Design and Application of Cellular Concrete on a Mexican Residential Building and Its Influence on Energy Savings in Hot Climates: Projections to 2050

Featured Application

Abstract

1. Introduction

1.1. Lightweight Construction Materials

1.2. Impact of Lightened Materials on the Thermal Performance of Buildings

1.3. Hot Climate Energy Requirements and Codes

1.4. Energy Use Increase Due to Climate Change

1.5. Assessment and Early Design Strategies in Residential Buildings to Mitigate Climate Change

2. Materials and Methods

2.1. Experimental Method

2.1.1. Theoretical Design of a Cellular Concrete Mixture.

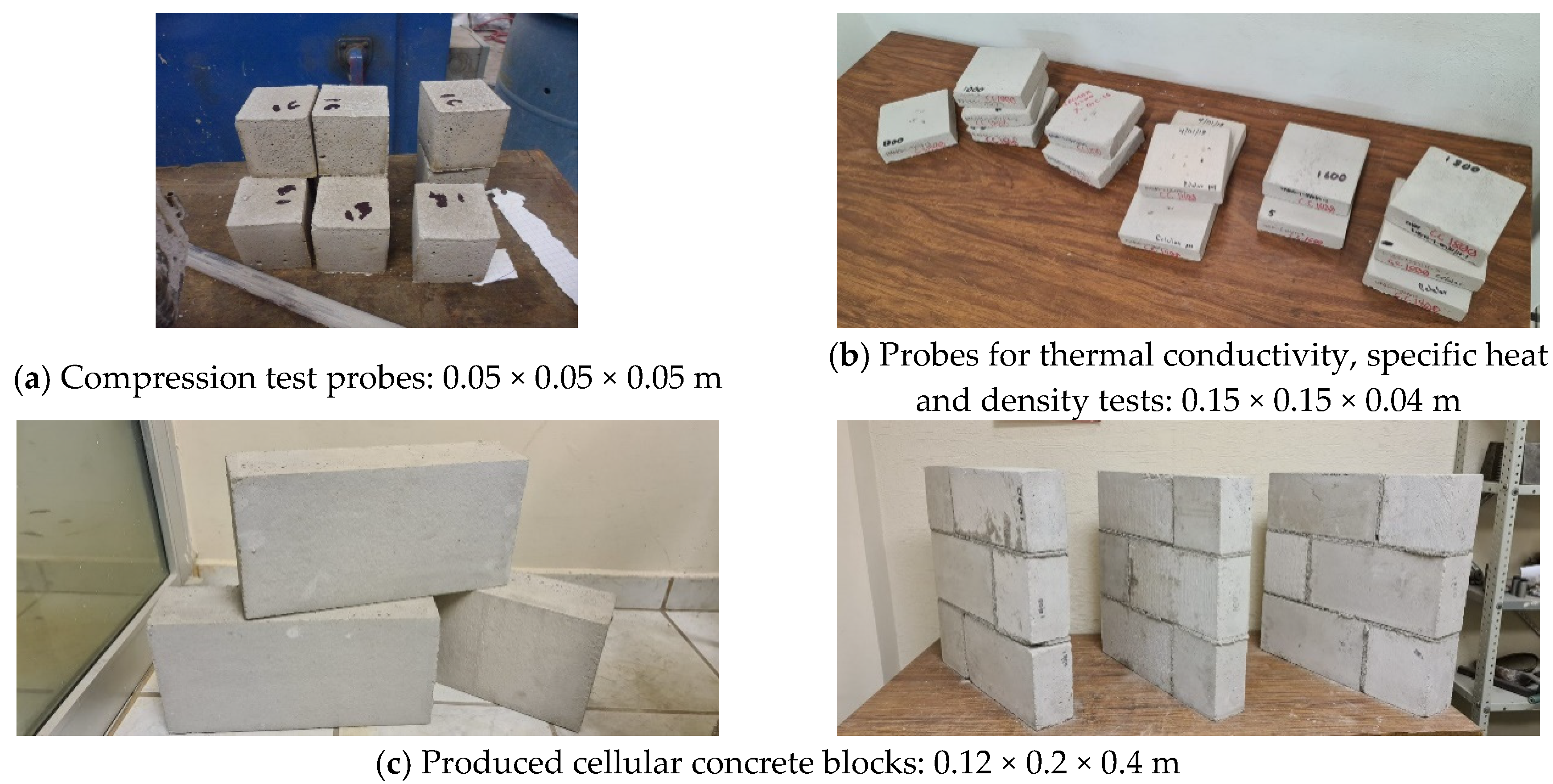

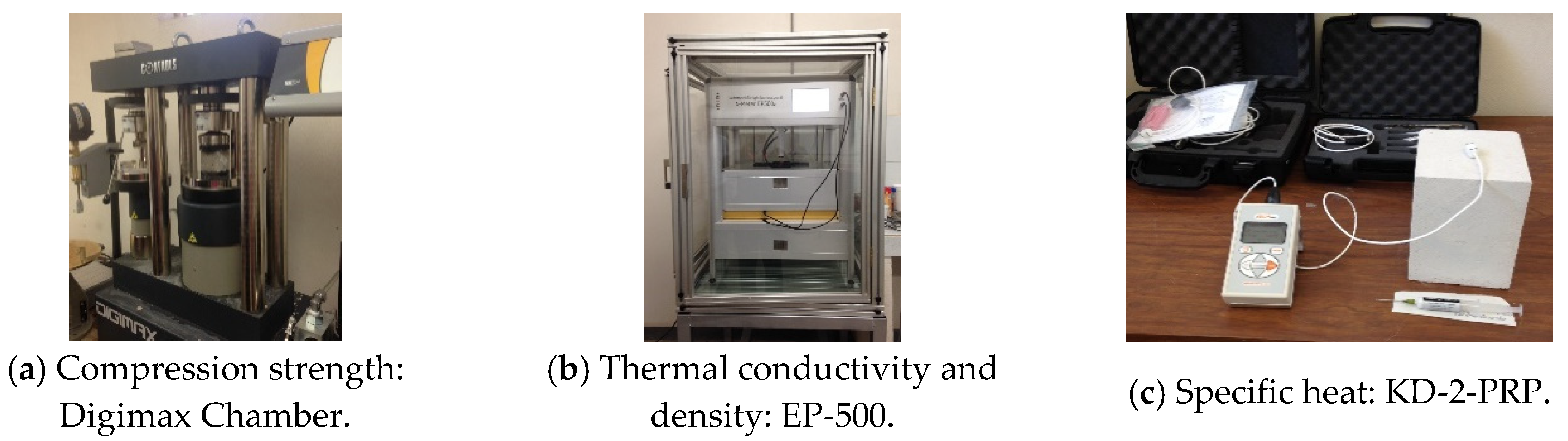

2.1.2. Manufacture of Samples and Construction Components

2.1.3. Measurement of Thermophysical Properties in the Dry State

2.2. Dynamic Simulation

2.2.1. Physical Model of the House and Location

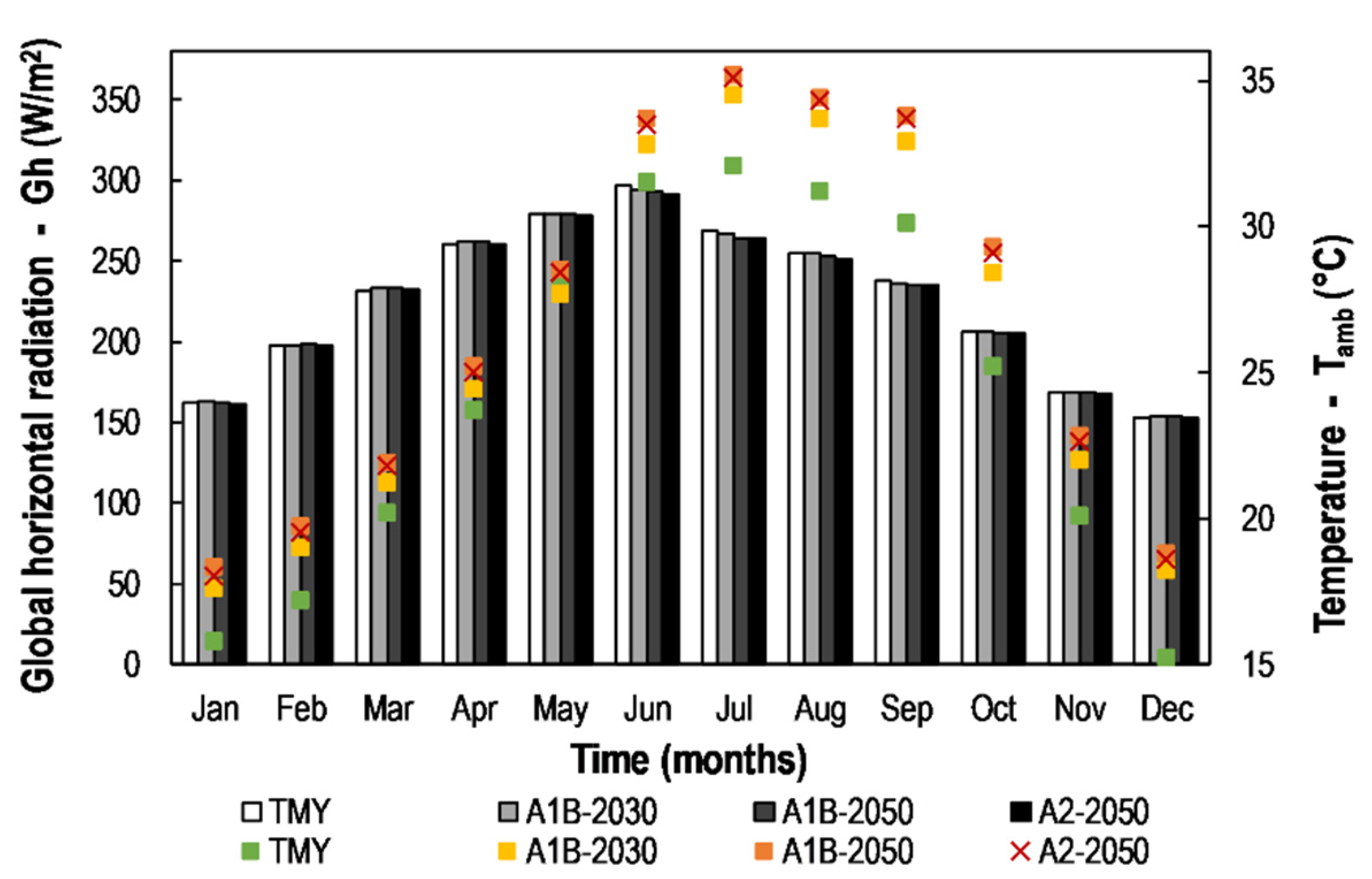

2.2.2. Climatic Conditions of the Arid Weather

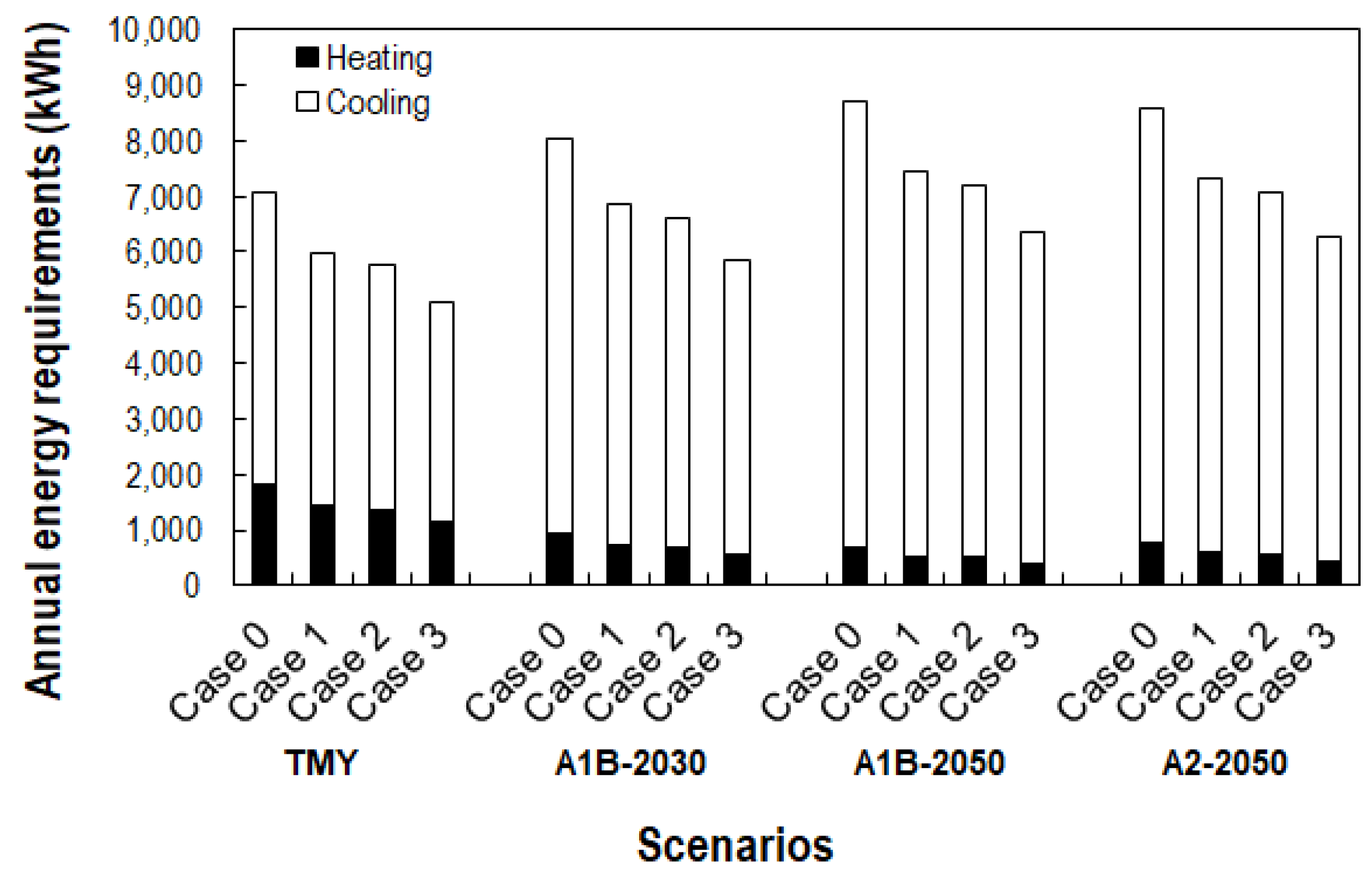

2.3. Case Studies

3. Results

3.1. Thermophysical Properties

3.2. Dynamic Simulations

3.2.1. Indoor Temperatures

3.2.2. Thermal Comfort

3.2.3. Annual Energy Demand

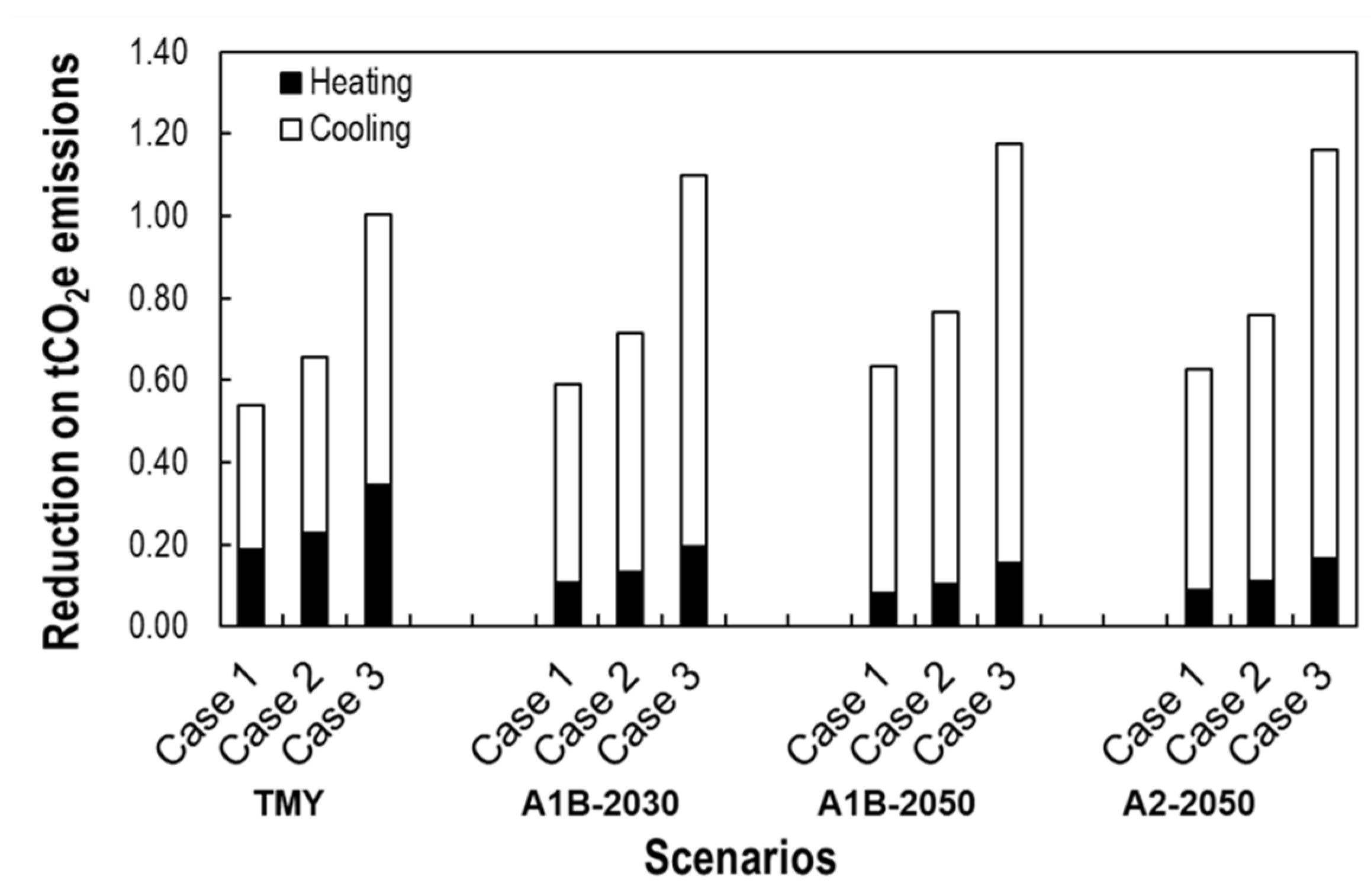

3.2.4. Reduction of Annual tCO2e Emissions

4. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ye, B.; Jiang, J.; Liu, J.; Zheng, Y.; Zhou, N. Research on quantitative assessment of climate change risk at an urban scale: Review of recent progress and outlook of future direction. Renew. Sustain. Energy Rev. 2021, 135, 110415. [Google Scholar] [CrossRef]

- Kang, J.N.; Wei, Y.M.; Liu, L.C.; Han, R.; Yu, B.Y.; Wang, J.W. Energy systems for climate change mitigation: A systematic review. Appl. Energy 2020, 263, 114602. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Urge-Vorsatz, D.; McNeil, M.A.; Barreneche, C.; Serrano, S. Investigating greenhouse challenge from growing trends of electricity consumption through home appliances in buildings. Renew. Sustain. Energy Rev. 2014, 36, 188–193. [Google Scholar] [CrossRef]

- Arreortua, L.A.S.; Montaño, A.M.P. Social housing and habitability in the periphery of metropolitan area of the valley of Mexico. Rev. Geogr. Norte Gd. 2020, 76, 51–69. [Google Scholar]

- Gomez, C.G.; Morales, G.B.; Torres, P.R. Sensación térmica percibida en vivienda económica y auto-producida, en periodo cálido, para clima cálido húmedo. Ambient. Constr. 2011, 11, 99–111. [Google Scholar] [CrossRef]

- Martínez-Montejo, S.A.; Sheinbaum-Pardo, C. The impact of energy efficiency standards on residential electricity consumption in Mexico. Energy Sustain. Dev. 2016, 32, 50–61. [Google Scholar] [CrossRef]

- McNeil, M.; Castellanos, S.; De Leon Barido, D.P.; Peréz, P.A.S. Mexico Space Cooling Electricity Impacts and Mitigation Strategies: Analysis Supporting the Summit on Space Cooling Research Needs and Opportunities in Mexico February 15–16 Casa de la Universidad de California, Mexico City; USAID: Washington, DC, USA, 2018. [Google Scholar]

- CONAVI—Comisión Nacional de Vivienda México. Código de Edificación de Vivienda; CONAVI: Ciudad de México, Mexico, 2010. [Google Scholar]

- Essid, N.; Eddhahak-Ouni, A.; Neji, J. Experimental and Numerical Thermal Properties Investigation of Cement-Based Materials Modified with PCM for Building Construction Use. J. Archit. Eng. 2020, 26, 04020018. [Google Scholar] [CrossRef]

- Nshimiyimana, P.; Messan, A.; Courard, L. Physico-mechanical and hygro-thermal properties of compressed earth blocks stabilized with industrial and agro by-product binders. Materials 2020, 13, 3769. [Google Scholar] [CrossRef]

- Iștoan, R.; Tămaș-Gavrea, D.R.; Manea, D.L. Experimental investigations on the performances of composite building materials based on industrial crops and volcanic rocks. Crystals 2020, 10, 102. [Google Scholar] [CrossRef]

- Kan, A.; Demirboǧa, R. A novel material for lightweight concrete production. Cem. Concr. Compos. 2009, 31, 489–495. [Google Scholar] [CrossRef]

- Chen, Y.X.; Wu, F.; Yu, Q.; Brouwers, H.J.H. Bio-based ultra-lightweight concrete applying miscanthus fibers: Acoustic absorption and thermal insulation. Cem. Concr. Compos. 2020, 114, 103829. [Google Scholar] [CrossRef]

- HEBEL Technical Sheet: Hebel. Available online: https://www.hebel.mx/pdf/fichas-tecnicas/v08.20/Block Solido Ficha Tecnica-v08.20.pdf (accessed on 17 November 2020).

- Shah, S.N.; Mo, K.H.; Yap, S.P.; Yang, J.; Ling, T.C. Lightweight foamed concrete as a promising avenue for incorporating waste materials: A review. Resour. Conserv. Recycl. 2021, 164, 105103. [Google Scholar] [CrossRef]

- Saheed, S.; Amran, Y.H.M.; El-Zeadani, M.; Aziz, F.N.A.; Fediuk, R.; Alyousef, R.; Alabduljabbar, H. Structural behavior of out-of-plane loaded precast lightweight EPS-foam concrete C-shaped slabs. J. Build. Eng. 2021, 33, 101597. [Google Scholar] [CrossRef]

- Zhou, Y.; Gong, G.; Huang, Y.; Chen, C.; Huang, D.; Chen, Z.; Guo, M. Feasibility of incorporating recycled fine aggregate in high performance green lightweight engineered cementitious composites. J. Clean. Prod. 2021, 280, 124445. [Google Scholar] [CrossRef]

- Kadela, M.; Kukiełka, A.; Małek, M. Characteristics of Lightweight Concrete Based on a Synthetic Polymer Foaming Agent. Materials 2020, 13, 4979. [Google Scholar] [CrossRef] [PubMed]

- Wagh, C.D.; Ranjani, G.; Kamisetty, A. Thermal Properties of Foamed Concrete: A Review. In Proceedings of the 3rd International Conference on Innovative Technologies for Clean and Sustainable Development, Chandigarh, India, 19–21 February 2020. [Google Scholar]

- Font, A.; Soriano, L.; Tashima, M.M.; Monzó, J.; Borrachero, M.V.; Payá, J. One-part eco-cellular concrete for the precast industry: Functional features and life cycle assessment. J. Clean. Prod. 2020, 269, 122203. [Google Scholar] [CrossRef]

- Sodangi, M.; Kazmi, Z.A. Integrated evaluation of the impediments to the adoption of coconut palm wood as a sustainable material for building construction. Sustainability 2020, 12, 7676. [Google Scholar] [CrossRef]

- Negro, E.; D’Amato, M.; Cardinale, N. Non-invasive Methods for Energy and Seismic Retrofit in Historical Building in Italy. Front. Built Environ. 2019, 5, 125. [Google Scholar] [CrossRef]

- Gandage, A.S.; Rao, V.R.V.; Sivakumar, M.V.N.; Vasan, A.; Venu, M.; Yaswanth, A.B. Effect of Perlite on Thermal Conductivity of Self Compacting Concrete. Procedia Soc. Behav. Sci. 2013, 104, 188–197. [Google Scholar] [CrossRef]

- Universal Technologies Concellmex S.A. DE C.V. Universal Technologies Concellmex Webpage. Available online: http://concellmex.com.mx/ (accessed on 17 November 2020).

- Font, A.; Borrachero, M.V.; Soriano, L.; Monzó, J.; Mellado, A.; Payá, J. New eco-cellular concretes: Sustainable and energy-efficient materials. Green Chem. 2018, 20, 4684–4694. [Google Scholar] [CrossRef]

- Bardenhagen, S.G.; Brydon, A.D.; Guilkey, J.E. Insight into the physics of foam densification via numerical simulation. J. Mech. Phys. Solids 2005, 53, 597–617. [Google Scholar] [CrossRef]

- Chica, L.; Alzate, A. Cellular concrete review: New trends for application in construction. Constr. Build. Mater. 2019, 200, 637–647. [Google Scholar] [CrossRef]

- Shafigh, P.; Asadi, I.; Akhiani, A.R.; Mahyuddin, N.B.; Hashemi, M. Thermal properties of cement mortar with different mix proportions. Mater. Constr. 2020, 70, 1–12. [Google Scholar] [CrossRef]

- Prusty, J.K.; Patro, S.K.; Basarkar, S.S. Concrete using agro-waste as fine aggregate for sustainable built environment—A review. Int. J. Sustain. Built Environ. 2016, 5, 312–333. [Google Scholar] [CrossRef]

- Eiras, J.N.; Segovia, F.; Borrachero, M.V.; Monzó, J.; Bonilla, M.; Payá, J. Physical and mechanical properties of foamed Portland cement composite containing crumb rubber from worn tires. Mater. Des. 2014, 59, 550–557. [Google Scholar] [CrossRef]

- ASTM International. ASTM C1693—11. Standard Specification for Autoclaved Aerated Concrete (AAC); ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- American Concrete Institute. ACI 523.3R-14 Guide for Cellular Concretes above 50 lb/ft 3 (800 kg/m3); American Concrete Institute: Farmington Hills, MI, USA, 2014; p. 17. [Google Scholar]

- Diario Oficial de la Federacion. NOM-018-ENER-2011. Aislantes Térmicos Para Edificaciones. Características y Métodos de Prueba; Secretaria de Energia: Mexico City, Mexico, 2011. [Google Scholar]

- NMX-C-460-ONNCCE-2009. Industria de la Construcción—Aislamiento Térmico—Valor “R” para las Envolventes de Vivienda por Zona Térmica para la República Mexicana—Especificaciones y Verificación; ONNCCE: Mexico City, Mexico, 2009.

- International Organization for Standardization. ISO 10456:2007 Building Materials and Products—Hygrothermal Properties—Tabulated Design Values and Procedures for Determining Declared and Design Thermal Values; International Organization for Standardization: Geneva, Switzerland, 2007; p. 25. [Google Scholar]

- Diario Oficial de la Federacion. NOM-020-ENER-2011. Envolvente de Edificios Para Uso Habitacional; Secretaria de Energia: Mexico City, Mexico, 2011. [Google Scholar]

- Diario Oficial de la Federacion. NOM-008-ENER-2001. Eficiencia Energetica en Edificaciones, Envolvente de Edificios no Residenciales; Secretaria de Energia: Mexico City, Mexico, 2001. [Google Scholar]

- Oropeza-Perez, I.; Ostergaard, P.A. Energy saving potential of utilizing natural ventilation under warm conditions—A case study of Mexico. Appl. Energy 2014, 130, 20–32. [Google Scholar] [CrossRef]

- Comisión Nacional para el Uso Eficiente de la Energía (CONUEE). Estudio de Caracterización del Uso de Aire Acondicionado en Viviendas de Interés Social en México; Secretaria de Energia: Mexico City, Mexico, 2016; p. 80. [Google Scholar]

- de Buen Rodríguez, O.; Hernández-Pérez, F.; Navarrete, J.I. Análisis de la Evolución del Consumo Eléctrico del Sector Residencial Entre 1982 y 2014 e Impactos de Ahorro de Energía por Políticas Públicas; Secretaria de Energia: Mexico City, Mexico, 2016; p. 12. [Google Scholar]

- Zhu, M.; Pan, Y.; Huang, Z.; Xu, P. An alternative method to predict future weather data for building energy demand simulation under global climate change. Energy Build. 2016, 113, 74–86. [Google Scholar] [CrossRef]

- Huld, T.; Paietta, E.; Zangheri, P.; Pascua, I.P. Assembling typical meteorological year data sets for building energy performance using reanalysis and satellite-based data. Atmosphere 2018, 9, 53. [Google Scholar] [CrossRef]

- Hosseini, M.; Bigtashi, A.; Lee, B. Generating future weather files under climate change scenarios to support building energy simulation—A machine learning approach. Energy Build. 2021, 230, 110543. [Google Scholar] [CrossRef]

- Farah, S.; Whaley, D.; Saman, W.; Boland, J. Integrating climate change into meteorological weather data for building energy simulation. Energy Build. 2019, 183, 749–760. [Google Scholar] [CrossRef]

- Pyrgou, A.; Castaldo, V.L.; Pisello, A.L.; Cotana, F.; Santamouris, M. Differentiating responses of weather files and local climate change to explain variations in building thermal-energy performance simulations. Sol. Energy 2017, 153, 224–237. [Google Scholar] [CrossRef]

- Chakraborty, D.; Elzarka, H.; Bhatnagar, R. Generation of accurate weather files using a hybrid machine learning methodology for design and analysis of sustainable and resilient buildings. Sustain. Cities Soc. 2016, 24, 33–41. [Google Scholar] [CrossRef]

- Hong, T.; Chang, W.; Lin, H. A Sensitivity Study of Building Performance Using 30-Year Actual Weather Data. In Proceedings of the 13th Conference of International Building Performance Simulation Association, Chambéry, France, 26–28 August 2013; pp. 1–8. [Google Scholar]

- Taseska, V.; Markovska, N.; Callaway, J.M. Evaluation of climate change impacts on energy demand. Energy 2012, 48, 88–95. [Google Scholar] [CrossRef]

- Clarke, L.; Eom, J.; Marten, E.H.; Horowitz, R.; Kyle, P.; Link, R.; Mignone, B.K.; Mundra, A.; Zhou, Y. Effects of long-term climate change on global building energy expenditures. Energy Econ. 2018, 72, 667–677. [Google Scholar] [CrossRef]

- Cellura, M.; Guarino, F.; Longo, S.; Tumminia, G. Climate change and the building sector: Modelling and energy implications to an office building in southern Europe. Energy Sustain. Dev. 2018, 45, 46–65. [Google Scholar] [CrossRef]

- Wang, H.; Chen, Q. Impact of climate change heating and cooling energy use in buildings in the United States. Energy Build. 2014, 82, 428–436. [Google Scholar] [CrossRef]

- Resch, E.; Andresen, I.; Cherubini, F.; Brattebø, H. Estimating dynamic climate change effects of material use in buildings—Timing, uncertainty, and emission sources. Build. Environ. 2021, 187, 107399. [Google Scholar] [CrossRef]

- Karimpour, M.; Belusko, M.; Xing, K.; Boland, J.; Bruno, F. Impact of climate change on the design of energy efficient residential building envelopes. Energy Build. 2015, 87, 142–154. [Google Scholar] [CrossRef]

- Figueiredo, R.; Nunes, P.; Panão, M.J.N.O.; Brito, M.C. Country residential building stock electricity demand in future climate—Portuguese case study. Energy Build. 2020, 209, 109694. [Google Scholar] [CrossRef]

- Wong, S.L.; Wan, K.K.W.; Li, D.H.W.; Lam, J.C. Impact of climate change on residential building envelope cooling loads in subtropical climates. Energy Build. 2010, 42, 2098–2103. [Google Scholar] [CrossRef]

- Pérez-Andreu, V.; Aparicio-Fernández, C.; Martínez-Ibernón, A.; Vivancos, J.L. Impact of climate change on heating and cooling energy demand in a residential building in a Mediterranean climate. Energy 2018, 165, 63–74. [Google Scholar] [CrossRef]

- Invidiata, A.; Ghisi, E. Impact of climate change on heating and cooling energy demand in houses in Brazil. Energy Build. 2016, 130, 20–32. [Google Scholar] [CrossRef]

- Verichev, K.; Zamorano, M.; Carpio, M. Effects of climate change on variations in climatic zones and heating energy consumption of residential buildings in the southern Chile. Energy Build. 2020, 215, 109874. [Google Scholar] [CrossRef]

- Flores-Larsen, S.; Filippín, C.; Barea, G. Impact of climate change on energy use and bioclimatic design of residential buildings in the 21st century in Argentina. Energy Build. 2019, 184, 216–229. [Google Scholar] [CrossRef]

- Gercek, M.; Arsan, Z.D. Energy and environmental performance based decision support process for early design stages of residential buildings under climate change. Sustain. Cities Soc. 2019, 48, 101580. [Google Scholar] [CrossRef]

- NMX-C-077-ONNCCE-1997: Industria de la Construcción—Agregados para Concreto—Análisis Granulométrico—Método de Prueba; ONNCCE: Mexico City, Mexico, 1997.

- Borbon-Almada, A.; Rodriguez-Muñoz, N.; Najera-Trejo, M. Energy and Economic Impact on the Application of Low-Cost Lightweight Materials in Economic Housing Located in Dry Climates. Sustainability 2019, 11, 1586. [Google Scholar] [CrossRef]

- NMX-C-144-ONNCCE-2015: Industria de la Construcción—Cementantes Hidráulicos—Requisitos Para El Aparato Usado En la Determinación de la Fluidez de Morteros; ONNCCE: Mexico City, Mexico, 2015.

- NMX-C-061-ONNCCE-2015. Industria de la Construcción—Cementantes Hidráulicos—Determinación de la Resistencia a la Compresión de Cementantes Hidráulicos; ONNCCE: Mexico City, Mexico, 2015. [Google Scholar]

- GACETA. Oficial de la Ciudad de México Norma Técnica Complementaria para Mampostería. Reglamento de Construcción del Distrito Federal; Gobierno de la Ciudad de Mexico: Mexico City, Mexico, 2020. [Google Scholar]

- NMX-C-486-ONNCCE-2014: Industria de la Construcción—Mampostería—Mortero para Uso Estructural—Especificaciones y Métodos de Ensayo; ONNCCE: Mexico City, Mexico, 2014.

- ASTM International. ASTM C109/C109M. Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens); ASTM International: West Conshohocken, PA, USA, 2016; p. 10. [Google Scholar]

- International Organization for Standardization. ISO 8302:1991 Thermal Insulation—Determination Of Steady-State Thermal Resistance and Related Properties—Guarded Hot Plate Apparatus; International Organization for Standardization: Geneva, Switzerland, 1991. [Google Scholar]

- ASTM International. ASTM C177—19: Standard Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the Guarded-Hot-Plate Apparatus; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Comite Europeen de Normalisation. EN 1946-2:1999. Thermal Performance of Building Products and Components—Specific Criteria for the Assessment of Laboratories Measuring Heat Transfer Properties—Part 2: Measurements by Guarded Hot Plate Method; Comite Europeen de Normalisation: Brussels, Belgium, 1999. [Google Scholar]

- Asociación Española de Normalización (UNE). UNE-EN 12664:2002: Thermal Performance of Building Materials and Products. Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods. Dry and Moist Products of Medium and Low Thermal Resistance; Asociación Española de Normalización (UNE): Madrid, Spain, 2002. [Google Scholar]

- Asociación Española de Normalización (UNE). UNE-EN 12667:2002. Thermal Performance of Building Materials and Products. Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods. Products of High and Medium Thermal Resistance; Asociación Española de Normalización (UNE): Madrid, Spain, 2002. [Google Scholar]

- Asociación Española de Normalización (UNE). UNE-EN 12939:2001. Thermal Performance of Building Materials and Products—Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Thick Products of High and Medium Thermal Resistance; Asociación Española de Normalización (UNE): Madrid, Spain, 2001. [Google Scholar]

- Deutsches Institut für Normung. DIN 52612-2:1984. Testing of Thermal Insulating Materials. Determination of Thermal Conductivity by Means of the Guarded Hot Plate Apparatus. Conversion of the Measured Values for Building Applications; Deutsches Institut für Normung (DIN): Berlin, Germany, 1984. [Google Scholar]

- ASTM International. ASTM D5334 Standard Test Method for Determination of Thermal Conductivity of Soil and Soft Rock by Thermal Needle Probe Procedure 8; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASHRAE. ASHRAE 55:2004 Thermal Environmental Conditions for Human Occupancy; ASHRAE: Atlanta, GA, USA, 2004; p. 30. [Google Scholar]

- Instituto Nacional de Estadística y Geografía Population Census. Available online: https://www.inegi.org.mx/programas/intercensal/2015/#Tabulados (accessed on 12 November 2020).

- Secretaria de Energia & Banco Mundial. Evaluación Rápida del Uso de la Energía; Secretaria de Energia: Hermosillo, Sonora, Mexico, 2016. [Google Scholar]

- Intergovernmental Panel on Climate Change (IPCC). Special Report Emissions Scenarios: Summary for Policymakers; United Nations Environment Program (UNEP): Nairobi, Kenya, 2000. [Google Scholar]

- Intergovernmental Panel on Climate Change. Special Report on Emission Scenarios; Cambridge University Press: Cambridge, UK, 2000. [Google Scholar]

- Ni, F.M.W.; Averyanov, S.; Melese, E.; Tighe, S. Characterization of lightweight cellular concrete. In Proceedings of the 7th International Material Speciaty Confenrence 2018, Held as Part of the Canadian Society Civil Engineering Annual Conference, Fredericton, NB, Canada, 13–18 June 2018; Volume 1923, pp. 45–55. [Google Scholar]

- Mohd Sari, K.A.; Mohammed Sani, A.R. Applications of Foamed Lightweight Concrete. MATEC Web Conf. 2017, 97, 1–5. [Google Scholar] [CrossRef]

- Comisión Reguladora de Energía. Gobierno de México Factor de emisión del Sistema Eléctrico Nacional 2019. Available online: https://www.gob.mx/cms/uploads/attachment/file/538473/Factor_emision_electrico_2019.pdf (accessed on 17 November 2020).

| Property | Control | C1 | C2 | C3 | C4 | C5 | C6 |

|---|---|---|---|---|---|---|---|

| Mixture density (kg/m3) | 2135 | 1800 | 1600 | 1400 | 1200 | 1000 | 800 |

| Mixture volume (m3) | 1.000 | 0.8432 | 0.7496 | 0.6569 | 0.5622 | 0.4685 | 0.3748 |

| Cement CPC 30R (kg) | 6.225 | 5.243 | 4.661 | 4.078 | 3.495 | 2.913 | 2.330 |

| Sand (kg) | 21.225 | 17.896 | 15.91 | 13.91 | 11.93 | 9.942 | 7.95 |

| Water (kg) | 4.575 | 3.861 | 3.43 | 3.00 | 2.574 | 2.145 | 1.71 |

| Foam (kg) | 0 | 0.141 | 0.22 | 0.31 | 0.39 | 0.478 | 0.563 |

| Fluidity (%) | 106 | 124 | 125 | 125 | 122 | 122 | 122 |

| Global Horizontal Radiation (Gh, W/m2) | Temperatures (°C) | |||||||

|---|---|---|---|---|---|---|---|---|

| TMY | A1B-2030 | A1B-2050 | A2-2050 | TMY | A1B-2030 | A1B-2050 | A2-2050 | |

| Average | 226.55 | 226.37 | 225.62 | 224.74 | 24.15 | 25.99 | 26.75 | 26.59 |

| Maximum | 1206.00 | 1111.00 | 1156.00 | 1124.00 | 42.40 | 46.10 | 45.40 | 46.50 |

| Minimum | ∕ | ∕ | ∕ | ∕ | 3.00 | 4.50 | 5.80 | 5.20 |

| Case | Wall Composition | Mixture (Agreement with Table 1) |

|---|---|---|

| Case 0 | Concrete hollow block | Control |

| Case 1 | Solid cellular block (1800 kg/m3) | C1 |

| Case 2 | Solid cellular block (1600 kg/m3) | C2 |

| Case 3 | Filler cellular material (800 kg/m3) | C6 |

| Property | C1-1800 | C2-1600 | C3-1400 | C4-1200 | C5-1000 | C6-800 |

|---|---|---|---|---|---|---|

| Density (kg/m3) | 1810 | 1610 | 1457 | 1216 | 1065 | 863 |

| Thermal conductivity (W/m·K) | 0.2958 | 0.2517 | 0.2480 | 0.2057 | 0.1682 | 0.1399 |

| Compression strength (kg/cm2) | 88.8 | 77.5 | 54.3 | 18.6 | 10.4 | 8.3 |

| Volumetric specific heat (MJ/(m3·K) | 1.56 | 1.64 | 1.14 | 1.34 | 0.92 | 1.72 |

| Case | Wall Composition | Rvalue (m2·K/W) |

|---|---|---|

| Case 0 | Concrete hollow block | 0.2874 |

| Case 1 | Solid cellular block (1800 kg/m3) | 0.5131 |

| Case 2 | Solid cellular block (1600 kg/m3) | 0.5841 |

| Case 3 | Filler cellular material (800 kg/m3) | 0.9651 |

| Case | TMY | A1B-2030 | A1B-2050 | A2-2050 | |

|---|---|---|---|---|---|

| Average temperatures (Tavg, °C) | Case 0 | 26.32 | 28.04 | 28.80 | 28.61 |

| Case 1 | 26.47 | 28.20 | 28.95 | 28.76 | |

| Case 2 | 26.51 | 28.23 | 28.99 | 28.80 | |

| Case 3 | 26.67 | 28.39 | 29.14 | 28.95 | |

| Maximum temperatures (Tmax, °C) | Case 0 | 39.13 | 41.55 | 42.48 | 41.59 |

| Case 1 | 38.85 | 41.24 | 42.16 | 41.22 | |

| Case 2 | 38.69 | 41.07 | 41.98 | 41.09 | |

| Case 3 | 38.41 | 40.75 | 41.62 | 40.98 | |

| Case 0 | 39.13 | 41.55 | 42.48 | 41.59 | |

| Maximum temperatures (Tmin, °C) | Case 0 | 11.07 | 12.58 | 13.54 | 13.07 |

| Case 1 | 11.77 | 13.25 | 14.24 | 13.74 | |

| Case 2 | 12.01 | 13.52 | 14.49 | 14.00 | |

| Case 3 | 12.62 | 14.18 | 15.10 | 14.65 | |

| Case 0 | 11.07 | 12.58 | 13.54 | 13.07 |

| Case | TMY | A1B-2030 | A1B-2050 | A2-2050 | |

|---|---|---|---|---|---|

| Average PMV | Case 0 | 0.39 | 0.80 | 0.98 | 0.94 |

| Case 1 | 0.43 | 0.84 | 1.02 | 0.98 | |

| Case 2 | 0.44 | 0.85 | 1.03 | 0.99 | |

| Case 3 | 0.48 | 0.89 | 1.07 | 1.02 | |

| Maximum PMV | Case 0 | 3.43 | 3.99 | 4.21 | 4.00 |

| Case 1 | 3.36 | 3.92 | 4.14 | 3.91 | |

| Case 2 | 3.32 | 3.88 | 4.09 | 3.88 | |

| Case 3 | 3.25 | 3.79 | 4.00 | 3.85 | |

| Case 0 | 3.43 | 3.99 | 4.21 | 4.00 | |

| Maximum PMV | Case 0 | −3.42 | −3.03 | −2.78 | −2.90 |

| Case 1 | −3.24 | −2.85 | −2.60 | −2.73 | |

| Case 2 | −3.18 | −2.78 | −2.53 | −2.66 | |

| Case 3 | −3.01 | −2.61 | −2.38 | −2.48 | |

| Case 0 | −3.42 | −3.03 | −2.78 | −2.90 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borbon-Almada, A.C.; Lucero-Alvarez, J.; Rodriguez-Muñoz, N.A.; Ramirez-Celaya, M.; Castro-Brockman, S.; Sau-Soto, N.; Najera-Trejo, M. Design and Application of Cellular Concrete on a Mexican Residential Building and Its Influence on Energy Savings in Hot Climates: Projections to 2050. Appl. Sci. 2020, 10, 8225. https://doi.org/10.3390/app10228225

Borbon-Almada AC, Lucero-Alvarez J, Rodriguez-Muñoz NA, Ramirez-Celaya M, Castro-Brockman S, Sau-Soto N, Najera-Trejo M. Design and Application of Cellular Concrete on a Mexican Residential Building and Its Influence on Energy Savings in Hot Climates: Projections to 2050. Applied Sciences. 2020; 10(22):8225. https://doi.org/10.3390/app10228225

Chicago/Turabian StyleBorbon-Almada, Ana C., Jorge Lucero-Alvarez, Norma A. Rodriguez-Muñoz, Manuel Ramirez-Celaya, Samuel Castro-Brockman, Nicolas Sau-Soto, and Mario Najera-Trejo. 2020. "Design and Application of Cellular Concrete on a Mexican Residential Building and Its Influence on Energy Savings in Hot Climates: Projections to 2050" Applied Sciences 10, no. 22: 8225. https://doi.org/10.3390/app10228225

APA StyleBorbon-Almada, A. C., Lucero-Alvarez, J., Rodriguez-Muñoz, N. A., Ramirez-Celaya, M., Castro-Brockman, S., Sau-Soto, N., & Najera-Trejo, M. (2020). Design and Application of Cellular Concrete on a Mexican Residential Building and Its Influence on Energy Savings in Hot Climates: Projections to 2050. Applied Sciences, 10(22), 8225. https://doi.org/10.3390/app10228225