Mechanical Stability of Hybrid Corrugated Sandwich Plates under Fluid-Structure-Thermal Coupling for Novel Thermal Protection Systems

Abstract

1. Introduction

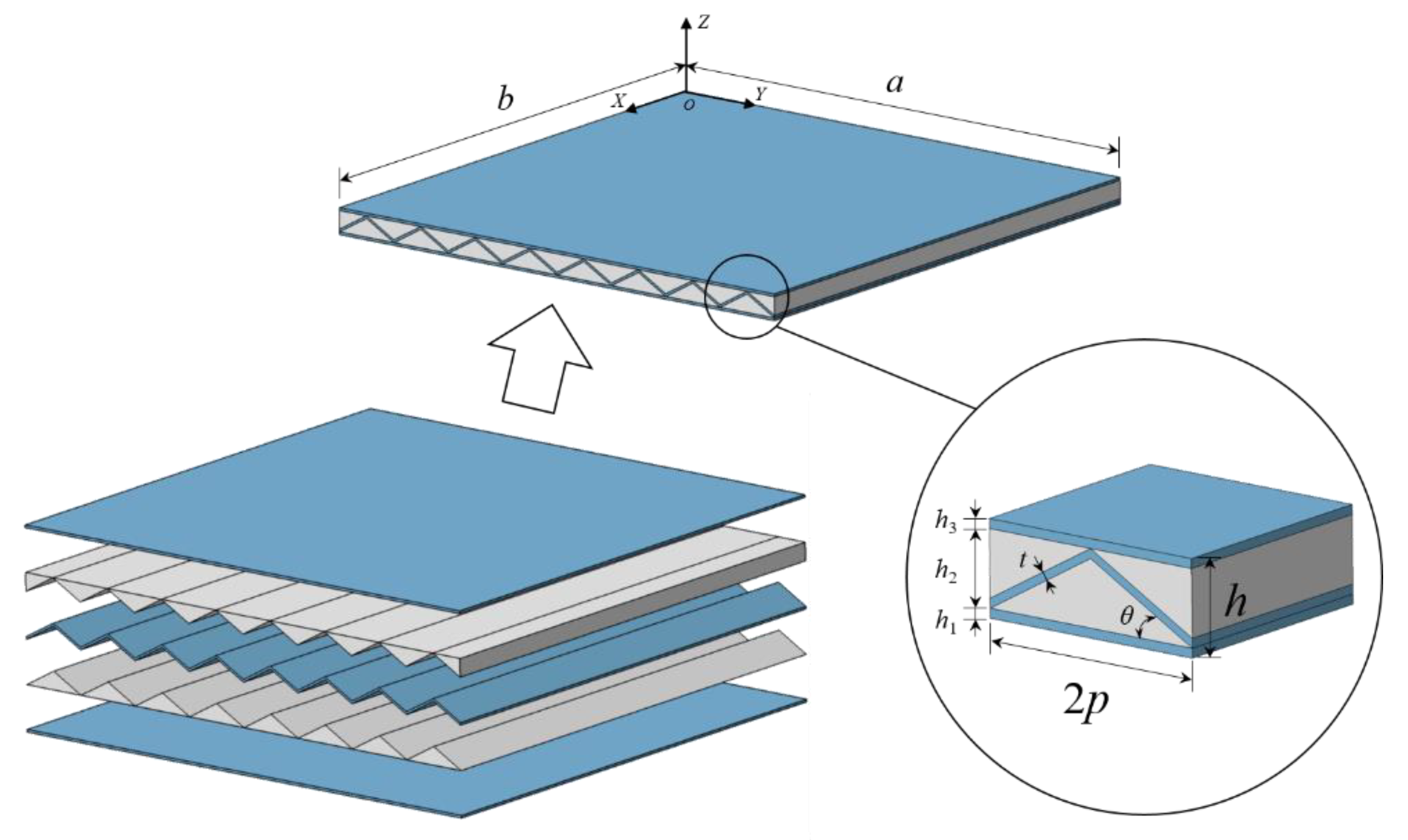

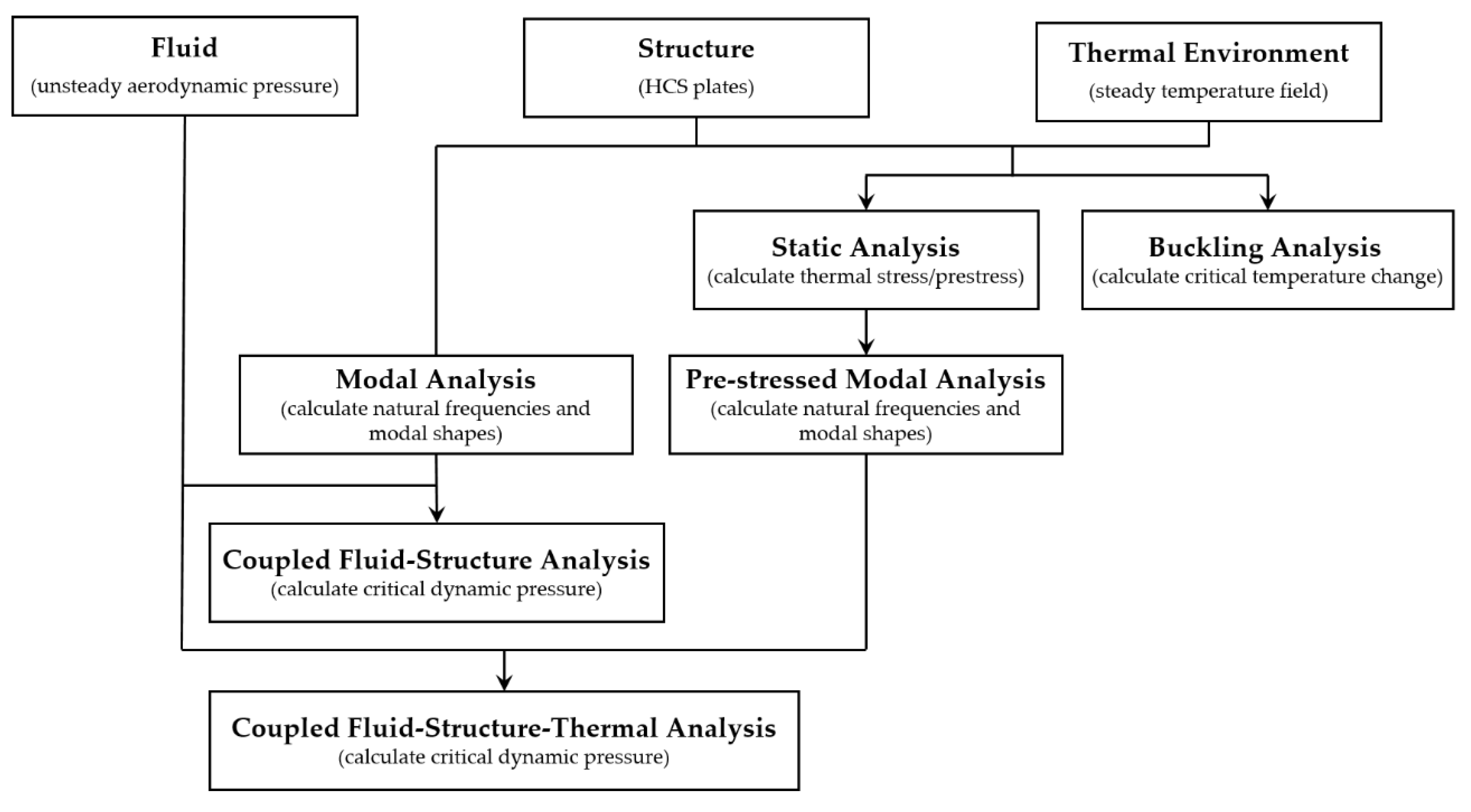

2. Methods

2.1. Layerwise Theory

2.2. Strain-Displacement Relations

2.3. Stress-Strain Relations

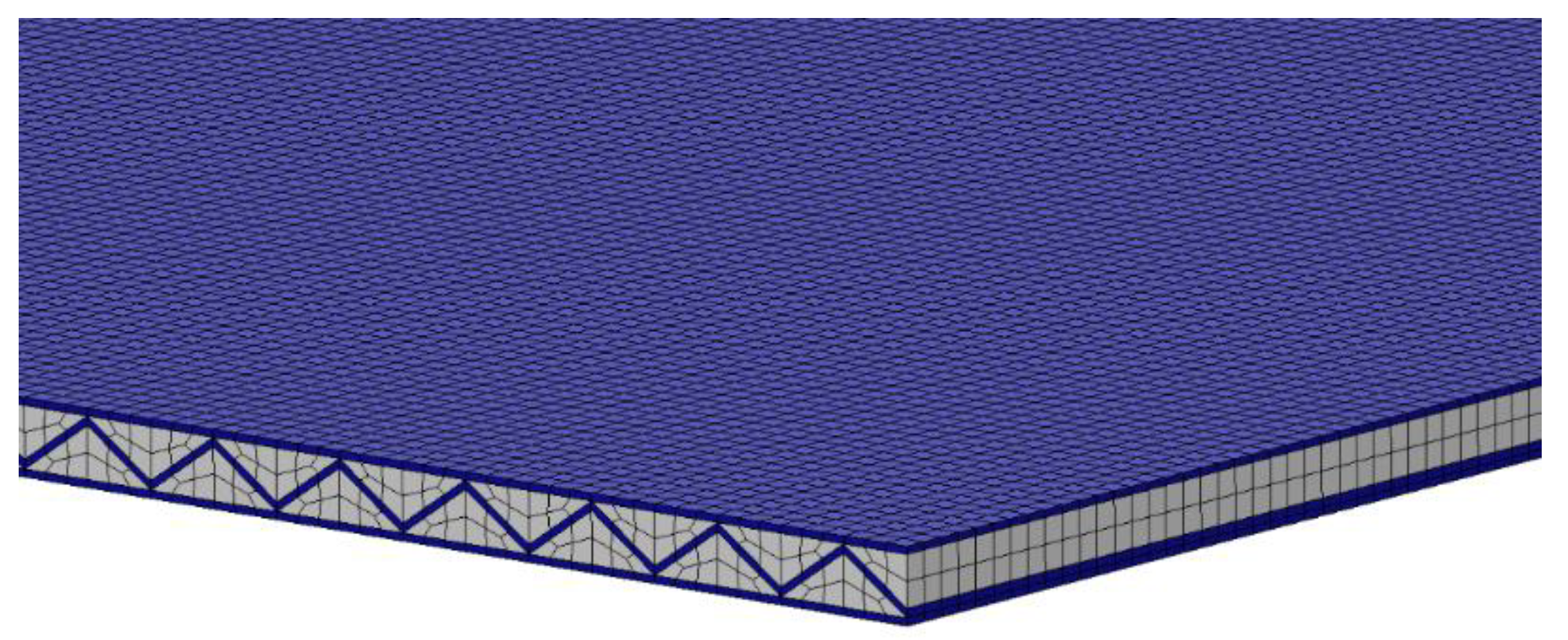

2.4. Finite Element Method

2.4.1. Kinetic Energy

2.4.2. Potential Energy

2.4.3. Work Done by External Force

2.4.4. Governing Equations

2.4.5. Solution Procedure

3. Numerical Examples and Results

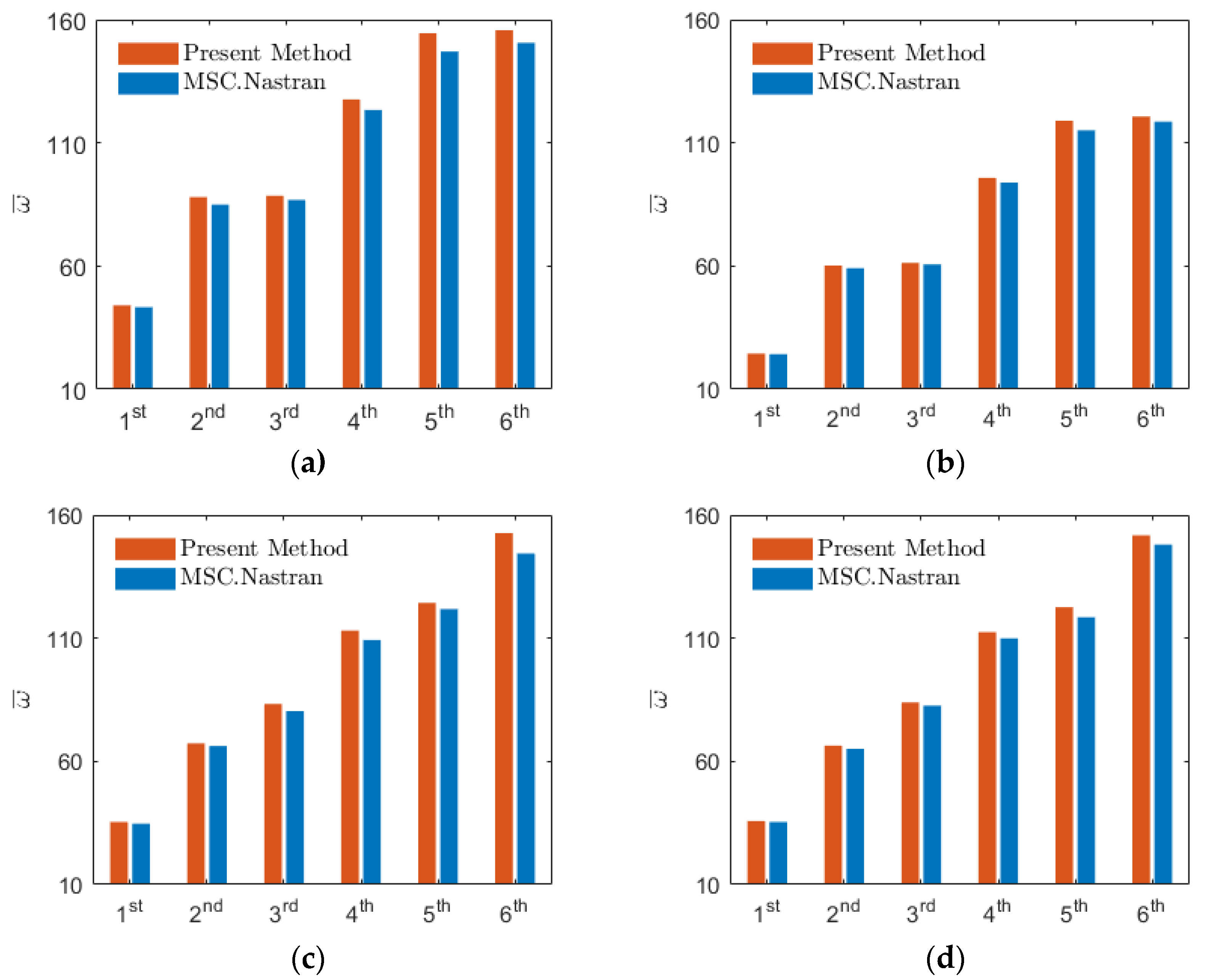

3.1. Validation Study

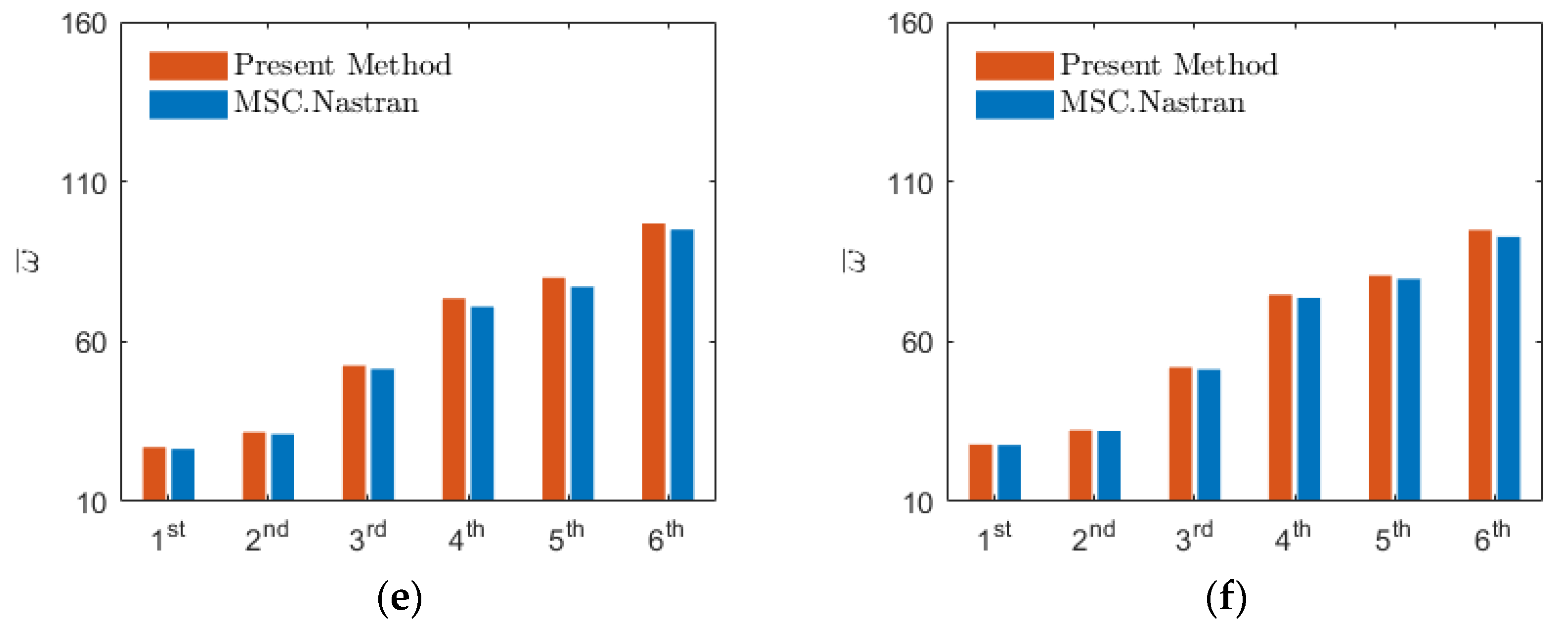

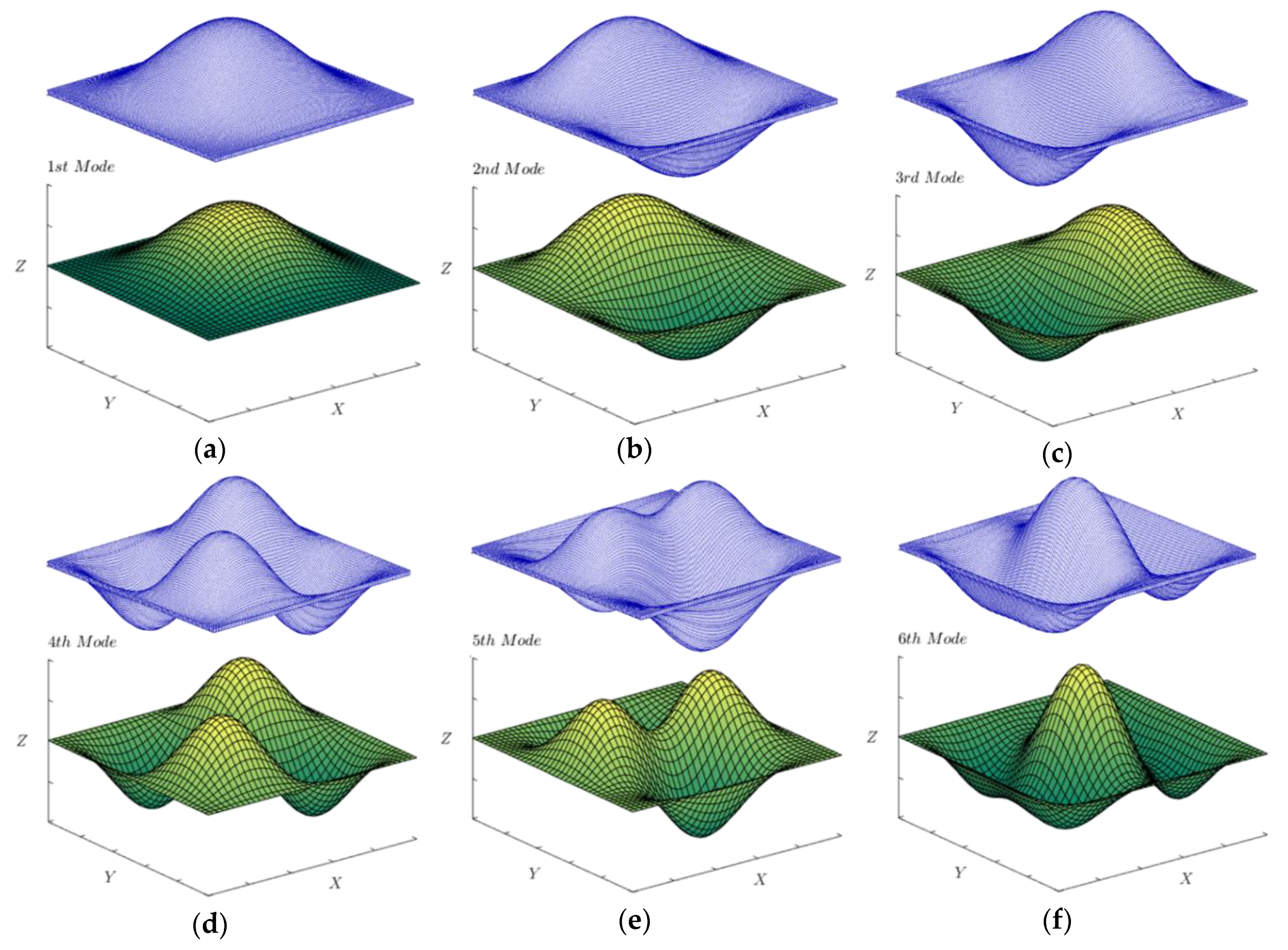

3.2. Buckling Amalysis and Pre-Stressed Modal Analysis

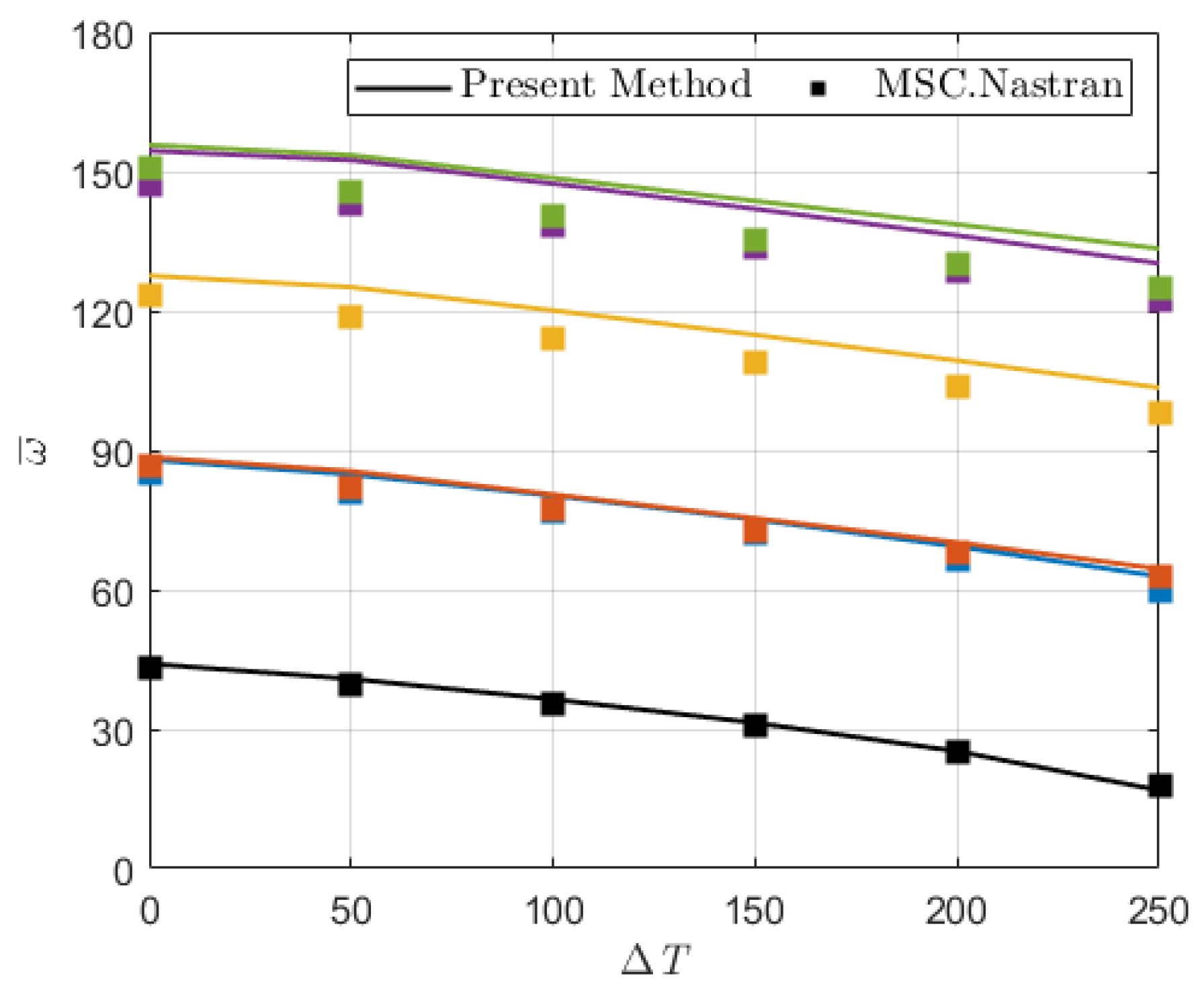

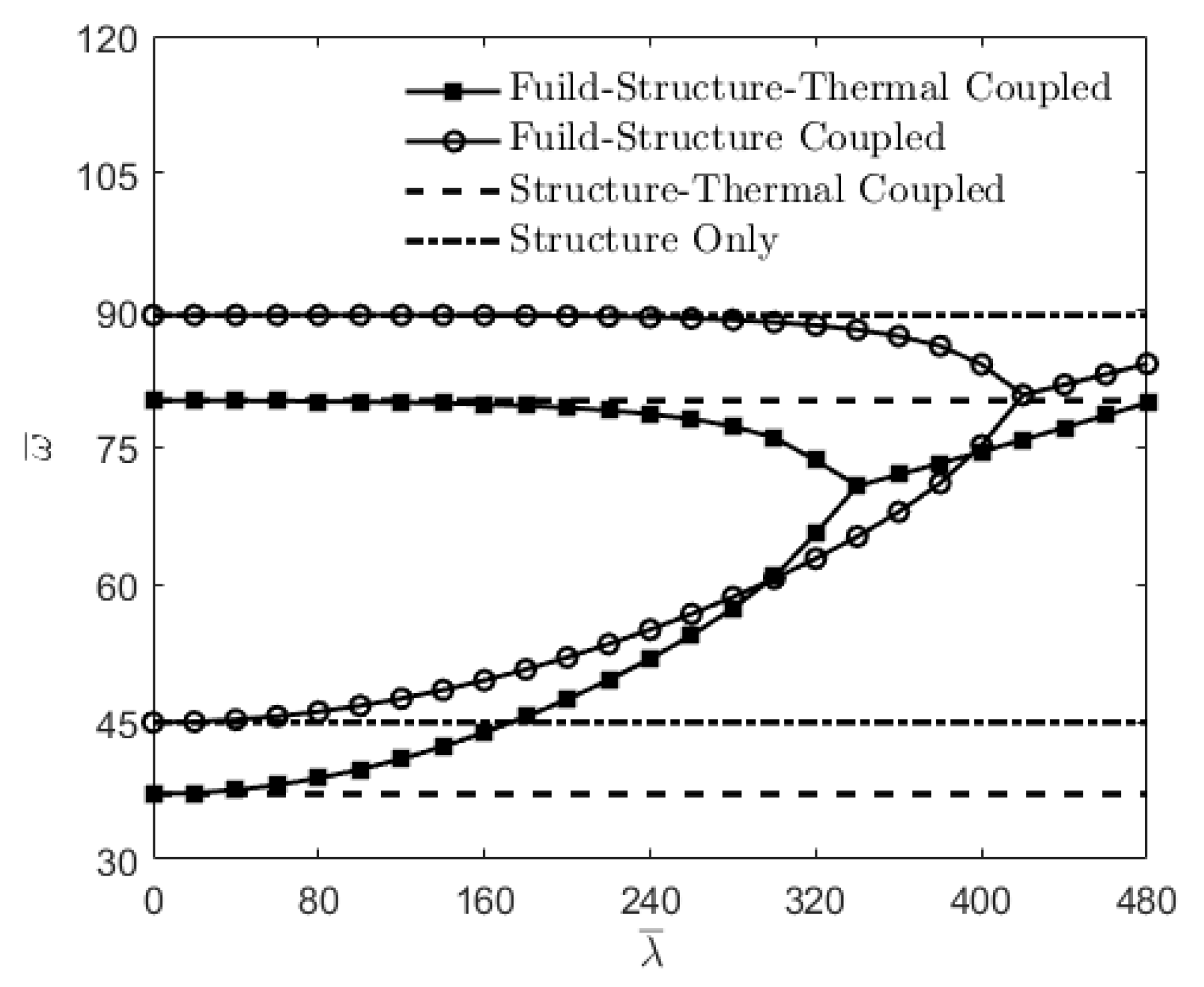

3.3. Coupled Fluid-Structure-Thermal Analysis

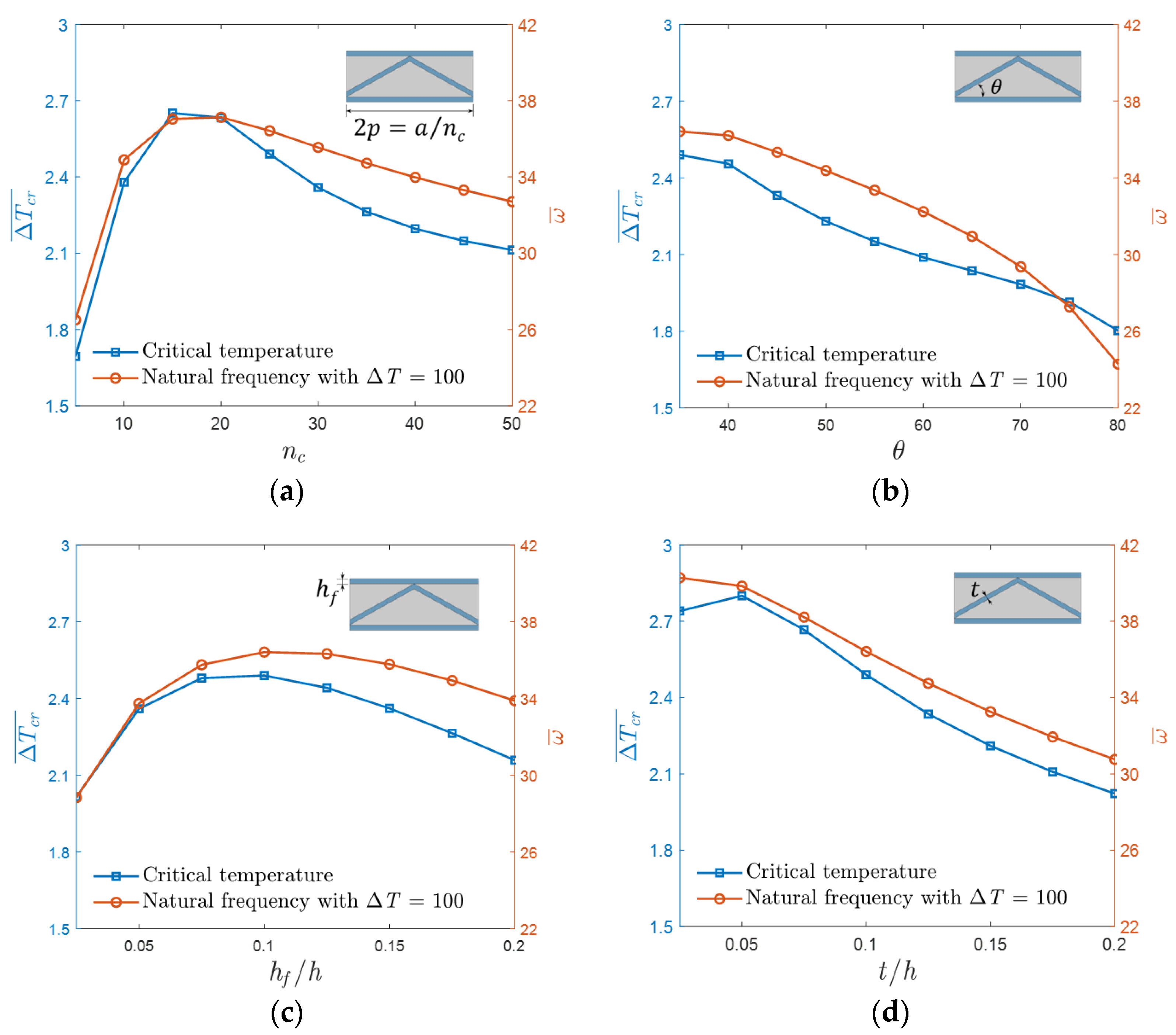

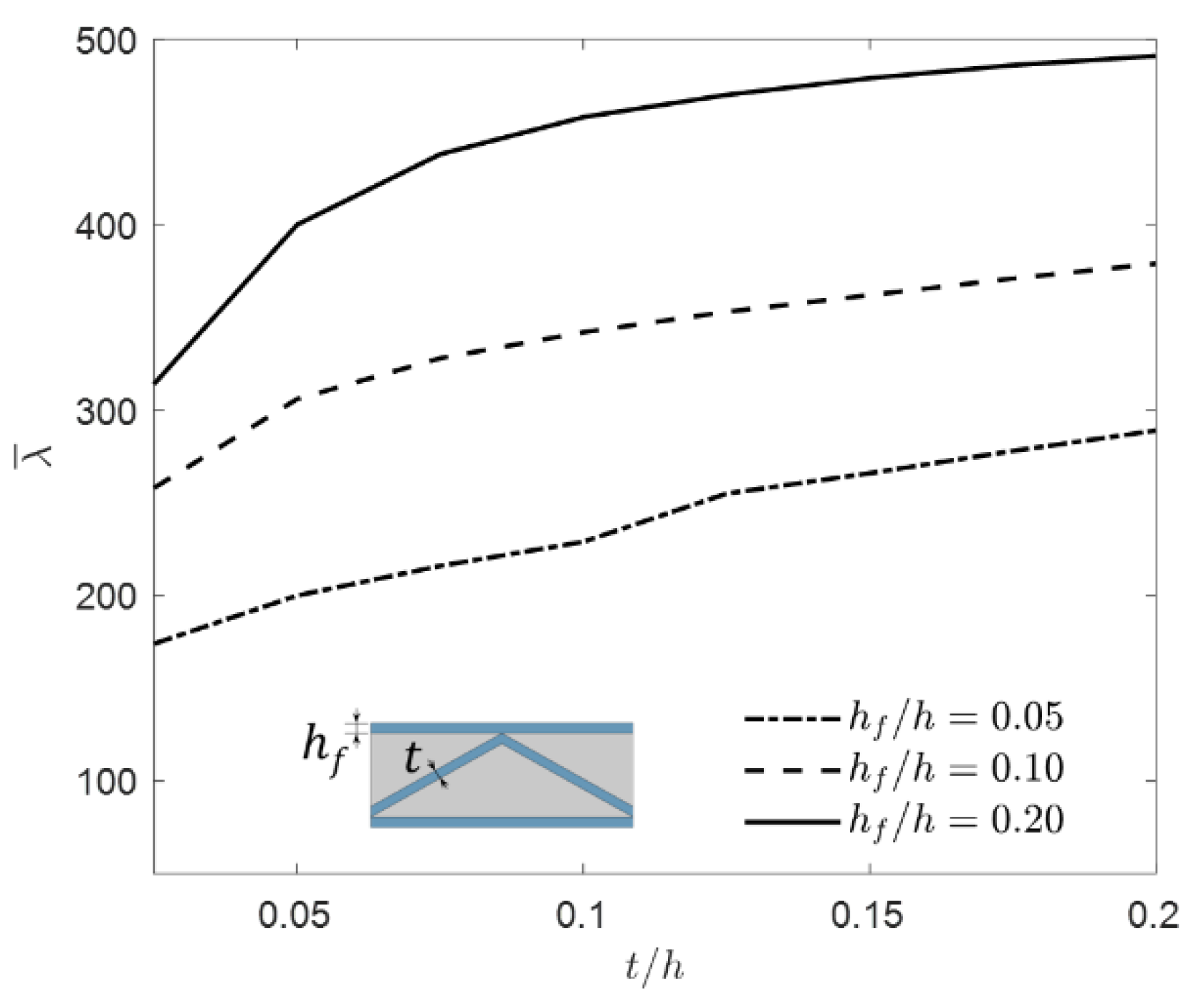

3.3.1. Parameter Study under Uniform Temperature Field

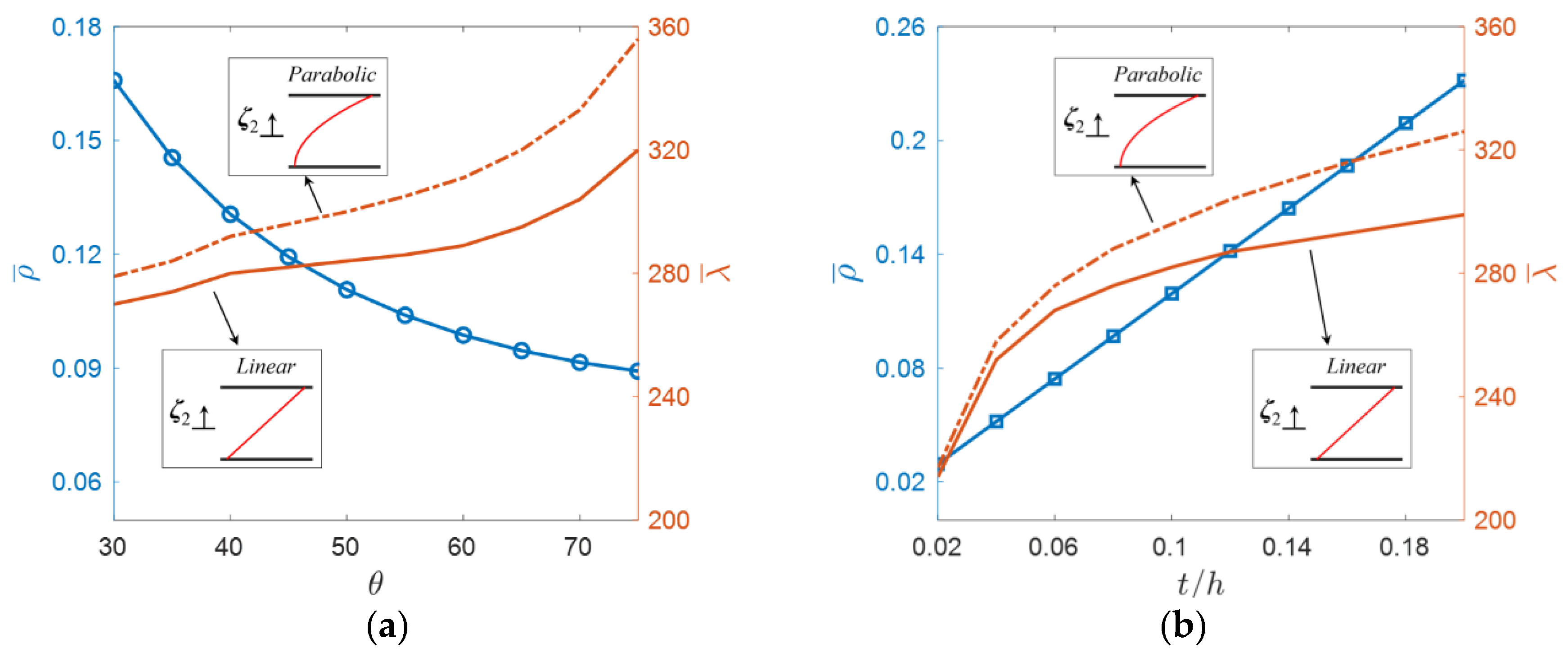

3.3.2. Parameter Study under Uneven Temperature Field

4. Discussion

5. Conclusions

- The present method for the coupled fluid-structure-thermal analysis of the HCS plates possesses both computational accuracy and efficiency.

- The dynamic instability of the HCS plates can be induced by fluid-structure coupling and further accelerated by involved thermal effects.

- As for frequency characteristics of the HCS plates, unsteady aerodynamic pressure causes two adjacent frequency curves to gradually coalesce with each other, meanwhile, temperature change causes natural frequencies to decrease, resulting in an earlier occurrence of the frequency coalescence.

- The influences of design variables on dynamic instability and thermal buckling instability show opposite tendencies, and therefore a tradeoff is required for the TPS design.

- A linear assumption of temperature fields through plate thickness brings out conservative solutions compared to parabolic distribution, providing safety margins in the preliminary design.

- The present analytical model and numerical results for the HCS plates provide design guidance in terms of the practical application of the novel TPS.

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Vaziri, A.K.; Xue, Z.Y.; Hutchinson, J.W. Metal sandwich plates with polymer foam-filled cores. J. Mech. Mater. Struct. 2006, 1, 97–127. [Google Scholar] [CrossRef]

- Han, B.; Zhang, Z.J.; Zhang, Q.C.; Zhang, Q.; Lu, T.J.; Lu, B.H. Recent advances in hybrid lattice-cored sandwiches for enhanced multifunctional performance. Extrem. Mech. Lett. 2017, 10, 58–69. [Google Scholar] [CrossRef]

- Zhu, L.; Liu, W.; Fang, H.; Chen, J.; Zhuang, Y.; Han, J. Design and simulation of innovative foam-filled lattice composite bumper system for bridge protection in ship collisions. Compos. Part B Eng. 2019, 157, 24–35. [Google Scholar] [CrossRef]

- Amraei, M.; Shahravi, M.; Noori, Z.; Lenjani, A. Application of aluminium honeycomb sandwich panel as an energy absorber of high-speed train nose. J. Compos. Mater. 2014, 48, 1027–1037. [Google Scholar] [CrossRef]

- Mozafari, H.; Khatami, S.; Molatefi, H. Out of plane crushing and local stiffness determination of proposed foam filled sandwich panel for Korean Tilting Train eXpress—numerical study. Mater. Des. 2015, 66, 400–411. [Google Scholar] [CrossRef]

- Shams, A.; Stark, A.; Hoogen, F.; Hegger, J.; Schneider, H. Innovative sandwich structures made of high performance concrete and foamed polyurethane. Compos. Struct. 2015, 121, 271–279. [Google Scholar] [CrossRef]

- Lu, T.J.; Liu, T.; Deng, Z.C. Thermoelastic properties of sandwich material with pin-reinforced foam cores. Sci. China Ser. E Technol. Sci. 2008, 51, 2059–2074. [Google Scholar] [CrossRef]

- Guo, K.; Xu, Y. Random vibration suppression of a truss core sandwich panel using independent modal resonant shunt and modal criterion. Appl. Sci. 2017, 7, 496. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, W.; Gao, D.; Xiao, L.; Han, L. Experimental study on dynamic compression mechanical properties of aluminum honeycomb structures. Appl. Sci. 2020, 10, 1188. [Google Scholar] [CrossRef]

- Valdevit, L.; Wei, Z.; Mercer, C.; Zok, F.W.; Evans, A.G. Structural performance of near-optimal sandwich panels with corrugated cores. Int. J. Solids Struct. 2006, 43, 4888–4905. [Google Scholar] [CrossRef]

- Glass, D.E. Ceramic matrix composite (CMC) thermal protection systems (TPS) and hot structures for hypersonic vehicles. In Proceedings of the 15th AIAA Space Planes and Hypersonic Systems and Technologies Conference, Dayton, OH, USA, 28 April–1 May 2008. [Google Scholar]

- Lurie, S.A.; Solyaev, Y.O.; Volkov-Bogorodskiy, D.B.; Bouznik, V.M.; Koshurina, A.A. Design of the corrugated-core sandwich panel for the arctic rescue vehicle. Comp. Struct. 2017, 160, 1007–1019. [Google Scholar] [CrossRef]

- Le, W.T.; Goo, N.S. Thermomechanical performance of bio-inspired corrugated-core sandwich structure for a thermal protection system panel. Appl. Sci. 2019, 9, 5541. [Google Scholar] [CrossRef]

- Zhang, J.; Supernak, P.; Mueller-Alander, S.; Wang, C.H. Improving the bending strength and energy absorption of corrugated sandwich composite structure. Mater. Des. 2013, 52, 767–773. [Google Scholar] [CrossRef]

- Yan, L.L.; Yu, B.; Han, B.; Chen, C.Q.; Zhang, Q.C.; Lu, T.J. Compressive strength and energy absorption of sandwich panels with aluminum foam-filled corrugated cores. Compos. Sci. Technol. 2013, 86, 142–148. [Google Scholar] [CrossRef]

- Yan, L.L.; Ham, B.; Yu, B.; Chen, C.Q.; Zhang, Q.C.; Lu, T.J. Three-point bending of sandwich beams with aluminum foam-filled corrugated cores. Mater. Design. 2014, 60, 510–519. [Google Scholar] [CrossRef]

- Yu, B.; Han, B.; Ni, C.Y.; Zhang, Q.C.; Chen, C.Q.; Lu, T.J. Dynamic crushing of all-metallic corrugated panels filled with close-celled aluminum foams. J. Appl. Mech. T. ASME 2015, 82, 011006. [Google Scholar] [CrossRef]

- Han, B.; Qin, K.K.; Yu, B.; Zhang, Q.C.; Chen, C.Q.; Lu, T.J. Design optimization of foam-reinforced corrugated sandwich beams. Compos. Struct. 2015, 130, 52–62. [Google Scholar] [CrossRef]

- Han, B.; Qin, K.K.; Zhang, Q.C.; Zhang, Q.; Lu, T.J.; Lu, B.H. Free vibration and buckling of foam-filled composite corrugated sandwich plates under thermal loading. Compos. Struct. 2017, 172, 173–189. [Google Scholar] [CrossRef]

- Yang, J.S.; Ma, L.; Schröder, K.U.; Chen, Y.L.; Li, S.; Wu, L.Z.; Schmidt, R. Experimental and numerical study on the modal characteristics of hybrid carbon fiber composite foam filled corrugated sandwich cylindrical panels. Polym. Test. 2018, 68, 8–18. [Google Scholar] [CrossRef]

- Taghizadeh, S.A.; Farrokhabadi, A.; Liaghat, G.; Pedram, E.; Malekinejad, H.; Mohammadi, S.F.; Ahmadi, H. Characterization of compressive behavior of PVC foam infilled composite sandwich panels with different corrugated core shapes. Thin Wall. Struct. 2019, 135, 160–172. [Google Scholar] [CrossRef]

- Bapanapalli, S.K.; Martinez, O.M.; Gogu, C.; Sankar, B.V.; Haftka, R.T.; Blosser, M.L. Analysis and design of corrugated-core sandwich panels for thermal protection system of space vehicles. In Proceedings of the 47th AIAA Structures, Structural Dynamics and Materials Conference, Newport, MM, USA, 1–4 May 2006. [Google Scholar]

- Gogu, C.; Bapanapalli, S.K.; Haftka, R.T.; Sankar, B.V. Comparison of materials for an integrated thermal protection system for spacecraft reentry. J. Spacecr. Rocket. 2009, 46, 501–513. [Google Scholar] [CrossRef]

- Martinez, O.A.; Sankar, B.V.; Haftka, R.T.; Bapanapalli, S.K.; Blosser, M.L. Micromechanical analysis of composite corrugated-core sandwich panels for integral thermal protection systems. AIAA J. 2007, 45, 2323–2336. [Google Scholar] [CrossRef]

- Martinez, O.A.; Sankar, B.; Haftka, R.; Blosser, M.L. Two-dimensional orthotropic plate analysis for an integral thermal protection system. AIAA J. 2012, 50, 387–398. [Google Scholar] [CrossRef]

- Sharma, A.; Sankar, B.V.; Haftka, R.T. Homogenization of plates with microstructure and application to corrugated core sandwich panels. In Proceedings of the 51st AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Orlando, FL, USA, 12–15 April 2010. [Google Scholar]

- Xie, G.; Wang, Q.; Sunden, B.; Zhang, W. Thermomechanical optimization of lightweight thermal protection system under aerodynamic heating. Appl. Therm. Eng. 2013, 59, 425–434. [Google Scholar] [CrossRef]

- Gu, L.; Wang, Y.; Shi, S.; Dai, C. An approach for bending and transient dynamic analysis of integrated thermal protection system with temperature-dependent material properties. Compos. Struct. 2017, 159, 128–143. [Google Scholar] [CrossRef]

- Gong, C.; Wang, Y.; Gu, L.; Shi, S. An approach for stress analysis of corrugated-core integrated thermal protection system under thermal and mechanical environment. Compos. Struct. 2018, 185, 1–26. [Google Scholar] [CrossRef]

- Dorsey, J.T.; Poteet, C.C.; Wurster, K.E.; Chen, R.R. Metallic Thermal Protection System Requirements, Environments, and Integrated Concepts. J. Spacecr. Rocket. 2004, 41, 162–172. [Google Scholar] [CrossRef]

- Huang, D.; Friedmann, P.P.; Rokita, T. Aerothermoelastic Scaling Laws for Hypersonic Skin Panel Configurations with Arbitrary Flow Orientation. AIAA J. 2019, 57, 4377–4392. [Google Scholar] [CrossRef]

- Jouneghani, F.Z.; Dimitri, R.; Bacciocchi, M. Tornabene, F. Free vibration analysis of functionally graded porous doubly-curved shells based on the first-order shear deformation theory. Appl. Sci. 2017, 7, 1252. [Google Scholar] [CrossRef]

- Tornabene, F.; Fantuzzi, N.; Bacciocchi, M.; Viola, E.; Reddy, J.N. A numerical investigation on the natural frequencies of FGM sandwich shells with variable thickness by the local generalized differential quadrature method. Appl. Sci. 2017, 7, 131. [Google Scholar] [CrossRef]

- Allahkarami, F.; Tohidi, H.; Dimitri, R.; Tornabene, F. Dynamic stability of bi-directional functionally graded porous cylindrical shells embedded in an elastic foundation. Appl. Sci. 2020, 10, 1345. [Google Scholar] [CrossRef]

- Plagianakos, T.S.; Saravanos, D.A. Higher-order layerwise laminate theory for the prediction of interlaminar shear stresses in thick composite and sandwich composite plates. Compos. Struct. 2009, 87, 23–25. [Google Scholar] [CrossRef]

- Pandey, S.; Pradyumna, S. A new C0 higher-order layerwise finite element formulation for the analysis of laminated and sandwich plates. Compos. Struct. 2015, 131, 1–16. [Google Scholar] [CrossRef]

- Tornabene, F.; Fantuzzi, N.; Bacciocchi, M.; Reddy, J.N. An equivalent layer-wise approach for the free vibration analysis of thick and thin laminated and sandwich shells. Appl. Sci. 2017, 7, 17. [Google Scholar] [CrossRef]

- Zhao, R.; Yu, K.; Hulbert, G.M.; Wu, Y.; Li, X. Piecewise shear deformation theory and finite element formulation for vibration analysis of laminated composite and sandwich plates in thermal environments. Compos. Struct. 2017, 160, 1060–1083. [Google Scholar] [CrossRef]

| Young’s Modulus (MPa) | Poisson Ratio | Density (kg/m3) | Thermal Expansion Coefficient (10−6/K) | |

|---|---|---|---|---|

| Rohacell 31 | 36 | 0.2 | 31 | 37 |

| Rohacell 51 | 70 | 0.3 | 51 | 33 |

| Rohacell 71 | 105 | 0.25 | 75 | 30 |

| Alporas | 1000 | 0.15 | 230 | 22 |

| Young’s Modulus (GPa) | Poisson Ratio | Density (kg/m3) | Thermal Expansion Coefficient (10−6/K) | |

|---|---|---|---|---|

| Ti-6Al-4V | 114 | 0.33 | 4430 | 8.6 |

| 304 stainless steel | 210 | 0.3 | 7900 | 12 |

| Aluminum 1050 | 69 | 0.25 | 2705 | 23.6 |

| Materials | |||||||

|---|---|---|---|---|---|---|---|

| Base | Ti | Steel | Al | Ti | Steel | Al | |

| Foam | |||||||

| Empty | 2.35 | 2.39 | 2.35 | 338 | 306 | 193 | |

| RC31 | 2.49 | 2.45 | 2.39 | 342 | 307 | 195 | |

| RC51 | 2.64 | 2.52 | 2.41 | 346 | 310 | 197 | |

| RC71 | 2.59 | 2.50 | 2.39 | 345 | 309 | 196 | |

| AC | 2.43 | 2.45 | 2.33 | 346 | 310 | 198 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhuang, W.; Yang, C.; Wu, Z. Mechanical Stability of Hybrid Corrugated Sandwich Plates under Fluid-Structure-Thermal Coupling for Novel Thermal Protection Systems. Appl. Sci. 2020, 10, 2790. https://doi.org/10.3390/app10082790

Zhuang W, Yang C, Wu Z. Mechanical Stability of Hybrid Corrugated Sandwich Plates under Fluid-Structure-Thermal Coupling for Novel Thermal Protection Systems. Applied Sciences. 2020; 10(8):2790. https://doi.org/10.3390/app10082790

Chicago/Turabian StyleZhuang, Wenzheng, Chao Yang, and Zhigang Wu. 2020. "Mechanical Stability of Hybrid Corrugated Sandwich Plates under Fluid-Structure-Thermal Coupling for Novel Thermal Protection Systems" Applied Sciences 10, no. 8: 2790. https://doi.org/10.3390/app10082790

APA StyleZhuang, W., Yang, C., & Wu, Z. (2020). Mechanical Stability of Hybrid Corrugated Sandwich Plates under Fluid-Structure-Thermal Coupling for Novel Thermal Protection Systems. Applied Sciences, 10(8), 2790. https://doi.org/10.3390/app10082790