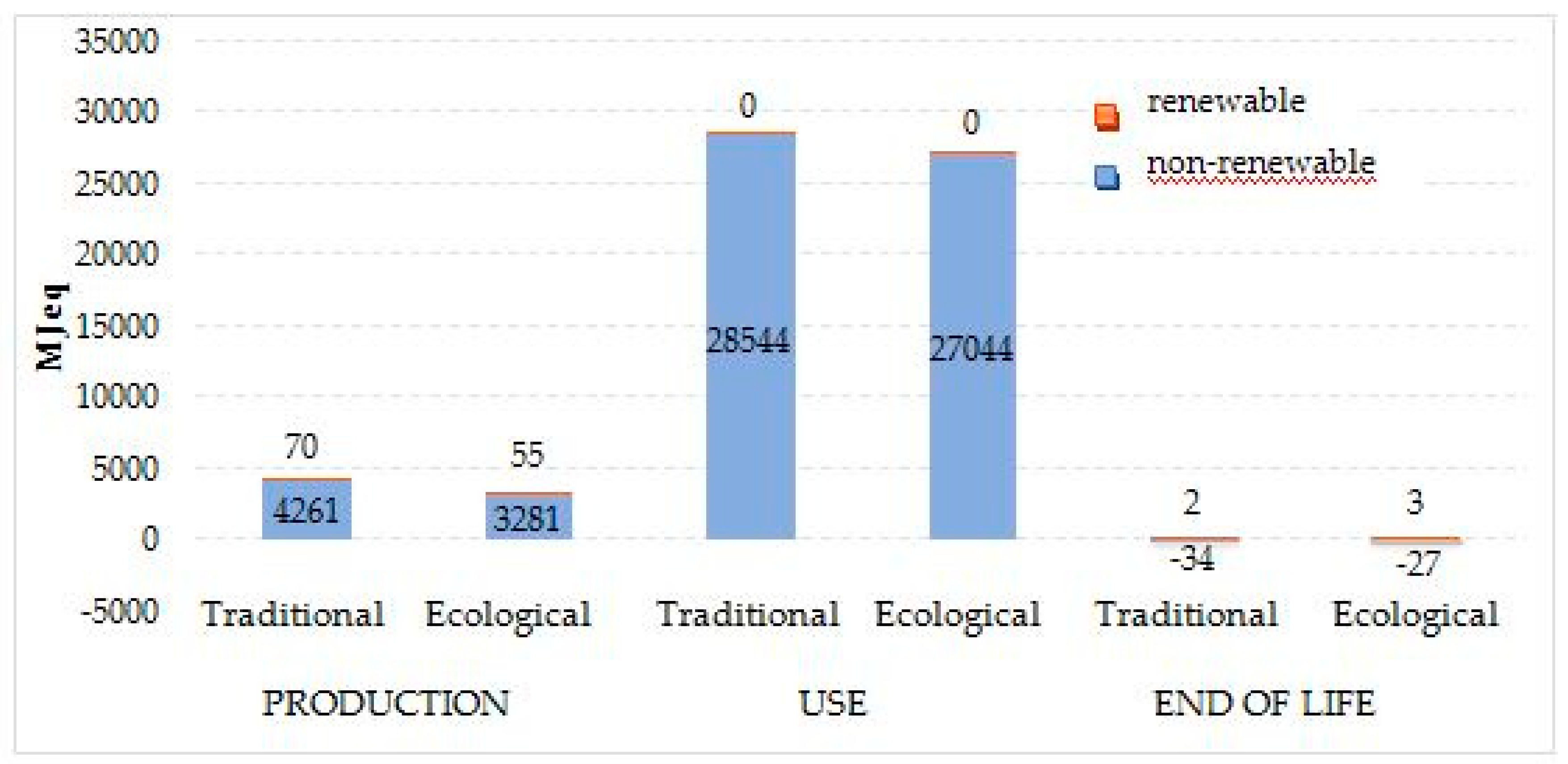

The results are summarized in three sections, corresponding to the respective assessment methods Eco-indicator 99 (

Section 4.1), CED (

Section 4.2), and IPCC (

Section 4.3). The results from the characterization stage are given in

Table 2, and from the grouping and weighting stages in

Table 3,

Table 4,

Table 5,

Table 6,

Table 7 and

Table 8 and

Figure 5,

Figure 6,

Figure 7,

Figure 8,

Figure 9 and

Figure 10. The results describe each stage of traditional and ecological tire life cycles, accounting for their total life cycle impact and five environmental damage categories eliciting the highest levels of detrimental effects established in the study: carcinogens, respiratory inorganics, climate change, acidification/eutrophication, and fossil fuels. The outcomes of the study are the environmental factors quantified as eco-indicator points (Pt), i.e., easily comprehensible parameters facilitating the comparative analysis of dissimilar environmental impacts. One thousand points express an annual impact of an average European resident on the environment.

4.1. Eco-Indicator 99

Table 2 presents the results of the characterization of environmental consequences occurring in the material life cycle of a traditional and ecological car tire based on impact categories. Among substances detrimental to human health, these were the inorganic compounds causing respiratory diseases that were established to have the highest negative impact. Their maximum emissions levels were obtained in the use-stage of the traditional tire (1.09 × 10

−3 DALY). The analyses indicate that the recycling processes would result in the reduction of their environmental impact over the entire life by a total of 8.54 × 10

−7 DALY, and in the case of the ecological tire by a total of 1.49 × 10

−6 DALY. Among the factors of a negative effect on animal health and life, ecotoxic substances were determined to be the leading cause of hazard. Their emissions reach the highest level in the production of the traditional tire (2.90 × 10 PAF × m

2 × year). Recycling at the end of the product use stage of the life cycle would minimized the negative impact by 2.87 × 10

−1 × PAF × m

2 × year in the conventional tire and 4.66 × 10

−1 × PAF × m

2 × year in the eco-tire. Considering the hazards to plant organisms, the strongest negative effect is concerned with acidification or eutrophication of the natural environment. The highest level of the compound emissions responsible for these effects relate to the use of the traditional tire (3.64 × 10 PDF × m

2 × year). Recycling would reduce the negative impact by a total of 4.45 × 10

−2 PDF × m

2 × year (the traditional tire) and by −7.83 × 10

−2 × PDF × m

2 × year (the ecological tire). Considering elevated energy consumption on account of raw material extraction, the highest level of harmful impact in this respect was recorded in fossil fuels. As in the previous cases, the most resource-engaging phase was the use of the traditional tire (4.11 × 10

3 MJ). It was estimated that over the entire life cycle of the traditional tire, recycling would introduce total energy savings amounting to 5.95 MJ, and in the eco-tire 8.32 MJ.

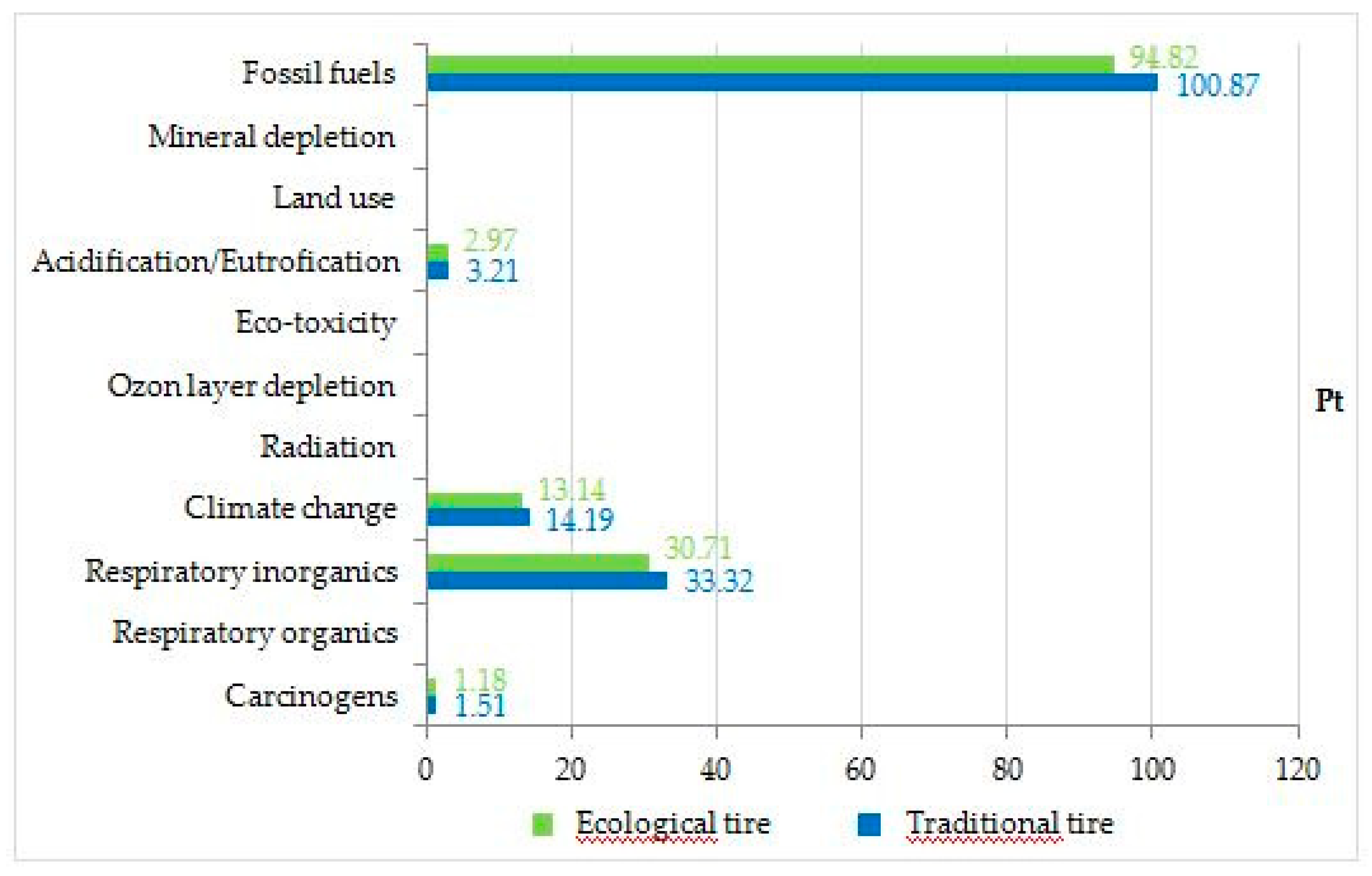

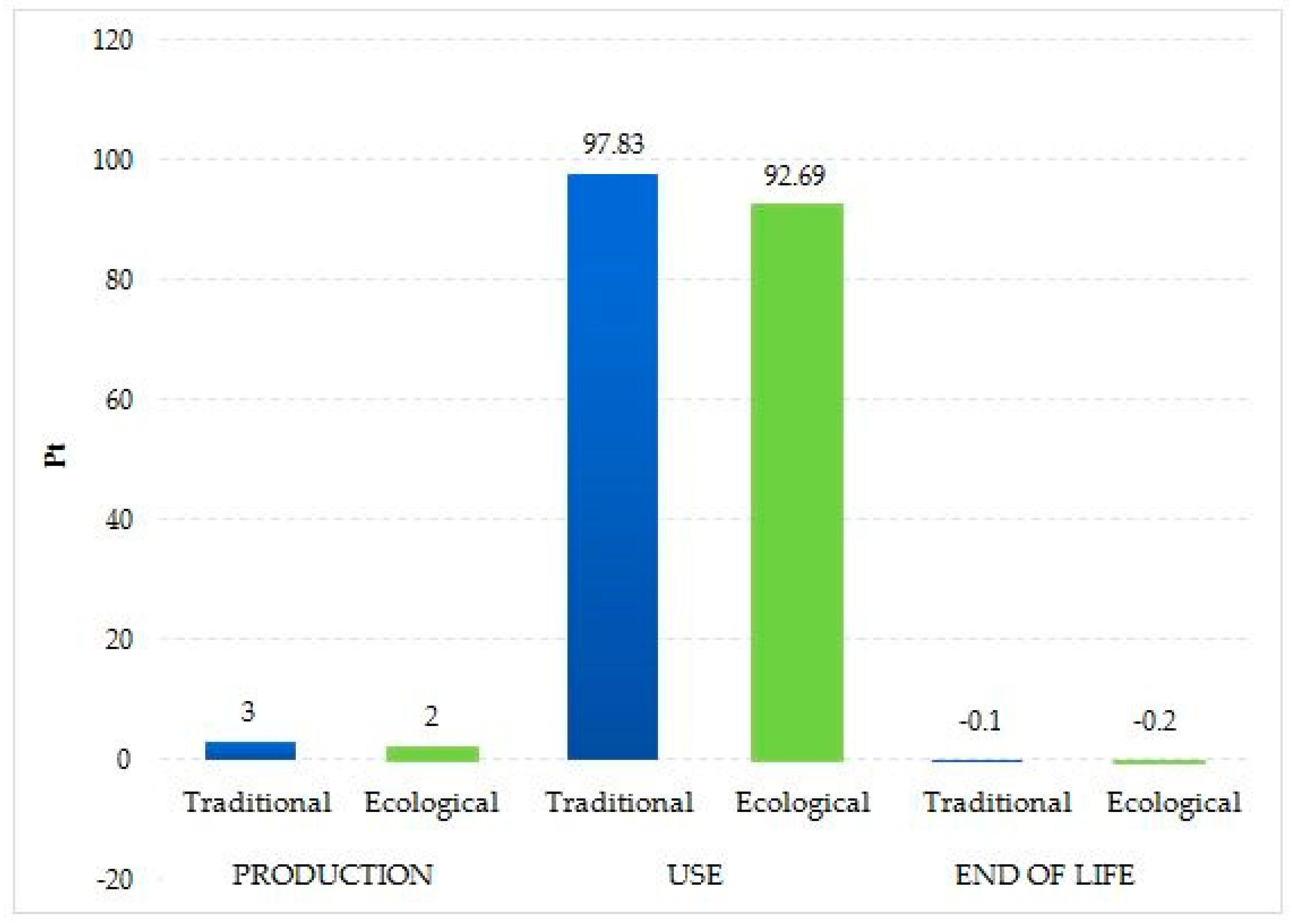

One of the key purposes of LCM is to determine elements in the life cycle of a given product that exert the heaviest impact on the environment. In traditional and ecological tires, the impact categories that were shown to have the most substantial negative consequences for the environment are, in the order of magnitude, the extraction of fossil fuels (an aggregate score for the traditional tire was 100.87 Pt and 94.82 Pt for the eco-tire), emissions of respiratory inorganic substances (33.32 Pt—the traditional tire, 30.71 Pt—the eco-tire), emissions of compounds causing climate change (14.19 Pt—the traditional tire, 13.14—the eco-tire), and acidification/eutrophication emissions (3.21 Pt—the traditional tire, 2.97 Pt—the eco-tire). For both tire technologies, the highest negative emission rates occurred in the use stage (

Figure 5).

Table 3 shows the grouping and weighting results concerning the environmental impact at particular stages of the traditional and ecological tire life cycle, divided into impact categories. The negative environmental impact was the highest in the fossil fuel extraction. The total ecological burden of this activity was estimated in the traditional tire at 97.8 Pt, and 92.7 Pt in the case of the eco-tire technology. Recycling is likely to cause a 0.14 Pt reduction in the environmental impact of the traditional tire life cycle, and a 0.2 Pt decrease in the ecological tire. Considering the secondary factors, it was found that inorganic substances linked to respiratory diseases and compounds that cause climate change also exhibit a particularly adverse impact on the environment. For both categories, the strongest negative effect rates were calculated in the tire use stage. On the other hand, the category that displayed the lowest ecological threat concerned compounds contributing to the ozone layer depletion in the traditional and ecological tire life cycle.

The grouping and weighting of consequences to the environment for carcinogens with respect to the products life cycles are shown in

Table 4 and

Figure 6. Unlike in the previously reported results, the highest hazard on the part of carcinogens was determined for the production stage of the tires’ life cycle: 1.51 Pt for the traditional tire and 1.17 Pt for the ecological tire. Considering particular chemicals, arsenic and cadmium ion emissions were found to reach particularly high levels, specifically, for As ions: 1.35 Pt (the traditional tire) and 1.05 Pt (the eco-tire), and for Cd ions: 0.12 Pt (the traditional tire) and 0.11 Pt (the ecological tire). The emissions levels could be improved by recycling, which would drive the decrease in the ecological burden of the entire life cycle of traditional tires by as much as 4.62 × 10

−3 Pt (As ions) and 1.35 × 10

−4 Pt (Cd ions). Exposure to arsenic compounds results in gastrointestinal irritation, vomiting and diarrhea, as well as skin lesions. In extreme cases, it can lead to death. Long-term exposure most often causes vascular diseases and the development of lung, skin, liver, kidney, and bladder cancer. Arsenic is usually present in the presence of other heavy metals, which increases the risk of interactions between them [

50]. The toxic effect of cadmium is mainly related to its presence in the body in the form of free cadmium ions. It causes chronic poisoning, affects the metabolism of calcium and phosphorus compounds, and damages the proper mineralization of bones, increasing their fragility. Its harmful influence mainly affects the excretory and respiratory systems and the circulatory system [

53,

54].

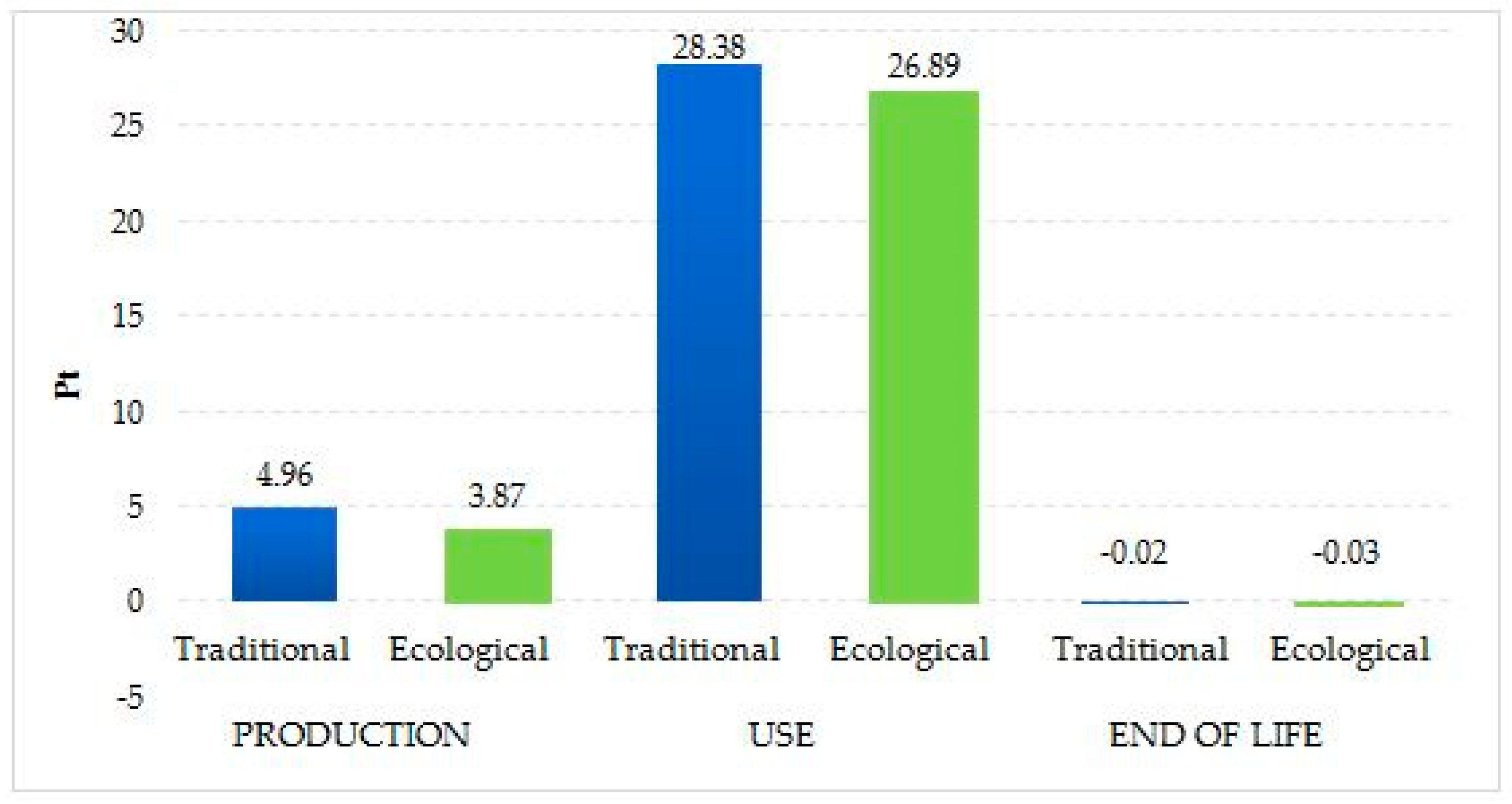

Several observations emerge from the results of grouping and weighting performed to determine the environmental consequences resulting from the emissions of respiratory inorganic compounds throughout the traditional and ecological tire life cycle (

Table 5 and

Figure 7). The emission hazard was the highest in the tire use stage, amounting to 28.38 Pt in the case of the traditional tire and 26.89 Pt for the ecological tire. Sulphur oxide and nitrogen dioxide emissions were shown to constitute the greatest threat to health. For the former, they were 15.8 Pt (the traditional tire) and 15.0 Pt (the ecological tire), and for the latter 10.0 Pt (the traditional tire) and 9.49 Pt (the ecological tire), respectively. In both tires, recycling in the post-consumer waste management phase could bring in the drop in the harmful effect of Sulphur oxide by 4.07 × 10

−3 Pt in relation to the life cycle of the traditional tire and by 3.60 × 10

−3 Pt—the ecological tire. Sulphur dioxide is one of the most dangerous air pollutants. It is a colorless, highly toxic gas with a suffocating odor. Its high concentration in the air can damage the respiratory tract, while in plants it causes the death of leaves, reacting with water vapor or water droplets in clouds creates sulfuric acid, and forms sulphates with dust. Sulphur oxides also contribute to the occurrence of acid rain. The influence of nitrogen oxides also significantly affects the quality of the atmospheric air. Nitrogen dioxide (NO

2) is commonly found in work and municipal environments, resulting from the combustion of nitrogen-containing organic substances. Acute nitrogen dioxide poisoning causes pulmonary edema which can be fatal. Moreover, this compound may act clastogenic and contribute to the development of neoplasms. Sulphur compounds and NOx are the main components of London-type smog [

55].

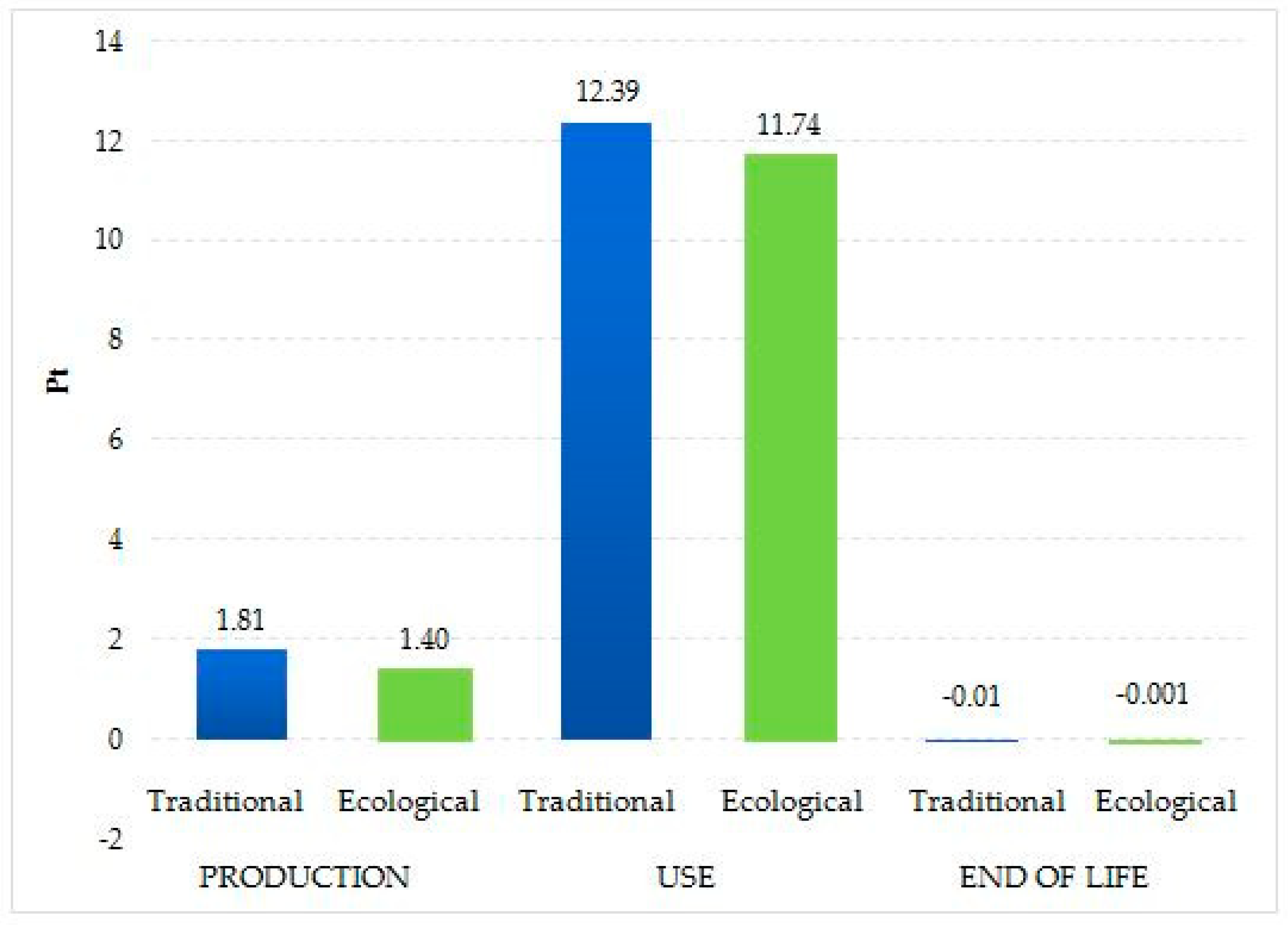

Table 6 and

Figure 8 contain the results of grouping and weighting the environmental burden concerned with the emission of hazardous compounds—potential climate change factors. In the category of impact in question, the source of the most critical environmental impact should be traced to the stage of tire use: 12.39 Pt in the traditional tire technology and 11.74 Pt in the eco-tire life cycle. The highest emission levels were displayed for carbon dioxide. Recycling would curb the detrimental effect of carbon dioxide on the environment by 1.03 × 10

−2 Pt in the life cycle of the traditional tire and by 1.24 × 10

−3 Pt for the ecological tire. There are many risks to human health in a car tire plant. The increase in the amount of this poisonous gas in the room negatively affects the well-being of employees. Carbon dioxide is a colorless, odorless, and non-flammable gas. It is heavier than air and has a choking effect on humans, but in low concentration it is not toxic to the human body. Therefore, it should be ensured that the chemical composition of the air in the production plant is slightly different from the natural (fresh) air. The increase in carbon dioxide content in the room causes the worker to have an adverse effect of hyperventilation, i.e., abnormal and rapid breathing. At higher concentrations, it may lead to unconsciousness and even loss of life [

54,

55].

Table 7 and

Figure 9 report the results of grouping and weighting the environmental effect of acidification/eutrophication agents linked to the traditional and ecological car tire life cycle. The direst consequences were linked to the tire use-stage, which was where the highest values of the eco-indicator points were estimated: 2.84 Pt for the conventional tire manufacturing technology and 2.69 Pt for the ecological tire. Among the compounds promoting acidification/eutrophication, nitrogen dioxide (1.76 × 10

−3 Pt traditional tire, 2.72 × 10

−3 ecological tire) and Sulphur oxide (7.61 × 10

−4 Pt traditional tire) displayed particularly high ecological damage rates. If implemented, the post-consumer waste management of car tires could help reduce the detrimental impact of Sulphur oxide emissions over the entire life cycle of the traditional tire by 2.32 × 10

−4 Pt and the ecological tire by 2.06 × 10

−4 Pt.

Grouping and weighting results of the environmental consequences of fossil fuel mining that occur in the traditional and ecological car tire life cycle are presented in

Table 8 and

Figure 10. The highest negative environmental impact was observed in the use-stage of both products’ life cycles: 97.83 Pt for the traditional tire design and 92.69 Pt for the ecological tire. Among the investigated processes, natural gas production exhibited a particularly high detrimental effect on the environment. The quantified effect of this factor was estimated at 97.69 Pt in the traditional tire manufacturing and 92.55 Pt in the ecological one.