Coupling and Decoupling Measurement Method of Complete Geometric Errors for Multi-Axis Machine Tools

Abstract

Featured Application

Abstract

1. Introduction

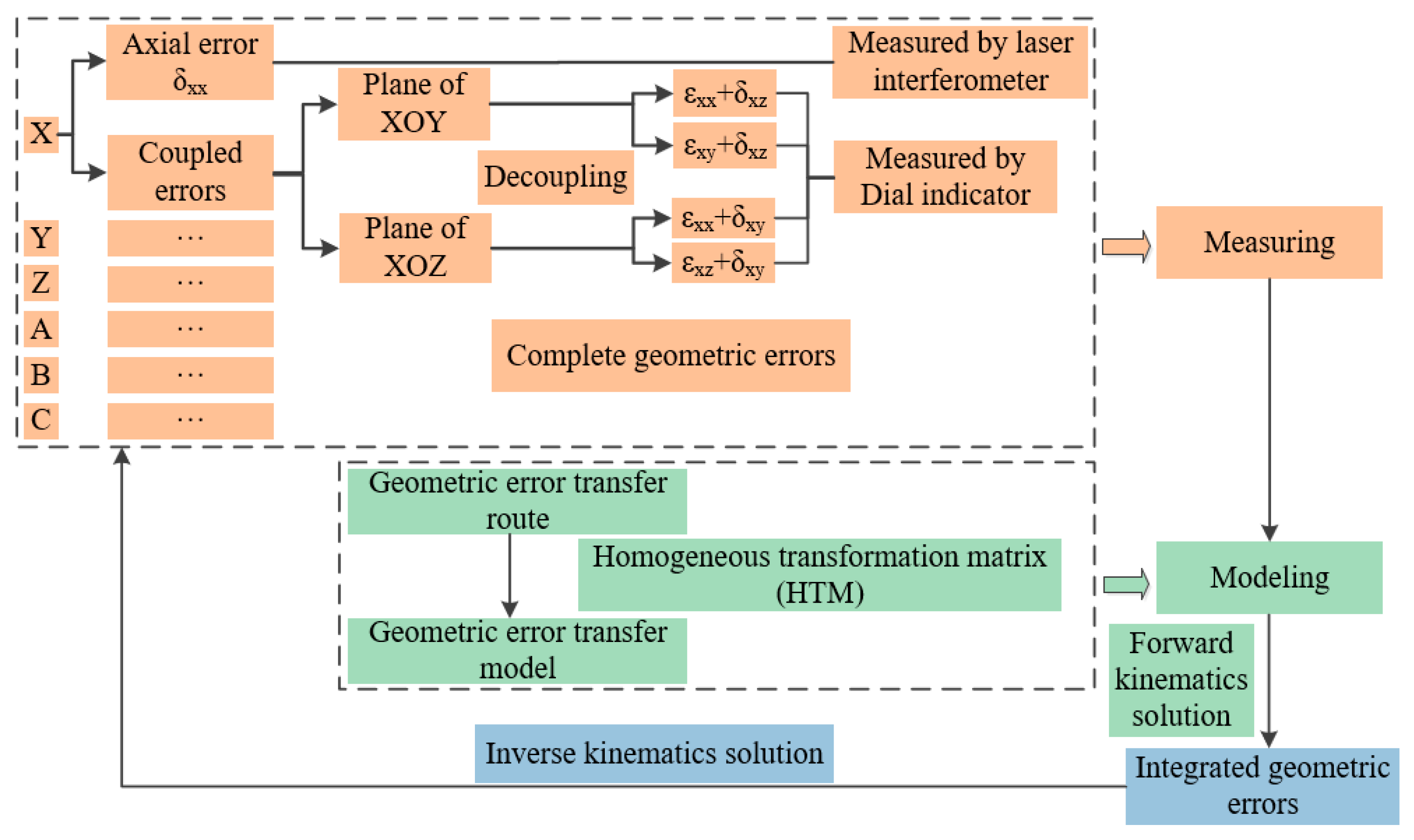

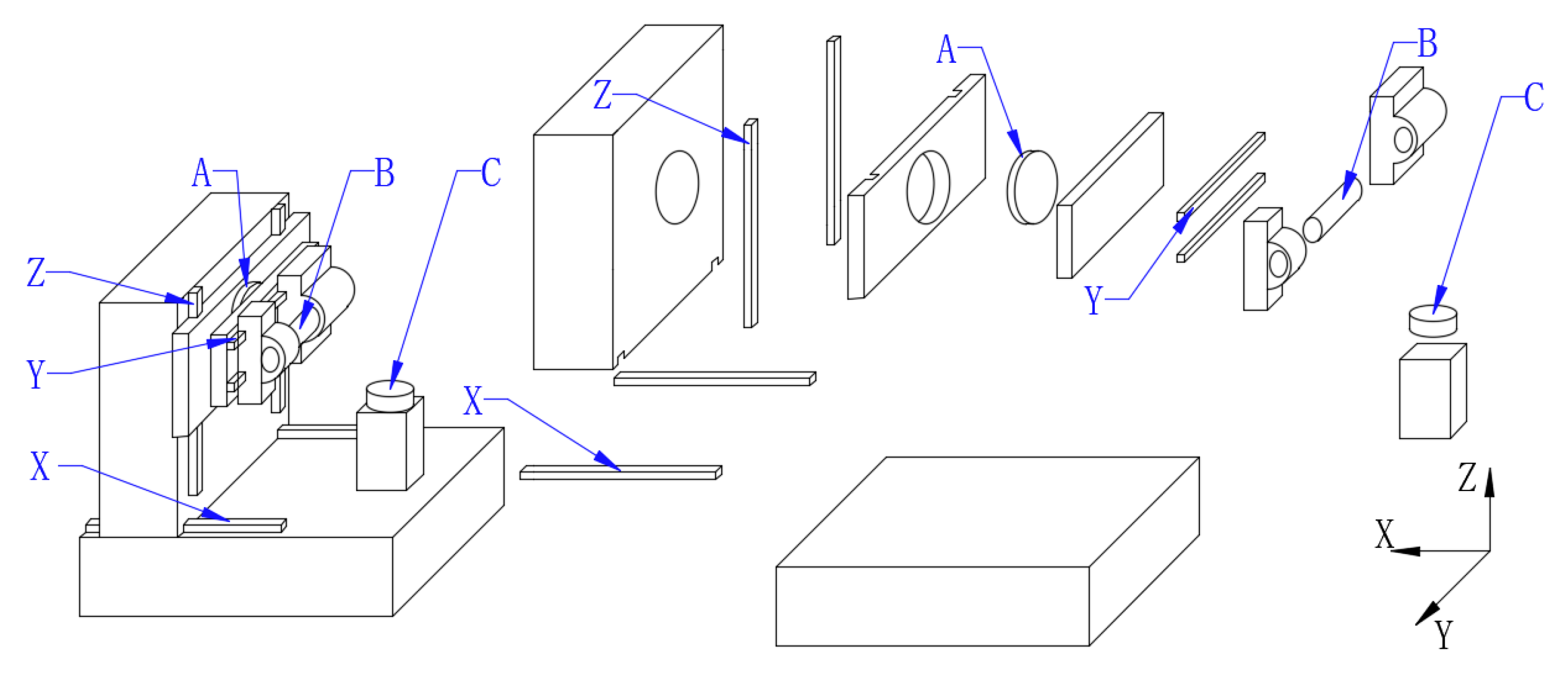

2. Measurement of Complete Geometric Errors

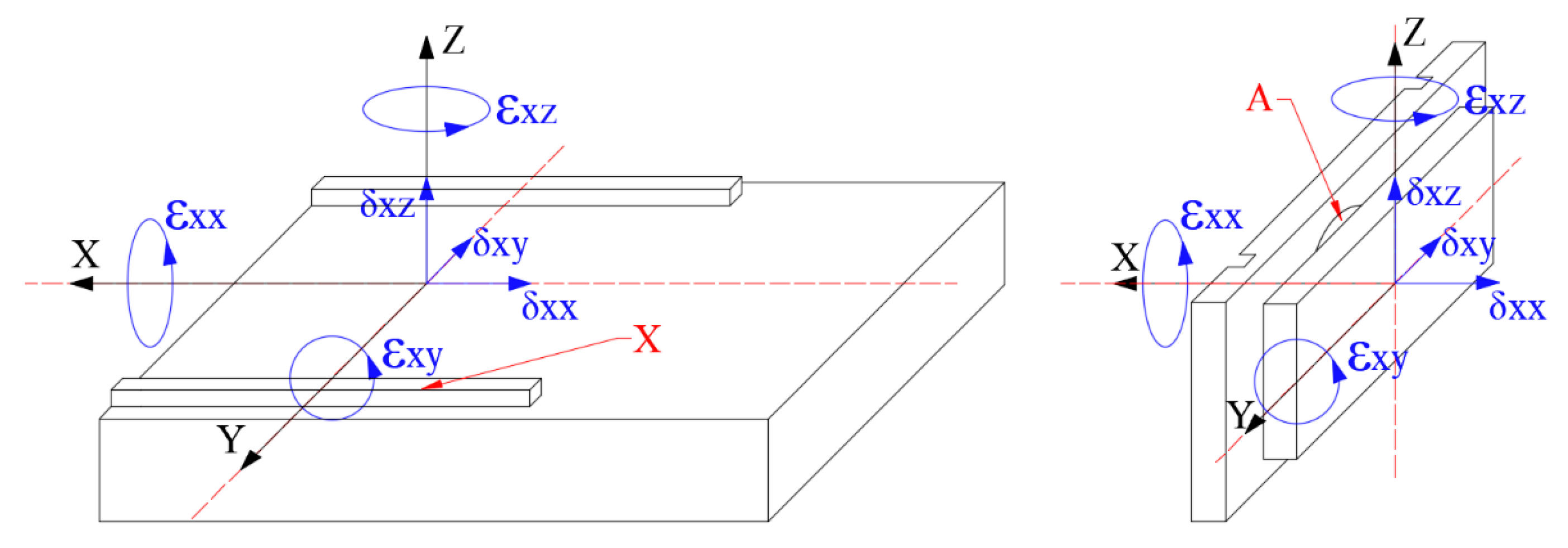

2.1. Complete Geometric Errors of Multi-Axis Machine Tools

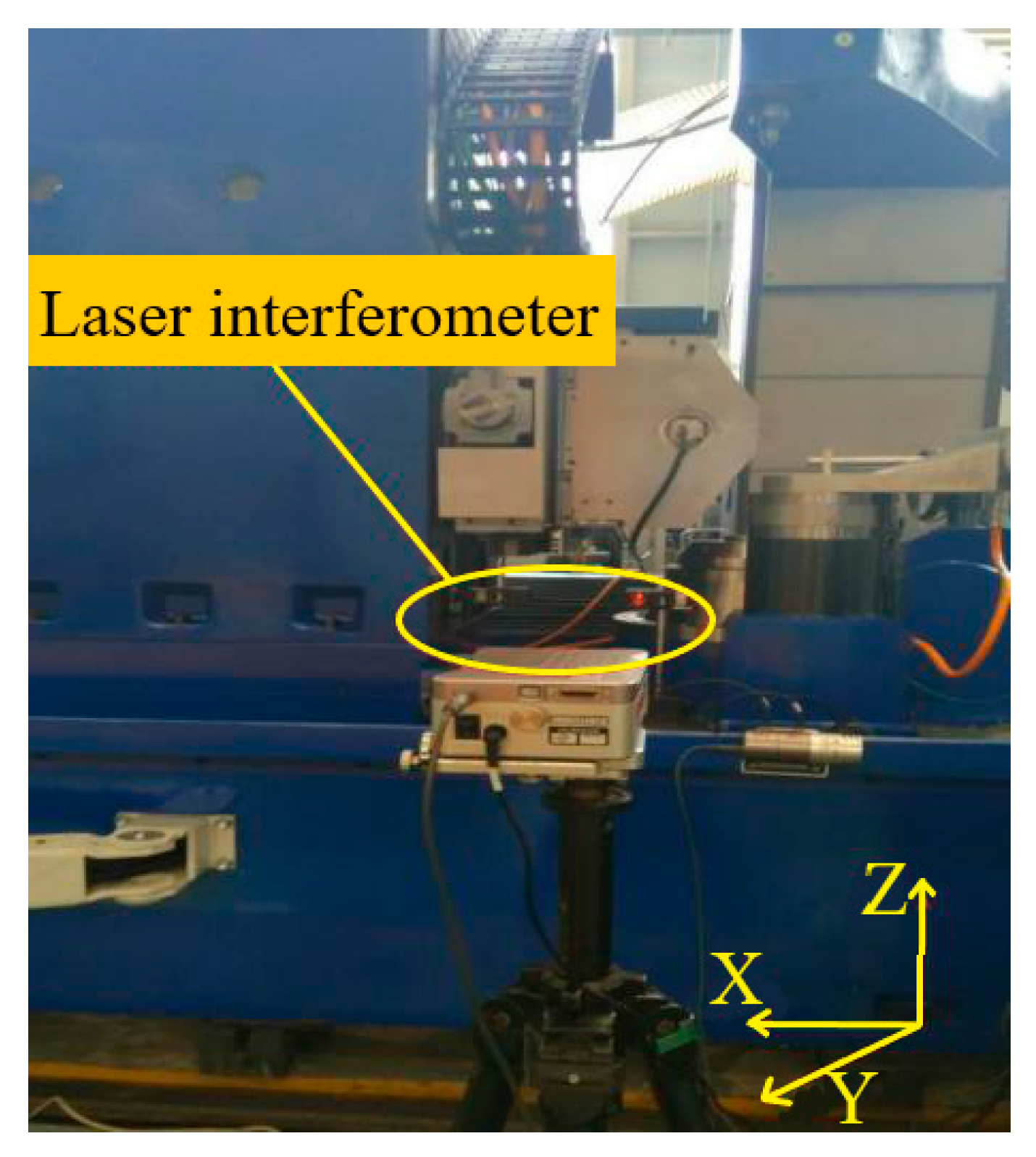

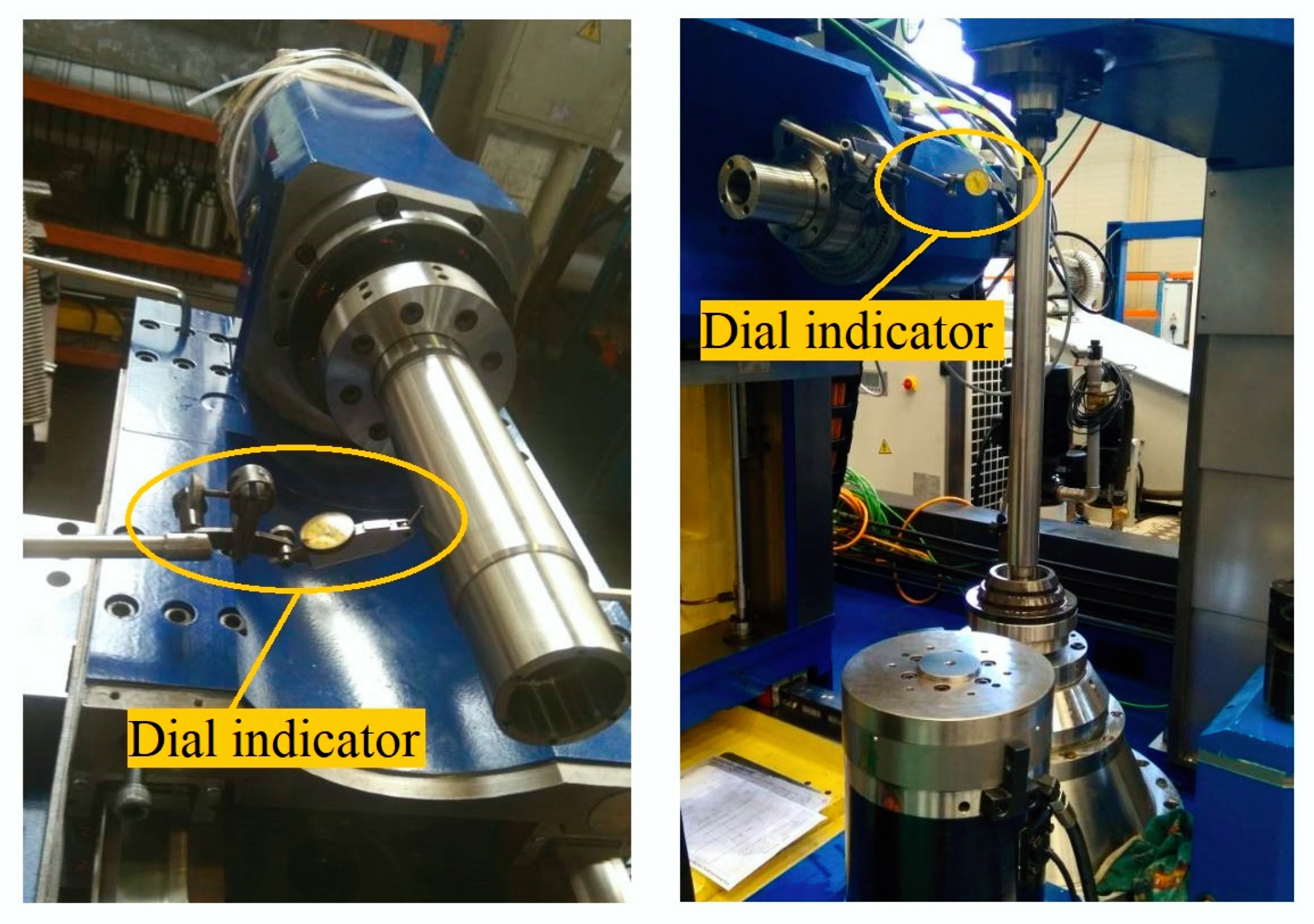

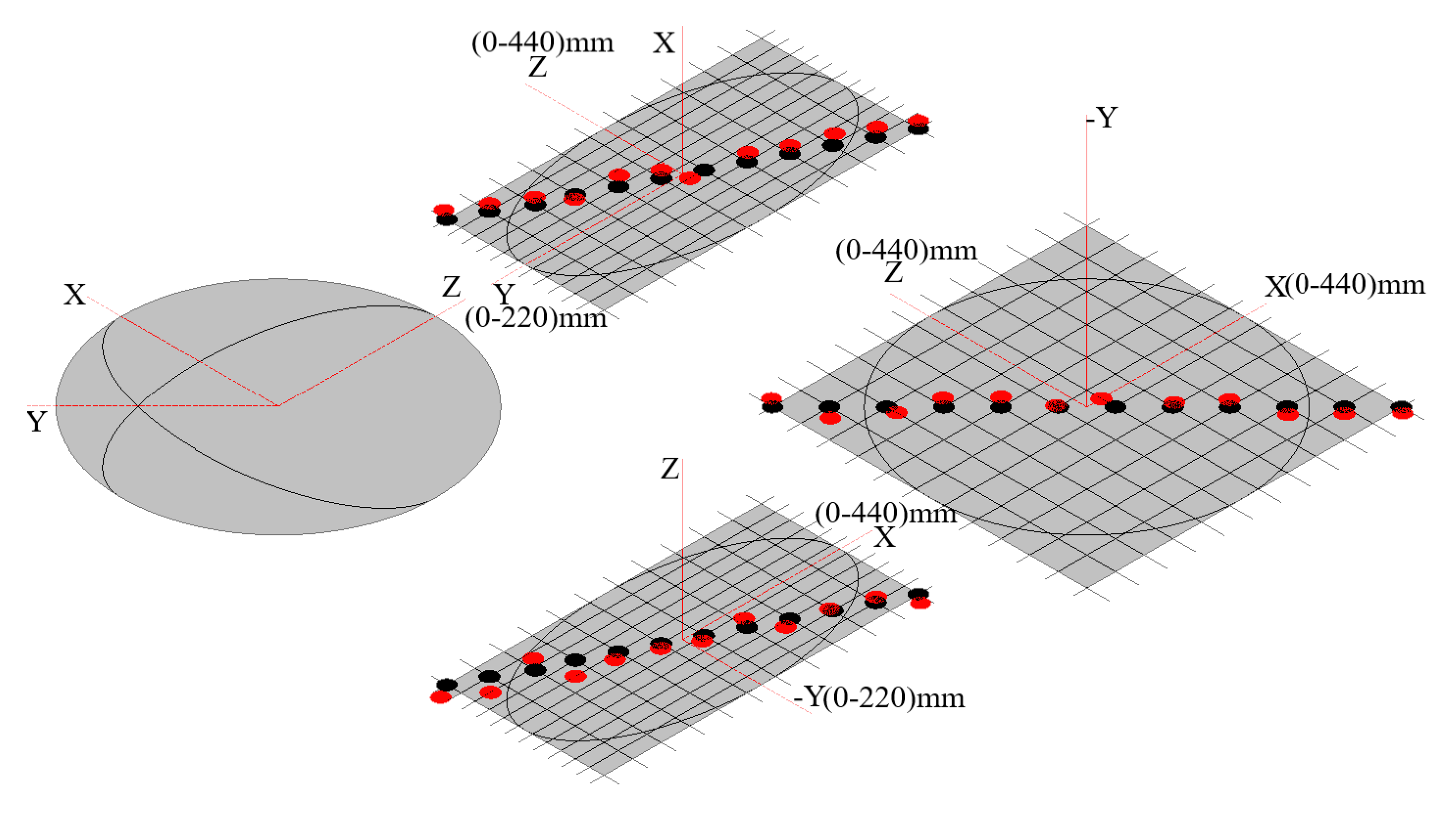

2.2. Measurement of Axial Displacement Errors

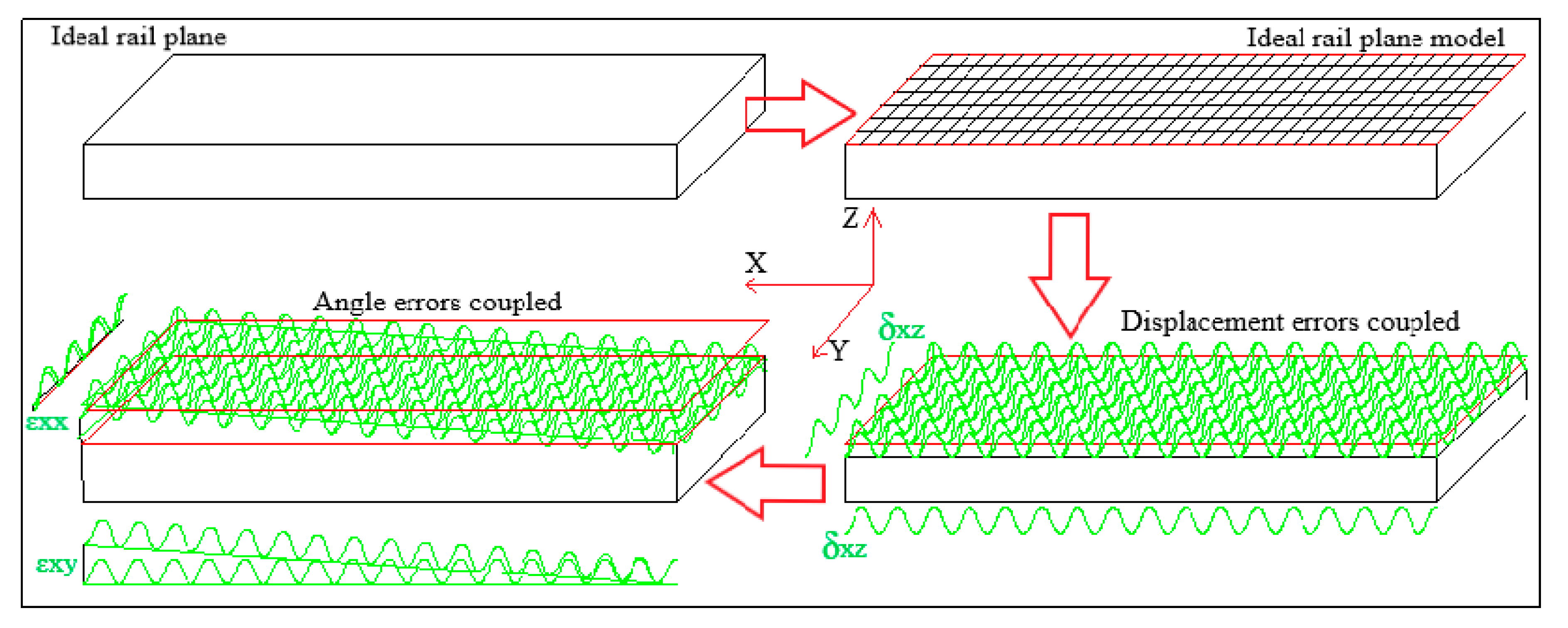

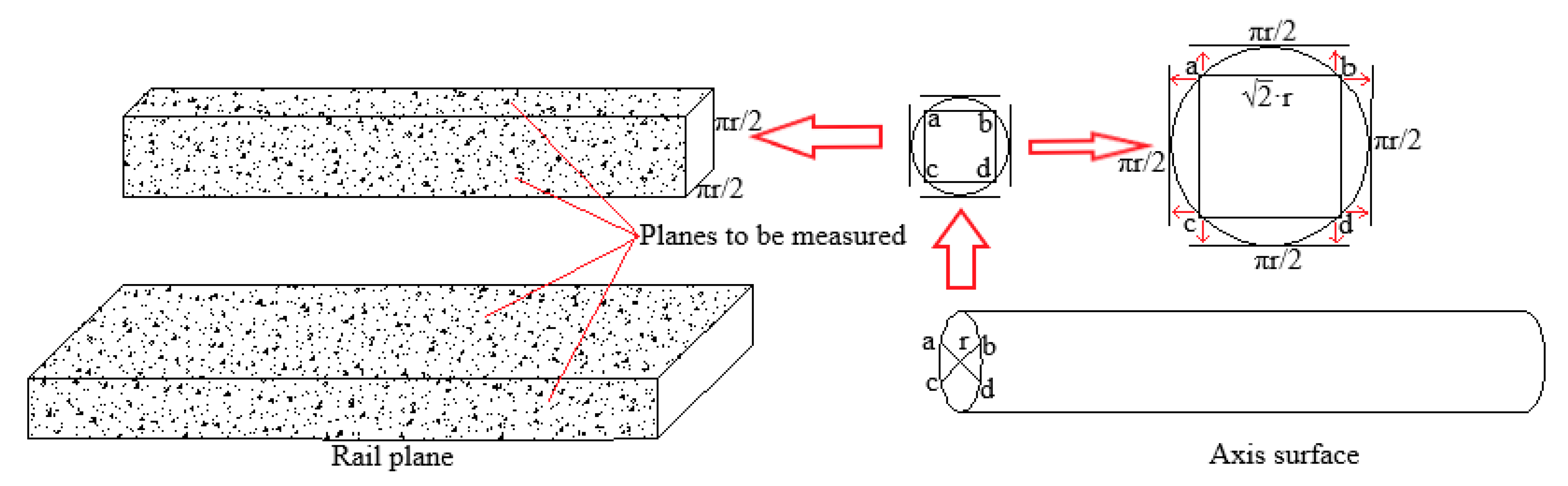

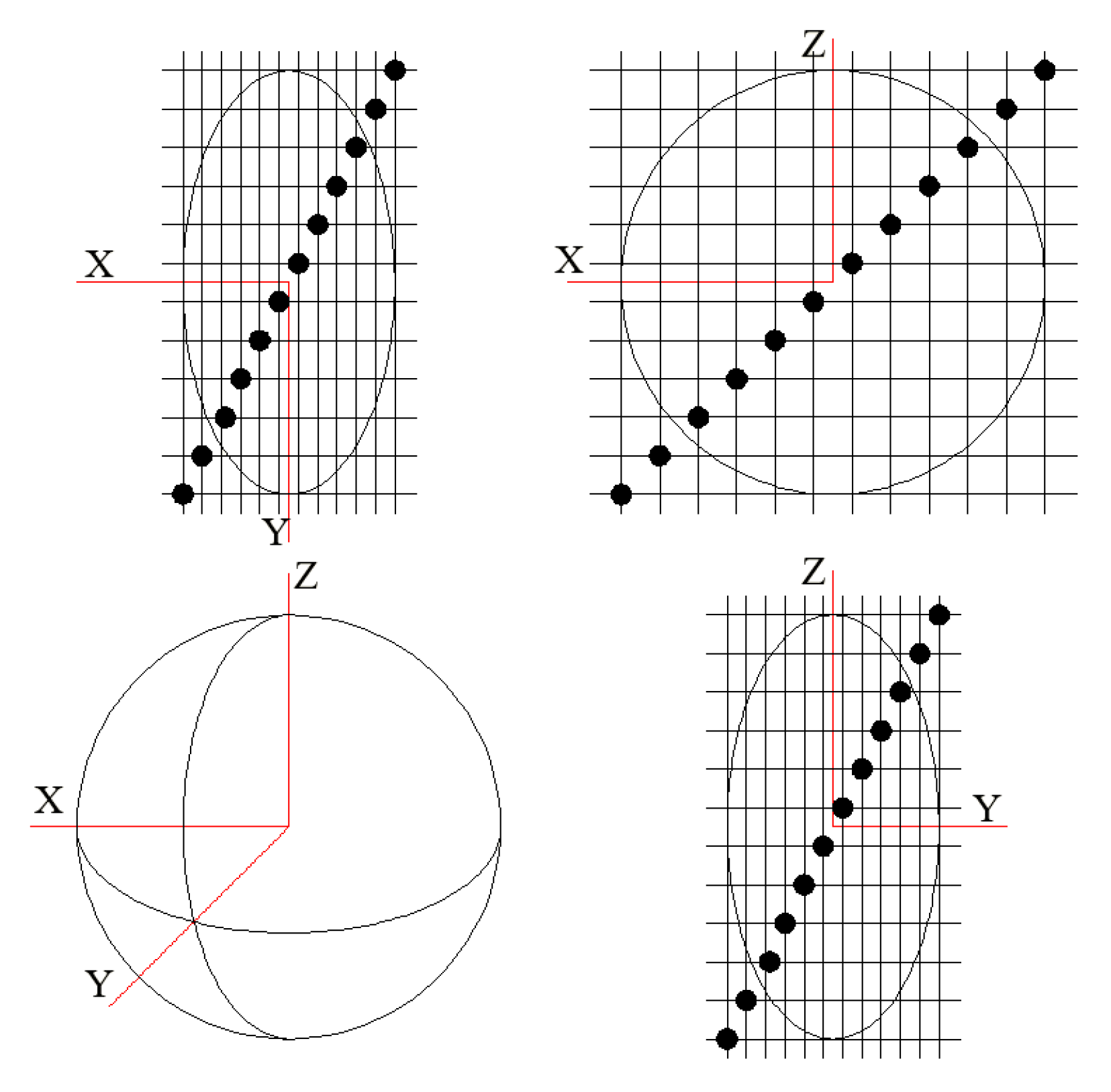

2.3. Measurement of Coupled Geometric Errors

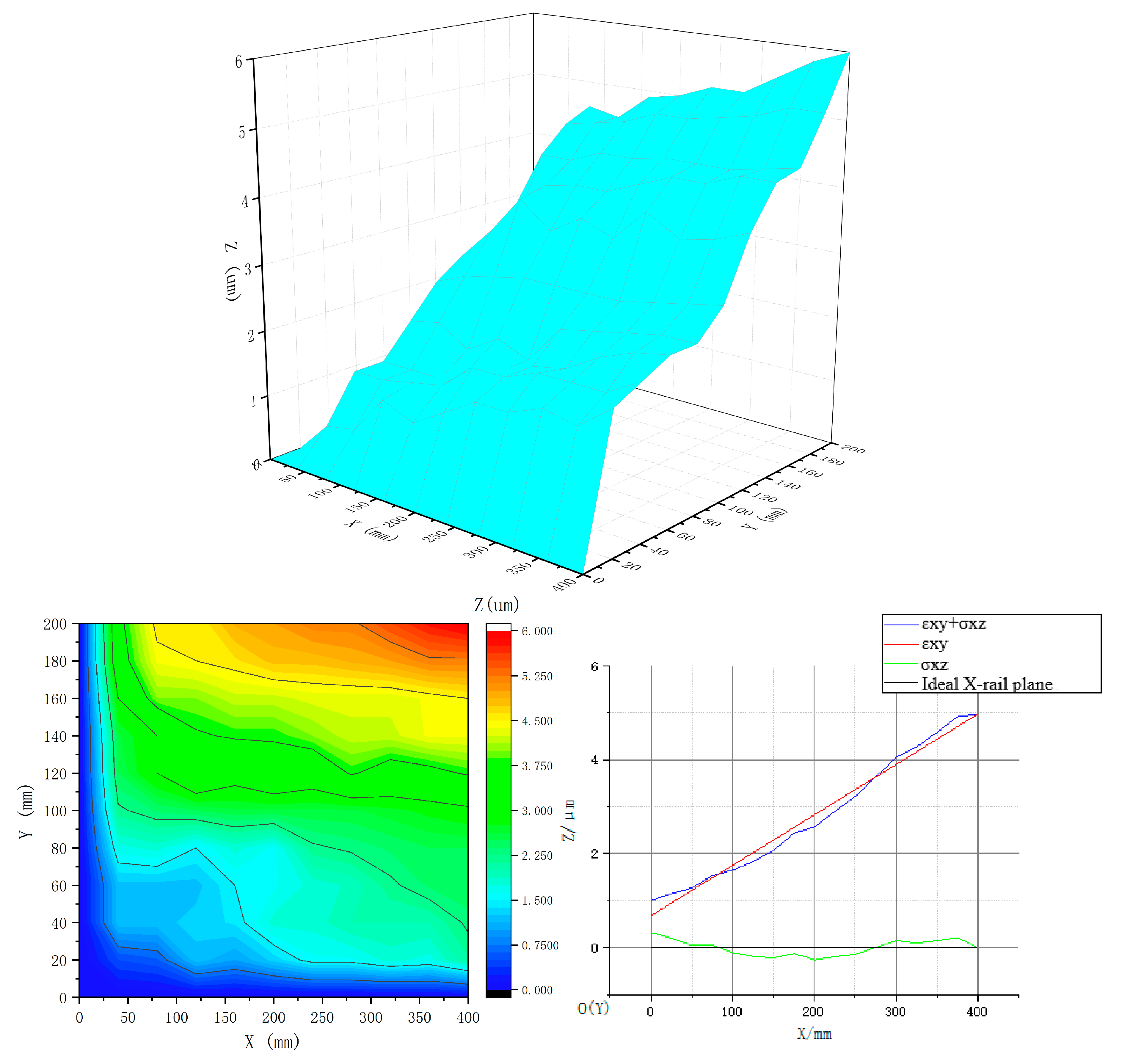

- Set m and n points along the X and Y direction and measure shape errors of these m × n points.

- Set the cross-sectional plane along each transverse and longitudinal line.

- Fit shape errors along each transverse and longitudinal line.

- Decouple error items of εxx and δxz in the YOZ cross-sectional plane, and εxy and δxz in the XOZ plane.

- The tilt angles of the fitting line are angle error items of εxx and εxy. The difference between the shape errors and fitting values along each transverse and longitudinal line is the displacement errors item of εxx, as shown in Figure 7.

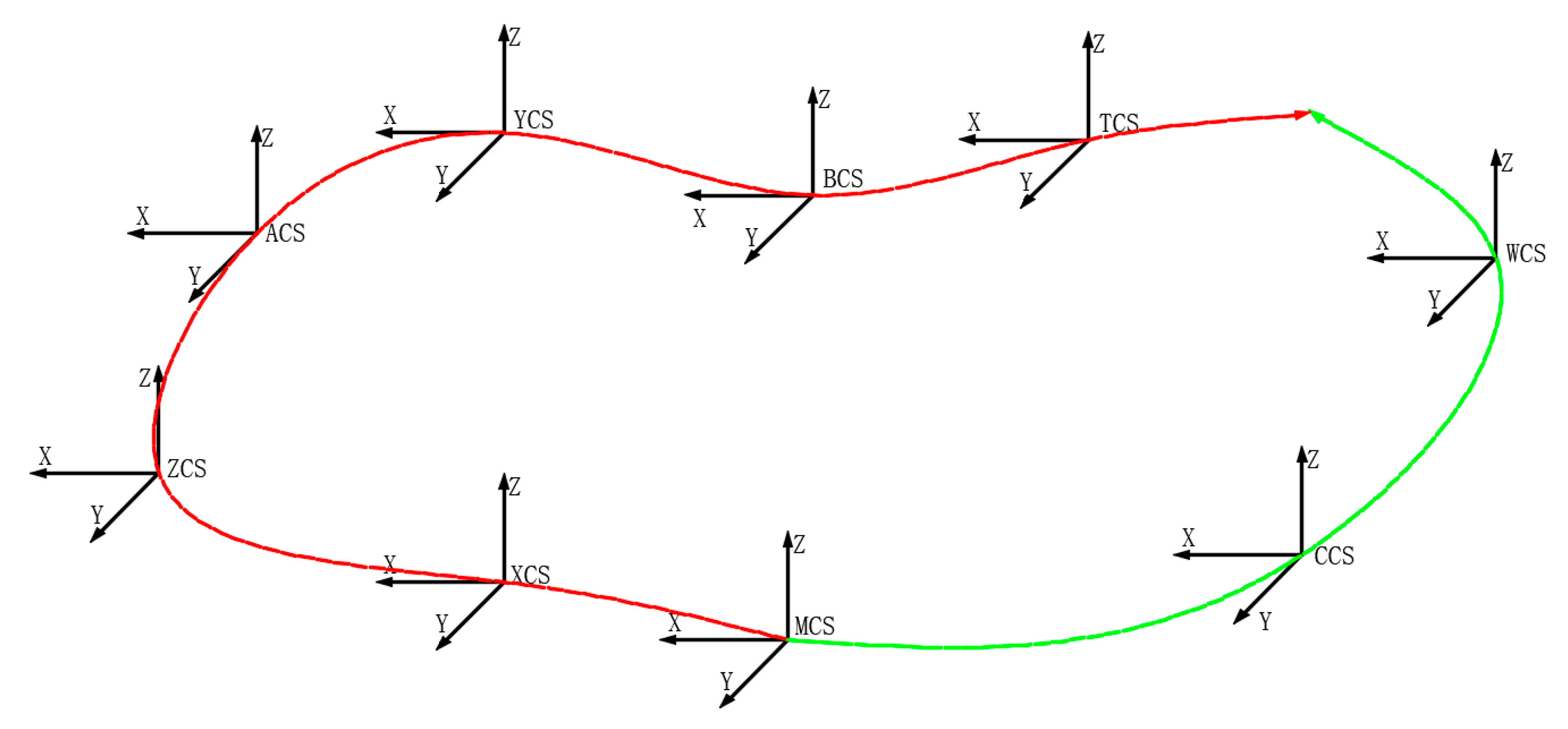

3. Geometric Error Transfer Modeling

| X (0–440) (mm) | Y (0–220) (mm) | Z (0–440) (mm) |

| A (−45–45) (Degree/°) | B (0–360) (Degree/°) | C (0–360) (Degree/°) |

3.1. Geometric Error Transfer Modeling based on HTM

3.2. Forward and Inverse Kinematics Solutions

4. Calculation of Integrated Geometric Errors

| X:( −1.2, 3.0, 4.2, 1.25, 0.85943, 0.61593) | A:( −2.4, −4.0, −6.2, 1.0, −0.862, 0.563) |

| Y:( −3.8, 1.0, 6.4, 0.63584, 0.56, 0.27658) | B:(5.6, 0.5, ₋4.4, −0.267, 0.87, −0.581) |

| Z:( −3.4, −5.6, 0.2, 0.33456, 0.42638, 0.06) | C:( −4.2, −2.4, 3.2, 0.264, −0.795, 0.4) |

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| i | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| xi | 0 | 40 | 80 | 120 | 160 | 200 | 240 | 280 | 320 | 360 | 400 | 440 |

| δxx(μm) | −1.2 | 1.6 | 3.2 | 4.0 | 6.2 | 3.2 | 1.4 | 2.4 | 4.2 | 6.2 | 7.4 | 3.5 |

| δxy(μm) | 3.0 | 1.4 | 0.6 | −2.2 | −2.8 | −3.2 | −1.4 | 1.6 | 1.8 | 2.6 | 0.4 | 0.1 |

| δxz(μm) | 4.2 | 1.8 | 2.6 | −1.4 | −2.6 | −3.8 | −1.4 | 2.8 | 1.6 | 3.6 | 1.2 | 0.7 |

| εxx(°) | 1.25 | 1 | 1.25 | 0.75 | 0.63 | −0.25 | −0.5 | −0.25 | 0.13 | 0.5 | 0.6 | 0.4 |

| εxy(°) | 0.85943 | |||||||||||

| εxz(°) | 0.61593 | |||||||||||

| i | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Yi(mm) | 0 | 20 | 40 | 60 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 220 |

| δyx(μm) | −3.8 | 2.4 | 2.6 | −4.4 | −4.2 | −3.2 | −2.2 | 4.0 | −4.0 | 4.2 | −3.4 | −1.0 |

| δyy(μm) | 1.0 | 0 | 1.4 | 4.2 | 6.6 | 2.2 | 0.8 | 3.4 | 5.4 | 5.8 | 3.0 | 3.0 |

| δyz(μm) | 6.4 | 2.2 | −4.2 | −1.8 | −2.0 | 4.6 | 4.4 | 5.6 | 8.4 | 5.2 | 3.2 | 2.9 |

| εyx(°) | 0.63584 | |||||||||||

| εyy(°) | 0.56 | 0.07 | 0.35 | 0.27 | 0.85 | 0.48 | −0.22 | 0.11 | 0.87 | 0 | 0.77 | 0.37 |

| εyz(°) | 0.27658 | |||||||||||

| i | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| zi | 0 | 40 | 80 | 120 | 160 | 200 | 240 | 280 | 320 | 360 | 400 | 440 |

| δzx(μm) | −3.4 | 3.6 | 1.2 | −2.4 | −2.6 | 0.8 | 7.2 | 4.8 | −2.8 | 0.6 | 0.8 | 0.7 |

| δzy(μm) | −5.6 | 5.4 | −6.8 | −2.2 | 6.2 | −6.0 | 7.6 | −2.6 | 0.2 | 2.8 | 0.8 | −0.0 |

| δzz(μm) | 0.2 | −2.2 | −3.8 | −3.4 | −2.4 | −2.6 | −3.4 | 0.6 | 0.8 | −3.4 | 0.6 | −1.7 |

| εzx(°) | 0.33456 | |||||||||||

| εzy(°) | 0.42638 | |||||||||||

| εzz(°) | 0.06 | −0.45 | -0.89 | −0.26 | −0.05 | −0.19 | 0.59 | 0.35 | −0.42 | −0.86 | 0.77 | −0.12 |

| i | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| αi (°) | 0 | 30 | 60 | 90 | 120 | 150 | 180 | 210 | 240 | 270 | 300 | 330 |

| δAx(μm) | −2.4 | |||||||||||

| δAy(μm) | −4.0 | −2.8 | −3.2 | −1.6 | −1.8 | −1.4 | 5.2 | -5.8 | 3.2 | 1.6 | 0.4 | −0.9 |

| δAz(μm) | −6.2 | −5.8 | 0.6 | 0.6 | −4.2 | 4.0 | 3.6 | 2.8 | −5.0 | −3.8 | −1.8 | −1.3 |

| εAx(°) | 1 | −0.02 | −0.43 | 0.71 | −0.76 | −0.73 | 0.55 | −0.93 | −0.31 | −0.32 | −0.05 | −0.03 |

| εAy(°) | −0.862 | |||||||||||

| εAz(°) | 0.563 | |||||||||||

| i | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| βi(°) | −45 | −37.5 | −30 | −22.5 | −15 | −7.5 | 0 | 7.5 | 15 | 22.5 | 30 | 37.5 |

| δBx(μm) | −4.2 | −1.6 | −2.2 | −2.4 | 4.8 | −3.6 | 5.6 | 1.6 | 0.6 | 2.2 | 0.8 | 0.1 |

| δBy(μm) | 0.5 | |||||||||||

| δBz(μm) | 2.6 | −0.4 | 0.2 | 2.2 | −3.2 | −2.8 | −4.4 | −3.6 | −3.4 | −1.8 | 4.0 | −0.9 |

| εBx(°) | −0.267 | |||||||||||

| εBy(°) | 0.62 | −0.17 | 0.94 | 0.88 | 0.45 | 0.75 | 0.87 | 0.24 | 0.16 | 0.48 | 0.20 | 0.49 |

| εBz(°) | −0.581 | |||||||||||

| i | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| γi(°) | 0 | 30 | 60 | 90 | 120 | 150 | 180 | 210 | 240 | 270 | 300 | 330 |

| δCx(μm) | −4.2 | 2.8 | 7.8 | 0.8 | 3.4 | 1.6 | 0.6 | −6.4 | −1.2 | −5.6 | 5.4 | 0.4 |

| δCy(μm) | −2.4 | −3.2 | 0.4 | 1.6 | 2.8 | 4.8 | −2.2 | 0.2 | 1.0 | −3.6 | 1.8 | 0.1 |

| δCz(μm) | 3.2 | |||||||||||

| εCx(°) | 0.264 | |||||||||||

| εCy(°) | −0.795 | |||||||||||

| εCz(°) | 0.4 | 0.2 | −0.1 | −0.5 | 0.4 | 0.3 | −0.3 | 0.4 | −0.5 | 0.1 | −0.2 | 0.0 |

References

- Villeneuve, F.; Legoff, O.; Landon, Y. Tolerancing for manufacturing: A three-dimensional model. Int. J. Prod. Res. 2001, 39, 1625–1648. [Google Scholar] [CrossRef]

- Vignat, F.; Villeneuve, F. 3D transfer of tolerances using a SDT approach: Application to turning process. J. Comput. Inf. Sci. Eng. 2003, 3, 45–53. [Google Scholar] [CrossRef]

- Kamali Nejad, M.; Vignat, F.; Villeneuve, F. Simulation of the geometrical defects of manufacturing. Int. J. Adv. Manuf. Technol. 2009, 45, 631–648. [Google Scholar] [CrossRef]

- Kamali Nejad, M.; Vignat, F.; Villeneuve, F. Tolerance analysis in machining using the model of manufactured part (MMP)—Comparison and evaluation of three different approaches. Int. J. Comput. Integr. Manuf. 2012, 25, 136–149. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, C.; Chen, Y.; Zha, J.; Wang, T. Influence of geometric errors of guide rails and table on motion errors of hydrostatic guideways under quasi-static condition. Int. J. Mach. Tools Manuf. 2018, 125, 55–67. [Google Scholar] [CrossRef]

- Samper, S.; Giordano, M. Taking into account elastic displacements in 3D tolerancing Models and application. J. Mater. Process. Tech. 1998, 78, 156–162. [Google Scholar] [CrossRef]

- Giordano, M.; Pairel, E.; Samper, S. Tolerance analysis and synthesis, method of domains. In Geometric Tolerancing of Products, 7th ed.; Villeneuve, F., Mathieu, L., Eds.; John Wiley and Sons: Hoboken, NJ, USA, 2013; pp. 151–181. [Google Scholar]

- Samper, S.; Formosa, F. Form defects tolerancing by natural modes analysis. J. Comput. Inf. Sci. Eng. 2007, 7, 44–51. [Google Scholar]

- Samper, S.; Adragna, P.; Favreliere, H.; Pillet, M. Modeling of 2D and 3D assemblies taking into account form errors of plane surfaces. J. Comput. Inf. Sci. Eng. 2009, 9, 041005. [Google Scholar]

- Grandjean, J.; Ledoux, Y.; Samper, S.; Favrelière, H. Form errors impact in a rotating plane surface assembly. Procedia CIRP 2013, 10, 178–185. [Google Scholar] [CrossRef]

- Desrochers, A.; Clément, A. A dimensioning and tolerancing assistance model for CAD/CAM systems. Int. J. Adv. Manuf. Tech. 1994, 9, 352–361. [Google Scholar] [CrossRef]

- Desrochers, A.; Ghie, W.; Laperrière, L. Application of a unified Jacobian-Torsor model for tolerance analysis. J. Comput. Inf. Sci. Eng. 2003, 3, 2–14. [Google Scholar] [CrossRef]

- Desrochers, A. Geometrical variations management in a multi-disciplinary environment with the Jacobian-Torsor model. In Models for Computer Aided Tolerancing in Design and Manufacturing; Davidson, J.K., Ed.; Springer: Dordrecht, The Netherlands, 2007; pp. 75–84. [Google Scholar]

- Abenhaim, G.N.; Desrochers, A.; Tahan, A.S. An investigation of the repeatability of nonrigid parts measurements: A case study of an aluminum panel. Procedia CIRP 2013, 10, 105–111. [Google Scholar] [CrossRef][Green Version]

- Shen, Z.; Ameta, G.; Shah, J.J.; Davidson, J.K. A comparative study of tolerance analysis methods. J. Comput. Inf. Sci. Eng. 2005, 5, 247–256. [Google Scholar] [CrossRef]

- Ameta, G.; Serge, S.; Giordano, M. Comparison of spatial math models for tolerance analysis: Tolerance-maps, deviation domain, and TTRS. J. Comput. Inf. Sci. Eng. 2011, 11, 021004. [Google Scholar] [CrossRef]

- Ameta, G.; Singh, G.; Davidson, J.K.; Shah, J.J. Tolerance-maps to model composite positional tolerancing for patterns of features. J. Comput. Inf. Sci. Eng. 2018, 18, 031003. [Google Scholar] [CrossRef]

- Chen, J.; Ho, B.; Lee, H.; Pan, S.; Hsieh, T. Research on geometric errors measurement of machine tools using auto-tracking laser interferometer. World J. Eng. Sci. 2018, 6, 631–636. [Google Scholar] [CrossRef][Green Version]

- Peng, W.; Xia, H.; Chen, X.; Lin, Z.; Wang, Z.; Li, H. Position-dependent geometric errors measurement and identification for rotary axis of multi-axis machine tools based on optimization method using double ball bar. Int. J. Adv. Manuf. Technol. 2018, 99, 2295–2307. [Google Scholar] [CrossRef]

- Peng, W.; Xia, H.; Wang, S.; Chen, X. Measurement and identification of geometric errors of translational axis based on sensitivity analysis for ultra-precision machine tools. Int. J. Adv. Manuf. Technol. 2018, 94, 2905–2917. [Google Scholar] [CrossRef]

- Xia, H.; Peng, W.; Ouyang, X.; Chen, X.; Chen, X.; Wang, S. Identification of geometric errors of rotary axis on multi-axis machine tool based on kinematic analysis method using double ball bar. Int. J. Mach. Tools Manuf. 2017, 122, 161–175. [Google Scholar] [CrossRef]

- Ibaraki, S.; Goto, S.; Tsuboi, K.; Saito, N.; Kojima, N. Kinematic modeling and error sensitivity analysis for on-machine five-axis laser scanning measurement under machine geometric errors and workpiece setup errors. Int. J. Adv. Manuf. Technol. 2018, 96, 4051–4062. [Google Scholar] [CrossRef]

- Ibaraki, S.; Nagai, Y. Formulation of the influence of rotary axis geometric errors on five-axis on-machine optical scanning measurement-application to geometric error calibration by “chase-the-ball” test. Int. J. Adv. Manuf. Technol. 2017, 92, 4263–4273. [Google Scholar] [CrossRef]

- Guo, S.; Jiang, G.; Mei, X.; Tao, T. Measurement and identification of geometric errors for turntable-tilting head type five-axis machine tools. Opt. Precis. Eng. 2018, 26, 2684–2694. [Google Scholar]

- Zhang, L.; Zha, J.; Zou, C.; Chen, X.; Chen, Y. A new method for field dynamic balancing of rigid motorized spindles based on real-time position data of CNC machine tools. Int. J. Adv. Manuf. Technol. 2019, 102, 1181–1191. [Google Scholar] [CrossRef]

- Yang, R.; Tan, K.K.; Tay, A.; Huang, S.; Sun, J.; Fuh, J. An RBF neural network approach to geometric error compensation with displacement measurements only. Neural. Comput. Appl. 2017, 28, 1235–1248. [Google Scholar] [CrossRef]

- Min, J. Measurement method of screw thread geometric error based on machine vision. Meas. Control 2018, 51, 304–310. [Google Scholar] [CrossRef]

- Yang, J.; Ding, H. A new position independent geometric errors identification model of five-axis serial machine tools based on differential motion matrices. Int. J. Mach. Tools. Manuf. 2016, 104, 68–77. [Google Scholar] [CrossRef]

- Lee, K.; Lee, J.; Yang, S. Optimal on-machine measurement of position-independent geometric errors for rotary axes in five-axis machines with a universal head. Int. J. Precis. Eng. Manuf. 2018, 19, 545–551. [Google Scholar] [CrossRef]

- Xing, K.; Achiche, S.; Esmaeili, S.; Mayer, J.R.R. Comparison of direct and indirect methods for five-axis machine tools geometric error measurement. Procedia CIRP 2018, 78, 231–236. [Google Scholar] [CrossRef]

- Aguado, S.; Santolaria, J.; Samper, D.; Aguilar, J.J.; Velázquez, J. Improving a real milling machine accuracy through an indirect measurement of its geometric errors. J. Manuf. Syst. 2016, 40, 26–36. [Google Scholar] [CrossRef]

- Chen, J.; Lin, S.; Zhou, X. A comprehensive error analysis method for the geometric error of multi-axis machine tool. Int. J. Mach. Tools Manuf. 2016, 106, 56–66. [Google Scholar] [CrossRef]

- Chen, Y.; Lin, W.; Liu, C. Design and experimental verification of novel six-degree-of freedom geometric error measurement system for linear stage. Opt. Laser Eng. 2017, 92, 94–104. [Google Scholar] [CrossRef]

- Hsieh, T.; Chen, P.; Jywe, W.; Chen, G.; Wang, M. A geometric error measurement system for linear guideway assembly and calibration. Appl. Sci. 2019, 9, 574. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, B.; Feng, Q. Measurement system and model for simultaneously measuring 6DOF geometric errors. Opt. Express. 2017, 25, 20993–21007. [Google Scholar] [CrossRef] [PubMed]

- Ding, S.; Huang, X.; Yu, C.; Wang, W. Actual inverse kinematics for position-independent and position-dependent geometric error compensation of five-axis machine tools. Int. J. Mach. Tools Manuf. 2016, 111, 55–62. [Google Scholar] [CrossRef]

| X-Axis | Y-Axis | Z-Axis | A-Axis | B-Axis | C-Axis | |

|---|---|---|---|---|---|---|

| Displacement errors | δxx | δyx | δzx | δAx | δBx | δCx |

| δxy | δyy | δzy | δAy | δBy | δCy | |

| δxz | δyz | δzz | δAz | δBz | δCz | |

| Angle errors | εxx | εyx | εzx | εAx | εBx | εCx |

| εxy | εyy | εzy | εAy | εBy | εCy | |

| εxz | εyz | εzz | εAz | εBz | εCz |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Ran, Y.; Zhang, S.; Li, Y. Coupling and Decoupling Measurement Method of Complete Geometric Errors for Multi-Axis Machine Tools. Appl. Sci. 2020, 10, 2164. https://doi.org/10.3390/app10062164

Wang H, Ran Y, Zhang S, Li Y. Coupling and Decoupling Measurement Method of Complete Geometric Errors for Multi-Axis Machine Tools. Applied Sciences. 2020; 10(6):2164. https://doi.org/10.3390/app10062164

Chicago/Turabian StyleWang, Hongwei, Yan Ran, Shengyong Zhang, and Yulong Li. 2020. "Coupling and Decoupling Measurement Method of Complete Geometric Errors for Multi-Axis Machine Tools" Applied Sciences 10, no. 6: 2164. https://doi.org/10.3390/app10062164

APA StyleWang, H., Ran, Y., Zhang, S., & Li, Y. (2020). Coupling and Decoupling Measurement Method of Complete Geometric Errors for Multi-Axis Machine Tools. Applied Sciences, 10(6), 2164. https://doi.org/10.3390/app10062164