Abstract

The aim of this research is to investigate the energy sustainability of cross-laminated timber (CLT) and straw residential buildings in the Cold and Severe Cold Regions of China. In the study, three building materials, namely reinforced concrete (RC), CLT, and straw bale, are used separately to design the building envelope in reference residential buildings in different climate zones. The energy consumption during the operation phase of these buildings is then simulated using Integrated Environmental Solutions—Virtual Environment software (IES-VE). The results show that both CLT and straw buildings are more efficient than reinforced concrete with a reduction in energy consumption during the operational phase. Overall, the calculated heating energy-saving ratios for CLT buildings in Hailar, Harbin, Urumchi, Lanzhou, and Beijing are 3.04%, 7.39%, 7.43%, 12.69%, and 13.41%, respectively, when compared with RC. The calculated energy-saving ratios for heating in straw buildings in comparison with RC in these cities are 8.04%, 22.09%, 22.17%, 33.02%, and 34.28%, respectively. The results also reveal that a south orientation of the main building facade results in approximately 5% to 7% energy reduction in comparison with east or west orientations, and as the building height increases, energy consumption decreases gradually. Although RC is the most frequently used building material in Cold and Severe Cold regions in China, as bio-based building materials, there is great potential to promote CLT and straw bale construction in view of the energy sustainability features.

1. Introduction

1.1. Energy Consumption of Residential Buildings in Northern China

1.1.1. Overall Energy Consumption

Due to the rapid economic growth and increasing urbanization, China has become the largest energy consuming nation, accounting for 23.6% of global energy consumption in 2018 [1]. Energy consumption in China has increased from 1.4 × 109 tons of standard coal equivalent in 2000 to 4.1 × 109 tons of standard coal equivalent in 2017 [2]. Amongst all energy uses, the building sector accounts for 31.4% of the total [3]. The International Energy Agency (IEA) also announced that the total energy consumption in China would be 170,277 PJ or 5.81 × 109 tons of standard coal equivalent by the year 2030, and energy use in the building sector would account for 44,547 PJ. In recent years, residential buildings accounted for the majority of newly constructed buildings in China, with approximately 70% to 80% of the total built areas in 2015–2019 [4,5].

By 2017, 14.0 billion m2 of buildings had been installed with centralized heating systems in the cities of northern China [6]. According to the standard GB50178-93 released by the Housing and Urban-Rural Development Ministry of the People’s Republic of China, there are five climate regions which are established to classify the thermal technical designs of buildings in China [7]. These five climatic regions are the Severe Cold regions, the Cold regions, the Temperate regions, the Hot Summer and Cold Winter regions, and the Hot Summer and Warm Winter regions [7]. The large part of Northern China, which accounts for about two-thirds of the total area of mainland China, is located in Severe Cold and Cold regions (Figure 1) [8]. Due to the poor-quality building thermal performance and the requirements for higher indoor temperatures, heating energy consumption reached accounted for 44.7% of total residential energy in these areas in 2017 [9].

Figure 1.

Climatic regions of China.

1.1.2. Energy Policies in China

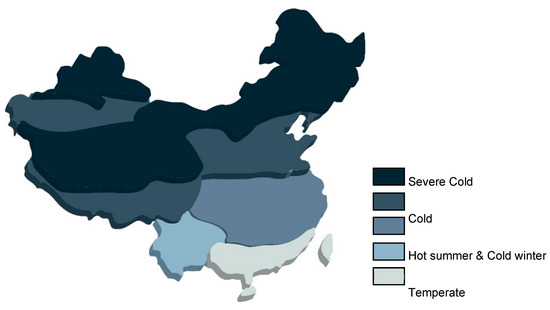

In China, the total energy consumption in 2018 was 4.64 billion tons of standard coal equivalent, 7.7 times more than in 1978 [10]. The main energy structure of China in 2018 is shown in Figure 2. Although the proportion of coal consumption dropped to 59.0% of total energy consumption, with a decrease of 1.4% in 2018 in comparison with the previous year, fossil fuels are still the dominant energy source in China. Due to policies favoring the use of renewable and clean energy, the energy structure has improved in recent years. However, fossil fuel energy sources such as coal and petroleum will remain the major energy sources in China for the next 30 years [11].

Figure 2.

Energy consumption in China.

As early as the 1980s, China had started to promote energy efficiency policies and standards for the building industry [8]. JGJ26-86 is the first energy efficiency standard for civil buildings relating to residential buildings [12]. The Chinese government has issued a series of policies and plans to promote energy efficiency in the building industry since 1986 [13]. The 13th Five-Year Energy Development Plan, which was released in 2016, planned that the peak energy consumption would be limited at approximately 5.0 billion TCE by 2020 [14]. Many provinces in northern China responded to this plan and issued a series of policies. Shandong province provided special funds for energy saving in buildings and green building development, and allowed financial institutions to offer preferential policies to consumers who buy green houses with lower interest rates on mortgages since 2019 [15]. Qinghai Province made these policies compulsory as all new residential buildings had to meet the Green Building Standards after 2018 [16]. Heilongjiang Province put forward a series of energy policies and decreed that green buildings should account for at least 50% of newly constructed buildings after 2018 [17].

1.2. Bio-Based Building Materials in Northern China

1.2.1. Bio-Based Building Material Policies

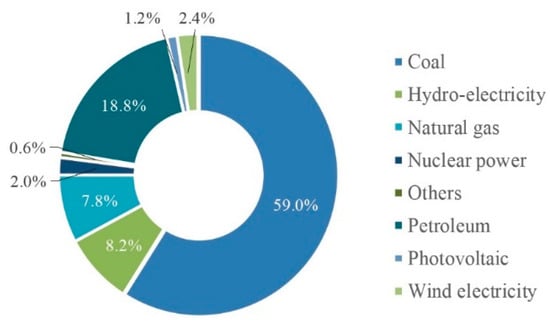

Bio-based building materials are derived from plant, tree, or animal sources. The advantage of these materials is that they are renewable, practically globally distributed in a variety of forms, easily sourced, and readily adaptable to requirements and application [18]. The staple bio-based building materials in China are timber, bamboo, and straw bale. In Northern China, there are abundant forest resources The forest areas in this region have increased by 70% from 1978 to 2015, expanding from 122 million hectares to 208 million hectares [19]. Similarly, the rice-growing areas in Northeast China account for approximately one-third of the total land area. As shown in Figure 3, the woodland and the agricultural land occupy the majority of the land with 40.9% and 33.4%, respectively [20]. Therefore, in Northern China, timber and straw bales are two building materials that are widely applied in and available for all bio-based buildings.

Figure 3.

Spatial distribution of land coverage categories in Northeast China.

Encouraging the application of environment-friendly and energy-saving materials for new buildings is an important component of Chinese energy policy [21]. The government has produced action plans for the production and application of green building materials. Preferential tax policies are offered for projects or products that meet and exceed building energy efficiency standards [22]. The Action Plan for Promoting the Production and Application of Green Building Materials released by the Ministry of Housing and Urban-Rural Development (MHURD) announced the application of green building materials should account for 30% in new buildings, 50% in green buildings, 70% in pilot demonstration projects, and 80% in the reconstruction of existing buildings [23]. The government also supports the use of bio-based building materials such as straw, bamboo, timber, etc. [23]. In Heilongjiang province, the government has made it a priority to promoting green energy-saving technologies and building materials [24]. In Shandong province, the government provides special funds for green building materials [25].

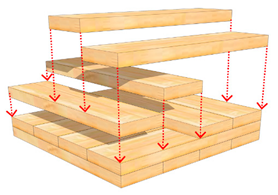

1.2.2. Timber

Due to its high strength, light weight, cost effectiveness, and renewable nature, timber has been widely applied in the building industry for many centuries [26]. Initial research into laminated timber products and construction started in the 19th century [27]. P. Schuler and R. Guyer suggested this concept and built the first residential buildings using solid wood panels in 1993 [27]. In the timber building industry, cross laminated timber (CLT) is one of the most significant building materials that has been used in the building industry in Europe since the early 1990s [28,29]. CLT is a walling system making up of solid timber panels. These panels can be designed to construct walls, roofs, and floor slabs [28]. The first residential building using CLT construction was built by Moser in 1995 and it reflected the development of CLT at that time [30].

During the last two decades, CLT has been widely applied and gained double-digit growth in Europe [31]. The facilities for CLT production grew between 15% and 20% up to 2014. Worldwide production volumes of CLT increased to 625,000 m³ in 2014 [32]. Although CLT was used as a building material in Germany, Austria, and Switzerland at first [33], it has become a product of considerable interest in Canada, the United States, Japan, China, and New Zealand These countries have become involved in the research, development, production, use, and standardization of this innovative engineered wood [33].

Existing studies on the properties of CLT have shown that CLT construction has advantages in fire resistance, thermal performance, and the potential for carbon sequestration in the building structure [33,34,35,36,37,38,39,40,41,42,43]. Other studies indicates that CLT buildings are structurally sound against the risk of collapse under a Maximum Credible Earthquake [34]. Many research projects have focused on the fire resistance of timber construction [35,36,37]. CLT has been proven to have good fire resistance because the charring surface protects the underlying timber from being destroyed [38,39]. Ambrose Dodoo et al. found that a low-energy version of CLT buildings results in the lowest life cycle carbon emissions while conventional beam-and-column buildings produce the highest life cycle carbon emissions, with a reduction of 9% of total carbon emissions in CLT buildings. This is calculated for material production and building construction, space heating and ventilation (for a 50 year period), and demolition [40]. Setter Lewis et al. indicated that the use of CLT in the construction of single-family homes results in annual energy cost savings across all climates considered in the study, with higher savings in cold climates than in hot climates. The CLT building reduced annual heating energy in Minneapolis by 38%, and annual cooling energy in Phoenix by 17% [41]. Khavari Ali found that CLT buildings are much more efficient for regions where heating energy accounts for the lion’s share of overall consumption and the overall energy savings reached 10% in Duluth [42]. Darby et al. indicated the carbon benefits for a CLT solution for a mid-rise residential building in comparison with a more conventional reinforced concrete solution, and the embodied carbon of the CLT frame building was 655t CO2, 1006t CO2 lower than the reinforced concrete (RC) frame equivalent [43].

1.2.3. Straw Bale

Straw is a by-product of cereal farming [44]. The history of straw bale application in buildings can be traced back to the invention of bailing machines [45,46]. The first straw bale construction was built in Nebraska in the late 19th century. This oldest existing straw bale building is a two-story ranch which was built in Nebraska in 1914 [47,48]. Modern straw bale buildings were developed in California in the 1980s [46]. One of the first known residential straw bale buildings was a small dwelling built by Bob Matthews of the Institute for Social Inventions in 1995 [49]. In the UK, a wider application of straw bale buildings has developed, including the EcoDepot in York, offices and auction premises for Sworders Ltd. (the largest straw bale building yet built in the UK) at Stansted, Essex, and the large sawmill for Greyfield Timber in Dartington, Devon [48].

The straw bale construction technique was initially introduced to Northern China by the Adventist Development and Relief Agency (ADRA) in 1998 [50]. The project was funded by the ADRA/China, Central Government, and Local Governments in northern China, and more than 600 straw bale buildings were constructed by 2006 [51]. Informed by the practices of the ADRA project, a different design of straw bale building was developed in Jilin province [52]. Existing studies indicated that straw bale construction had great potential to reduce energy use in residential buildings due to its high thermal resistance properties. The first investigation into the thermal conductivity of straw bales was carried out in the University of Arizona, which used the modified guarded hot plate method. This showed that straw bale buildings had the potential to save considerable energy [53]. Studies on the performance of straw bales in a house built in the south Germany indicated that straw bale construction had good thermal response to the cold weather in Germany [54]. Investigations into reinforcing earth plasters with straw and wood shavings indicated that straw bales were superior in both thermal and hygroscopic performance to existing construction [55]. D’Alessandro et al. demonstrated that the use of straw bales in walls was capable of reducing energy and the carbon embodied in the building by using Life Cycle Assessments [56]. González found that embodied energy and carbon dioxide in local straw solutions was far lower than for fired clay bricks, concrete blocks, and insulated cavity walls [57]. Larisa Brojan et al. demonstrated that straw bale wall construction has a negative value of −50.037 kgCO2eq and brick wall construction has 61.548 kgCO2eq by comparing the global warming potential (GWP). Straw bale wall systems are all natural and completely recyclable, which results in lower energy requirements in all aspects when compared with the brick system [58].

1.3. Study Scope and Objectives

Although timber and straw have been proven to be low-carbon and energy-saving building materials, there is limited research examining the application and energy-saving potential of these bio-based building materials in the Cold and Severe Cold regions of China. This research uses residential case study buildings with a comparison of the energy performance of reinforced concrete, cross laminated timber, and straw bales in the context of life cycle assessment. The evaluation and comparisons are mainly focused on operational heating and cooling energy use in the Cold and Severe Cold regions of China.

2. Simulation Environment and Introduction of Case Buildings

2.1. Basic Information about the Five Selected Cities

As mentioned above, China is classified into five different climate regions, namely the Severe Cold Region, Cold Region, Hot-Summer Cold-Winter Region, Hot-Summer Warm-Winter Region, and Temperate Region, which are established to accommodate the thermal-technical design of buildings in China. In this paper, in order to evaluate the energy performance of RC, timber, and straw buildings, five major cities in the Cold and Severe Cold regions of China were selected to provide the building simulation environment. Each city is located in a different climate sub-region (Figure 4). The basic location and climatic information for the five study cities are presented in Table 1 and Figure 4.

Figure 4.

Location of the five study cities.

Table 1.

Data for the five study cities.

Buildings in the Cold and Severe Cold regions have to follow local construction regulations which define the structural criteria, the insulation properties for opaque walls floors and roofs, and the thermal and optical performance of windows and skylights. Amongst these regulations, thermal insulation is one of the most important factors and is enforced strictly due to the low external temperatures in winter. The basic thermal design parameters are presented in Table 2.

Table 2.

Basic design parameters for the five study cities.

2.2. Details of Simulation Buildings

2.2.1. Parameters of Case Study Buildings

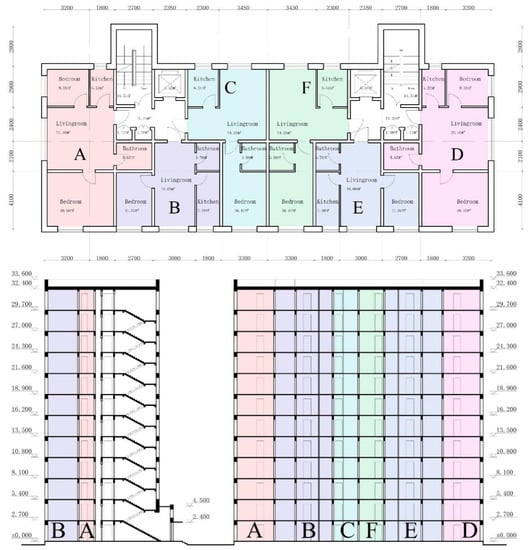

For this research, an actual residential building that has been constructed in Harbin was selected as the case study building. This is a very typical residential building in Northern China. Figure 5 presents the floor plans of the building, and Table 3 presents the basic architectural design parameters of the building. The original building has an RC framed structure, RC slabs (full weight), and RC block infill walls.

Figure 5.

Standard floor plan and sections of the residential case study building.

Table 3.

Design parameters for the residential case study building.

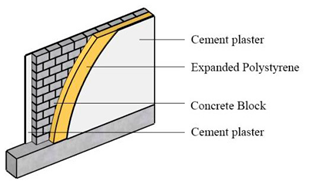

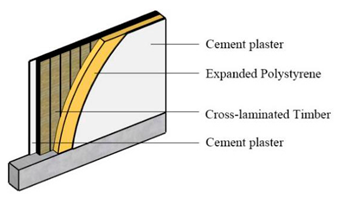

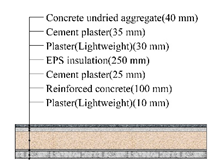

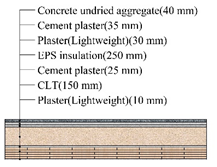

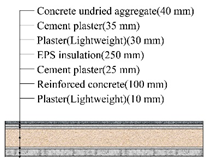

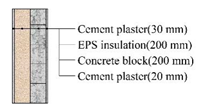

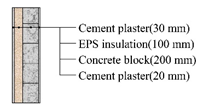

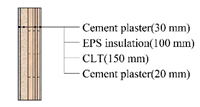

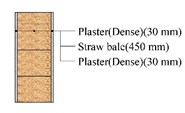

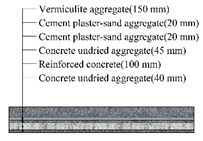

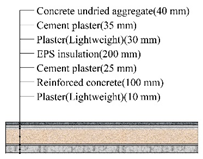

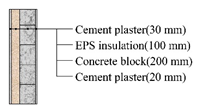

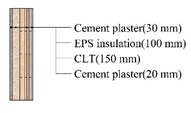

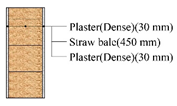

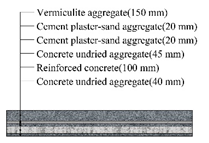

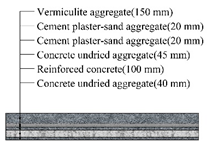

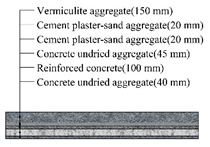

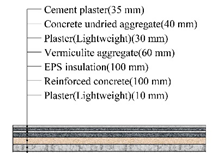

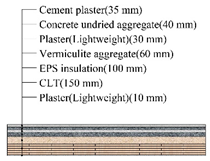

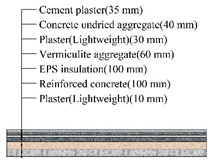

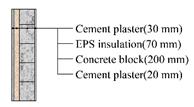

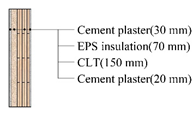

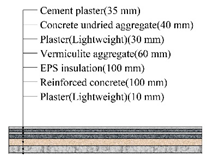

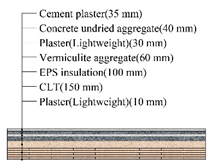

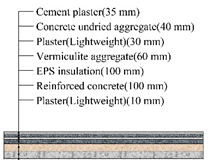

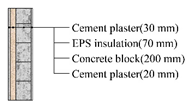

2.2.2. Building Materials and Structural Design

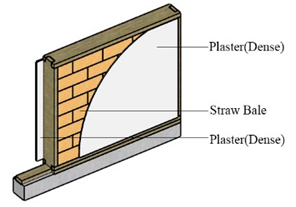

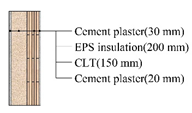

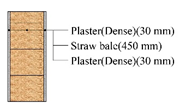

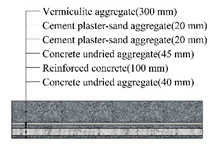

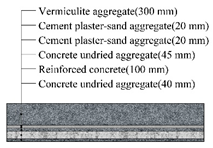

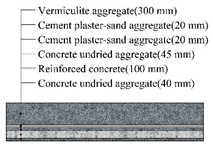

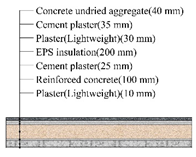

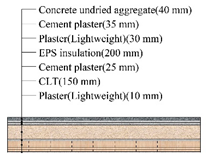

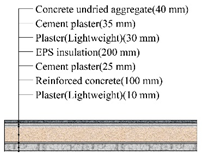

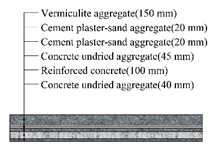

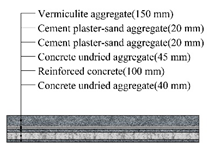

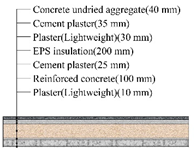

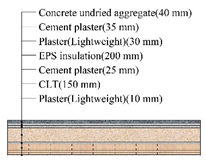

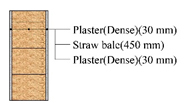

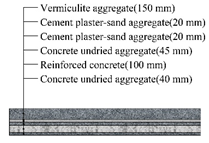

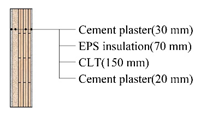

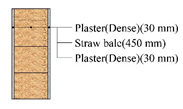

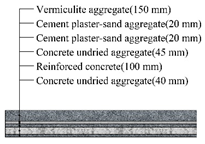

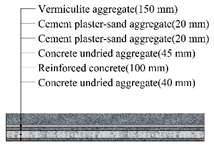

In the building simulation process, the building materials and structure were redesigned according to the different climate zones. Besides the cross laminated timber and straw bales mentioned above, there were also other bio-based materials used for walling constructions, such as coffee chaff. Ricciardi et al. studied the environmental sustainability of coffee chaff using a ‘‘cradle-to-gate” approach and concluded that the coffee chaff could be an excellent environmental friendly sound insulation material for the building industry [59]. However, in this paper, three different building materials, namely reinforced concrete, cross laminated timber, and straw bales, were used separately to create the case study buildings due to the real application in China. The details of the three materials are presented in Table 4.

Table 4.

Layout of building materials.

The thermal conductivities of the simulation building materials are tabulated in Table 5. The thermal properties of the concrete buildings were designed as per required in the JGJ26-2010, whereas the thermal properties of the CLT buildings are as per required by the construction requirements. As a result, due to the CLT having higher thermal resistances than concrete, the U-values of the roofing constructions of the CLT buildings are slightly lower than the ones in the concrete buildings. For the straw bale buildings, the roof constructions are the same as those of the concrete building. Due to the highest thermal resistance of straw bales in the walling constructions in this research, the overall U-value of straw bale walls is the lowest in this research (0.160W/(m2·K)).

Table 5.

The thermal conductivities of the simulation building materials.

In order to reflect the actual situation in each climate region, the structure of the original building was redesigned as necessary to meet the local building regulations. When compared with the RC building, the basic dimensions of the CLT and straw buildings, such as floor height, building orientation, ground areas, and major functions, remain the same as for the reference concrete building. The RC structural design complies strictly with the local Code for Seismic Design of Buildings (GB50011-2010). CLT and straw are not widely used as building materials in China at present, and hence there are no local building design standards available for residential building design. Therefore, this study applied the Euro-code 5 and relevant documents for the CLT structural design. The straw bale building could not be designed as a load-bearing structure due to the material attributes. Therefore, the load-bearing structure and functional organization of the building remained unchanged. Only non-load-bearing walls were replaced in the straw bale building. The infilled straw walling design data in this study was selected from existing references [60,61]. The details of the roof, external wall, and ground design details in the five cities are presented in Table 6, Table 7, Table 8, Table 9 and Table 10.

Table 6.

Details of roof, external wall, and ground designs in Hailar.

Table 7.

Details of roof, external wall, and ground designs in Harbin.

Table 8.

Details of roof, external wall, and ground designs in Urumqi.

Table 9.

Details of roof, external wall, and ground designs in Lanzhou.

Table 10.

Details of roof, external wall, and ground designs in Beijing.

3. Methodology

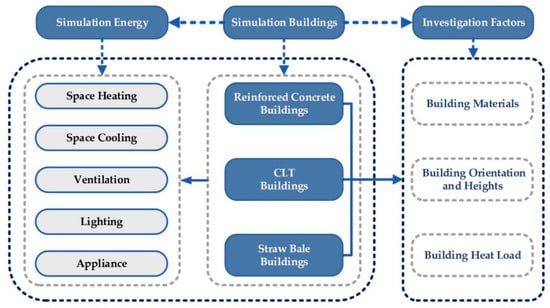

3.1. Study Scope

In this research, the scope was focused on building energy consumption during the operational phase, which accounts for approximately 70%–80% of the whole building energy consumption during its life cycle (Figure 6). According to the design standard for the energy efficiency of residential buildings in Severe Cold and Cold regions (JGJ 26-2010), energy consumption for lighting, heating, cooling, ventilation, and appliances is simulated using the commercial software IES (Integrated Environmental Solution)-VE. During the simulation process, the following factors were investigated as keynotes.

Figure 6.

Flowchart of the study.

- (1)

- Building materials. The initial building constructed in RC was simulated as a reference, and the building material was then replaced by the two bio-based building materials, namely CLT and straw bales, in the following simulation process. The energy efficiency of the three building materials was studied and compared.

- (2)

- Heating load. According to the existing research, heating energy consumption is dominant in the Cold and Severe Cold regions [62]. Reduction of the heating energy consumption in the building is effective in lowering the overall energy consumption in these regions. The thermal performance of the three materials during heating was studied.

- (3)

- Building orientation and height. In the Cold and Severe Cold regions, building orientation is frequently planned to take maximum advantage of daily and seasonal variations of sunlight. In the simulation process, the main orientation of the studied residential building was changed from the east to the west in steps of 10 degrees. The influence of building orientation on building energy consumption and the differences in energy efficiency for each floor were also examined.

3.2. Simulation Parameters

As mentioned above, five major categories of energy use during the building operation phase, namely lighting, space heating, space cooling, ventilation, and appliances, were simulated in this study. The life of the residential building was set at 50 years. The heat given off by the occupants in the main rooms (living room and bedroom) was also taken into account. The room occupancy parameters are presented in Table 11. Other simulation parameters were set as follows.

Table 11.

Room occupancy parameters.

(1) Space Cooling and Space Heating

According to the local residential building regulations in China, the indoor temperature of the main rooms is to be controlled between 18 °C and 26 °C. In actual conditions, the heating system is operated for 24 h in the Cold and Severe Cold regions during the heating season. The minimum indoor temperature in auxiliary space is not to fall below 12 °C. The cooling system will run if the indoor temperature exceeds 26 °C during working hours. The simulation parameters for space cooling and space heating are displayed in Table 12 and Table 13.

Table 12.

Simulation parameters for cooling operation in the five cities.

Table 13.

Simulation parameters for heating operation in the five cities.

(2) Ventilation

Both natural ventilation and infiltration were considered in the simulation. The infiltration occurred over 24 h with a maximum flow rate of 0.300 ach/h, and the natural ventilation was defined separately according to the climate locations. Taking Hailar as an example, the simulation parameters for natural ventilation in Hailar are tabulated in Table 14.

Table 14.

Simulation parameters of natural ventilation in Hailar.

(3) Appliances

The appliances that are operated in each household can vary significantly depending on the habits of the occupants. In this study, only the most commonly used appliances were considered. The parameters for this equipment are tabulated in Table 15. The lighting hours and power density are tabulated in Table 16.

Table 15.

Simulation parameters for equipment usage in the five cities.

Table 16.

Simulation parameters for lighting in the five cities.

4. Results and Discussion

(1) Building materials. The simulation results for energy consumption during the operational stage for the RC, CLT, and straw bale residential buildings are presented in Table 17, Table 18 and Table 19. The results indicate that when compared with RC, both the straw and the CLT buildings can result in lower energy consumption in any climate sub-regions. The CLT and straw buildings save approximately 3%–5% of energy in the Severe Cold Region and 13%–15% of energy in the Cold Region during the operational stage when compared with RC buildings. However, overall building energy consumption in the Severe Cold region is 60%–70% more than in the Cold region.

Table 17.

Annual energy consumption of the RC building in the five cities (kWh/m2).

Table 18.

Annual energy consumption of CLT building in the five cities (kWh/ m2).

Table 19.

Annual energy consumption of straw building in the five cities (kWh/ m2).

The research results have identified notable impact of thermal property differences of walling constructions on the energy consumption. Both the CLT buildings and the straw bale buildings feature notable lower energy consumption than the concrete buildings. Due to the straw bale walls having lower U-value than the other walling constructions in this research, the straw bale buildings consume the least energy for heating and cooling in the studied cities in Severe Cold regions and Cold regions. It should be noted that amongst all three building materials, straw has the best energy-saving performance due to its lower U-value. However, the straw bale external walls are much thicker than the RC and CLT external walls. Taking the external wall design in Harbin as an example, the thicknesses for RC, CLT, and straw bale are 350 mm, 300 mm, and 510 mm, respectively. Obviously, more interior space is occupied by the straw building envelope. As a result, the buildings would benefit from the low U-value straw bale walls in the Severe Cold regions, whereas the CLT walls features in slightly lower energy efficiency levels than the straw bale walls with notable reductions of walling thickness. The straws are baled by a straw strapping machine, which is a specific piece of equipment used for straw bale production. The current dimension of a straw bale produced by this machine is approximately 450 mm deep. With improvements to the straw strapping machine, the depth of a straw bale can be reduced to 300 to 350 mm. In addition, unlike the RC and CLT building system, the straw bales cannot be used to design a load-bearing structure due their properties. The straw bales can be used in the design of a multiple-ribbed composite wall with load-bearing materials, such as timber, steel, and RC.

In this paper, all the wall construction designs strictly follow the national building codes and the existing local construction methods. However, some studies revealed that the layer succession order of the opaque walls would have an impact on the thermal performance of walls. Leccese, Salvadori et al. highlighted that the positioning and thickness distribution of the insulation material may affect the dynamic thermal performance of walls [63]. Fantozzi, Galbiati et al. pointed out that the proper sequence of resistive and capacitive layers would improve the performance of lightweight walls [64]. The thermal performance of walls would more or less affect the energy performance of buildings. In addition, the effects of bio-based building materials on the energy performance of buildings during the operation stage have been investigated in this study. There are references using the life cycle cost analysis as an approach to improve the energy performance of buildings [65]. The effect of materials on the energy performance of buildings in view of life cycle cost and layer succession order of the opaque walls will be studied in the future research.

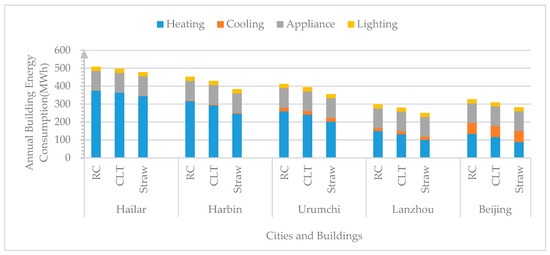

(2) Heating and cooling loads. Figure 7 presents the annual building energy consumption in the five cities. Overall, the calculated heating energy-saving ratios of the CLT buildings in Hailar, Harbin, Urumchi, Lanzhou, and Beijing are 3.04%, 7.39%, 7.43%, 12.69%, and 13.41% respectively. The ratios for straw buildings are 8.04%, 22.09%, 22.17%, 33.02%, and 34.28%, respectively. In the Severe Cold region, heating energy is the major demand, accounting for 60%–70% of total energy consumption, followed by the appliance energy and lighting. In contrast, heating energy accounts for 30%–50% of the total energy in the Cold region. In these climates, thermal insulation is crucial to lower overall energy consumption. Hence, timber and straw have significant advantages due to their superior thermal resistance.

Figure 7.

Annual building energy consumption in five cities (Building orientation: South).

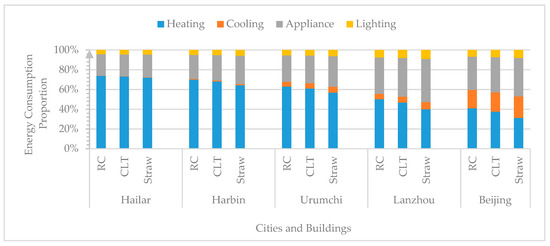

Figure 8 indicates that there is a risk of overheating with CLT and straw bale buildings in comparison with RC structures. This means that more energy would be required for cooling of the timber and straw buildings in summer. Thermal mass is a property of the building material that enables it to store heat, providing inertia against temperature fluctuations. Amongst these three materials, straw bale has the lowest thermal mass, followed by CLT and RC. Hence, in terms of thermal mass and thermal comfort in the summer, CLT and straw bales may not be suitable alternative building materials for climate regions with considerable cooling requirements.

Figure 8.

Annual building energy consumption proportion in five cities (Building orientation: South).

Although the thermal performance of RC is not as good as that of CLT and straw bales, reinforced concrete is the most widely applied building material in Northern China. The market for CLT and straw bales is still in development in China. There are only two CLT factories at present, located in Dalian, Liaoning Province and Ningbo, Zhejiang Province. The initial material cost of CLT and straw bale buildings may not be as competitive as that of RC buildings at present. However, with the development of bio-based building materials promoted by government, there is great potential to develop the timber and straw industry in the cold regions.

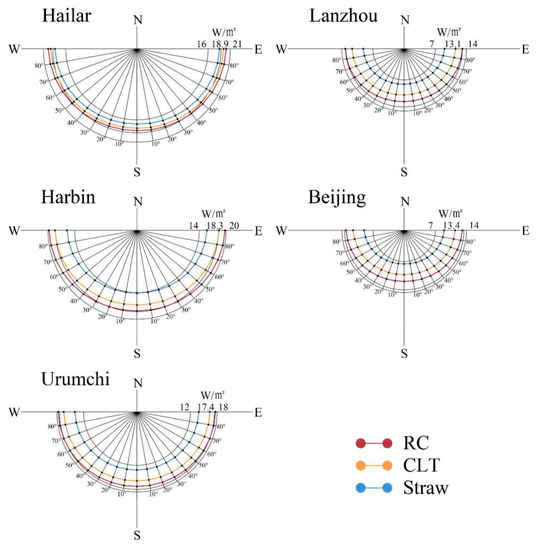

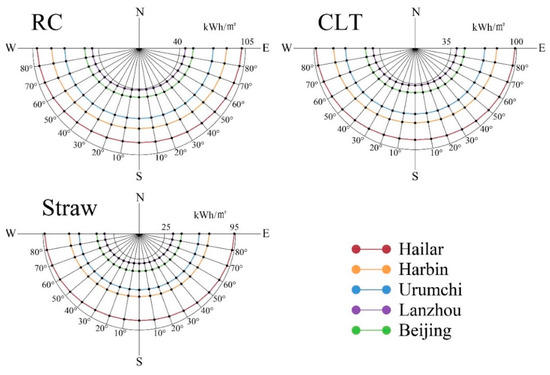

(3) Building orientation and building height. The results from the building orientation simulation indicate that building position is a major factor with an effect on energy performance. The south is the best principal orientation for buildings located in the Cold and Severe Cold regions. Energy consumption increases gradually when the main facade of the building moves to the west or the east. Figure 9 and Figure 10 present the heating and cooling load of the RC, CLT, and straw buildings located with different orientations. These figures demonstrate that a south-facing facade has approximately 5%–7% less energy demand than one facing east or west. These results are useful to assess the influence of orientation on energy consumption when designing a building in these climate regions.

Figure 9.

Annual heating load for building in the five study cities with different orientation.

Figure 10.

Annual heating load for buildings in the five cities with different orientation.

The simulation results for energy consumption by building floor indicate that with an increase in building height, the energy consumption decreases gradually (Table 20). The energy consumption on the top and bottom floors of the building are apparently higher than on the other floors. Although CLT and straw are ideal materials for external walls and roof, they are not suitable for the floors. The energy consumption on the ground floor is approximately 50%–60% above the average for all buildings. The results also demonstrate that the middle floors of the building are the most energy-efficient areas.

Table 20.

Energy consumption of RC, CLT, and straw buildings in the five cities (kWh/m2).

5. Conclusions

This research investigates the energy sustainability of CLT and straw residential buildings in the Cold and Severe Cold Regions of China. Overall, the calculated heating energy-saving ratios of CLT buildings for Hailar, Harbin, Urumchi, Lanzhou, and Beijing are 3.04%, 7.39%, 7.43%, 12.69%, and 13.41%, respectively, when compared with RC. The heating energy-saving ratios for straw bale buildings in these cities are 8.04%, 22.09%, 22.17%, 33.02%, and 34.28%, respectively. Although RC is the most frequently used building material in these climate regions, there is great potential for the use of CLT and straw in this construction market.

This analysis also provides an assessment of the influence of orientation on building energy consumption. From the aspect of heating energy conservation, south-facing is the preferred orientation for buildings located in the Cold and Severe Cold regions of China. South-facing buildings require 5%–7% less energy than those facing east or west. In terms of building height, as the building height increases, the household energy consumption decreases gradually.

The analysis confirms that, as bio-based building materials, CLT and straw are more energy efficient than RC in the Cold and Severe Cold regions, reducing the heating energy requirements. There is great potential for the promotion of the bio-based building material in Severe Cold region and Cold region in China.

The energy-saving potential of the bio-based building materials may also be presented in the regions sharing similar climatic regions with northern China worldwide. As more energy-efficient buildings are in need to reduce environmental impacts of building industries in the cold regions worldwide, the applications of bio-based buildings materials, including CLT, Straw Bale, and so forth, will have similar energy-saving potential as in China.

Author Contributions

Conceptualization, H.G. and X.Y.; methodology, S.Z. and L.H.; software, S.Z. and L.H.; validation, T.Q., W.S.; formal analysis, S.Z.; investigation, T.Q.; resources, W.S.; data curation, S.Z.; writing—original draft preparation, H.G.; writing—review and editing, H.G.; visualization, S.Z.; supervision, X.Y.; project administration, S.Z.; funding acquisition, H.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by National Natural Science Foundation of China, grant number 51608144; and Heilongjiang Provincial Natural Science Foundation of China, grant number LH2019E110.

Conflicts of Interest

The authors declare no conflict of interest.

References

- British Petroleum. BP Statistical Review of World Energy; British Petroleum: London, UK, 2019; p. 2018. [Google Scholar]

- National Bureau of Statistics of China. China Energy Statistical Yearbook (2018); China Statistics Press: Beijing, China, 2018. (In Chinese)

- Yuan, T.; Zhu, N.; Shi, Y.; Chang, C.; Yang, K.; Ding, Y. Sample data selection method for improving the prediction accuracy of the heating energy consumption. Energy Build. 2018, 158, 234–243. [Google Scholar] [CrossRef]

- Chiara, D.; Lavagno, E.; Mutani, G. Chinese residential energy demand: Scenarios to 2030 and policies implication. Energy Build. 2015, 89, 49–60. [Google Scholar] [CrossRef]

- Hu, S.; Yan, D.; Guo, S.; Cui, Y.; Dong, B. A survey on energy consumption and energy usage behavior of households and residential building in urban China. Energy Build. 2017, 148, 366–378. [Google Scholar] [CrossRef]

- The State Development and Reform Commission. Winter Clean Heating Plan in Northern China (2017–2021); The State Development and Reform Commission: Beijing, China, 2017; p. 56. (In Chinese)

- Chen, S.; Li, N.; Guan, J.; Xie, Y.; Sun, F.; Ni, J. A statistical method to investigate national energy consumption in the residential building sector of China. Energy Build. 2008, 40, 654–665. [Google Scholar] [CrossRef]

- Zhao, M.; Künzel, H.M.; Antretter, F. Parameters influencing the energy performance of residential buildings in different Chinese climate zones. Energy Build. 2015, 96, 64–75. [Google Scholar] [CrossRef]

- Building Energy Conservation Research Center, Tsinghua University. China Building Energy Saving Annual Development Research Report 2019; Tsinghua University: Beijing, China, 2019. (In Chinese) [Google Scholar]

- China Electric Power Planing & Engineering Institute. China Energy Development Report 2018; China Electric Power Planing & Engineering Institute: Beijing, China, 2018. (In Chinese)

- Cnpc Economics & Technology Research Institute. World and China’s Energy Outlook in 2050 (2019); Cnpc Economics & Technology Research Institute: Beijing, China, 2019. (In Chinese) [Google Scholar]

- Ministry of Construction of the People’s Republic of China. Energy Conservation Design Standard for New Heating Residential Buildings; Institute of Standard Quota of Ministry of Construction of People’s Republic of China: Beijing, China, 1996; Volume JGJ26-95, p. 30.

- Zhang, G.; Gao, X.; Wang, Y.; Guo, J.; Wang, S. Measurement, Coordination and Evolution of Energy Conservation and Emission Reduction Policies in China: Based on the Research of the Policy Data from 1978 to 2013. China Popul. Resour. Environ. 2014, 24, 62–73. [Google Scholar] [CrossRef]

- National Development and Reform Commission; National Energy Administration. Circular of the National Development and Reform Commission and the State Energy Administration on Printing and Distributing the 13th Five Year Plan for Energy Development. Available online: http://www.gov.cn/xinwen/2017-01/17/content_5160588.htm (accessed on 20 December 2019). (In Chinese)

- People’s Government of Shandong Province. Measures to Promote the Development of Green Building in Shandong Province. Available online: http://www.shandong.gov.cn/art/2019/1/28/art_2259_30552.html (accessed on 20 December 2019). (In Chinese)

- General Office of Qinghai Provincial Government. Notice of the General Office of the People’s Government of Qinghai Province on Printing and Distributing the Work Plan of Building Qinghai into a National Clean Energy Demonstration Province (2018–2020). Available online: http://zwgk.qh.gov.cn/zdgk/zwgkzfxxgkml/zfxxaqsc/201812/t20181229_32671.html (accessed on 21 December 2019). (In Chinese)

- Department of Housing and Urban-Rural Development of Heilongjiang Province. Notice on Implementing the Implementation Plan of Green Building Action in Heilongjiang Province and Accelerating the Development of Green Building. Available online: http://zfcxjst.hlj.gov.cn/plus/view.aspx?aid=47856 (accessed on 21 December 2019). (In Chinese)

- Jones, D. 1-Introduction to the Performance of Bio-Based Building Materials. In Performance of Bio-Based Building Materials; Jones, D., Brischke, C., Eds.; Woodhead Publishing: Cambridge, UK, 2017. [Google Scholar] [CrossRef]

- Ke, S.; Qiao, D.; Zhang, X.; Feng, Q. Changes of China’s forestry and forest products industry over the past 40 years and challenges lying ahead. For. Policy Econ. 2019, 106, 101949. [Google Scholar] [CrossRef]

- Mao, D.; He, X.; Wang, Z.; Tian, Y.; Xiang, H.; Yu, H.; Man, W.; Jia, M.; Ren, C.; Zheng, H. Diverse policies leading to contrasting impacts on land cover and ecosystem services in Northeast China. J. Clean. Prod. 2019, 240, 117961. [Google Scholar] [CrossRef]

- National Development and Reform Comission; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Green Building Action Plan. Available online: http://www.nea.gov.cn/2013-01/07/c_132085767.htm (accessed on 22 December 2019). (In Chinese)

- Stanić, A.; Hudobivnik, B.; Brank, B. Economic-design optimization of cross laminated timber plates with ribs. Compos. Struct. 2016, 154, 527–537. [Google Scholar] [CrossRef]

- Ministry of Industry and Information Technology of the People’s Republic of China; Ministry of Housing and Urban Rural Development of the People’s Republic of China. Action Plan for Promoting the Production and Application of Green Building Materials. Available online: http://www.mohurd.gov.cn/wjfb/201509/t20150906_224666.html (accessed on 15 November 2019).

- Government of Heilongjiang Province. Implementation Plan of Green Building Action in Heilongjiang Province; Government of Heilongjiang Province: Harbin, China, 2018.

- People’s Government of Shandong Province. Opinions of Shandong Provincial People’s Government on Vigorously Promoting Green Building; People’s Government of Shandong Province: Jinan, China, 2013.

- Forest Products Laboratory (US). Wood Handbook: Wood as an Engineering Material; United States Department of Agriculture Forest Service: Washington, DC, USA, 2010; Volume 190, p. 509.

- Rattasepp, T.; Mang, H.J.B. Regarding stability of flat edge supported hypar shells in timber with straight-lined edge girders. Bauingenieur 1989, 64, 255–266. (In German) [Google Scholar]

- Lehmann, S.; Hamilton, C. Sustainable Infill Development Using Low Carbon CLT Prefabrication: Adaptation for the South Australian Context; Zero Waste SA Research Centre for Sustainable Design and Behaviour: University of South Australia, Adelaide, Australia, 2011. [Google Scholar]

- Gagnon, S.; Pirvu, C. Cross-Laminated Timber (ÇTK) Handbook; FPInnovations: Vancouver, QC, Canada, 2012; p. 594. [Google Scholar]

- Moser, K. Dickholz through vacuum. Bau. Holz 1995, 11, 941–947. (In German) [Google Scholar]

- Crespell, P.; Gagnon, S. Cross Laminated Timber: A Primer; Fpinnovations: Vancouver, QC, Canada, 2010. [Google Scholar]

- Plackner, H. Undisputable—Solid Timber has Created Its Market; Holzkurier BSP Special: Berlin, Germany, 2014. (In German) [Google Scholar]

- Brandner, R.; Flatscher, G.; Ringhofer, A.; Schickhofer, G.; Thiel, A. Cross laminated timber (CLT): Overview and development. Eur. J. Wood Wood Prod. 2016, 74, 331–351. [Google Scholar] [CrossRef]

- Shahnewaz, M.; Tannert, T.; Alam, M.S.; Popovski, M. Seismic Performance of Cross Laminated Timber (CLT) Platform Building by Incremental Dynamic Analysis. In Proceedings of the 39th IABSE Symposium–Engineering the Future, Vancouver, QC, Canada, 21–23 September 2017; pp. 422–428. [Google Scholar]

- Takeda, H.; Mehaffey, J. WALL2D: A model for predicting heat transfer through wood-stud walls exposed to fire. Fire Mater. 1998, 22, 133–140. [Google Scholar] [CrossRef]

- König, J. Timber Frame Assemblies Exposed to Standard and Parametric Fires. Part 2 A Design Model for Standard Fire Exposure. 2000. Available online: https://pdfs.semanticscholar.org/016e/1f82cb5825db687d7f44b0e4fee1114d400c.pdf (accessed on 15 November 2019).

- Young, S.; Clancy, P. Structural modelling of light-timber framed walls in fire. Fire Saf. J. 2001, 36, 241–268. [Google Scholar] [CrossRef]

- Frangi, A.; Fontana, M.; Hugi, E.; Jübstl, R. Experimental analysis of cross-laminated timber panels in fire. Fire Saf. J. 2009, 44, 1078–1087. [Google Scholar] [CrossRef]

- Lineham, S.A.; Thomson, D.; Bartlett, A.I.; Bisby, L.A.; Hadden, R.M. Structural response of fire-exposed cross-laminated timber beams under sustained loads. Fire Saf. J. 2016, 85, 23–34. [Google Scholar] [CrossRef]

- Dodoo, A.; Gustavsson, L.; Sathre, R. Lifecycle carbon implications of conventional and low-energy multi-storey timber building systems. Energy Build. 2014, 82, 194–210. [Google Scholar] [CrossRef]

- Setter, L.; Smoorenburg, E.; Wijesuriya, S.; Tabares-Velasco, P.C. Energy and hygrothermal performance of cross laminated timber single-family homes subjected to constant and variable electric rates. J. Build. Eng. 2019, 25, 100784. [Google Scholar] [CrossRef]

- Khavari Ali, M.; Pei, S.; Tabares-Velasco Paulo, C. Energy Consumption Analysis of Multistory Cross-Laminated Timber Residential Buildings: A Comparative Study. J. Archit. Eng. 2016, 22, 04016002. [Google Scholar] [CrossRef]

- Darby, H.; Elmualim, A.A.; Kelly, F. A case study to investigate the life cycle carbon emissions and carbon storage capacity of a cross laminated timber, multi-storey residential building. In Proceedings of the Sustainable Building Conference, Munich, Germany, 10–12 September 2013; pp. 10–12. [Google Scholar]

- Khan, T.S.; Mubeen, U. Wheat straw: A pragmatic overview. Curr. Res. J. Biol. Sci. 2012, 4, 673–675. [Google Scholar]

- Lacinski, P.; Bergeron, M. Serious Straw Bale, A Home Construction Guide for All Climates; Chelsea Green Publishing Company: White River Junction, VT, USA, 2000. [Google Scholar]

- King, B. Design of Straw Bale Buildings: The State of the Art; Green Books: Cambridge, UK, 2006. [Google Scholar]

- Minke, G.; Mahlke, F. Building with Straw: Design and Technology of a Sustainable Architecture; Birkhauser: Basel, Switzerland, 2005. [Google Scholar]

- Goodhew, S.; Carfrae, J.; De Wilde, P. Briefing: Challenges related to straw bale construction. In Proceedings of the Institution of Civil Engineers-Engineering Sustainability; Thomas Telford Ltd.: London, UK, 2010; pp. 185–189. [Google Scholar]

- Nickson, C. Straw Bale Construction. Available online: http://www.sustainablebuild.co.uk/constructionstrawbale.html (accessed on 5 December 2019).

- Cui, R.; Zhang, S.; Peng, Y. The Application of Grass-Brick Building in Northeast China. Construction of Small Towns 2001, 90. Available online: http://118.24.11.132:81/kns/brief/Default_Result.aspx (accessed on 15 December 2019). (In Chinese).

- Gao, X.S.; Adventist Development Relief Agency (ADRA). China Development Brief. Available online: http://www.chinadevelopmentbrief.org.cn/news-13062.html (accessed on 27 July 2019).

- Cao, B.Z.; Zhao, Y.M.; Duan, W.F.; Bai, A.H. The possibility analysis on application of new light-weight steel straw bale thermal insulating dwellings in northeast rural areas. New Build. Mater. 2010, 37, 34–36. [Google Scholar]

- McCabe, J. The Thermal Resistivity of Straw Bales for Construction; University of Arizona Environmental Research Laboratory (UAERL): Tucson, AZ, USA, 1993; p. 17. [Google Scholar]

- Ashour, T.; Georg, H.; Wu, W. Performance of straw bale wall: A case of study. Energy Build. 2011, 43, 1960–1967. [Google Scholar] [CrossRef]

- Ashour, T.; Wieland, H.; Georg, H.; Bockisch, F.; Wu, W. The influence of natural reinforcement fibres on insulation values of earth plaster for straw bale buildings. Mater. Des. 2010, 31, 4676–4685. [Google Scholar] [CrossRef]

- D’Alessandro, F.; Bianchi, F.; Baldinelli, G.; Rotili, A.; Schiavoni, S. Straw bale constructions: Laboratory, in field and numerical assessment of energy and environmental performance. J. Build. Eng. 2017, 11, 56–68. [Google Scholar] [CrossRef]

- González, A.D. 21-Assessment of the energy and carbon embodied in straw and clay masonry blocks. In Eco-Efficient Masonry Bricks and Blocks; Pacheco-Torgal, F., Lourenço, P.B., Labrincha, J.A., Kumar, S., Chindaprasirt, P., Eds.; Woodhead Publishing: Oxford, UK, 2015; pp. 461–480. [Google Scholar] [CrossRef]

- Brojan, L.; Petric, A.; Clouston, P. Comparative study of brick and straw bale wall systems from environmental, economical and energy perspectives. ARPN J. Eng. Appl. Sci. 2013, 8, 920–926. [Google Scholar]

- Ricciardi, P.; Torchia, F.; Belloni, E.; Lascaro, E.; Buratti, C. Environmental characterisation of coffee chaff, a new recycled material for building applications. Constr. Build. Mater. 2017, 147, 185–193. [Google Scholar] [CrossRef]

- Yin, X.; Lawrence, M.; Maskell, D.; Chang, W.S. Construction and monitoring of experimental straw bale building in northeast China. Constr. Build. Mater. 2018, 183, 46–57. [Google Scholar] [CrossRef]

- Yin, X.; Lawrence, M.; Maskell, D. Straw bale construction in northern China – Analysis of existing practices and recommendations for future development. J. Build. Eng. 2018, 18, 408–417. [Google Scholar] [CrossRef]

- Dong, Y.; Cui, X.; Yin, X.; Chen, Y.; Guo, H. Assessment of Energy Saving Potential by Replacing Conventional Materials by Cross Laminated Timber (CLT)—A Case Study of Office Buildings in China. Appl. Sci. 2019, 9, 858. [Google Scholar] [CrossRef]

- Leccese, F.; Salvadori, G.; Asdrubali, F.; Gori, P. Passive thermal behaviour of buildings: Performance of external multi-layered walls and influence of internal walls. Appl. Energy 2018, 225, 1078–1089. [Google Scholar] [CrossRef]

- Fantozzi, F.; Galbiati, P.; Leccese, F.; Salvadori, G.; Rocca, M. Thermal analysis of the building envelope of lightweight temporary housing. J. Phys. Conf. Ser. 2014, 547. [Google Scholar] [CrossRef]

- Fantozzi, F.; Gargari, C.; Rovai, M.; Salvadori, G. Energy Upgrading of Residential Building Stock: Use of Life Cycle Cost Analysis to Assess. Interventions on Social Housing in Italy. Sustainability 2019, 11, 1452. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).