Development of Alfa Fiber-Based Mortar with Improved Thermo-Mechanical Properties

Abstract

1. Introduction

2. Materials and Methods

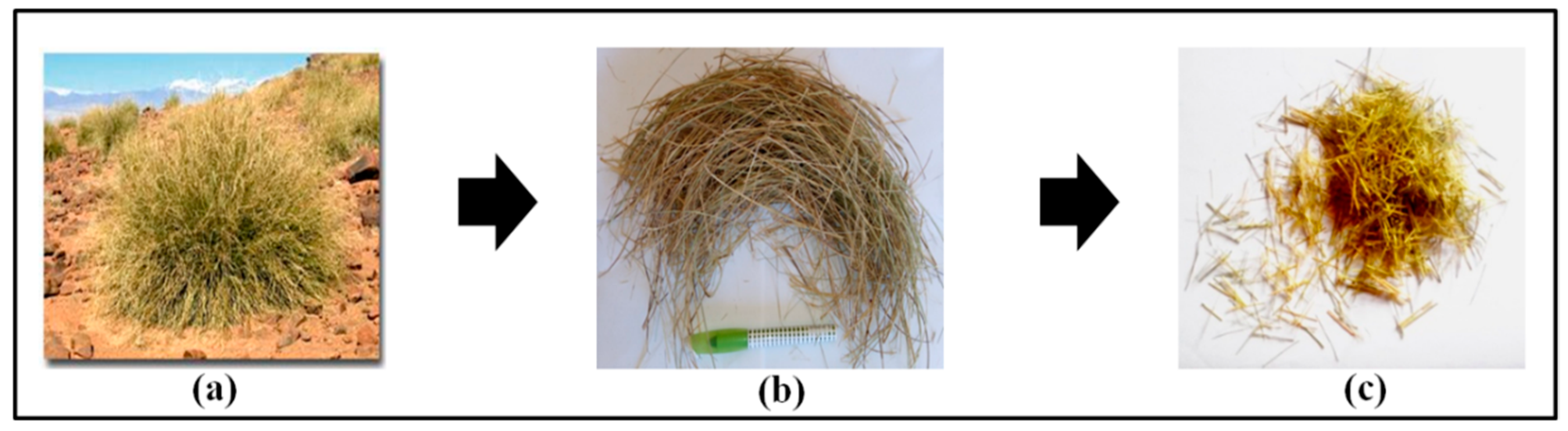

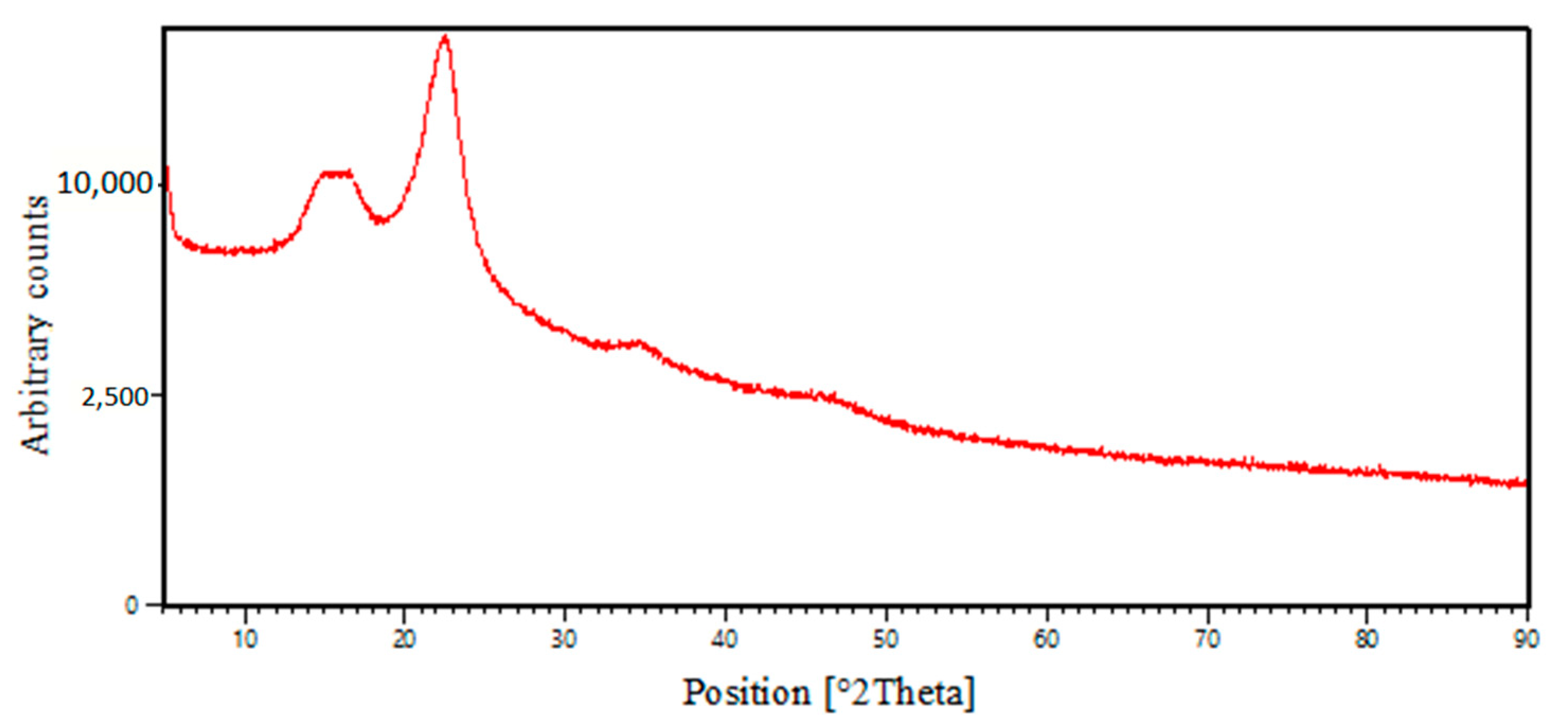

2.1. Material Selection

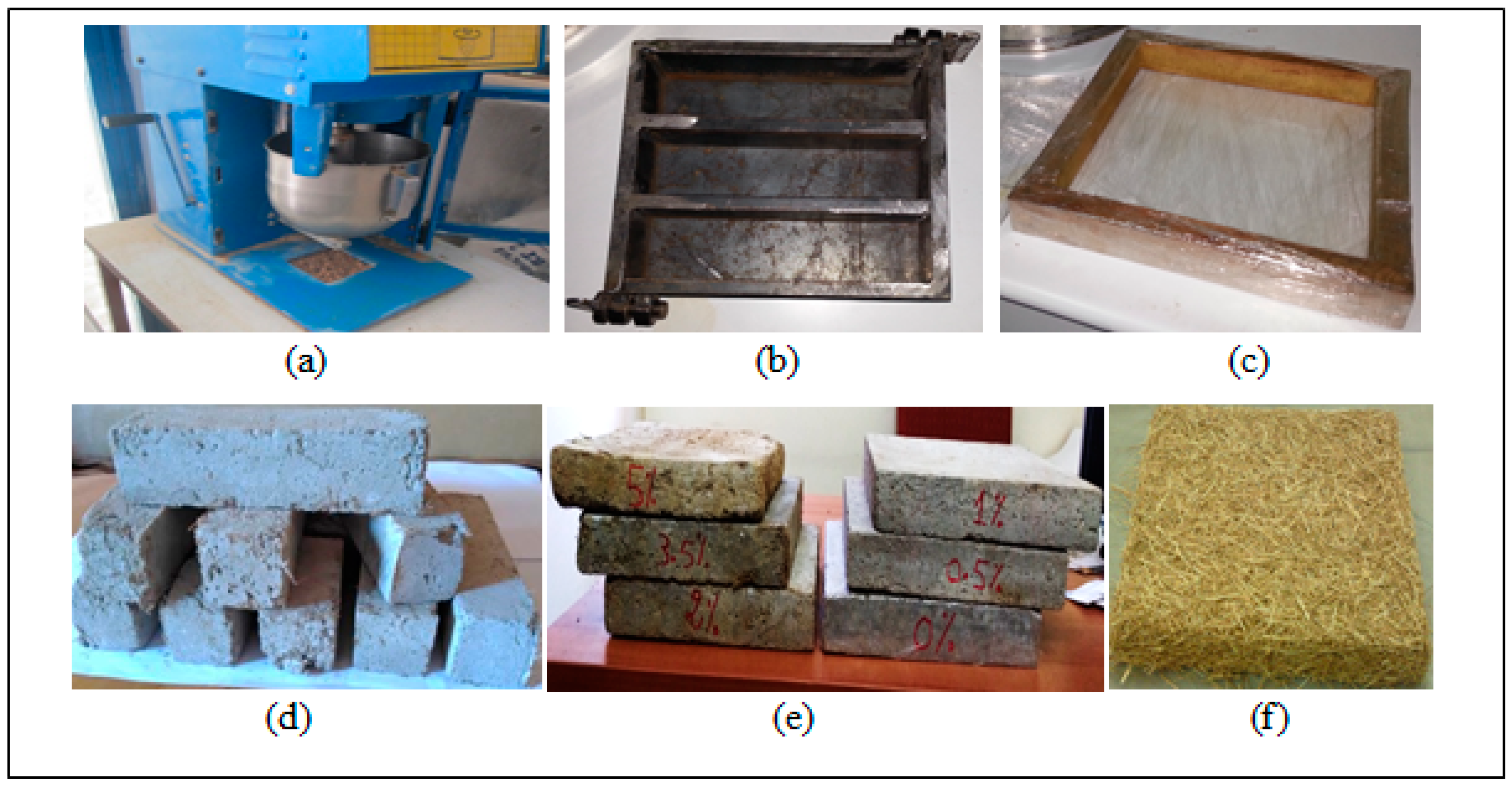

2.2. Preparation of the Alfa Fiber Composite Test Specimens

2.3. Measurement Instruments and Experimental Methods Description

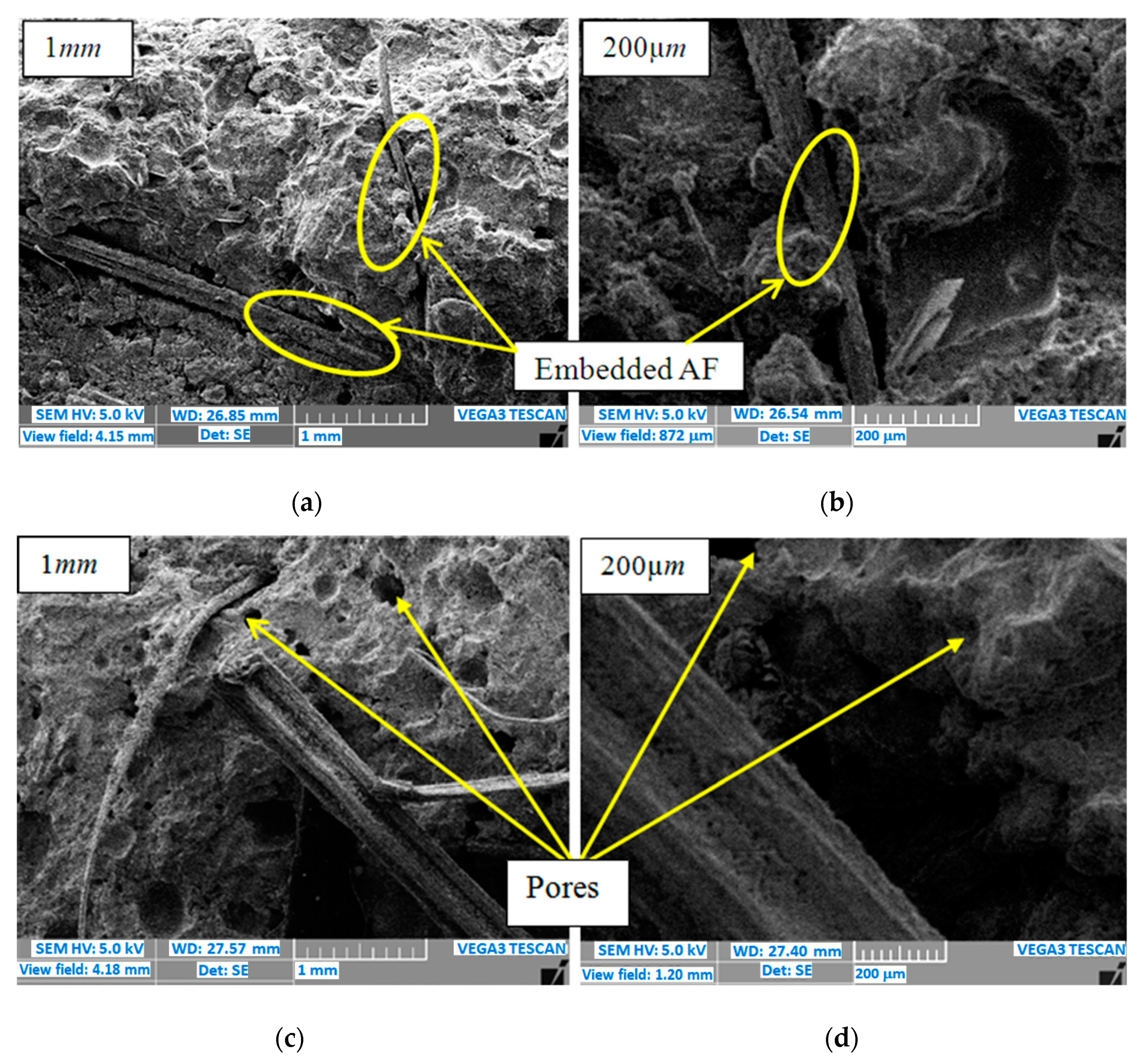

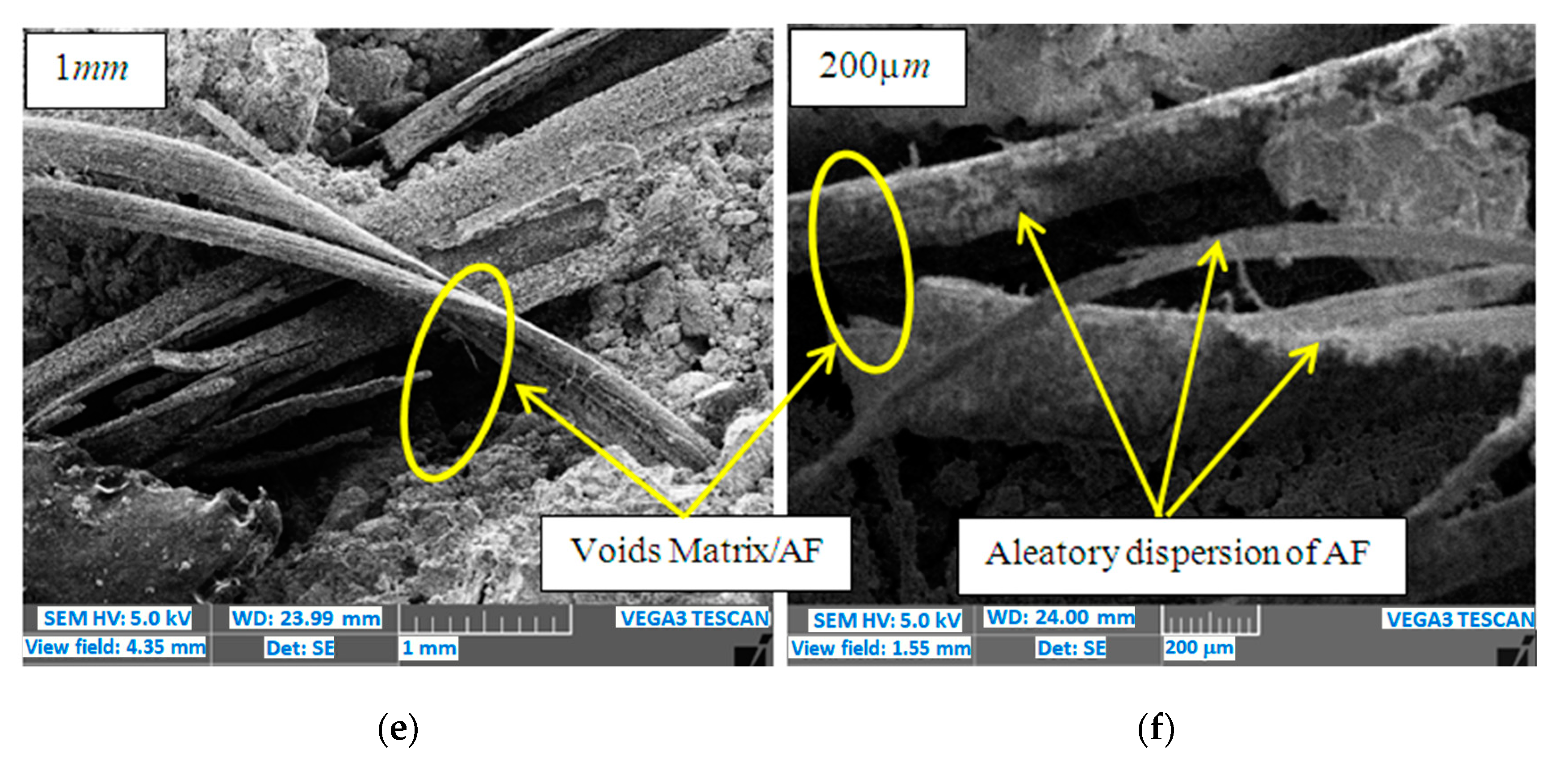

2.3.1. Scanning Electron Microscopy (SEM) Morphological Observation

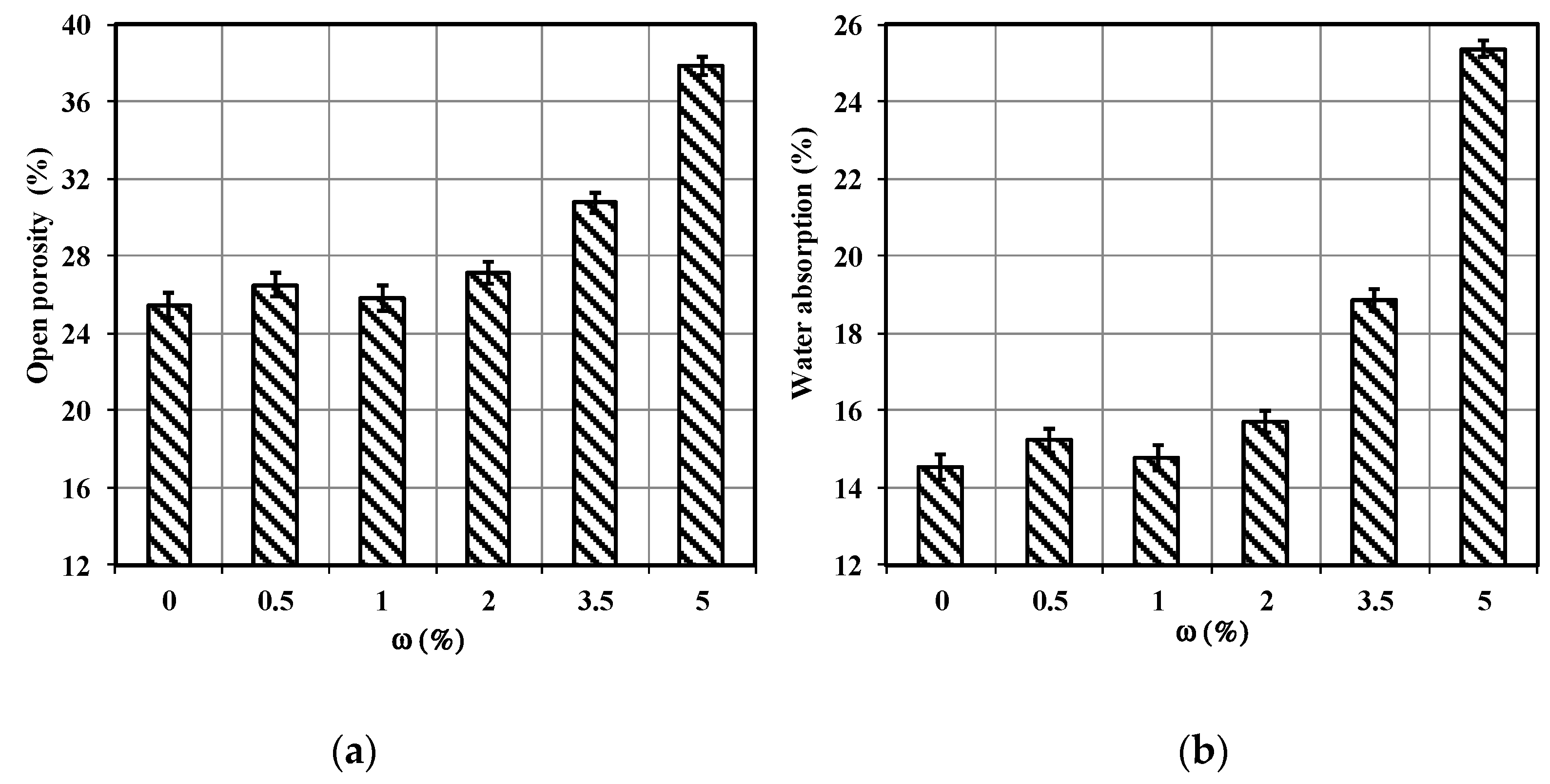

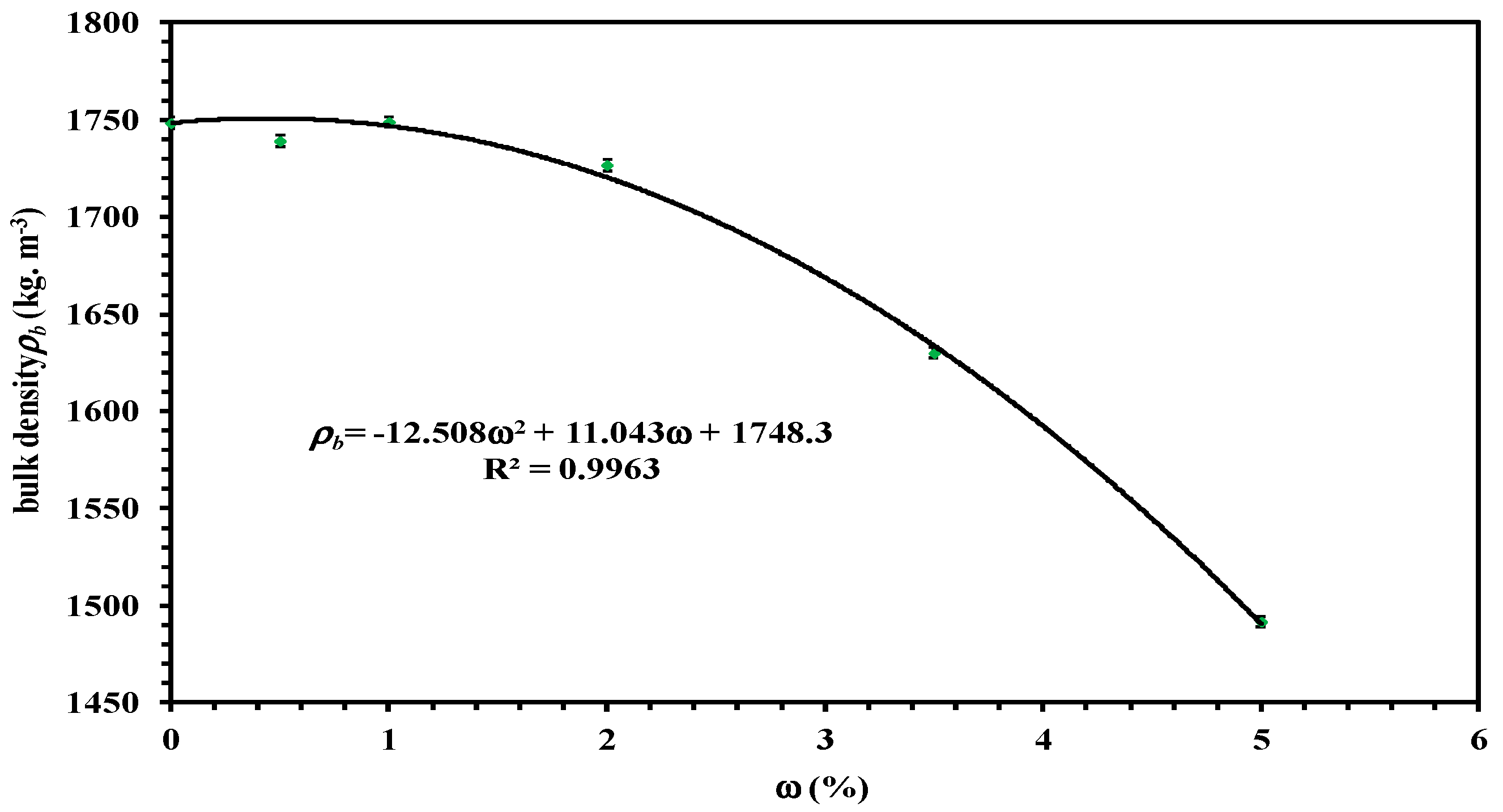

2.3.2. Open Porosity, Water Absorption, and Bulk Density

2.3.3. Thermo-Mechanical Characterization Methods

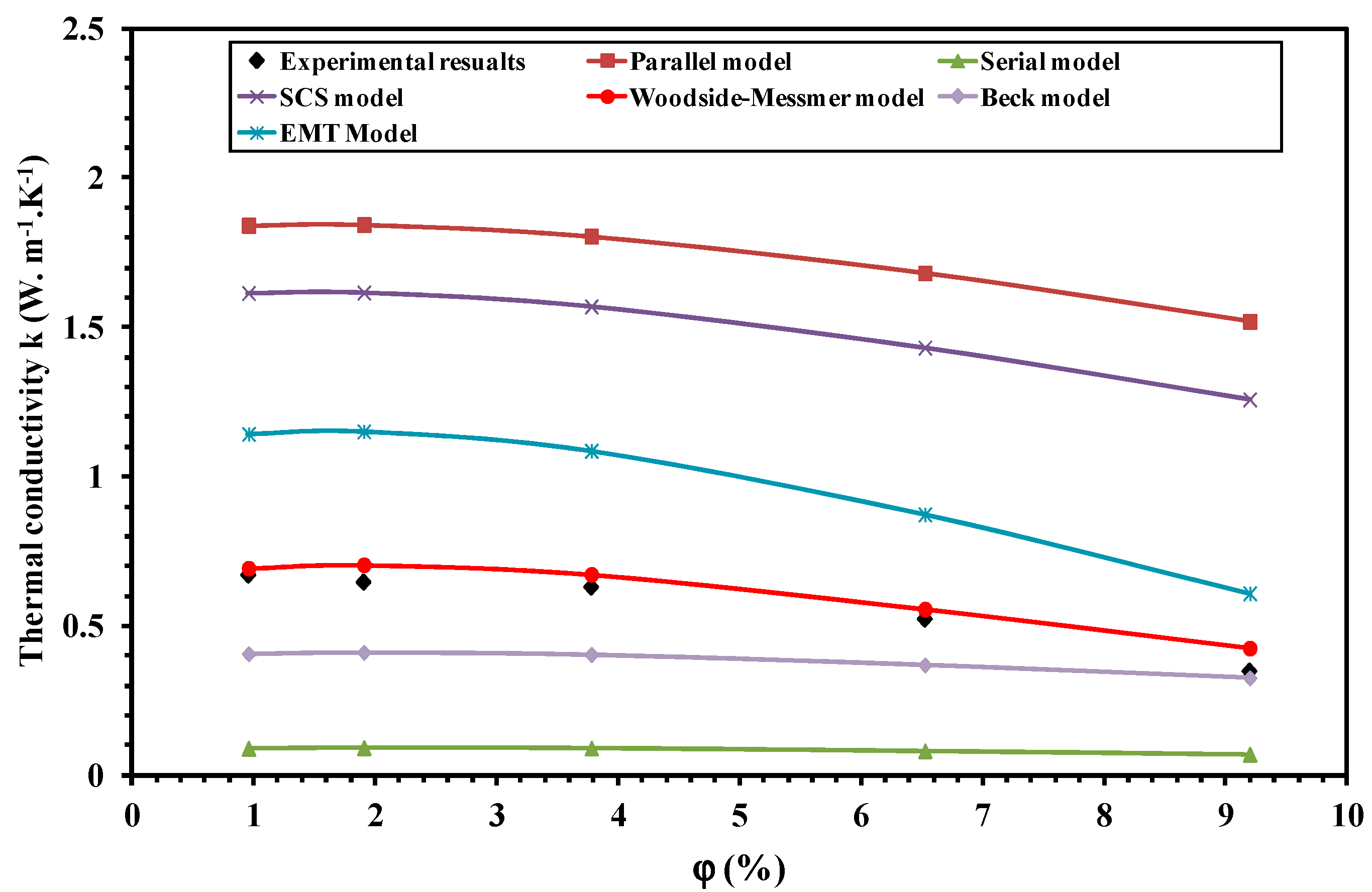

2.4. Thermal Conductivity Prediction Models

3. Results and Discussions

3.1. SEM Morphological Analysis of the Alfa Fiber Reference Mortar (AFRM) Composites

3.2. Thermophyical Performance Analysis

3.2.1. Open Porosity, Water Absorption, and Bulk Density

3.2.2. Thermal Conductivity Measurements

3.2.3. Intrinsic Thermal Conductivities Determination

3.2.4. Predicted Thermal Conductivities Comparison

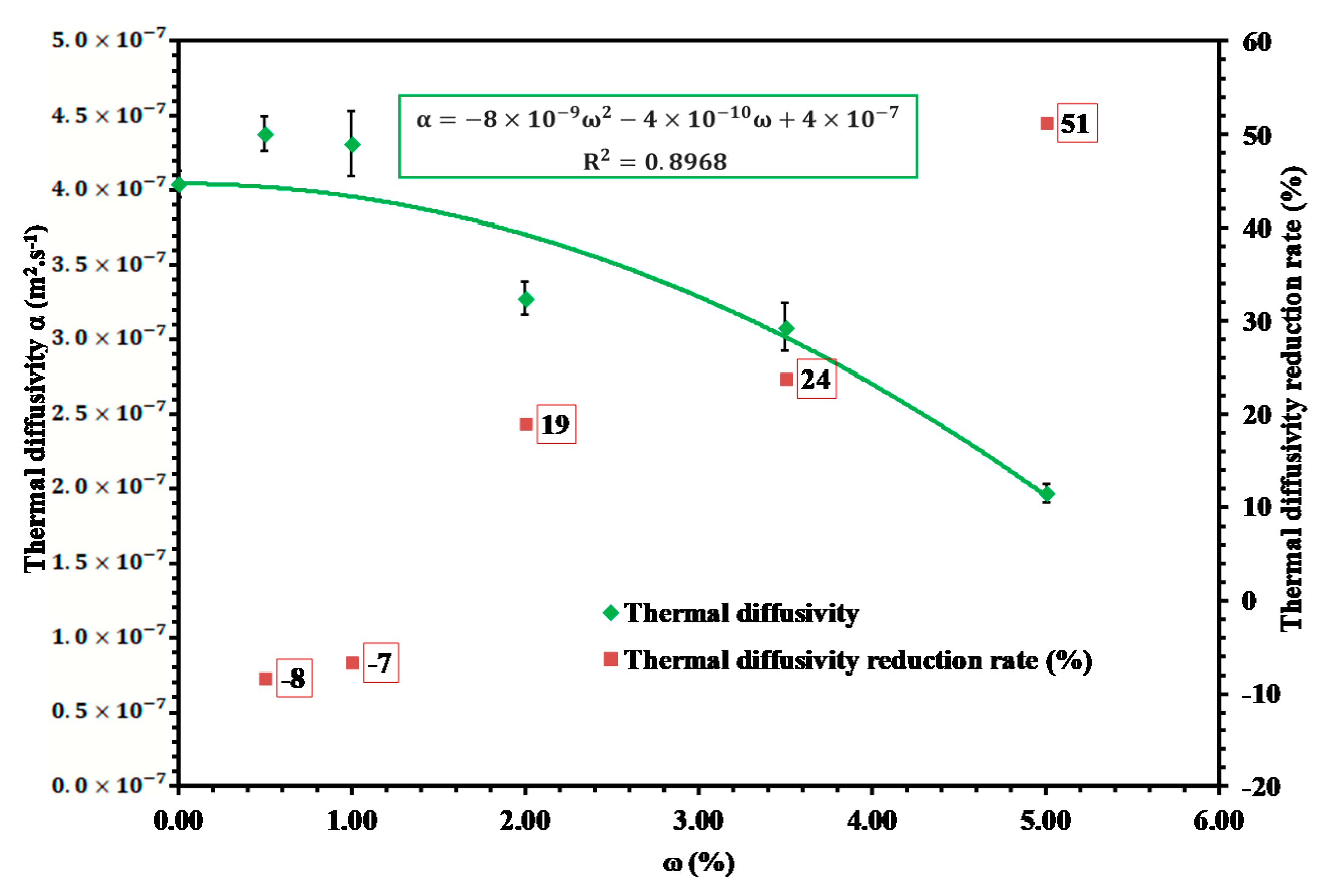

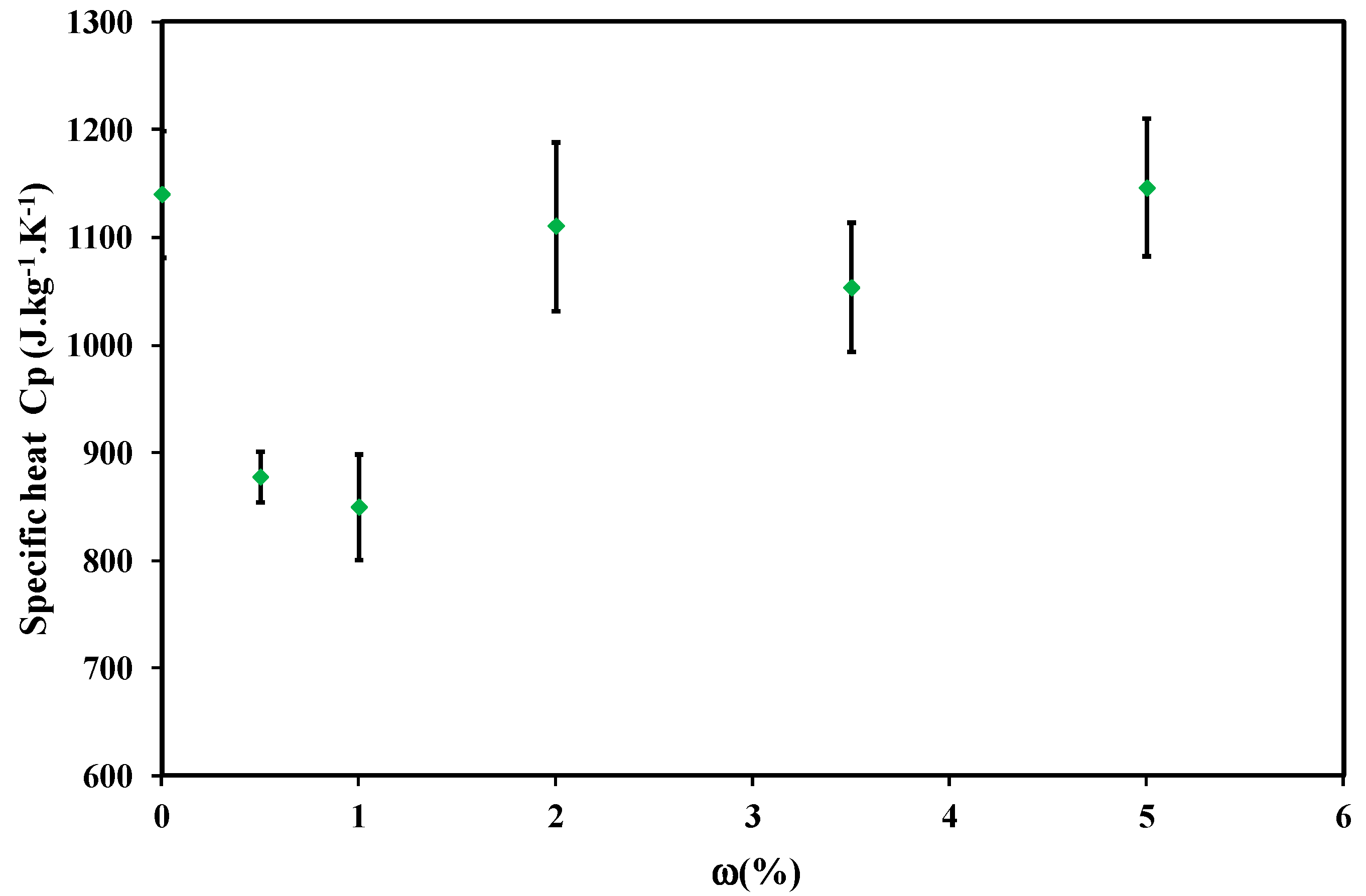

3.2.5. Thermal Diffusivity

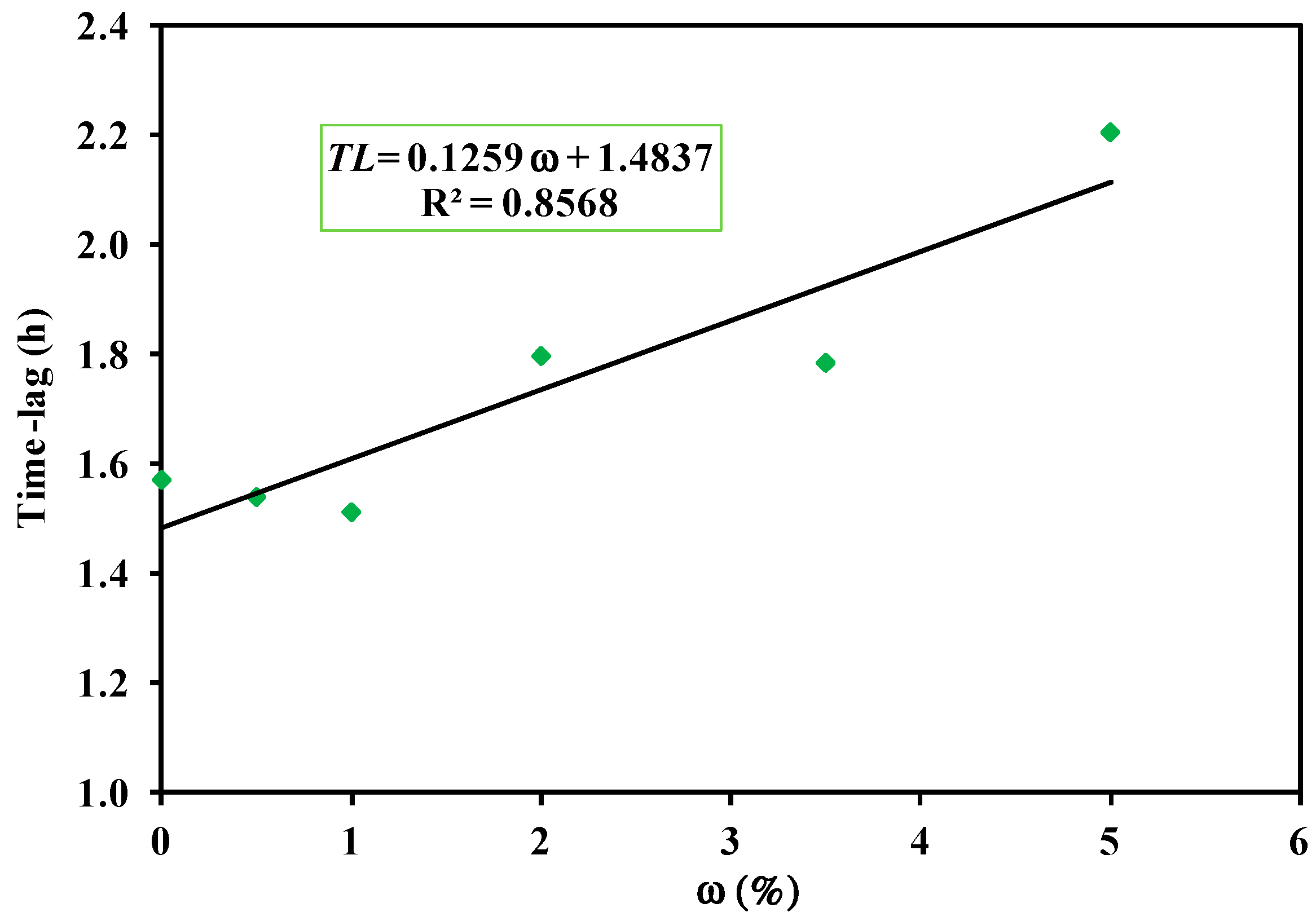

3.3. Time-Lag

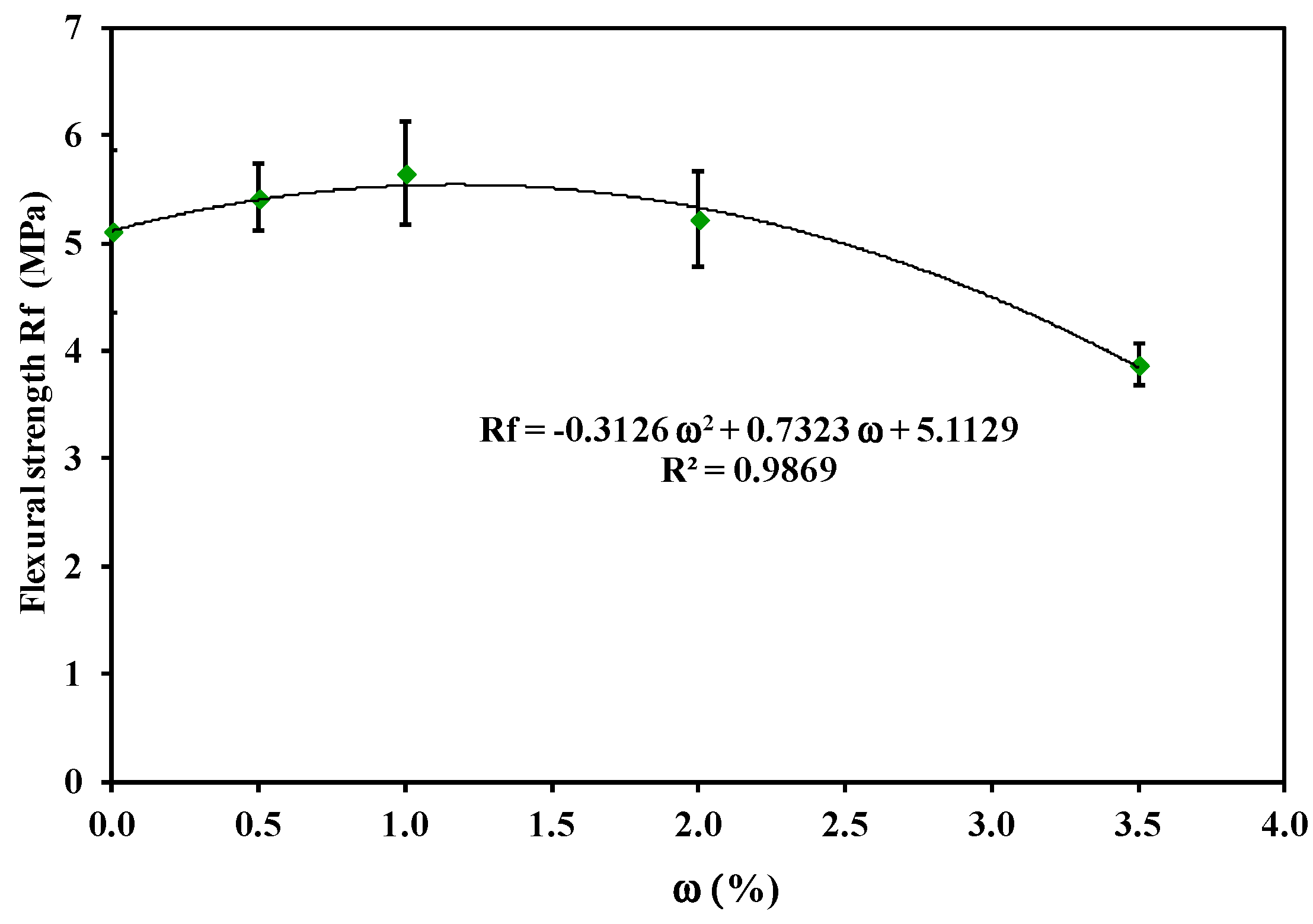

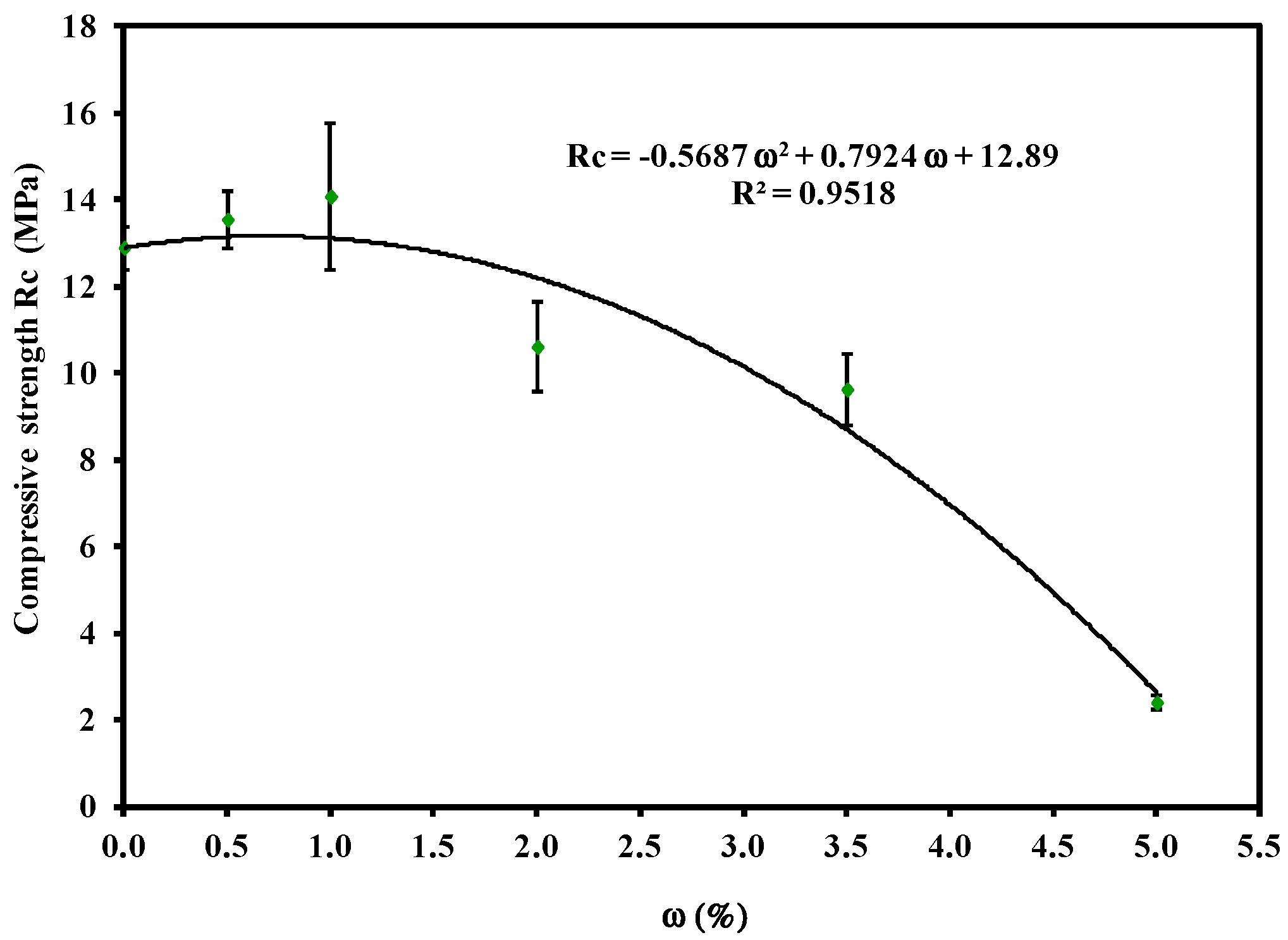

3.4. Mechanical Performance Analysis

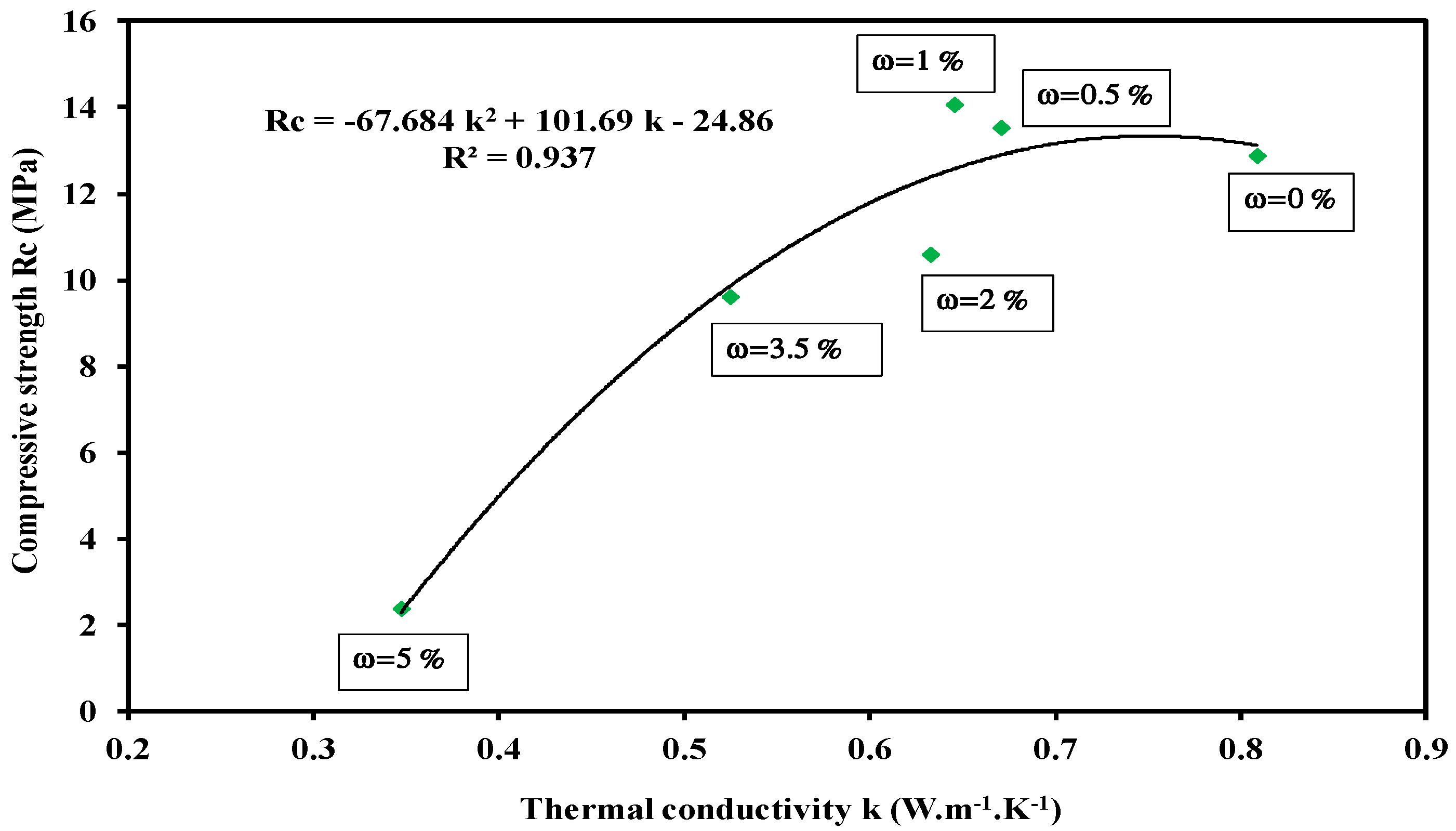

3.5. Material Classification of the Developed Composite Based on Compressive Strength and Thermal Conductivity

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pacheco, T.F.; Jalali, S. Cementitious building materials reinforced with vegetable fibres: A review. Constr. Build. Mater. 2011, 25, 575–581. [Google Scholar] [CrossRef]

- De Carvalho Bello, C.B.; Boem, I.; Cecchi, A.; Gattesco, N.; Oliveira, D.V. Experimental tests for the characterization of sisal fiber reinforced cementitious matrix for strengthening masonry structures. Constr. Build. Mater. 2019, 219, 44–55. [Google Scholar] [CrossRef]

- Ali, M.; Liu, A.; Sou, H.; Chouw, N. Mechanical and dynamic properties of coconut fibre reinforced concrete. Constr. Build. Mater. 2012, 30, 814–825. [Google Scholar] [CrossRef]

- Seng, B.; Magniont, C.; Lorente, S. Characterization of a precast hemp concrete. Part I: Physical and thermal properties. J. Build. Eng. 2019, 24, 1–46. [Google Scholar] [CrossRef]

- Elsaid, A.; Dawood, M.; Seracino, R.; Bobko, C. Mechanical properties of kenaf fiber reinforced concrete. Constr. Build. Mater. 2011, 25, 1991–2001. [Google Scholar] [CrossRef]

- Nadhari, W.N.A.W.; Danish, M.; Nasir, M.S.R.M.; Geng, B.J. Mechanical properties and dimensional stability of particleboard fabricated from steam pre-treated banana trunk waste particles. J. Build. Eng. 2019, 26, 22–25. [Google Scholar] [CrossRef]

- Belakroum, R.; Gherfi, A.; Bouchema, K.; Gharbi, A.; Kerboua, Y.; Kadja, M.; Maalouf, C.; Mai, T.H.; El Wakil, N.; Lachi, M. Hygric buffer and acoustic absorption of new building insulation materials based on date palm fibers. J. Build. Eng. 2017, 12, 132–139. [Google Scholar] [CrossRef]

- Muhtar; Dewi, S.M.; Wisnumurti; Munawir, A. Enhancing bamboo reinforcement using a hose-clamp to increase bond-stress and slip resistance. J. Build. Eng. 2019, 26, 1–13. [Google Scholar] [CrossRef]

- Kesikidou, F.; Stefanidou, M. Natural fiber-reinforced mortars. J. Build. Eng. 2019, 25, 1–6. [Google Scholar] [CrossRef]

- Elhamdouni, Y.; Khabbazi, A.; Benayad, C.; Dadi, A.; Ahmid, O.I. Effect of fiber alfa on thermophysical characteristics of a material based on clay. Energy Procedia 2015, 74, 718–727. [Google Scholar] [CrossRef]

- Rogge, E. Extraction et Etude des Propriétés Physiques et Mécaniques des Fibres d’Alfa (Esparto grass) en vue d’Applications Textiles. Master’s Thesis, Ecole Nationale Supérieure d’Ingénieurs Sud-Alsace (UHA), Mulhouse, France, 2010. [Google Scholar]

- L’alfa. Importance écologique et socio-économique. Portail de l’agriculture marocaine. Terre Vie 2002, 61–62, 1–3. [Google Scholar]

- Couderc, R. Une «cueillette industrielle»: L’alfa en Algérie. Méditerranée 2016, 19, 3–16. [Google Scholar] [CrossRef]

- Dallel, M. Evaluation du Potentiel Textile des Fibres d’Alfa (Stipa Tenacissima L.): Caractérisation Physico-Chimique de la Fibre au Fil. Ph.D. Thesis, Haute Alsace University, Mulhouse, France, 2012. [Google Scholar]

- Korjenic, A.; Petránek, V.; Zach, J.; Hroudová, J. Development and performance evaluation of natural thermal-insulation materials composed of renewable resources. J. Build. Eng. 2011, 43, 2518–2523. [Google Scholar] [CrossRef]

- Paiva, M.C. Alfa fibres: Mechanical, morphological and interfacial characterization. Compos. Sci. Technol. 2007, 67, 1132–1138. [Google Scholar] [CrossRef]

- Mounir, J.; Slah, W.B.M.; Mohamed, B. Characterization of mechanical extracted alfa fibres. Int. J. Fiber Text. Res. 2014, 4, 1–4. [Google Scholar]

- Krobba, B.; Bouhicha, M.; Zaidi, A.; Lakhdari, M. Formulation of a repair mortar based on dune sand and natural microfibers. Concr. Solut. 2014, 91–95. [Google Scholar]

- Jaballi, H.; Miraoui, S.; Hassis, I. Optimization of flexural strength and thermal conductivity of mortar reinforced with alfa fibers. Appl. Mech. Mater. 2015, 799–800, 794–799. [Google Scholar] [CrossRef]

- El Hamdouni, Y.; Khabbazi, A.; Benayad, C.; Dadi, A.; Idriss Ahmid, O. Contribution to the thermal and mechanical behavior of the two materials at the base of clay reinforced by fibers ALFA and of straw fibers. Res. J. Appl. Sci. Eng. Technol. 2016, 12, 490–497. [Google Scholar] [CrossRef]

- Braiek, A.; Karkri, M.; Adili, A.; Ibos, L.; Ben Nasrallah, S. Estimation of the thermophysical properties of date palm fibers/gypsum composite for use as insulating materials in building. Energy Build. 2017, 140, 268–279. [Google Scholar] [CrossRef]

- Taoukil, D.; El Bouardi, A.; Ajzoul, T.; Ezbakhe, H. Effect of the incorporation of wood wool on thermo physical proprieties of sand mortars. KSCE J. Civ. Eng. 2012, 16, 1003–1010. [Google Scholar] [CrossRef]

- Maghchiche, A.; Haouam, A.; Immirzi, B. Extraction and characterization of algerian alfa grass short fibers (stipa tenacissima). Chem. Chem. Technol. 2013, 7, 339–344. [Google Scholar] [CrossRef]

- Kriker, A.; Debicki, G.; Bali, A.; Khenfer, M.M.; Chabannet, M. Mechanical properties of date palm fibres and concrete reinforced with date palm fibres in hot-dry climate. Cem. Concr. Compos. 2005, 27, 554–564. [Google Scholar] [CrossRef]

- IMANOR. Liants Hydraulique-Ciments Composition, Spécifications et Critères de Conformité; NM 10.01.004; IMANOR: Rabat, Morocco, 2003.

- AFNOR. Essais Pour Déterminer les Caractéristiques Géométriques des Granulats—Partie 8: Évaluation des Fines—Équivalent de Sable; NF EN 933-8 (NF P 18-622-8); AFNOR: Paris, France, 1999. [Google Scholar]

- AFNOR. Méthodes D’essai des Ciments, Partie I. Détermination des Résistances Mécaniques; NF EN 196-1; AFNOR: Paris, France, 1995. [Google Scholar]

- ASTM International. Standard Test Methods for Apparent Porosity, Water Absorption, Apparent Specific Gravity, and Bulk Density of Burned Refractory Brick and Shapes by Boiling Water; ASTM C20-00; ASTM Int.: West Conshohocken, PA, USA, 2000; Volume 3, PA 19428-2959. [Google Scholar]

- Menguy, G.; Laurent, M.; Moutarda, A.; Leveau, J. Cellule de Mesure des Caractéristiques Thermophysiques des Matériaux E1700. Société Weber Broutin; Bulletin Technique, Deltalab: Carcassonne, France, 1986. [Google Scholar]

- Boumhaout, M.; Boukhattem, L.; Hamdi, H.; Benhamou, B. Thermomechanical characterization of a bio-composite building material: Mortar reinforced with date palm fibers mesh. Constr. Build. Mater. 2017, 135, 241–250. [Google Scholar] [CrossRef]

- AFNOR. Techniques des Essais sur les Liants Hydrauliques; NM 10.1.005; AFNOR: Paris, France, 1994. [Google Scholar]

- Cabaleiro, D.; Nimo, J.; Pastoriza-Gallego, M.J.; Piñeiro, M.M.; Legido, J.L.; Lugo, L. Thermal conductivity of dry anatase and rutile nano-powders and ethylene and propylene glycol-based TiO2 nanofluids. J. Chem. Thermodyn. 2015, 83, 67–76. [Google Scholar] [CrossRef]

- Beck, J.M.; Beck, A.E. Computing thermal conductivities of rocks from chips and conventional specimens. J. Geophys. Res. 1965, 70, 5227–5239. [Google Scholar] [CrossRef]

- Woodside, W.; Messmer, J.H. Thermal conductivity of porous media. I. Unconsolidated Sands. J. Appl. Phys. 1961, 32, 1688. [Google Scholar] [CrossRef]

- Boutin, C. Conductivité thermique du béton cellulaire autoclavé: Modélisation par méthode autocohérente. Mater. Struct. 1996, 29, 609–615. [Google Scholar] [CrossRef]

- Benazzouk, A.; Douzane, O.; Mezreb, K.; Laidoudi, B.; Quéneudec, M. Thermal conductivity of cement composites containing rubber waste particles: Experimental study and modelling. Constr. Build. Mater. 2008, 22, 573–579. [Google Scholar] [CrossRef]

- Bederina, M.; Marmoret, L.; Mezreb, K.; Khenfer, M.M.; Bali, A.; Quéneudec, M. Effect of the addition of wood shavings on thermal conductivity of sand concretes: Experimental study and modelling. Constr. Build. Mater. 2007, 21, 662–668. [Google Scholar] [CrossRef]

- Mark, C.; Burns, P.J.; Sommerfeld, R.A. Quasi-steady temperature gradient metamorphism in idealized, dry snow. Numer. Heat Transf. Part. A Appl. 1994, 25, 259–278. [Google Scholar]

- Maxwell, D.C. A Treatise of Electricity and Magnetism, 3rd ed.; Dover Publications Inc.: New York, NY, USA, 1954; Volume 1–2. [Google Scholar]

- Krischer, O. Die Wissenschaftlichen Grundlagen der Trocknungstechnik; Springer: Berlin/Heidlberg, Germany, 1963; Volume 1. [Google Scholar]

- Dawood, E.T.; Ramli, M. Properties of high-strength flowable mortar reinforced with palm fibers. Int. Sch. Res. Netw. 2012, 1–5. [Google Scholar] [CrossRef]

- Belhadj, B.; Bederina, M.; Makhloufi, Z.; Goullieux, A.; Quéneudec, M. Study of the thermal performances of an exterior wall of barley straw sand concrete in an arid environment. Energy Build. 2015, 87, 166–175. [Google Scholar] [CrossRef]

- Taallah, B.; Guettala, A. The mechanical and physical properties of compressed earth block stabilized with lime and filled with untreated and alkali-treated date palm fibers. Constr. Build. Mater. 2016, 104, 52–62. [Google Scholar] [CrossRef]

- Bal, H.; Jannot, Y.; Gaye, S.; Demeurie, F. Measurement and modelisation of the thermal conductivity of a wet composite porous medium: Laterite based bricks with millet waste additive. Constr. Build. Mater. 2013, 41, 586–593. [Google Scholar] [CrossRef]

- Rahim, M.; Douzane, O.; Tran Le, A.D.; Langlet, T. Effect of moisture and temperature on thermal properties of three bio-based materials. Constr. Build. Mater. 2016, 111, 119–127. [Google Scholar] [CrossRef]

- Boukhattem, L.; Boumhaout, M.; Hamdi, H.; Benhamou, B. Moisture content influence on the thermal conductivity of insulating building materials made from date palm fibers mesh. Constr. Build. Mater. 2017, 148, 811–823. [Google Scholar] [CrossRef]

- Chikhi, M. Young’s modulus and thermophysical performances of bio-sourced materials based on date palm fibers. Energy Build. 2016, 129, 589–597. [Google Scholar] [CrossRef]

- Krobba, B.; Bouhicha, M.; Kenai, S.; Courard, L. Formulation of low cost eco-repair mortar based on dune sand and Stipa tenacissima microfibers plant. Constr. Build. Mater. 2018, 171, 950–959. [Google Scholar] [CrossRef]

- Miraoui, I.; Jaballi, S.; Hassis, H. Analysis of the mechanical properties of mortar reinforced with long unidirectional alfa fibers in different curing conditions. Mech. Compos. Mater. 2016, 52, 545–554. [Google Scholar] [CrossRef]

- Rilem, L. Functional classification of lightweight concrete. Mater. Struct. 1978, 11, 281–283. [Google Scholar]

| Constituents | SiO2 | Al2O3 | K2O | Fe2O3 | Na2O | MgO | CaO | P2O5 | TiO2 | SO3 | Cl |

| Content (%) | 68.51 | 13.55 | 3.95 | 2.83 | 2.72 | 2.64 | 1.62 | 0.16 | 0.7 | 0.01 | 0.005 |

| Model | Equation | Comment | Reference | |

|---|---|---|---|---|

| Parallel | (4) | : Volume ratio of solid matrix of AF per absolute volume of sample. : Absolute density of composite. : Total porosity. : Intrinsic thermal conductivities of AF and reference mortar (RM) respectively. : Thermal conductivity of air. : Weight content of AF per weight of mixture. : Bulk density of composite. and : Absolute densities of reference mortar and AF. | [32,33,34] | |

| (5) | ||||

| (6) | ||||

| (7) | ||||

| Serial | (8) | |||

| Beck’s | (9) | |||

| Woodside and Messmer | (10) | |||

| Auto-coherent | (11) | : Volume ratio of (air + AF) in the sample. : Concentration of AF in relation to components (air + AF) in the sample. | [35,36,37] | |

| Effective medium theory (EMT) | (12) | : Volume ratio of solid matrix of AF per volume of sample. : Volume ratio of solid matrix of mortar per volume of sample. : Volume ratio of solid matrix of air per volume of sample. | [38,39] | |

| (13) | ||||

| Krischer–Kroll | (14) | : Volume fraction of the layers oriented perpendicular to the heat flux direction | [40] | |

| Composites | RM | AFRM 0.5% | AFRM 1% | AFRM 2% | AFRM 3.5% | AFRM 5% |

|---|---|---|---|---|---|---|

| Pt (%) | 28.10 | 28.20 | 27.46 | 27.72 | 30.84 | 35.86 |

| () | 2433 | 2422 | 2411 | 2389 | 2357 | 2326 |

| () | 1263 | |||||

| Material (e = 20 cm) | Time-Lag (h) | |||

|---|---|---|---|---|

| AFRM | 1492 | 0.58 | 1.97 × 107 | 10.37 |

| Hemp concrete | 440 | 1.81 | 2.27 × 107 | 9.6 |

| Cellular concrete | 600 | 1.43 | 2.74 × 107 | 8.6 |

| Earth block | 1850 | 0.20 | 5.24 × 107 | 6.2 |

| Solid brick | 1950 | 0.23 | 5.41 × 107 | 6.3 |

| Concrete | 2300 | 0.11 | 7.93 × 107 | 5.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sakami, S.; Boukhattem, L.; Boumhaout, M.; Benhamou, B. Development of Alfa Fiber-Based Mortar with Improved Thermo-Mechanical Properties. Appl. Sci. 2020, 10, 8021. https://doi.org/10.3390/app10228021

Sakami S, Boukhattem L, Boumhaout M, Benhamou B. Development of Alfa Fiber-Based Mortar with Improved Thermo-Mechanical Properties. Applied Sciences. 2020; 10(22):8021. https://doi.org/10.3390/app10228021

Chicago/Turabian StyleSakami, Siham, Lahcen Boukhattem, Mustapha Boumhaout, and Brahim Benhamou. 2020. "Development of Alfa Fiber-Based Mortar with Improved Thermo-Mechanical Properties" Applied Sciences 10, no. 22: 8021. https://doi.org/10.3390/app10228021

APA StyleSakami, S., Boukhattem, L., Boumhaout, M., & Benhamou, B. (2020). Development of Alfa Fiber-Based Mortar with Improved Thermo-Mechanical Properties. Applied Sciences, 10(22), 8021. https://doi.org/10.3390/app10228021