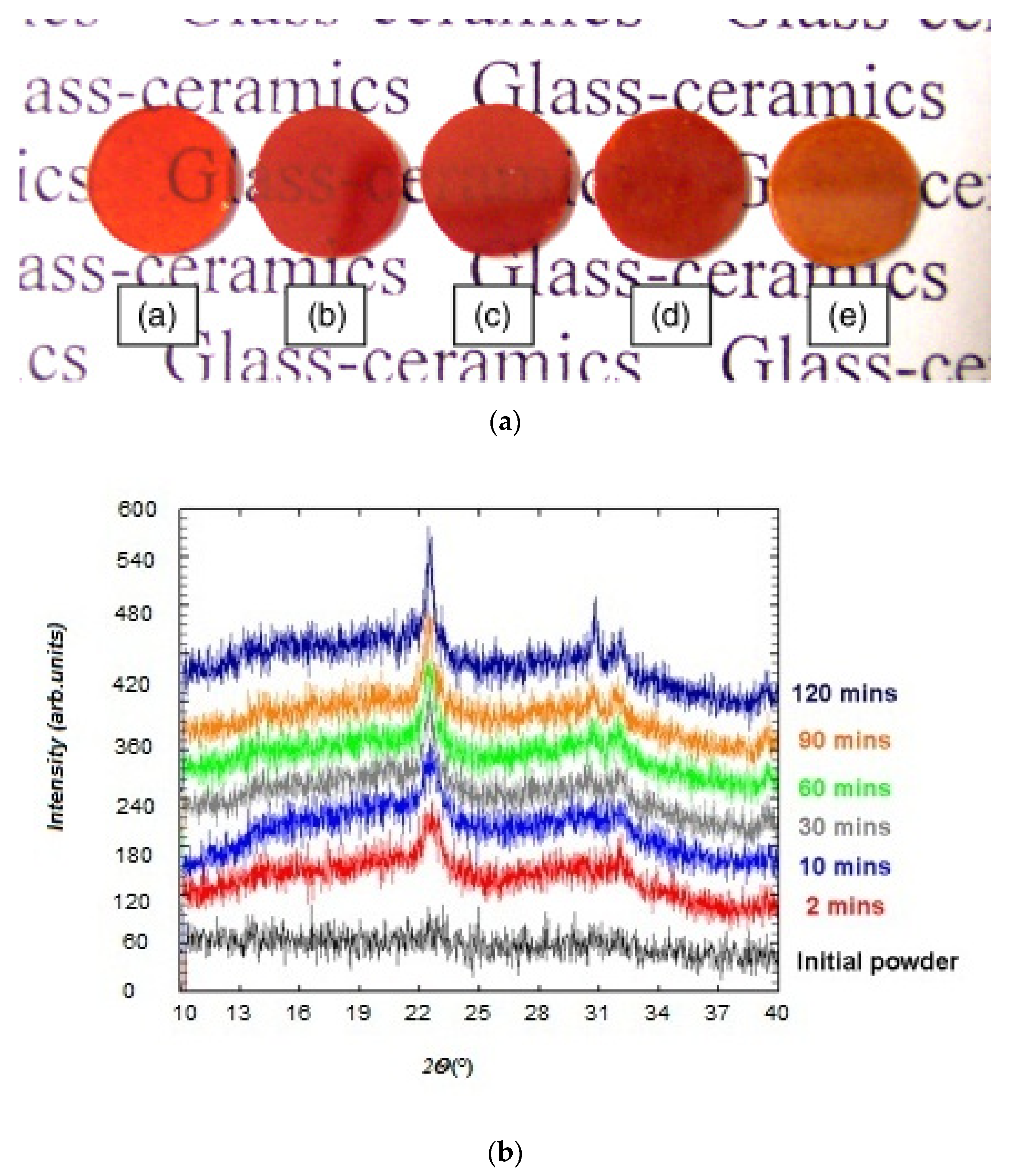

- Mansour, F.A.; Karpukhina, N.; Grasso, S. The effect of spark plasma sintering onlithiumdisilicate glass-ceramics. Dent. Mater. 2015, 31, 226–235. [Google Scholar] [CrossRef]

- He, T.; He, Q.; Wang, N. Synthesis of nano-sized YSZ powders from glycine-nitrate process and optimization of their properties. J. Alloy. Compd. 2005, 396, 309–315. [Google Scholar] [CrossRef]

- Alvarez-Clemares, I.; Mata-Osoro, G.; Fernandez, A.; Lopez-Esteban, S.; Pecharroman, C.; Palomares, J. Transparent alumina/ceria nanocomposites by spark plasma sintering. Adv. Eng. Mater. 2010, 12, 1154–1160. [Google Scholar] [CrossRef]

- Chaim, R.; Kalina, M.; Shen, J.Z. Transparent yttrium aluminum garnet (YAG) ceramics by spark plasma sintering. J. Eur. Ceram. Soc. 2007, 27, 3331–3337. [Google Scholar] [CrossRef]

- Hua, Z.W.; Xua, X.D.; Jun, W.; Liu, P.; Li, D.Z.; Wang, X.D.; Zhang, J.; Xu, J.; Tang, D.Y. Fabrication and spectral properties of Dy:Y2O3 transparent ceramics. J. Eur. Ceram. Soc. 2018, 29, 1981–1985. [Google Scholar] [CrossRef]

- Bigotta, S.; Galecki, L.; Katz, A.; Böhmler, J.; Lemonnier, S.; Barraud, E.; Leriche, A.; Eichhorn, M. Resonantly pumped eye-safe Er3+:YAG SPS-HIP ceramic laser. Opt. Express 2018, 26, 3435–3442. [Google Scholar] [CrossRef]

- Wagner, A.; Ratzker, B.; Kalabukhov, S. Highly-doped Nd:YAG ceramics fabricated by conventional and high pressure SPS. Ceram. Int. 2017, 45, 12279–12284. [Google Scholar] [CrossRef]

- Valiev, D.; Stepanov, S.; Khasanov, O.E.; Dvilis, E.; Polisadova, E.; Paygin, V. Synthesis and optical properties of Tb3+ or Dy3+-doped MgAl2O4 transparent ceramics. Opt. Mater. 2019, 91, 396. [Google Scholar] [CrossRef]

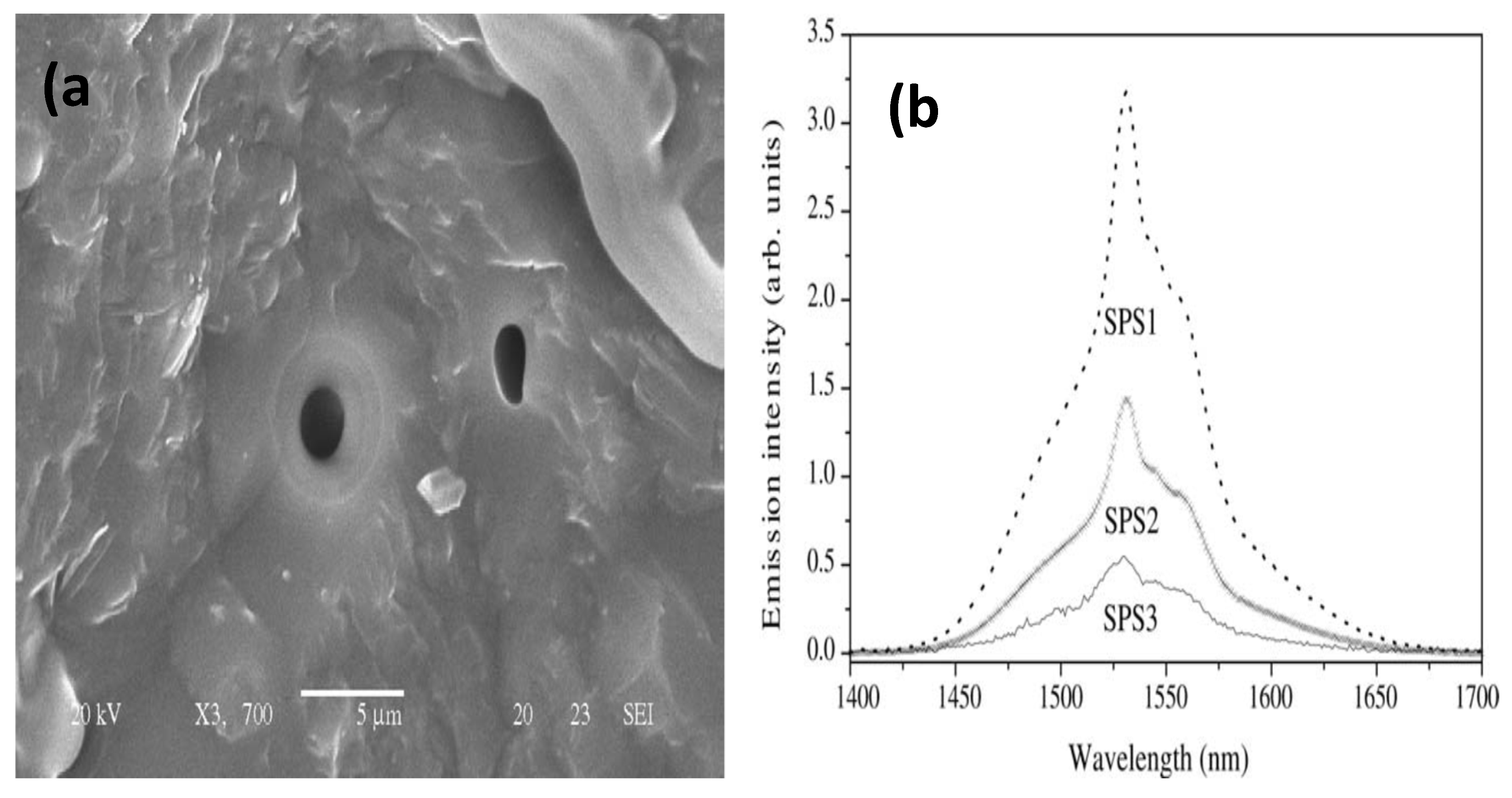

- Riello, P.; Bucella, S.; Zamengo, L.; Anselmi-Tamburini, U.; Francini, R.; Pietrantoni, S.; Munir, Z.A. Erbium-doped, LAS glass ceramics prepared by spark plasma sintering (SPS). J. Eur. Ceram. Soc. 2006, 26, 3301–3306. [Google Scholar] [CrossRef]

- Chen, Q.Z.; Thompson, I.D.; Boccaccini, A.R. 45S5 Bioglass®-derived glass–ceramic scaffolds for bone tissue engineering. Biomaterials 2006, 27, 2414–2425. [Google Scholar] [CrossRef] [PubMed]

- Esteban, S.L.; Bartolome, J.F.; Diaz, L.A.; Tejeda, L.E.; Prado, C.; Piriz, R.L.; Torrecillas, R.; Moya, J.S. Mechanical performance of a biocompatible biocide soda–lime glass-ceramic. J. Mech. Behav. Biomed. Mater. 2014, 34, 302–312. [Google Scholar] [CrossRef]

- Le, F.; Engqvist, H.; Wei, X. Highly translucent and strong ZrO2-SiO2nanocrystalline glass ceramic prepared by sol-gel method and spark plasma sintering with fine 3D microstructure for dental restoration. J. Eur. Ceram. Soc. 2017, 37, 4067–4081. [Google Scholar]

- Kim, S.; Kim, B.; Kim, H. Optical properties of densified phosphor-inglass LED encapsulantsby spark plasma sintering. Opt. Mater. Express 2017, 7, 4304–4315. [Google Scholar] [CrossRef]

- Delaizir, G.; Dollé, M.; Rozier, P.; Zhang, X.H. Spark Plasma Sintering: An Easy way to Make Infrared Transparent Glass-Ceramics. J. Am. Ceram. Soc. 2010, 93, 2495–2498. [Google Scholar] [CrossRef]

- Hubert, M.; Delaizir, G.; Monnier, J.; Godart, C.; Ma, H.L.; Zhang, X.-H.; Calvez, L. An Innovative Approach to Develop Highly Performant Chalcogenide Glasses and Glass-Ceramics Transparent in the Infrared Range. Opt. Express 2011, 19, 23513–23522. [Google Scholar] [CrossRef]

- Delaizir, G.; Gueguen, Y.; Hubert, M. Investigation of the mechanisms involved in the sintering of chalcogenide glasses and the preparation of glass-ceramics by spark plasma sintering. J. Am. Ceram Soc. 2012, 95, 2211–2217. [Google Scholar] [CrossRef]

- Bertrand, A.; Carreaud, J.; Delaizir, G.; Duclere, J.R.; Colas, M.; Cornette, J.; Vandenhende, M.; Couderc, V.; Thomas, P. A comprehensive study of the carbon contamination in tellurite glasses and glass-ceramics sintered by spark plasma sintering (SPS). J. Am. Ceram. Soc. 2014, 97, 163–172. [Google Scholar] [CrossRef]

- Xue, B.; Calvez, L.; Nazabal, V.; Zhang, X.H.; Delaizir, G.; Monnier. J. Mechanical milling and SPS used to obtain GeS2-βGeS2, infrared glass-ceramic. J Non-Cryst Solids 2013, 377, 240–244. [Google Scholar] [CrossRef]

- Cui, S.; Boussard-pledel, C.; Calvez, L.; Rojas, F.; Chen, K.; Ning, H.; Reece, M.J.; Guizouarn, T.; Bureau, B. Comprehensive study of tellurium based glass ceramics for thermoelectric application. Adv. Appl. Ceram. 2015, 114, S42–S47. [Google Scholar] [CrossRef]

- Hémono, N.; Pierre, G.; Muñoz, F.; de Pablos-Martín, A.; Pascual, M.J.; Durán, A. Processing of transparent glass-ceramics by nanocrystallisation of LaF3. J. Eur. Ceram. Soc. 2009, 29, 2915–2920. [Google Scholar] [CrossRef]

- Gorni, G.; Cosci, A.; Pelli, S.; Pascual, L.; Durán, A.; Pascual, M.J. Transparent Oxyfluoride Nano-Glass Ceramics Doped with Pr3+ and Pr3+–Yb3+ for NIR Emission. Front. Mater. 2017, 3, 58. [Google Scholar] [CrossRef]

- De Pablos-Martín, A.; Ristic, D.; Bhattacharyya, S.; Höche, T.; Mather, G.C.; Ramírez, M.O.; Soria, S.; Ferrari, M.; Righini, G.C.; Bausá, L.E.; et al. Effects of Tm3+ additions on the crystallization of LaF3 nanocrystals in oxyfluoride glasses: Optical characterization and up-conversion. J. Am. Ceram. Soc. 2013, 96, 447–457. [Google Scholar]

- De Pablos-Martín, A.; Hémono, N.; Mather, G.C.; Bhattacharyya, S.; Höche, T.; Bornhöft, H.; Deubener, J.; Muñoz, F.; Durán, A.; Pascual, M.J. Crystallizationkinetics of LaF3nanocrystals in an oxyfluoride glass. J. Am. Ceram. Soc. 2011, 94, 2420–2428. [Google Scholar] [CrossRef]

- Velázquez, J.J.; Balda, R.; Fernández, J.; Gorni, G.; Pascual, L.; Chen, G.; Sundararajan, M.; Durán, A.; Pascual, M.J. Transparent oxyfluoride glass-ceramics with NaGdF4 nanocrystals doped with Pr3+ and Pr3+-Yb3+. J. Lumin. 2018, 193, 61–69. [Google Scholar] [CrossRef]

- De Pablos-Martín, A.; Ramírez, M.O.; Durán, A.; Bausá, L.E.; Pascual, M.J. Tm3+doped oxy-fluoride glass-ceramics containing NaLaF4nano-crystals. Opt. Mater. 2010, 33, 180–185. [Google Scholar] [CrossRef]

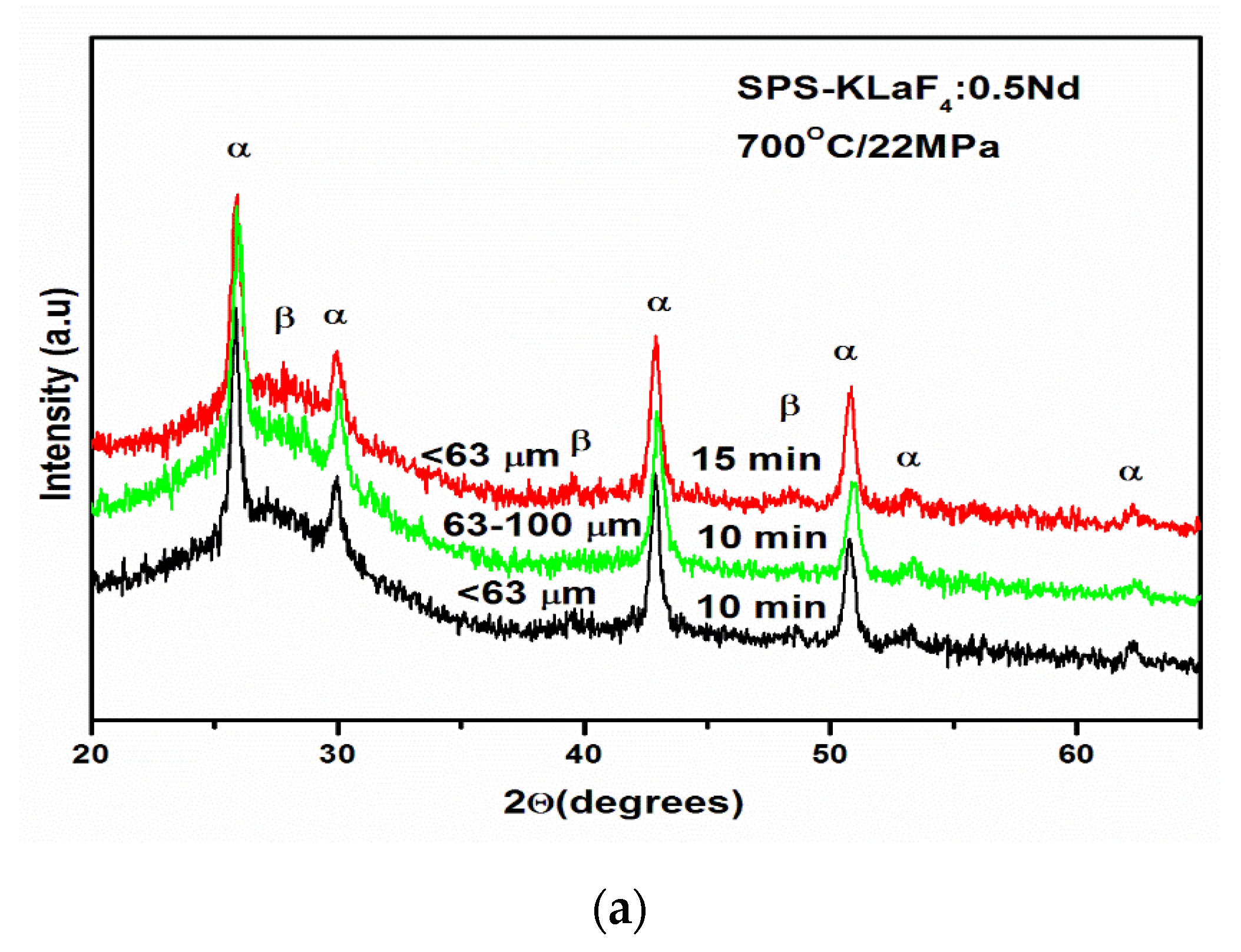

- Cabral, A.A.; Balda, R.; Fernández, J.; Gorni, G.; Velazquez, J.; Pascual, L.; Durán, A.; Pascual, M.J. Phase evolution of KLaF4 nanocrystals and its effects on the photoluminescence of Nd3+ doped transparent oxyfluoride glass-ceramics. CrystEngComm 2018, 20, 5760–5771. [Google Scholar] [CrossRef]

- De Pablos-Martin, A.; Patzig, C.; Höche, T.; Duran, A.; Pascual, M.J. Distribution of thulium in Tm3+-doped oxyfluoride glasses and glass-ceramics. CrystEngComm 2013, 15, 6979–6985. [Google Scholar] [CrossRef]

- De Pablos-Martín, A.; Muñoz, F.; Mather, G.C.; Patzig, C.; Bhattacharyya, S.; Jinschek, J.R.; Höche, T.; Durán, A.; Pascual, M.J. KLaF4nanocrystallisation in oxyfluoride glass-ceramics. CrystEngComm 2013, 15, 10323–10332. [Google Scholar] [CrossRef]

- Gorni, G.; Velázquez, J.J.; Mather, G.C.; Durán, A.; Chen, G.; Sundararajan, M.; Balda, R.; Fernández, J.; Pascual, M.J. Selective excitation in transparent oxyfluoride glass-ceramics doped with Nd3+. J. Eur. Ceram. Soc. 2017, 37, 1695–1706. [Google Scholar] [CrossRef]

- Gorni, G.; Balda, R.; Fernández, J.; Pascual, L.; Durán, A.; Pascual, M.J. Effect of the heat treatment on the spectroscopic properties of Er3+-Yb3+-doped transparent oxyfluoridenano-glass-ceramics. J. Lumin. 2018, 93, 51–60. [Google Scholar] [CrossRef]

- Gorni, G.; Velázquez, J.J.; Mosa, J.; Balda, R.; Fernández, J.; Durán, A.; Castro, Y. Transparent Glass-Ceramics Produced by Sol-Gel: A Suitable Alternative for Photonic Materials. Materials 2018, 11, 212. [Google Scholar] [CrossRef]

- Velazquez, J.J.; Balda, R.; Fernández, J.; Gorni, G.; Mather, G.C.; Pascual, L.; Duran, A.; Pascual, M.J. Transparent glass-ceramics of sodium-lutetium fluoride codoped with erbium and ytterbium. J. Non-Cryst. Solids 2018, 501, 136–144. [Google Scholar] [CrossRef]

- Pascual, M.J.; Garrido, C.; Durán, A.; Miguel, A.; Pascual, L.; De Pablos-Martín, A.; Fernández, J.; Balda, R. Optical properties of transparent glass-ceramics containingEr3+-doped sodium lutetium fluoride nanocrystals. Int. J. Appl. Glas. Sci. 2016, 7, 27–40. [Google Scholar] [CrossRef]

- Gorni, G.; Pascual, M.J.; Caballero, A.; Velázquez, J.J.; Mosa, J.; Castro, Y.; Durán, A. Crystallization mechanism in sol-gel oxyfluoride glass-ceramics. J. Non-Cryst. Solids 2018, 501, 145–152. [Google Scholar] [CrossRef]

- Velázquez, J.J.; Mosa, J.; Gorni, G.; Durán, A.; Castro, Y. Transparent SiO2-GdF3 sol–gel nano-glass ceramics for optical applications. J. Sol-Gel Sci. Technol. 2019, 89, 322–332. [Google Scholar] [CrossRef]

- Velazquez, J.J.; Mosa, J.; Gorni, G.; Balda, R.; Fernández, J.; Pascual, L.; Duran, A.; Castro, Y. Novel sol-gel SiO2-NaGdF4transparent nano-glass-ceramics. J. Non-Cryst. Solids 2019, 520, 19447. [Google Scholar] [CrossRef]

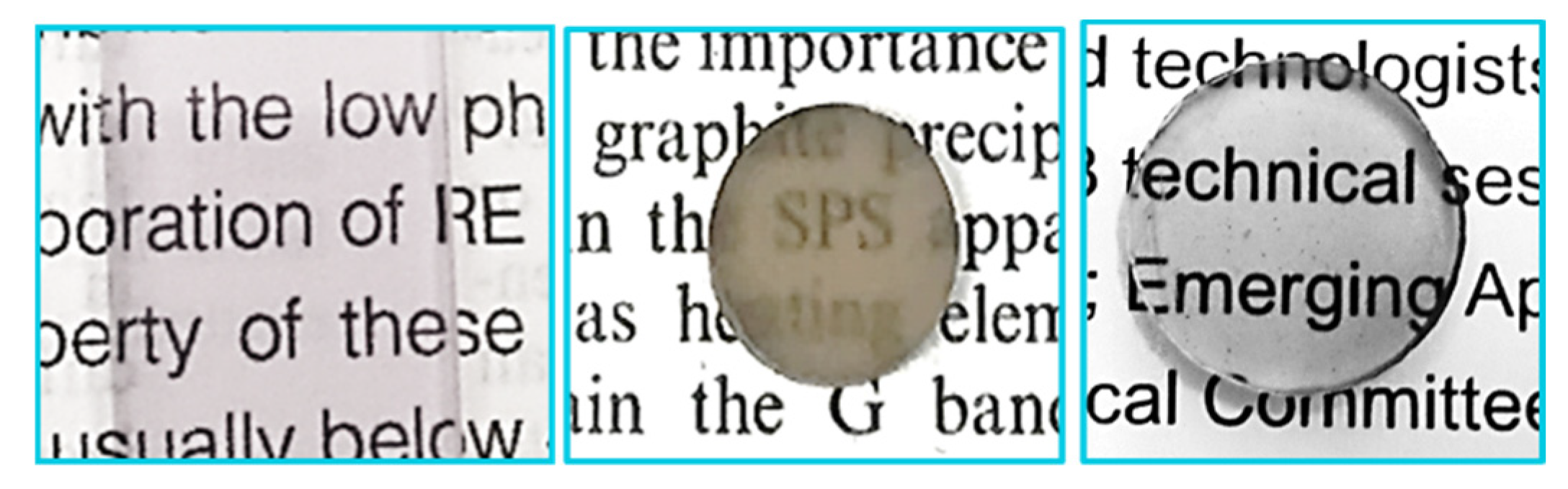

- Babu, S.; Balda, R.; Cabral, A.A.; Fernández, J.; Sedano, M.; Galusek, D.; Durán, A.; Pascual, M.J. KLaF4:Nd3+ doped transparent glass-ceramic materials synthesized by Spark Plasma Sintering (SPS) for solid-state laser applications. J. Eur. Ceram. 2020. submitted. [Google Scholar]

| Variables related to the starting powders (material variables) | Powder: shape, size, size distribution, agglomeration, mixture, etc. |

| Chemistry: composition, impurities, non-stoichiometry, homogeneity. | |

| Parameters related to sintering conditions (process variables) | Temperature, time, pressure, atmosphere, heating and cooling rate, etc. |

| Process/Properties | SPS Sintering | Conventional Method |

|---|---|---|

| Temperature rise rate | Excellent | Difficult |

| Temperature cooling rate | Fast | Slow |

| Homogeneity | Excellent | Fair |

| Temperature rise time | Fast | Slow |

| Holding time | Short | Long |

| Influence of pressure | Excellent | Absence |

| Transparency | Excellent | Good |

| Grain boundary controlled sintering | Excellent | - |

| Control of the nanometric size of the crystals | Excellent | Excellent |

| Carbon contamination | High | None |

| Densification | Excellent | Excellent |

| Mechanical strength | Excellent | Good |

| Processed using | Powder particles | Bulk sample |

| Mass Production | Difficult | Excellent |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singarapu, B.; Galusek, D.; Durán, A.; Pascual, M.J. Glass-Ceramics Processed by Spark Plasma Sintering (SPS) for Optical Applications. Appl. Sci. 2020, 10, 2791. https://doi.org/10.3390/app10082791

Singarapu B, Galusek D, Durán A, Pascual MJ. Glass-Ceramics Processed by Spark Plasma Sintering (SPS) for Optical Applications. Applied Sciences. 2020; 10(8):2791. https://doi.org/10.3390/app10082791

Chicago/Turabian StyleSingarapu, Babu, Dušan Galusek, Alicia Durán, and María Jesús Pascual. 2020. "Glass-Ceramics Processed by Spark Plasma Sintering (SPS) for Optical Applications" Applied Sciences 10, no. 8: 2791. https://doi.org/10.3390/app10082791

APA StyleSingarapu, B., Galusek, D., Durán, A., & Pascual, M. J. (2020). Glass-Ceramics Processed by Spark Plasma Sintering (SPS) for Optical Applications. Applied Sciences, 10(8), 2791. https://doi.org/10.3390/app10082791