1. Introduction

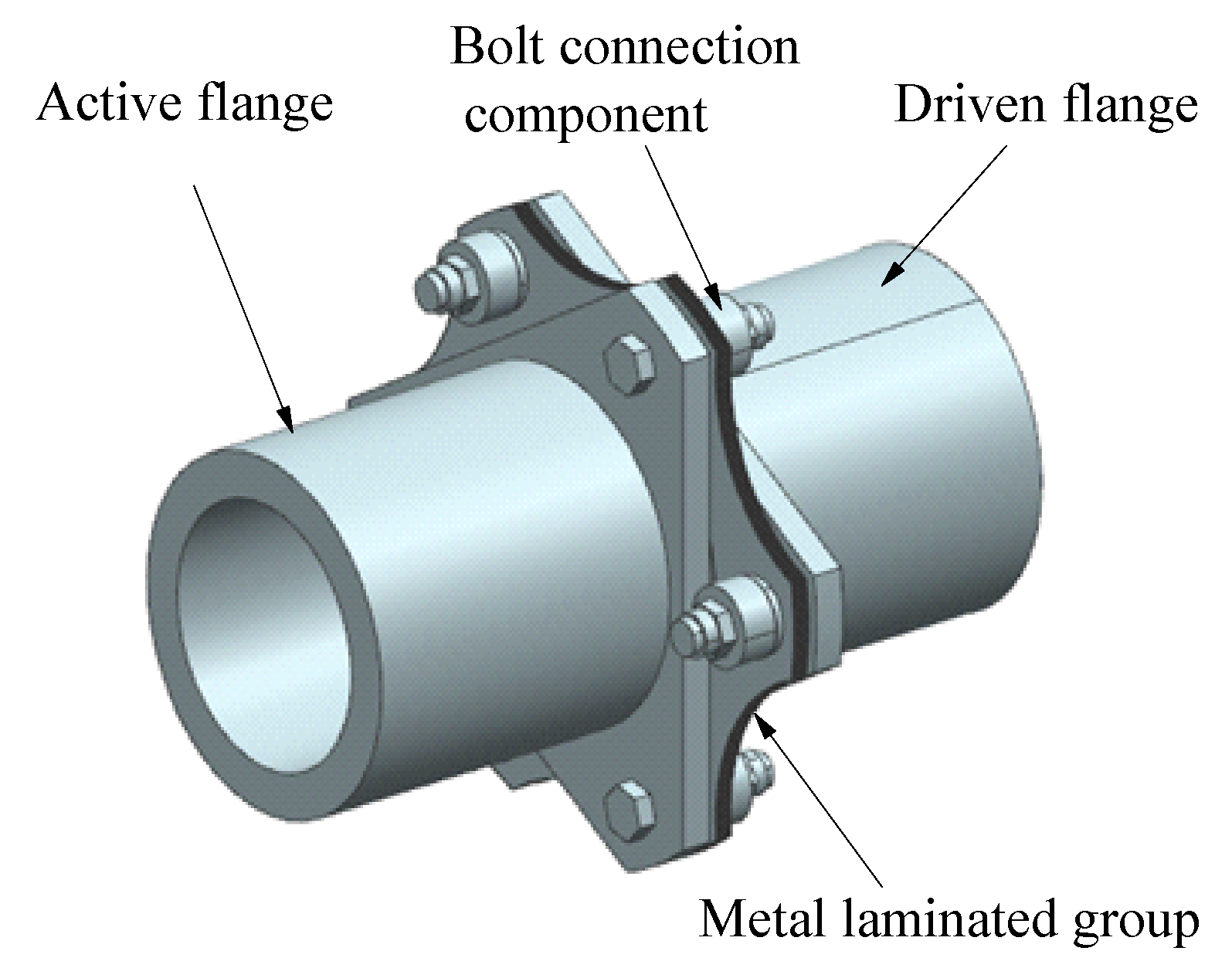

Laminated membrane coupling is an all-metal dry flexible coupling, which can compensate relative displacements between the driving and driven shafts through the elastic deformation of the laminated group. Superior characteristics of these couplings, including the compact structure, reliable connection, simple maintenance and excellent environmental adaptability, have led to the widespread use of these components in diverse industrial applications such as petroleum and chemical industry, aviation, ships and wind turbines [

1,

2].

Different types of laminated membrane couplings have been proposed so far. These couplings can be divided into the ring type, spoke type, multilateral type, connecting rod type and the waist type. Among these types, the waist type lamination can achieve the optimal stress distribution on the premise of the least material without a remarkable impact on its performance [

3]. Studies show that the waist type lamination has reasonable elasticity. However, the manufacturing process of this type of coupling is relatively complicated.

Laminated membrane coupling plays a key role in mechanical power transmission. Its working reliability is directly related to the safety of the power transmission device and even the whole system. On the other hand, the stiffness of the laminated membrane coupling reflects its ability to compensate misalignment displacements, which is the basic index that must be considered for evaluating the coupling characteristics. Accordingly, the systematic study of the stiffness characteristics of the laminated membrane coupling is of significant importance to analyze the shaft vibration deeply and accurately. Then a reliable guarantee can be provided for the safe operation of the power plant.

Reviewing the literature indicates that many scholars have carried out investigations on laminated membrane coupling. Kilaekim studied the correlation between the low cycle fatigue properties and the adhesive properties of laminations [

4]. Shen Tuliufang studied the stress of laminated membrane coupling subjected to diverse torques and axial loads, and emphatically compared the influence of different transmitted powers and axial displacements on the laminated stress [

5]. Furthermore, Shentu Liufang et al. applied MATLAB software to optimize laminated parameters of the coupling [

6]. Caliciotti proposed a heuristic adaptive truncation criterion based on linear search and internal iteration of truncated Newton method. The effectiveness and robustness of the adaptive criterion were verified by numerical experience of unconstrained optimization problems, which has important reference significance for optimization problems [

7,

8]. Kazerounian and Duong performed a finite element analysis and found that the structural performance of the flexible tapered diaphragm coupling, which is applied in the aerospace industry, is mainly related to the outer diameter of lamination and the stress intensity at the joint of the rim support structure. Then they designed an asymmetric tapered diaphragm structure [

9]. Khosravi carried out an efficient and accurate nonlinear finite element analysis and proposed an optimization design method for thin-walled structures. He modified the composite laminated plate element to consider the bending coupling effect of the diaphragm [

10]. Ganesan et al. proposed an effective surface shell element to analyze the geometric nonlinearity of composite laminated structures by the common rotational method, and then analyzed some laminated composite structures with nonlinear geometries [

11]. Khosravi et al. proposed an effective surface shell element to analyze the geometric nonlinearity of laminated structures with materials by the common rotation method. They showed that the proposed method can be applied to analyze the limit load of laminated structures [

12]. Moreover, Cheng Ming studied the stress characteristics of the square laminated membrane coupling and then analyzed the influence of the guard plate on the laminated stress [

13]. Zhong Kai et al. conducted a detailed analysis on the membrane stress of the high-power laminated membrane coupling, pointed out the stress distribution characteristics of the elastic element and calculated its torsional stiffness [

14]. Shen Tuliufang proposed a four-hole joint bearing coupling structure to improve the angular displacement compensation ability of the laminated membrane coupling between two shafts. Then they analyzed the maximum stress position and non-centering compensation ability of three different coupling sizes through mechanical experiments and finite element simulation methods [

15]. Deng Guanglin et al. studied the strength and stiffness of the diaphragm assembly in direct contact with plates in the diaphragm assembly, and analyzed the influence of the number of layers of the diaphragm assembly and the preload value of the diaphragm assembly gasket on the strength and stiffness of the diaphragm assembly [

16]. Wang Wei applied the finite element method and established a model for the multi-layer contact coupling. He demonstrated that results obtained from the stress calculation can more accurately show the stress characteristics of elastic elements when the comparison is made with the conventional single-chip model [

17]. Sun Chenglong et al. established the stiffness model for the diaphragm of the joint type laminated membrane coupling based on the relevant mathematical expressions and classical mechanics. They showed that the compensation ability of the joint laminated membrane coupling for radial and angular displacements is far better than that of the ordinary laminated membrane coupling [

18,

19]. Nie Junfeng proposed a mathematical model for the contact stiffness of the lamination group and showed the accuracy and superiority of the lamination group for calculating the stiffness of the lamination coupling [

20]. Recently, Liu Jingming applied the finite element simulation method to analyze the correlation between structural parameters and the torsional stiffness of the laminated membrane coupling, and found that the laminated thickness, the diameter and total number of bolts have a certain impact on the torsional stiffness of the coupling [

21]. More recently, Liang Youtao et al. analyzed the influence of the bolt-predicted force and the friction coefficient on the stress and stiffness of laminated membrane coupling. They utilized the finite element method and studied the correlation between the misalignment slip and nonlinear characteristics of the coupling [

22].

Reviewing the literature indicates that in the majority of performed numerical simulations for investigating laminated membrane couplings, the surface shear and extrusion caused by small relative motions between laminations are ignored. Moreover, it is assumed that the external load is evenly distributed in each lamination. Based on these assumptions, only the single lamination was analyzed. However, the contact stiffness is produced in laminated contact. This is especially more pronounced for extreme deformations and heavy loads. In these cases, the shear, radial and torsional stresses and angular deformations caused by the contact cannot be ignored. In real applications, the internal contact between laminations and the contact between laminations and the gasket affect the lamination state. Therefore, calculate the overall stiffness of the lamination coupling, which is not in line with the actual working condition. In other words, it is necessary to consider the elastic deformation and the contact deformation of the lamination surface, and study the lamination coupling as a whole.

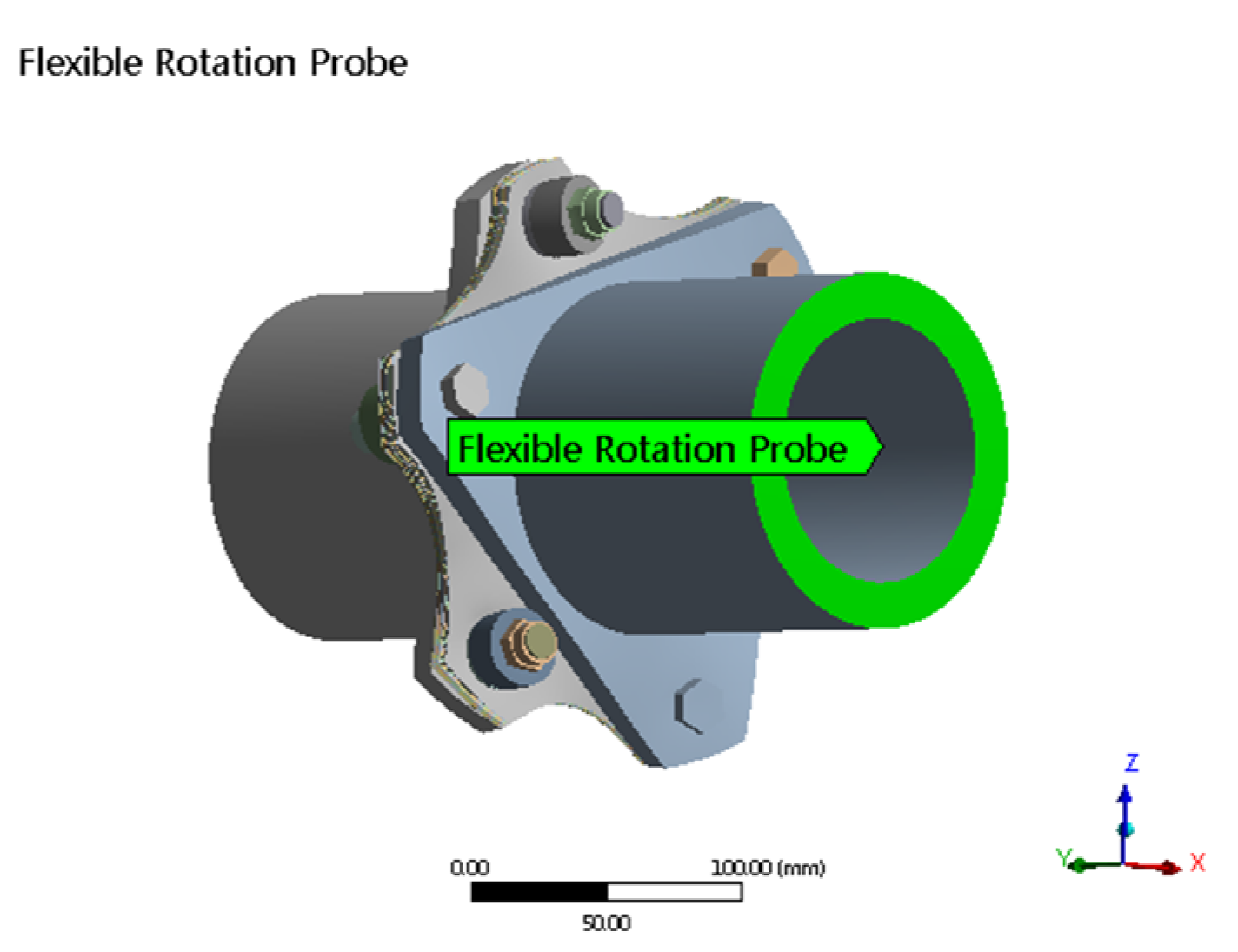

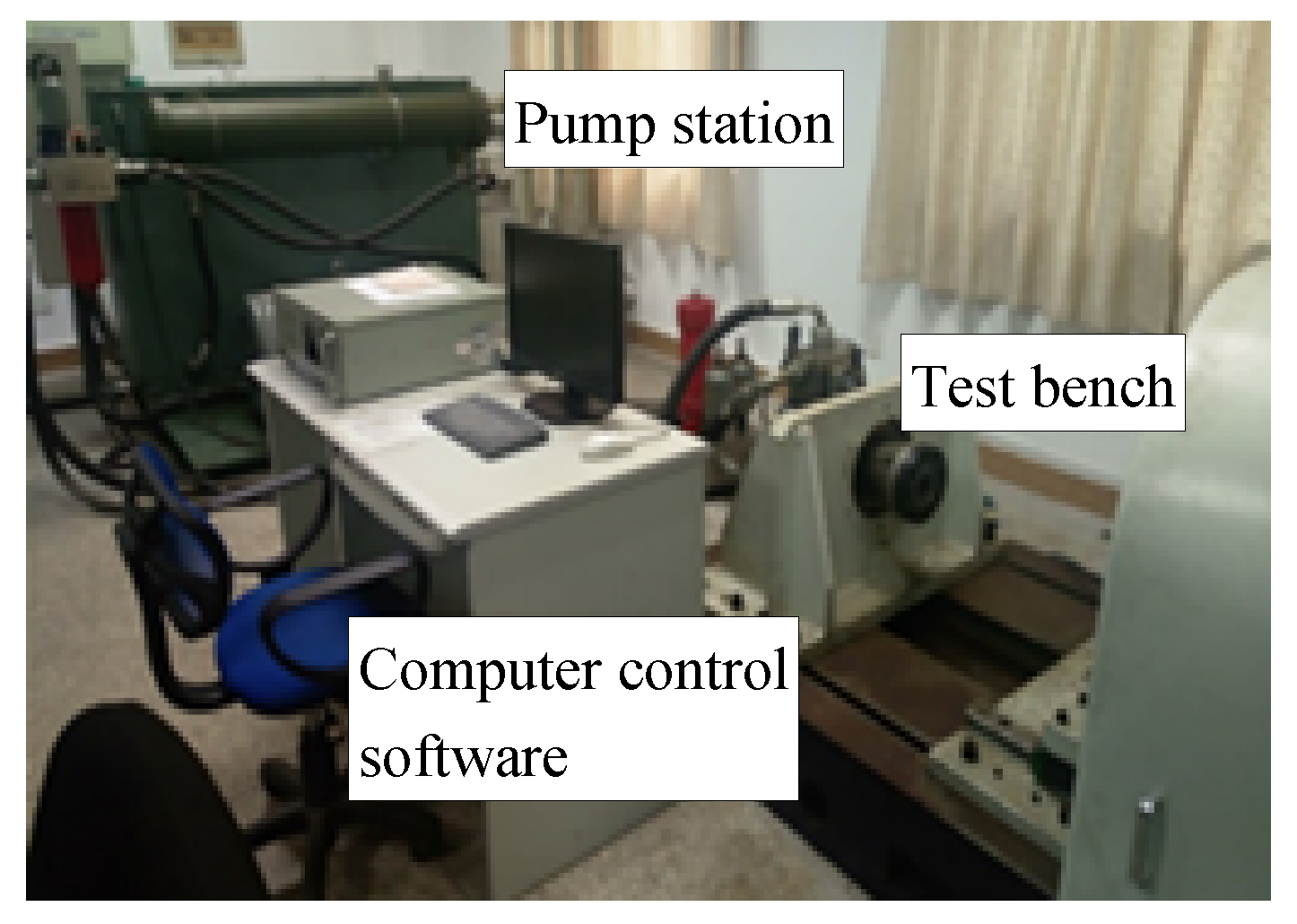

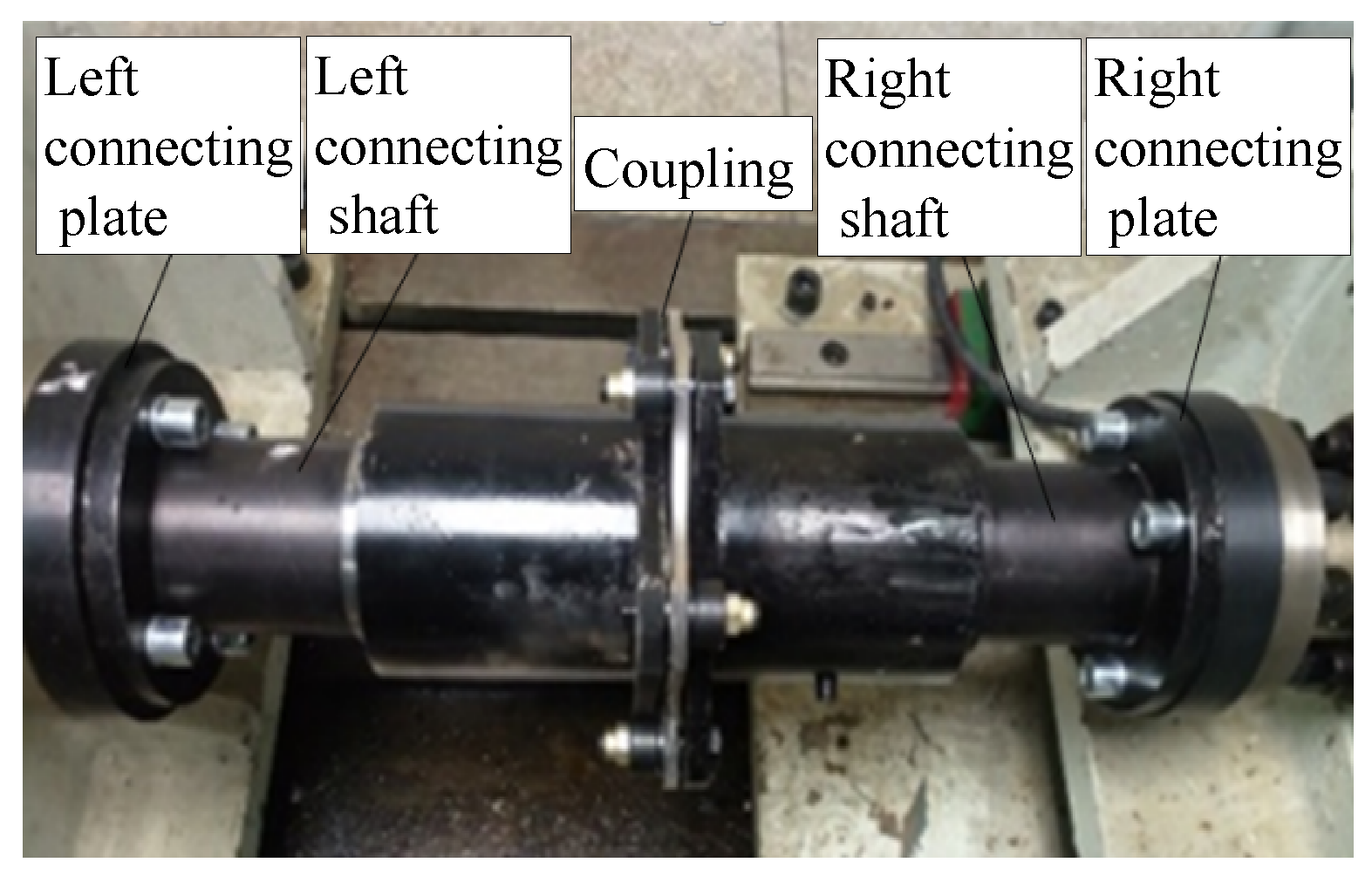

In the present study, it is intended to establish a finite element model of the waist type laminated membrane coupling. To this end, contacts between 16 pieces of laminations are considered. Moreover, an appropriate mesh is utilized and boundary conditions are set. Four stiffness characteristics of the coupling, including the torsional, axial, radial and angular stiffness are analyzed, and the torsional stiffness is verified through the static torsional test. In order to investigate the influence of the flange elasticity and the friction between laminations on the stiffness characteristics of the coupling, different flange stiffness, pre-tightening bolt forces and friction coefficients are considered in simulations. It is expected that the present study can provide a reference for designing the lamination coupling.

3. Investigating the Influence of the Flange Elasticity on the Stiffness of the Laminated Membrane Coupling

The main flexible components of laminated membrane couplings are laminated groups with multi-layer close fitting. It is worth noting that laminated groups are key components for transmitting the mechanical power and torque, compensating the displacement between the master and the slave, and compensating misalignments between the moving shafts. Scholars have performed many investigations on this issue. However, the majority of these investigations are focused on the stiffness of laminated groups and consider the flange as a rigid body. Studies show that the flange elasticity also affects the coupling stiffness. Therefore, it is intended to study the influence of the flange elasticity on the stiffness of the laminated membrane coupling through the comparative analysis of the coupling stiffness.

In order to investigate the flange impact on the overall stiffness of the coupling, the simulation in

Section 2.2 is used to analyze the laminated membrane coupling and obtain the stiffness of the laminated membrane coupling. Then the influence of the flange deformation is not considered, and the simulation stiffness of the laminated group model is calculated separately. The elastic modulus of the flange plate is set to 2 × 10

15 Pa, which means that the flange plate is considered as a rigid body and the deformation of flange plate is ignored. Then the calculation is carried out again until the stiffness of the lamination group is calculated.

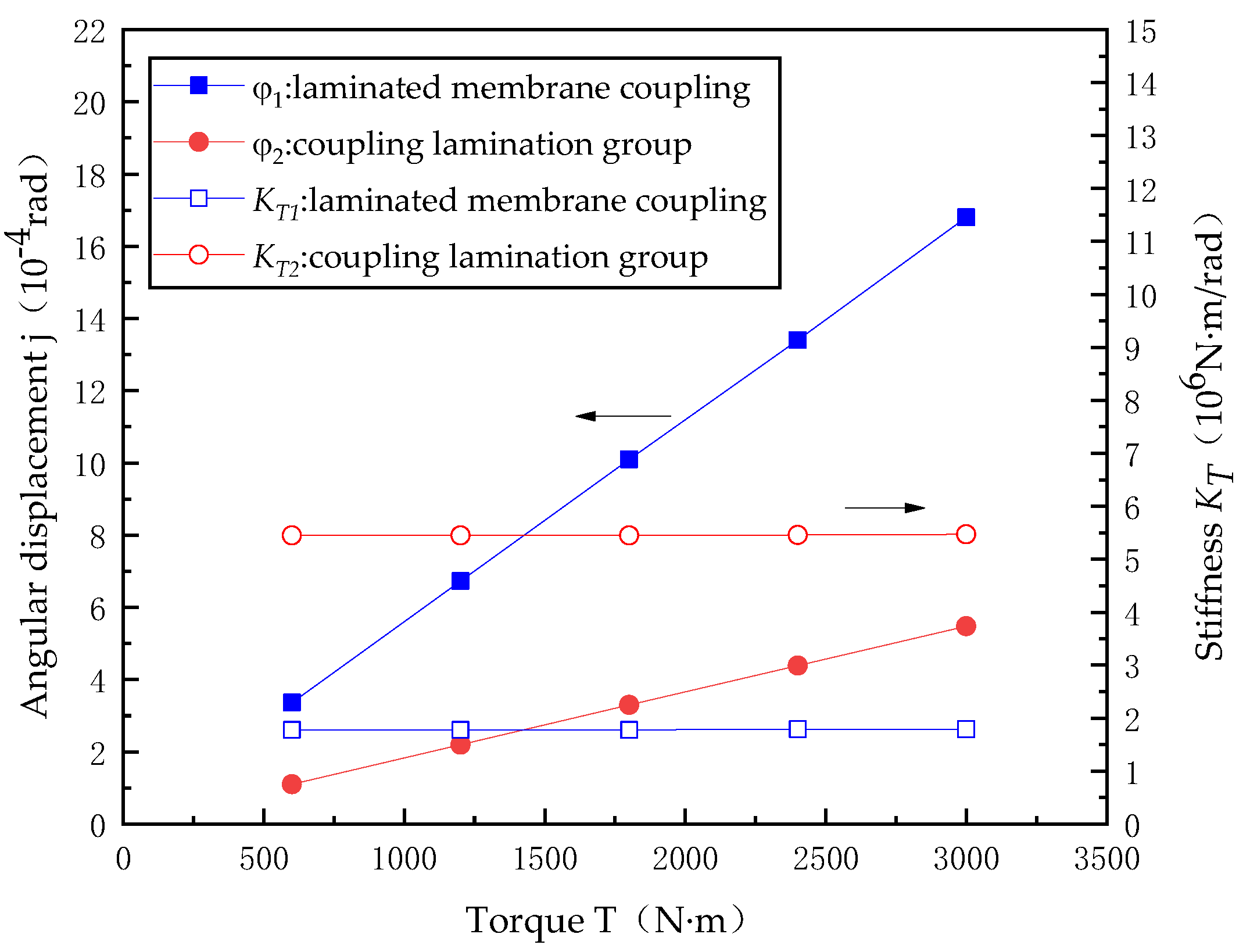

3.1. Torsional Stiffness Analysis of the Laminated Membrane Coupling and the Lamination Group

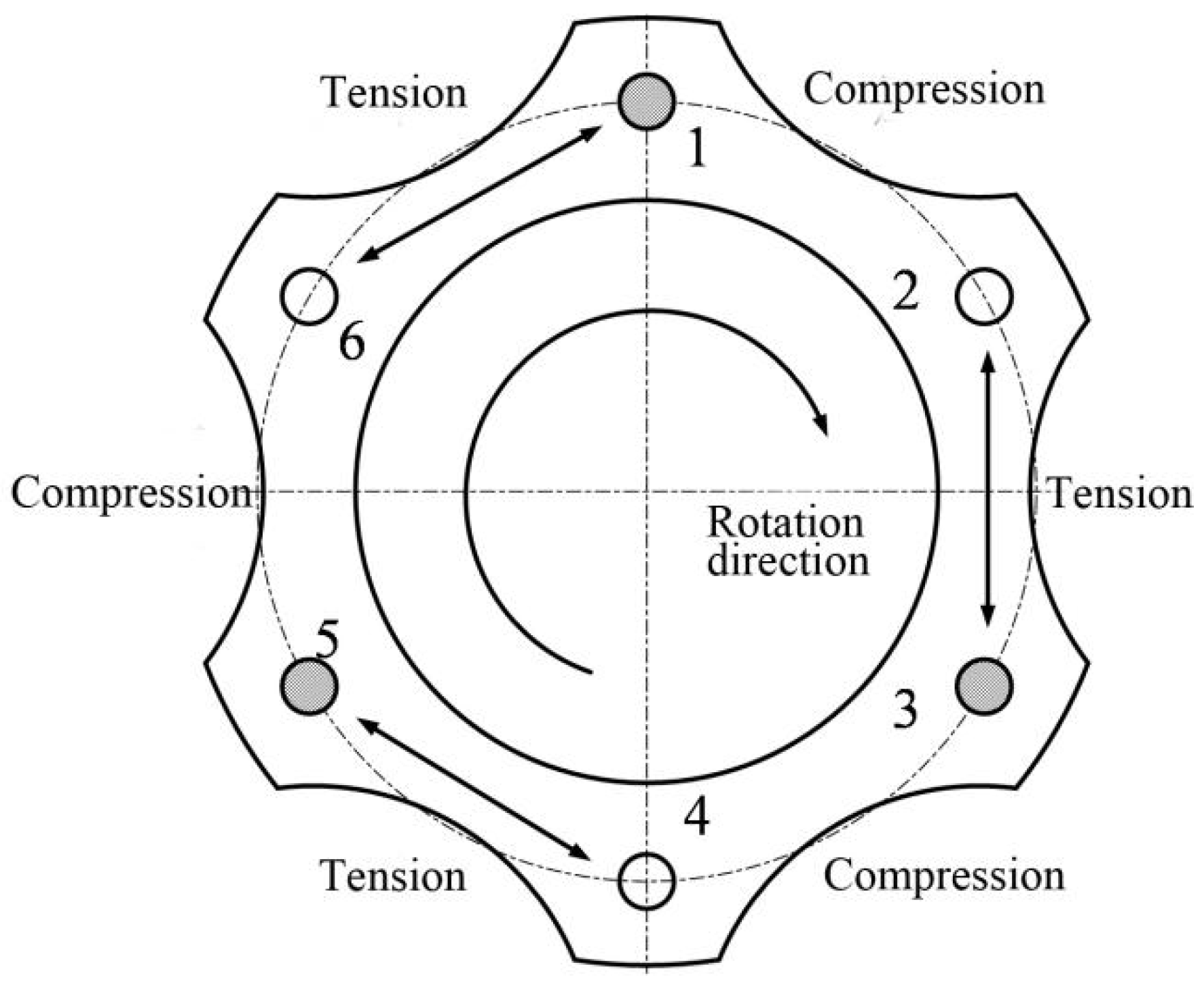

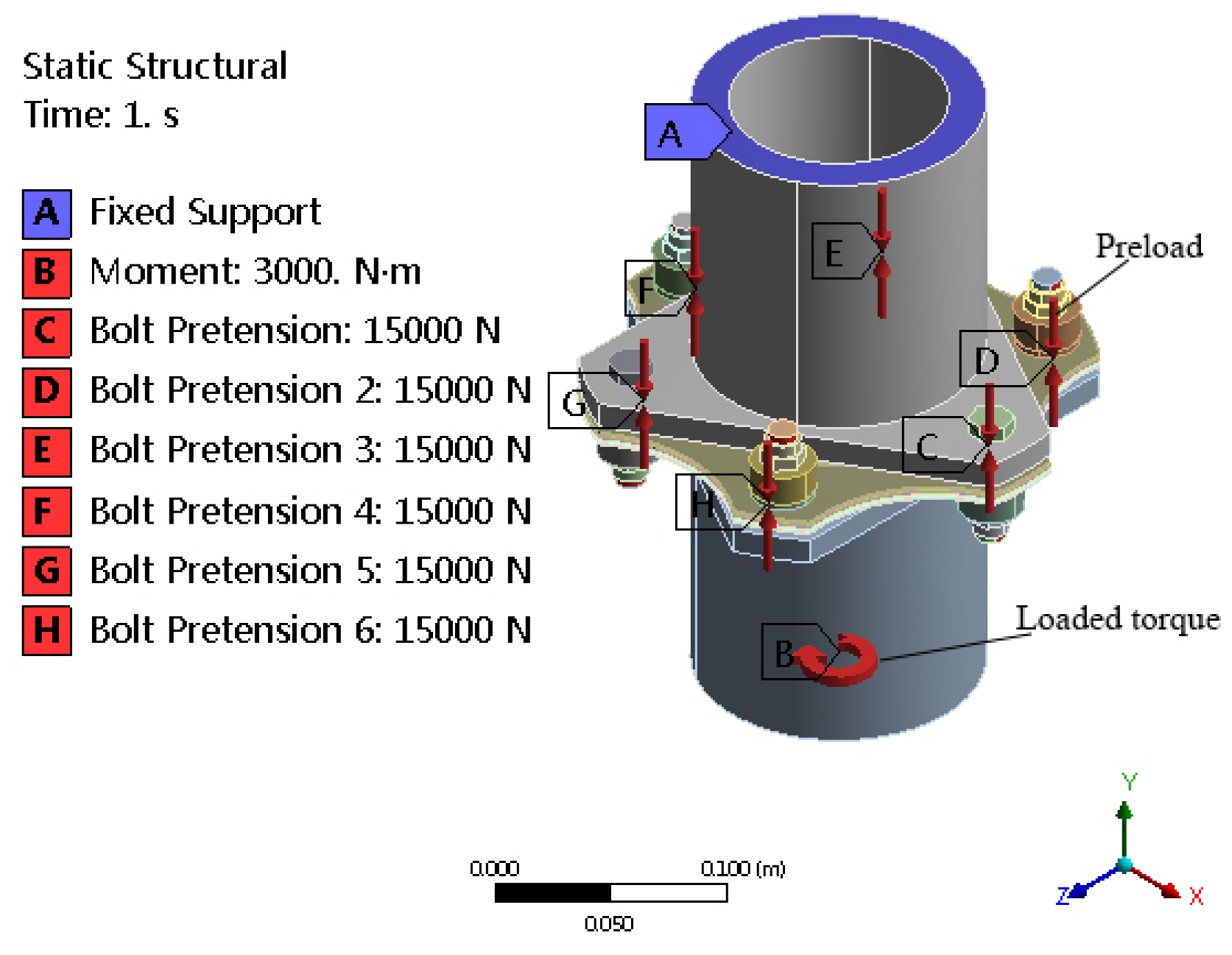

In this section, the driven flange is fixed and a torque of 3000 N·m is applied on the active flange. Then the load sub-step method, which is divided into five sub-steps, is applied to analyze the torsional stiffness of the laminated membrane coupling and the lamination group.

The end face of the driven flange is set to fixed support, and two load steps are set for load application, as shown in

Figure 13. On the sides of the six bolts, the ‘bolt pre-tightening force of 15 kN is set’ in the first step, and ‘lock is set’ in the second step. Tabular data is used to load the end face of the active flange. The first step is set to 0, the second step is to apply a torque of 3000 N·m, and the second step is to set 5 sub-steps, and the loading torque is 600 N·m, 1200 N·m, 1800 N·m, 2400 N·m and 3000 N·m respectively.

Through the simulation analysis, the corresponding rotational angular displacement of the laminated membrane coupling and the lamination group for torques of 600 N·m, 1200 N·m, 1800 N·m, 2400 N·m and 3000 N·m can be obtained. Then the torsional stiffness can be calculated by Equation (1).

Figure 14 shows the corresponding rotation angular displacement and torsional stiffness of the laminated membrane coupling and the coupling laminated group under different torque loads. It can be seen from the figure that the torque and rotational angular displacement of laminated membrane coupling has a certain nonlinear correlation within the range of 0–3000 N·m, and the same is true for the coupling lamination group. For the laminated membrane coupling, the torsional stiffness is estimated to 1.8 × 10

6 N·m/rad. Furthermore, for the coupling lamination group, the torsional stiffness is approximately 5.45 × 10

6 N·m/rad. Since the stiffness value is large, it can be considered that the laminated membrane coupling is rigid along the torsional direction.

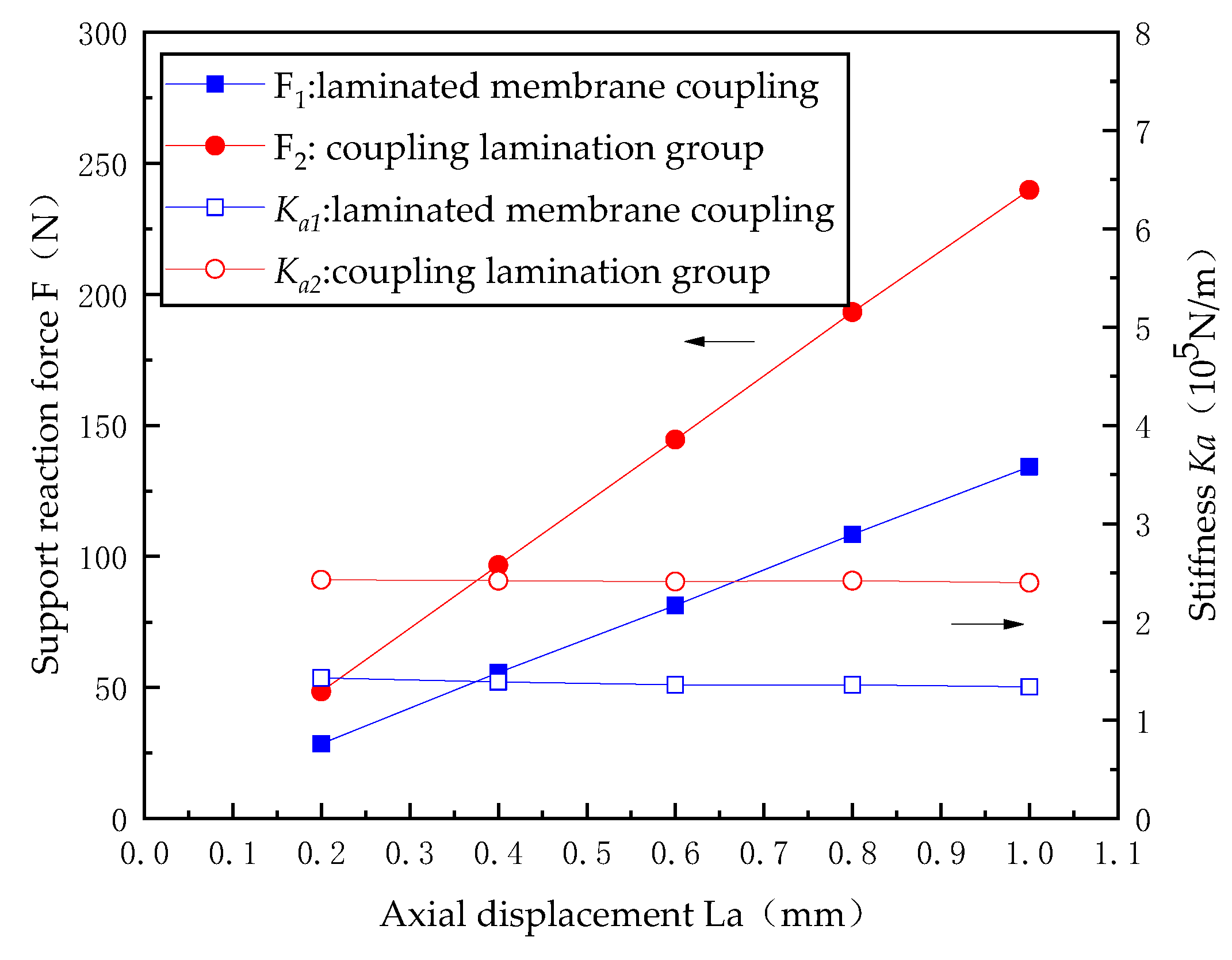

3.2. Axial Stiffness Analysis of the Laminated Membrane Coupling and the Lamination Group

In this section, the pre-tightening force of connecting bolts between the driving and driven flanges is set to 15,000 N. After fixing the driven flange, an axial displacement of 1 mm is applied on the active flange. Then the load sub-step method, which is divided into 5 sub-steps, is applied to analyze the axial stiffness of the laminated membrane coupling and the lamination group.

The end face of the driven flange is set to “fixed support”, and two load steps are set to apply the load, as shown in

Figure 15. On the side of the six bolts, the preload of the first bolt is set to 15 kN. Then ‘set the lock’ is applied in the second step. Table data is then used to load the end face of the active flange. The first step is set to 0, and the second step is set to 1 mm axial displacement. In the second step, five sub steps were set up, and the loading displacements were 0.2 mm, 0.4 mm, 0.6 mm, 0.8 mm and 1 mm, respectively.

Through the simulation analysis, the corresponding reaction forces of the laminated membrane coupling and the lamination group for axial displacements of 0.2 mm, 0.4 mm, 0.6 mm, 0.8 mm and 1 mm are obtained. In this case, the axial stiffness

Ka of the laminated membrane coupling and the lamination group can be expressed as:

Figure 15 shows the corresponding reaction force and axial stiffness of the laminated membrane coupling and the coupling lamination group are loaded under different axial displacements loads. It can be seen from the figure that for a small displacement range (i.e., axial displacement 0–1 mm), there is a nonlinear correlation between the axial force and displacement of the laminated membrane coupling, and the same is true for the coupling lamination group. In this range, the axial stiffness of the laminated membrane coupling is approximately 1.4 × 10

5 N/m. Meanwhile, it is found that the axial stiffness of the coupling lamination group is approximately 2.40 × 10

5 N/m. It should be indicated that this stiffness value is relatively small so that the laminated membrane coupling can be considered as a flexible component along the axial direction.

3.3. Radial Stiffness Analysis of the Laminated Membrane Coupling and the Lamination Group

In this section, the pre-tightening force of connecting bolts between the driving and driven flanges are set to 15,000 N. After fixing the driven flange, a radial displacement of 0.5 mm is applied on the active flange. Then the sub-step method, which is divided into five sub-steps, is applied to analyze the radial stiffness of the laminated membrane coupling and the lamination group.

In the software, the cylindrical surfaces of the three bolts connected with the driven flange are set as fixed support constraints, the loading process is divided into two load steps, the first step is to set the bolt preload of 15 kN, and the second step is to set the lock. The cylindrical surfaces of the three bolts connected with the active flange are subjected to a displacement load in the X direction, and use tabular data to load, the first step is set to 0, the second step is set to 5 mm displacement load, and five sub-steps are set, the loads of the five sub-steps are 0.1 mm, 0.2 mm, 0.3 mm, 0.4 mm and 0.5 mm respectively.

From the structure of the laminated membrane coupling, it can be seen that the effect of the radial displacement in the X and Z direction on the coupling is different, so the same displacement constraint is also applied in the Z- direction for analysis.

Through the simulation analysis, the corresponding reaction force of laminated membrane coupling and the lamination group for the radial displacement of 0.1 mm, 0.2 mm, 0.3 mm, 0.4 mm and 0.5 mm are obtained. Then the radial stiffness

Kr of the laminated membrane coupling and the lamination group can be calculated as the following:

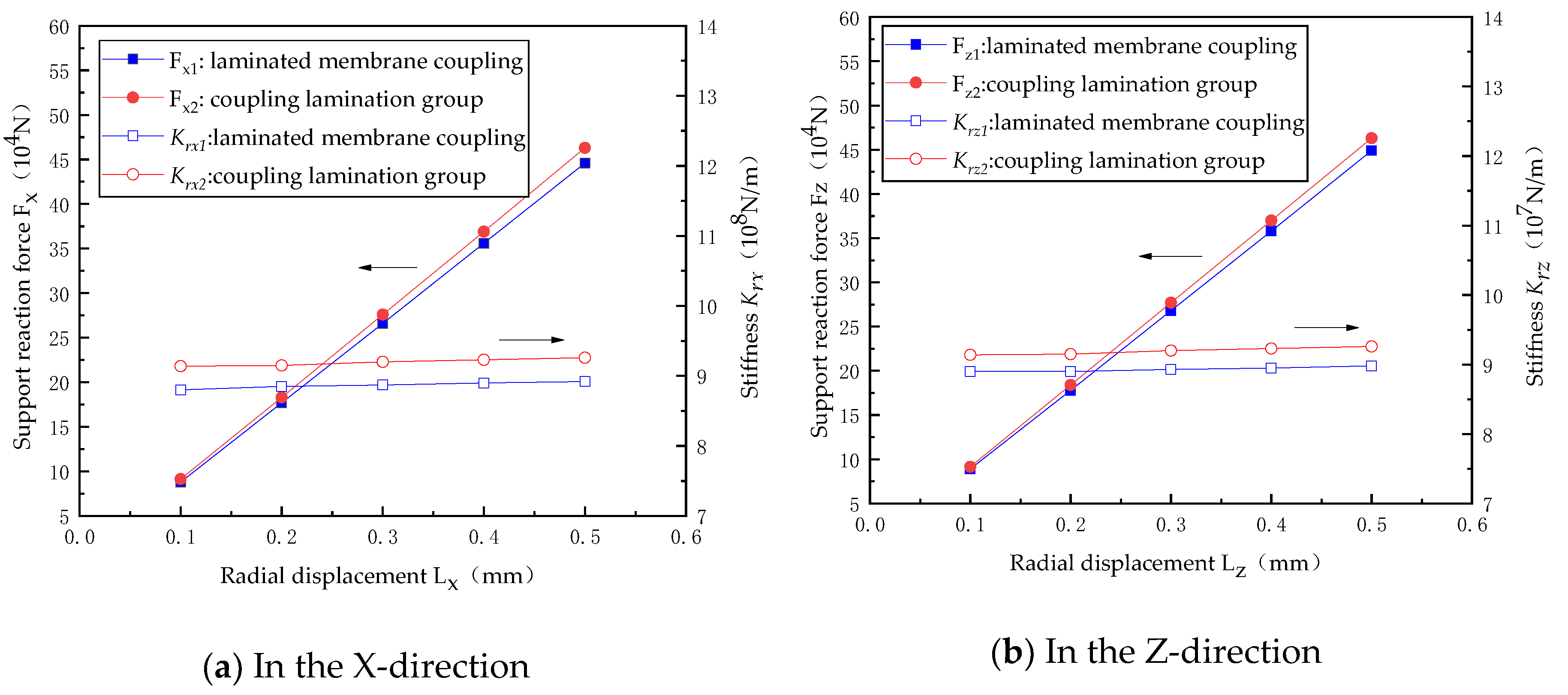

Figure 16 shows the reaction force and the corresponding stiffness of the radial displacement along the X- and Z- directions of the laminated membrane coupling and the coupling lamination group in each load sub-step.

Figure 16 demonstrates that for small displacements (i.e., radial displacements within the range of 0–0.5 mm), there is a nonlinear correlation between the radial force and displacement of the laminated membrane coupling along X- and Z-directions. The same is true for the coupling lamination group. Moreover, it is observed that the radial stiffness along the X-direction is slightly less than that along the Z-direction. In other words, for the laminated membrane coupling, the radial stiffness along the X-direction is about 8.92 × 10

8 N/m, while the radial stiffness along the Z-direction is about 8.98 × 10

8 N/m. For the coupling lamination group, the stiffness along the X-direction varies within the range of 9.14 × 10

8–9.26 × 10

8 N/m, while that along the Z-direction varies within the range of 9.16 × 10

8–9.26 × 10

8 N/m. In a word, both stiffness values are large so that the laminated membrane coupling along the radial direction can be considered as a rigid component.

3.4. Angular Stiffness Analysis of the Laminated Membrane Coupling and the Lamination Group

In this analysis, the pre-tightening force of connecting bolts between driving and driven flanges are set to 15 kN. After fixing the driven flange, a rotational angle of 0.5° is applied on the active flange. Then the load sub-step method, which is divided into five sub-steps, is applied to analyze the angular stiffness of the laminated membrane coupling and the lamination group.

In the software, the end face of the driven flange is set as a fixed support constraint. The loading process is divided into two load steps, load on the sides of six bolts, set a pre-tightening force of 15 Kn in the first step, and lock in the second. An angular displacement load in the X direction is applied to the end face of the active flange. Through the tabular data tool, the first step is set to 0°, the second step is set to 0.5°, the second load step is divided into five sub-steps, the values are 0.1°, 0.2°, 0.3°, 0.4° and 0.5°respectively.

It can be seen from the structure of the laminated group that the effect of the angular displacement in the X and Z direction on the coupling is different, so the same angular displacement in the Z direction is also applied for analysis.

Through the simulation analysis, the reaction moment of the laminated membrane coupling and the lamination group at the rotational angles of 0.1°, 0.2°, 0.3°, 0.4° and 0.5°can be obtained. In this case, the angular stiffness

Kα of the laminated membrane coupling and the lamination group can be expressed as:

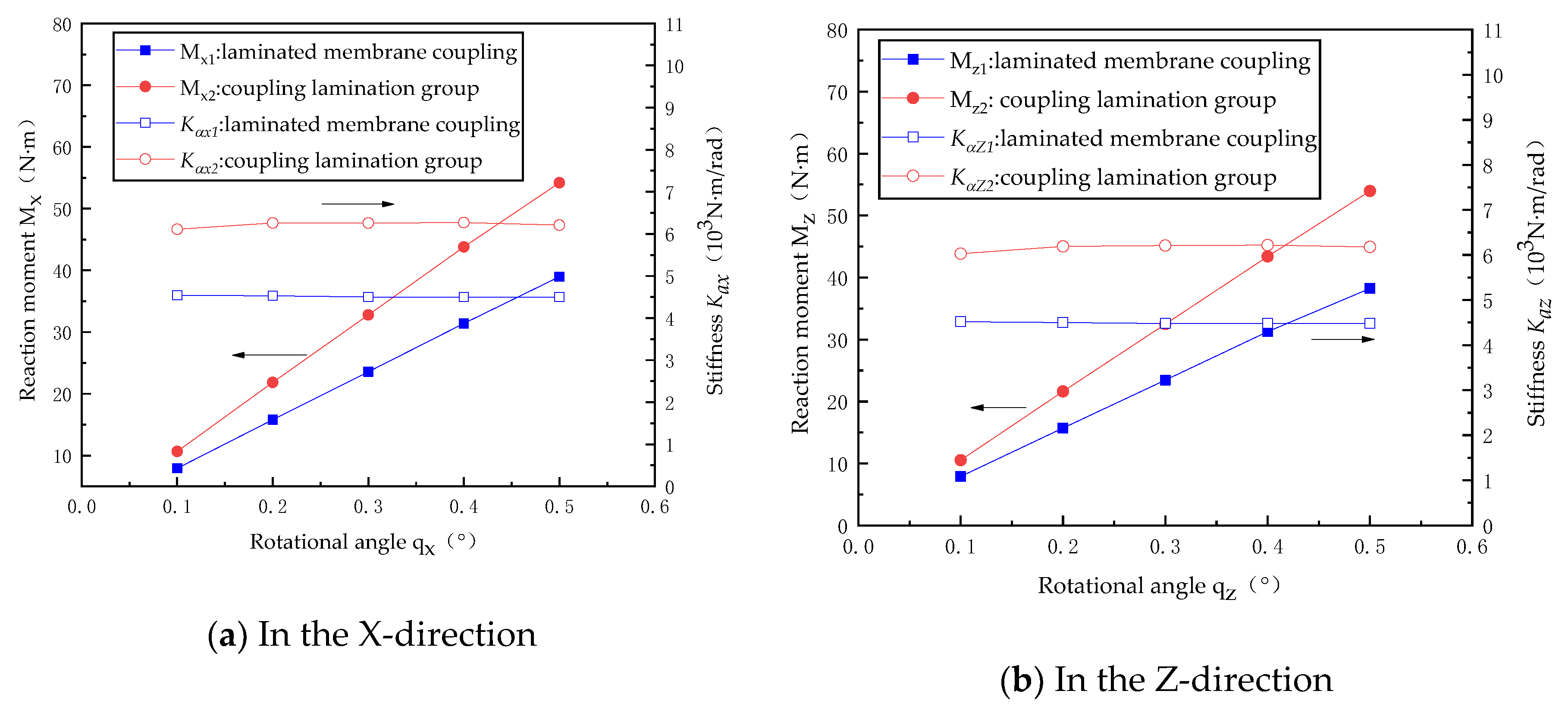

Figure 17 shows the reaction moment and the corresponding stiffness of different rotational angles along the X and Z directions of the laminated membrane coupling and the coupling lamination group in each load sub-step.

Figure 17 indicates that for a small displacement range (i.e., rotational angles within the range of 0–0.5°), there is a nonlinear correlation between the bending moment and displacement of the laminated membrane coupling along the X- and Z-directions. The same is true for the coupling lamination group. Moreover, it is found that the angular stiffness along the X-direction is slightly greater than that along the Z-direction. In other words, for the laminated membrane coupling, the angular stiffness along the X-direction is about 4.50 × 10

3 N·m/rad, while that along the Z-direction is about 4.48 × 10

3 N·m/rad. For the coupling lamination group, the stiffness along the X-direction varies within the range of 6.11 × 10

3–6.21 × 10

3 N·m/rad, while that along the Z-direction varies within the range of 6.03 × 10

3–6.18 × 10

3 N·m/rad. Anyway, both stiffness values are relatively small so that the laminated membrane coupling along the circumferential direction can be assumed as flexible.

3.5. The Influence of the Flange Elasticity on Different Stiffness of the Laminated Membrane Coupling

In the foregoing sections, the finite element simulation is performed to obtain the torsional, radial, axial and angular stiffness of the coupling and lamination group.

Table 4 shows the obtained results in this regard. It indicates that the order of magnitude of torsional and radial stiffness is far greater than that of the axial and angular stiffness, indicating that the laminated membrane coupling is rigid in torsion and radial directions. Subsequently, it can mainly provide compensation for axial and angular displacements. Moreover, it is found that all stiffness values of the whole coupling are smaller than the corresponding stiffness of the lamination group, which is in line with the actual situation. This can be interpreted as the following: existence of the flange is equivalent to the series connection with the lamination group along the torsional, axial, radial and angular directions. On the other hand, series connection reduces the total stiffness of the system. In other words, the flange imposes the biggest reduction in the overall torsional stiffness of the coupling. This reduction can be up to 0.33 laminated group stiffness. Meanwhile, axial, angular and radial stiffness of the flange can reduce the overall torsional stiffness of the coupling up to 0.58, 0.73 and 0.97 laminated group radial stiffness, respectively. Therefore, the flange influence on the stiffness of the coupling is in order of torsional, axial, angular and radial stiffness.

4. Analyzing the Friction Impact on the Stiffness of the Laminated Membrane Coupling

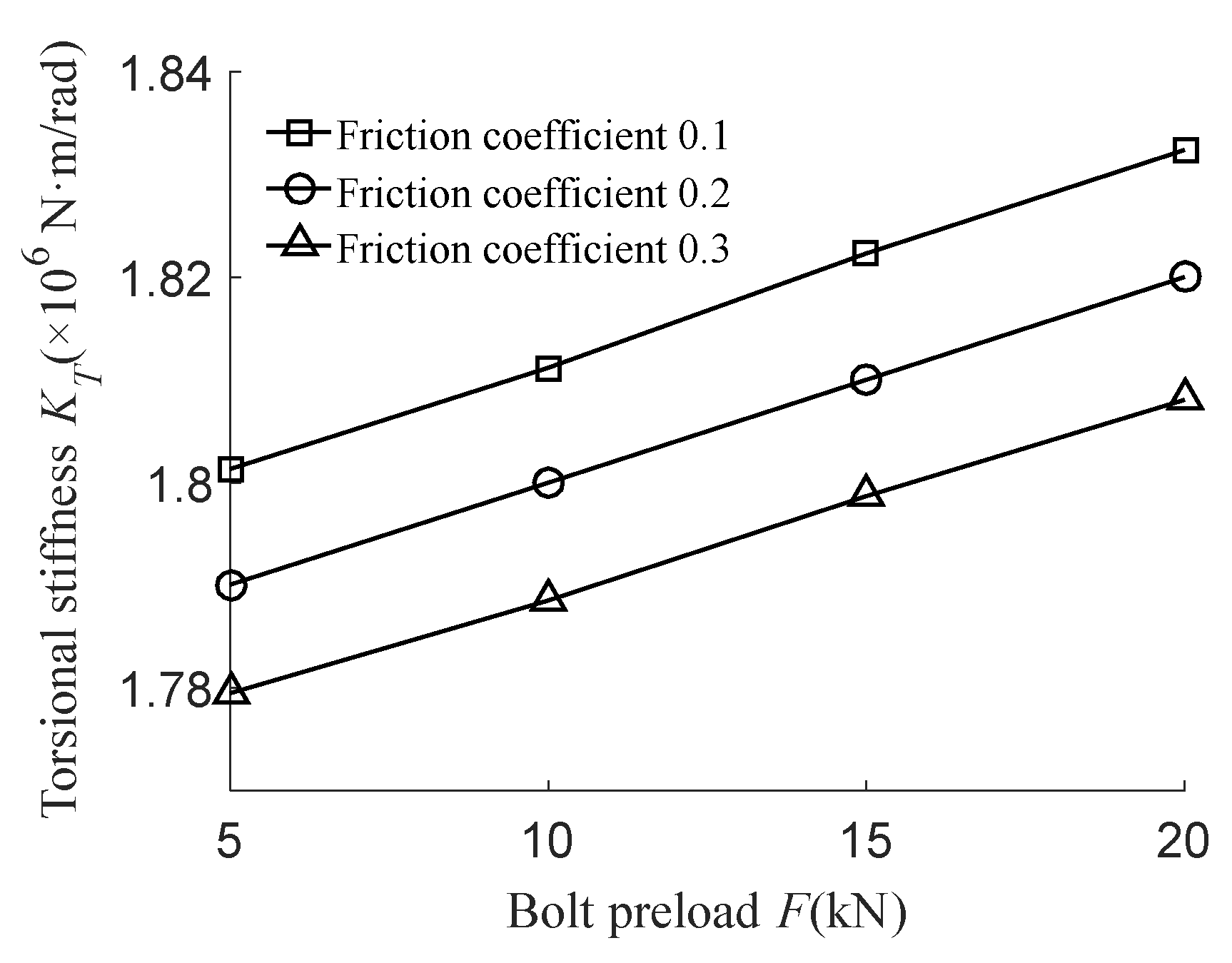

The friction force is affected by pre-tightening force and friction coefficient. In this section, it is intended to analyze the influence of bolt pre-tightening force and friction coefficient on the stiffness of the laminated membrane coupling to investigate the influence of the friction force on the torsional, axial, radial and angular stiffness of the laminated membrane coupling.

4.1. Analyzing the Influence of the Bolt Preload on the Stiffness of the Laminated Membrane Coupling

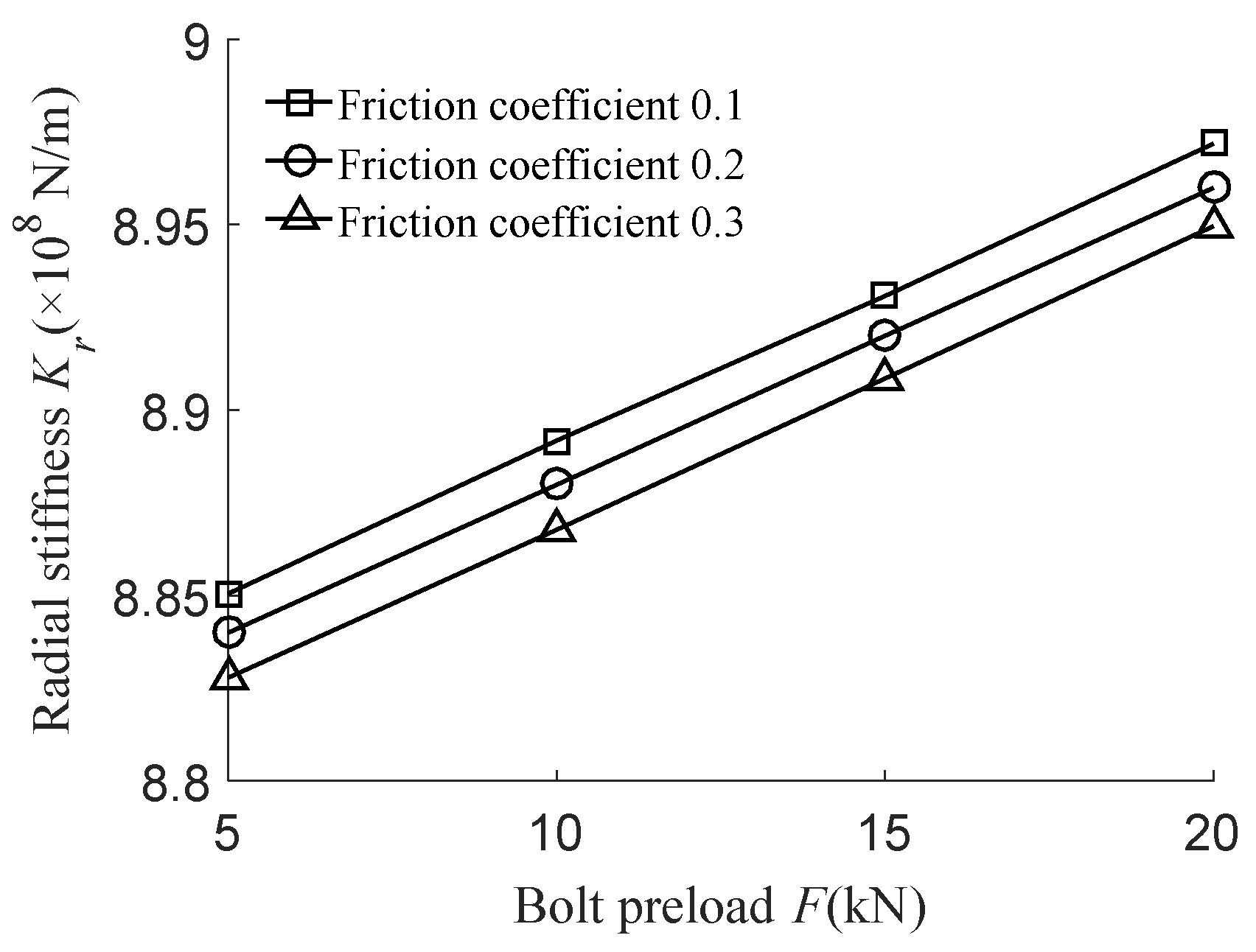

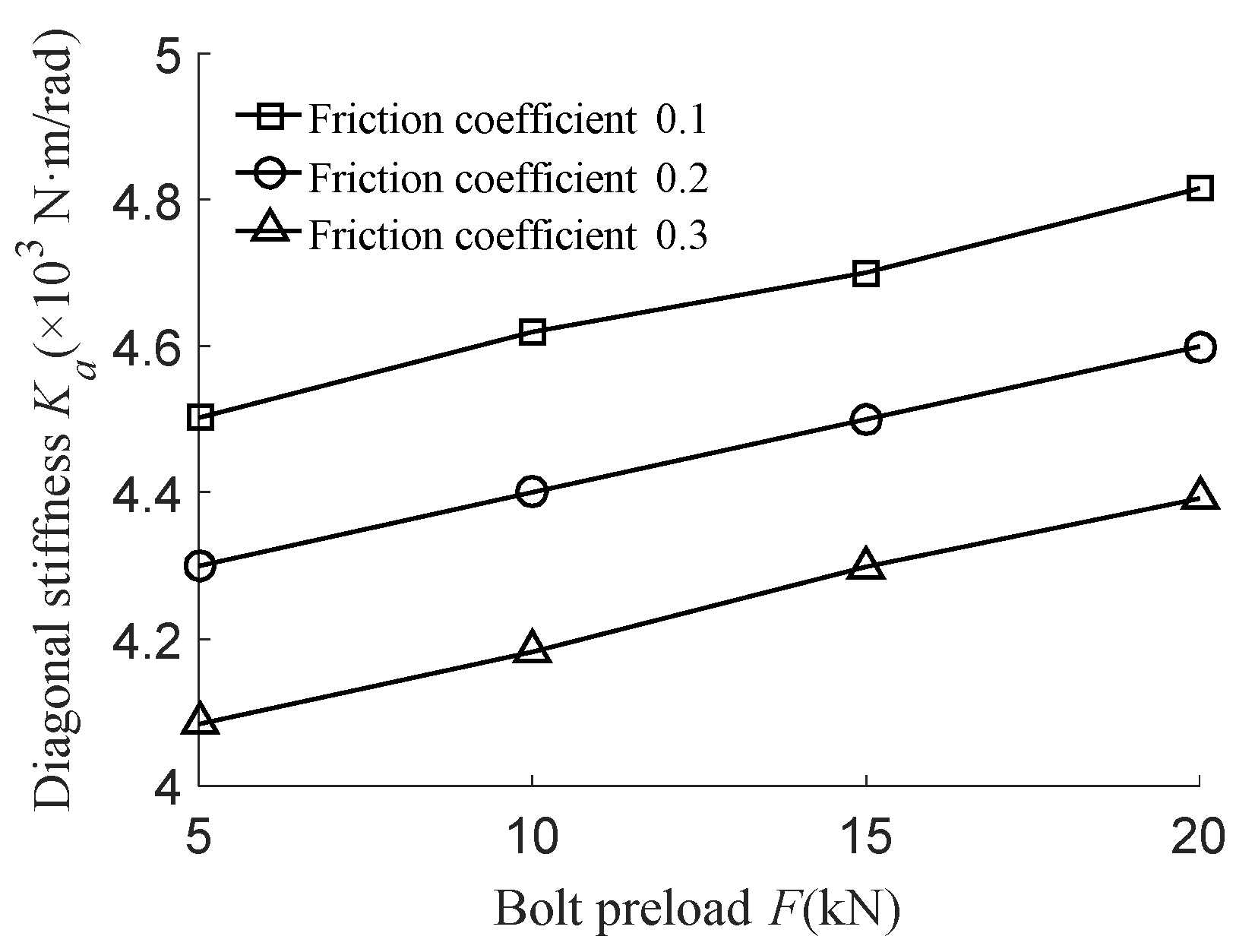

In this section, the influence of the bolt preload on the stiffness of laminated membrane coupling with constant coupling dimensions is studied. In order to facilitate the comparison, only stiffness values obtained from the last sub-step of the second load step is taken for the analysis. The torque, axial displacement, radial displacement, and the rotational angle is set to 3000 N·m, 1 mm, 0.5 mm and 0.5°. It should be indicated that since the radial and angular stiffness along X- and Z-directions have negligible differences, they are analyzed along the X-direction.

For the foregoing loads, the bolt preload is set to 5 kN, 10 kN, 15 kN and 20 kN, respectively, and the other boundary conditions are remained unchanged.

Moreover, friction coefficient is set to 0.1, 0.2 and 0.3, respectively, to investigate the influence of the bolt preload on various stiffness settings.

Figure 18,

Figure 19,

Figure 20 and

Figure 21 show that when the friction coefficient is set to 0.1, 0.2 and 0.3, increasing the bolt preload will increase torsional, axial, radial and angular stiffness of the laminated membrane coupling. Furthermore, when the preload increases from 5 kN to 20 kN, the variation of torsional, axial, radial, and angular stiffness are 1.6%, 66%, 1.1% and 5.2%, respectively. It is found that the bolt preload has the greatest impact on the axial stiffness, which is far greater than other stiffness.

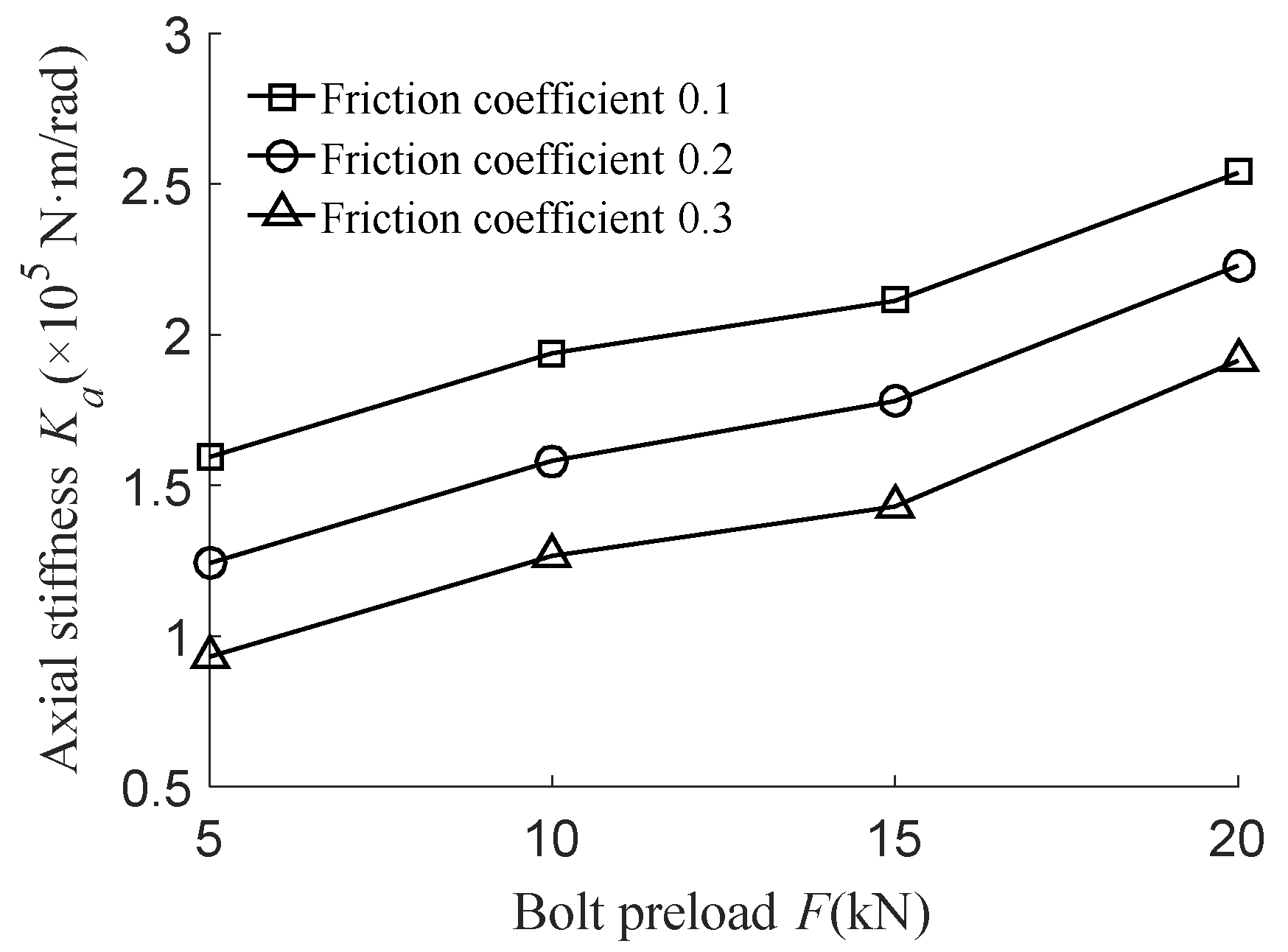

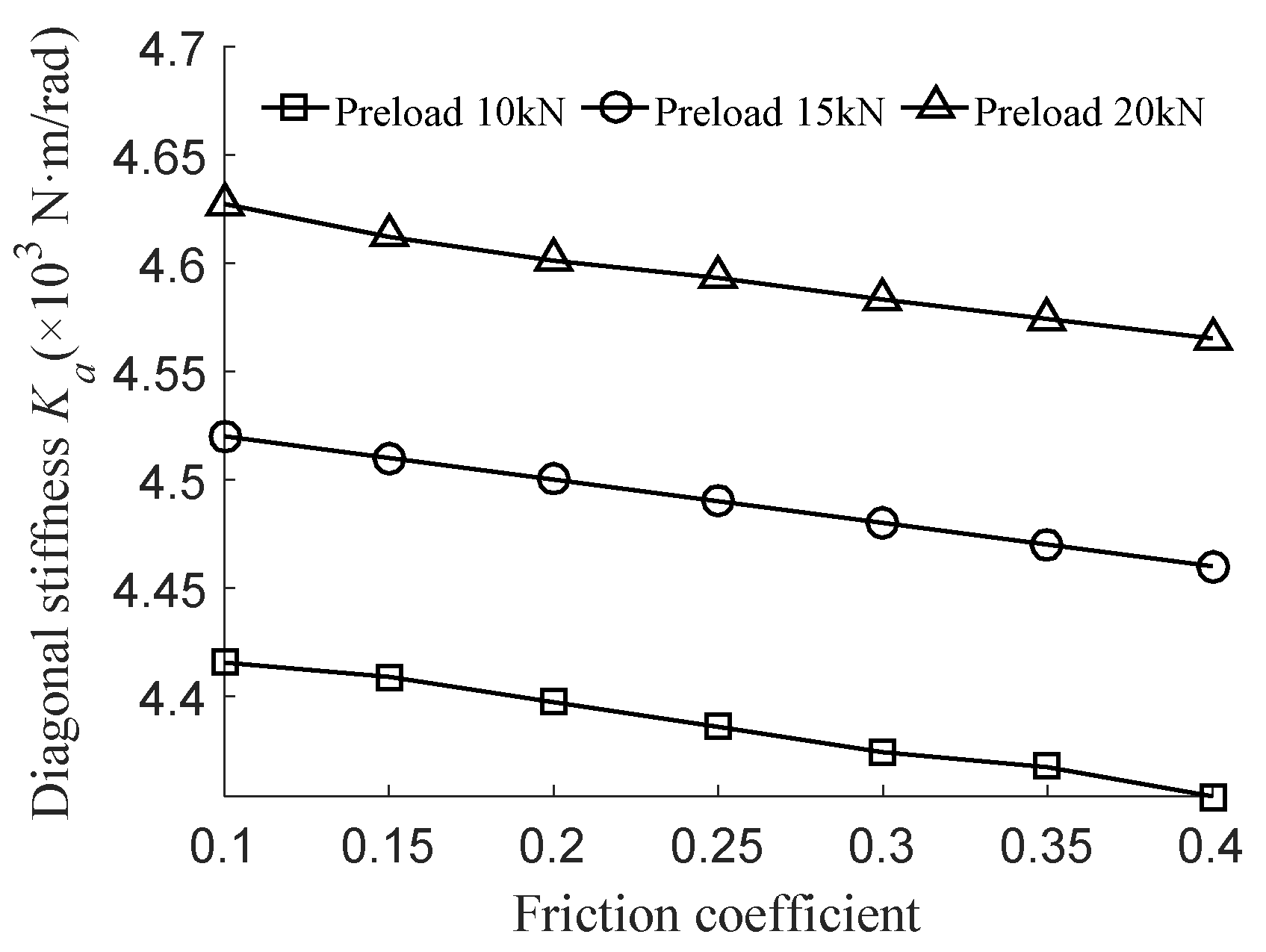

4.2. Analyzing the Influence of Friction Coefficient on the Stiffness of the Laminated Membrane Coupling

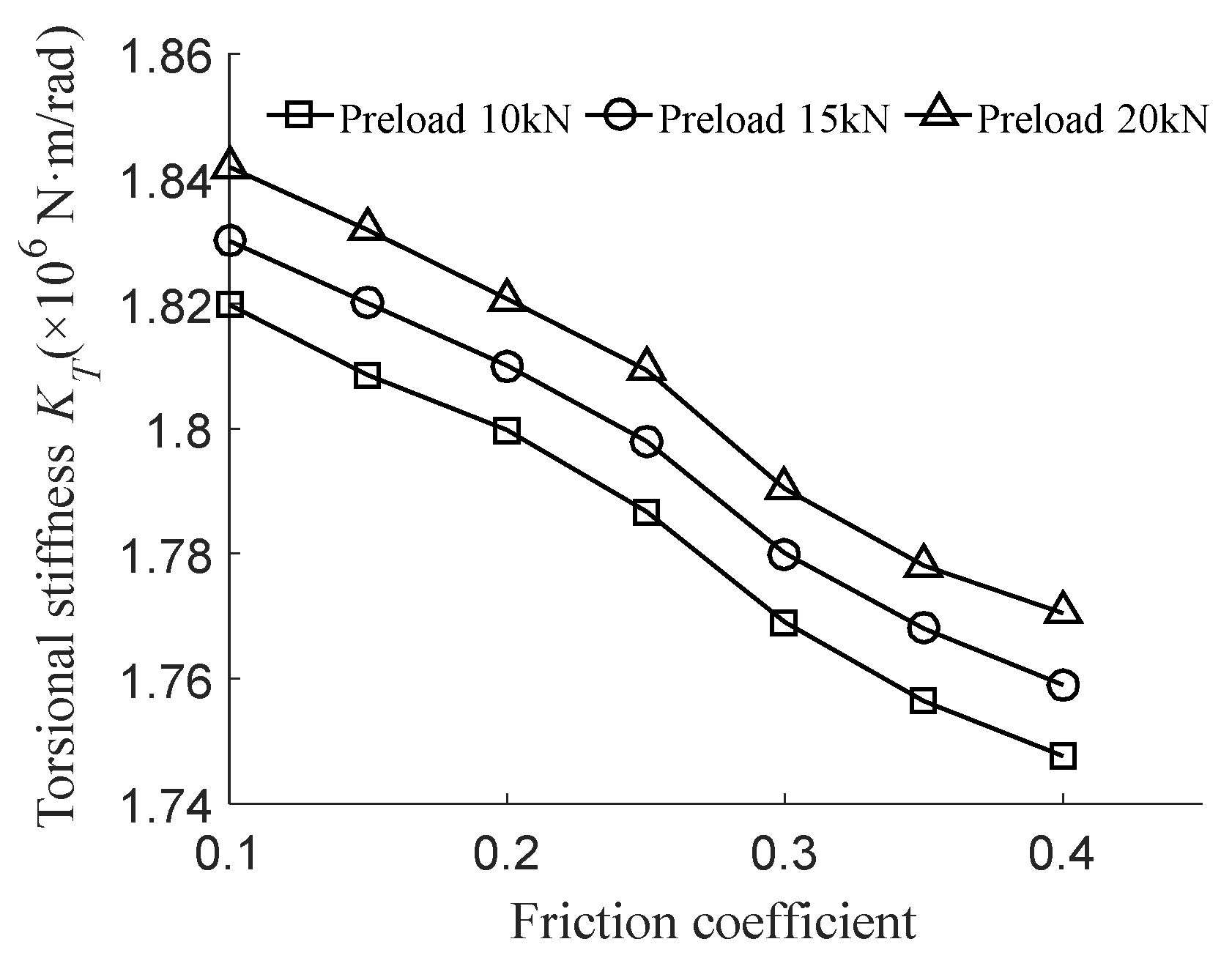

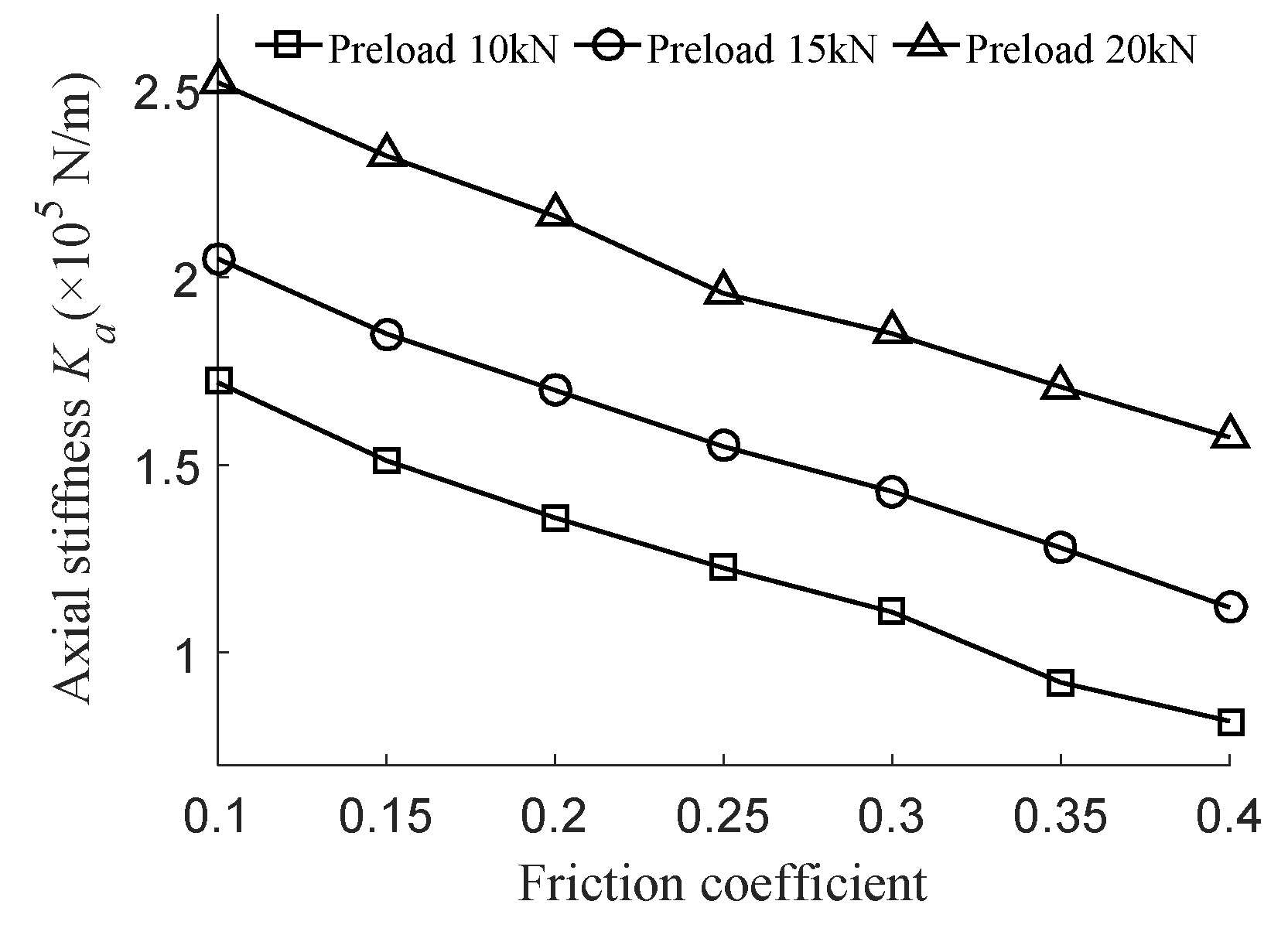

The influence of friction coefficient between laminations with constant coupling dimensions on the coupling stiffness is studied. For above mentioned various loads, the friction coefficient between the laminations is set to 0.1, 0.15, 0.2, 0.25, 0.3, 0.35 and 0.4 respectively, while other boundary conditions are remained unchanged to study the influence of friction coefficient on various stiffness of the coupling.

Moreover, the bolt preload is set to 10 kN, 15 kN and 20 KN to get the influence of friction coefficient value on various stiffness settings with different bolt preloads.

Figure 22,

Figure 23,

Figure 24 and

Figure 25 show that when the bolt preload is 10 kN, 15 kN and 20 kN, increasing the friction coefficient will reduce the torsional, axial, radial and angular of the laminated membrane coupling. More specifically, when friction coefficient increases from 0.1 to 0.4, variations of torsional, axial, radial and angular are 4.4%, 46%, 0.6% and 1.1%, respectively.