Abstract

Twenty-five percent of steamed millet flour (MF) and different contents of dietary fiber (DF) were added to wheat flour (WF). The results showed that 25% of steamed MF and DF had significant effects (p < 0.05) on dough farinographical and tensile properties. With the increase of DF content, the hardness of the steamed bread increased, the elasticity decreased significantly, and the sensory acceptability decreased. The results of digestion showed that the content of rapidly digested starch (RDS) and slowly digested starch (SDS) in MF steamed bread decreased with the increase of DF, while resistant starch (RS) increased. Meanwhile, the starch hydrolysis rate, hydrolysis index (HI), and glycemic index (GI) decreased significantly (p < 0.05), and protein digestibility decreased gradually. Comprehensive evaluation showed that the 2% DF sample had good sensory performance and medium GI, which is beneficial to the control of blood sugar levels. These good functional properties could meet the requirements of a healthy diet.

1. Introduction

Cereal grains are one of the most important parts of the human diet. Due to the progress of grain processing technology and people’s taste requirements, grain production has been gradually refined. A heavy loss of nutrients and biological active ingredient was thereby incurred. Changes in lifestyle and in the intake of refined cereals lead to serious loss of nutrients and bioactive ingredients in cereals. A variety of chronic diseases such as obesity, cardiovascular disease, and cancer are increasing in an exponential manner globally. The intake of refined grains is closely linked to many chronic diseases. Consumption of wholegrain foods which contain a certain amount of dietary fiber (DF) and micronutrients can reduce the risk of these diseases and have beneficial effects on lowering blood lipids and glucose, improving insulin resistance, etc. [1]. Developed countries such as the United States and Sweden have made progress in the research and development of whole grains. Wholegrain products in the American market account for about 40% of all cereal products and more than 70% of the high-end products [2]. However, presently, most of the cereal bran is still used as fodder, which results in wasted resources, especially DF in less-developed countries.

Millet is a type of cereal commonly grown in most Asian and African countries as well as parts of Europe. Millet is listed as the sixth grain crop in the world in terms of production [3]. It has numerous advantages such as drought resistance, insect resistance, short growth duration, and high yield. It contains a variety of carbohydrates, proteins, fats, vitamins and minerals, and other essential nutrients, as well as abundant phytochemicals, which are associated with antioxidant properties and inhibit the action of malignant cell proliferation [4]. Millet flour products such as muffins, breads, and noodles are widely popular due to their good storage capacity, high nutrition, and hypoglycemic properties. Moreover, previous studies found that grain showed ideal quality characteristics and special aroma components after heat treatment, and the shelf life of grain flour products was prolonged under heat treatment [5,6]. Therefore, millet with heat treatment also has good application prospects in food processing.

Steamed bread, which is mainly made with wheat flour, yeast, and water, is an important traditional staple food in China. In recent years, steamed bread has drawn more and more attention worldwide due to its nutritional properties. Supplementation of other cereals and DF is an effective way to improve the nutritional and functional quality of steamed bread [7]. The visco-elastic property of steamed bread is mainly ascribed to the gluten protein of flour [8]. The addition of millet flour or DF to dough could improve its nutritional quality but decrease the strength quality because of the effect of gluten dilution. Consequently, in this study, millet bran DF and steamed millet flour (due to its positive effects on the farinographical properties and tensile properties of dough, based on our early research) were chosen as new functional ingredients in steamed bread [9]. The purpose of this was to investigate the effects of different proportions of DF on the rheological properties, steamed bread quality, and digestive properties of mixed dough and to provide a reference for the development of dietary-fiber-rich products in the future.

2. Materials and Methods

2.1. Materials and Chemicals

Millet was provided by Research Institute, Shanxi Academy of Agricultural Sciences, Changzhi, Shanxi, China. Millet bran was obtained after shelling and peeling off the millet. Commercial refined wheat flour and yeast were purchased from the local market of Zhengzhou in China.

Heat-stable α-amylase, glucoamylase and neutral protease were obtained from Yuanye Bio-Technology Co., Ltd. (Shanghai, China) and Solarbio Science and Technology Co., Ltd. (Beijing, China), respectively. Pancreatic α-amylase (22 UI/g), pepsin (1:3000), and trypsin (1:250) were purchased from Sigma-Aldrich, St. Louis, MO, USA. Amyloglucosidase and glucose oxidase–peroxidase kit (GOPOD) were purchased from Megazyme, Wicklow, Ireland. Coomass Brilliant Blue G250 was obtained from Guoan Biotechnology Co., Ltd., Xi’an, China. Bovine serum albumin and other analytical-grade solvents were obtained from Yuanye Bio-Technology Co., Ltd., Shanghai, China.

2.2. Preparation of Millet Flour

The millet was cleaned, dehulled, and pulverized into flour (Sieve Mesh No. 51 m). Then the millet flour was steamed at 100 °C for 10 min under atmospheric pressure. After being cooled to room temperature, the steamed flour was packaged in an air-tight container for further use. The steamed millet flour contained 13.77 g/100 g moisture, 9.19 g/100 g protein, 2.71 g/100 g crude fat, 70.32 g/100 g starch, 1.98 g/100 g dietary fiber, and 1.03 g/100 g ash.

2.3. Preparation of Millet Bran DF

Millet bran was defatted by hexyl hydride and ground to pass through a sieve (Sieve Mesh No. 51 m) for DF preparation. Extraction of DF was performed based on AOAC Official Method 991.43 with modifications. Briefly, defatted millet bran was subjected to sequential enzymatic digestion by heat-stable α-amylase (pH 6.5, 95 °C water bath, 30 min), glucoamylase (pH 4.0–4.5, 100–300 U/g, 60 °C water bath, 30 min), and neutral protease (pH 7.0–7.8, 100 U/g, 40 °C water bath, 30 min) to remove starch and protein. After enzyme inactivation (boiling water bath, 10 min) and centrifugation (3500 r/min, 20 min), the residue was dried at 60 °C overnight in a vacuum oven. The dried fiber fractions (crude DF) contained 4.21 g/100 g moisture, 1.59 g/100 g protein, 0.83 g/100 g crude fat, 0.68 g/100 g starch, 89.75 g/100 g dietary fiber, and 6.16 g/100 g ash. Then, millet bran DF was gained after grinding and sieving.

2.4. Dough Rheological Properties

The basic ratio of steamed millet flour was kept constant at 25%, which was demonstrated to have a beneficial effect on dough rheological properties in our previous research [9]. Millet bran DF was added in the proportions of 0, 2%, 4%, 6%, 8%, and 10%, and then made up to 100% by wheat flour. Measurements of water absorption (WA), dough development time (DDT), dough stability time (DST), softening degree (SD), and farinograph quality number (FQN) were carried out by using a Farinograph (Brabender GmbH & Co. KG, Duisburg, Germany). The dough extensible area (A), extension (E), tensile resistance (R), maximum tensile resistance (Rm), and extension ratio (R/E) were determined at 45 min, 90 min, and 135 min by using an Extensograph (Brabender GmbH & Co. KG, Duisburg, Germany).

2.5. Making Procedure of Steamed Bread

Steamed bread was produced according to a reported method with modifications [10]. The following ingredients were used in the preparation of steamed bread: water (56 g/100 g), yeast (1 g/100 g), steamed millet flour (25 g/100 g). Steamed breads were prepared with different ingredients by adding millet flour and different contents (0, 2%, 4%, 6%, 8%, and 10%) of DF to wheat flour. Wheat flour steamed bread was used as the control. After mixing and kneading these ingredients into dough, the dough was placed into a fermentation cabinet at 35 °C. After 2 h, the dough was kneaded and fermented for 30 min again, then divided into several pieces (50 g per piece). Dough pieces were rounded and molded manually and steamed for 40 min using a steam tray and boiling water. The steamed breads were cooled to room temperature for further analysis.

2.6. Color Evaluation of Steamed Bread

The color of steamed bread samples was measured using an automatic chromaticity instrument (SC-80, Kang Guang optical instrument Co., Ltd., Beijing, China), which needed to be calibrated with a whiteboard and blackboard before measurement. The measured values included L* (whiteness/darkness), a* (redness/greenness), and b* (yellowness/blueness). Then, the total color difference (ΔE*), hue angle (ho), and Chroma (C) were calculated according to Iglesias-Puig et al. [11]. Average values were obtained after 6 replications at different locations.

2.7. Textural Analysis of Steamed Bread

Textural analysis was performed according to the method described by Liu et al. [12]. The TA.XTplus Texture Analyser (Stable Micro Systems Ltd., Surrey, UK) was equipped with a P36 probe, and steamed breads were sliced vertically to get the middle pieces (25 mm thickness). The TPA (Texture Profile Analysis) test profile gave the parameters of hardness, springiness, cohesiveness, gumminess, chewiness, and resilience. The test parameters were as follows: pre-test speed was 2.0 mm/s, test speed was 1.0 mm/s, post-test speed was 1.0 mm/s and trigger force was 5g, compression time (the time of compressing the crumb center at 50% previous height) was 5 s. Average values were obtained after multiple measurements.

2.8. Sensory Evaluation of Steamed Bread

Sensory analysis of the steamed breads was performed by a 10-person evaluation panel within 2 h before or after meals, and evaluation criteria scores were given according to the LS/T 3204–1993 (Chinese Industry Standard). In this phase, the volume of steamed bread was measured by the millet seed displacement method, then the specific volume was calculated as the ratio between the volume (mL) and weight (g) of steamed bread. The evaluation criteria and scores are as follows: Appearance and shape (15 Points): Evaluation based on surface smoothness and morphology; Porosity (15 Points): Evaluation based on the fineness of the pores; Elasticity (20 Points): Evaluation based on resilience after finger press; Mouth satisfaction (10 Points): Evaluation based on chewing viscosity; Flavor (15 Points): Evaluation based on taste and fermented aroma; Color (15 Points): Evaluation according to the brightness and uniformity of the color; Specific volume (10 Points): This score is 10 when the specific volume is greater than or equal to 2.30 mL/g and is decreased by 1 point when the value decreases by 0.1 mL/g.

2.9. In Vitro Digestibility of Steamed Bread

2.9.1. Starch Digestibility

The starch content was calculated by using the method of AOAC 2002.02, and the glucose content was measured by the GOPOD kit.

Starch content (%) = Glucose content × 0.9 × 100%;

Total starch (%) = [Digestible starch (DS) + Resistant starch (RS)] × 100%;

Slowly digested starch (SDS) (%) = [Digestible starch (DS) − Rapidly digested starch (RDS)] × 100%.

The in vitro starch digestion and glycemic index of steamed bread were determined according to methods described by Liu et al. and Moraes et al. [13,14]. White bread was used as the reference food to estimate the hydrolysis index (HI = 100).

Starch hydrolysis rate (%) = (Glucose content in hydrolysate × 0.9)/Total starch × 100%

Area under hydrolysis rate curve (AUC, 0–180 min) = C∞(tf − t0) − (C∞/k)[1 − exp[−k(tf − t0)]];

Hydrolysis index (HI) = AUCsample/AUCwhite bread;

Glycemic index (GI) = 39.71 + 0.549 × HI.

Here, t0 represents the initial time (0 min), tf represents the end time (180 min), C∞ represents the equilibrium concentration, and k is a constant.

2.9.2. Protein Digestibility

The in vitro protein digestibility of steamed breads was determined according to the methods of Rizzello et al., with some modifications [15]. A quantity of 100 mg steamed bread was pre-incubated with 7.5 mL HCL (0.1 mol/L) at 37 °C for 5 min, then 1.5 mg pepsin (1:3000, Sigma-Aldrich, St. Louis, MO, USA) was added and incubated at 37 °C for 2 h. Samples were taken at 0, 30, 60, 90, and 120 min, respectively, and the reaction was stopped by adjusting the pH to 7.0 with 2 mol/L NaOH. A volume of 3.75 mL phosphate buffer (pH 8.0) and 2 mg trypsin (1:250) were added to the 120 min digestive juice and incubated at 37 °C after mixing. Similarly, samples were taken at 30, 60, 90, and 120 min, respectively, and the reaction was stopped by adding 10 mL trichloroacetic acid (20%, w/v). Then, undigested protein precipitated out, and the solution was made up to 100 mL with distilled water and then centrifuged (5000 r/min, 20 min). The concentration of protein in the supernatant was determined by a Bradford protein assay kit (Beyotime Biotechnology Co., Ltd., Shanghai, China). The protein digestibility rate was expressed as the percentage of the total protein, which was hydrolyzed by the enzyme.

2.10. Statistical Analysis

The analytical determinations were carried out in triplicate except for special indications. Statistical analyses were performed using SPSS (Version 20.0) and Origin (Version 7.5). Values were expressed as the mean ± standard deviation (‘x ± SD). p < 0.05 was considered to be statistically significant.

3. Results and Discussion

3.1. Rheological Characteristics

3.1.1. Effects of DF and Millet Flour on the Farinographical Properties of Mixed Dough

There were significant changes in the farinographical behavior of mixed dough measured by the farinograph with the addition of DF and steamed millet flour, as shown in Table 1. The addition of 25% of steamed millet flour had an adverse effect on the farinographical properties of mixed dough which was attributed to the gluten-free nature of millet flour. The farinographical properties were further weakened with the addition of DF. The WA rate had an important influence on the distribution of gluten and the formation of the network structure of the mixed dough. Compared with the control group, the WA rate of the dough added with 25% steamed millet flour decreased by 4.8%. With the increase of DF content, the WA rate rose at first and then decreased, and the differences were not significant, which might be caused by the hydrogen bonding of hydrophilic hydroxyl and water molecules in DF [16]. Rieder’s research also found that the WA rate of mixed dough increased with the addition of barley bran or oat bran [17]. The DDT declined with the addition of steamed millet flour and DF, but there were no significant differences among the samples. The DST decreased significantly by 2.2–3.68 min with the addition of substitution. In general, the stability value is an index that represents the dough strength, with higher values indicating stronger dough. The lowest stability value was 5.87 min, which was found in the mixed dough with 10% DF. Moreover, as the DF content in dough increased, the SD of the dough increased and FQN decreased, which also indicated that the strength and kneading resistance were weakened. To summarize, the farinographical properties were acceptable though weakened after supplementation with steamed millet flour and DF.

Table 1.

The farinographical properties of mixed dough (n = 3).

3.1.2. Effects of DF and Millet Flour on the Extensographical Properties of Mixed Dough

Extensograph measurements provided useful information about the viscoelastic behavior of dough. The different influences of steamed millet flour and DF on the extensographical properties of mixed dough are presented in Table 2. In the same fermentation time, with the addition of steamed millet flour and increasing DF content, the extensible area, extension, and maximum tensile resistance of the mixed dough exhibited a downward trend, which indicated that the toughness and gas retention capacity of the dough decreased. Similar characteristics were also reported by Fendri, where dough extensibility was reduced as fiber was added [18]. This could be explained by the dilution of wheat gluten and the increasing content of DF possibly disrupting the gluten network in the mixed dough. In addition, tensile resistance reached a maximum at first when the steamed millet flour was added and then reduced. Likewise, the extension ratio increased with the addition of steamed millet flour and increasing content of DF from 2% to 6% and then decreased at the content of 8%. It is possible that the starch in the steamed millet flour was gelatinized, degraded, and combined with protein to form a composite which caused the dough to have increasing tensile resistance. Nawrocka et al. reported that tensile resistance increased and the extensibility decreased significantly with the addition of fiber [16]. Moreover, with the extension of fermentation time, the dough extensible area, tensile resistance, maximum tensile resistance, and extension ratio increased, but the extension declined slightly. It might be speculated that the extensographical properties would be desirable when the fermentation time is prolonged.

Table 2.

Extensographical properties of mixed dough (n = 3).

3.2. Color Evaluation of Steamed Bread

The effects of steamed millet flour and DF on the color of steamed bread are shown in Table 3. Compared with the control group, the addition of steamed millet flour and DF reduced the L* value and the a* value, while the b* value increased significantly (p < 0.05) with the increasing content of supplements, which indicated that the color of the samples was darker and yellower. This result might be related to the colors of millet flour and DF themselves, and other research also showed that the color of products with dietary fiber and miscellaneous grains was darker [18]. Moreover, the ΔE* values increased significantly (p < 0.05), and the ΔE* values of WF&MF (75% wheat flour and 25% steamed millet flour) and 2% DF were 0.38 and 0.77, respectively. This showed that the color difference was not obvious to the human eye (ΔE* values were less than 1); therefore, the addition of millet flour and DF might be desirable for steamed bread.

Table 3.

Color evaluation of steamed bread with steamed millet flour and DF (n = 6).

3.3. Textural Analysis of Steamed Bread

The texture analysis results of the steamed bread with millet flour and DF are shown in Table 4. The hardness, adhesiveness, and chewiness of the sample with 25% steamed millet flour were significantly increased (p < 0.05) compared with the 100% wheat flour sample. Hardness is mainly related to the density, and chewiness represents the strength of the internal resistance of the food structure; both of them are relatively important indicators for measuring the quality of flour products. The springiness, cohesiveness, and resilience decreased with the addition of 25% steamed millet flour. The viscoelastic properties of steamed bread mainly depend on the gluten from wheat flour, so the variation trend above might be due to the dilution of gluten content with the addition of steamed millet flour, which led to a decrease in the ability of the dough to retain gas and hindered the formation of the gluten network structure [8]. In addition, the downward trend of the parameters was aggravated following the increase of DF content, i.e., the texture properties of the steamed bread were weakened. In addition, research has proved that DF could interact with starch due to the water binding and embedding capacity, which might delay the aging of starch and help to maintain the texture characteristics of flour products during storage [19].

Table 4.

Texture parameters of steamed breads with steamed millet flour and DF.

3.4. Sensory Evaluation of Steamed Bread

The results of sensory evaluation of the steamed bread obtained from mixed flour, based on the different contents of steamed millet flour, DF, and wheat flour, are shown in Table 5. Obviously, the evaluation results of groups with millet flour and DF were lower than those of pure wheat flour, and this was consistent with the results of Table 3 and Table 4. In particular, the specific volume deteriorated rapidly with the substituted flour addition. Variation of the specific volume had a strong effect on other fundamental features, and the retained gas fraction could directly impact the crumb structure [20]. However, the overall score of the group with 25% steamed millet flour and 2% DF was acceptable. Although the addition of substituted flour destroyed the gluten network structure to a certain extent, its appearance and toughness remained relatively good, and the flavor was slightly better than that of the control, which can probably be attributed to the unique flavor of the millet flour and more aroma components released after heat treatment. However, with the DF content increasing gradually, the indexes of the steamed bread deteriorated sharply, which might be due to the dilution of the gluten content and the rough taste of DF itself.

Table 5.

Sensory evaluation of steamed bread with steamed millet flour and DF.

3.5. In Vitro Digestibility

3.5.1. Starch Digestibility

RDS can be digested and absorbed and release energy quickly in the oral cavity and small intestine. Although SDS is digested slowly, it can be absorbed completely in the small intestine and maintain blood glucose homeostasis for a long time. RS cannot be digested in the small intestine but can be utilized by the intestinal flora in the large intestine, which has the effects of preventing colon cancer, lowering the glycemic index, and regulating serum cholesterol levels [21]. The contents of RDS, SDS, and RS were calculated according to the methods mentioned in Section 2.9.1. As shown in Table 6, with the increase of DF addition, the content of RDS and SDS decreased gradually, and the content of RS increased gradually. In general, the RS content is relevant to food processing, temperature, storage conditions, starch gelatinization, and coagulation. Therefore, starch granules of steamed millet flour would be destroyed by heat treatment, then the release of amylose and the increase of linear–linear and linear–branched bonding might cause a rise in the RS content [13]. With the increase of DF content, RDS and SDS declined gradually; in contrast, RS increased. Bae et al. also found higher RS content in an in vitro wheat starch gel digestion model with added dietary fiber, which is consistent with the current research [22]. The results showed that partial substitution with millet flour and DF was beneficial for hyperglycemic people in comparison with steamed bread made from pure wheat flour.

Table 6.

The rapidly digested starch (RDS), slowly digested starch (SDS), and resistant starch (RS) content of steamed breads (dry basis %).

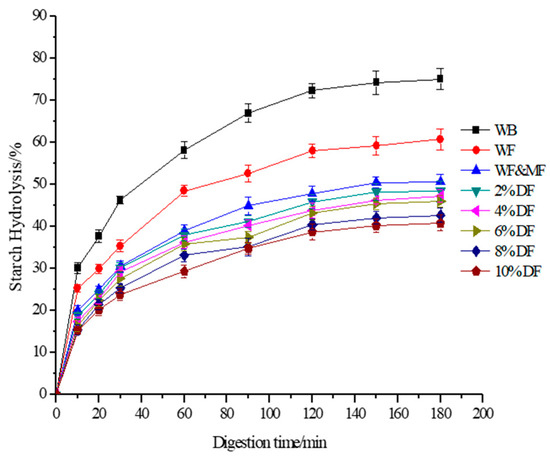

Figure 1 shows that with the extension of hydrolysis time, the starch hydrolysis rate of the steamed bread presented a rapid increase within 30 min and thereafter a relative plateau, which is similar to the trend of starch hydrolysis kinetics of wheat flour gel with apple dietary fiber [22]. The starch hydrolysis rate of the reference food (white bread) reached 75.03%, while the rates for WF and WF&MF were 60.72% and 50.65%, respectively, at the end of digestion (180 min). In addition, the starch hydrolysis rate was decreased with the addition of DF, and the rate for the 10% DF group dropped to 40.83%; this might be because the starch granules were wrapped in the pores of DF, thus blocking the reaction between starch and amylase [23]. Furthermore, DF could compete for water molecules with starch as a result of its strong water binding capacity and cause a reduction in the starch gelatinization degree and starch hydrolysis rate in the steamed bread [24], which coincides with the increase of RS content found above.

Figure 1.

Effects of various samples on starch digestibility in vitro. WB represents the reference food (white bread) in this section.

The area under the starch hydrolysis rate curve (AUC) of samples was calculated; the AUCs of WF, WF with MF, and WF with MF and 2% DF were 8717.83, 7826.25, and 6951.20, respectively. As the amount of added DF increased, the AUC gradually decreased. According to the AUC of the reference food (white bread) (10,878.25), the starch hydrolysis index (HI) values of WF, WF with MF, and WF with MF and 2% DF were calculated to be 80.14, 66.98, and 63.90, respectively, and the glycemic index (GI) values were 83.70, 76.48, and 74.79, respectively. Similarly, HI and GI presented a significant downward trend with the addition of DF (p < 0.05). Based on the GI classification (high: GI > 75; intermediate: GI 55–75; low GI: GI < 55) [25], the samples in this study could be classified as having a high GI for WF and WF&MF and an intermediate GI for the others. Ren et al. found that steamed bread with millet flour showed a low GI and that GI was positively correlated with RDS content [26], which is consistent with the results of this study.

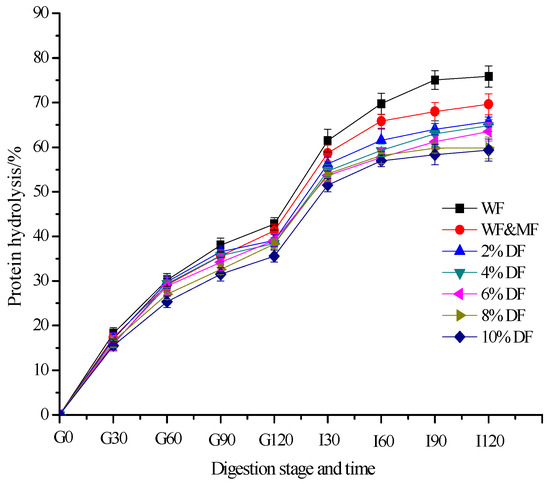

3.5.2. Protein Digestibility

The protein hydrolysis of the steamed breads is shown in Figure 2. The protein hydrolysis rates of samples showed a rapid upward trend during the process of pepsin digestion, but the difference among the samples was not significant. During the process of trypsin digestion, the protein hydrolysis rate continued to rise; there was a slight difference within 30 min and thereafter an increasing gap appeared between the groups. At the end of the two phases of protease digestion (I120), the protein hydrolysis rates achieved by WF and WF&MF were 75.85% and 69.63%, respectively. Meanwhile, some food treatments might cause a reduction due to the formation of protein aggregation or S–S bonds [27]. Then, the digestion rate decreased with the addition of DF, and the 10% DF group achieved a rate of 35.60% at the end of digestion. Protein digestibility might be related to the process and composition of food. Research has also showed that relatively high protein digestibility is relevant to non-fiber carbohydrates, and the protein digestibility decreases with increasing fiber content [28]. As a consequence, we may draw a conclusion that too much dietary fiber is unfavorable for protein digestion of steamed bread.

Figure 2.

Effects of various samples on protein digestibility in vitro. G0, G30, G60, G90, and G120 represent the protein hydrolysis times of 0, 30, 60, 90, and 120 min, respectively, during gastric phase; I30, I60, I90 and I120 represent the protein hydrolysis times of 0, 30, 60, 90, and 120 min, respectively, during intestinal phase.

4. Conclusions

In this study, millet bran DF and millet flour were added as ingredients to produce a steamed bread that was rich in dietary fiber and had good processed properties and functional activity. Although the substitution of steamed millet flour and DF had a negative effect on the properties of the mixed dough, it was acceptable for the production of steamed bread. Meanwhile, the addition of steamed millet flour and DF also weakened the bread’s sensory and digestive properties. However, a lower glycemic index of the steamed bread with millet/DF substitution was found in comparison with pure wheat flour bread, which could meet the requirements of a healthy diet. The development of dietary-fiber-rich products is of great significance in the food industry. Mixed flour with coarse cereals and dietary fiber could be of nutritional benefit.

Author Contributions

Y.L. and J.L. collected the data and drafted the manuscript; Y.Z. and L.W. helped to modify the manuscript; R.S. designed the study and proofread and revised the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the China Agriculture Research System, CARS-07-E-2 the Key Research and Development (R&D) Projects of Shanxi Province (general project) (Agricultural field), 201803D221013-2, and the Natural Science Foundation of China (No. 31671856).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Franz, M.; Sampson, L. Challenges in developing a whole grain database: Definitions, methods and quantification. J. Food Compos. Anal. 2006, 19, S38–S44. [Google Scholar] [CrossRef]

- Reicks, M.; Jonnalagadda, S.; Albertson, A.M.; Joshi, N. Total dietary fiber intakes in the US population are related to whole grain consumption: Results from the National Health and Nutrition Examination Survey 2009 to 2010. Nutr. Res. 2014, 34, 226–234. [Google Scholar] [CrossRef] [PubMed]

- Verma, S.; Srivastava, S.; Tiwari, N. Comparative study on nutritional and sensory quality of barnyard and foxtail millet food products with traditional rice products. J. Food Sci. Tech. 2015, 52, 5147–5155. [Google Scholar] [CrossRef] [PubMed]

- Devi, P.B.; Vijayabharathi, R.; Sathyabama, S.; Malleshi, N.G.; Priyadarisini, V.B. Health benefits of finger millet (Eleusine coracana L.) polyphenols and dietary fiber: A review. J. Food Sci. Tech. 2014, 51, 1021–1040. [Google Scholar] [CrossRef]

- Stojceska, V.; Butler, F.; Gallagher, E.; Keehan, D. A comparison of the ability of several small and large deformation rheological measurements of wheat dough to predict baking behaviour. J. Food Eng. 2007, 83, 475–482. [Google Scholar] [CrossRef]

- Vidya, S.; Ravi, R.; Bhattacharya, S. Effect of thermal treatment on selected cereals and millets flour doughs and their baking quality. Food Bioprocess. Tech. 2012, 6, 1218–1227. [Google Scholar] [CrossRef]

- Wang, P.; Tao, H.; Jin, Z.; Xu, X. Impact of water extractable arabinoxylan from rye bran on the frozen steamed bread dough quality. Food Chem. 2016, 200, 117–124. [Google Scholar] [CrossRef]

- Fu, J.T.; Chang, Y.H.; Shiau, S.Y. Rheological, antioxidative and sensory properties of dough and Mantou (steamed bread) enriched with lemon fiber. LWT-Food Sci. Technol. 2015, 61, 56–62. [Google Scholar] [CrossRef]

- Shen, R.L.; LÜ, J.; Zhang, X.W.; Du, W.J.; Jiang, L.B.; Dong, J.L. Rheological properties of wheat dough added millet flour with different thermal treatments. J. Triticeae Crops 2016, 36, 1540–1546. [Google Scholar]

- Sun, R.; Zhang, Z.M.; Hu, X.J.; Xing, Q.H.; Zhuo, W.Y. Effect of wheat germ flour addition on wheat flour, dough and Chinese steamed bread properties. J. Cereal Sci. 2015, 64, 153–158. [Google Scholar] [CrossRef]

- Iglesias-Puig, E.; Monedero, V.; Haros, M. Bread with whole quinoa flour and bifidobacterial phytases increases dietary mineral intake and bioavailability. LWT-Food Sci. Technol. 2015, 60, 71–77. [Google Scholar] [CrossRef]

- Liu, C.; Liu, L.; Li, L.M.; Hao, C.M.; Zheng, X.L.; Bian, K.; Zhang, J.; Wang, X.X. Effects of different milling processes on whole wheat flour quality and performance in steamed bread making. LWT-Food Sci. Technol. 2015, 62, 310–318. [Google Scholar] [CrossRef]

- Liu, H.; Guo, X.D.; Li, Y.L.; Li, H.M.; Fan, H.H.; Wang, M. In Vitro digestibility and changes in physicochemical and textural properties of tartary buckwheat starch under high hydrostatic pressure. J. Food Eng. 2016, 189, 64–71. [Google Scholar] [CrossRef]

- Moraes, E.A.; Marineli, R.D.; Lenquiste, S.A.; Steel, C.J.; de Menezes, C.B.; Queiroz, V.A.; Marostica, M.R. Sorghum flour fractions: Correlations among polysaccharides, phenolic compounds, antioxidant activity and glycemic index. Food Chem. 2015, 180, 116–123. [Google Scholar] [CrossRef] [PubMed]

- Rizzello, C.G.; Lorusso, A.; Montemurro, M.; Gobbetti, M. Use of sourdough made with quinoa (Chenopodium quinoa) flour and autochthonous selected lactic acid bacteria for enhancing the nutritional, textural and sensory features of white bread. Food Microbiol. 2016, 56, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Nawrocka, A.; Miś, A.; Szymańska-Chargot, M. Characteristics of relationships between structure of gluten proteins and dough rheology–Influence of Dietary Fibres Studied by FT-Raman Spectroscopy. Food Biophys. 2015, 11, 81–90. [Google Scholar] [CrossRef]

- Rieder, A.; Holtekjølen, A.K.; Sahlstrøm, S.; Moldestad, A. Effect of barley and oat flour types and sourdoughs on dough rheology and bread quality of composite wheat bread. J. Cereal Sci. 2012, 55, 44–52. [Google Scholar] [CrossRef]

- Fendri, L.B.; Chaari, F.; Maaloul, M.; Kallel, F.; Abdelkafi, L.; Chaabouni, S.E.; Ghribi-Aydi, D. Wheat bread enrichment by pea and broad bean pods fibers: Effect on dough rheology and bread quality. LWT-Food Sci. Technol. 2016, 73, 584–591. [Google Scholar] [CrossRef]

- Huang, G.H.; Guo, Q.B.; Wang, C.; Ding, H.H.; Cui, S.W. Fenugreek fibre in bread: Effects on dough development and bread quality. LWT-Food Sci. Technol. 2016, 71, 274–280. [Google Scholar] [CrossRef]

- Verdú, S.; Barat, J.M.; Grau, R. Improving bread-making processing phases of fibre-rich formulas using chia (Salvia hispanica) seed flour. LWT-Food Sci. Technol. 2017, 84, 419–425. [Google Scholar] [CrossRef]

- Linsberger-Martin, G.; Lukasch, B.; Berghofer, E. Effects of high hydrostatic pressure on the RS content of amaranth, quinoa and wheat starch. Starch-Stärke 2012, 64, 157–165. [Google Scholar] [CrossRef]

- Bae, I.Y.; Jun, Y.; Lee, S.; Lee, H.G. Characterization of apple dietary fibers influencing the in vitro starch digestibility of wheat flour gel. LWT-Food Sci. Technol. 2016, 65, 158–163. [Google Scholar] [CrossRef]

- Agama-Acevedo, E.; Islas-Hernández, J.J.; Pacheco-Vargas, G.; Osorio-Díaz, P.; Bello-Pérez, L.A. Starch digestibility and glycemic index of cookies partially substituted with unripe banana flour. LWT-Food Sci. Technol. 2012, 46, 177–182. [Google Scholar] [CrossRef]

- Oh, I.K.; Bae, I.Y.; Lee, H.G. In vitro starch digestion and cake quality: Impact of the ratio of soluble and insoluble dietary fiber. Int. J. Biol. Macromol. 2014, 63, 98–103. [Google Scholar] [CrossRef]

- Wolever, T.M.; Jenkins, D.J.; Jenkins, A.L.; Josse, R.G. The glycemic index: Methodology and clinical implications. Am. J. Clin. Nutr. 1991, 54, 846–854. [Google Scholar] [CrossRef]

- Ren, X.; Chen, J.; Wang, C.; Molla, M.M.; Diao, X.M.; Shen, Q. In Vitro starch digestibility, degree of gelatinization and estimated glycemic index of foxtail millet-derived products: Effect of freezing and frozen storage. J Cereal Sci. 2016, 69, 166–173. [Google Scholar] [CrossRef]

- Angioloni, A.; Collar, C. Effects of pressure treatment of hydrated oat, finger millet and sorghum flours on the quality and nutritional properties of composite wheat breads. J. Cereal Sci. 2012, 56, 713–719. [Google Scholar] [CrossRef]

- Wu, T.; Taylor, C.; Nebl, T.; Ng, K.; Bennett, L.E. Effects of chemical composition and baking on in vitro digestibility of proteins in breads made from selected gluten-containing and gluten-free flours. Food Chem. 2017, 233, 514–524. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).