Selection of the Optimal Actions for Crashing Processes Duration to Increase the Robustness of Construction Schedules

Abstract

1. Introduction

1.1. Motivation

1.2. Literature Review

2. Materials and Methods

2.1. Simulation Technique for Construction Project Planning

2.2. Modeling Process Duration with Risk

2.3. Proposed Method to Improve Construction Schedule Robustness

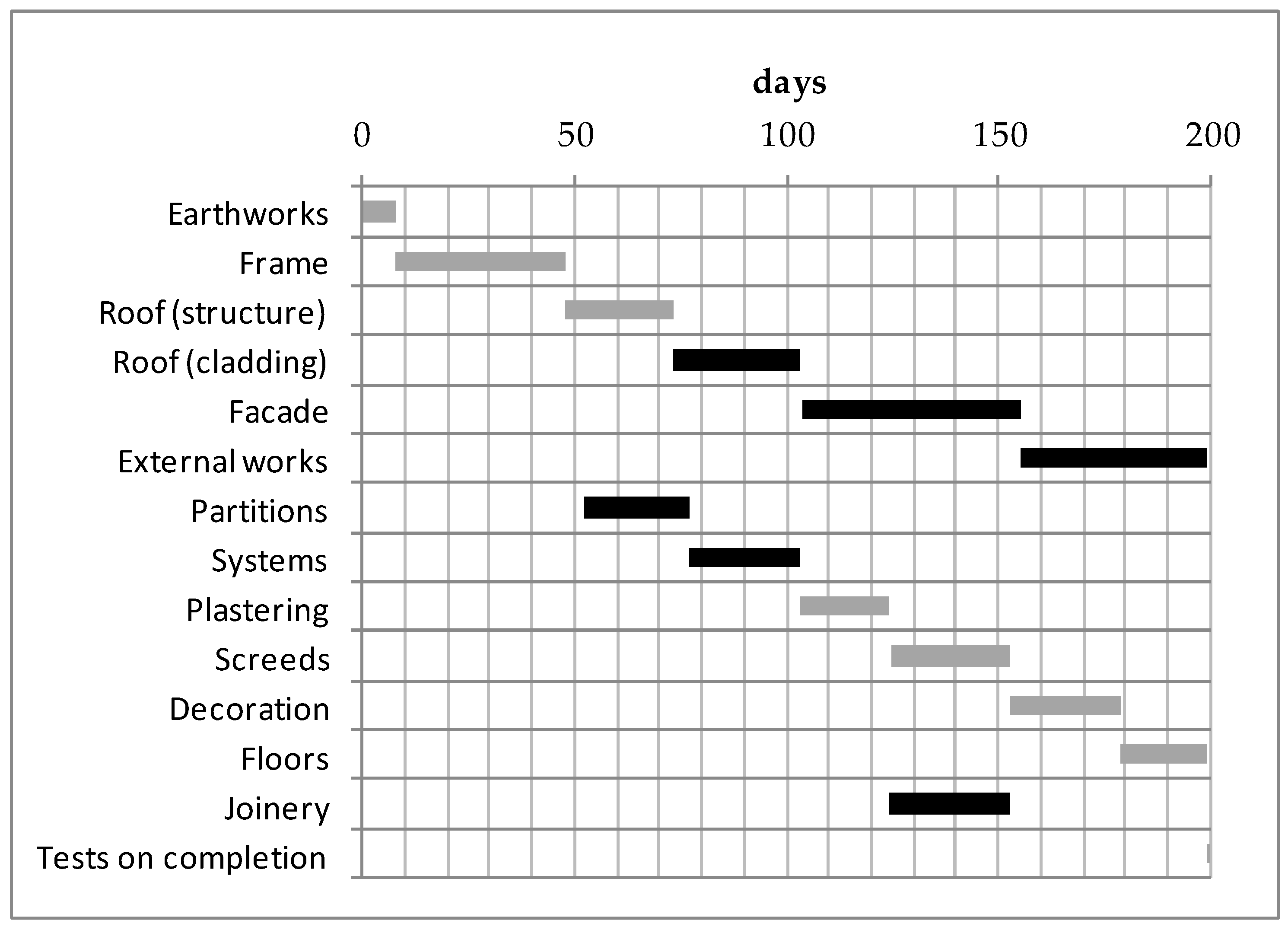

- Constructing the project’s network model (breaking down the scope into processes, allocating resources (crews/subcontractors), defining relationships between processes, defining process durations).

- Creating the baseline schedule and specifying processes whose start dates must be protected against delays, then determining the unit costs of delaying their start.

- Designing variants of actions to reduce process durations and determining their costs.

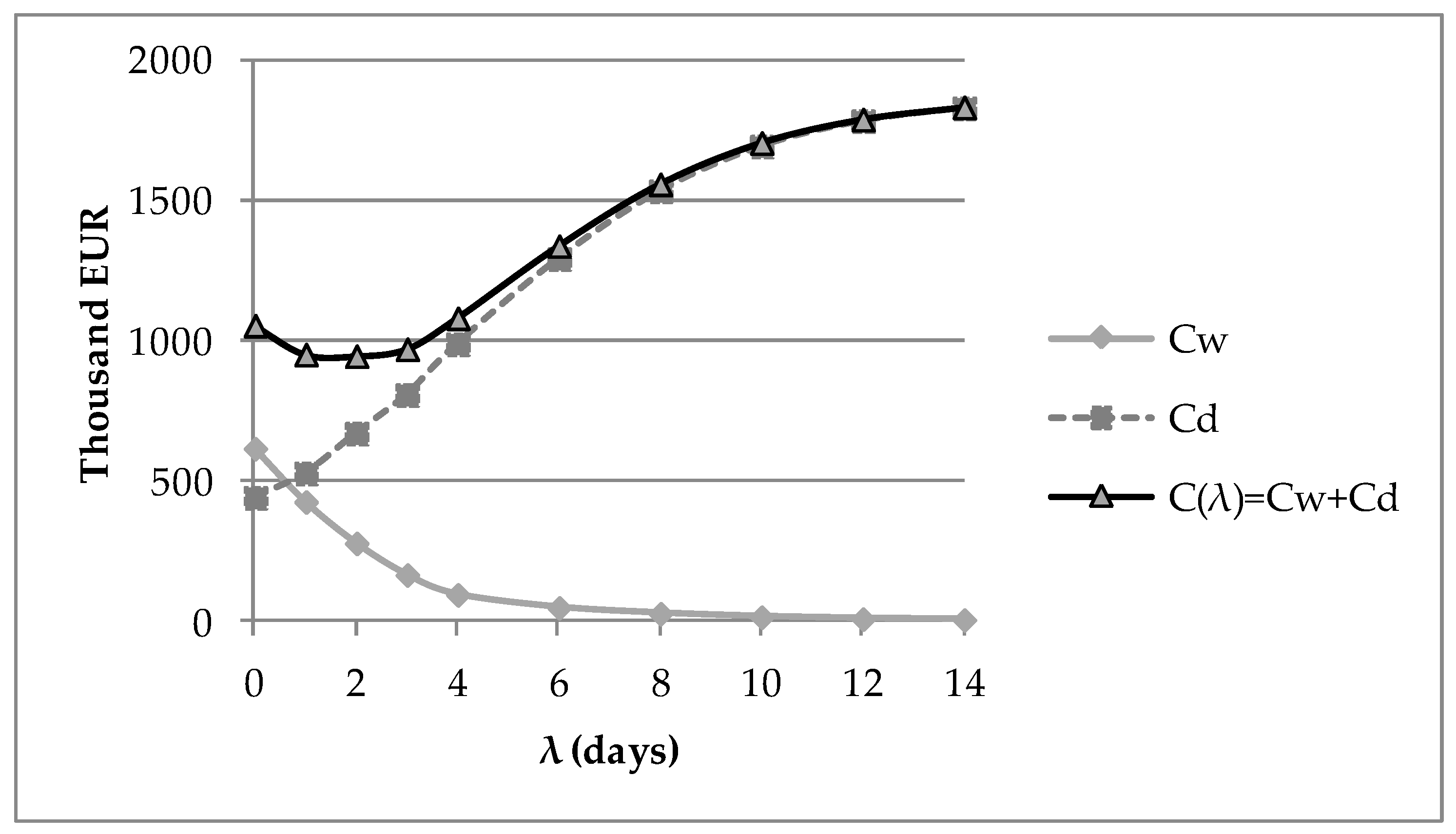

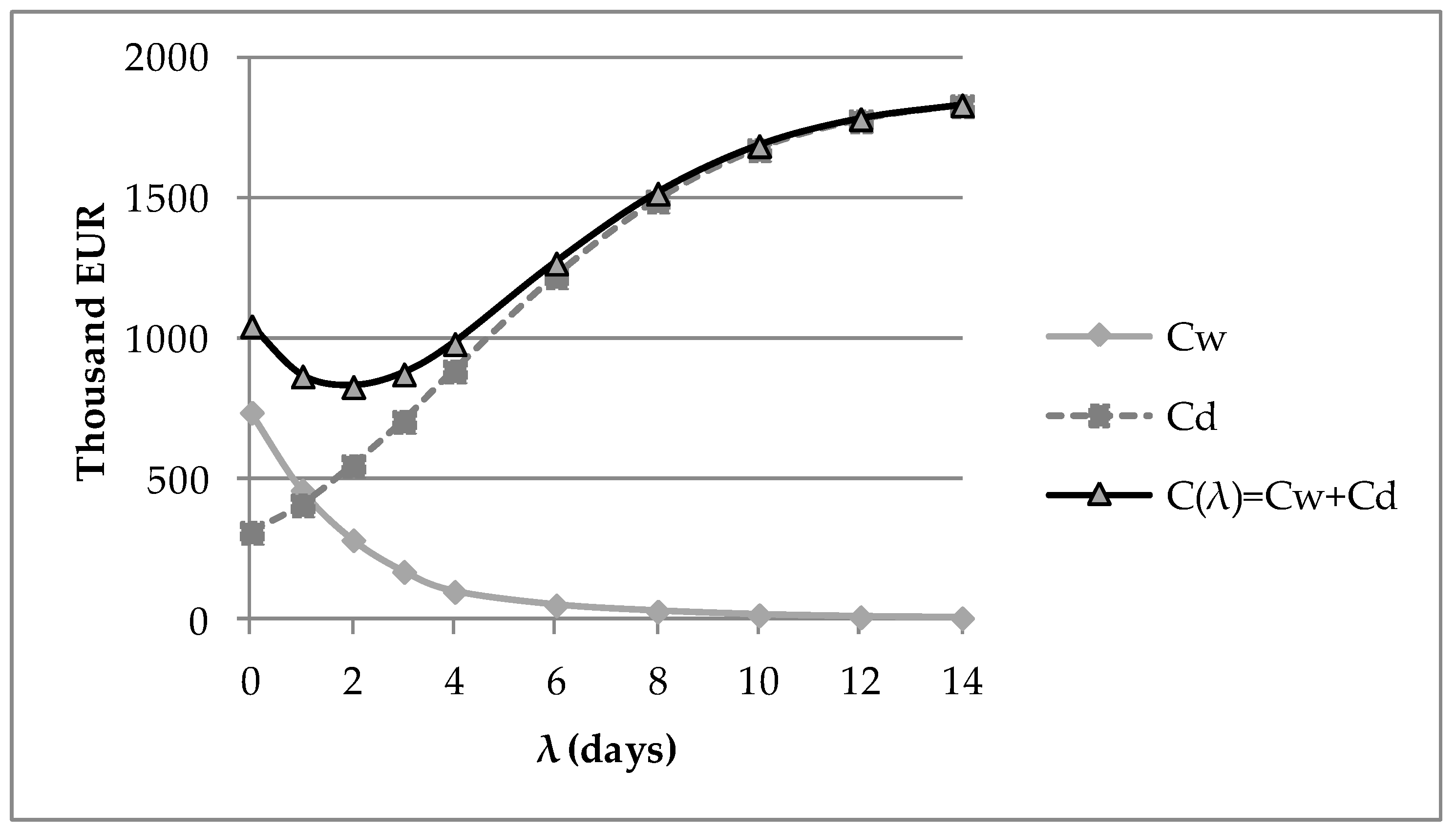

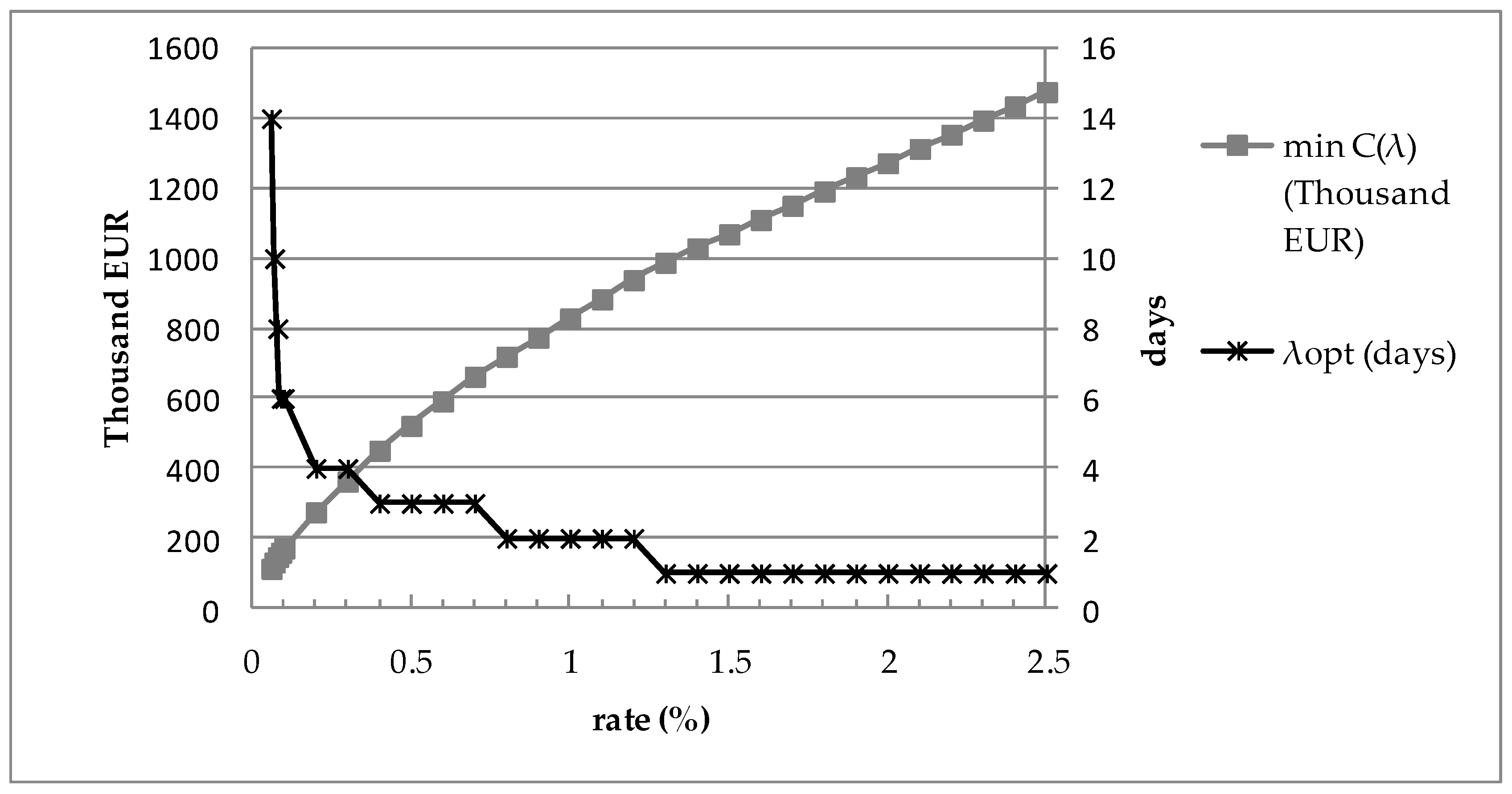

- Simulation studies of the project implementation model for various time reduction policies.

- Finding the optimal time reduction modes.

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Majid, M.Z.A.; McCaffer, R. Factors on non-excusable delays that influence contractors’ performance. J. Manag. Eng. 1998, 14, 42–49. [Google Scholar] [CrossRef]

- Skorupka, D. Identification and Initial Risk Assessment of Construction Projects in Poland. J. Manag. Eng. 2008, 24, 120–127. [Google Scholar] [CrossRef]

- Flanagan, R.; Norman, G. Risk Management and Construction; Blackwell Publishing: Oxford, UK, 1993. [Google Scholar]

- Zou, P.X.; Zhang, G.; Wang, J. Understanding the key risks in construction projects in China. Int. J. Proj. Manag. 2007, 25, 601–614. [Google Scholar] [CrossRef]

- Ibadov, N.; Kulejewski, J. Construction projects planning using network model with the fuzzy decision node. Int. J. Environ. Sci. Technol. 2019, 16, 4347–4354. [Google Scholar] [CrossRef]

- Edwards, P.J.; Bowen, P.A. Risk and risk management in construction projects: Concepts, terms and risk categories re-defined. J. Constr. Procure. 2000, 5, 42–57. [Google Scholar]

- Golenko-Ginzburg, D. Stochastic Network Models in Innovative Projecting; Science Book Publishing House: Voronezh, Russia, 2011. [Google Scholar]

- Mohan, S.; Gopalakrishnan, M.; Balasubramanian, H.; Chandrashekar, A. A lognormal approximation of activity duration in PERT using two time estimates. J. Oper. Res. Soc. 2007, 58, 827–831. [Google Scholar] [CrossRef]

- McCombs, E.L.; Elam, M.E.; Pratt, D.B. Estimating Task Duration in PERT using the Weibull Probability Distribution. J. Mod. Appl. Stat. Methods 2009, 8, 282–288. [Google Scholar] [CrossRef]

- Dawood, N. Estimating project and activity duration: A risk management approach using network analysis. Constr. Manag. Econ. 1998, 16, 41–48. [Google Scholar] [CrossRef]

- Johnson, D. The triangular distribution as a proxy for the beta distribution in risk analysis. J. R. Stat. Soc. Ser. D Stat. 1997, 46, 387–398. [Google Scholar] [CrossRef]

- Williams, T.M. Practical use of distributions in network analysis. J. Oper. Res. Soc. 1992, 43, 265–270. [Google Scholar] [CrossRef]

- Kotz, S.; Van Dorp, J.R. Beyond Beta—Other Continuous Families of Distributions with Bounded Support and Applications; World Scientific Pub Co Pte Ltd.: Singapore, 2004. [Google Scholar]

- Vose, D. Risk Analysis: A Quantitative Guide; John Wiley and Sons Inc.: Hoboken, NJ, USA, 2008. [Google Scholar]

- Abourizk, S.; Wales, R. Combined Discrete-Event/Continuous Simulation for Project Planning. J. Constr. Eng. Manag. 1997, 123, 11–20. [Google Scholar] [CrossRef]

- Lee, H.-S.; Shin, J.-W.; Park, M.; Ryu, H.-G. Probabilistic Duration Estimation Model for High-Rise Structural Work. J. Constr. Eng. Manag. 2009, 135, 1289–1298. [Google Scholar] [CrossRef][Green Version]

- Shahin, A.; Abourizk, S.; Mohamed, Y.; Fernando, S. Simulation modeling of weather-sensitive tunnelling construction activities subject to cold weather. Can. J. Civ. Eng. 2014, 41, 48–55. [Google Scholar] [CrossRef]

- Lu, M.; Abourizk, S. Simplified CPM/PERT Simulation Model. J. Constr. Eng. Manag. 2000, 126, 219–226. [Google Scholar] [CrossRef]

- Shi, J.J. Activity-Based Construction (ABC) Modeling and Simulation Method. J. Constr. Eng. Manag. 1999, 125, 354–360. [Google Scholar] [CrossRef]

- Lee, D.-E.; Bae, T.-H.; Arditi, D. Advanced Stochastic Schedule Simulation System. Civ. Eng. Environ. Syst. 2011, 29, 1–18. [Google Scholar] [CrossRef]

- Sadeghi, N.; Fayek, A.R.; Ingolfsson, A. Simulation-Based Approach for Estimating Project Completion Time of Stochastic Resource–Constrained Project Networks. J. Comput. Civ. Eng. 2012, 26, 558–560. [Google Scholar] [CrossRef]

- Lee, D.-E. Probability of Project Completion Using Stochastic Project Scheduling Simulation. J. Constr. Eng. Manag. 2005, 131, 310–318. [Google Scholar] [CrossRef]

- Aziz, R.F. RPERT: Repetitive-Projects Evaluation and Review Technique. Alex. Eng. J. 2014, 53, 81–93. [Google Scholar] [CrossRef]

- Jaskowski, P.; Biruk, S. The method for improving stability of construction project schedules through buffer allocation/statybos vykdymo grafiko stabilumo užtikrinimas paskirstant laiko rezervus. Technol. Econ. Dev. Econ. 2011, 17, 429–444. [Google Scholar] [CrossRef]

- Leu, S.-S.; Hung, T.-H. An optimal construction resource leveling scheduling simulation model. Can. J. Civ. Eng. 2002, 29, 267–275. [Google Scholar] [CrossRef]

- Biruk, S.; Rzepecki, Ł. Simulation model for resource-constrained construction project. Open Eng. 2019, 9, 211–217. [Google Scholar] [CrossRef]

- Gupta, D.; Maravelias, C.T. On the design of online production scheduling algorithms. Comput. Chem. Eng. 2019, 129, 106517. [Google Scholar] [CrossRef]

- Gupta, D.; Maravelias, C.T. Framework for studying online production scheduling under endogenous uncertainty. Comput. Chem. Eng. 2020, 135, 106670. [Google Scholar] [CrossRef]

- Van De Vonder, S.; Demeulemeester, E.; Herroelen, W. Proactive heuristic procedures for robust project scheduling: An experimental analysis. Eur. J. Oper. Res. 2008, 189, 723–733. [Google Scholar] [CrossRef]

- Balouka, N.; Cohen, I. A robust optimization approach for the multi-mode resource-constrained project scheduling problem. Eur. J. Oper. Res. 2019. [CrossRef]

- Moonseo, P.; Feniosky, P.-M. Reliability buffering for construction projects. J. Constr. Eng. Manag. 2004, 130, 626–637. [Google Scholar]

- Herroelen, W.; Leus, R. The construction of stable project baseline schedules. Eur. J. Oper. Res. 2004, 156, 550–565. [Google Scholar] [CrossRef]

- Goldratt, E.M. Critical Chain; The North River Press: Great Barrington, MA, USA, 1997. [Google Scholar]

- Van De Vonder, S.; Demeulemeester, E.; Herroelen, W.; Leus, R. The use of buffers in project management: The trade-off between stability and makespan. Int. J. Prod. Econ. 2005, 97, 227–240. [Google Scholar] [CrossRef]

- Połoński, M.; Pruszyński, K. Impact of Baseline Terms on the Course of Critical Paths and Time Buffers in the Modified Goldratt’s Method. Arch. Civ. Eng. 2013, 59, 313–320. [Google Scholar] [CrossRef][Green Version]

- Van De Vonder, S.; Demeulemeester, E.; Leus, R. The trade-off between stability and makespan in resource-constrained project scheduling. Int. J. Prod. Res. 2006, 44, 215–236. [Google Scholar] [CrossRef]

- Jaskowski, P. Methodology for enhancing reliability of predictive project schedules in construction. Ekspolatacja i Niezawodn. Maint. Reliab. 2015, 17, 470–479. [Google Scholar] [CrossRef]

- Rostami, S.; Creemers, S.; Leus, R. New strategies for stochastic resource-constrained project scheduling. J. Sched. 2018, 21, 349–365. [Google Scholar] [CrossRef]

- Suwa, H. A new when-to-schedule policy in online scheduling based on cumulative task delays. Int. J. Prod. Econ. 2007, 110, 175–186. [Google Scholar] [CrossRef]

- Chakrabortty, R.K.; Rahman, H.F.; Ryan, M.J. Efficient priority rules for project scheduling under dynamic environments: A heuristic approach. Comput. Ind. Eng. 2020, 140, 106287. [Google Scholar] [CrossRef]

- Wang, Y.; He, Z.; Kerkhove, L.-P.; Vanhoucke, M. On the performance of priority rules for the stochastic resource constrained multi-project scheduling problem. Comput. Ind. Eng. 2017, 114, 223–234. [Google Scholar] [CrossRef]

- Janczura, M.; Kuchta, D. Proactive and reactive scheduling in practice. Res. Pap. Wrocław Univ. Econ. 2011, 238, 34–51. [Google Scholar]

- Van De Vonder, S.; Ballestín, F.; Demeulemeester, E.; Herroelen, W. Heuristic procedures for reactive project scheduling. Comput. Ind. Eng. 2007, 52, 11–28. [Google Scholar] [CrossRef]

- Paslawski, J. Flexibility Approach in Construction Process Engineering/Lankstumas Statybos Proceso Inžinerijoje. Technol. Econ. Dev. Econ. 2008, 14, 518–530. [Google Scholar] [CrossRef][Green Version]

- Deblaere, F.; Demeulemeester, E.; Herroelen, W. Reactive scheduling in the multi-mode RCPSP. Comput. Oper. Res. 2011, 38, 63–74. [Google Scholar] [CrossRef]

- Yang, K.-K. A comparison of dispatching rules for executing a resource-constrained project with estimated activity durations. Omega 1998, 26, 729–738. [Google Scholar] [CrossRef]

- Law, A.; Kelton, W.D. Simulation Modeling and Analysis, 3rd ed.; McGraw-Hill Education: Boston, MA, USA, 2000. [Google Scholar]

- Miłosz, M.; Pastuszak, Z.; Miłosz, E. Decision-making simulation games as a tool for verifying enterprise logistic strategies. In Proceedings of the INTED2015: 9th International Technology, Education and Development Conference, Madrid, Spain, 2–4 March 2015; pp. 3558–3567. [Google Scholar]

- Elmaghraby, S.E. On criticality and sensitivity in activity networks. Eur. J. Oper. Res. 2000, 127, 220–238. [Google Scholar] [CrossRef]

- Demeulemeester, E.L.; Herroelen, W.S. Project Scheduling, A Research Handbook; Kluwer Academic Publishers: Boston, MA, USA, 2002. [Google Scholar]

| i | Process Name | Minimal Duration (Days) | Maximal Duration (Days) | Mode (Days) | Expected Value (Days) | Cost (EUR) |

|---|---|---|---|---|---|---|

| tai | tbi | tmi | ti | ci | ||

| 1 | Earthworks | 5 | 13 | 6 | 8 | 200,000 |

| 2 | Frame | 33 | 48 | 39 | 40 | 24,000,000 |

| 3 | Roof (structure) | 19 | 32 | 24 | 25 | 140,000 |

| 4 | Roof (cladding) | 20 | 37 | 33 | 30 | 175,000 |

| 5 | Facade | 42 | 62 | 49 | 51 | 165,000 |

| 6 | External works | 39 | 49 | 44 | 44 | 125,000 |

| 7 | Partitions | 19 | 32 | 24 | 25 | 340,000 |

| 8 | Systems | 20 | 26 | 32 | 26 | 600,000 |

| 9 | Plastering | 14 | 27 | 22 | 21 | 170,000 |

| 10 | Screeds | 21 | 35 | 28 | 28 | 320,000 |

| 11 | Decoration | 21 | 31 | 26 | 26 | 230,000 |

| 12 | Floors | 16 | 26 | 18 | 20 | 80,000 |

| 13 | Joinery | 26 | 33 | 28 | 29 | 500,000 |

| 14 | Tests on completion | 1 | 1 | 1 | 1 | 0 |

| i | Process Name | Minimal Duration (Days) | Maximal Duration (Days) | Mode (Days) | Expected Value (Days) | Cost (EUR) |

|---|---|---|---|---|---|---|

| tai1 | tbi1 | tmi1 | ti1 | ci1 | ||

| 2 | Frame | 32 | 44 | 35 | 37 | 25,000,000 |

| 3 | Roof (structure) | 17 | 27 | 22 | 22 | 150,000 |

| 4 | Roof (cladding) | 21 | 36 | 27 | 28 | 185,000 |

| 5 | Facade | 39 | 57 | 48 | 48 | 195,000 |

| 6 | External works | 36 | 43 | 38 | 39 | 160,000 |

| 7 | Partitions | 16 | 29 | 21 | 22 | 355,000 |

| 8 | Systems | 20 | 24 | 28 | 24 | 720,000 |

| 9 | Plastering | 12 | 25 | 20 | 19 | 180,000 |

| 10 | Screeds | 21 | 33 | 24 | 26 | 340,000 |

| 11 | Decoration | 19 | 29 | 24 | 24 | 250,000 |

| 12 | Floors | 14 | 24 | 16 | 18 | 95,000 |

| 13 | Joinery | 24 | 31 | 26 | 27 | 620,000 |

| i | Process Name | Minimal Duration (Days) | Maximal Duration (Days) | Mode (Days) | Expected Value (Days) | Cost (EUR) |

|---|---|---|---|---|---|---|

| tai2 | tbi2 | tmi2 | ti2 | ci2 | ||

| 2 | Frame | 30 | 39 | 33 | 34 | 26,500,000 |

| 3 | Roof (structure) | 16 | 21 | 20 | 19 | 165,000 |

| 4 | Roof (cladding) | 16 | 30 | 20 | 22 | 200,000 |

| 5 | Facade | 36 | 51 | 39 | 42 | 220,000 |

| 6 | External works | 31 | 40 | 37 | 36 | 180,000 |

| 7 | Partitions | 15 | 25 | 20 | 20 | 380,000 |

| 8 | Systems | 15 | 22 | 26 | 21 | 900,000 |

| 9 | Plastering | 10 | 23 | 15 | 16 | 200,000 |

| 10 | Screeds | 17 | 28 | 21 | 22 | 355,000 |

| 11 | Decoration | 17 | 25 | 21 | 21 | 285,000 |

| 12 | Floors | 12 | 20 | 16 | 16 | 100,000 |

| 13 | Joinery | 20 | 29 | 23 | 24 | 705,000 |

| Case | λ | |||||||

|---|---|---|---|---|---|---|---|---|

| I | 0 | 2.0170 | 2.4767 | 3.5912 | 0.8064 | 0.8705 | 4.1804 | 6.8009 |

| II | 0 | 0.5744 | 1.1926 | 1.7892 | 0.3075 | 0.567 | 1.6492 | 1.5647 |

| 1 | 0.8067 | 1.3093 | 1.9607 | 0.4225 | 0.6224 | 1.899 | 1.9133 | |

| 2 | 1.0812 | 1.4799 | 2.1809 | 0.5515 | 0.6938 | 2.2433 | 2.3916 | |

| 3 | 1.3551 | 1.6813 | 2.4390 | 0.6728 | 0.7593 | 2.6359 | 2.9381 | |

| 4 | 1.5962 | 1.8885 | 2.7090 | 0.7656 | 0.8186 | 3.0373 | 3.5479 | |

| 6 | 1.8647 | 2.1944 | 3.1113 | 0.8064 | 0.866 | 3.6283 | 4.6561 | |

| 8 | 1.9758 | 2.3692 | 3.3577 | 0.8064 | 0.8705 | 3.9299 | 5.5422 | |

| 10 | 2.0126 | 2.4507 | 3.4987 | 0.8064 | 0.8705 | 4.0787 | 6.1302 | |

| 12 | 2.0170 | 2.4695 | 3.5582 | 0.8064 | 0.8705 | 4.1432 | 6.4640 | |

| 14 | 2.0170 | 2.4752 | 3.5813 | 0.8064 | 0.8705 | 4.1678 | 6.6369 | |

| III | 0 | 0.3996 | 1.0807 | 1.5231 | 0.2531 | 0.5611 | 0.7877 | 1.0931 |

| 1 | 0.6393 | 1.1681 | 1.7651 | 0.4023 | 0.6183 | 1.1684 | 1.4434 | |

| 2 | 0.9419 | 1.3128 | 2.0323 | 0.5515 | 0.6934 | 1.6552 | 1.9456 | |

| 3 | 1.2521 | 1.5042 | 2.3074 | 0.6728 | 0.7593 | 2.181 | 2.5129 | |

| 4 | 1.5239 | 1.7265 | 2.5748 | 0.7656 | 0.8185 | 2.6871 | 3.1614 | |

| 6 | 1.8480 | 2.0809 | 3.0018 | 0.8064 | 0.866 | 3.4279 | 4.3833 | |

| 8 | 1.9747 | 2.3255 | 3.3029 | 0.8064 | 0.8705 | 3.8276 | 5.3736 | |

| 10 | 2.0126 | 2.4296 | 3.4705 | 0.8064 | 0.8705 | 4.0335 | 6.0459 | |

| 12 | 2.0170 | 2.4647 | 3.5501 | 0.8064 | 0.8705 | 4.1266 | 6.4243 | |

| 14 | 2.0170 | 2.4752 | 3.5789 | 0.8064 | 0.8705 | 4.1635 | 6.6190 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biruk, S.; Jaśkowski, P. Selection of the Optimal Actions for Crashing Processes Duration to Increase the Robustness of Construction Schedules. Appl. Sci. 2020, 10, 8028. https://doi.org/10.3390/app10228028

Biruk S, Jaśkowski P. Selection of the Optimal Actions for Crashing Processes Duration to Increase the Robustness of Construction Schedules. Applied Sciences. 2020; 10(22):8028. https://doi.org/10.3390/app10228028

Chicago/Turabian StyleBiruk, Sławomir, and Piotr Jaśkowski. 2020. "Selection of the Optimal Actions for Crashing Processes Duration to Increase the Robustness of Construction Schedules" Applied Sciences 10, no. 22: 8028. https://doi.org/10.3390/app10228028

APA StyleBiruk, S., & Jaśkowski, P. (2020). Selection of the Optimal Actions for Crashing Processes Duration to Increase the Robustness of Construction Schedules. Applied Sciences, 10(22), 8028. https://doi.org/10.3390/app10228028