Review and Development Trend of Digital Hydraulic Technology

Abstract

1. Introduction

2. Review of Digital Hydraulic Technology

2.1. Definition of Digital Hydraulic Technology

2.2. Classification of Digital Hydraulic Technology

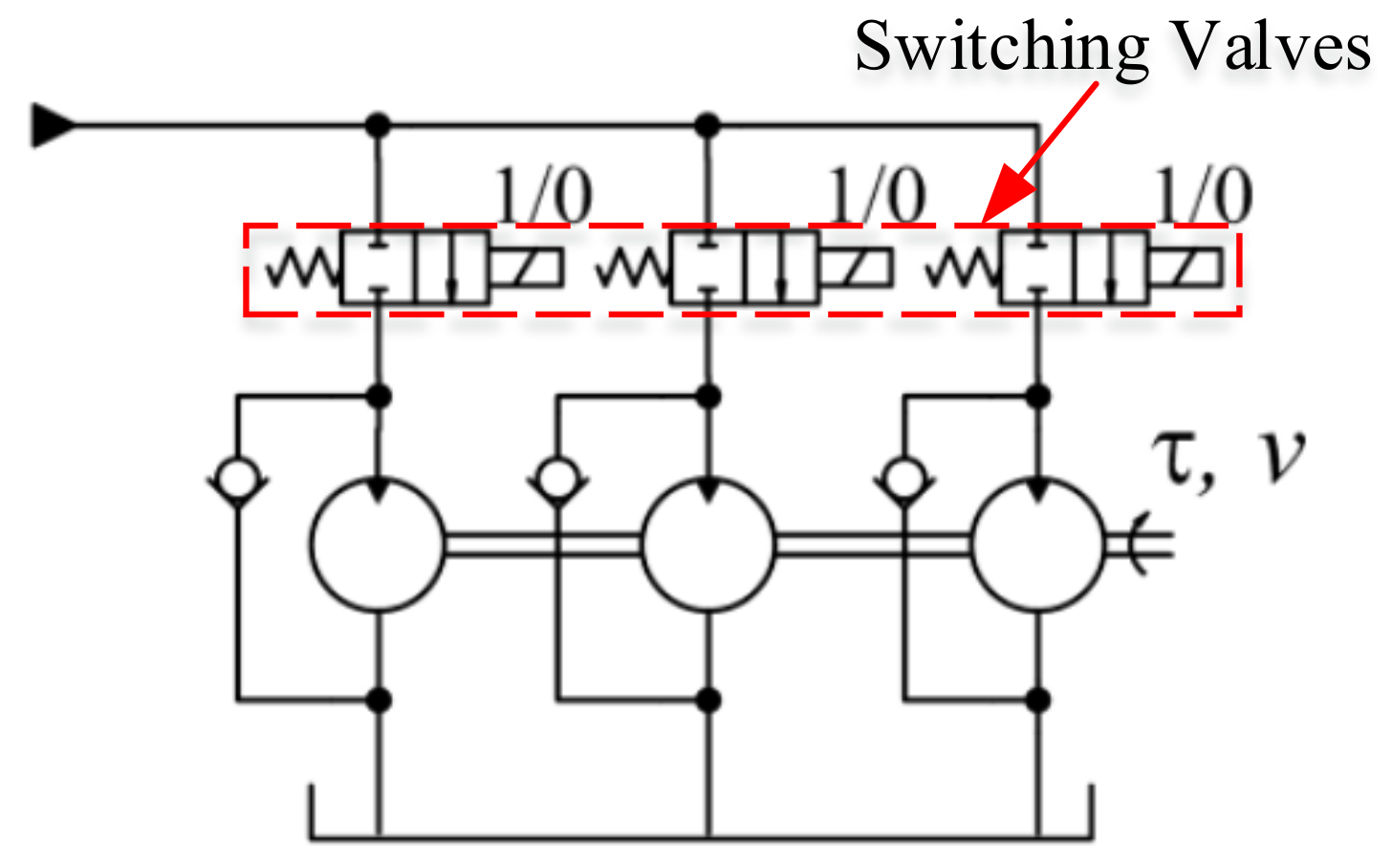

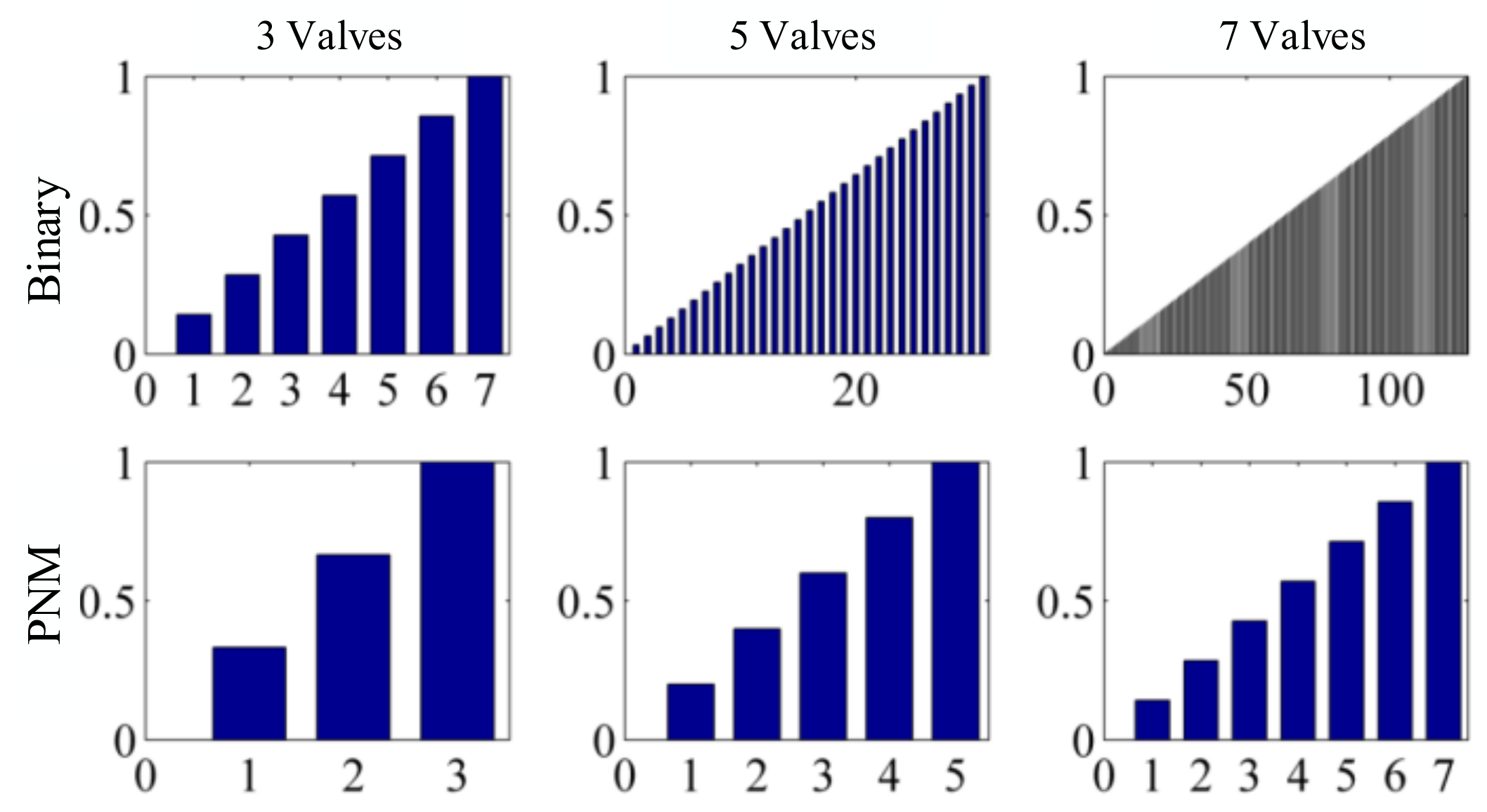

2.2.1. Parallel Digital Hydraulic Technology

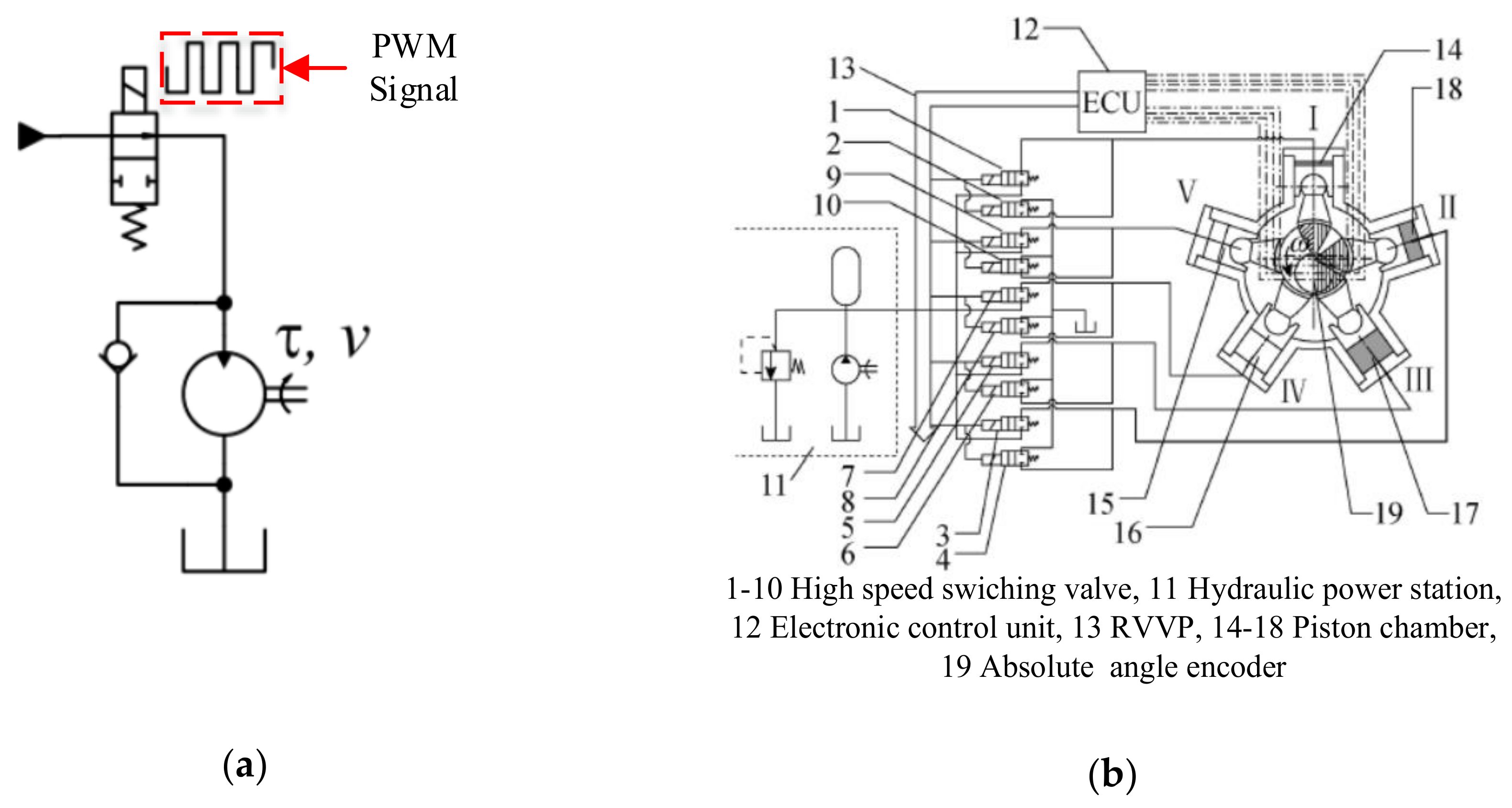

2.2.2. High-Speed Switching Digital Hydraulic Technology

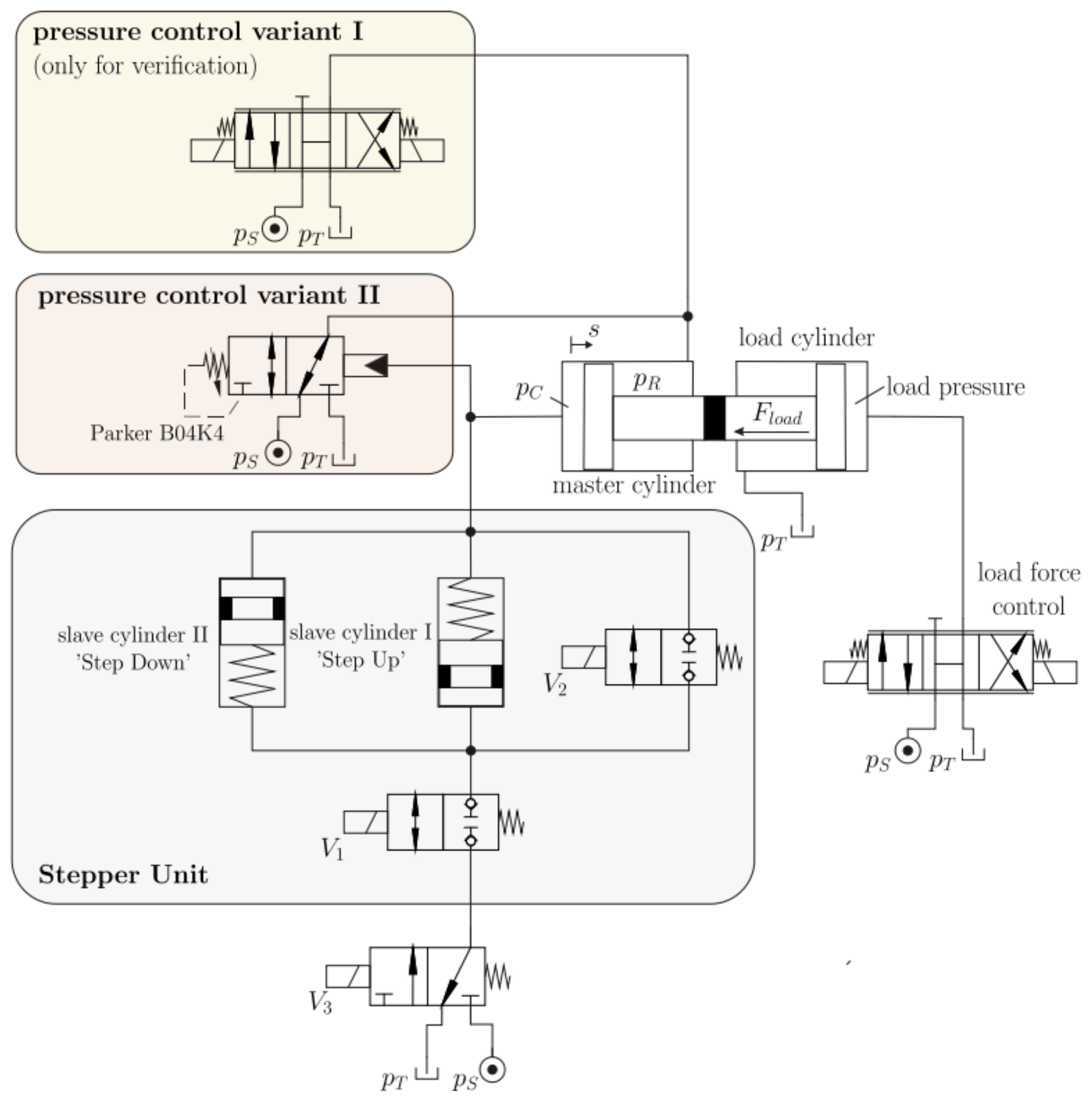

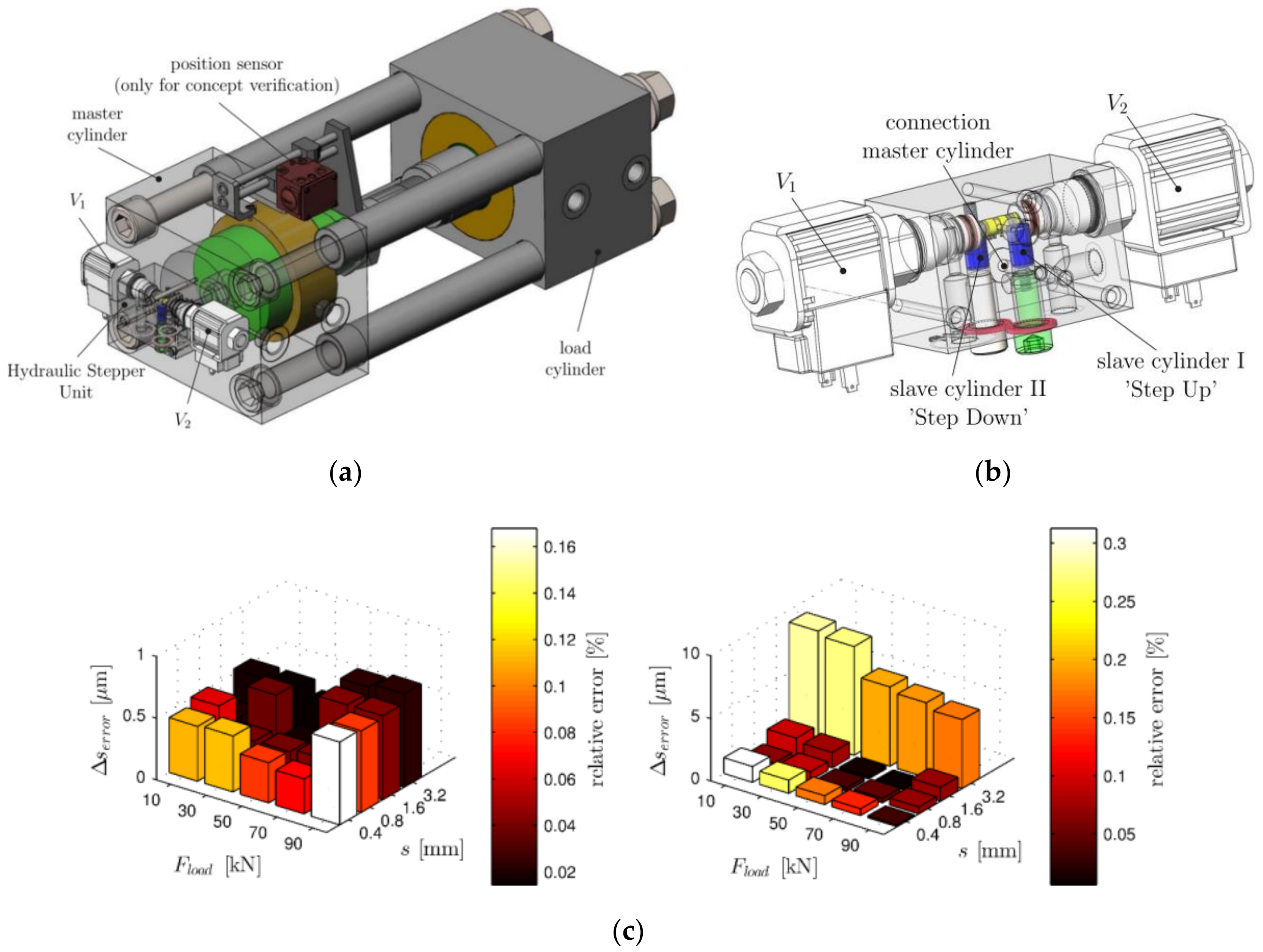

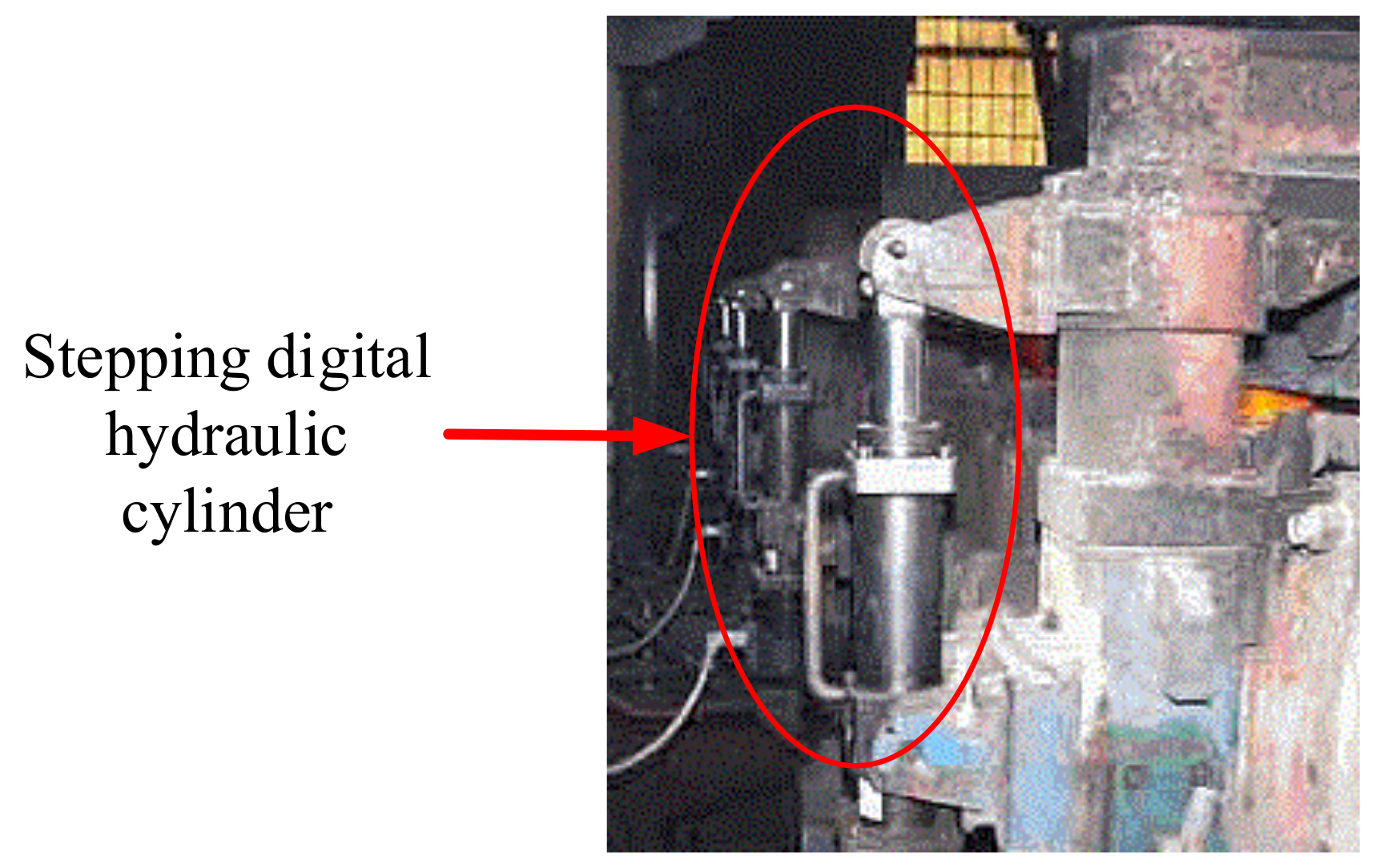

2.2.3. Stepping Digital Hydraulic Technology

3. Digital Hydraulic Components

3.1. Digital Hydraulic Valve

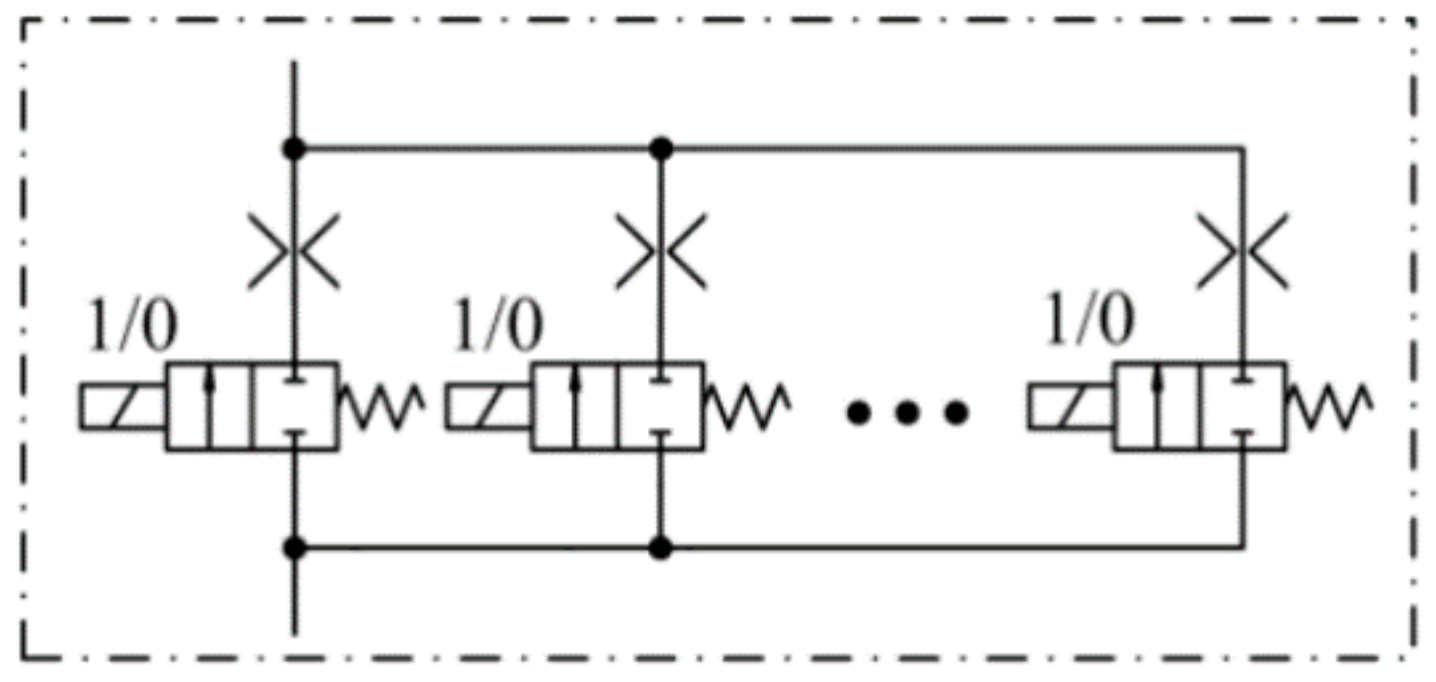

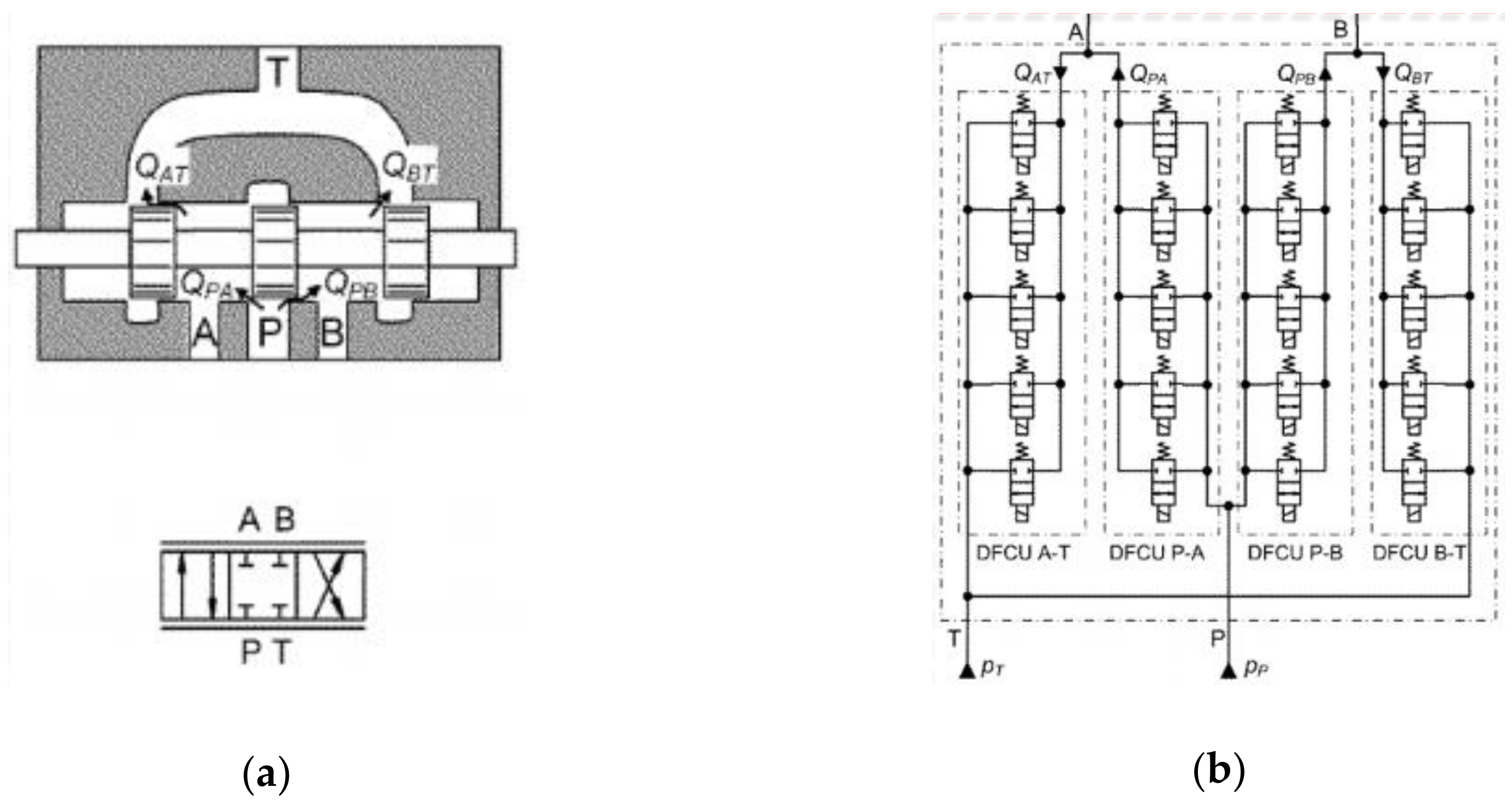

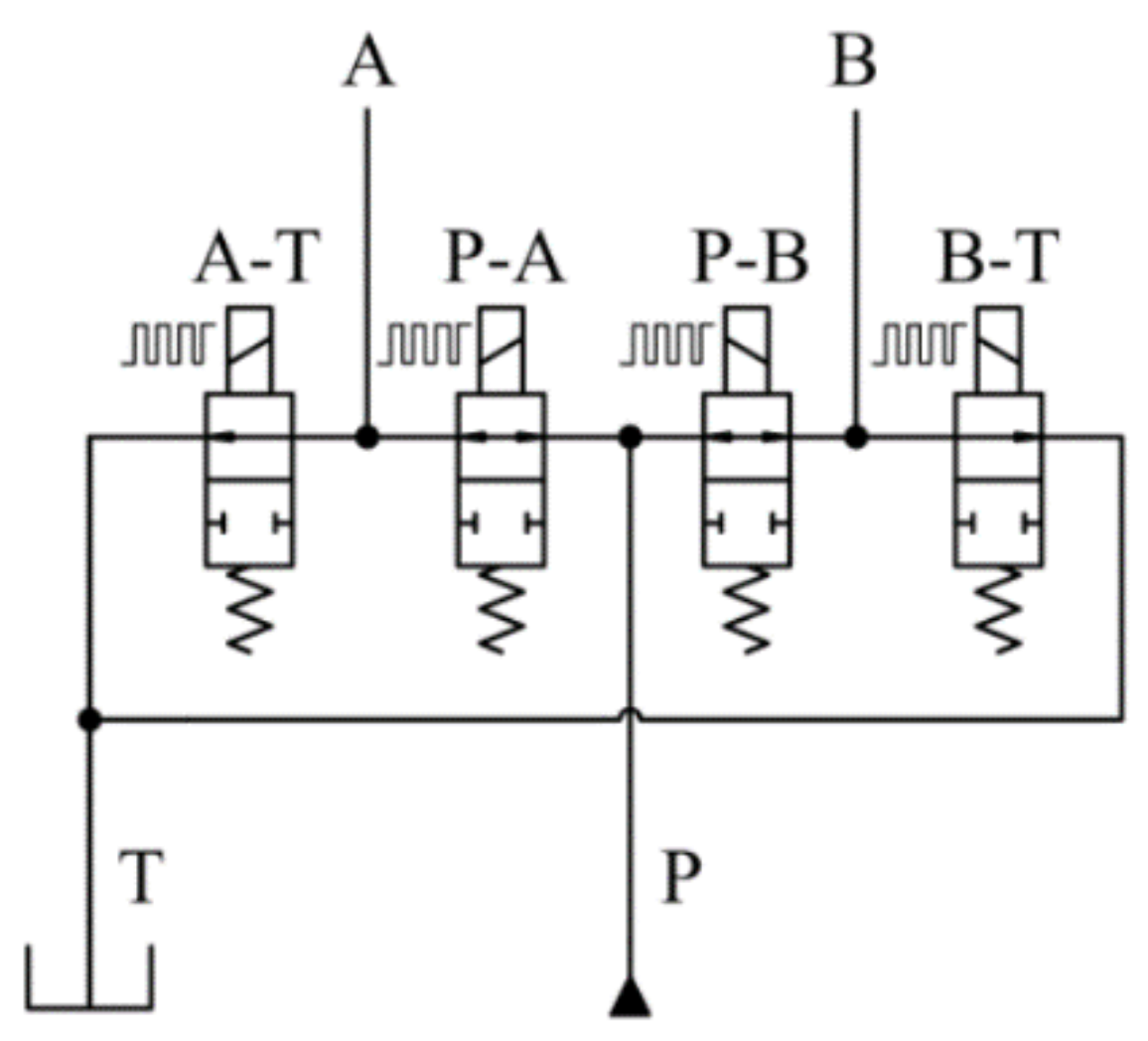

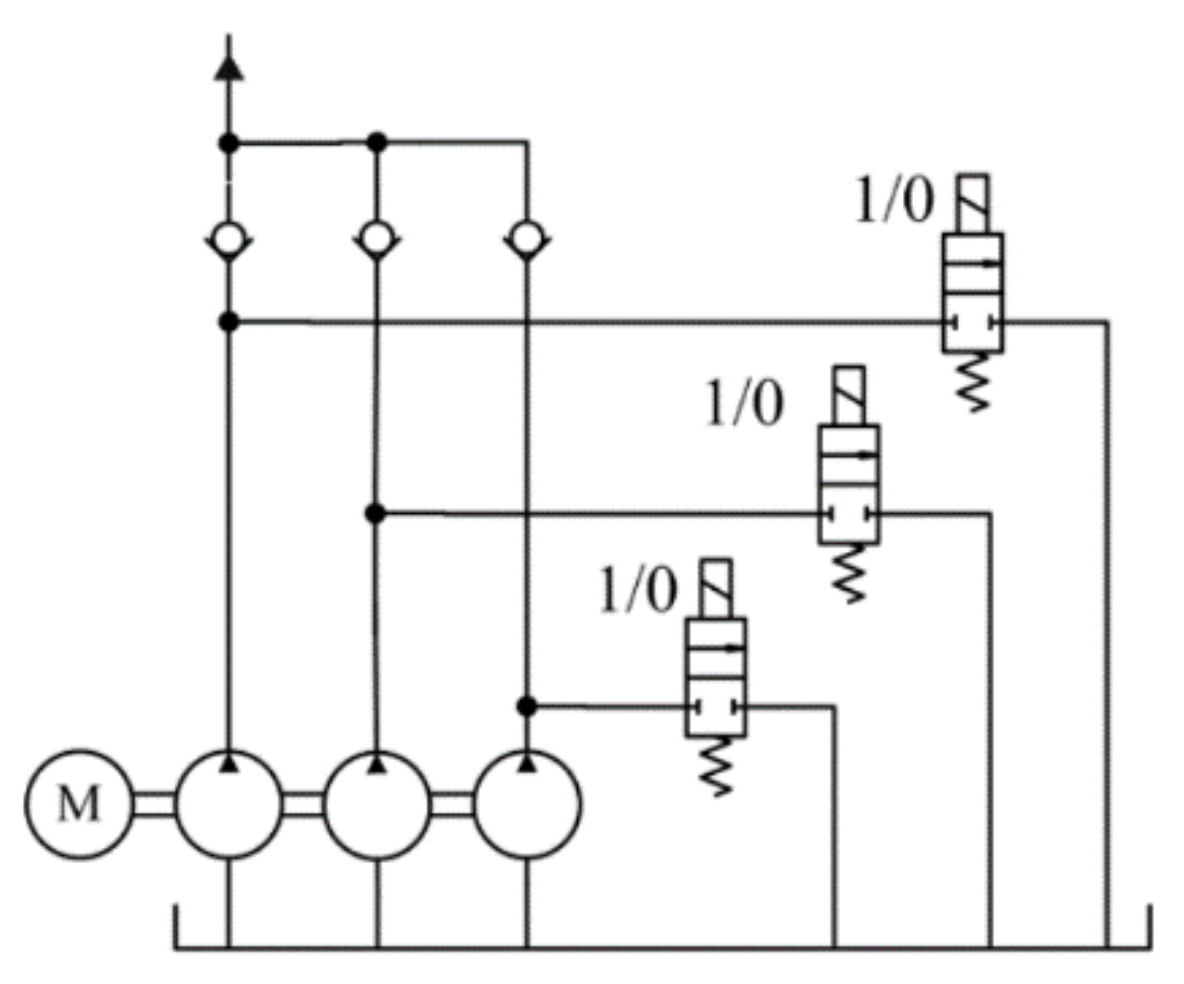

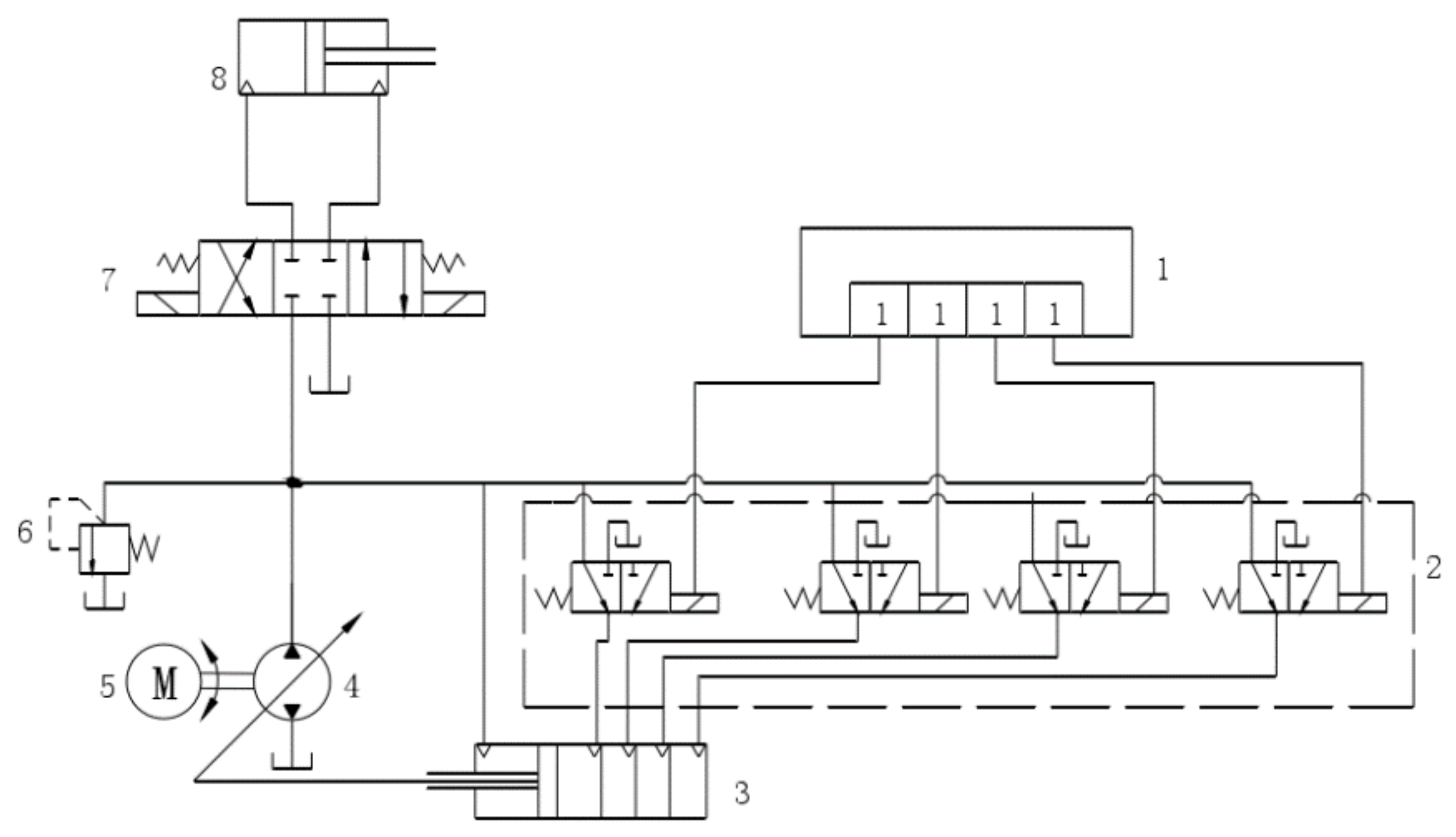

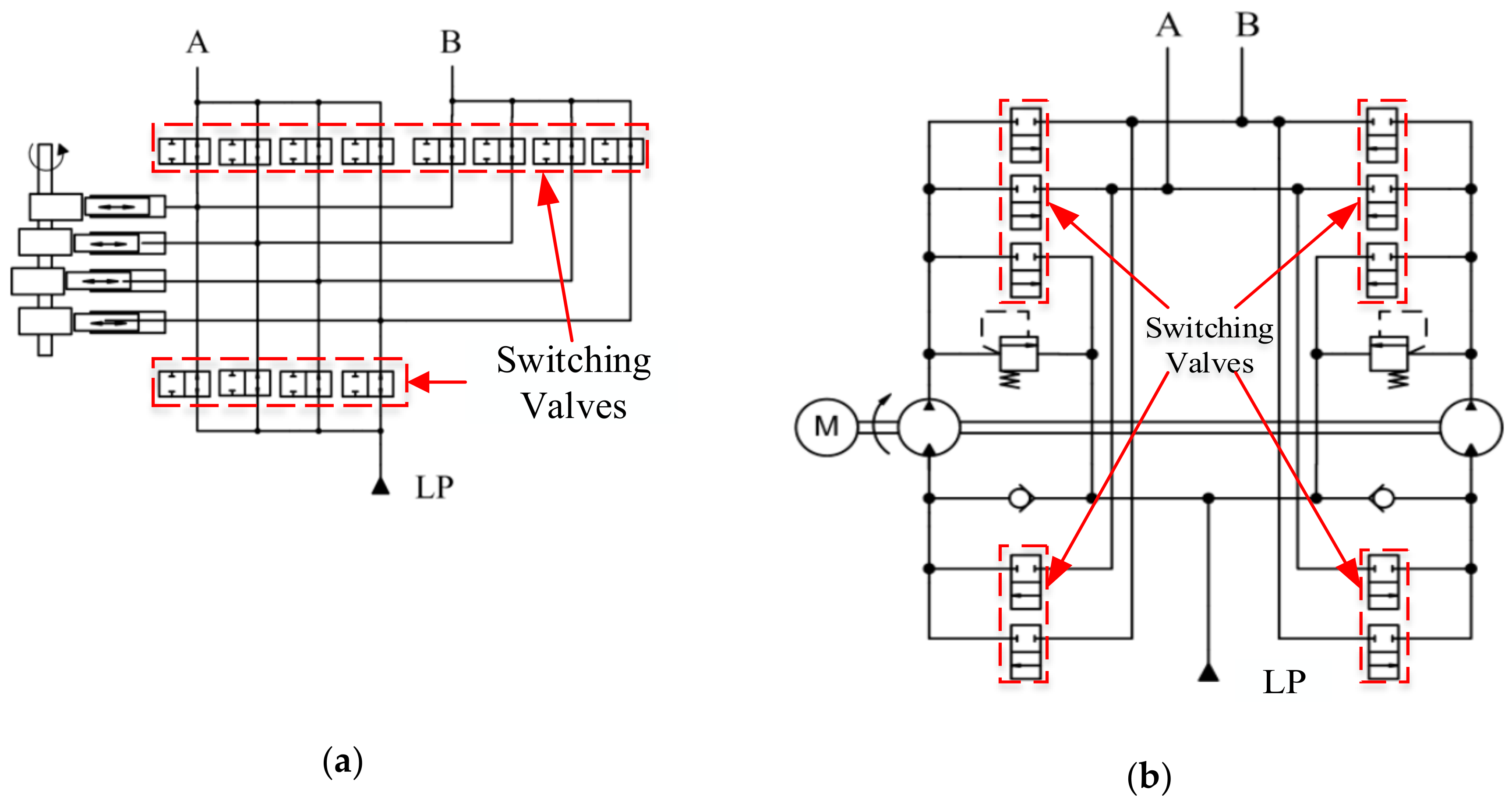

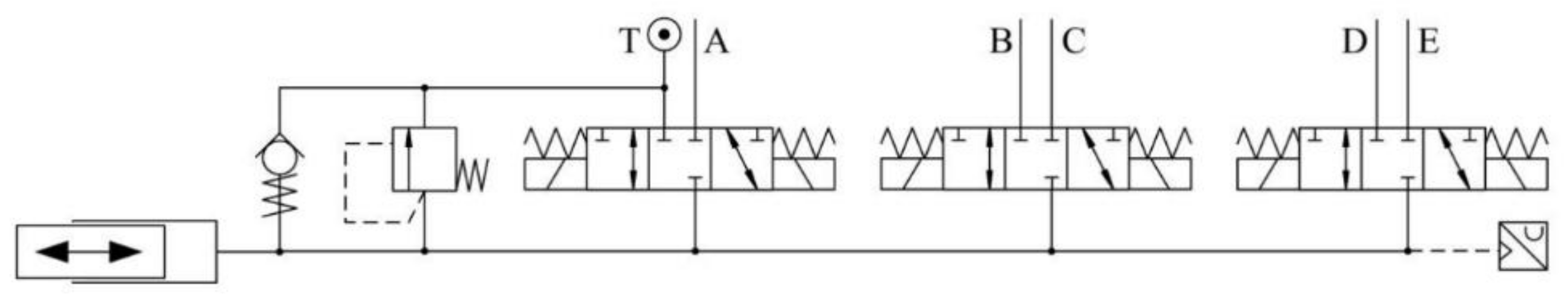

3.1.1. Parallel Digital Hydraulic Valves

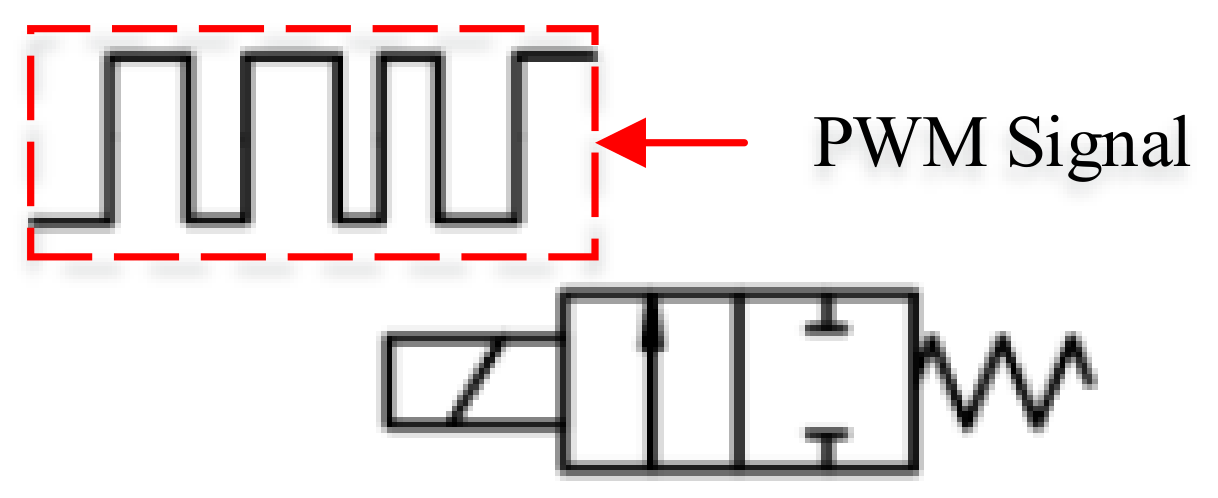

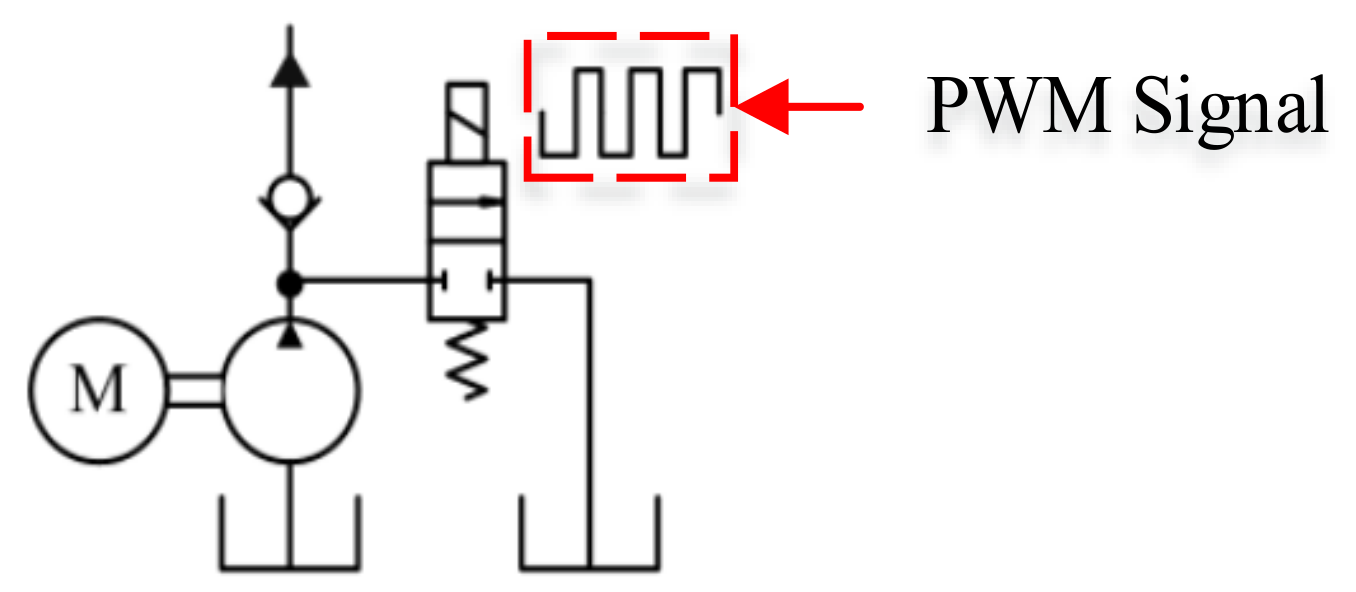

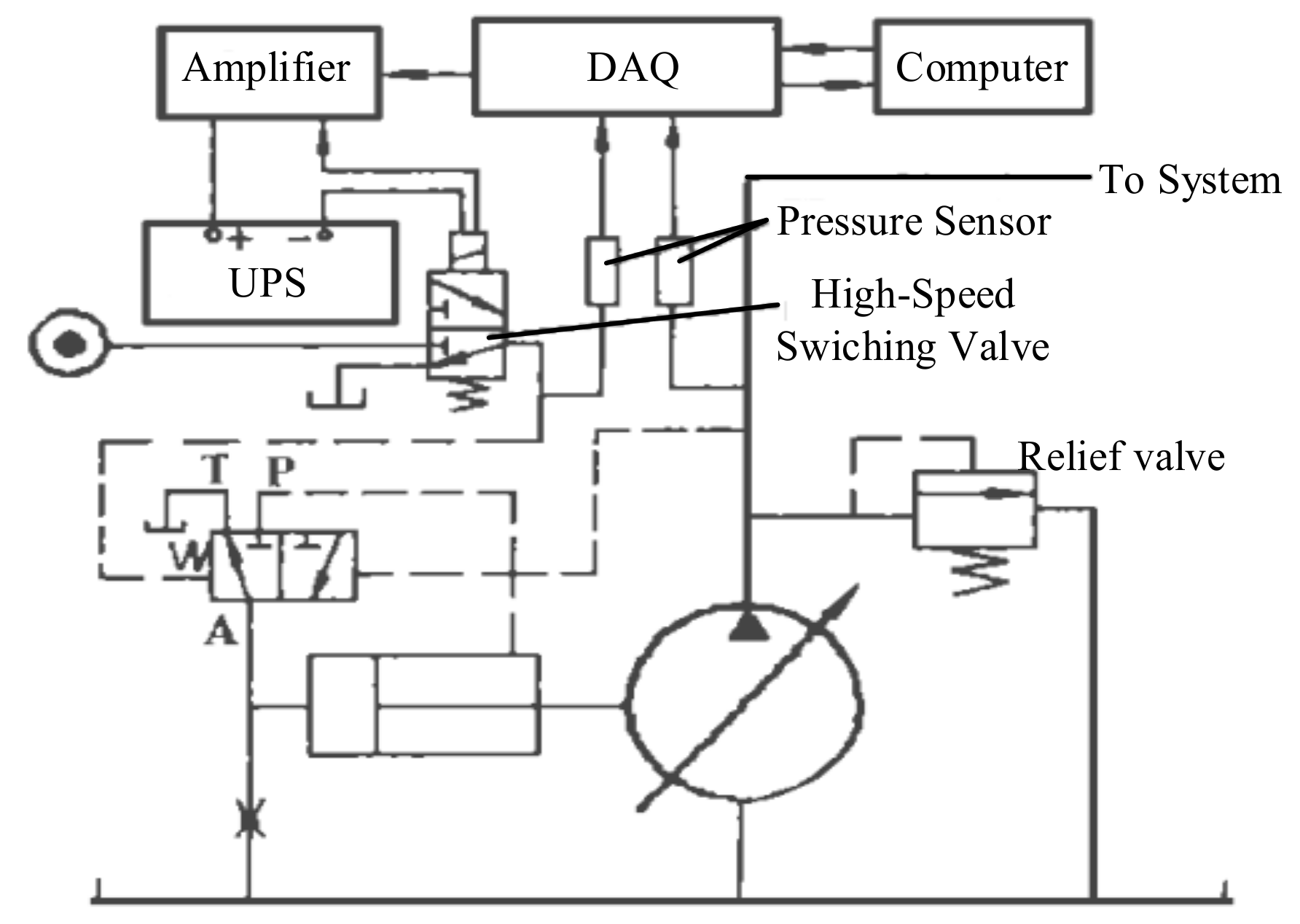

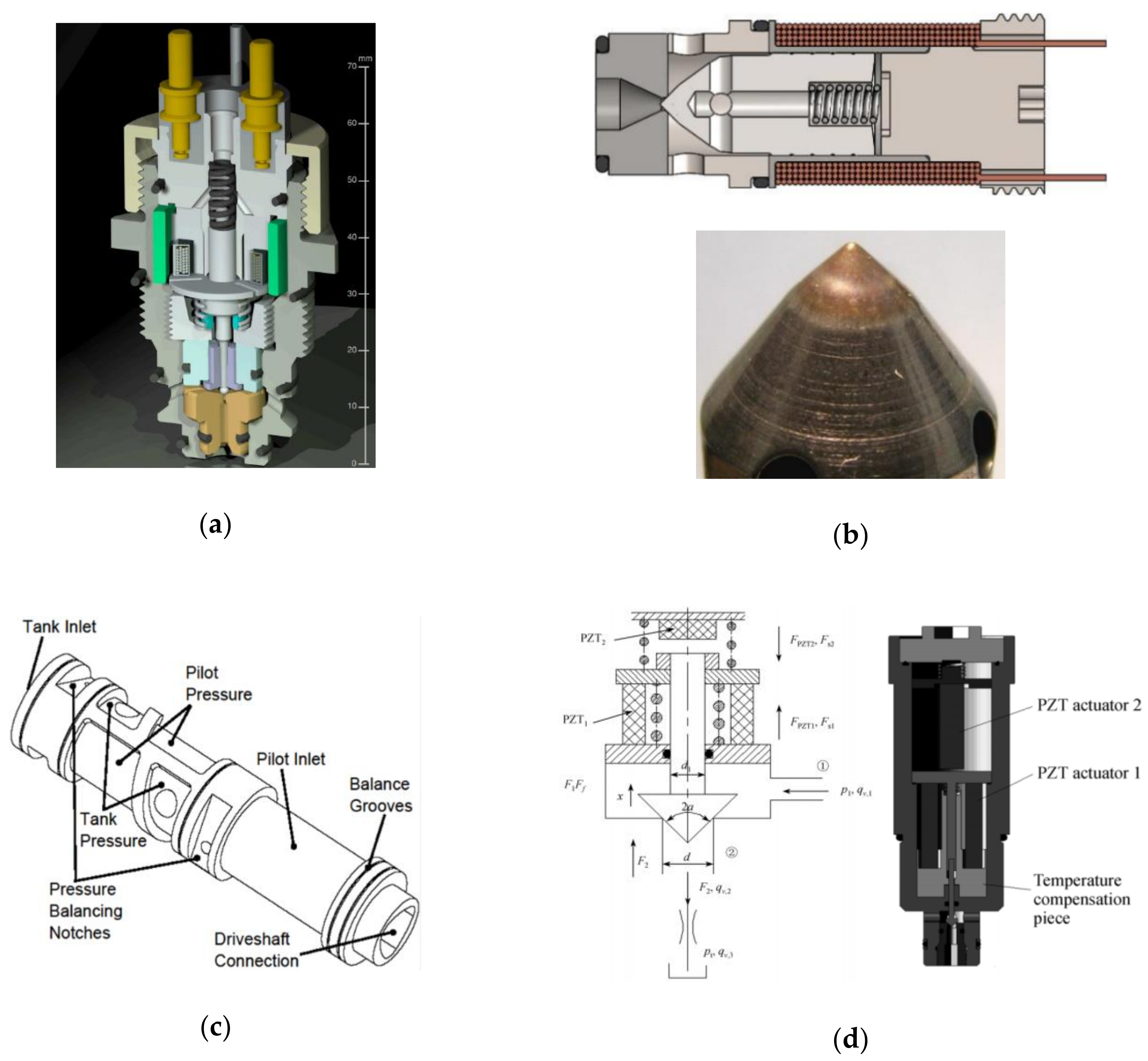

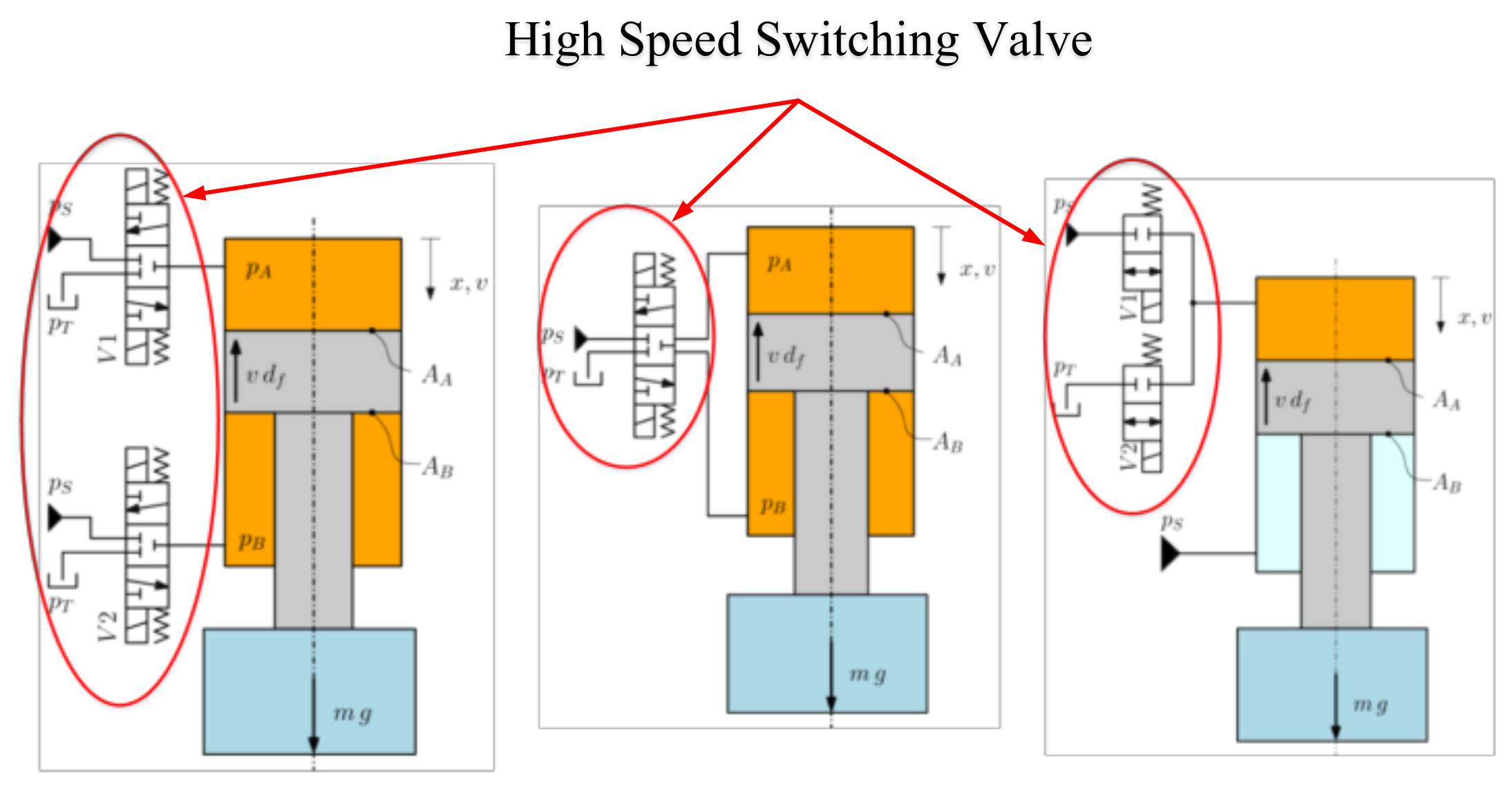

3.1.2. High-Speed Switching Digital Hydraulic Valve

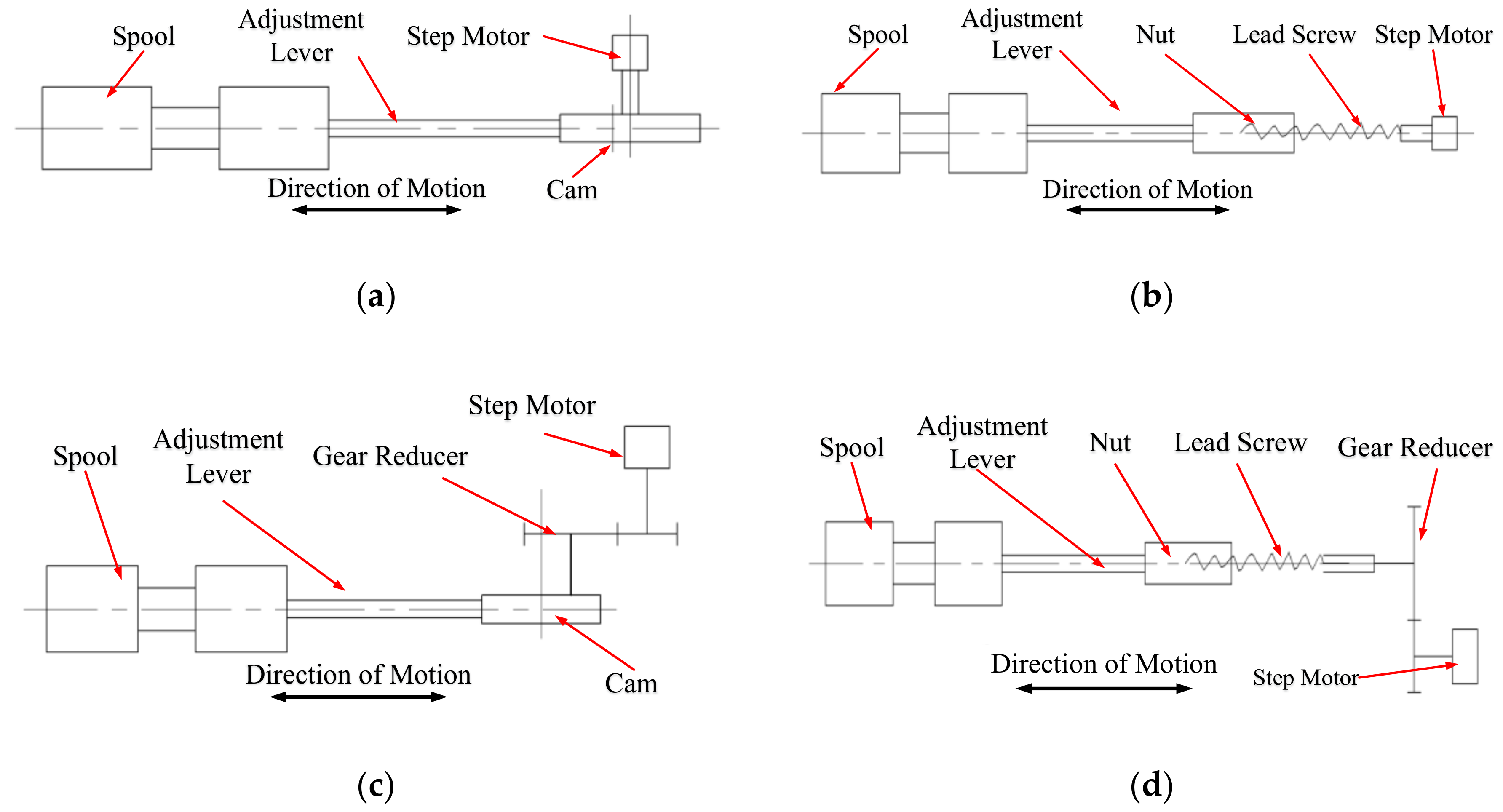

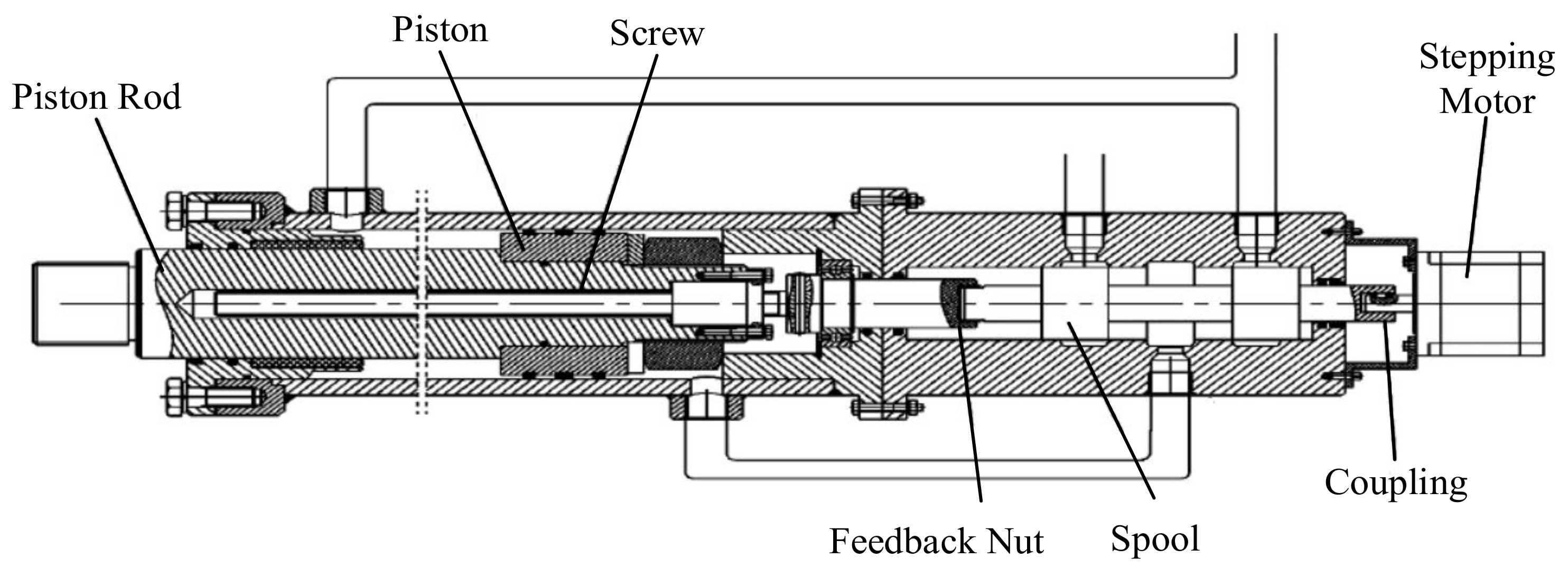

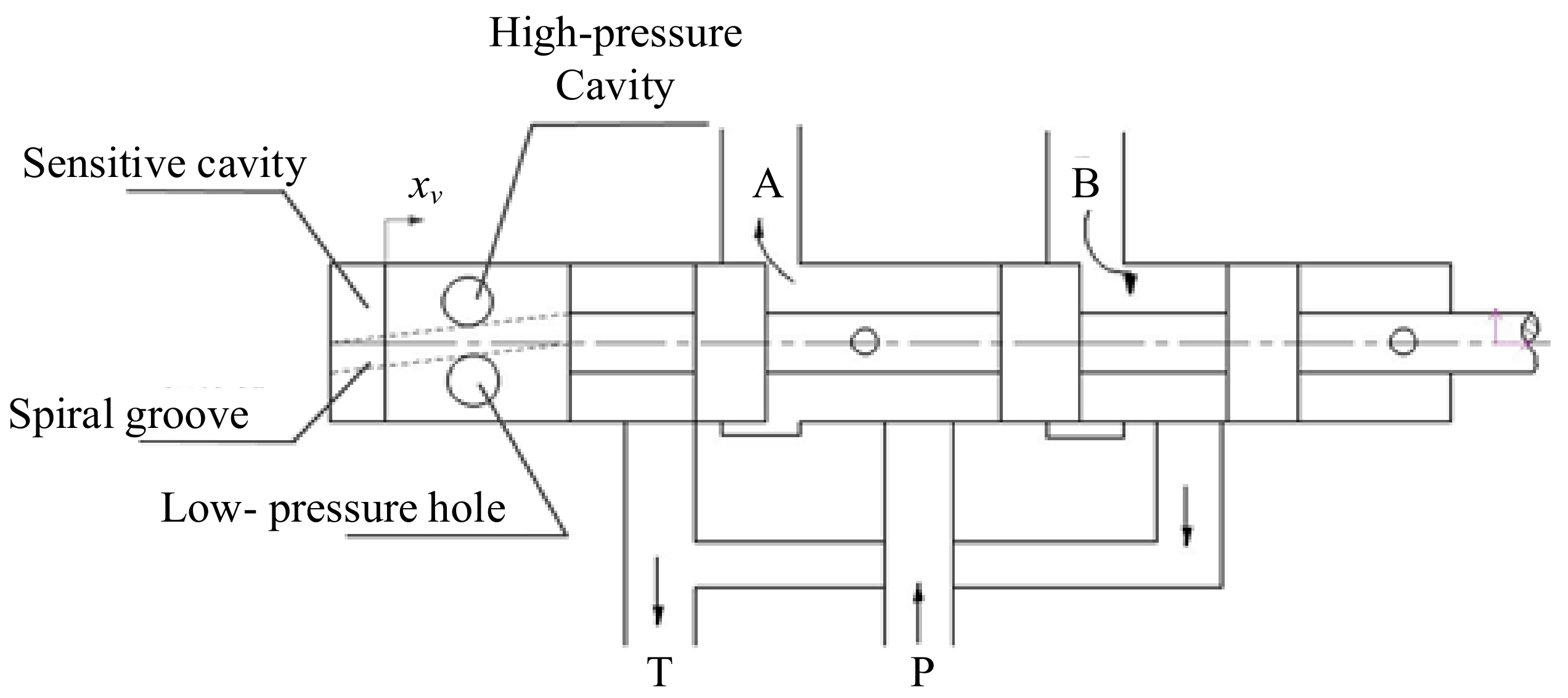

3.1.3. Stepping Digital Hydraulic Valve

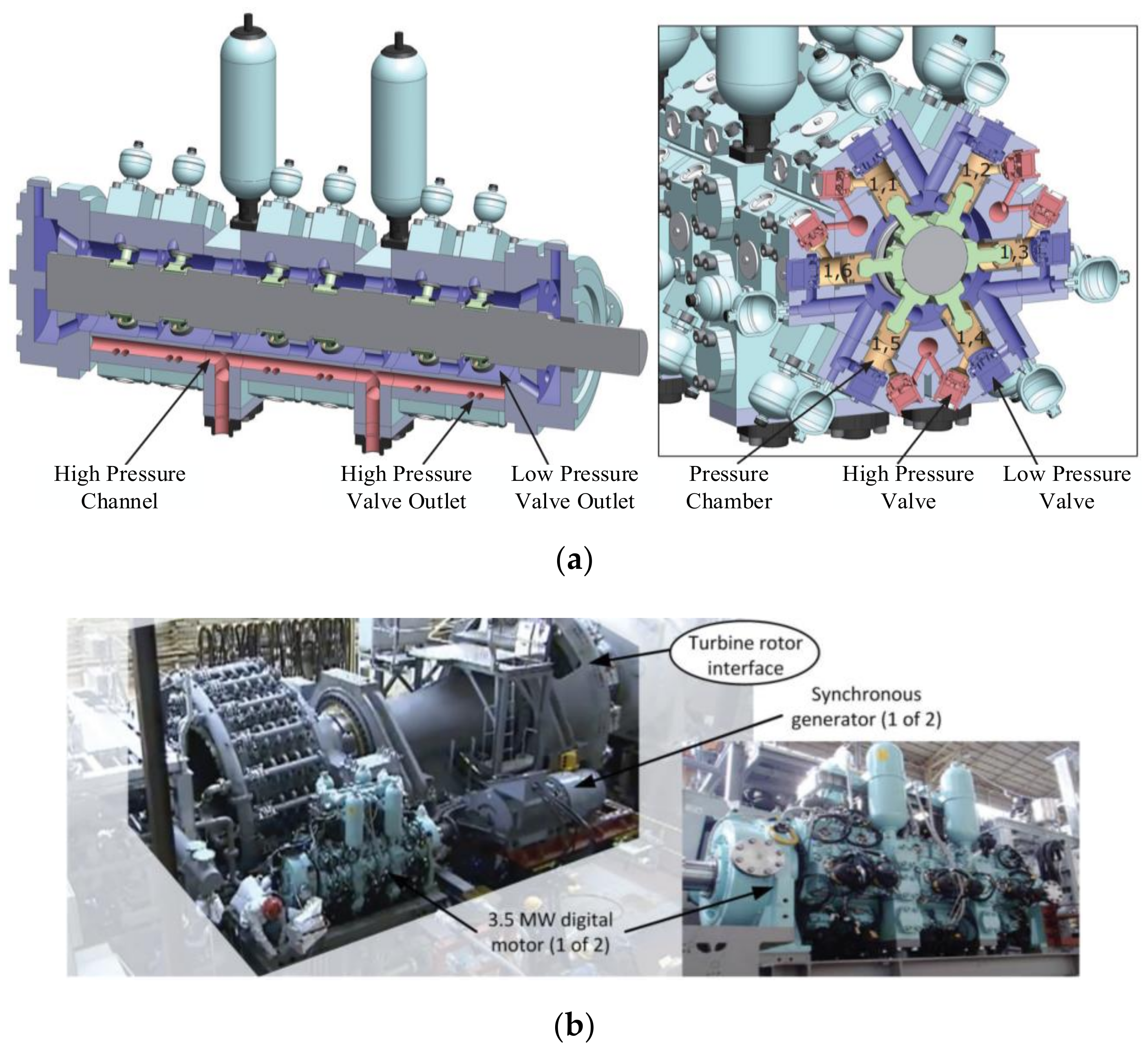

3.2. Digital Hydraulic Pump

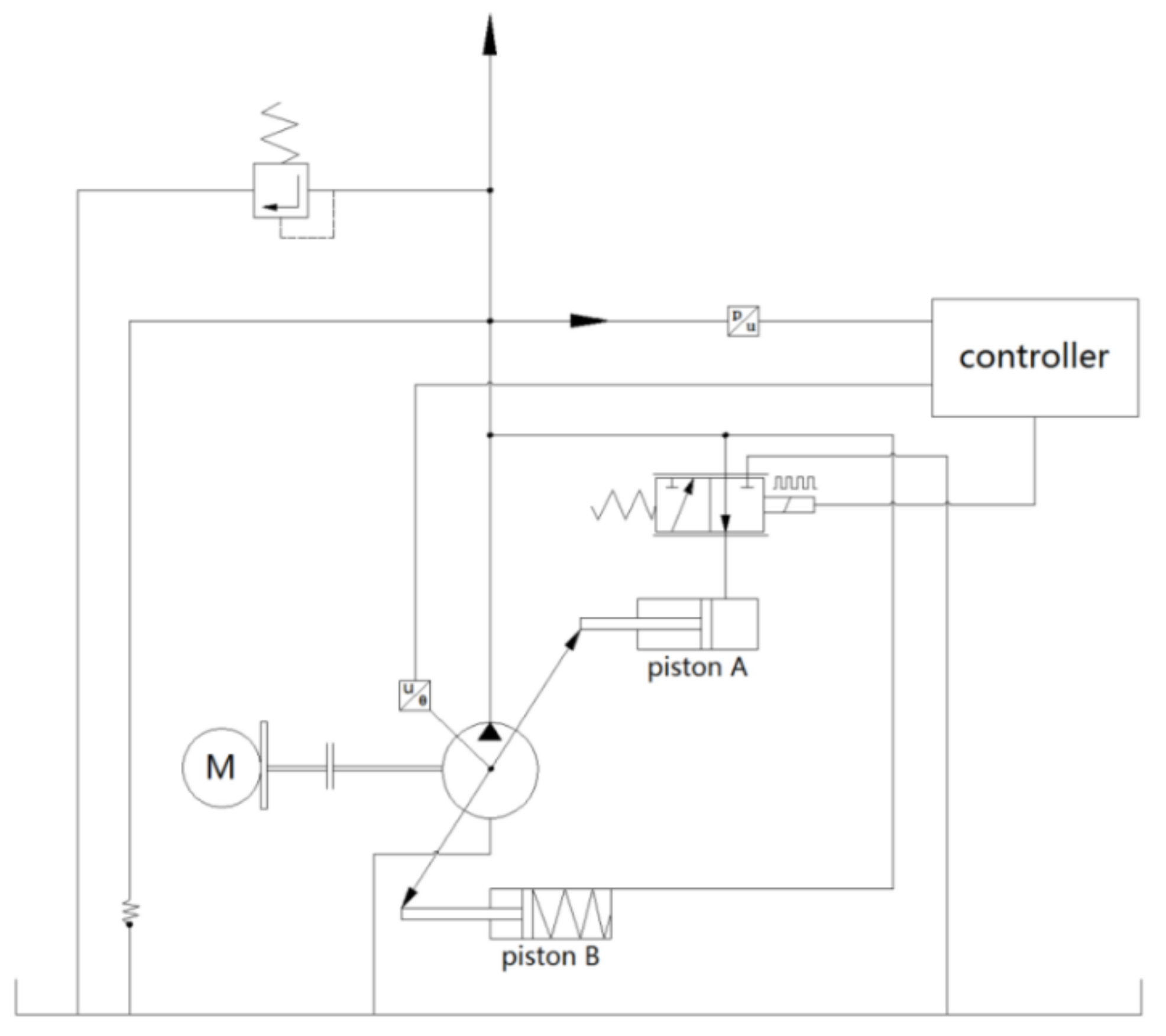

3.2.1. Variable Output Control of Quantitative Pump

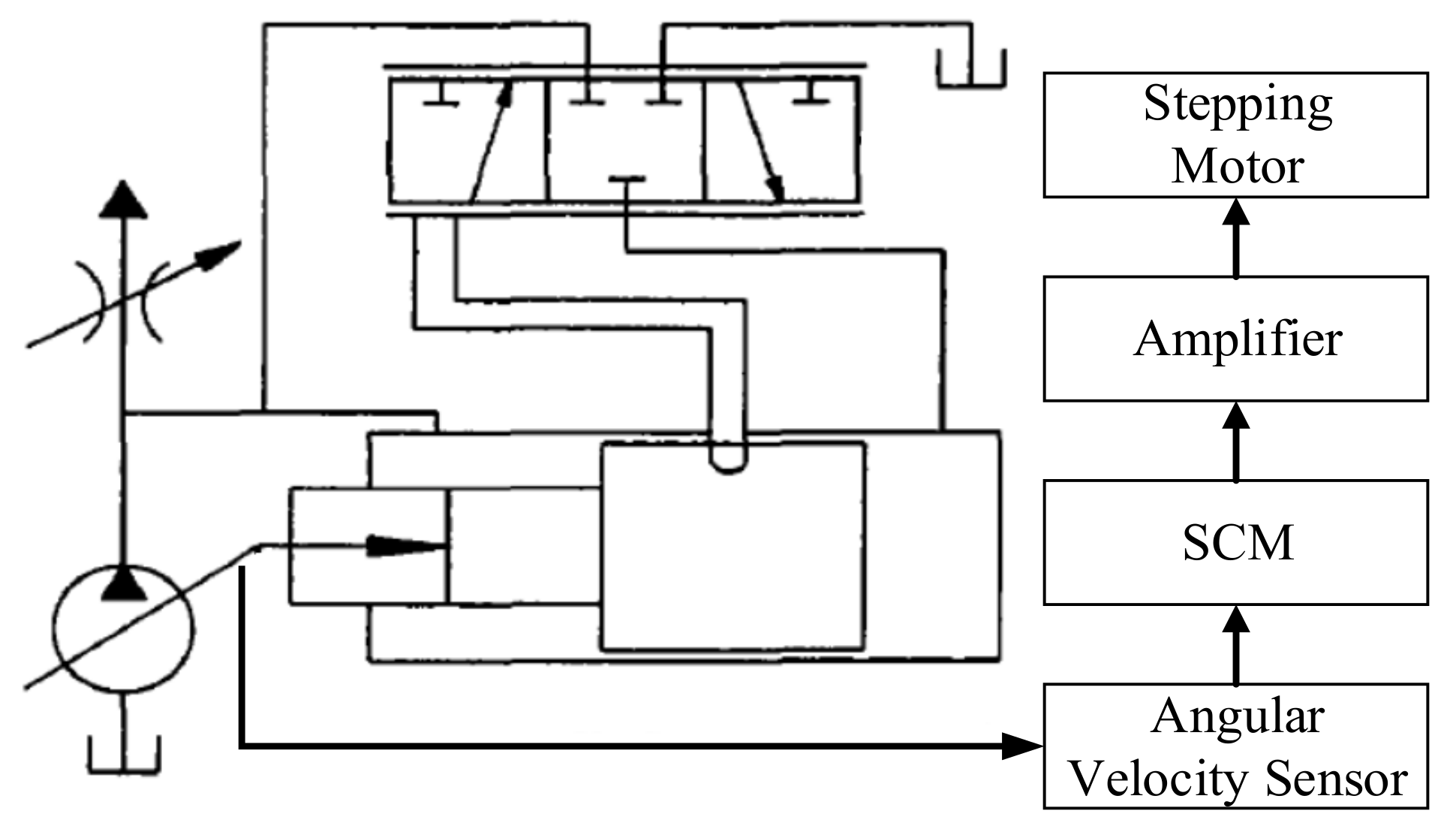

3.2.2. Digital Control of a Variable Pump

3.3. Digital Hydraulic Transformer

3.4. Digital Hydraulic Power Control System

3.5. Digital Hydraulic Actuator

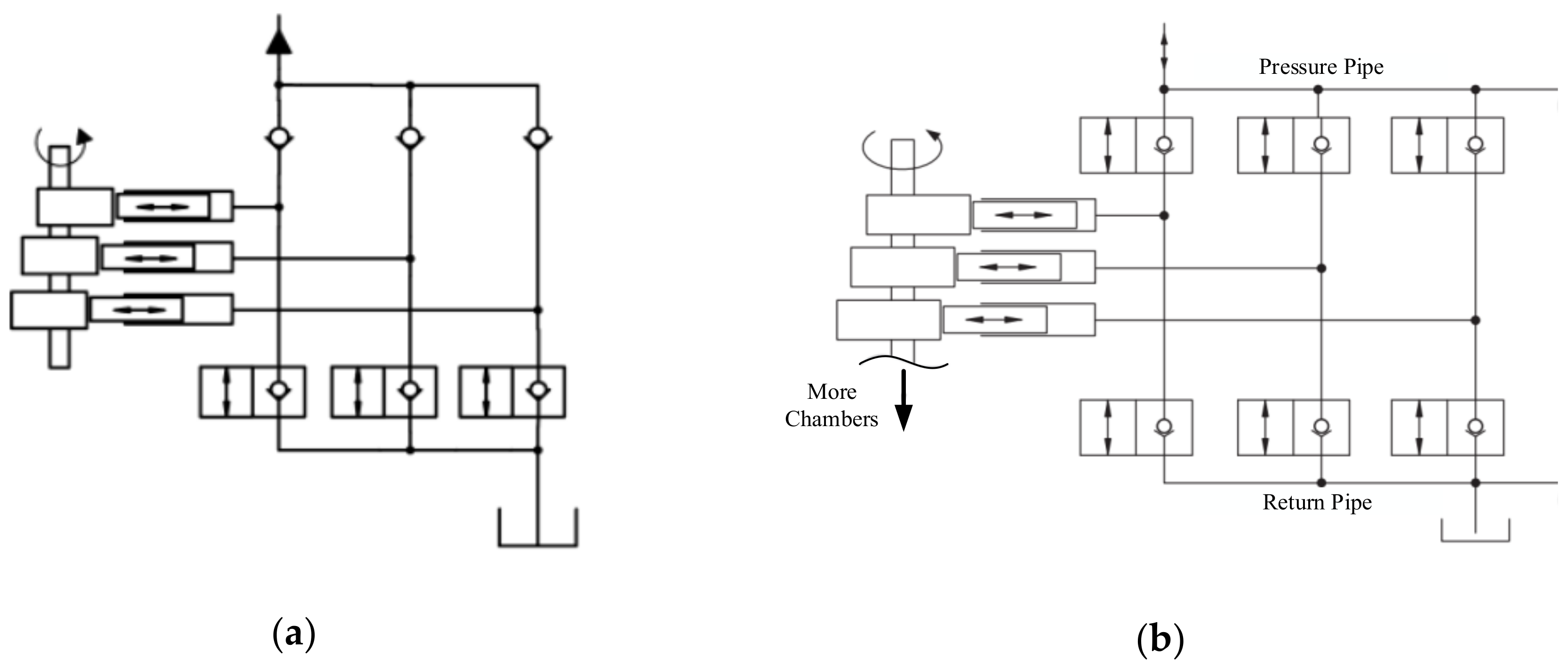

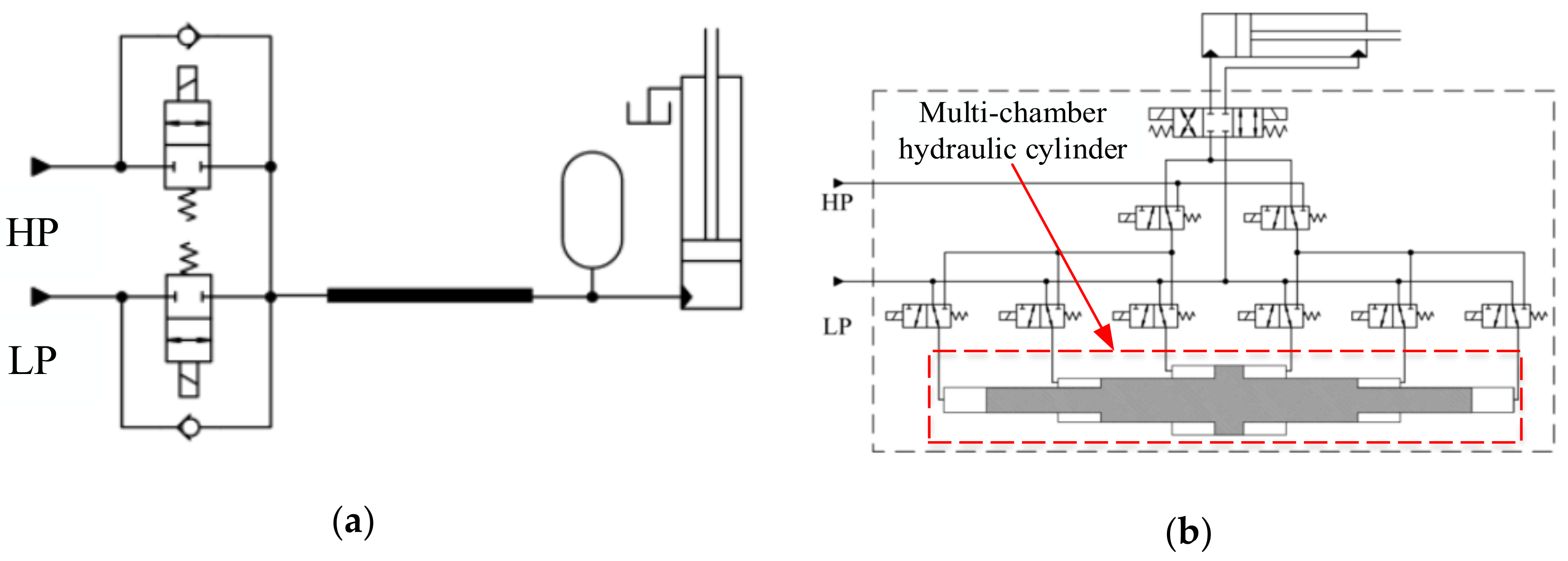

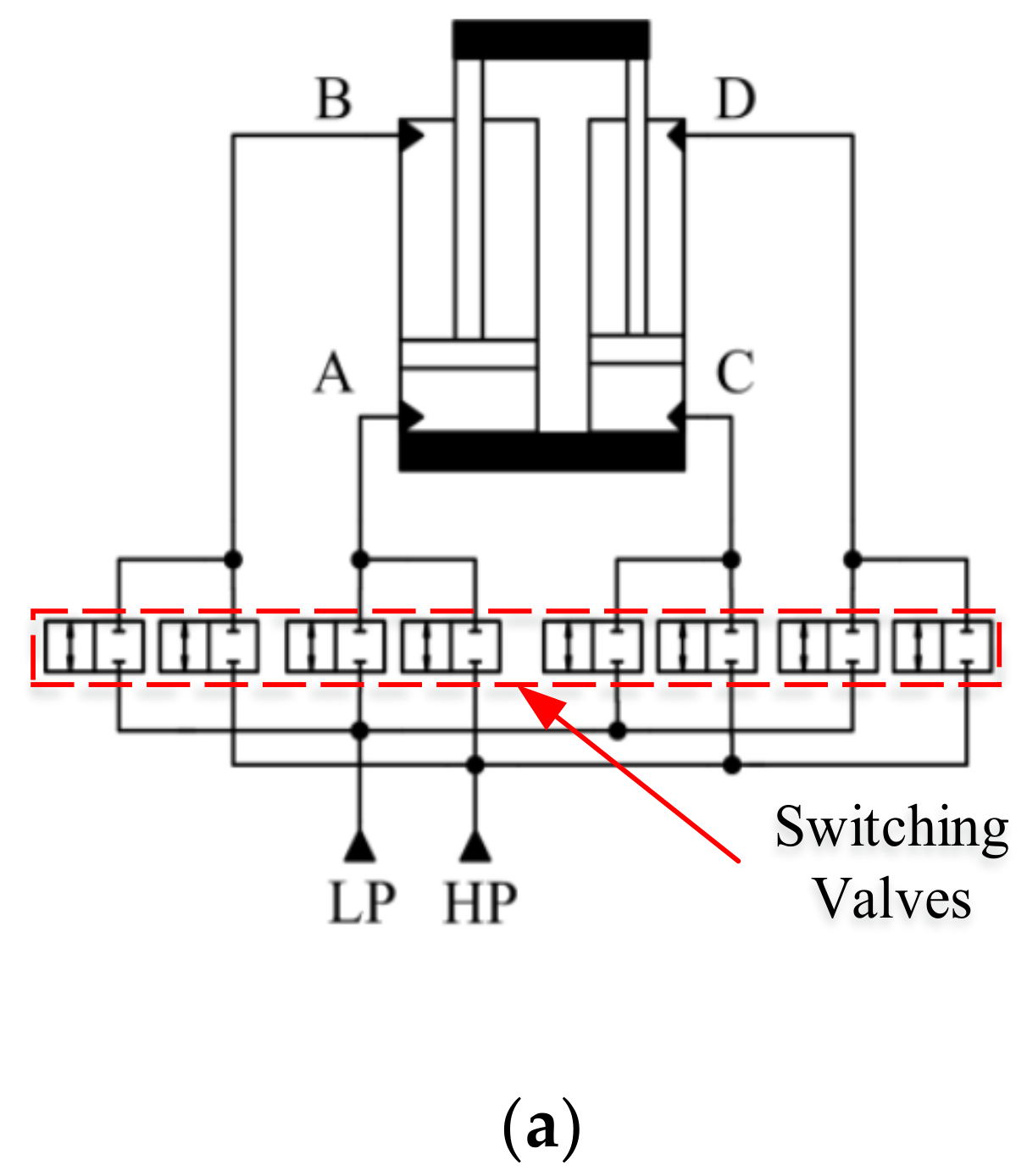

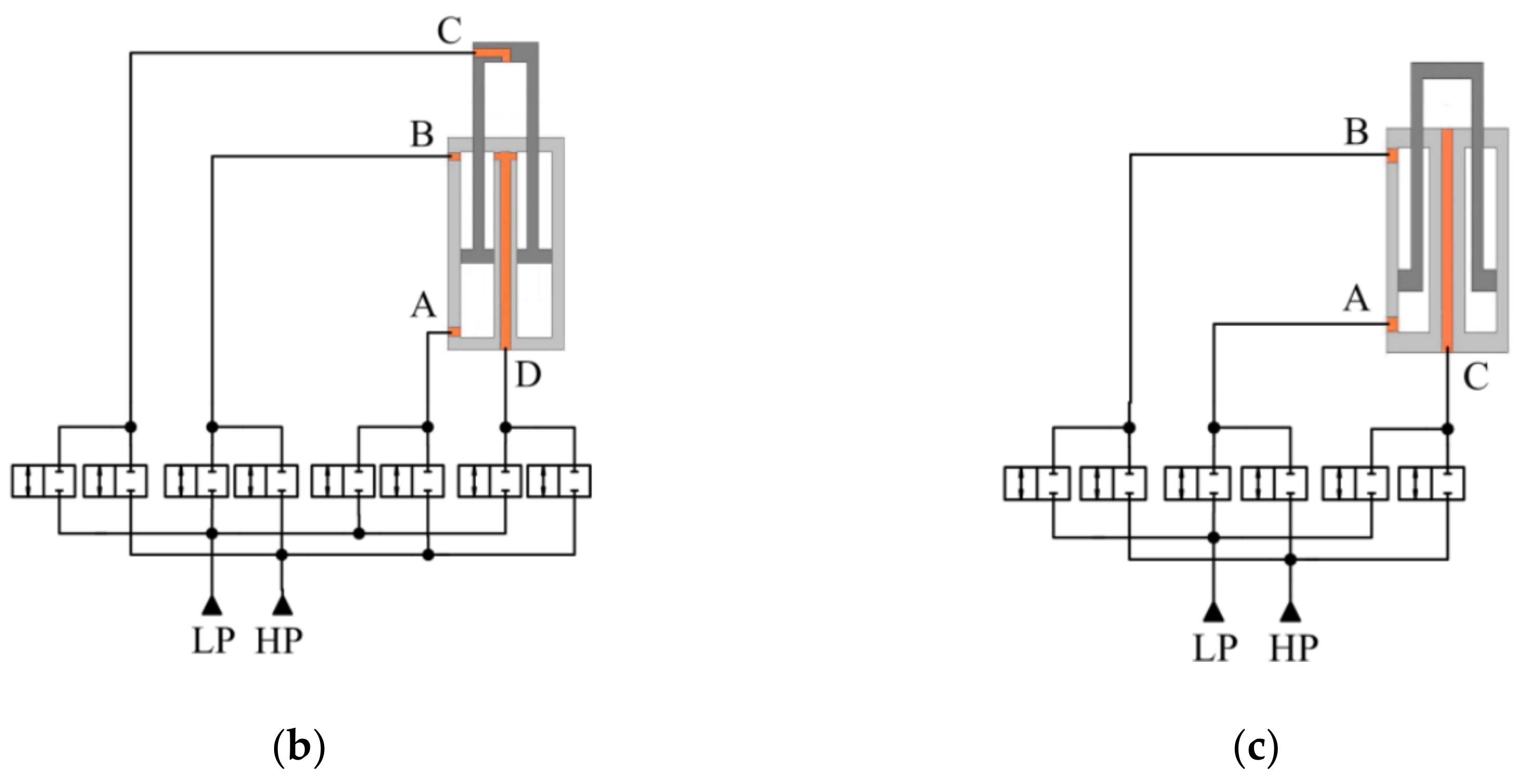

3.5.1. Digital Hydraulic Cylinder

3.5.2. Digital Hydraulic Motor

4. Features and Advantages of Digital Hydraulic Technology

4.1. Features of Digital Hydraulic Technology

4.1.1. Discrete Output

4.1.2. Fast Response Time Independent of Amplitude

4.2. Advantages of Digital Hydraulic Technology

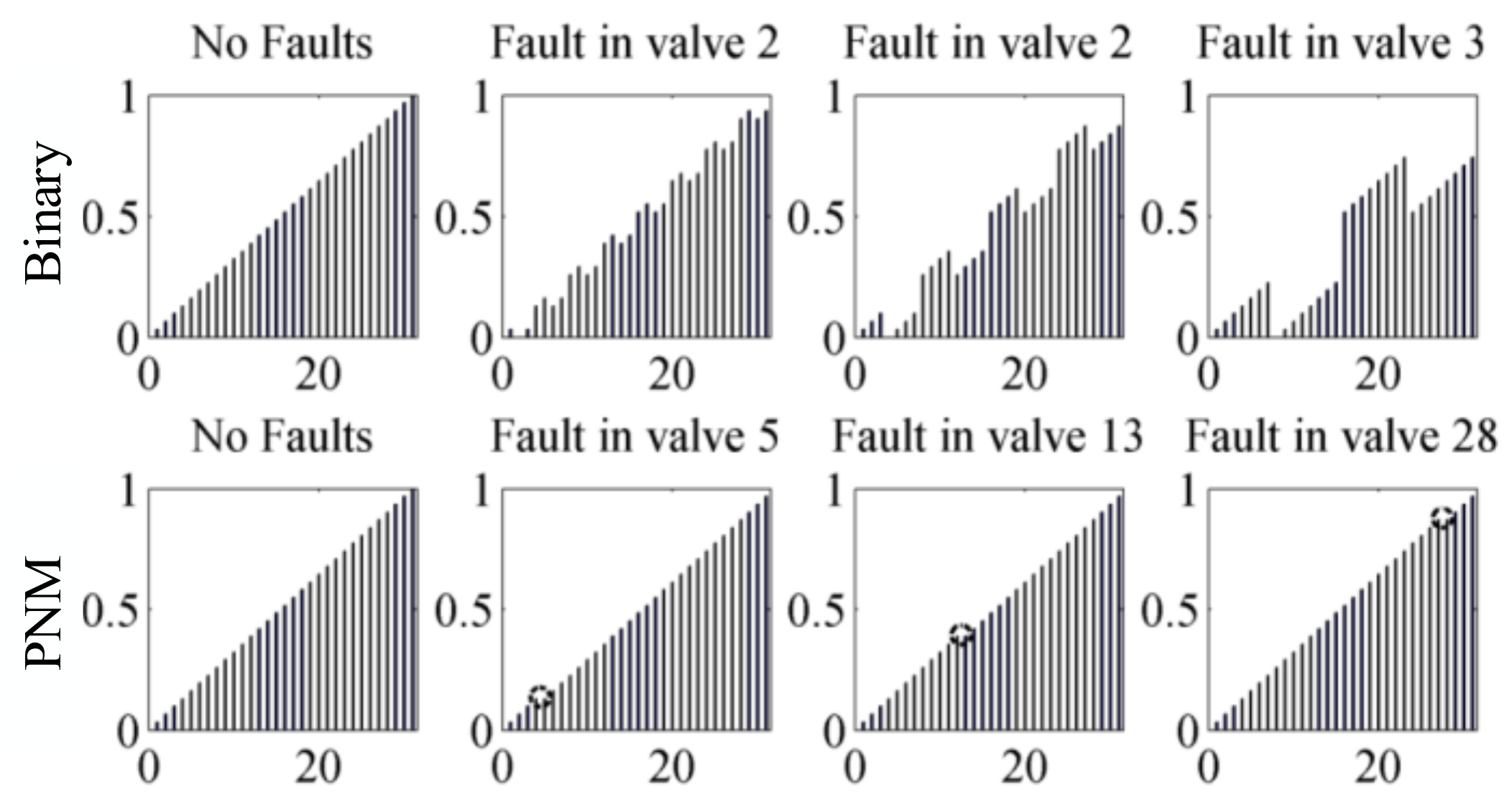

4.2.1. Fault-Tolerance Performance

4.2.2. Precise Lossless Control

4.2.3. High Accuracy Sensorless Control

4.3. Advantages and Challenges of Digital Hydraulic Technology

- Digital hydraulic technology directly adopts the digital signal to control without D/A conversion, which simplifies the control mode; makes the signal data storage, processing and transmission more convenient; and has stronger disturbance rejection ability, which is helpful for improving the robustness of the system.

- The digital hydraulic system has a better integration and programmability which can improve the application and maintenance performance of the system. It also facilitates networking of the system.

- The performance of the system depends on the control of the combination state of components rather than the performance of individual components. Therefore, simple and reliable components can be widely used to improve the robustness and fault-tolerance performance of the system.

- The digital hydraulic system avoids the use of proportional and servo components, and it improves the anti-pollution performance.

- It is easier to realize independent metering control. And because of the switching control mode, the system can reduce the throttle loss and improve efficiency.

- Digital hydraulic technology has obvious advantages, but there are also challenges to limit its application.

- The high frequency switching of the components can cause noise and pressure impact.

- The durability of high-speed switching hydraulic technology severely limits its application at present.

- The parallel digital hydraulic technology needs to use a large number of components, and such a situation would cause a dramatic increase in size and cost.

- A complex, unconventional control strategy would also bring difficulties to the application of digital hydraulic technology.

5. Developments and the Current Situation of Digital Hydraulic Technology

5.1. Parallel Digital Hydraulic Technology

5.1.1. Parallel Digital Hydraulic Components

5.1.2. Application of the Parallel Digital Hydraulic Technology

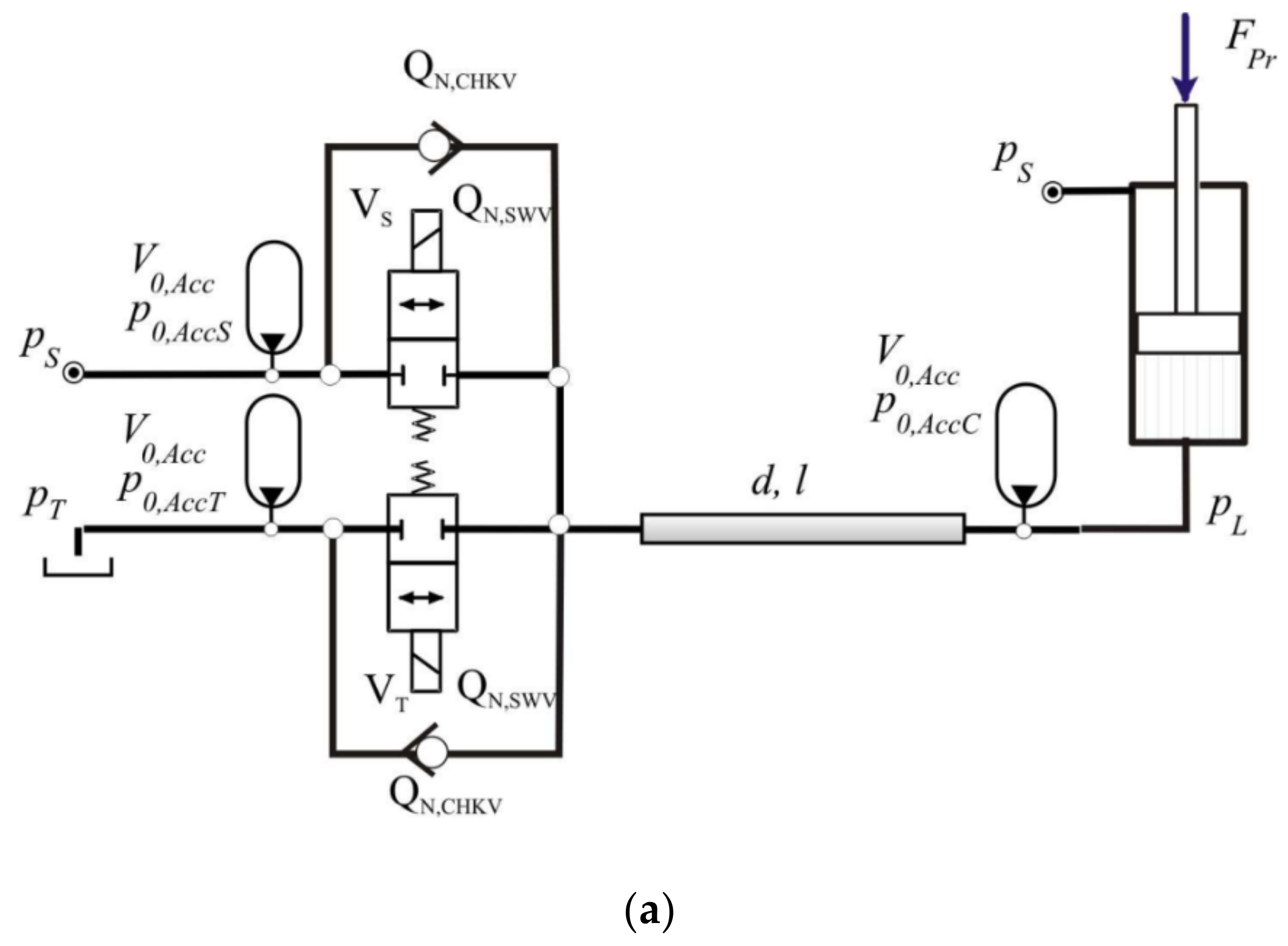

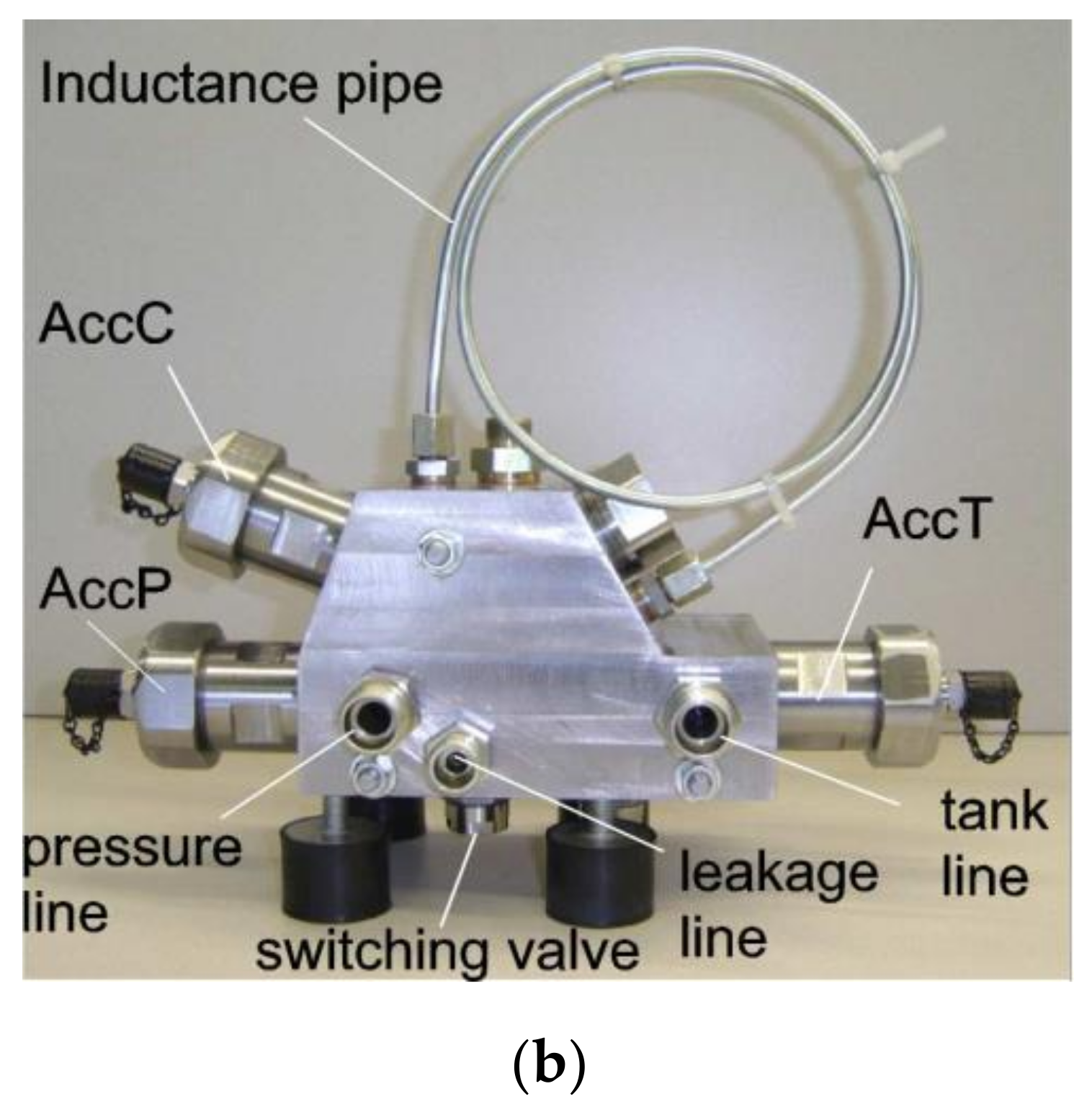

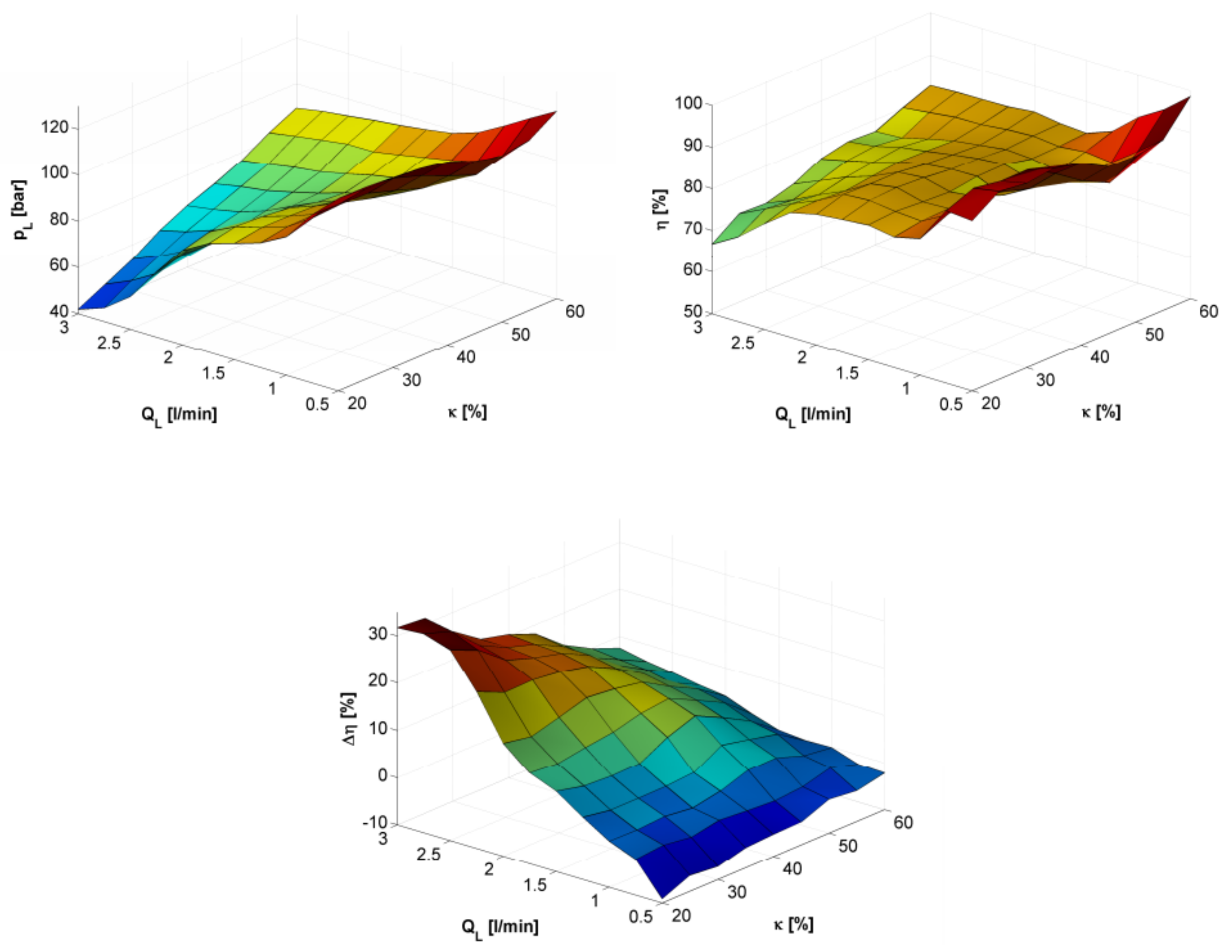

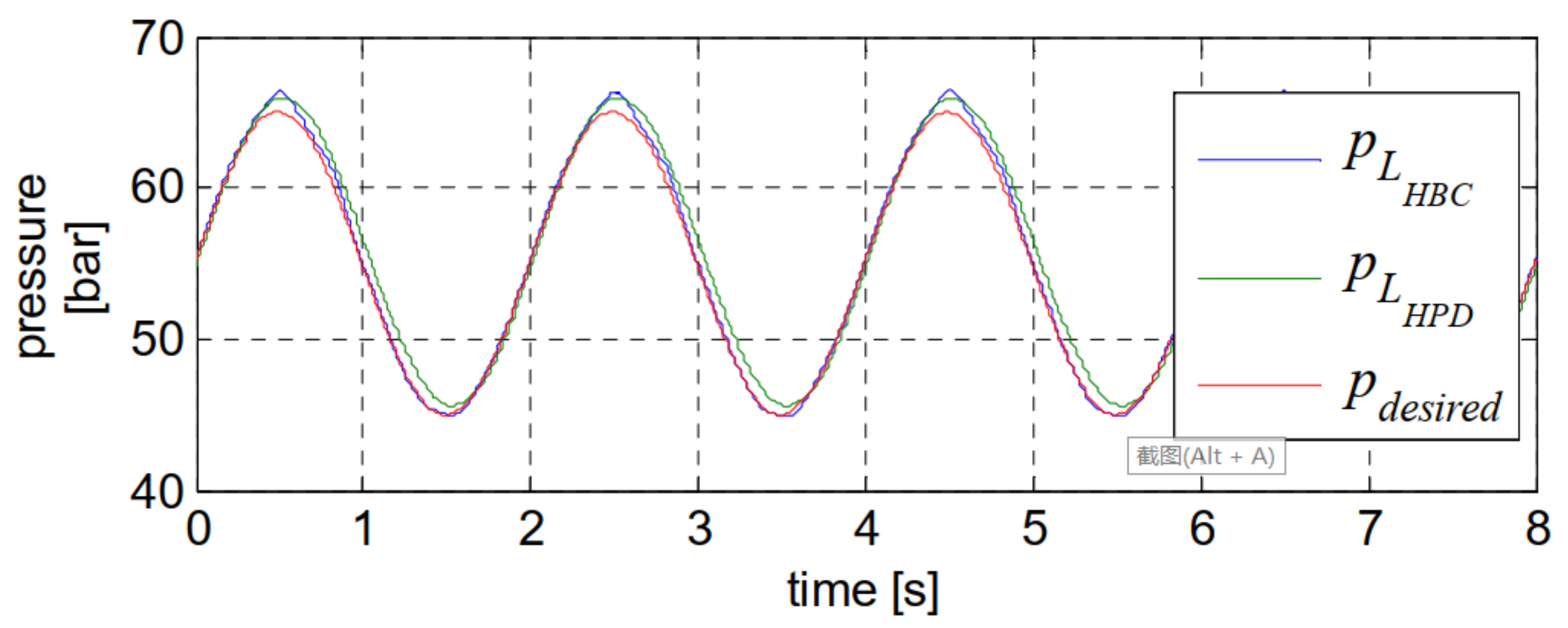

5.2. High-Speed Switching Digital Hydraulic Technology

5.2.1. High-Speed Switching Digital Hydraulic Valve

5.2.2. Applications of High-Speed Switching Hydraulic Technology

5.3. Stepping Digital Hydraulic Technology

5.3.1. Stepping Digital Hydraulic Components

5.3.2. Applications of Stepping Digital Hydraulic Technology

6. Developing Trend of the Digital Hydraulic Technology

6.1. Development of a New Valve Prototype

6.2. Integration of Digital Hydraulic Technology

6.3. Improvement of Energy Efficiency

7. Conclusions

- With the continuous promotion of “Industry 4.0” in the world, traditional hydraulic technology has been marginalized because of its low energy efficiency and lack of intelligence. The digital hydraulic technology will be able to make up for the defects of the traditional hydraulic technology, and play a greater role in intelligent factories and intelligent manufacturing.

- With the advantages of great fault-tolerance and fast response performance, parallel digital hydraulic technology has become one of the mainstream research directions in digital hydraulic technology. But it still needs to solve the problems of high cost and large volume after a large number of switching components are connected in parallel. At the same time, the lack of accurate and suitable control algorithms of parallel systems has also become an important factor hindering the development of parallel digital hydraulic technology.

- High-speed switching digital hydraulic technology is also one of the main research directions in digital hydraulic technology. It can achieve precise lossless control performance, and its response time can also reach considerable millisecond level. However, the development and application of high-speed switching digital hydraulic technology are restricted by the vibration, noise, pulsation and other problems caused by the frequent opening and closing of high-speed switching valve, and the lives of high-speed switch components themselves. At the same time, the problem of high-speed switching valves’ insufficient service lives also needs to be solved.

- The development of stepping digital hydraulic technology started earlier. And it is famous for its high accuracy, sensorless control performance which can greatly simplify a system and improve the system’s usability and maintainability. However, the application and development of digital hydraulic technology are limited because the stepping motor is prone to being out-of-step at high frequency. In recent years, with the continuous development and improvement of parallel technology and high-speed switching technology, the stepping digital hydraulic technology has faded out of the mainstream research direction of digital hydraulic technology.

- The “Workshop on Digital Fluid Power” held by Tampere university is the most famous academic conference on digital hydraulic technology in the world. Looking at the papers published in the conference in recent years, it can be seen that the main research directions of researchers on digital hydraulic technology are focused on control algorithms, new valve prototypes, digital pump motors, etc. The purpose of researchers is to further improve the energy efficiency, reliability and practicability of digital hydraulic technology, and lay a foundation for promoting the practical application of digital hydraulic technology.

Author Contributions

Funding

Conflicts of Interest

References

- Lu, Y. History progress and prospects of fluid power transmission and control. Chin. J. Mech. Eng. 2010, 46, 1–9. [Google Scholar]

- Ba, K.; Yu, B.; Zhu, Q.; Gao, Z.; Kong, X. The position-based impedance control combined with compliance-eliminated and feedforward compensation for HDU of legged robot. J. Frankl. Inst. 2019, 356, 9232–9253. [Google Scholar] [CrossRef]

- Ba, K.; Yu, B.; Gao, Z.; Ma, G.; Kong, X. An improved force-based impedance control method for the legged robot HDU. Isa Trans. 2019, 84, 187–205. [Google Scholar] [CrossRef] [PubMed]

- Achten, P. Convicted to innovation in fluid power. Proc. Inst. Mech. Eng. Part I 2010, 224, 619–621. [Google Scholar] [CrossRef]

- Kagoshima, M.; Komiyama, M.; Nanjo, T.; Tsutsui, A. Development of new kind of hybrid excavator. Res. Dev. Kobe Steel Eng. Rep. 2007, 57, 66–69. [Google Scholar]

- Scheidl, R. Discussion: Is the future of fluid power digital? Proc. Inst. Mech. Eng. Part I 2012, 226, 724–727. [Google Scholar]

- Yang, H. Progress and Trend of Construction Machinery Intelligence; Construction Machinery Technology and Management: Beijing, China, 2017; pp. 19–21. [Google Scholar]

- Linjama, M. Digital Fluid Power—State of the Art. In Proceedings of the Twelfth Scandinavian International Conference on Fluid Power, Tampere, Finland, 18–20 May 2011. [Google Scholar]

- Linjama, M. On The Numerical Solution of Steady-State Equations of Digital Hydraulic Valve Actuator System. In Proceedings of the Eighth Workshop on Digital Fluid Power, Tampere, Finland, 24–25 May 2016. [Google Scholar]

- Zhao, X. Research on the Theory and Application of HGDV pulse Modulation Switching Digital Hydraulic Valve. Master’s Thesis, Lanzhou University of Technology, Lanzhou, China, 2005. [Google Scholar]

- Yang, H. Development direction of digital hydraulic valve technology. In Proceedings of the Shanghai: 9th FPTC-2016, Shanghai, China, 21–24 November 2016. [Google Scholar]

- Breidi, F.; Helmus, T.; Lumkes, J. The Impact of Peak-and-Hold and Reverse Current Solenoid Driving Strategies on the Dynamic Performance of Commercial Cartridge Valves in a Digital Pump/Motor. Int. J. Fluid Power 2015, 17, 37–47. [Google Scholar] [CrossRef]

- Ding, X. Research on Digital Hydraulic Valve Controlling Axial Piston Pump. Master’s Thesis, Taiyuan University of Science and Technology, Taiyuan, China, 2015. [Google Scholar]

- Wang, Q. Study of the Digital Control Variable Axial Piston Pump and its SCM Control. Master’s Thesis, Shenyang University of Technology, Shenyang, China, 2015. [Google Scholar]

- Liu, Z. Research on Electro-Hydraulic Digital Control of Constant Pressure Variable Pump System. Mach. Tool Hydraul. 2001, 2, 29–31. [Google Scholar]

- Yang, H.; Ouyang, X.; Xu, B. Development status of hydraulic transformer. J. Mech. Eng. 2003, 39, 1–5. [Google Scholar] [CrossRef]

- Shi, G.; Yu, L.; Qi, L. Simulation of Radial Piston Constant Flow Pump with Digital Distribution under Random Low Speed Driving. In Proceedings of the Eighth Workshop on Digital Fluid Power, Tampere, Finland, 24–25 May 2016. [Google Scholar]

- Kogler, H.; Scheidl, R.; Ehrentraut, M.; Guglielmino, E.; Semini, C.; Caldwell, D.G. A Compact Hydraulic Switching Converter for Robotic Applications. In Proceedings of the Fluid Power and Motion Control (FPMC2010), Bath, UK, 15–17 September 2010; Johnston, D.N., Plummer, A., Eds.; Hadleys Ltd.: Theale, UK, 2010; pp. 55–68. [Google Scholar]

- Plöckinger, A.; Grad, C.; Scheid, R. High Accuracy Sensorless Hydraulic Stepping Actuator. In Proceedings of the Eighth Workshop on Digital Fluid Power, Tampere, Finland, 24–25 May 2016. [Google Scholar]

- Rickenberg, F. Valve. U.S. Patent No. 1757059, 30 April 1930. [Google Scholar]

- Murphy, R.; Weil, J. Hydraulic Control System. U.S. Patent No. 3038449, 20 June 1962. [Google Scholar]

- Virvalo, T. Cylinder Speed Synchronization. Hydraul. Pneum. 1978, 31, 55–57. [Google Scholar]

- Linjama, M.; Koskinen, K.T.; Vilenius, M. Pseudo-Proportional Position Control of Water Hydraulic Cylinder Using On/Off Valves. In Proceedings of the Fifth JFPS International Symposium on Fluid Power, Nara, Japan, 12–15 November 2002; pp. 155–160. [Google Scholar]

- Laamanen, A.; Linjama, M.; Tammisto, J.; Koskinen, K.T.; Vilenius, M. Velocity Control of Water Hydraulic Motor. In Proceedings of the Fifth JFPS International Symposium on Fluid Power, Nara, Japan, 12–15 November 2002; pp. 167–172. [Google Scholar]

- Laamanen, A.; Linjama, M.; Vilenius, M. Characteristics of a Digital Flow Control Unit with PCM Control. In Proceedings of the Seventh Triennial International Symposium on Fluid Control, Measurement and Visualization, Sorrento, Italy, 25–28 August 2003. ISBN 0-9533991-4-1. [Google Scholar]

- Linjama, M.; Koskinen, K.T.; Vilenius, M. Accurate Trajectory Tracking Control of Water Hydraulic Cylinder with Non-Ideal on/Off Valves. Int. J. Fluid Power 2002, 4, 7–16. [Google Scholar] [CrossRef]

- Linjama, M.; Vilenius, M. Improved Digital Hydraulic Tracking Control of Water Hydraulic Cylinder Drive. Int. J. Fluid Power 2005, 6, 29–39. [Google Scholar] [CrossRef]

- Siivonen, L.; Linjama, M.; Huova, M.; Vilenius, M. Pressure based fault detection and diagnosis of a digital valve system. In Proceedings of the Power Transmission and Motion Control (PTMC 2007), Bath, UK, 12–14 September 2007; Johnston, D.N., Plummer, A., Eds.; Hadleys Ltd.: Theale, UK, 2007; pp. 67–79. [Google Scholar]

- Siivonen, L.; Linjama, M.; Huova, M.; Vilenius, M. Jammed On/Off Valve Fault Compensation with Distributed Digital Valve System. Int. J. Fluid Power 2009, 10, 73–82. [Google Scholar] [CrossRef]

- Linjama, M.; Huova, M.; Vilenius, M. Online Minimization of Power Losses in Distributed Digital Hydraulic Valve System. In Proceedings of the 6th International Fluid Power Conference Dresden, Dresden, Germany, 1–2 April 2008; Volume 1, pp. 157–171. [Google Scholar]

- Huova, M.; Karvonen, M.; Ahola, V.; Linjama, M.; Vilenius, M. Energy Efficient Control of Multiactuator Digital Hydraulic Mobile Machine. In Proceedings of the 7th International Fluid Power Conference, Aachen, Germany, 22–24 March 2010; Volume 1, pp. 25–36. [Google Scholar]

- Linjama, M.; Hopponen, V.; Ikonen, A.; Rintamäki, P.; Vilenius, M.; Pietola, M. Design and Implementation of Digital Hydraulic Synchronization and Force Control System. In Proceedings of the 11th Scandinavian International Conference on Fluid Power SICFP’09, Linköping, Sweden, 2–4 June 2009. 13p. [Google Scholar]

- Hopponen, V.; Linjama, M.; Ikonen, A.; Rintamäki, P.; Pietola, M.; Vilenius, M. Energy Efficient Digital Hydraulic Force Control. In Proceedings of the 11th Scandinavian International Conference on Fluid Power SICFP’09, Linköping, Sweden, 2–4 June 2009. 11p. [Google Scholar]

- Linjama, M.; Karvonen, M. Digital Microhydraulics. In Proceedings of the First Workshop on Digital Fluid Power, Tampere, Finland, 3 October 2008; Linjama, M., Laamanen, A., Eds.; pp. 141–152. [Google Scholar]

- Linjama, M.; Huova, M.; Karhu, O.; Huhtala, K. Energy Efficient Tracking Control of a Mobile Machine Boom Mockup. In Proceedings of the Eighth Workshop on Digital Fluid Power, Tampere, Finland, 24–25 May 2016. [Google Scholar]

- Pugh, B. The Hydraulic Age—Public Power Supplies before Electricity; Mechanical Engineering Publications Ltd.: London, UK, 1980; 176p. [Google Scholar]

- Lambeck, R.P. Hydraulic Pumps and Motors: Selection and Application for Hydraulic Power Control Systems; Dekker: New York, NY, USA, 1983; 154p. [Google Scholar]

- Moorhead, J.R. Saving Energy with “Digital” Pump Systems. Mach. Des. 1984, 56, 40–44. [Google Scholar]

- Rampen, W.H.S.; Salter, S.H. The Digital Displacement Hydraulic Piston Pump. In Proceedings of the 9th International Symposium on Fluid Power, Cambridge, UK, 25–27 April 1990; BHR Group: Cambridge, UK, 1990; pp. 33–46. [Google Scholar]

- Ehsan, M.; Rampen, W.H.S.; Salter, S.H. Modeling of Digital-Displacement Pump-Motors and Their Application as Hydraulic Drives for Nonuniform Loads. Asme J. Dyn. Syst. Meas. Control 2000, 122, 210–215. [Google Scholar] [CrossRef]

- Payne, G.S.; Kiprakis, A.E.; Ehsan, M.; Rampen, W.H.S.; Chick, J.P.; Wallace, A.R. Efficiency and Dynamic Performance of Digital DisplacementTM Hydraulic Transmission in Tidal Current Energy Converters. Proc. Inst. Mech. Eng. Part A 2007, 221, 207–218. [Google Scholar] [CrossRef]

- Tammisto, J.; Huova, M.; Heikkilä, M.; Linjama, M.; Huhtala, K. Measured Characteristics of an In-Line Pump with Independently Controlled Pistons. In Proceedings of the 7th International Fluid Power Conference, Aachen, Germany, 22–24 March 2010; Volume 1, pp. 361–372. [Google Scholar]

- Lumkes, J.; Batdorff, M.; Mahrenholz, J. Characterization of Losses in Virtually Variable Displacement Pumps. Int. J. Fluid Power 2009, 10, 17–27. [Google Scholar] [CrossRef]

- Merril, K.J.; Lumkes, J.H., Jr. Operating Strategies and Valve Requirements for Digital Pump/Motors. In Proceedings of the 6th FPNI—PhD Symposium, West Lafayette, IN, USA, 15–19 June 2010; pp. 249–258. [Google Scholar]

- Huova, M.; Laamanen, A. Control of Three-Chamber Cylinder with Digital Valve System. In Proceedings of the Second Workshop on Digital Fluid Power, Linz, Austria, 12–13 November 2009; Scheidl, R., Winkler, B., Eds.; pp. 94–105. [Google Scholar]

- Linjama, M.; Vihtanen, H.-P.; Sipola, A.; Vilenius, M. Secondary Controlled Multi-Chamber Hydraulic Cylinder. In Proceedings of the 11th Scandinavian International Conference on Fluid Power SICFP’09, Linköping, Sweden, 2–4 June 2009. 15p. [Google Scholar]

- De Gier, G. Hydraulic Cylinder for Use in a Hydraulic Tool. Patent EP1580437, 15 September 2004. [Google Scholar]

- Bishop, E.D. Digital Hydraulic Transformer—Approaching Theoretical Perfection in Hydraulic Drive Efficiency. In Proceedings of the Ninth Scandinavian International Conference on Fluid Power, Linköping, Sweden, 2–4 June 2009. 19p. [Google Scholar]

- Linjama, M.; Huhtala, K. Digital pump-motor with independent outlets. In Proceedings of the 11th Scandinavian International Conference on Fluid Power SICFP’09, Linköping, Sweden, 2–4 June 2009. 16p. [Google Scholar]

- Linjama, M.; Tammisto, J. New Alternative for Digital Pump-Motor Transformer. In Proceedings of the Second Workshop on Digital Fluid Power, Linz, Austria, 12–13 November 2009; Scheidl, R., Winkler, B., Eds.; pp. 49–61. [Google Scholar]

- Heikkilä, M.; Tammisto, J.; Huova, M.; Huhtala, K.; Linjama, M. Experimental Evaluation of a Piston-Type Digital Pump-Motor-Transformer with Two Independent Outlets. In Proceedings of the Fluid Power and Motion Control (FPMC 2010), Bath, UK, 15–17 September 2010; Johnston, D.N., Plummer, A., Eds.; pp. 83–97. [Google Scholar]

- Heikkilä, M.; Tammisto, J.; Linjama, M.; Huhtala, K. Digital Hydraulic Power Management System—Measured Characteristics of a Second Prototype. In Proceedings of the Eighth Workshop on Digital Fluid Power, Tampere, Finland, 24–25 May 2016. [Google Scholar]

- Ersfolk, J.; Boström, P.; Timonen1, V.; Westerholm1, J.; Wiik, J.; Karhu, O.; Linjama, M.; Waldén, M. Optimal Digital Valve Control Using Embedded, GPU. In Proceedings of the Eighth Workshop on Digital Fluid Power, Tampere, Finland, 24–25 May 2016. [Google Scholar]

- Ballard, R.L. System for Minimizing Skidding. U.S. Patent No 3528708, 18 February 1968. [Google Scholar]

- Wennmacher, G. Untersuchung und Anwendung Schnellschaltender Elektrohydraulischer Ventile für den Einsatz in Kraftfahrzeugen. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 1995. [Google Scholar]

- Seilly, A.H. Helenoid Actuators—A New Definition in Extremely Fast Acting Solenoids. SAE Paper, 790119; SAE International: Warrendale, PA, USA, 1979. [Google Scholar]

- Seilly, A.H. Colenoid Actuators-Further Developments in Extremely Fast Acting Solenoids. SAE Paper, 810462; SAE International: Warrendale, PA, USA, 1979. [Google Scholar]

- Beck, N.J.; Barkhimer, R.L.; Calkins, M.A.; Johnson, W.P.; Weseloh, W.E. Direct Digital Control of Electronic Unit Injectors, SAE 840273; SAE International: Warrendale, PA, USA, 1979; pp. 21332–21340. [Google Scholar]

- Tanaka, H. Digital Control and Application of Hydraulic and Pneumatic; Chongqing University Press: Chongqing, China, 1992. [Google Scholar]

- Tanaka, H. Research on high speed electromagnetic on-off valve. Transaclions Jsme 1984, 50, 1594–1601. [Google Scholar] [CrossRef]

- Tanaka, H. Digital control and its application. Oil Air Compression Design. 1984, 22, 16–23. [Google Scholar]

- Tanaka, H.; Tanaka, H.; Araki, K. Digital control of three-way high-speed solenoid valve. Trans. Jsme (B) 1984, 50, 2663–2666. [Google Scholar] [CrossRef]

- Zou, Z. Research on 2D Digital Valve and Electromechanical Converter. Master’s Thesis, Zhejaing University of Technology, Hangzhou, China, 2010. [Google Scholar]

- Florian, M.; Rudolf, S. Development and Experimental Results of a Small Fast Switching Valve Derived from Fuel Injection Technology. In Proceedings of the Eighth Workshop on Digital Fluid Power, Tampere, Finland, 24–25 May 2016. [Google Scholar]

- Paloniitty, M.; Matti, L.; Huhtala, K. Durability Study on High Speed Water Hydraulic Miniature On/Off-Valve. In Proceedings of the Eighth Workshop on Digital Fluid Power, Tampere, Finland, 24–25 May 2016. [Google Scholar]

- Rannow, M.B.; Li, P.Y.; Chase, T.R. Discrete Piston Pump/Motor Using a Mechanical Rotary Valve Control Mechanism. In Proceedings of the Eighth Workshop on Digital Fluid Power, Tampere, Finland, 24–25 May 2016. [Google Scholar]

- Ouyang, X.; Yang, H.Y.; Jiang, H.; Xu, B. Simulation of the Piezoelectric High-speed on/off Valve. Chin. Sci. Bull. 2008, 53, 2706–2711. [Google Scholar] [CrossRef]

- Liu, P.; Fan, L.; Hayat, Q.; Xu, D.; Ma, X.; Song, E. Research on Key Factors and Their Interaction Effects of Electromagnetic Force of High-Speed Solenoid Valve. Sci. World J. 2014, 2014, 567242. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Ruan, J.; Nie, W. Dynamic response analysis of high-speed locking valve. J. Mech. Electr. Eng. 2008, 25, 69–72. [Google Scholar] [CrossRef]

- Plöckinger, A.; Scheidl, R.; Winkler, B. Performance, Durability and Applications of a Fast Switching Valve. In Proceedings of the Second Workshop on Digital Fluid Power, Linz, Austria, 12–13 November 2009; Scheidl, R., Winkler, B., Eds.; pp. 129–143. [Google Scholar]

- Zöppig, V.; Neumann, K. Switching Magnetic Valve Electronics. In Proceedings of the 7th International Fluid Power Conference (7th IFK), Aachen, Germany, 22–24 March 2010; Volume 2, pp. 407–418. [Google Scholar]

- Zhong, Q.; Zhang, B.; Yang, H.; Ma, J.; Fung, R. Performance analysis of a high-speed on/off valve based on an intelligent pulse-width modulation control. Adv. Mech. Eng. 2017, 9. [Google Scholar] [CrossRef]

- Peng, S. The Definition of a Zero-Flowrate-Switching Controller. In Proceedings of the Eighth Workshop on Digital Fluid Power, Tampere, Finland, 24–25 May 2016. [Google Scholar]

- Sauer-Danfoss. PVE Series 4 for PVG 32, PVG 100 and PVG 120, Technical Information. In Sauer-Danfoss Brochure No 520L0553 Rev EA; Sauer-Danfoss: Ames, IA, USA, 2010; 32p. [Google Scholar]

- Becker, U. The Behavior of a Position Controlled Actuator with Switching Valves. In Proceedings of the Fourth Scandinavian International Conference on Fluid Power, Tampere, Finland, 26–29 September 1995; pp. 160–167. [Google Scholar]

- Muto, T.; Yamada, H.; Tsuchiya, S. A Precision Driving System Composed of a Hydraulic Cylinder and High-Speed ON/OFF Valves. In Proceedings of the 49th National Conference on Fluid Power, Las Vegas, NV, USA, 19–21 March 2002; pp. 627–638. [Google Scholar]

- Roemer, D.B.; Norgaard, C.; Bech, M.M.; Johansen, P. Valve and Manifold Considerations for Efficient Digital Hydraulic Machines. In Proceedings of the Eighth Workshop on Digital Fluid Power, Tampere, Finland, 24–25 May 2016. [Google Scholar]

- Helmus, T.; Breidi, F.J., Jr. Simulation of a Variable Displacement Mechanically Actuated Digital Pump Unit. In Proceedings of the Eighth Workshop on Digital Fluid Power, Tampere, Finland, 24–25 May 2016. [Google Scholar]

- Zhang, B.; Hong, H.; Zhong, Q.; Guan, R.; Yang, H. A Pilot Control Method for a Variable Displacement Axial Piston Pump Using Switching Technology. In Proceedings of the Eighth Workshop on Digital Fluid Power, Tampere, Finland, 24–25 May 2016. [Google Scholar]

- Haas, R.; Hinterbichler, C.; Lukachev, E.; Schoberl, M. Optimal Digital Hydraulic Feed-forward Control Applied to Simple Cylinder Drives. In Proceedings of the Eighth Workshop on Digital Fluid Power, Tampere, Finland, 24–25 May 2016. [Google Scholar]

- Scheidl, R.; Riha, G. Energy Efficient Switching Control by a Hydraulic Resonance-Converter. In Proceedings of the Workshop on Power Transmission and Motion Control (PTMC 1999), Bath, UK, 8–11 September 1999; Burrows, C.R., Edge, K.A., Eds.; pp. 267–273. [Google Scholar]

- Scheidl, R.; Mikota, G. The Role of Resonance in Elementary Hydraulic Switching Control. Proc. Inst. Mech. Eng. Part I 2003, 217, 469–480. [Google Scholar] [CrossRef]

- Nostrani, M.P.; Galloni, A.; Raduenz, H.; De Negri, V.J. Theoretical and Experimental Analysis of a Hydraulic Step-Down Switching Converterfor Position and Speed Control. In Proceedings of the Eighth Workshop on Digital Fluid Power, Tampere, Finland, 24–25 May 2016. [Google Scholar]

- Shi, G.; Lee, B.; Yang, L. On the Control Strategy for Pneumatic Robot Driven by High Speed Solenoid On/OFF Valves above Rough Ground. In Proceedings of the Eighth Workshop on Digital Fluid Power, Tampere, Finland, 24–25 May 2016. [Google Scholar]

- Liu, B. The Study of Exactly Congtrol Stepping Motor. Master’s Thesis, Shandong University, Jinan, China, 2010. [Google Scholar]

- Trostmann, E. Water Hydraulics Control Technology; Danfoss: Nordborg, Denmark, 1996. [Google Scholar]

- Koskinen, K.T.; Vilenius, M.J.; Virvalo, T. Water as a pressure medium in position servo systems. In Proceedings of the Forth Scandinavian International Conference on Fluid Power, Tampere, Finland, 26–29 September 1995. [Google Scholar]

- Urata, E.; Miyakawa, S.; Yamashina, C.; Nakao, Y.; Usami, Y.; Shinoda, M. Development of a water hydraulic servovalve. Jsme Int. J. Ser. B 1998, 41, 286–294. [Google Scholar] [CrossRef][Green Version]

- Zhang, Q. Research on the Static and Dynamic Characteristics of the 2D Digital Valve and Compensation of the Dead Zone Nonlinear. Master’s Thesis, Zhejiang University of Technology, Hangzhou, China, 2011. [Google Scholar]

- Li, S.; Ruan, J.; Meng, B. Dither Compensation Technology for Hysteresis of 2D Digital Valve. Trans. Chin. Soc. Agric. Mach. 2012, 42, 208–218. [Google Scholar]

- Katakura, H.; Yamane, R.; Takenka, T. Fundamental research on digital positioning by several hydraulic cylinder and a microcomputer. J. Jpn. Hydraul. Pneum. Soc. 1991, 22, 63–70. [Google Scholar]

- Yang, S. Unusual Hydraulic Synchronization and By-talking Experience on Innovation. Hydraul. Pneum. Seals 2015. [Google Scholar] [CrossRef]

- Yang, T. Talking about the Digital Hydraulic by YIMEIBO. Hydraul. Pneum. Seals 2017, 37, 16–19. [Google Scholar]

- Aemetec Co. Ltd. [EB/OL]. Available online: http://www.china-hydraulic.com/ (accessed on 17 October 2019).

- Huova, M.; Plöckinger, A. Improving Resolution of Digital Hydraulic Valve System by Utilizing Fast Switching Valves. In Proceedings of the Third Workshop on Digital Fluid Power, Tampere, Finland, 13–14 October 2010; Laamanen, A., Linjama, M., Eds.; pp. 79–92. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Kong, X.; Yu, B.; Ba, K.; Jin, Z.; Kang, Y. Review and Development Trend of Digital Hydraulic Technology. Appl. Sci. 2020, 10, 579. https://doi.org/10.3390/app10020579

Zhang Q, Kong X, Yu B, Ba K, Jin Z, Kang Y. Review and Development Trend of Digital Hydraulic Technology. Applied Sciences. 2020; 10(2):579. https://doi.org/10.3390/app10020579

Chicago/Turabian StyleZhang, Qiwei, Xiangdong Kong, Bin Yu, Kaixian Ba, Zhengguo Jin, and Yan Kang. 2020. "Review and Development Trend of Digital Hydraulic Technology" Applied Sciences 10, no. 2: 579. https://doi.org/10.3390/app10020579

APA StyleZhang, Q., Kong, X., Yu, B., Ba, K., Jin, Z., & Kang, Y. (2020). Review and Development Trend of Digital Hydraulic Technology. Applied Sciences, 10(2), 579. https://doi.org/10.3390/app10020579