Modeling the Drying of Capillary-Porous Materials in a Thin Layer: Application to the Estimation of Moisture Content in Thin-Walled Building Blocks

Abstract

1. Introduction

2. Materials and Methods

2.1. Main Concepts and Definitions

2.2. Substantiation of the Model

2.3. Newton’s Model

- (1)

- Do the moisture values calculated by formula (8) differ from the values determined using other models, for example, Newton’s model MR = e−kt [17]?

- (2)

- To what basis (w.b. or d.b.) do the simulation results correspond?

3. Results and Discussion

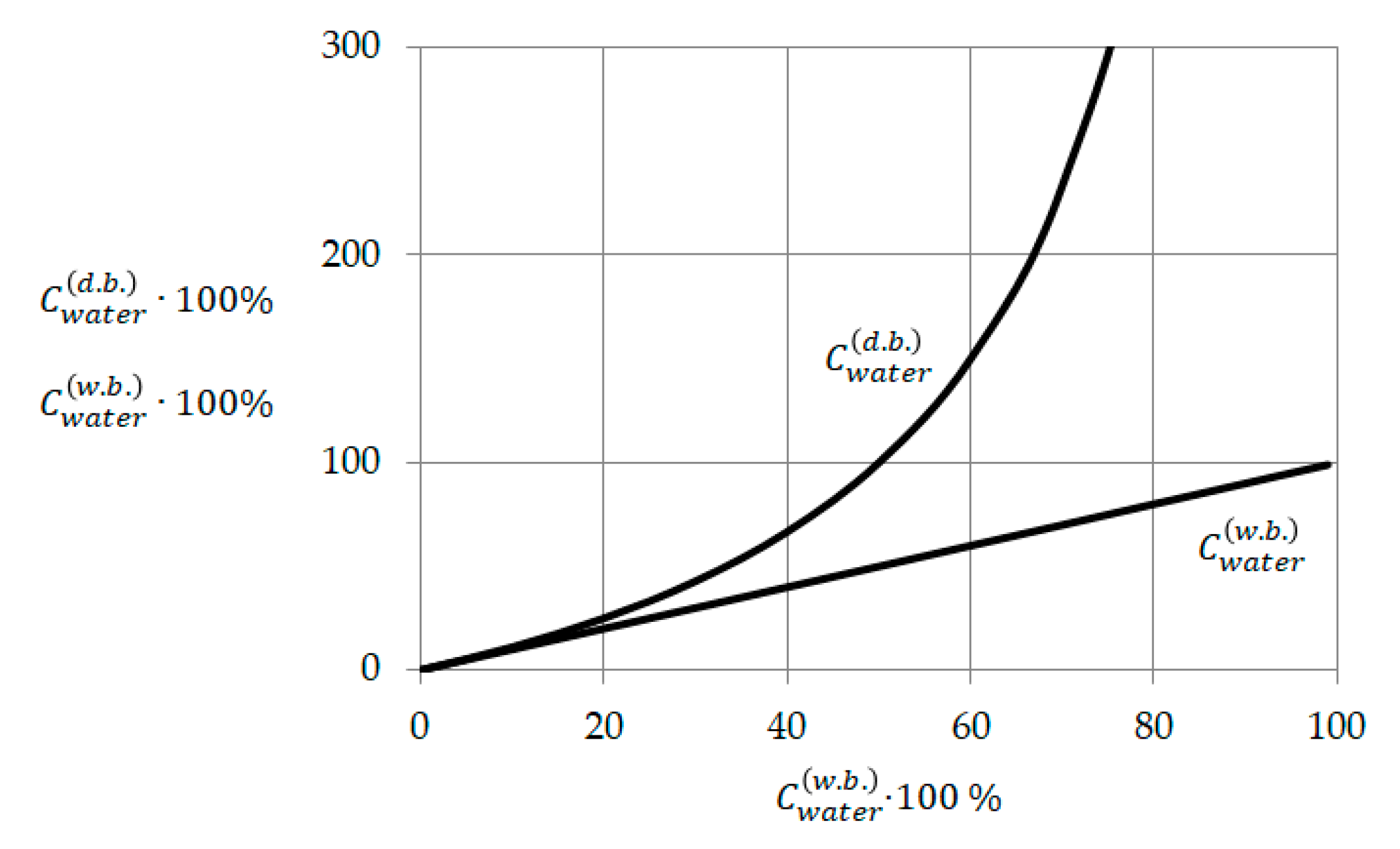

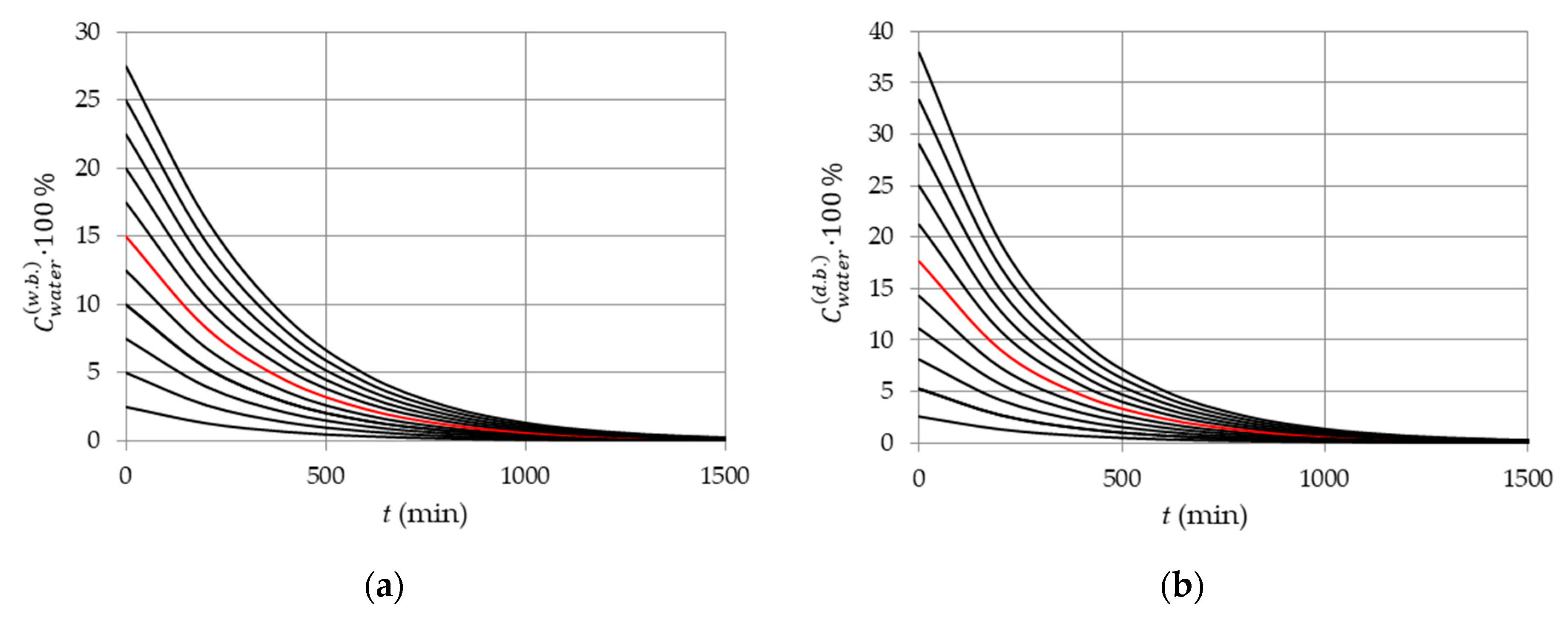

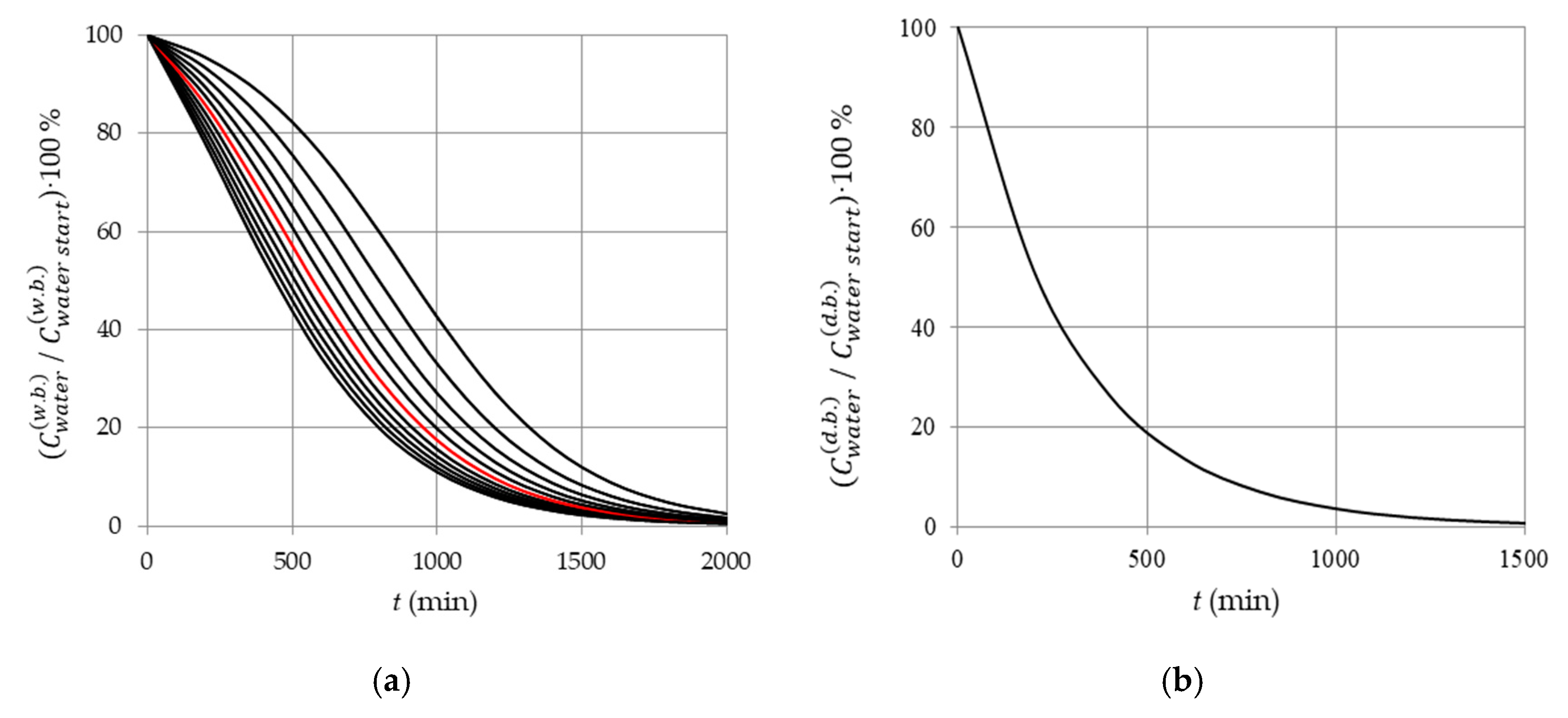

3.1. Influence of Initial Material Moisture Content (Wet Basis and Dry Basis)

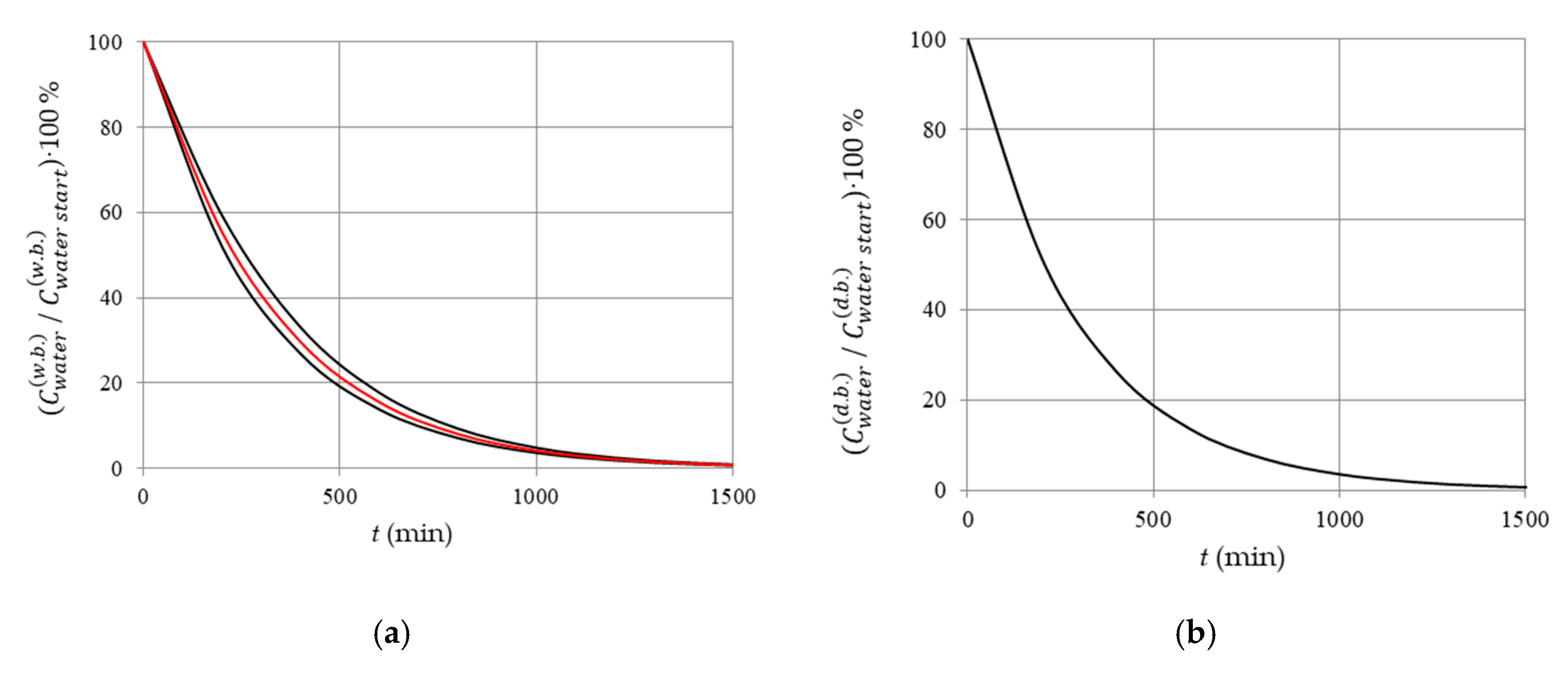

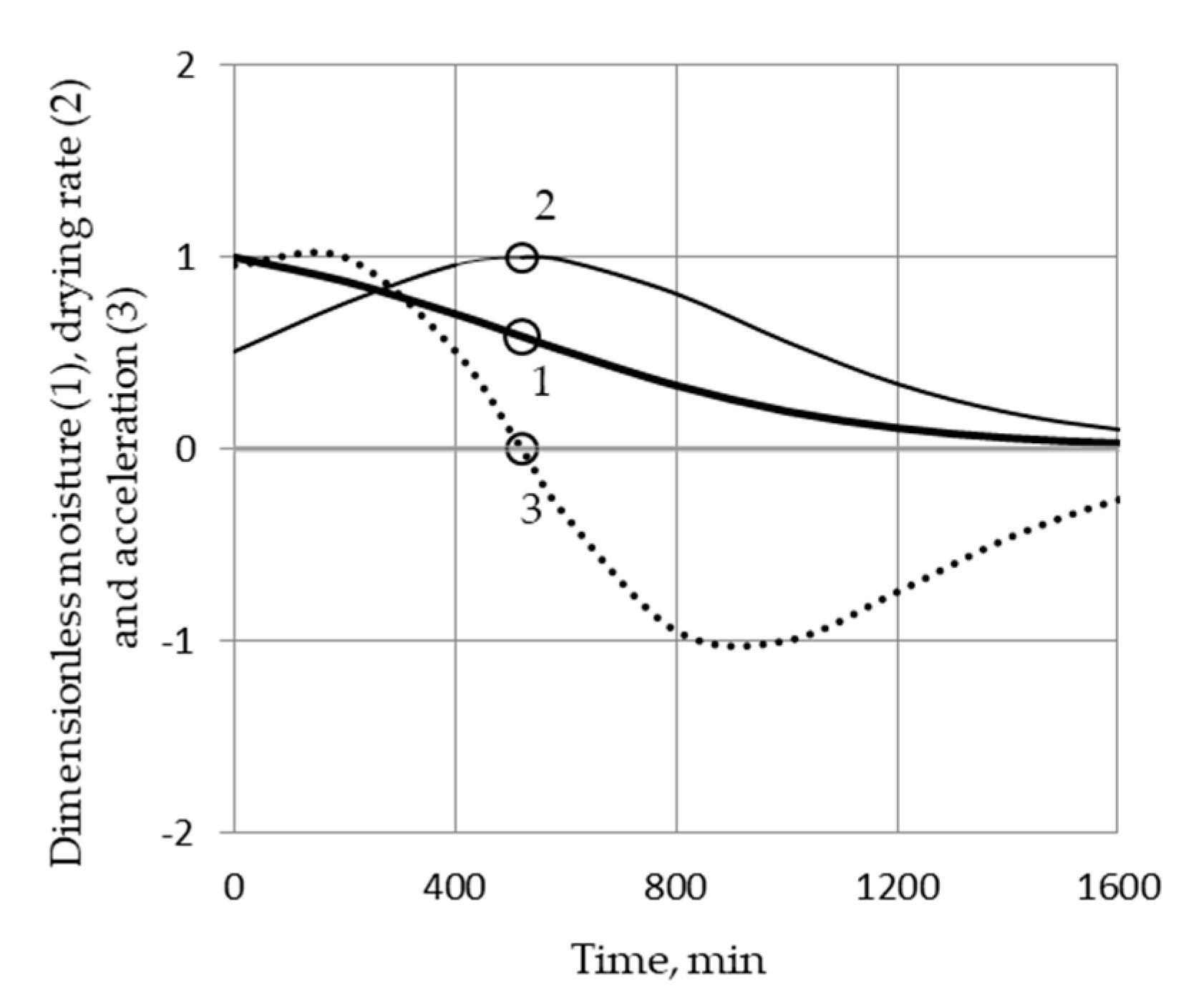

3.2. Inflection Point on the Drying Curve and the Rate of the Drying Process

3.3. Influence of Drying Temperature

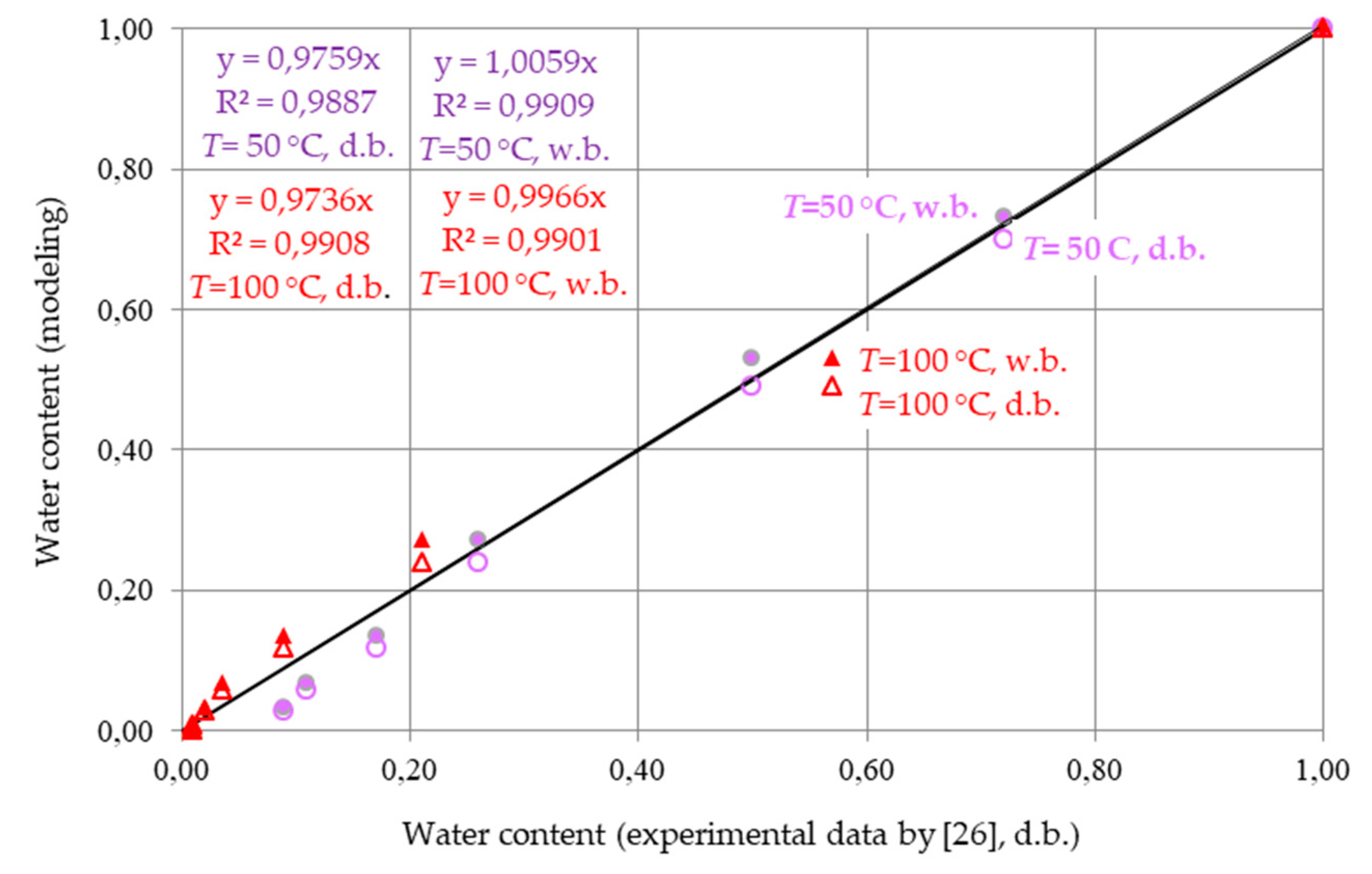

3.4. Comparison with the Experimental Data on Drying Ceramic Blocks for Construction, Known from the Literature

3.5. Analysis of the Results: Methodological Aspects

4. Conclusions

- (1)

- A mathematical model has been developed for thin-layer drying of a capillary-porous material with direct consideration of its initial moisture content and drying temperature, along with indirect consideration of the influence of other factors.

- (2)

- Using the developed model, the analysis of the features of the drying process of materials with high and low initial moisture content has been carried out. The dependence of the ratios of the normalized moisture content on the choice of the basis (w.b. or d.b.) has been proved.

- (3)

- It is shown that the function of normalized moisture content (w.b.) directly depends on the initial moisture content and, as a consequence, is more informative than the function of normalized moisture content (d.b.), in which the initial moisture content is indirectly and indiscernibly taken into account in combination with the temperature and other technological factors of drying. It was found that if the initial moisture content (w.b.) is in the range (0.5; 1.0), then the rate of the drying process reaches an extreme in this range. An analytical relationship for determining the time at which the drying rate is extreme has been substantiated.

- (4)

- The developed mathematical model of thin-layer drying makes it possible to predict changes in the moisture content of the material and the duration of its drying, depending on the initial moisture content of the material and the drying temperature. Thus, the number of indirectly taken into account factors has been reduced, which, accordingly, increases the predictive capabilities of the model when justifying recommendations for improving drying technologies in the interests of sustainable development.

- (5)

- The adequacy of the model and the assessment of the reliability of the results of model calculations are confirmed by their agreement with the experimental data related to the drying of ceramic blocks for construction, known from the literature.

Author Contributions

Funding

Conflicts of Interest

References

- Kucuk, H.; Midilli, A.; Kilic, A.; Dincer, I. A Review on Thin-Layer Drying-Curve Equations. Dry. Technol. 2014, 32, 757–773. [Google Scholar] [CrossRef]

- Jayas, D.S.; Cenkowski, S.; Pabis, S.; Muir, W.E. Review of thin-layer drying and wetting equations. Dry. Technol. 1991, 9, 551–588. [Google Scholar] [CrossRef]

- Ostanek, J.; Ileleji, K. Conjugate heat and mass transfer model for predicting thin-layer drying uniformity in a compact, crossflow dehydrator. Dry. Technol. 2020, 38, 775–792. [Google Scholar] [CrossRef]

- Visser, R.; Berkett, H.; Spinelli, R. Determining the effect of storage conditions on the natural drying of radiata pine logs for energy use. N. Z. J. Sci. 2014, 44. [Google Scholar] [CrossRef]

- Asdrubali, F.; Ferracuti, B.; Lombardi, L.; Guattari, C.; Evangelisti, L.; Grazieschi, G. A review of structural, thermo-physical, acoustical, and environmental properties of wooden materials for building applications. Build. Environ. 2017, 114, 307–332. [Google Scholar] [CrossRef]

- Sadłowska-Sałęga, A.; Wąs, K. Risk of Moisture in Diffusionally Open Roofs with Cross-Laminated Timber for Northern Coastal Climates. Buildings 2020, 10, 10. [Google Scholar] [CrossRef]

- Teaca, C.A.; Roşu, D.; Mustaţă, F.; Rusu, T.; Roşu, L.; Roşca, I.; Varganici, C.D. Natural Bio-Based Products for Wood Coating and Protection against Degradation: A Review. Bio. Resour. 2019, 14, 4873–4901. [Google Scholar] [CrossRef]

- Pecenko, R.; Challamel, N.; Colinart, T.; Picandet, V. Semi-analytical solution of Luikov equations for time-periodic boundary conditions. Int. J. Heat Mass. Transfer. 2018, 124, 533–542. [Google Scholar] [CrossRef]

- Silva, W.P.; Silva, C.M.D.P.S.; Silva, L.D.; Farias, V.S.O. Drying of clay slabs: Experimental determination and prediction by two-dimensional diffusion models. Ceram. Int. 2013, 39, 7911–7919. [Google Scholar] [CrossRef]

- Mitterpach, J.; Igaz, R.; Štefko, J. Environmental evaluation of alternative wood-based external wall assembly. Acta Fac. Xylol. Zvolen Res. Publica Slovaca 2020, 62, 133–149. [Google Scholar] [CrossRef]

- Huang, S.; He, Q.; Miao, Z.; Wan, K.; Wan, Y. Multiphysics modeling of water transport in high-intensity lignite drying process on pore scale. Energy Sources Part A Recovery Util. Environ. Effects 2018, 40, 2580–2589. [Google Scholar] [CrossRef]

- Golisz, E.; Jaros, M.; Głowacki, S. Modelling of biomass temperature in the drying process. E3S Web Conf. 2020, 154, 1004. [Google Scholar] [CrossRef]

- Defraeye, T. Advanced Computational Modelling for Drying Processes—A Review. Appl. Energy 2014, 131, 323–344. [Google Scholar] [CrossRef]

- Agbossou, K.; Napo, K.; Chakraverty, S. Mathematical Modelling and Solar Tunnel Drying Characteristics of Yellow Maize. Am. J. Food Sci. Technol. 2016, 4, 115–124. [Google Scholar] [CrossRef]

- Cuevas, M.; Martínez-Cartas, M.L.; Pérez-Villarejo, L.; Hernández, L.; García-Martín, J.F.; Sánchez, S. Drying kinetics and effective water diffusivities in olive stone and olive-tree pruning. Renew. Energy 2019, 132, 911–920. [Google Scholar] [CrossRef]

- Soodmand-Moghaddam, S.; Sharifi, M.; Zareiforoush, H.; Mobli, H. Mathematical modeling of lemon verbena leaves drying in a continuous flow dryer equipped with a solar pre-heating system. Qual. Assur. Saf. Crop. Foods 2020, 12, 57–66. [Google Scholar] [CrossRef]

- Górnicki, K.; Kaleta, A.; Choińska, A. Suitable model for thin-layer drying of root vegetables and onion. Int. Agrophys. 2020, 1, 79–86. [Google Scholar] [CrossRef]

- Kantyshev, A.V.; Zaitseva, M.I.; Kolesnikov, G.N. Model of wood impregnation after incomplete drying as an additional energy management tool. J. Phys. Conf. Ser. 2019, 1333, 032033. [Google Scholar] [CrossRef]

- Ivanova, M.; Katrandzhiev, N.; Dospatliev, L. Using some mathematical models in modeling mushroom drying (agaricus bisporus). Int. J. Appl. Math. 2020, 33, 109–124. [Google Scholar] [CrossRef]

- Nigay, N.A.; Kuznetsov, G.V.; Syrodoy, S.V.; Gutareva, N.Y. Estimation of energy consumption for drying of forest combustible materials during their preparation for incineration in the furnaces of steam and hot water boilers. Energy Sources Part A Recovery Util. Environ. Effects 2020, 42, 1997–2005. [Google Scholar] [CrossRef]

- Oosawa, K.; Kanematsu, Y.; Kikuchi, Y. Forestry and Wood Industry. In Energy Technology Roadmaps of Japan; Kato, Y., Koyama, M., Fukushima, Y., Nakagaki, T., Eds.; Springer: Tokyo, Japan, 2016. [Google Scholar] [CrossRef]

- Dong, W.; Chen, Y.; Bao, Y.; Fang, A. A validation of dynamic hygrothermal model with coupled heat and moisture transfer in porous building materials and envelopes. J. Build. Eng. 2020, 101484. [Google Scholar] [CrossRef]

- Caccavale, P.; De Bonis, M.V.; Ruocco, G. Conjugate Heat and Mass Transfer in Drying: A Modeling Review. J. Food Eng. 2016, 176, 28–35. [Google Scholar] [CrossRef]

- Koukouch, A.; Bakhattar, I.; Asbik, M.; Idlimam, A.; Zeghmati, B.; Aharoune, A. Analytical solution of coupled heat and mass transfer equations during convective drying of biomass: Experimental validation. Heat Mass Transf. 2020, 56, 1971–1983. [Google Scholar] [CrossRef]

- Luikov, A.V. Systems of differential equations of heat and mass transfer in capillary-porous bodies. Int. J. Heat Mass Transf. 1975, 18, 1–14. [Google Scholar] [CrossRef]

- Da Silva, A.M.V.; Delgado, J.M.P.Q.; Guimarães, A.S.; de Lima, W.M.P.B.; Gomez, R.S.; de Farias, R.P.; de Lima, E.S.; de Lima, A.G.B. Industrial Ceramic Blocks for Buildings: Clay Characterization and Drying Experimental Study. Energies 2020, 13, 2834. [Google Scholar] [CrossRef]

- De Vasconcellos, M.A.; de Brito Correia, B.R.; Brandão, V.A.A.; de Oliveira, I.R.; Santos, R.S.; de Oliveira Neto, G.L.; de Lucena Silva, L.P.; de Lima, A.G.B. Convective Drying of Ceramic Bricks by CFD: Transport Phenomena and Process Parameters Analysis. Energies 2020, 13, 2073. [Google Scholar] [CrossRef]

- Merlin, O.; Olivera-Guerra, L.; Hssaine, B.A.; Amazirh, A.; Rafi, Z.; Ezzahar, J.; Gentinec, P.; Khabbab, S.; Gascoina, S.; Er-Raki, S. A phenomenological model of soil evaporative efficiency using surface soil moisture and temperature data. Agric. For. Meteorol. 2018, 256, 501–515. [Google Scholar] [CrossRef]

- Bisson, A.; Rigacci, A.; Lecomte, D.; Rodier, E.; Achard, P. Drying of silica gels to obtain aerogels: Phenomenology and basic techniques. Dry. Technol. 2003, 21, 593–628. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kolesnikov, G.; Gavrilov, T. Modeling the Drying of Capillary-Porous Materials in a Thin Layer: Application to the Estimation of Moisture Content in Thin-Walled Building Blocks. Appl. Sci. 2020, 10, 6953. https://doi.org/10.3390/app10196953

Kolesnikov G, Gavrilov T. Modeling the Drying of Capillary-Porous Materials in a Thin Layer: Application to the Estimation of Moisture Content in Thin-Walled Building Blocks. Applied Sciences. 2020; 10(19):6953. https://doi.org/10.3390/app10196953

Chicago/Turabian StyleKolesnikov, Gennadiy, and Timmo Gavrilov. 2020. "Modeling the Drying of Capillary-Porous Materials in a Thin Layer: Application to the Estimation of Moisture Content in Thin-Walled Building Blocks" Applied Sciences 10, no. 19: 6953. https://doi.org/10.3390/app10196953

APA StyleKolesnikov, G., & Gavrilov, T. (2020). Modeling the Drying of Capillary-Porous Materials in a Thin Layer: Application to the Estimation of Moisture Content in Thin-Walled Building Blocks. Applied Sciences, 10(19), 6953. https://doi.org/10.3390/app10196953