Reactance Regulation Using Coils with Perpendicular Magnetic Field in the Tubular Core design

Abstract

Featured Application

Abstract

1. Introduction

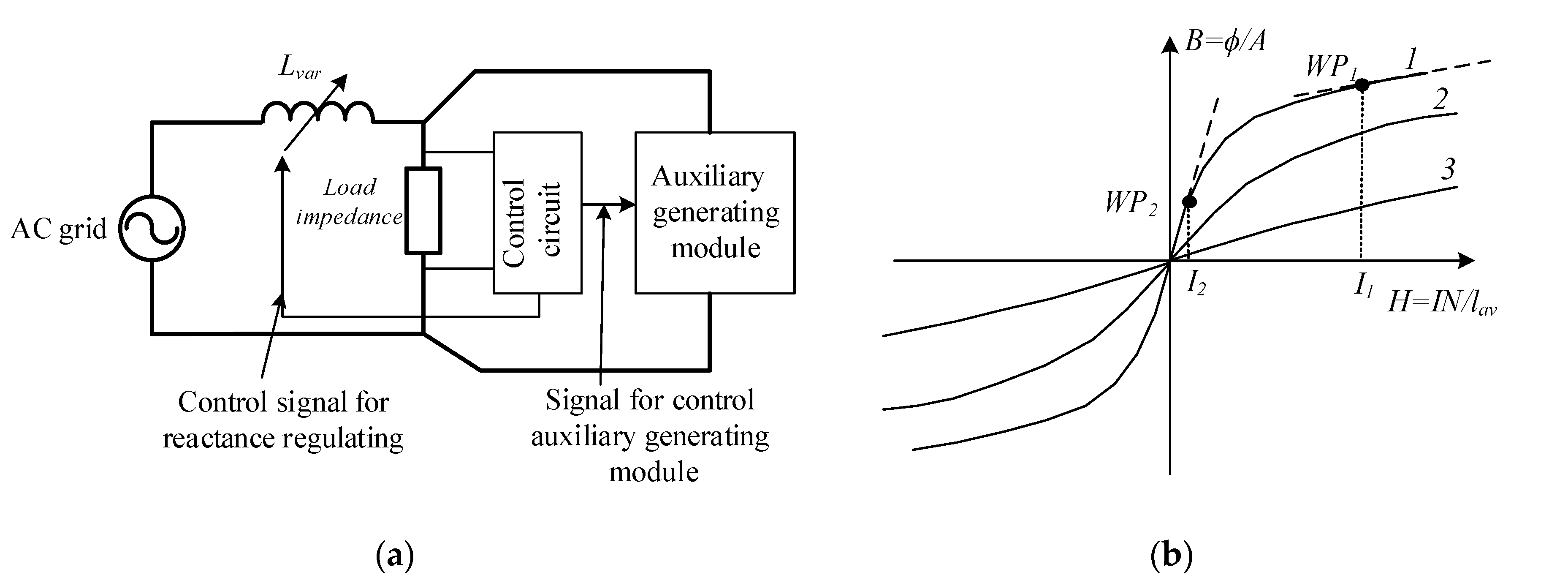

2. Method of Power Flow Control

3. Materials and Methods

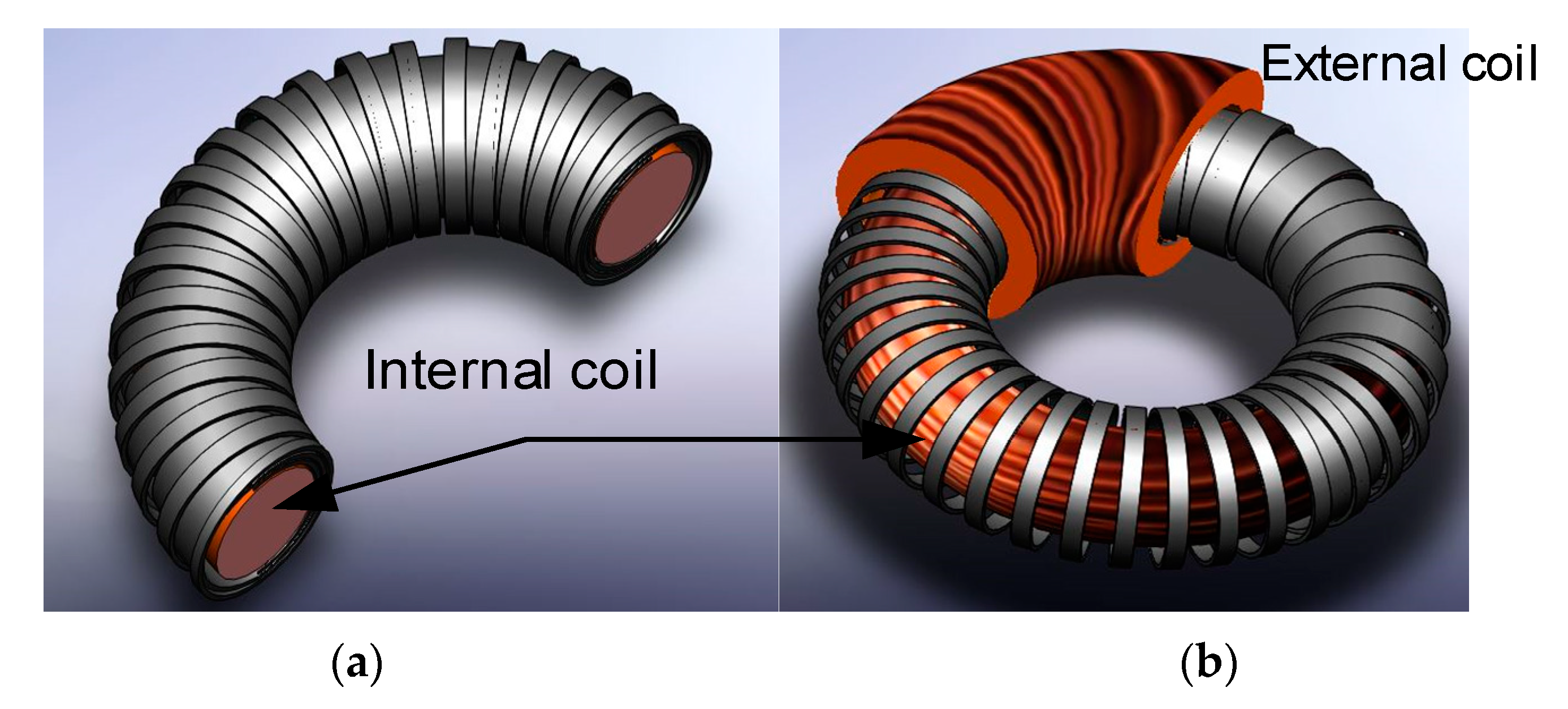

3.1. Proposed Designs

3.2. The Analytical Background for the Calculation of Magnetic Coupling

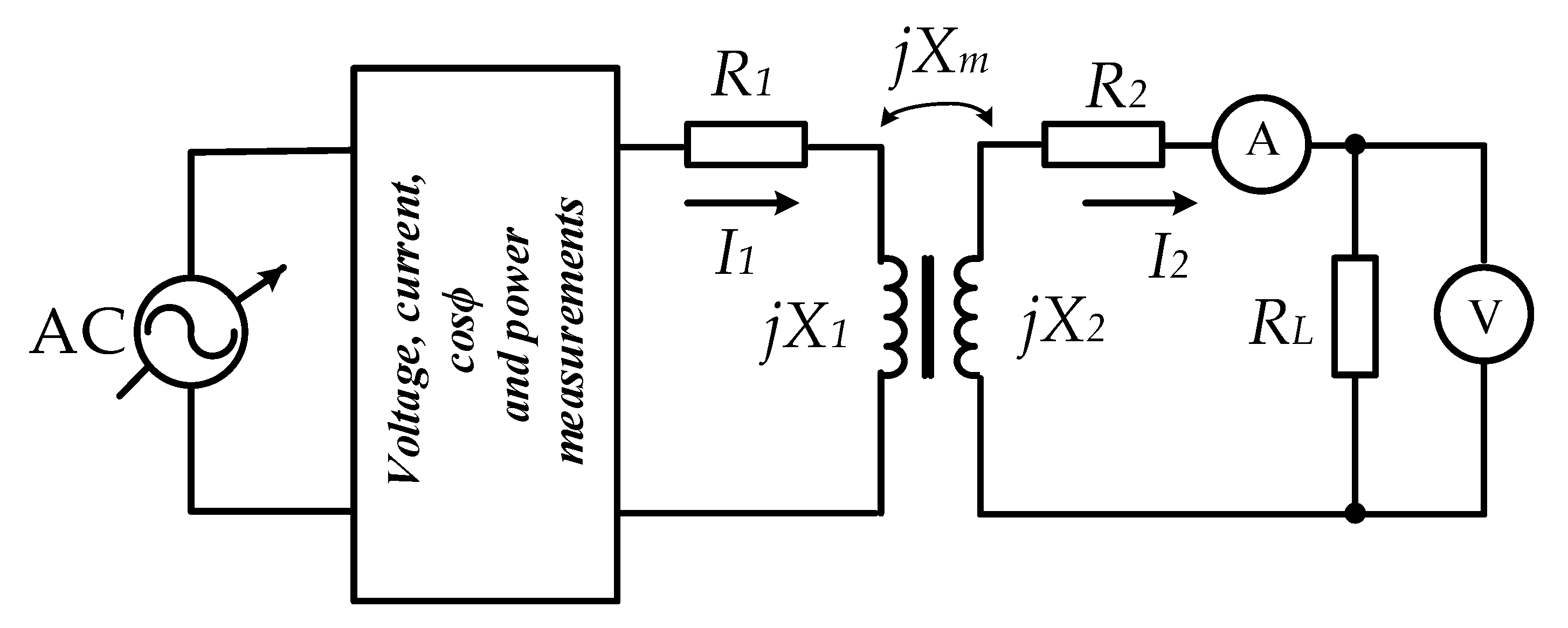

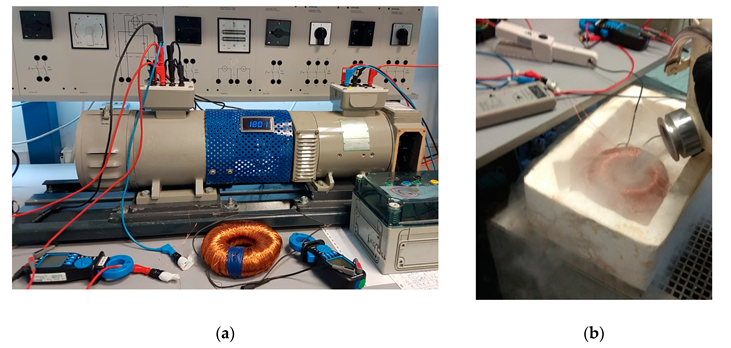

3.3. Experimental Setup

3.4. Controllability

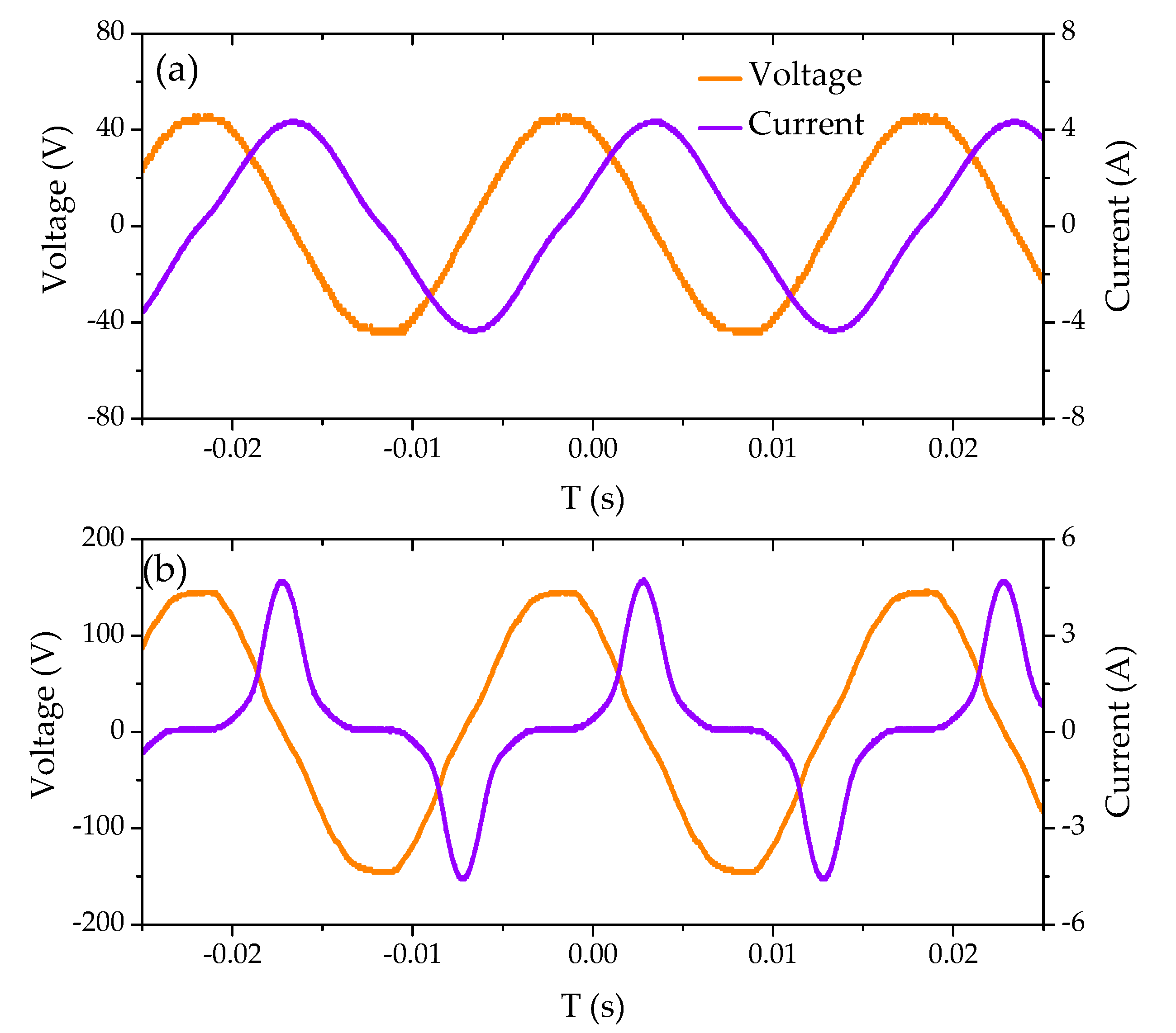

4. Results and Discussion

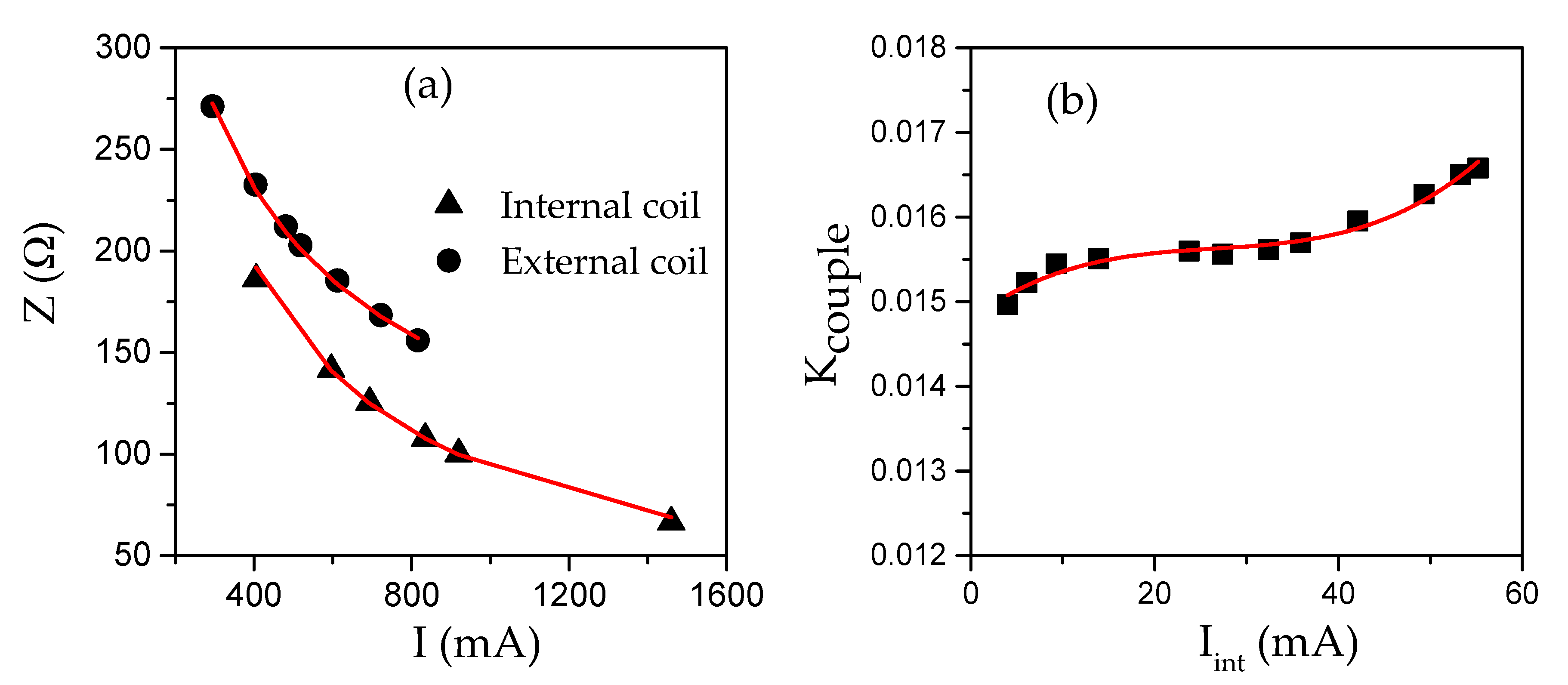

4.1. Magnetic Coupling

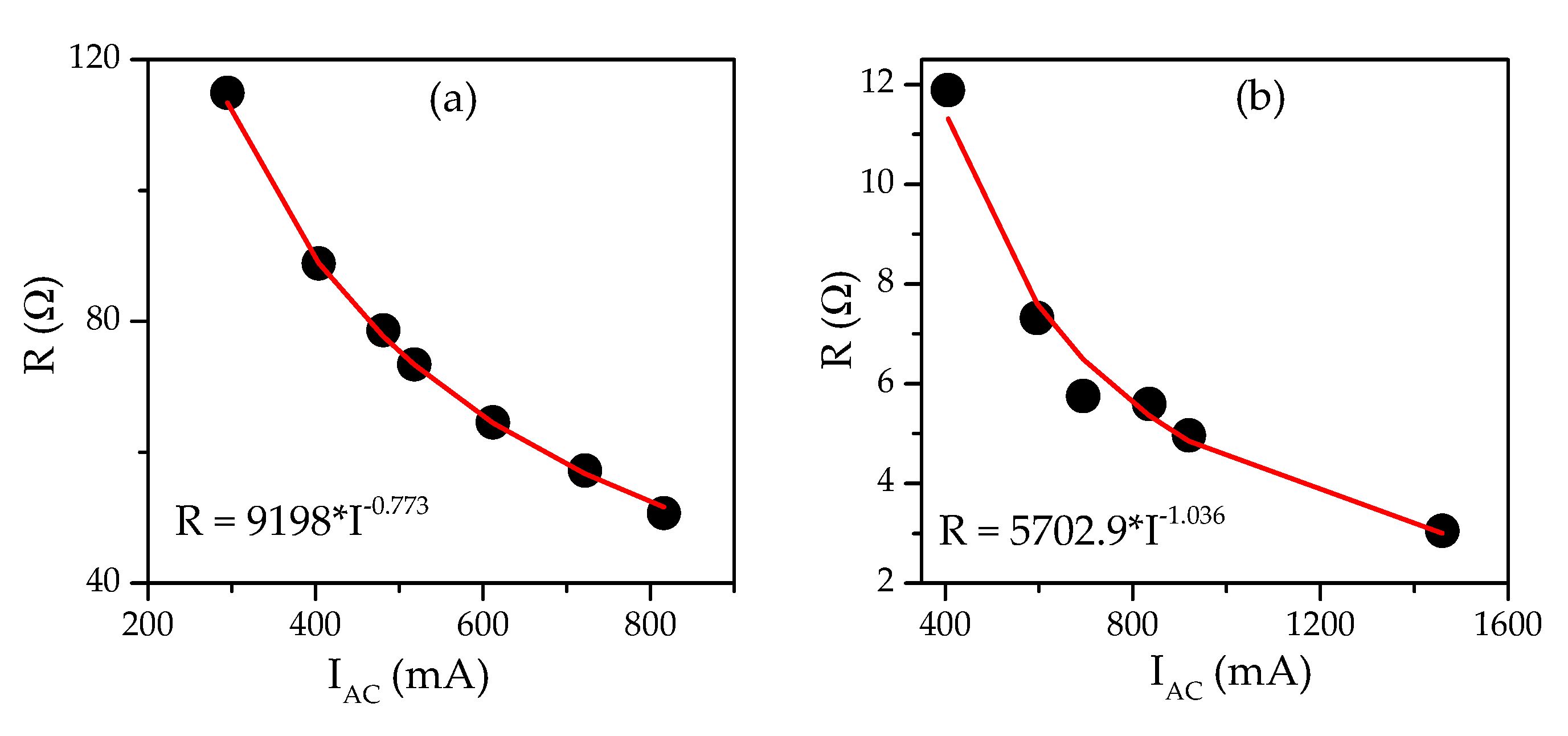

4.2. Resistance and Reactance of Coils

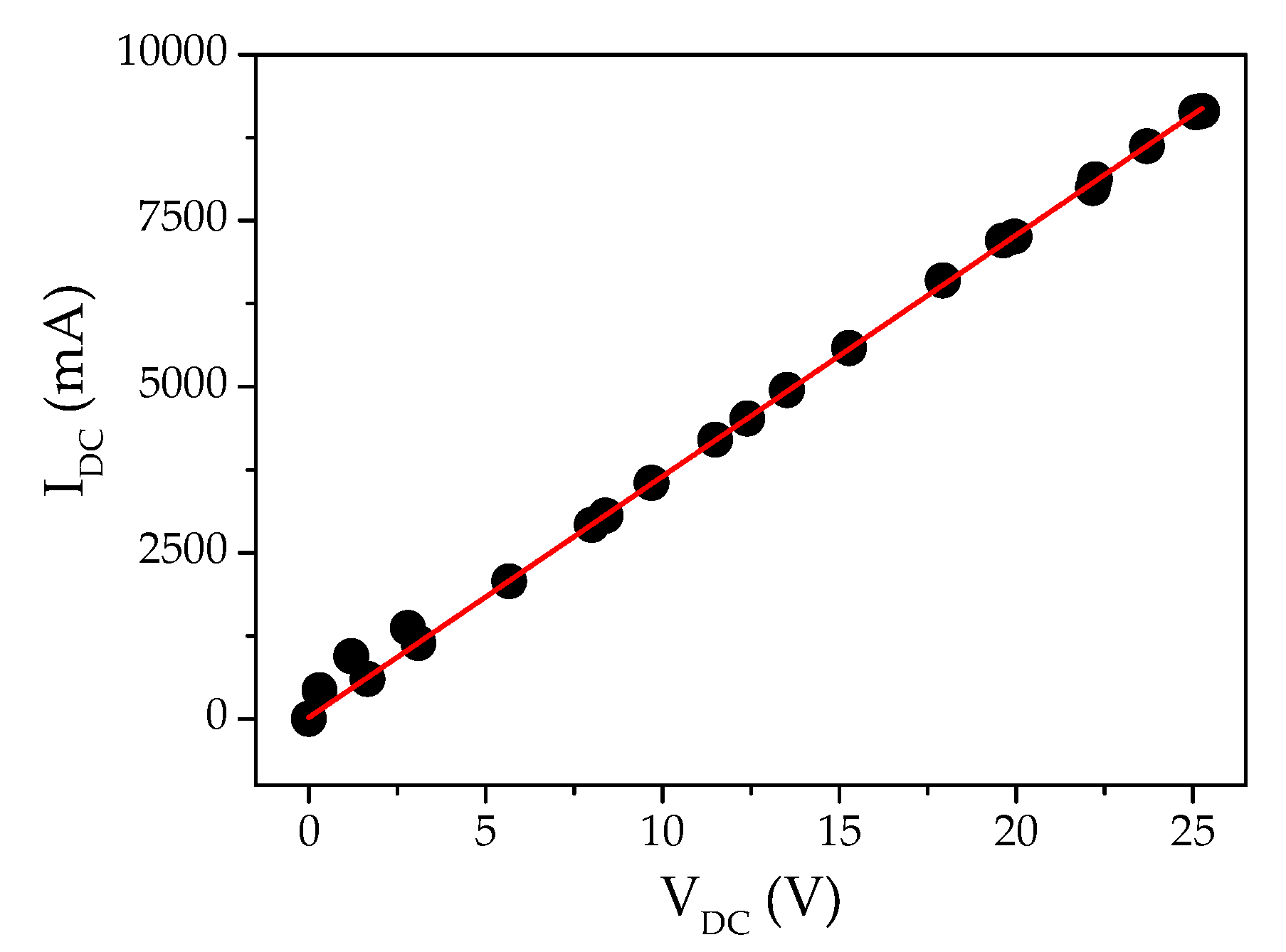

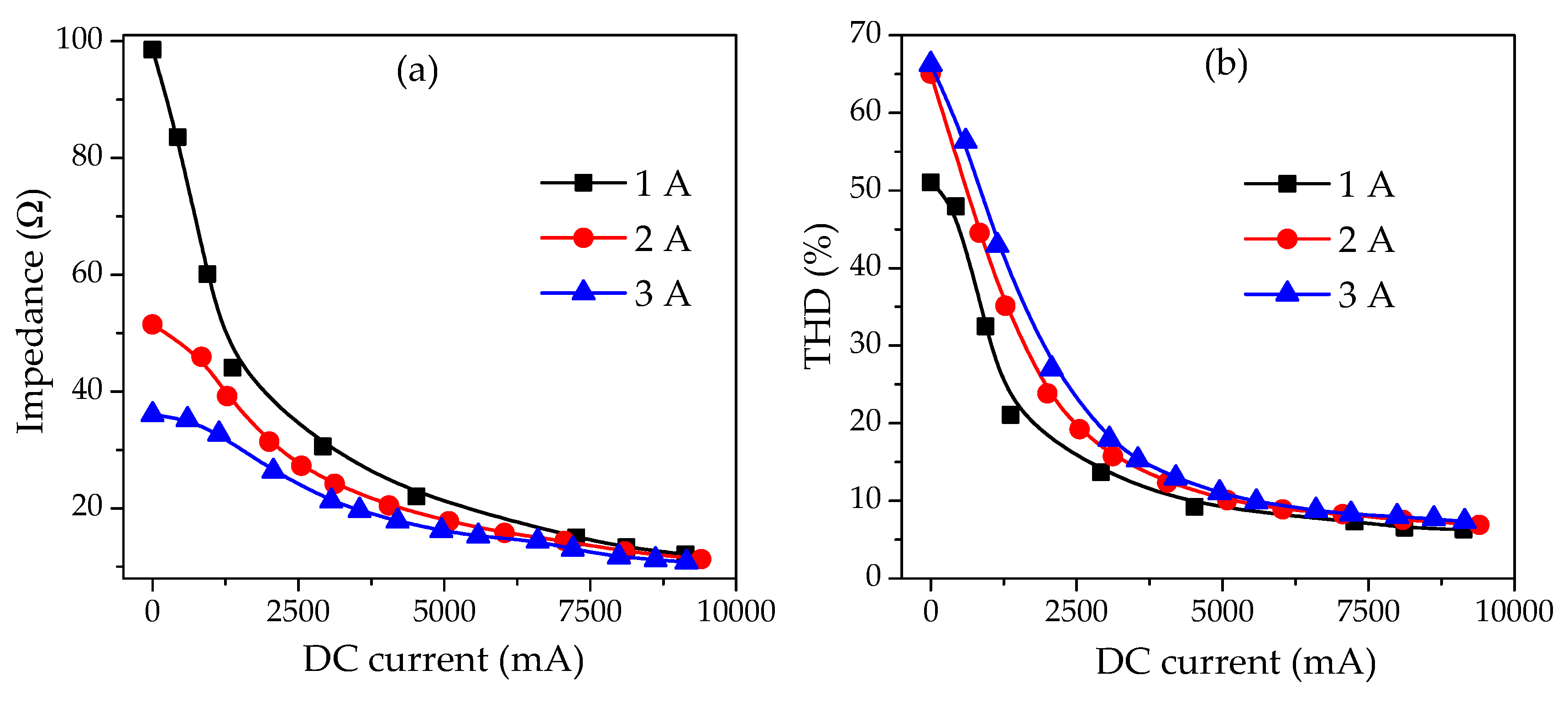

4.3. Controllability

4.4. Parameters of the Equivalent Circuit

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Balzamov, D.S.; Akhmetova, I.G.; Balzamova, E.Y.; Oykina, G.I.; Bronsrkaya, V.V. Options for organizing own sources of energy supply at the facilities of generating companies based on steam screw machines. J. Phys. Conf. Ser. 2019, 1399, 055018. [Google Scholar] [CrossRef]

- Kubarkov, Y.P.; Makarov, Y.V.; Golubeva, K.A. Application of distributed generation for optimization of voltage levels in power electric systems with active-adaptive network based on genetic algorithm. In Proceedings of the Dynamics of Systems, Mechanisms and Machines (Dynamics), Omsk, Russia, 14–16 November 2017; pp. 1–4. [Google Scholar]

- Gerislioglu, B.; Ozturk, F.; Sanli, A.E.; Gunlu, G. The multi-windings forward structure battery balancing. In Proceedings of the 11th International Conference on Electronics, Computer and Computation (ICECCO), Abuja, Nigeria, 29 September–1 October 2014; pp. 1–4. [Google Scholar]

- Baev, I.; Dzyuba, A.; Solovyeva, I.; Kuzmina, N. Improving the efficiency of using smalldistributed generation systems through mechanisms of demand management for electricity and gas. Int. J. Energy Prod. Manag. 2018, 3, 277. [Google Scholar]

- Zafar, R.; Mahmood, A.; Razzaq, S.; Ali, W.; Naeem, U.; Shehzad, K. Prosumer based energy management and sharing in smart grid. Renew. Sust. Energy Rev. 2018, 82, 1675. [Google Scholar] [CrossRef]

- Liu, N.; Yu, X.; Wang, C.; Wang, J. Energy sharing management for microgrids with PV prosumers: A stackelberg game approach. IEEE Trans. Industr. Inform. 2017, 13, 1088. [Google Scholar] [CrossRef]

- Espe, E.; Potdar, V.; Chang, E. Prosumer Communities and Relationships in Smart Grids: A Literature Review, Evolution and Future Directions. Energies 2018, 11, 2528. [Google Scholar] [CrossRef]

- Rajput, S.; Averbukh, M.; Yahalom, A.; Minav, T. An Approval of MPPT Based on PV Cell’s Simplified Equivalent Circuit During Fast-Shading Conditions. Electronics 2019, 8, 1060. [Google Scholar] [CrossRef]

- Drabek, T.; Dybowski, P. Control of prosumer energy sources in power grid feeded by three-phase distribution transformer. In Proceedings of the 15th Selected Issues of Electrical Engineering and Electronics (WZEE), Zakopane, Poland, 8–10 December 2019; pp. 1–6. [Google Scholar]

- McGranaghan, M.; Houseman, D.; Schmitt, L.; Cleveland, F.; Lambert, E. Enabling the integrated grid: Leveraging data to integrate distributed resources and customers. IEEE Power Energy Mag. 2015, 14, 83. [Google Scholar] [CrossRef]

- Dileep, G. A survey on smart grid technologies and applications. Renew. Energy 2020, 146, 2589. [Google Scholar] [CrossRef]

- Rajput, S.; Amiel, I.; Sitbon, M.; Aharon, I.; Averbukh, M. Control the Voltage Instabilities of Distribution Lines using Capacitive Reactive Power. Energies 2020, 13, 875. [Google Scholar] [CrossRef]

- Bouzid, A.M.; Guerrero, J.M.; Cheriti, A.; Bouhamida, M.; Sicard, P.; Benghanem, M. A survey on control of electric power distributed generation systems for microgrid applications. Renew. Sust. Energy Rev. 2015, 44, 751. [Google Scholar] [CrossRef]

- Guihong, F.; Fengxiang, W.; Jin, W. Design principles of magnetically controlled reactor. In Proceedings of the Fifth International Conference on Electrical Machines and Systems (IEEE Cat. No. 01EX501), Shenyang, China, 18–20 August 2001; pp. 212–214. [Google Scholar]

- Li, D.; Tian, J. A novel variable reactor with transformer and inverter control. In Proceedings of the International Conference on Electrical Machines and Systems, Wuhan, China, 17–20 October 2008; pp. 4440–4443. [Google Scholar]

- Mingxing, T.; Qingfu, L. Magnetic saturation type and transformer type controllable shunt reactor. High Volt. Eng. 2003, 7, 001. [Google Scholar]

- Yang, X.; Yue, C. Orthogonal flux controllable reactor for transmission lines. In Proceedings of the International Conference on Power System Technology, Hangzhou, China, 24–28 October 2010; pp. 1–4. [Google Scholar]

- Ben-Yaakov, S.; Peretz, M.M. A self-adjusting sinusoidal power source suitable for driving capacitive loads. IEEE Trans. Power Electr. 2006, 21, 890. [Google Scholar] [CrossRef]

- Shafaghatian, N.; Heidary, A.; Radmanesh, H.; Rouzbehi, K. Microgrids interconnection to upstream AC grid using a dual-function fault current limiter and power flow controller: Principle and test results. IET Energy Syst. Integr. 2019, 1, 269. [Google Scholar] [CrossRef]

- Wilson, T.G. The evolution of power electronics. IEEE Trans. Power Electr. 2000, 15, 439. [Google Scholar] [CrossRef]

- Dimitrovski, A.; Li, Z.; Ozpineci, B. Magnetic amplifier-based power-flow controller. IEEE Trans. Power Deliv. 2015, 30, 1708. [Google Scholar] [CrossRef]

- Young, M.A., II; Dimitrovski, A.D.; Patterson, R.W.; Liu, Y. Impacts of a Magnetic Amplifier-Based Power Flow Controller on Power System Distance Protection; Oak Ridge National Lab (ORNL): Oak Ridge, TN, USA, 2014. [Google Scholar]

- Lin, K.; Tomsovic, K.; Wan, Q.; Dimitrovski, A. A Study of Magnetic Amplifier-based Power Flow Controller for Power System Stability Improvement. Electr. Power Compon. Syst. 2016, 44, 966. [Google Scholar] [CrossRef]

- Ibrahim, R.A.; Hamad, M.S.; Ahmed, K.H.; Dessouky, Y.G.; Williams, B.W. Improved ride-through of PMSG wind turbine during symmetrical voltage dip using a magnetic amplifier. In Proceedings of the 2nd IET Renewable Power Generation Conference (RPG 2013), Beijing, China, 9–11 September 2013; pp. 1–6. [Google Scholar]

- Yaskiv, V.; Yaskiv, A.; Abramovitz, A.; Smedley, K. Performance evaluation of MagAmp regulated isolated AC-DC converter with high PF. In Proceedings of the 2014 IEEE ELEKTRO, Rajecke Teplice, Slovakia, 19–20 May 2014; pp. 411–416. [Google Scholar]

- O’Grady, C.M. Magnetic Amplifiers for Voltage Regulation Applications; Undergraduate Honors College, University of Arkansas: Fayetteville, NC, USA, 2015. [Google Scholar]

- Liu, W.; Luo, L.; Dong, S.; Lou, Y. Overview of power controllable reactor technology. Energy Procedia 2012, 17, 483–491. [Google Scholar] [CrossRef]

- Ko, J.-H.; Baek, S.-W.; Lee, K.-M.; Kim, H.-W.; Cho, K.-Y.; Kim, J.-M. Hybrid Current-Mode Control of PSFB Converter to Compensate Slew Interval and Prevent Magnetic Saturation of Transformers. Electronics 2020, 9, 1395. [Google Scholar] [CrossRef]

- Sedykh, O.A. Calculation of magnetic amplifiers with toroidal cores. Avtom. Telemekhanika 1956, 17, 445. [Google Scholar]

- Qiu, M.; Rao, S.; Zhu, J.; Fu, S.; Li, Z.; Liu, W.; Chen, P.; Gong, J. Energy storage characteristics of MJ-class toroidal HTS-SMES considering maximum value of perpendicular magnetic field. Energy Procedia 2017, 105, 4179–4184. [Google Scholar] [CrossRef]

- Aganza-Torres, A.; Pfeiffer, J.; Zacharias, P. Interleaved Buck Converter with Coupled Inductors as Auxiliary Bias-Current Source for Controllable Magnetic Devices. In Proceedings of the PCIM Europe Digital Days 2020; International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Berlin, Germany, 7–8 July 2020; pp. 1–8. [Google Scholar]

- Zacharias, P.; Kleeb, T.; Fenske, F.; Wende, J.; Pfeiffer, J. Controlled magnetic devices in power electronic applications. In Proceedings of the 19th European Conference on Power Electronics and Applications (EPE’17 ECCE Europe), Warsaw, Poland, 11–14 September 2017; pp. 1–10. [Google Scholar]

- Lokshin, E.; Minav, T.; Averbukh, M. Minimization Magnetic Coupling of Perpendicular Coils Winded Inside and Outside Toroidal Core made Thin Magnetic Ribbon. In Proceedings of the IEEE International Conference on the Science of Electrical Engineering in Israel (ICSEE), Eilat, Israel, 12–14 December 2018; pp. 1–4. [Google Scholar]

- Shirkoohi, G.; Arikat, M. Anisotropic properties of high permeability grain-oriented 3.25% si-fe electrical steel. IEEE Trans. Magn. 1994, 30, 928–930. [Google Scholar]

- Păltânea, V.; Paltanea, G. Study of the Magnetic Anisotropy of the Grain Oriented (GO) and Non-Oriented (NO) Silicon Iron Materials. Mater. Sci. Forum 2011, 670, 66–73. [Google Scholar]

- Chwastek, K.R.; Baghel, A.P.S.; De Campos, M.F.; Kulkarni, S.V.; Szczygłowski, J. A description for the anisotropy of magnetic properties of grain-oriented steels. IEEE Trans. Magn. 2015, 51, 1. [Google Scholar]

- Paltanea, V.M.; Paltanea, G.; Gavrila, H.; Dumitru, L. Experimental analysis of magnetic anisotropy in silicon iron steels using the single strip tester. In Proceedings of the 9th International Symposium on Advanced Topics in Electrical Engineering (ATEE), Bucharest, Romania, 7–9 May 2015; pp. 456–459. [Google Scholar]

- Irwin, J.D.; Nelms, R.M. Basic Engineering Circuit Analysis; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- TRMS Leakage Clamp (Metrel MD9272) with Power Functions. Available online: https://www.test-meter.co.uk/metrel-md-9272-trms-leakage-clamp-with-power-functions/ (accessed on 30 December 2019).

- APPA 90IV SERIES MULTIMETERS. Available online: http://www.appatech.com/en/product-553890/APPA-90IV-SERIES-MULTIMETERS-APPA-98IV.html (accessed on 4 June 2018).

- KEYSIGHT U1733C LCR Meter. Available online: https://www.keysight.com/en/pd-1984428-pn-U1732C/100hz-120hz-1khz-10khz-handheld-lcr-meter?cc=IL&lc=eng (accessed on 21 January 2020).

- 300kHz Bench LCR Meter. Available online: https://www.bkprecision.com/products/component-testers/891-300khz-bench-lcr-meter.html (accessed on 14 July 2020).

- Suresh, V.; Abudhahir, A. An analytical model for prediction of magnetic flux leakage from surface defects in ferromagnetic tubes. Meas. Sci. Rev. 2016, 16, 8–13. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rajput, S.; Lockshin, E.; Schochet, A.; Averbukh, M. Reactance Regulation Using Coils with Perpendicular Magnetic Field in the Tubular Core design. Appl. Sci. 2020, 10, 7645. https://doi.org/10.3390/app10217645

Rajput S, Lockshin E, Schochet A, Averbukh M. Reactance Regulation Using Coils with Perpendicular Magnetic Field in the Tubular Core design. Applied Sciences. 2020; 10(21):7645. https://doi.org/10.3390/app10217645

Chicago/Turabian StyleRajput, Shailendra, Efim Lockshin, Aryeh Schochet, and Moshe Averbukh. 2020. "Reactance Regulation Using Coils with Perpendicular Magnetic Field in the Tubular Core design" Applied Sciences 10, no. 21: 7645. https://doi.org/10.3390/app10217645

APA StyleRajput, S., Lockshin, E., Schochet, A., & Averbukh, M. (2020). Reactance Regulation Using Coils with Perpendicular Magnetic Field in the Tubular Core design. Applied Sciences, 10(21), 7645. https://doi.org/10.3390/app10217645