A Scoping Review on Virtual Reality-Based Industrial Training

Abstract

1. Introduction

2. Methodology

2.1. Research Questions

2.2. Document Search

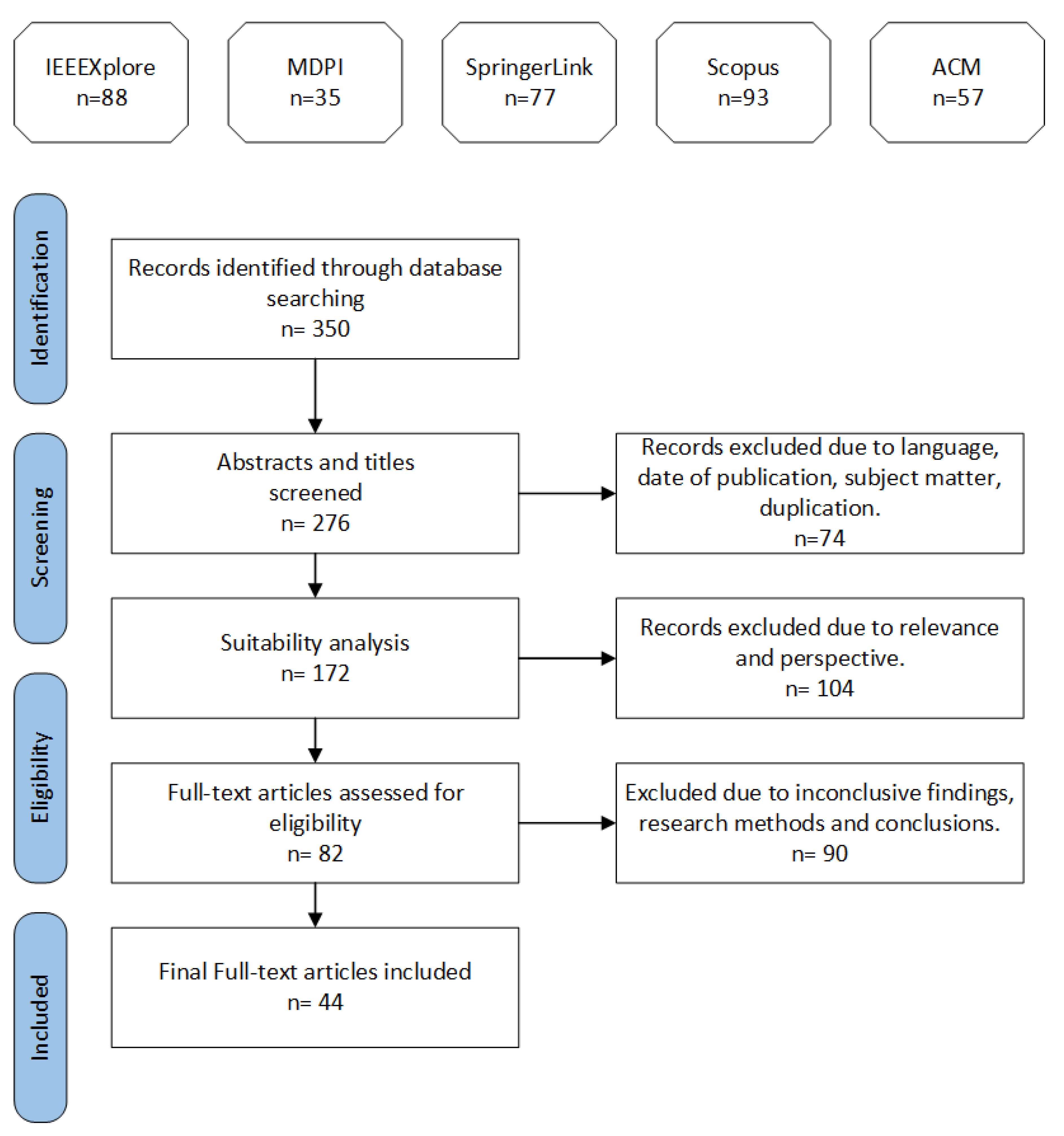

2.3. Paper Selection

2.4. Data Extraction

3. Results

3.1. Literature Review

3.1.1. Non-Industrial Training Based on Virtual Reality

3.1.2. Industrial Training

3.1.3. Industrial Training Based on Virtual Reality

3.2. Paper Selection

4. Discussion

4.1. Research Questions

4.2. Paper Selection Analysis

4.3. VR Challenges

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jaworski, C.; Ravichandran, S.; Karpinski, A.C.; Singh, S. The effects of training satisfaction, employee benefits, and incentives on part-time employees’ commitment. Int. J. Hosp. Manag. 2018, 74, 1–12. [Google Scholar] [CrossRef]

- Moreno, A.; Segura, Á.; Zlatanova, S.; Posada, J.; García-Alonso, A. Benefit of the integration of semantic 3D models in a fire-fighting VR simulator. Appl. Geomat. 2012, 4, 143–153. [Google Scholar] [CrossRef]

- Besbes, B.; Collette, S.N.; Tamaazousti, M.; Bourgeois, S.; Gay-Bellile, V. An interactive Augmented Reality system: A prototype for industrial maintenance training applications. In Proceedings of the 2012 IEEE International Symposium on Mixed and Augmented Reality (ISMAR), Georgia Tech, GA, USA, 5–8 November 2012. [Google Scholar] [CrossRef]

- Segura, Á.; Diez, H.V.; Barandiaran, I.; Arbelaiz, A.; Álvarez, H.; Simões, B.; Posada, J.; García-Alonso, A.; Ugarte, R. Visual computing technologies to support the Operator 4.0. Comput. Ind. Eng. 2020, 139, 105550. [Google Scholar] [CrossRef]

- Romero, D.; Stahre, J.; Taisch, M. The Operator 4.0: Towards socially sustainable factories of the future. Comput. Ind. Eng. 2020, 139, 106128. [Google Scholar] [CrossRef]

- Herrera, D.F.; Bolívar Acosta, S.; Quevedo, W.X.; Balseca, J.A.; Andaluz, V.H. Training for Bus Bodywork in Virtual Reality Environments. In Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer International Publishing: Cham, Switzerland, 2018; Volume 10850, pp. 67–85. [Google Scholar] [CrossRef]

- Garcia, C.; Naranjo, J.; Ortiz, A.; Garcia, M. An Approach of Virtual Reality Environment for Technicians Training in Upstream Sector; IFAC-PapersOnLine; Elsevier B.V.: Frankfurt, Germany, 2019; Volume 52. [Google Scholar] [CrossRef]

- Cýrus, J.; Krčmařík, D.; Petrů, M.; Kočí, J. Cooperation of Virtual Reality and Real Objects with HoloLens. Adv. Comput. Vis. 2020, 94–106. [Google Scholar] [CrossRef]

- Dixken, M.; Diers, D.; Wingert, B.; Hatzipanayioti, A.; Mohler, B.J.; Riedel, O.; Bues, M. Distributed, Collaborative Virtual Reality Application for Product Development with Simple Avatar Calibration Method. In Proceedings of the 2019 IEEE Conference on Virtual Reality and 3D User Interfaces (VR), Osaka, Japan, 23–27 March 2019; pp. 1299–1300. [Google Scholar] [CrossRef]

- Naranjo, J.E.; Ayala, P.; Altamirano, S.; Brito, G.; Garcia, M.V. Intelligent Oil Field Approach Using Virtual Reality and Mobile Anthropomorphic Robots. In Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer International Publishing: Cham, Switzerland, 2018; Volume 10851, pp. 467–478. [Google Scholar] [CrossRef]

- Naranjo, J.; Lozada, E.; Espín, H.; Beltran, C.; García, C.; García, M. Flexible Architecture for Transparency of a Bilateral Tele-Operation System implemented in Mobile Anthropomorphic Robots for the Oil and Gas Industry. IFAC-PapersOnLine 2018, 51. [Google Scholar] [CrossRef]

- Andaluz, V.H.; Pazmiño, A.; Perez, J.; Carvajal, C. Training of Tannery Processes Through Virtual Reality. In Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer International Publishing: Cham, Switzerland, 2017; Volume 2, pp. 75–93. [Google Scholar] [CrossRef]

- Andaluz, V.; Sanchez, J.; Sanchez, C.; Quevedo, W.; Varela, J.; Morales, J.; Cuzco, G. Multi-user Industrial Training and Education Environment. In Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer International Publishing: Cham, Switzerland, 2018; pp. 533–546. [Google Scholar]

- Garcia, C.A.; Naranjo, J.E.; Alvarez-M, E.; Garcia, M.V. Training virtual environment for teaching simulation and control of pneumatic systems. In Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer International Publishing: Cham, Switzerland, 2019; Volume 11613 LNCS, pp. 91–104. [Google Scholar]

- Caiza, G.; Garcia, C.A.; Naranjo, J.E.; Garcia, M.V. Flexible robotic teleoperation architecture for intelligent oil fields. Heliyon 2020, 6, e03833. [Google Scholar] [CrossRef]

- Bécue, A.; Maia, E.; Feeken, L.; Borchers, P.; Praça, I. A New Concept of Digital Twin Supporting Optimization and Resilience of Factories of the Future. Appl. Sci. 2020, 10, 4482. [Google Scholar] [CrossRef]

- Pusdá-Chulde, M.R.; Salazar-Fierro, F.A.; Sandoval-Pillajo, L.; Herrera-Granda, E.P.; García-Santillán, I.D.; De Giusti, A. Image Analysis Based on Heterogeneous Architectures for Precision Agriculture: A Systematic Literature Review. In Advances and Applications in Computer Science, Electronics and Industrial Engineering; Advances in Intelligent Systems and Computing; Springer International Publishing: Cham, Switzerland, 2020; Volume 1078, pp. 51–70. [Google Scholar]

- Detmer, F.J.; Hettig, J.; Schindele, D.; Schostak, M.; Hansen, C. Virtual and Augmented Reality Systems for Renal Interventions: A Systematic Review. IEEE Rev. Biomed. Eng. 2017, 10, 78–94. [Google Scholar] [CrossRef]

- Fernandez, A.; Insfran, E.; Abrahão, S. Usability evaluation methods for the web: A systematic mapping study. Inf. Softw. Technol. 2011, 53, 789–817. [Google Scholar] [CrossRef]

- Kurniawan, C.; Rosmansyah, Y.; Dabarsyah, B. A Systematic Literature Review on Virtual Reality for Learning. In Proceedings of the 2019 5th International Conference on Wireless and Telematics, ICWT 2019, Yogyakarta, Indonesia, 25–26 July 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Tricco, A.C.; Lillie, E.; Zarin, W.; O’Brien, K.K.; Colquhoun, H.; Levac, D.; Moher, D.; Peters, M.D.; Horsley, T.; Weeks, L.; et al. PRISMA Extension for Scoping Reviews (PRISMA-ScR): Checklist and Explanation. Ann. Intern. Med. 2018, 169, 467. [Google Scholar] [CrossRef] [PubMed]

- Hoyer, C.; Gunawan, I.; Reaiche, C.H. The Implementation of Industry 4.0—A Systematic Literature Review of the Key Factors. Syst. Res. Behav. Sci. 2020, 37, 557–578. [Google Scholar] [CrossRef]

- Fonseca, L.M. Industry 4.0 and the digital society: Concepts, dimensions and envisioned benefits. Proc. Int. Conf. Bus. Excell. 2018, 12, 386–397. [Google Scholar] [CrossRef]

- Kournaditis, K.; Chinello, F.; Venckute, S. Design of a Virtual Reality and Haptic Setup Linking Arousals to Training Scenarios: A Preliminary Stage. In Proceedings of the 25th IEEE Conference on Virtual Reality and 3D User Interfaces, VR 2018—Proceedings, Reutlingen, Germany, 18–22 March 2018; pp. 613–614. [Google Scholar] [CrossRef]

- Zou, L.; Higuchi, T.; Noma, H.; Roberto, L.G.; Isaka, T. Evaluation of a virtual reality-based baseball batting training system using instantaneous bat swing information. In Proceedings of the 26th IEEE Conference on Virtual Reality and 3D User Interfaces, VR 2019—Proceedings, Osaka, Japan, 23–27 March 2019; pp. 1289–1290. [Google Scholar] [CrossRef]

- Li, J. Design of Sports Training Information Platform Based on Virtual Reality. In Proceedings of the International Conference on Cyber Security Intelligence and Analytics (CSIA 2020), Haikou, China, 28–29 February 2020; pp. 10–17. [Google Scholar]

- Tseng, S.P.; Huang, M.W.; Liu, H.J.; Chung, C.C.; Chiu, C.M. A Virtual Reality Based Training System for Cultural Tourism. In Advances in Web-Based Learning—ICWL 2013 Workshops; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2015; Volume 8390, pp. 272–277. [Google Scholar] [CrossRef]

- Huang, Y.; Churches, L.; Reilly, B. A Case Study on Virtual Reality American Football Training. ACM Int. Conf. Proc. Ser. 2015, 1–5. [Google Scholar] [CrossRef]

- Jia, Y.; Campbell, A.G. Immersive virtual reality training tool for IoT device placement. ACM Int. Conf. Proc. Ser. 2017, 81–86. [Google Scholar] [CrossRef]

- Latoschik, M.E.; Lugrin, J.L.; Habel, M.; Roth, D.; Seufert, C.; Grafe, S. Breaking bad behavior: Immersive training of class room management. In Proceedings of the ACM Symposium on Virtual Reality Software and Technology, VRST, New York, NY, USA, 2 April 2016; pp. 317–318. [Google Scholar] [CrossRef]

- Pellett, K.; Zaidi, S.F.M. A framework for virtual reality training to improve public speaking. Proc. ACM Symp. Virtual Real. Softw. Technol. VRST 2019, 1–2. [Google Scholar] [CrossRef]

- Rajeswaran, P.; Kesavadas, T.; Jani, P.; Kumar, P. AirwayVR: Virtual reality trainer for endotracheal intubation-design considerations and challenges. In Proceedings of the 26th IEEE Conference on Virtual Reality and 3D User Interfaces, VR 2019—Proceedings, Osaka, Japan, 23–27 March 2019; pp. 1130–1131. [Google Scholar] [CrossRef]

- Mathur, A.S. Low cost virtual reality for medical training. In Proceedings of the 2015 IEEE Virtual Reality Conference, VR 2015—Proceedings, Arles, France, 23–27 March 2015; pp. 345–346. [Google Scholar] [CrossRef]

- Rooij, I.J.M.D.; Port, I.G.L.V.D.; Visser-meily, J.M.A.; Meijer, J.W.G. Virtual reality gait training versus non- virtual reality gait training for improving participation in subacute stroke survivors: Study protocol of the ViRTAS randomized controlled trial. Trials 2019, 20, 89. [Google Scholar] [CrossRef]

- Park, J.H.; Liao, Y.; Kim, D.R.; Song, S.; Lim, J.H.; Park, H.; Lee, Y.; Park, K.W. Feasibility and tolerability of a culture-based virtual reality (VR) training program in patients with mild cognitive impairment: A randomized controlled pilot study. Int. J. Environ. Res. Public Health 2020, 17, 3030. [Google Scholar] [CrossRef]

- Wang, X.; Wang, X. Virtual Reality training system for surgical anatomy. ACM Int. Conf. Proc. Ser. 2018, 30–34. [Google Scholar] [CrossRef]

- Posada, J.; Toro, C.; Barandiaran, I.; Oyarzun, D.; Stricker, D.; de Amicis, R.; Pinto, E.B.; Eisert, P.; Dollner, J.; Vallarino, I. Visual Computing as a Key Enabling Technology for Industrie 4.0 and Industrial Internet. IEEE Comput. Graph. Appl. 2015, 35, 26–40. [Google Scholar] [CrossRef] [PubMed]

- Zheng, J.; Shi, P.; Yu, H. A Virtual Reality Rehabilitation Training System Based on Upper Limb Exoskeleton Robot. In Proceedings of the 2018 10th International Conference on Intelligent Human-Machine Systems and Cybernetics (IHMSC), Hangzhou, China, 25–26 August 2018; pp. 220–223. [Google Scholar] [CrossRef]

- Werrlich, S.; Daniel, A.; Ginger, A.; Nguyen, P.A.; Notni, G. Comparing HMD-Based and Paper-Based Training. In Proceedings of the 2018 IEEE International Symposium on Mixed and Augmented Reality (ISMAR), Munich, Germany, 16–20 October 2018. [Google Scholar] [CrossRef]

- Cahyono, M.R.A. Design and development smart industrial training management software with artificial neural network (ANN) on Java. In Proceedings of the 2018 International Conference on Information and Communications Technology, ICOIACT 2018, Yogyakarta, Indonesia, 6–7 March 2018; pp. 220–225. [Google Scholar] [CrossRef]

- Mechlih, H. New employee education using 3D virtual manufacturing. In Proceedings of the 2016 13th Learning and Technology Conference, L and T 2016, Jeddah, Saudi Arabia, 10–11 April 2016; pp. 33–35. [Google Scholar] [CrossRef]

- Phakphonhamin, V.; Wongsawad, R.; Vichitwongsakorn, T. TPS training course for the production staff. In Proceedings of the 2018 5th International Conference on Business and Industrial Research: Smart Technology for Next Generation of Information, Engineering, Business and Social Science, ICBIR 2018, Bangkok, Thailand, 17–18 May, 2018; pp. 546–549. [Google Scholar] [CrossRef]

- Martin, J.; Bohuslava, J. Augmented reality as an instrument for teaching industrial automation. In Proceedings of the 2018 Cybernetics & Informatics (K&I), Lazy pod Makytou, Slovakia, 31 January–3 February 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Thomay, C.; Gollan, B.; Haslgrübler, M.; Ferscha, A.; Heftberger, J. The Other Kind of Machine Learning: Modeling Worker State for Optimal Training of Novices in Complex Industrial Processes. In Proceedings of the ICETA 2018—16th IEEE International Conference on Emerging eLearning Technologies and Applications, Stary Smokovec, Slovakia, 15–16 November 2018; pp. 577–582. [Google Scholar] [CrossRef]

- Wolfartsberger, J.; Niedermayr, D. Authoring-by-Doing: Animating Work Instructions for Industrial Virtual Reality Learning Environments. In Proceedings of the 2020 IEEE Conference on Virtual Reality and 3D User Interfaces Abstracts and Workshops (VRW), Atlanta, GA, USA, 22–26 March 2020; pp. 173–176. [Google Scholar] [CrossRef]

- Pérez, L.; Diez, E.; Usamentiaga, R.; García, D.F. Industrial robot control and operator training using virtual reality interfaces. Comput. Ind. 2019, 109, 114–120. [Google Scholar] [CrossRef]

- Roldán, J.J.; Crespo, E.; Martín-Barrio, A.; Peña-Tapia, E.; Barrientos, A. A training system for Industry 4.0 operators in complex assemblies based on virtual reality and process mining. Robot. Comput. Integr. Manuf. 2019, 59, 305–316. [Google Scholar] [CrossRef]

- Gavish, N.; Gutiérrez, T.; Webel, S.; Rodríguez, J.; Peveri, M.; Bockholt, U.; Tecchia, F. Evaluating virtual reality and augmented reality training for industrial maintenance and assembly tasks. Interact. Learn. Environ. 2015, 23, 778–798. [Google Scholar] [CrossRef]

- Li, B.; Bi, Y.; He, Q.; Ren, J.; Li, Z. A low-complexity method for authoring an interactive virtual maintenance training system of hydroelectric generating equipment. Comput. Ind. 2018, 100, 159–172. [Google Scholar] [CrossRef]

- Matsas, E.; Vosniakos, G.C. Design of a virtual reality training system for human–robot collaboration in manufacturing tasks. Int. J. Interact. Des. Manuf. 2017, 11, 139–153. [Google Scholar] [CrossRef]

- Nazir, S.; Manca, D. How a Plant Simulator can Improve Industrial Safety. Process Saf. Prog. 2015, 25, 326–330. [Google Scholar] [CrossRef]

- Vergnano, A.; Berselli, G.; Pellicciari, M. Interactive simulation-based-training tools for manufacturing systems operators: An industrial case study. Int. J. Interact. Des. Manuf. 2017, 11, 785–797. [Google Scholar] [CrossRef]

- Chrysoulas, C.; Homay, A.; Lemac, M. Teaching industrial automation concepts with the use of virtual/augmented reality-The IEC 61499 case. In Proceedings of the 2018 17th International Conference on Information Technology Based Higher Education and Training, ITHET 2018, Olhao, Portugal, 26–28 April 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Lacko, J. Health safety training for industry in virtual reality. In Proceedings of the 30th International Conference on Cybernetics and Informatics, K and I 2020, Velke Karlovice, Czech Republic, 29 January–1 February 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Lustosa, E.B.S.; De MacEdo, D.V.; Rodrigues, M.A.F. Virtual simulator for forklift training. In Proceedings of the 2018 20th Symposium on Virtual and Augmented Reality, SVR 2018, Foz do Iguacu, Brazil, 28–30 October 2018; pp. 18–26. [Google Scholar] [CrossRef]

- Mas, A.; Ismael, I.; Filliard, N. Indy: A virtual reality multi-player game for navigation skills training. In Proceedings of the 2018 IEEE 4th VR International Workshop on 3D Collaborative Virtual Environments, 3DCVE 2018, Reutlingen, Germany, 19 March 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Lopez, J.M.G.; Betancourt, R.O.J.; Arredondo, J.M.; Laureano, E.V.; Haro, F.R. Incorporating virtual reality into the teaching and training of Grid-Tie photovoltaic power plants design. Appl. Sci. 2019, 9, 4480. [Google Scholar] [CrossRef]

- Chiluisa, M.; Mullo, R.; Andaluz, V. Training in Virtual Environments for Hybrid Power Plant. Adv. Visual Comput. 2018, 8034, 193–204. [Google Scholar] [CrossRef]

- Bao, Z.; Wang, Y.; Yang, Z.; Zhu, C.; Jin, C. Design on the Virtual Maintenance Training System of Some-Type Equipment Based on the Virtual Reality; Springer: Singapore, 2019; Volume 527, pp. 479–487. [Google Scholar]

- Muszyńska, M.; Szybicki, D.; Gierlak, P.; Kurc, K.; Burghardt, A.; Uliasz, M. Application of Virtual Reality in the Training of Operators and Servicing of Robotic Stations. In Collaborative Networks and Digital Transformation. PRO-VE 2019. IFIP Advances in Information and Communication Technology; Springer International Publishing: Cham, Switzerland, 2019; Volume 568, pp. 594–603. [Google Scholar] [CrossRef]

- Abdul Aziz, F.; Alsaeed, A.S.M.A.; Sulaiman, S.; Ariffin, M.K.A.M.; Al-Arhabi, A.R.Y. Virtual Reality Training Platform in Onshore Pipeline. In Advances in Material Sciences and Engineering. Lecture Notes in Mechanical Engineering; Springer: Singapore, 2020; pp. 207–216. [Google Scholar] [CrossRef]

- Li, Y.; Wang, D.; Liu, Y. The Application of Virtual Reality Technology in Logistics Training. In Advances in Intelligent, Interactive Systems and Applications. IISA 2018. Advances in Intelligent Systems and Computing; Springer International Publishing: Cham, Switzerland, 2019; Volume 885, pp. 668–675. [Google Scholar]

- Markopoulos, E.; Luimula, M. Immersive Safe Oceans Technology: Developing Virtual Onboard Training Episodes for Maritime Safety. Future Intrernet 2020, 12, 80. [Google Scholar] [CrossRef]

- Mirauda, D.; Capece, N.; Erra, U. Sustainable Water Management: Virtual Reality Training for Open-Channel Flow Monitoring. Sustainability 2020, 12, 757. [Google Scholar] [CrossRef]

- Kang, H.; Kim, J. A study on design and case analysis of virtual reality contents developer training based on industrial requirements. Electronics 2020, 9, 437. [Google Scholar] [CrossRef]

- Pavan Kumar, B.N.; Balasubramanyam, A.; Patil, A.K.; Chethana, B.; Chai, Y.H. GazeGuide: An eye-gaze-guided active immersive UAV camera. Appl. Sci. 2020, 10, 1668. [Google Scholar] [CrossRef]

- Sror, L.; Vered, M.; Treger, I.; Levy-Tzedek, S.; Levin, M.F.; Berman, S. A virtual reality-based training system for error-augmented treatment in patients with stroke. In Proceedings of the 2019 International Conference on Virtual Rehabilitation (ICVR), Tel Aviv, Israel, 21–24 July 2019. [Google Scholar] [CrossRef]

- Akkil, D.; James, J.M.; Isokoski, P.; Kangas, J. GazeTorch: Enabling Gaze Awareness in Collaborative Physical Tasks. In Proceedings of the 2016 CHI Conference Extended Abstracts on Human Factors in Computing Systems, San Jose, CA, USA, 7–12 May 2016; Association for Computing Machinery: New York, NY, USA, 2016; pp. 1151–1158. [Google Scholar] [CrossRef]

- Pavan Kumar, B.N.; Patil, A.K.; Chethana, B.; Chai, Y.H. On-site 4-in-1 alignment: Visualization and interactive cad model retrofitting using uav, lidar’s point cloud data, and video. Sensors 2019, 19, 3908. [Google Scholar] [CrossRef]

- Zhang, G.; Hansen, J.P.; Minakata, K. Hand- and Gaze-Control of Telepresence Robots. In Proceedings of the 11th ACM Symposium on Eye Tracking Research & Applications, Denver, CO, USA, 25–28 June 2019; Association for Computing Machinery: New York, NY, USA, 2019. [Google Scholar] [CrossRef]

- Anthes, C.; García-Hernández, R.J.; Wiedemann, M.; Kranzlmüller, D. State of the art of virtual reality technology. In Proceedings of the 2016 IEEE Aerospace Conference, Big Sky, MT, USA, 5–12 March 2016; pp. 1–19. [Google Scholar]

- Coburn, J.Q.; Freeman, I.; Salmon, J.L. A Review of the Capabilities of Current Low-Cost Virtual Reality Technology and Its Potential to Enhance the Design Process. J. Comput. Inf. Sci. Eng. 2017, 17, 031013. [Google Scholar] [CrossRef]

- Alizadehsalehi, S.; Hadavi, A.; Chuenhuei Huang, J. Virtual Reality for Design and Construction Education Environment. J. Constr. Eng. Manag. 2019, 294–308. [Google Scholar] [CrossRef]

- Chang, S.; Chen, W. Does visualize industries matter? A technology foresight of global Virtual Reality and Augmented Reality Industry. In Proceedings of the 2017 International Conference on Applied System Innovation (ICASI), Sapporo, Japan, 13–17 May 2017; pp. 382–385. [Google Scholar]

- Turner, C.J.; Hutabarat, W.; Oyekan, J.; Tiwari, A. Discrete Event Simulation and Virtual Reality Use in Industry: New Opportunities and Future Trends. IEEE Trans. Hum. Mach. Syst. 2016, 46, 882–894. [Google Scholar] [CrossRef]

| Number | Research Question (RQ) | Motivation |

|---|---|---|

| RQ1 | What are the uses of VR in non-industrial training? | Identify the approaches used. |

| RQ2 | What types of technologies are used in industrial training other than VR? | Identify other technologies, apart from VR, used in industrial training. |

| RQ3 | What devices are used for VR industrial training? | Identify the devices used to generate immersive environments. |

| RQ4 | What are the users’ benefits of applying VR in industrial training? | Identify the advantages of VR in industrial training. |

| Number | Inclusion | Exclusion |

|---|---|---|

| C1 | Articles related to purposes of using virtual reality in industrial training | Duplicates from different databases |

| C2 | Articles published from 2015 to 2020 | Articles not related to virtual reality and industrial training |

| C3 | English written articles | Thesis |

| C4 | Articles related to purposes of using virtual reality in non industrial training | Studies published in other areas of knowledge |

| C5 | Articles related to non-VR industrial training | Review articles |

| Code | Title | Database | Year | Viewpoint | Authors | Objective |

|---|---|---|---|---|---|---|

| P1 | Low cost virtual reality for medical training | IEEEXplore | 2015 | VP1 | Mathur, A.S. | Using devices such as the Oculus Rift and Razer Hydra the authors propose a low cost virtual reality set-up for medical training and instruction purposes. |

| P2 | A Virtual Reality Based Training System for Cultural Tourism | SpringerLink | 2015 | VP1 | Tseng, S.P.; Huang, M.W.; Liu, H.J.; Chung, C.C.; Chiu, C.M. | This paper proposes a web-based 3D-panorama training system for tour guides to be applied in both the classroom and the scenic field. |

| P3 | How a Plant Simulator can Improve Industrial Safety | Scopus | 2015 | VP3 | Nazir, S.; Manca, D. | The article presents a solution for immersive training of industrial operators called Plant Simulator (PS). It combines a process and an accident simulator to reproduce typical and abnormal/accident scenarios dynamically. |

| P4 | Evaluating virtual reality and augmented reality training for industrial maintenance and assembly tasks | Scopus | 2015 | VP3 | Gavish, N.; Gutiérrez, T.; Webel, S.; Rodríguez, J.; Peveri, M.; Bockholt, U.; Tecchia, F. | Evaluate VR and AR systems efficiency and effectiveness compared to traditional training methods. It is done using four training groups in an electronic actuator assembly task. |

| P5 | Design of a virtual reality training system for human–robot collaboration in manufacturing tasks | Scopus | 2015 | VP3 | Matsas, E.; Vosniakos, G.C. | This research presents an interactive virtual reality training system called "beWare of the Robot" in terms of a game that simulates the cooperation between industrial robotic manipulators and humans. |

| P6 | A Case Study on Virtual Reality American Football Training | ACM | 2015 | VP1 | Huang, Y.; Churches, L.; Reilly, B. | Using the Oculus Rift HMD, a study of American football training through the use of virtual reality is presented. It is focused on student-athletes in an immersive virtual reality environment, where trainees experience the football gameplays created by their coaches. |

| P7 | New employee education using 3D virtual manufacturing | IEEEXplore | 2016 | VP2 | Mechlih, H. | This work presents a system using existing virtual manufacturing technology to improve the quality of new employee training, reduce the cost and the time consumed in preparation. |

| P8 | Breaking Bad Behavior: Immersive Training of Class Room Management | ACM | 2016 | VP1 | Latoschik, M.E.; Lugrin, J.L.; Habel, M.; Roth, D.; Seufert, C.; Grafe, S. | This article developed an immersive portable, low-cost Virtual Reality system to train classroom management skills. The trainee’s interface uses HMD and earphones for output. |

| P9 | Training of Tannery Processes Through Virtual Reality | SpringerLink | 2017 | VP3 | Andaluz, V.H.; Pazmiño, A.; Perez, J.; Carvajal, C. | The virtualization of the industrial tanning process to train operators through a virtual environment is presented. It uses the graphic engine Unity 3D and the Oculus Rift HMD. |

| P10 | Interactive simulation-based-training tools for manufacturing systems operators: an industrial case study | Scopus | 2017 | VP3 | Vergnano, A.; Berselli, G.; Pellicciari, M. | This paper reports a successful industrial case study concerning a new Simulation-Based-Training workbench used for steel plant operator training. It discusses both the virtual prototyping phase and the development of a real-time simulation architecture. |

| P11 | Immersive Virtual Reality Training Tool for IoT Device Placement | ACM | 2017 | VP1 | Jia, Y.; Campbell, A.G. | This paper outlines the results of creating a VR simulation of a generic space where IoT devices can be placed and then evaluated in real-time to test if their placement will be a viable network. |

| P12 | Design of a Virtual Reality and Haptic Setup Linking Arousals to Training Scenarios: A Preliminary Stage | IEEEXplore | 2018 | VP1 | Kournaditis, K.; Chinello, F.; Venckute, S. | This research develops an appraised, well-crafted VR puzzle game, questionnaires and sensors (skin conductance response/pulse) to design a two-phase explorative experiment linking arousal and performance during training in a Virtual Reality (VR) environment. |

| P13 | Visual computing technologies to support the Operator 4.0 | Scopus | 2018 | VP3 | Arbelaiz, Ander; Álvarez, Hugo; Simões, Bruno; Posada, Jorge; García-Alonso, Alejandro; Ugarte, Ramón | Present several practical developments where Visual Computing enables the augmented operator, the virtual operator and the collaborative operator. |

| P14 | Comparing HMD-based and Paper-based Training | IEEXplore | 2018 | VP2 | Werrlich, Stefan; Daniel, Austino; Ginger, Alexandra; Nguyen, Phuc Anh; Notni, Gunther | Measure the training transfer of an engine assembly training task. |

| P15 | A Virtual Reality Rehabilitation Training System Based on Upper Limb Exoskeleton Robot | IEEEXplore | 2018 | VP1 | Zheng, J.; Shi, P.; Yu, H. | The authors present a training system that consists of virtual reality rehabilitation games and data communication. A virtual reality training system based on an exoskeleton rehabilitation robot was designed for patients with upper extremity motor dysfunction. |

| P16 | Design and development smart industrial training management software with artificial neural network (ANN) on Java | IEEEXplore | 2018 | VP2 | Efanntyo.; Cahyono, M.R.A. | The authors present a smart industrial training design with ANN that aims to divide users into several levels and simplify the printing of reports. |

| P17 | TPS training course for the production staff | IEEEXplore | 2018 | VP2 | Phakphonhamin, V.; Wongsawad, R.; Vichitwongsakorn, T. | The research study aimed to develop a training course for the Toyota Production System for production staff and apply it to the standard course of the necessary knowledge about this system. |

| P18 | Augmented reality as an instrument for teaching industrial automation | IEEEXplore | 2018 | VP2 | Martin, J.; Bohuslava, J. | It introduces a learning system focused on teaching subjects from the field of industrial automation using the A-Frame framework in combination with the AR.js project. |

| P19 | The Other Kind of Machine Learning: Modeling Worker State for Optimal Training of Novices in Complex Industrial Processes | IEEEXplore | 2018 | VP2 | Thomay, C.; Gollan, B.; Haslgrübler, M.; Ferscha, A.; Heftberger, J. | A training station e-learning concept is detailed, with the purpose to automatically teach a novice worker the necessary steps to assemble an alpine ski without the need for constant human supervision. |

| P20 | Teaching industrial automation concepts with the use of virtual/augmented reality-The IEC 61499 case | IEEEXplore | 2018 | VP3 | Chrysoulas, C.; Homay, A.; Lemac, M. | A framework for teaching complex industrial automation concepts with the help of Virtual/Augmented reality to support higher education students better understand complex industrial automation concepts is developed. |

| P21 | Virtual simulator for forklift training | IEEEXplore | 2018 | VP3 | Lustosa, E.B.S.; DeMacEdo, D.V.; Rodrigues, M.A.F. | The Oculus Rift HMD and haptic control interfaces to train workers with a virtual simulator for forklift training are detailed. |

| P22 | Indy: A virtual reality multi-player game for navigation skills training | IEEEXplore | 2018 | VP3 | Mas, A.; Ismael, I.; Filliard, N. | Here it is developed Indy, a virtual reality system consisting of a collaborative game of treasure hunting. It improves learners’ attention on navigation tasks, implies their active engagement, and provides feedback on their achievements. |

| P23 | Training for Bus Bodywork in Virtual Reality Environments | SpringerLink | 2018 | VP3 | Herrera, D.F.; Bolívar Acosta, S.; Quevedo, W.X.; Balseca, J.A.; Andaluz, V.H. | The authors detail the Unity 3D graphic engine as a viable solution to develop a training system on electric welding applied to the automotive body assembly industry. |

| P24 | Training in Virtual Environments for Hybrid Power Plant | SpringerLink | 2018 | VP3 | Chiluisa, M.; Mullo, R.; Andaluz, V. | This study describes a Virtual Environments application for professionals in Electrical Power Systems training. The app is developed in the Game Engine Unity 3D and features three different modes. |

| P25 | A low-complexity method for authoring an interactive virtual maintenance training system of hydroelectric generating equipment | Scopus | 2018 | VP3 | Li, B.; Bi, Y.; He, Q.; Ren, J.; Li, Z. | An interactive virtual maintenance system of an entire hydroelectric generating equipment based on this apparatus’s interactive operation is established. |

| P26 | Virtual Reality Training System for Surgical Anatomy | ACM | 2018 | VP1 | Wang, X.; Wang, X. | This paper proposes a simulation anatomy system that can be applied to medical students’ anatomy learning. The system consists of scene construction, result determination and UI interface development. |

| P27 | Evaluation of a virtual reality-based baseball batting training system using instantaneous bat swing information | IEEEXplore | 2019 | VP1 | Zou, L.; Higuchi, T.; Noma, H.; Roberto, L.G.; Isaka, T. | The researches propose a Virtual Reality-based (VR) baseball batting system that provides instantaneous information as feedback. This information includes exact bat-ball impact location and angle, replay for swing timing and speed. |

| P28 | AirwayVR: Virtual reality trainer for endotracheal intubation-design considerations and challenges | IEEEXplore | 2019 | VP1 | Rajeswaran, P.; Kesavadas, T.; Jani, P.; Kumar, P. | This paper proposes the design considerations and challenges of a virtual reality-based simulation trainer for intubation training. It is twofold, an introductory platform to learn and practice intubation and as a Just-in-time training platform. |

| P29 | Incorporating virtual reality into the teaching and training of Grid-Tie photovoltaic power plants design | MDPI | 2019 | VP3 | Lopez, J.M.G.; Betancourt, R.O.J.; Arredondo, J.M.; Laureano, E.V.; Haro, F.R. | This paper reviews an initiative within the teaching-learning context, which aims to show the advantages of using virtual reality, to achieve teaching goals in a renewable energy course. |

| P30 | Virtual reality gait training versus non-virtual reality gait training for improving participation in subacute stroke survivors: study protocol of the ViRTAS randomized controlled trial | SpringerLink | 2019 | VP1 | Rooij, I.J.M.D.; Port, I.G.L.V.D.; Visser-meily, J.M.A.; Meijer, J.w.G. | The primary aim of this study is to examine the effect of VR gait training on participation in community-living people after stroke. |

| P31 | Design on the Virtual Maintenance Training System of Some-Type Equipment Based on the Virtual Reality | SpringerLink | 2019 | VP3 | Bao, Z.;Wang, Y.; Yang, Z.; Zhu, C.; Jin, C. | By analyzing the current problems of the type of equipment maintenance training and the advantages of virtual maintenance technology, this paper clarifies the system’s functional requirements. It also proposes a hierarchical and modular system design plan. |

| P32 | Application of Virtual Reality in the Training of Operators and Servicing of Robotic Stations | SpringerLink | 2019 | VP3 | Muszyn’ska, M.; Szybicki, D.; Gierlak, P.; Kurc, K.; Burghardt, A.; Uliasz, M. | The article uses virtual reality environments; thus, they are interactive and allow advanced operations without damaging expensive equipment. It discusses the use of virtual reality in training the service and maintenance of robots and robotic stations. |

| P33 | The Application of Virtual Reality Technology in Logistics Training | SpringerLink | 2019 | VP3 | Li, Y.; Wang, D.; Liu, Y. | This article researches the application of VR technology and the current situation of logistics training. It analyzes the specific directions of this application. |

| P34 | Industrial robot control and operator training using virtual reality interfaces | Scopus | 2019 | VP3 | Pérez, L.; Diez, E.; Usamentiaga, R.; García, D.F. | This paper runs on the synergies between virtual reality and robotics, presenting commercial gaming technologies’ use to create an immersive environment based on virtual reality. |

| P35 | A training system for Industry 4.0 operators in complex assemblies based on virtual reality and process mining | Scopus | 2019 | VP3 | Roldán, J.J.; Crespo, E.; Martín-Barrio, A.; Peña-Tapia, E.; Barrientos, A. | It presents a training system for industrial operators in assembly tasks. First, expert workers use an immersive VR interface to perform assemblies according to their experience. Then, process mining algorithms are applied to obtain assembly models from event logs. |

| P36 | A Framework for Virtual Reality Training to Improve Public Speaking | ACM | 2019 | VP1 | Pellett, K.; Zaidi, S.F.M. | This article proposes the use of 4.0 technologies to help people with problems to speak in public. The application of VR allows users to practice their type of speech and improve their linguistic skills. |

| P37 | Authoring-by-Doing: Animating Work Instructions for Industrial Virtual Reality Learning Environments | IEEEXplore | 2020 | VP3 | Wolfartsberger, J.; Niedermayr, D. | This paper describes the prototype for a Virtual Reality-supported learning and training application. It presents a concept to simplify the authoring process of content with additional focus on animating assembly procedures. |

| P38 | Health safety training for industry in virtual reality | IEEEXplore | 2020 | VP3 | Lacko, J. | The authors have developed a VR system that allows training operators in terms of safety and health at work. Various immersive environments are proposed to help workers make decisions at times of high stress within the industry. |

| P39 | A study on design and case analysis of virtual reality contents developer training based on industrial requirements | MDPI | 2020 | VP3 | Kang, H.; Kim, J. | An industrial demand-customized educational model and its operations based on a cooperative relationship between training institutions and industrial companies using collaborative projects and mentoring was designed. |

| P40 | Design of Sports Training Information Platform Based on Virtual Reality | SpringerLink | 2020 | VP1 | Li, J. | This paper proposes a specific way of designing a sports training information platform based on virtual reality and canny edge detection algorithms. It speeds up the construction of the information platform and provides a certain theoretical basis for future research on relevant aspects. |

| P41 | Virtual Reality Training Platform in Onshore Pipeline | SpringerLink | 2020 | VP3 | Abdul Aziz, F.; Alsaeed, A.S.M.A.; Sulaiman, S.; Ariffin, M.K.A.M.; Al-Arhabi, A.R.Y. | The oil and gas industry often requires people to work in hazardous environments. Thus, this paper reviews the possibility of implementing a VR training platform for industrial maintenance. |

| P42 | Immersive Safe Oceans Technology: Developing Virtual Onboard Training Episodes for Maritime Safety | MDPI | 2020 | VP3 | Markopoulos, E.; Luimula, M. | A VR system called Immersive Safe Oceans is presented. It is a cost-effective, portable technology that can be used on-board just in time or in maritime training centers. Four safety training scenarios were developed. |

| P43 | Feasibility and Tolerability of a Culture-Based Virtual Reality (VR) Training Program in Patients with Mild Cognitive Impairment: A Randomized Controlled Pilot Study | MDPI | 2020 | VP1 | Park, J.H.; Liao, Y.; Kim, D.R.; Song, S.; Lim, J.H.; Park, H.; Lee, Y.; Park, K.W. | The present study examined whether a culture-based VR training program is feasible and tolerable for patients with amnestic mild cognitive impairment. The VR-based program was designed based on Korean traditional culture and used attention, processing speed, executive function and memory conditions to stimulate cognitive function. |

| P44 | Sustainable Water Management: Virtual Reality Training for Open-Channel Flow Monitoring | MDPI | 2020 | VP3 | Mirauda, D.; Capece, N.; Erra, U. | The VR tool designed by these authors, aimed at technical and non-technical workforces in field activities, represents a Virtual Laboratory able to train on the standard techniques for the accurate monitoring of the water discharge in open-channel flows. |

| Code | Sample Size | Devices | User Feedback | Experience |

|---|---|---|---|---|

| P1 | None noted | Oculus Rift and Razer Hydra | Visual, haptic | Learn by doing. |

| P2 | 79 questionnaire, including 29 males and 50 females. | Flat screen (PC and smart tablet) | Visual, auditory | Virtually exploring places without physical visit. |

| P3 | None noted | Flat screen (PC) | Visual, auditory | Empowering the understanding, performance, responsiveness, and precision of industrial operators. |

| P4 | 40 expert technicians | Flat screen (PC) | Visual, auditory | Improve the efficiency of an electronic actuator assembly task. |

| P5 | 30 prefinal year mechanical engineering students. | Kinect, Leap Motion, Oculus Rift | Visual, auditory, haptic | Selection, manipulation, navigation, and, system control for building aerospace composite parts. |

| P6 | 17 football players, who all play the quarterback position ranging from 7th grade to collegiate juniors. | Oculus Rift, wireless Xbox controller | Visual, auditory, haptic | Experience the gameplay in the immersive virtual environment, freely switching camera views from bird’s-eye mode to 3rd-person mode following certain player on the field, and even directly be inside the player’s helmet. |

| P7 | None noted | Flat screen (PC) | Visual, auditory | Learn the theory behind an industrial robot and control an actual industrial robot through a web-based robot teach. |

| P8 | Simultaneously involved participant pairs of teacher and instructor. | Oculus Rift, Kinect | Visual, auditory | Manage disruptive student behavior in face-to-face, one-to-many teaching scenarios. |

| P9 | None noted | Leap Motion and Oculus Rift | Visual, auditory | Identification of instruments, machinery, processes, instructions and safety regulations of a tannery process. |

| P10 | None noted | Flat screen (PC) | Visual, auditory | Learn how to command complex automated machineries. |

| P11 | None noted | HTC VIVE | Visual | Gain intuitive knowledge into how they can correctly place devices in a building to create either a mesh network or fit into an existing wireless network infrastructure. |

| P12 | 12 trainees | Conductance and heart rate sensors, HTC VIVE, two single motors. | Visual, auditory, haptic | Link performance and arousal with VR stimulus. |

| P13 | None noted | The Oculus Rift HMD and the Leap Motion sensor. | Visual, auditory | The operator will learn very quickly and safely how a robotic arm behaves, reducing the stress produced with a real robotic arm. |

| P14 | 30 participants | The Microsoft HoloLens, a depth camera, integrated microphones, a light sensor, and a 2MP photo/ HD video camera. | Visual, auditory | Experiment the difference between conventional training and an HMD-based training. |

| P15 | None noted | Flat screen (PC) | Visual, auditory | Rehabilitation assessment, rehabilitation training and data management. |

| P16 | 20 participants | Flat screen (PC) | Visual | Archiving system efficiently and effectively. |

| P17 | 30 workers | Flat screen (PC) | Visual, auditory | Gain expertise in TPS. |

| P18 | None noted | Flat screen (PC, tablet) | Visual | Identify individual components or entire subsystems used in solving tasks. |

| P19 | None noted | RGB camera, 2 Kinects | Visual, auditory | Learn the necessary steps to assemble an alpine ski without the need for constant human supervision. |

| P20 | None noted | HTC VIVE | Visual, auditory | Learn complex industrial automation concepts with the help of Virtual/Augmented reality. |

| P21 | 11 participants | Logitech Driving Force GT steering wheel, the Microsoft Sidewinder Force Feedback 2 joystick stick and the Oculus Rift | Visual, auditory, haptic | Improve the skills of workers in the use of heavy machinery. |

| P22 | None noted | HTC VIVE | Visual, auditory | Focuses learners’ attention on navigation tasks. |

| P23 | None noted | HTC VIVE | Visual, auditory, haptic | Strengthen the recognition of automotive assembly processes. |

| P24 | None noted | HTC VIVE and Gear VR | Visual, auditory, haptic | Ensure a correct analysis and diagnosis of Hybrid Generation Systems. |

| P25 | None noted | Flat screen (PC) | Visual, auditory | Separate complex equipments into independent IVEs. |

| P26 | None noted | HTC VIVE | Visual, auditory, haptic | Learn the human chest anatomy. |

| P27 | VR-group and BC-group (5 left-handed and 5 right-handed people). | HTC VIVE | Visual, auditory | Obtain an instantaneous bat swing information as feedback. |

| P28 | None noted | HTC VIVE and Oculus Rift | Visual, auditory, haptic | Mentally prepare experts for a complex case prior to medical procedures. |

| P29 | 28 final year students in electrical engineering from the University of Colima. | Oculus Rift | Visual, auditory | Achieve teaching goals in a renewable energy course. |

| P30 | Virtual reality gait training (VRT) group and non-virtual reality gait training (non-VRT) group. | Flat screen (PC) | Visual, auditory, haptic | Experiment an in-tensive, variable and enjoyable therapy. |

| P31 | None noted | Flat screen (PC) | Visual, auditory | Improve the maintenance and support capability of the equipment. |

| P32 | None noted | Oculus Rift | Visual, auditory, haptic | Allow advanced operations without the risk of damaging expensive equipment. |

| P33 | None noted | Flat screen (PC) | Visual | Understand the specific directions of this application in logistics. |

| P34 | 12 people of three different profiles and experience (4 of each one) have participated in the validation and tests: (a) Robotic application engineers, (b) Robot operators, and (c) Assistant operators. | Oculus Rift and HTC VIVE | Visual | Understand the synergies between virtual reality and robotics. |

| P35 | 20 volunteers | HTC VIVE | Visual, auditory | Learn assembly tasks from expert workers. |

| P36 | None noted | HTC VIVE | Visual, auditory | Overcome glossophobia. |

| P37 | None noted | HTC VIVE | Visual, auditory | Simplify the authoring process of content with additional focus on animating assembly procedures. |

| P38 | Group A (37 users) and Group B (32 users) | HTC VIVE and Oculus Rift | Visual | Prevent injuries and economic damage in industries. |

| P39 | 27 trainees | Oculus Rift and Gear VR | Visual, auditory, haptic | Learn from an industrial demand-customized educational model |

| P40 | None noted | Flat screen (PC) | Visual, auditory | Improve sports skills |

| P41 | None noted | HTC VIVE | Visual, auditory, haptic | Learn maintenance in oil and gas industry |

| P42 | None noted | HTC VIVE | Visual, auditory, haptic | Make decisions under dangerous situations |

| P43 | VR group (n = 10) and a control group (n = 11) | HTC Vive | Visual, auditory | Improve cognitive function in these patients |

| P44 | 35 people | Oculus Rift | Visual, auditory | Support to technical and non-technical workforces in field activities. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naranjo, J.E.; Sanchez, D.G.; Robalino-Lopez, A.; Robalino-Lopez, P.; Alarcon-Ortiz, A.; Garcia, M.V. A Scoping Review on Virtual Reality-Based Industrial Training. Appl. Sci. 2020, 10, 8224. https://doi.org/10.3390/app10228224

Naranjo JE, Sanchez DG, Robalino-Lopez A, Robalino-Lopez P, Alarcon-Ortiz A, Garcia MV. A Scoping Review on Virtual Reality-Based Industrial Training. Applied Sciences. 2020; 10(22):8224. https://doi.org/10.3390/app10228224

Chicago/Turabian StyleNaranjo, Jose E., Diego G. Sanchez, Angel Robalino-Lopez, Paola Robalino-Lopez, Andrea Alarcon-Ortiz, and Marcelo V. Garcia. 2020. "A Scoping Review on Virtual Reality-Based Industrial Training" Applied Sciences 10, no. 22: 8224. https://doi.org/10.3390/app10228224

APA StyleNaranjo, J. E., Sanchez, D. G., Robalino-Lopez, A., Robalino-Lopez, P., Alarcon-Ortiz, A., & Garcia, M. V. (2020). A Scoping Review on Virtual Reality-Based Industrial Training. Applied Sciences, 10(22), 8224. https://doi.org/10.3390/app10228224