Cutting Path Planning Technology of Shearer Based on Virtual Reality

Abstract

1. Introduction

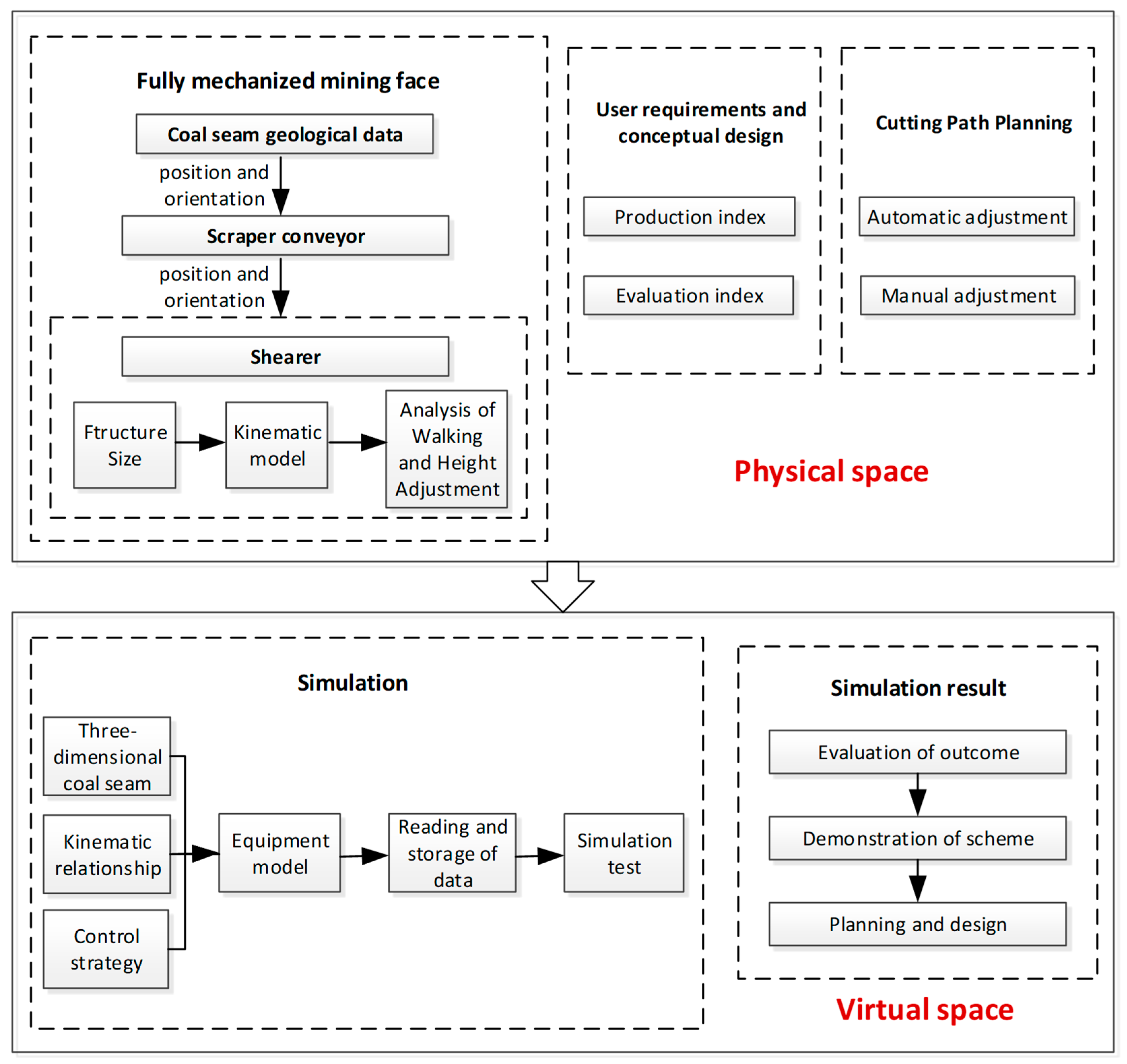

2. An Idea of Cutting Path Planning Technology of Shearer Based on Virtual Reality

- Based on the geometry model, movement model, and rule model of real equipment, the virtual model of the shearer operation was developed, which is completely consistent with reality.

- The Unity3D engine was used to build the model for the coal seam roof and floor (3D coal seam), and to obtain the orientation of the shearer and scraper conveyor; based on the geometry model, movement model, and rule model of real equipment, the virtual model of the shearer operation was developed, which is completely consistent with reality.

- The virtual Shearer was obtained to move and adjust the drum automatically on the 3D terrain;

- The prototype system was developed, different schemes simulated, and the simulation results processed and evaluated.

3. Kinematics Analysis and Cutting Path Planning Method of Real Shearer

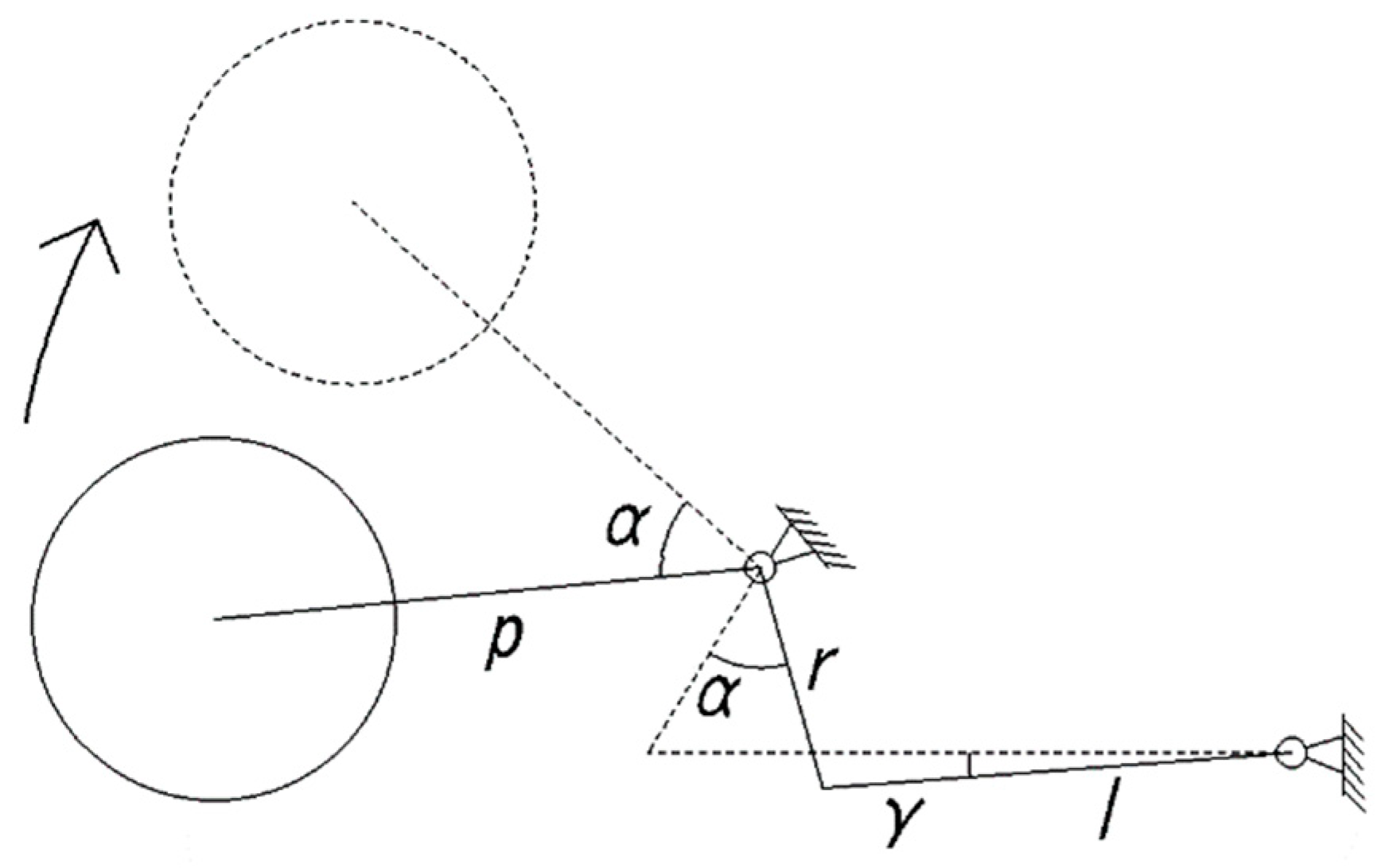

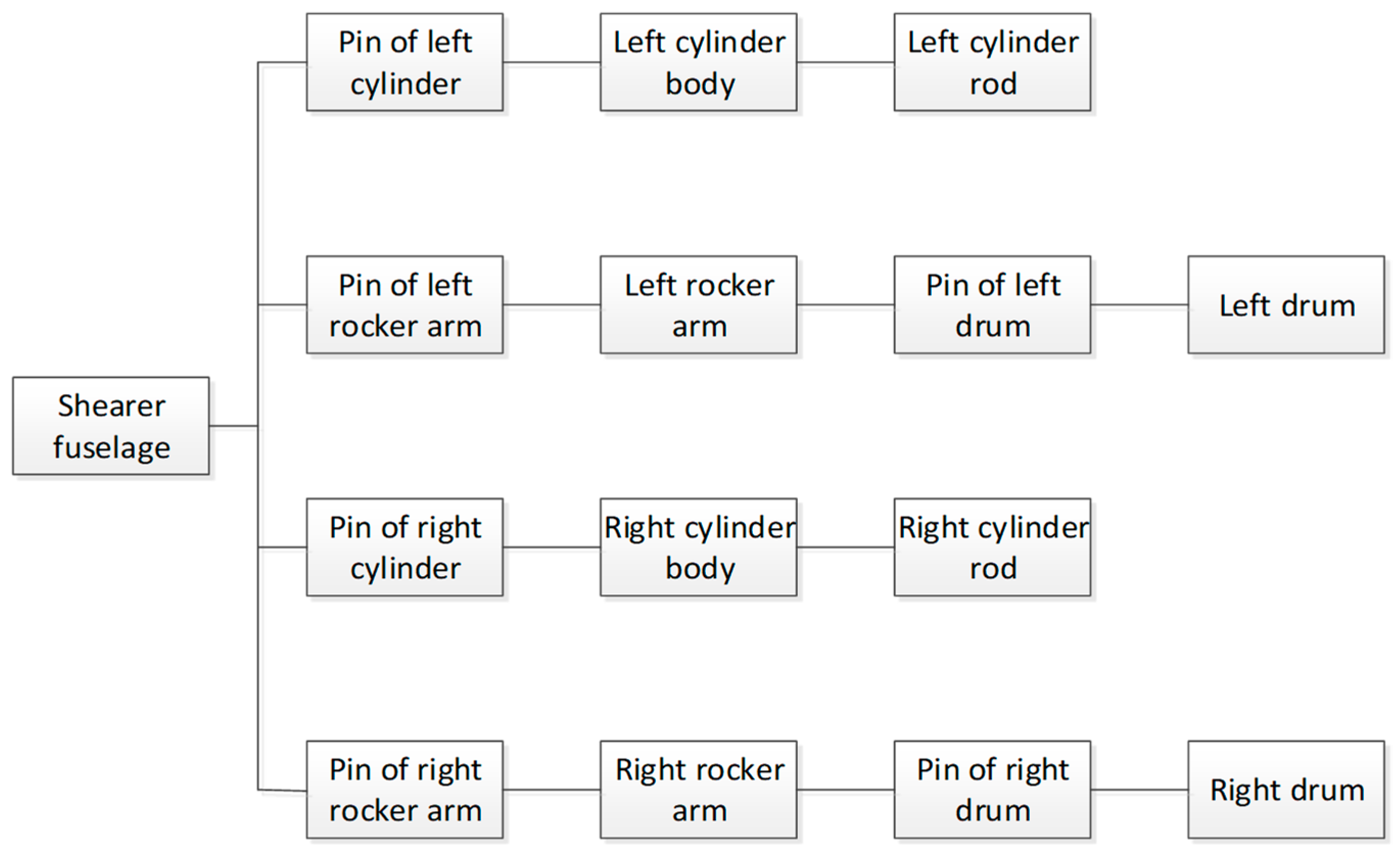

3.1. Kinematics Model of Shearer Height-Adjusting

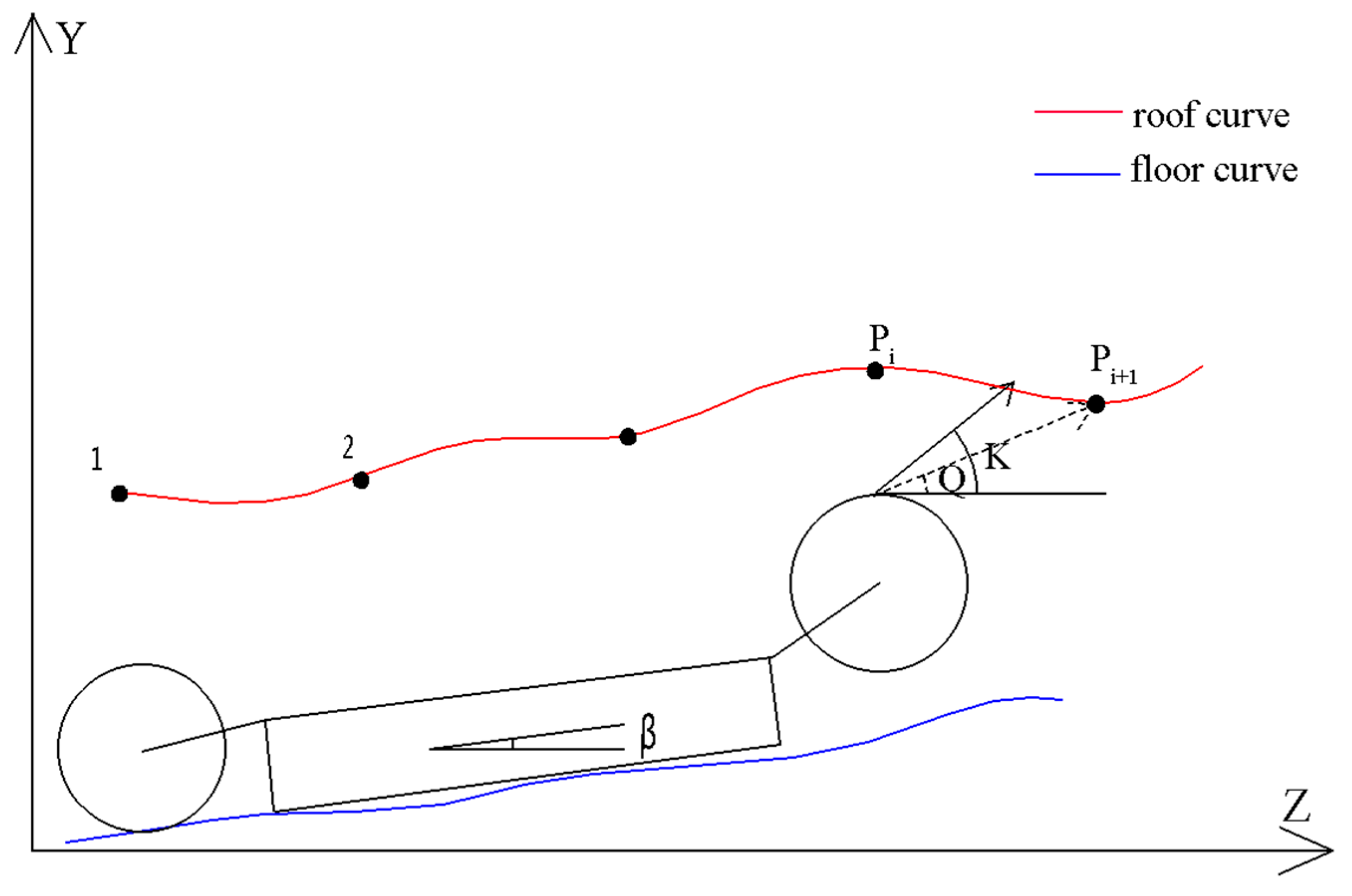

3.2. Kinematics Analysis of Shearer Height-Adjusting and Walking

3.3. Automatic Height-Adjusting Strategy

- the maximum height difference for lifting given by

- the minimum height difference for lifting

- the maximum height difference for lowering ,

- the range of height difference for no adjustment ,

- the minimum height difference for descending .

3.4. Selection of Operation Parameters of the Shearer

4. Virtual Cutting Path Planning Method of Shearer and Design of Prototype System

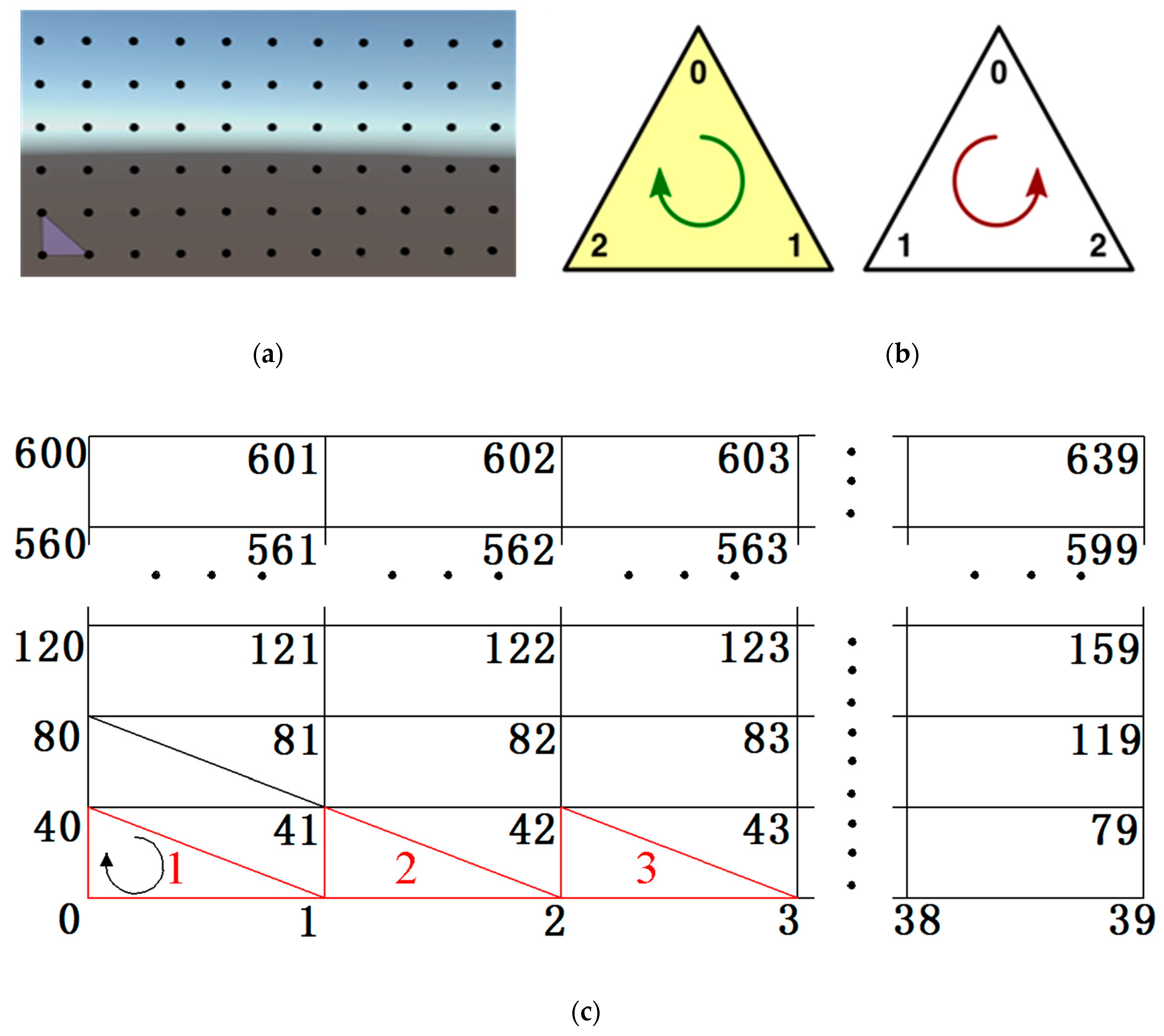

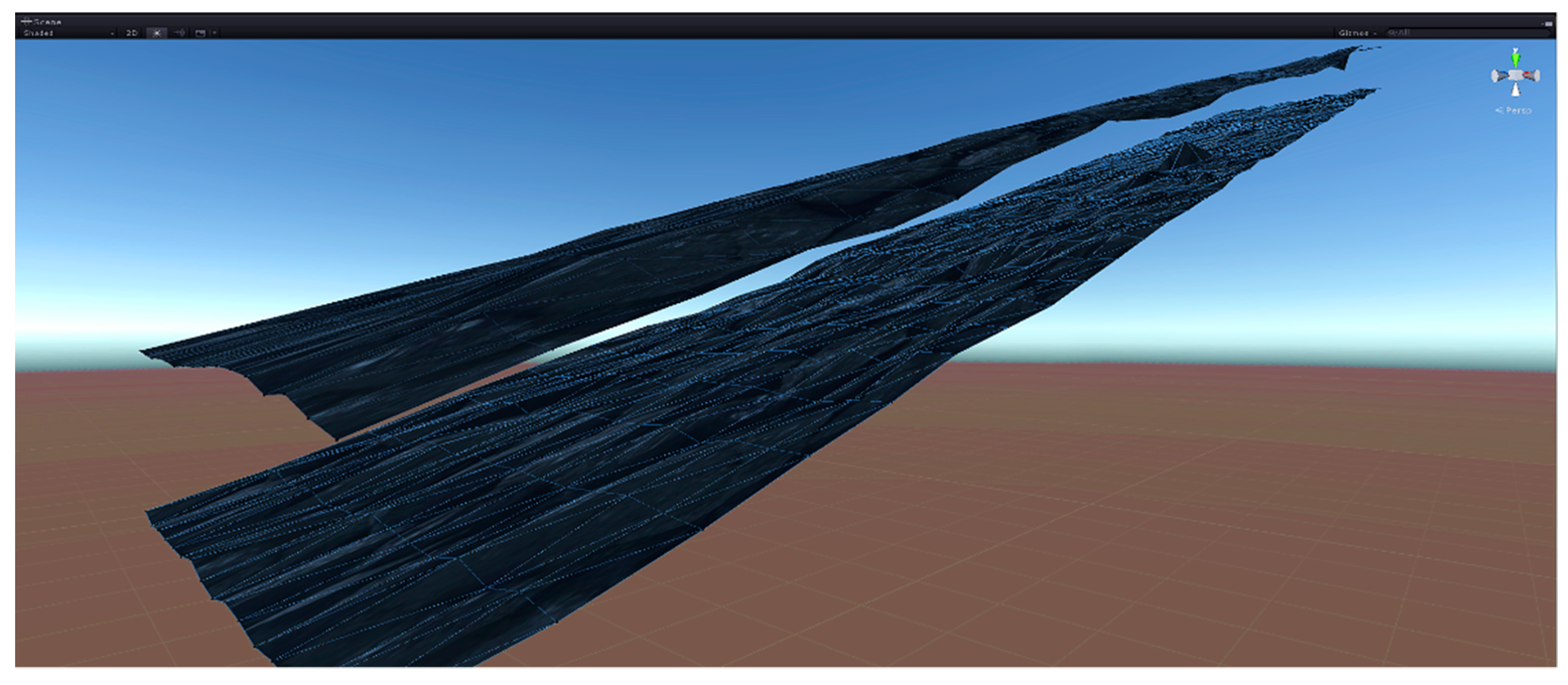

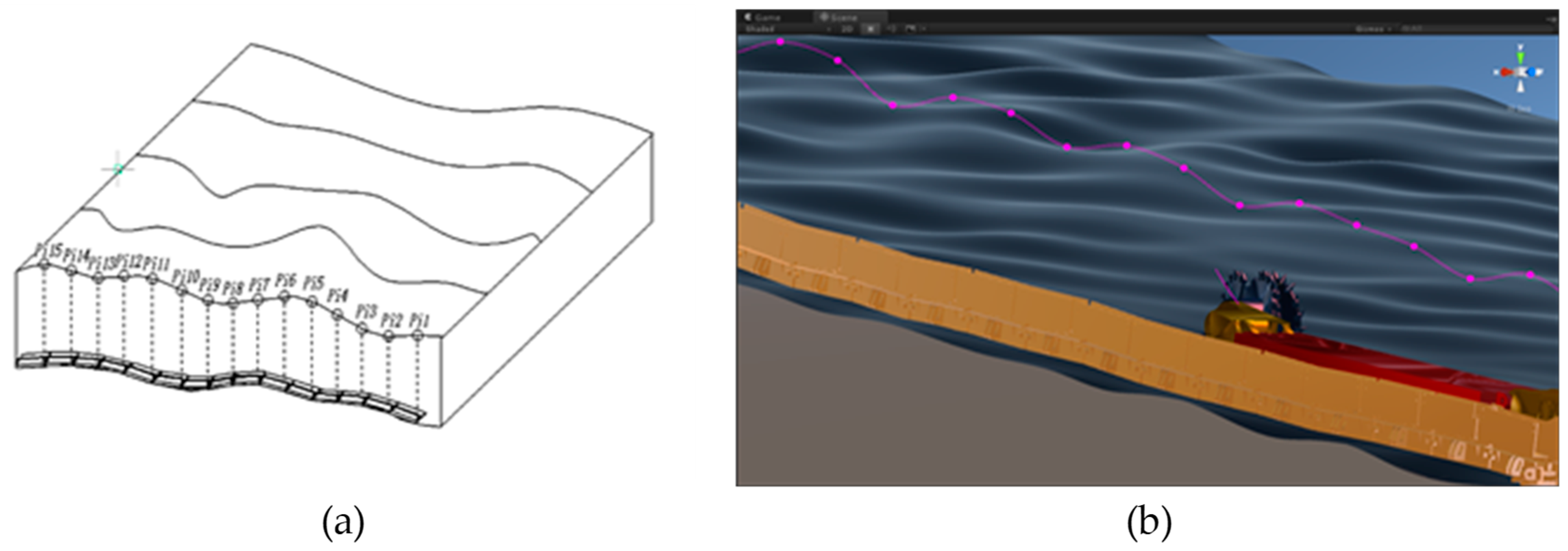

4.1. Key Technology for Modeling Coal Seam Roof and Floor

4.2. Key Technology for Combined Operation of Shearer and Scraper Conveyor

4.3. Key Technology of Virtual Cutting of Shearer

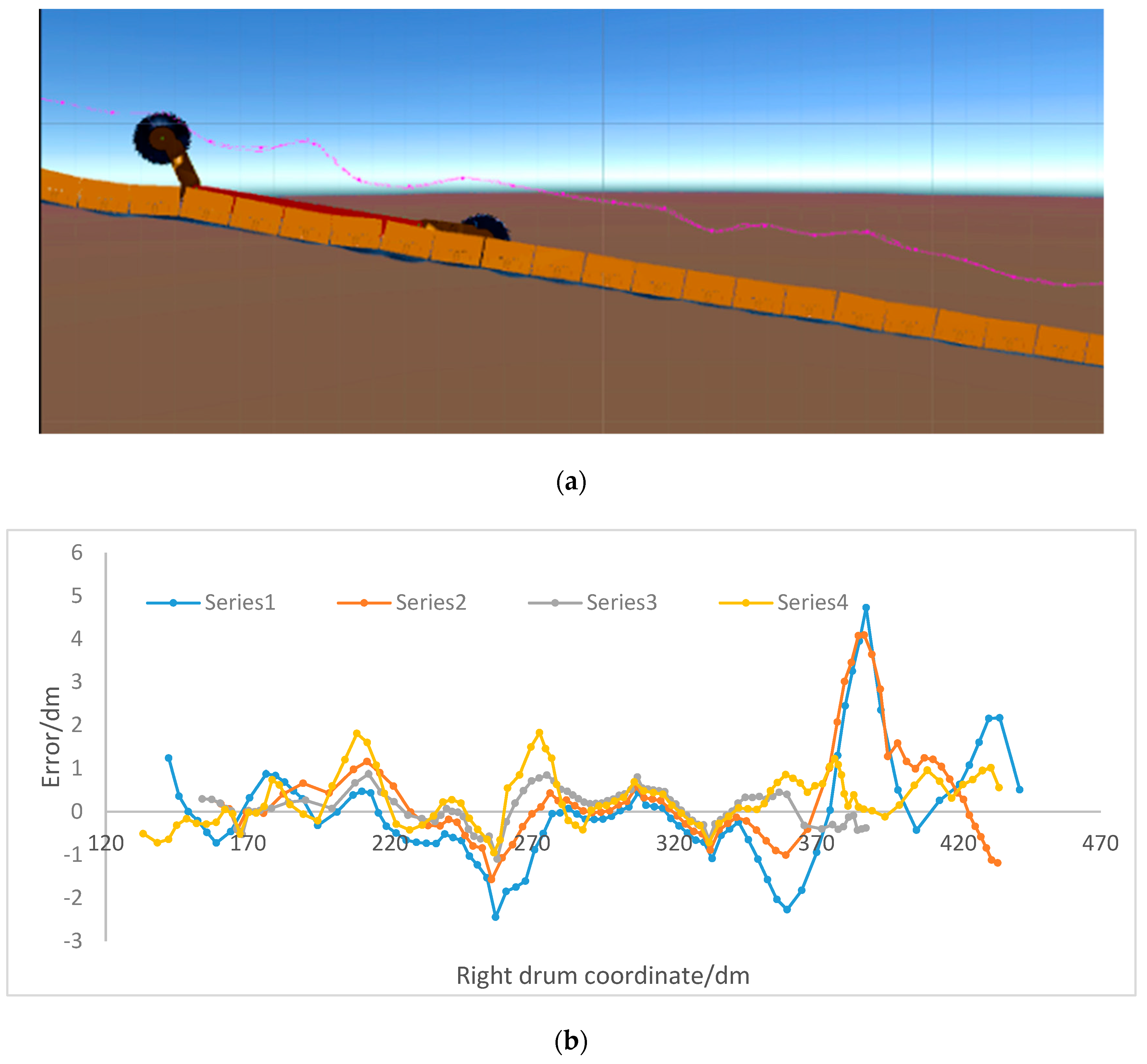

5. Simulation Experiment

5.1. Setting of Simulation Conditions

5.2. Analysis of Simulation Results

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ralston, J.C.; Hargrave, C.O.; Dunn, M.T. Longwall automation: Trend, challenges and opportunities. Int. J. Min. Sci. Technol. 2017, 27, 15–21. [Google Scholar] [CrossRef]

- Chad, O.H.; James, C.A.; Ralston, J.C. Infrastructure-based localization of automated coal mining equipment. Int. J. Coal Sci. Technol. 2017, 4, 252–264. [Google Scholar]

- Ottogalli, K.; Rosquete, D.; Amundarain, A.; Aguinaga, I. Flexible Framework to Model Industry 4.0 Processes for Virtual Simulators. Appl. Sci. 2019, 9, 4983. [Google Scholar] [CrossRef]

- Ralston, J.C.; Reid, D.C.; Dunn, M.T. Longwall automation: Delivering enabling technology to achieve safer and more productive underground mining. Int. J. Min. Sci. Technol. 2015, 25, 865–876. [Google Scholar] [CrossRef]

- Tibbett, A.E.; Greenberg, S.; Brazil, E. The use of virtual reality scientific visualization for investigation and exploration of block cave mining system data. In Proceedings of the Virtual Reality and Spatial Information Applications in the Mining Industry Conference, University of Pretoria, Pretoria, South Africa, 15–17 July 2015. [Google Scholar]

- Xie, J.C.; Yang, Z.J.; Wang, X.W. A Virtual Reality Collaborative Planning Simulator and its Method for Three Machines in a Fully Mechanized coal Mining Face. Arab. J. Sci. Eng. 2018, 43, 4835–4854. [Google Scholar] [CrossRef]

- Alam, K.M.; Saddik, A.E. C2PS: A Digital Twin Architecture Reference Model for the Cloud Based Cyber Physical System. IEEE Acess. 2017, 5, 2050–2062. [Google Scholar] [CrossRef]

- Stothard, P.; Squelch, A.; Stone, R.; Van Wyk, E.; Kizil, M. Taxonomy of interactive computer-based visualization systems and content for the mining industry—Part 2. Min. Technol. 2015, 124, 83–96. [Google Scholar] [CrossRef]

- Xie, J.C.; Wang, X.W.; Li, X. Research status and prospect of virtual reality technology in field of coal mine. Coal Sci. Technol. 2019, 47, 53–59. [Google Scholar]

- Tichon, J.; Burgesslimerick, R. A review of Virtual Reality as a medium for safety related training in Mining. J. Health Saf. Res. Pract. 2011, 3, 33–40. [Google Scholar]

- Zhang, L.L.; Tan, C.; Wang, Z.B.; Yang, X.F. Memory Cutting Path Optimization of the Shearer Based on Genetic Algorithm. Coal Eng. 2011, 2, 111–113. [Google Scholar]

- Liu, C.S.; Yang, Q. Simulation of shearer drum cutting with memory program controlling by fuzzy control. J. China Coal Soc. 2008, 7, 822–825. [Google Scholar]

- Si, L.; Wang, Z.B.; Liu, Y.W. Online Identification of Shearer Cutting State Using Infrared Thermal Images of Cutting Unit. Appl. Sci. 2018, 8, 1772. [Google Scholar] [CrossRef]

- Li, W.; Luo, C.M.; Yang, H.; Fan, Q.G. Memory cutting of adjacent coal seams based on a hidden Markov model. Arab. J. Geosci. 2014, 4, 5051–5060. [Google Scholar] [CrossRef]

- Gospodarczyk, P. Modeling and simulation of coal loading by cutting drum in flat seams. Arch. Min. Sci. 2016, 61, 365–379. [Google Scholar]

- Xu, J.; Wang, Z.B.; Tan, C. A Cutting Pattern Recognition Method for Shearers Based on Improved Ensemble Empirical Mode Decomposition and a Probabilistic Neural Network. Sensors 2015, 15, 27721–27737. [Google Scholar] [CrossRef] [PubMed]

- Lemon, A.M.; Jones, N.L. Building solid models from boreholes and user-defined cross-section. Comput. Geo-Inf. Sci. 2003, 29, 547–555. [Google Scholar] [CrossRef]

- Che, D.F.; Wu, L.X.; Chen, X.X. Modeling and visualizing methods for real 3D geosciences model based on amended generalized tri-prism(GTP). J. China Coal Soc. 2006, 31, 576–580. [Google Scholar]

- Michel, P.; Zhu, B.T. Knowledge-driven applications for geological modeling. J. Petrol. Sci. Eng. 2005, 47, 89–104. [Google Scholar]

- Tacher, L.; Pomian-srzednicki, I.; Parriaux, A. Geological uncertainties associated with 3D subsurface model. Comput. Geosci. 2006, 2, 212–221. [Google Scholar] [CrossRef]

- Chen, J.F.; Hsieh, H.N.; Do, Q.H. Evaluating teaching performance based on fuzzy AHP and comprehensive evaluation approach. Appl. Soft Comput. 2015, 28, 100–108. [Google Scholar] [CrossRef]

- Ko, Y.C. Application of Fuzzy Theory to the Evaluation Model of Product Assembly Design and Usability Operation Complexity. Appl. Sci. 2019, 9, 4055. [Google Scholar] [CrossRef]

- Wang, T.J. Research on Generalized Memory Cutting Technology of Thin Seam Shearer Based on Dynamic Fine Modeling; China University of mining and Technology (Beijing Campus): Beijing, China, 2003. [Google Scholar]

- Gao, C.Z.; Li, Y.Z.; Wang, T.L. Safety production evaluation of coal mine based on fuzzy comprehensive evaluation and AHP. Opencast Min. Technol. 2013, 11, 72–77. [Google Scholar]

- Mu, Y.Z.; Lu, Z.X.; Qiao, Y. A Comprehensive Evaluation Index System of Power Grid Security and Benefit Based on Multi-Operator Fuzzy Hierarchy Evaluation Method. Power System Technol. 2015, 1, 23–28. [Google Scholar]

| Judgment of Action | Before Adjustment | Specific Action | After Adjustment | |

|---|---|---|---|---|

| or | Too high or too low | Traction speed is reduced to a minimum, drum lifts | ||

| and | Lifting | K-Q > 0.02 | Traction speed is increased, drum lifts | |Q-K| ≤ 0.02 |

| Q-K > 0.02 | Traction speed is decreased, drum lifts | |||

| |Q-K| ≤ 0.02 | Traction speed is decreased, drum lifts | |||

| and | No adjustment | Traction speed is constant, drum is not adjusted | ||

| and | Descending | K-Q > 0.02 | Traction speed is increased, drum descends | |Q-K| ≤ 0.02 |

| Q-K > 0.02 | Traction speed is decreased, drum descends | |||

| |Q-K| ≤ 0.02 | Traction speed is constant, drum descends | |||

| Index | Recovery Rate (SSE) | Production Efficiency (min) | Others (Safety Degree, Labor Cost, etc.) |

|---|---|---|---|

| Scheme1 | 13.89 | 8 | 8 |

| Scheme2 | 92.5 | 7 | 8 |

| Scheme3 | 125.73 | 5.5 | 8 |

| Scheme4 | 40.96 | 8.5 | 2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Liu, Y.; Xie, J.; Wang, X.; Ge, X. Cutting Path Planning Technology of Shearer Based on Virtual Reality. Appl. Sci. 2020, 10, 771. https://doi.org/10.3390/app10030771

Li J, Liu Y, Xie J, Wang X, Ge X. Cutting Path Planning Technology of Shearer Based on Virtual Reality. Applied Sciences. 2020; 10(3):771. https://doi.org/10.3390/app10030771

Chicago/Turabian StyleLi, Juanli, Yang Liu, Jiacheng Xie, Xuewen Wang, and Xing Ge. 2020. "Cutting Path Planning Technology of Shearer Based on Virtual Reality" Applied Sciences 10, no. 3: 771. https://doi.org/10.3390/app10030771

APA StyleLi, J., Liu, Y., Xie, J., Wang, X., & Ge, X. (2020). Cutting Path Planning Technology of Shearer Based on Virtual Reality. Applied Sciences, 10(3), 771. https://doi.org/10.3390/app10030771