Two experiments are designed in order to test the performance of the SE-NSGA2. In the first experiment, the benchmark test function verifies that the proposed approach SE-NSGA2 has excellent convergence and distribution performance. In the second experiment, the case study verifies that the safety layout model is valid, and the SE-NSGA2 can generate a safe and useful layout where economics and safety reach the best equilibrium. Our experimental and statistical results of optimal layout plan for assembly lines increase by 14.5%, and the safety performance of assembly line layout increased by 20.63%.

4.1. Performance Comparison with Approach

The population size is 100, the maximum number of iterations is 10,000, the crossover probability is 0.8, and the mutation probability is 0.1. Two objective functions and six decision variables are established. When the DE strategy parameters are F = 0.5 and CR = 0.3, the global search algorithm yields the best convergence speed and search ability.

The benchmark functions ZDT1 and DTLZ1 are applied to evaluate the performance of NSGA-II [

8], MOCell [

38]. and SE-NSGA2 in order to verify the performance of SE-NSGA2. NSGA-II and MOCell are two mainstream multi-objective optimization methods, which have a good performance of the convergence effect. The NSGA-II [

8] is that GAs evolutionary algorithm has a strong global optimization capability. The proposed approach SE-NSGA2 is an improved approach of NSGA-II method. The MOCell algorithm [

38] has received wide attention due to its diversity performance. Therefore, the benchmark functions ZDT1 and DTLZ1 are applied in order to evaluate the performance of NSGA-II [

8], MOCell [

38], and SE-NSGA2.

The inverted generational distance (IGD) is an evaluation index that reflects the overall performance of the algorithm. The smaller the value, the better the overall convergence and distribution performance. The IGD expression (10) is

P is the set of the Pareto front uniformly distributed, |P| is the number of the solution set, Q is the optimal solution set in the Pareto front, and d(v, Q) is the smallest Euclidean distance from v to Q in the Pareto front. The smaller the value of d(v, Q) is, the better the convergence of the algorithm is. If this value is large, the distribution is scattered. The MOCell, NSGA-II, and SE-NSGA2 algorithms were compared based on the test function.

Table 3 presents the statistical quantitative results of the IGD values for 30 independent runs. The smaller the value, the better the performance of the corresponding method. The data in

Table 3 directly indicate that SE-NSGA2 performs better than the other methods, and the distribution and convergence of the solution set are better.

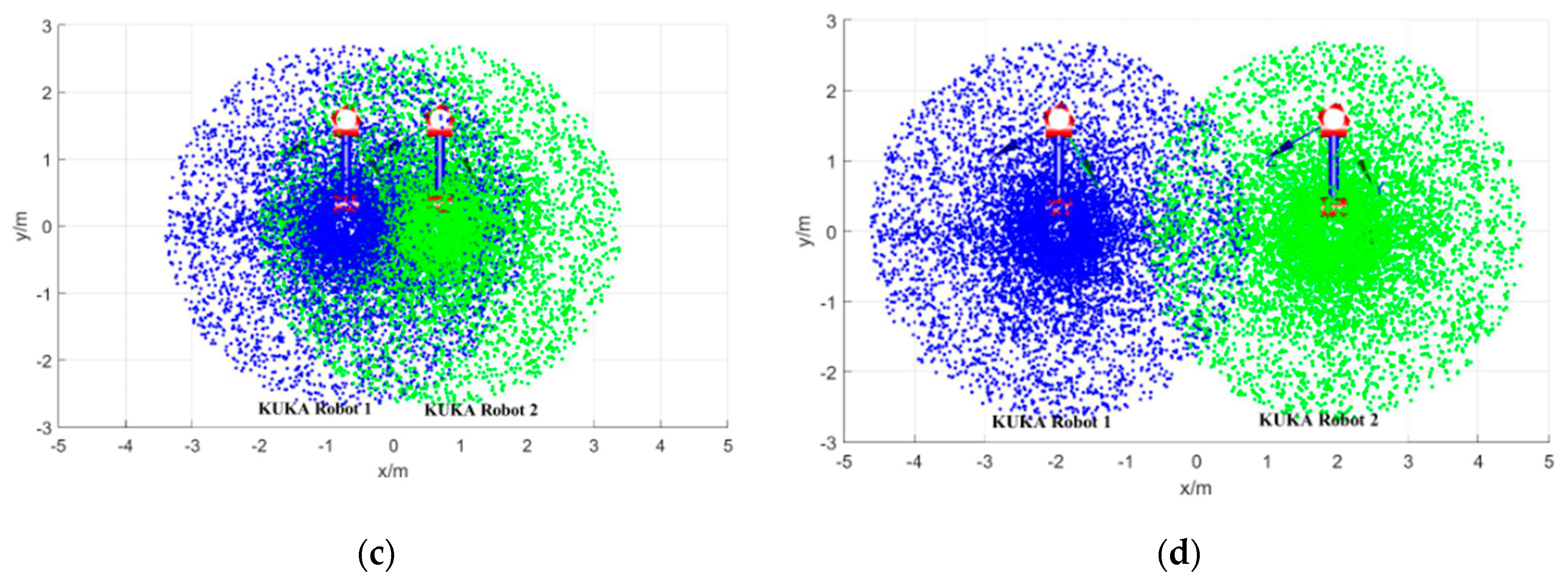

Three objective functions are established in order to observe and verify the algorithm performance based on convergence and diversity.

Figure 5 shows a 3D visualization of the Pareto front sets. The statistical results of the Pareto front are compared. The figure shows that the distribution and convergence of MOCell are worse than those of NSGA-II and SE-NSGA2. The Pareto sets of NSGA-II and SE-NSGA2 have dense points in the plot and, as indicated in

Table 3, the IGD value of SE-NSGA2 is smaller than the value of NSGA-II, which is, SE-NSGA2 yields convergence and distribution results. Moreover, when compared with the original algorithm, the proposed method increases the diversity and produces better distribution and convergence results with fewer overlapping solutions.

4.2. Case Study of Safe Layout

An automotive assembly line is selected as an example, in which the diversity of safety layout, safety, and economic benefits has been verified. The assembly line has ten pieces of equipment, including three robots.

Table 4 shows the equipment information. In the planning period t from M

i to M

j, D

ij is the distance.

Table 5 presents the material transportation cost per unit distance C

ij during period t.

Table 6 lists the demand for the assembly parts P

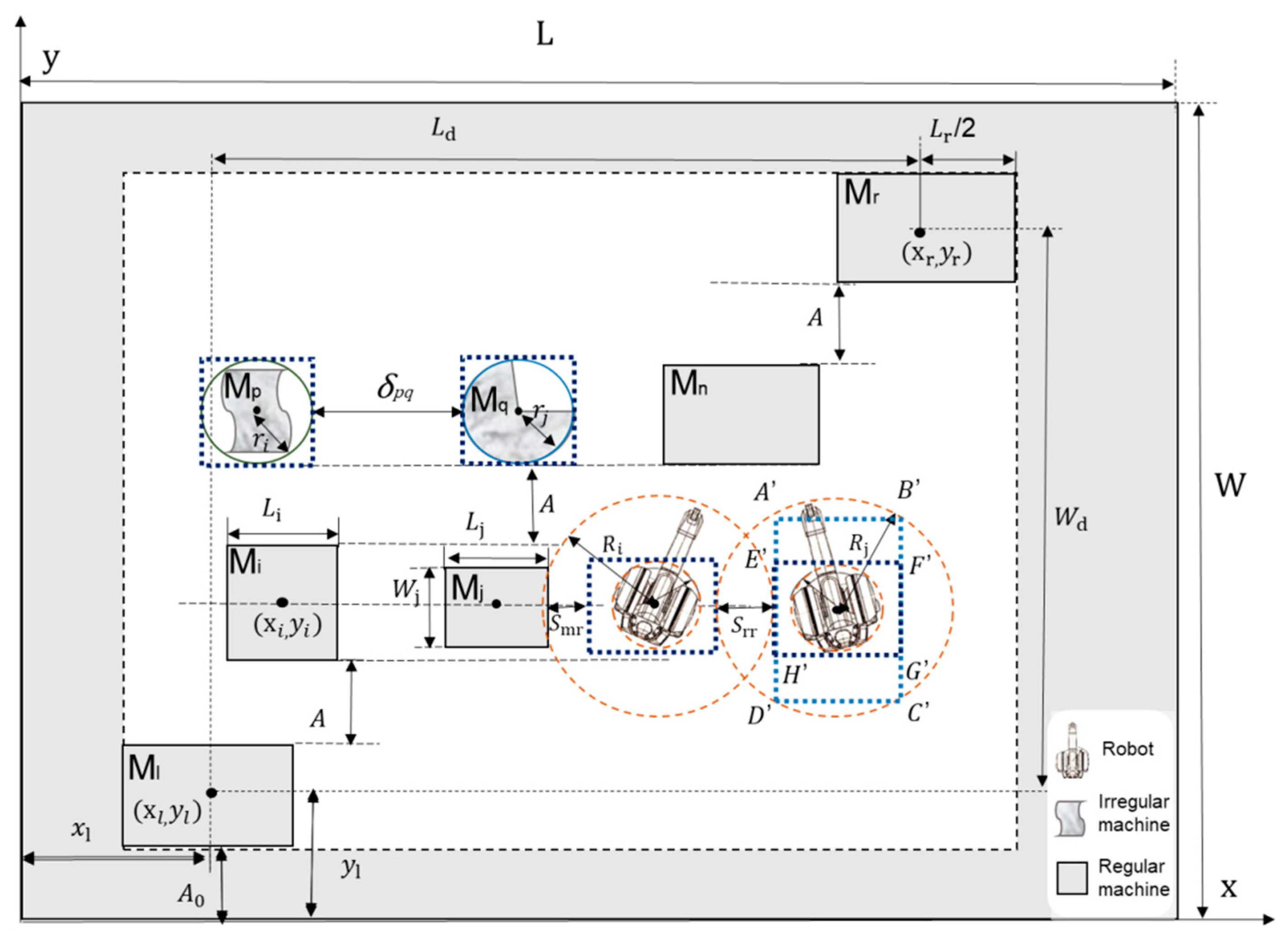

ij. The available layout area length is L = 22 m, the width is W = 12, and the line spacing is A = 1 m. The distance from the first line to the available edge is A0 = 1.5 m. The net distance between two facilities is δ

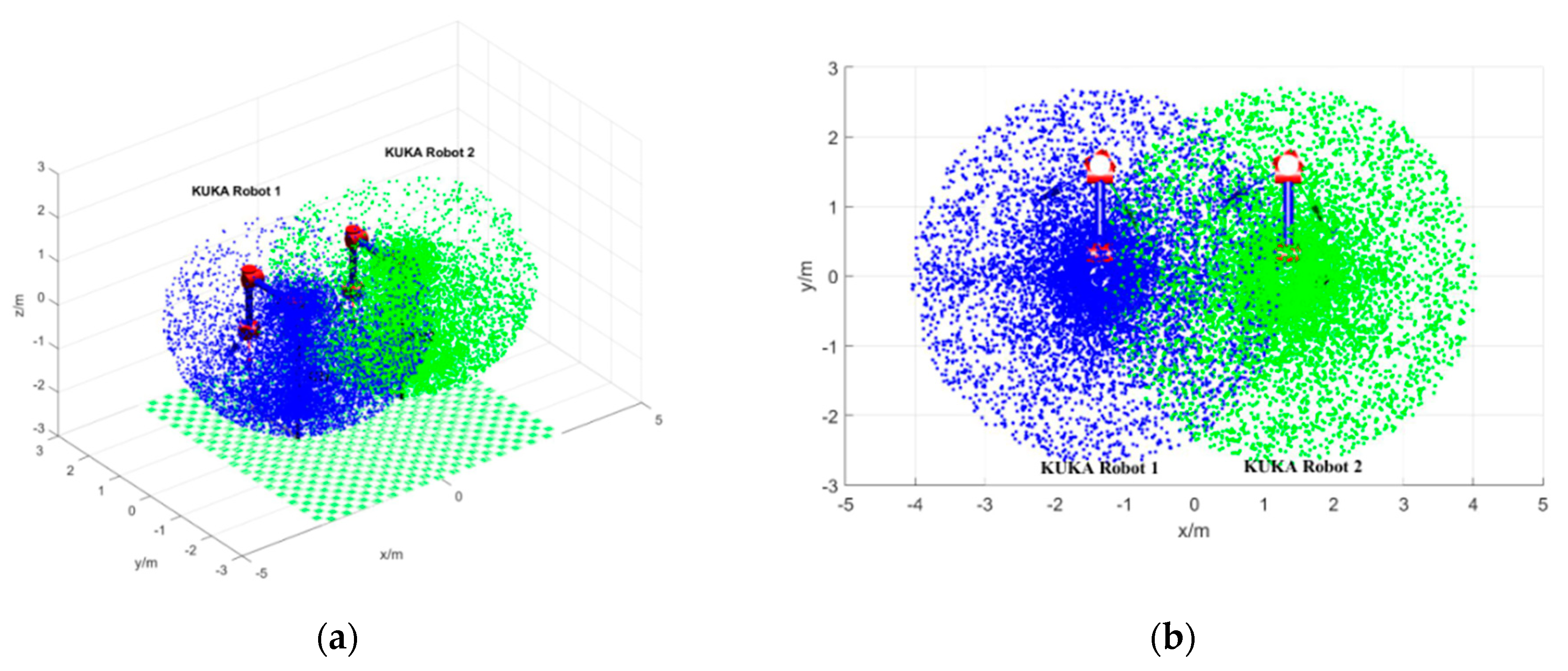

ij ∈ [0.1, 1.8]. The actual maximum motion range of the robotic arm is 5.2 m, which is shy of the rated maximum motion range of 5.4 m, as shown by the assembly range of the cloud points in

Figure 3. The assembly line includes the KUKA KR210 R2700 robots M4, M5, and M6, with a maximum working radius of 2.7 m and a robot base radius of 0.33 m. The experimental environment is Windows 10 system, Python 3.7.1, and Anaconda3.

Table 7 shows the process routes of the three assembly parts. The process quality, throughput, success rate, and downtime are assumed to be ideal. The process elements include machines and workstations. There is no robot for the P1 process element. For P2, M5, and M6 robots take the workpiece from the machine for cooperative assembly. In the process for P3, the M5 and M6 robots take the workpiece from the machine and perform the assembly.

Many researchers have verified that heuristic algorithms and heuristic algorithms are effective in solving the layout design problem. The proposed approach was compared with two mainstream multiobjective optimization methods. NSGA-II [

8], MOCell [

38], and SE-NSGA2 are used in order to solve the safety layout design of the assembly line. Optimization object is the same assembly line, and the compared environment is fair.

The diversity of a safe assembly line layout is verified. Comparative experiments prove that the safe layout model and SE-NSGA2 approach can effectively increase the number of optimal layout plans.

Table 8 shows the statistical results of the experiment over 30 independent runs. The data in the table indicate that the SE-NSGA2 approach is superior to other methods based on the number of optimal plans and diversity of plans. The comparison experiment uses the general layout model (GLM) [

17] and the safety layout model (SLM). When optimizing an assembly line layout with robots, if only the maximum working range of each robot is considered, then collaborative assembly cannot be achieved. Therefore, the comparison experiment selects the robot base as the optimized entity in order to ensure the operation requirements of collaborative assembly. In the general layout model, the Pareto optimal plans of three algorithms have little difference in percentage, but the Pareto solutions of SE-NSGA2 are not superior to others of diversity. The results are related to the determination of safety indicators in the proposed approach. The general layout model does not consider the assembly collaboration of robots and the safe assembly of robots with other devices. In the safe layout model, the SE-NSGA2 Pareto solution set has the most diverse plans, and the percentage of SE-NSGA2 optimal plans is superior to that of NSGA-II is 14.5%.

The safety performance of a safe assembly line layout is verified. The 3D scene is connected to the database in a data-driven manner in order to verify the feasibility and rationality of safe layouts and verify the effectiveness of safe layout plans. Irregularly shaped equipment modeling rules consider the 3D height information, which can reduce the risk of collision and increase the layout safety. The generated Pareto front set corresponds to the layout plan. There will be many unsafe layout solutions in the Pareto front if a multiobjective optimization method with irregularly shaped equipment is not employed. The P1, P2, and P3 products correspond to the determined process flows. Among them, the P1 Pareto front is a safe layout plan, and no collision occurs during assembly verification. The process flows that correspond to P2 and P3 include potential collisions during the assembly process. We focus on the interactions between two robots and between machines and robots in order to assess these collisions.

Because the coordinates of the center point of the collision area are constantly changing, the collision point is continuously covered, which is not easy for readers to observe. Therefore, we undertake statistical experiments to draw the projected area of the ground, as shown in

Figure 6, and the number of collisions in the unsafe layout, as shown in

Figure 7. Based on 30 independent operations, the ground projection areas where collisions occur in the Pareto front are shown in

Figure 6. If multiple collisions occur in each layout plan during the verification stage, then only the largest area of one collision will be counted. The solution statistics for the SE-NSGA2 approach are employed in order to obtain the initial solution set before γ safety indicator screening. Based on the results, the SE-NSGA2 approach has the smallest collision area, which is, the possibility of collision is the smallest used the SE-NSGA2. The unsafe layout of P2 products mainly occurs between robots and other devices, and the possibility of collision in MOCell method is 80.2% higher than that in SE-NSGA2, as shown in

Table 7. The unsafe layout of the P3 product mainly occurs between two robots. The collision probability of the NSGA2 method is 79.7% higher than that of the SE-NSGA2, and the collision probability of the MOCell method is 77.9% higher than that of the SE-NSGA2. P3 products are more likely to produce unsafe layouts than P2 products. In other words, the collaborative assembly of robots in the assembly of complex products will increase the possibility of unsafe layouts. The safety indicator that is proposed in this paper can filter out unsafe layouts, after γ safety indicator screening, all of the plans in the Pareto front are safe layouts by 3D validation.

After 30 independent operations,

Figure 7 shows the comparison of the number of collisions in the Pareto front solution set obtained by mathematical statistics. Among them, SE-NSGA2 has the least number of collisions. The demand for P2 products and P3 product parts each account for 50%, as shown in

Table 6. In the NSGAII method, the average number of collisions in the p2 stage is 5.18, and the average number of collisions in the p3 stage. The number of times is 7.20. The possibility of collision on the assembly line is 20.63%. The safety indicator that is proposed in this paper can filter out unsafe layouts and produce safe layouts. Overall, the safety of the assembly line layout is increased by 20.63%. SE-NSGA2 has significant advantages in the multiobjective optimization of assembly line safety. The layout improvement index is I,

is the number of collisions, and μ is the number of statistical experiment. The expression is (11).

Safe layouts are a prerequisite to guaranteeing optimize economics. These safe layouts can ensure the safety of the assembly work. It is not necessary to adjust the robot positions after continuous testing during assembly work to find the best posture for each robot in the assembly line and achieve a safe layout. In the experiment, if a collision occurs, the penalty cost is increased 10.

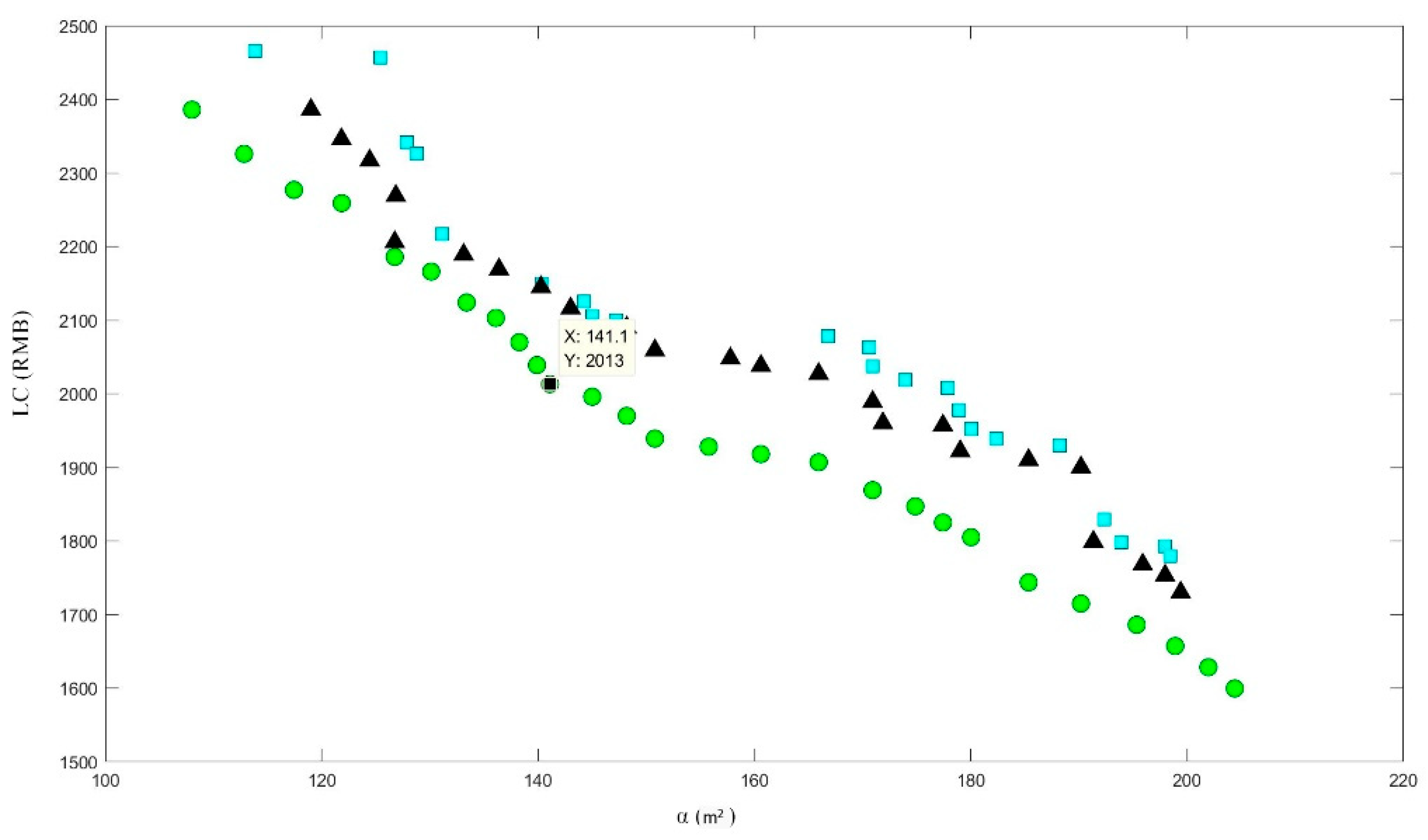

Figure 8 shows the schematic diagram of Pareto set is shown in. It can be seen from

Figure 8 that the distribution and diversity performance of SE-NSGA2 is better than the layout plan set of the MOCell and NSGA-II methods. Moreover, the convergence effect of SE-NSGA2 is better than other methods. The two optimization goals of floor space and logistics cost are inversely proportional. P and Q are partial plans that are selected from the Pareto optimal front solution set for this approach.

Table 9 presents safety layout information.

Because assembly line layout is a complex problem, it is difficult to obtain one optimal solution in the Pareto solution set, as shown in

Figure 6 and

Table 9. It is necessary to determine the final layout design plan for an assembly line according to the target weights or user preferences. This layout scheme can reflect the characteristics of the Pareto solution set. When the material cost is low, the area that is occupied is generally high.

SE-NSGA2 is an effective way to aid in decision-making and solve multiobjective problems. In the experiment, we assumed that the weighting factors of the two goals were equivalent. It is reasonable to integrate expert knowledge and experience and assembly line requirements in practical applications and assign optimization target weights. The 3D scene is connected to the database in a data-driven manner in order to verify the feasibility and rationality of safe layouts and verify the effectiveness of safe layout plans.

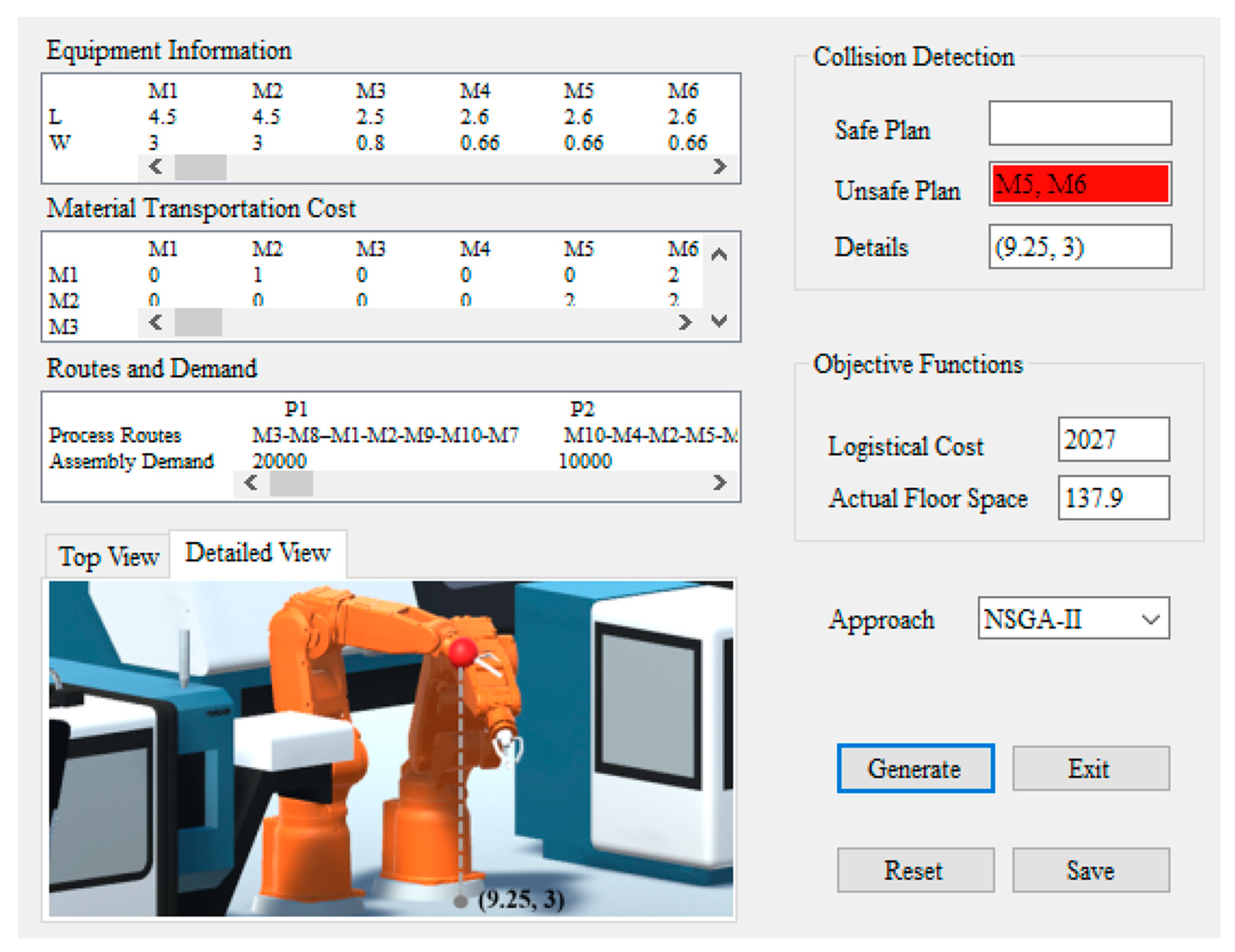

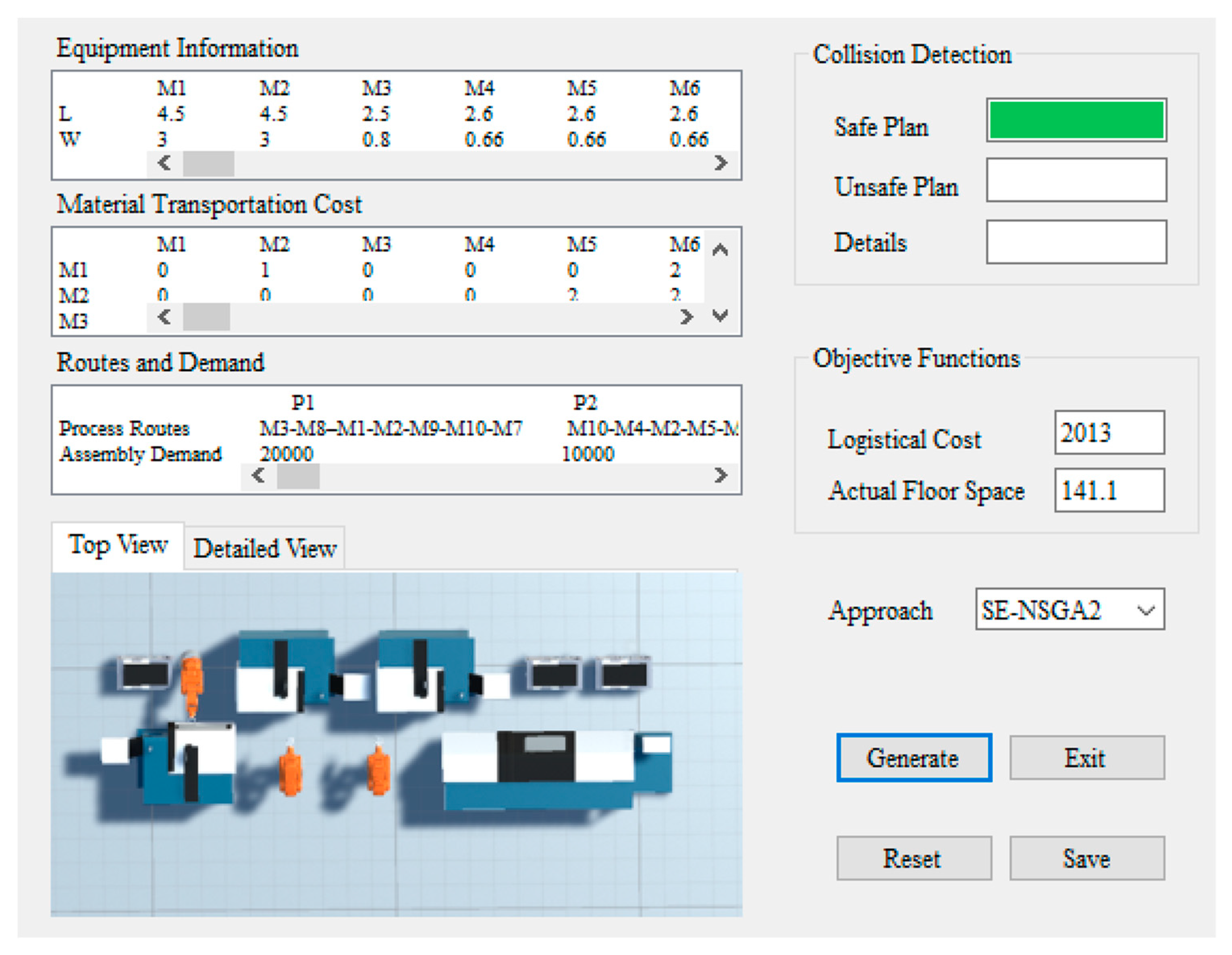

A user interface is designed to facilitate the non-professionals operation. The software has completed the national project acceptance and achieved a satisfactory user experience. According to the chosen approach, an assembly line layout design is generated by clicking a generated button. The SE-NSGA2, NSGA-II, and MOCell approaches can be selected. The top view and detailed view of the layout can be viewed in the visualization window. 3D collision detection verification is performed on the layout design plan in order to ensure a safe layout plan. When the layout design is safe, it is displayed in green. In the user interface, when the plan is unsafe, it is displayed in red. Simultaneously, the equipment name of the unsafe layout and ground projection coordinates of the first collision is displayed in the details. The collision occurs between the end-of-arm tooling of robot M5 and robot arm of M6, and the ground projection point where collisions occur is (9.25, 3), as shown in

Figure 9. Layout plan P is optimal, and it is generated with SE-NSGA2.

Figure 10 shows a user interface of the 3D visualized top view layout.