Modelling of Electromagnetic Energy Harvester with Rotational Pendulum Using Mechanical Vibrations to Scavenge Electrical Energy

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

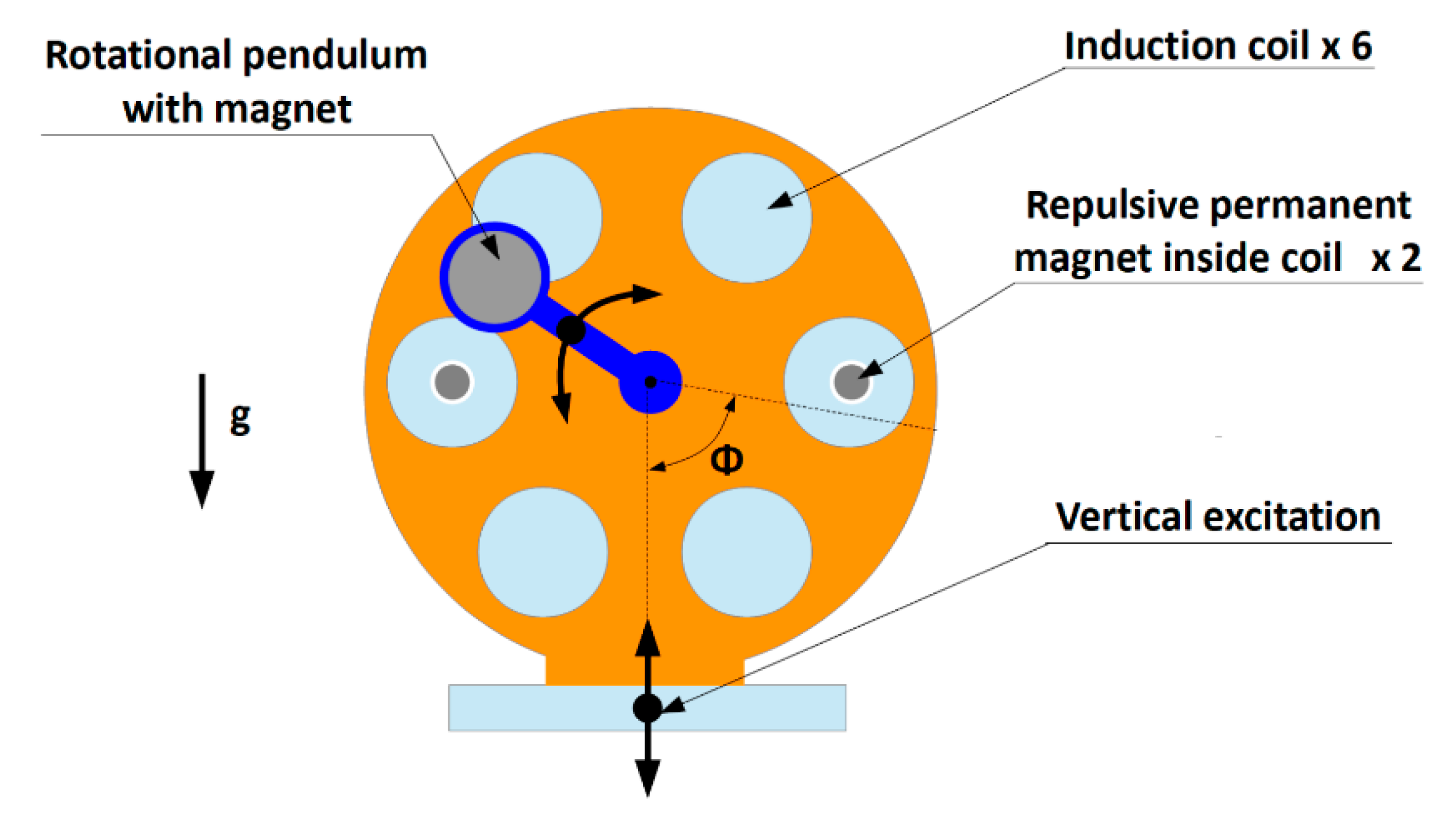

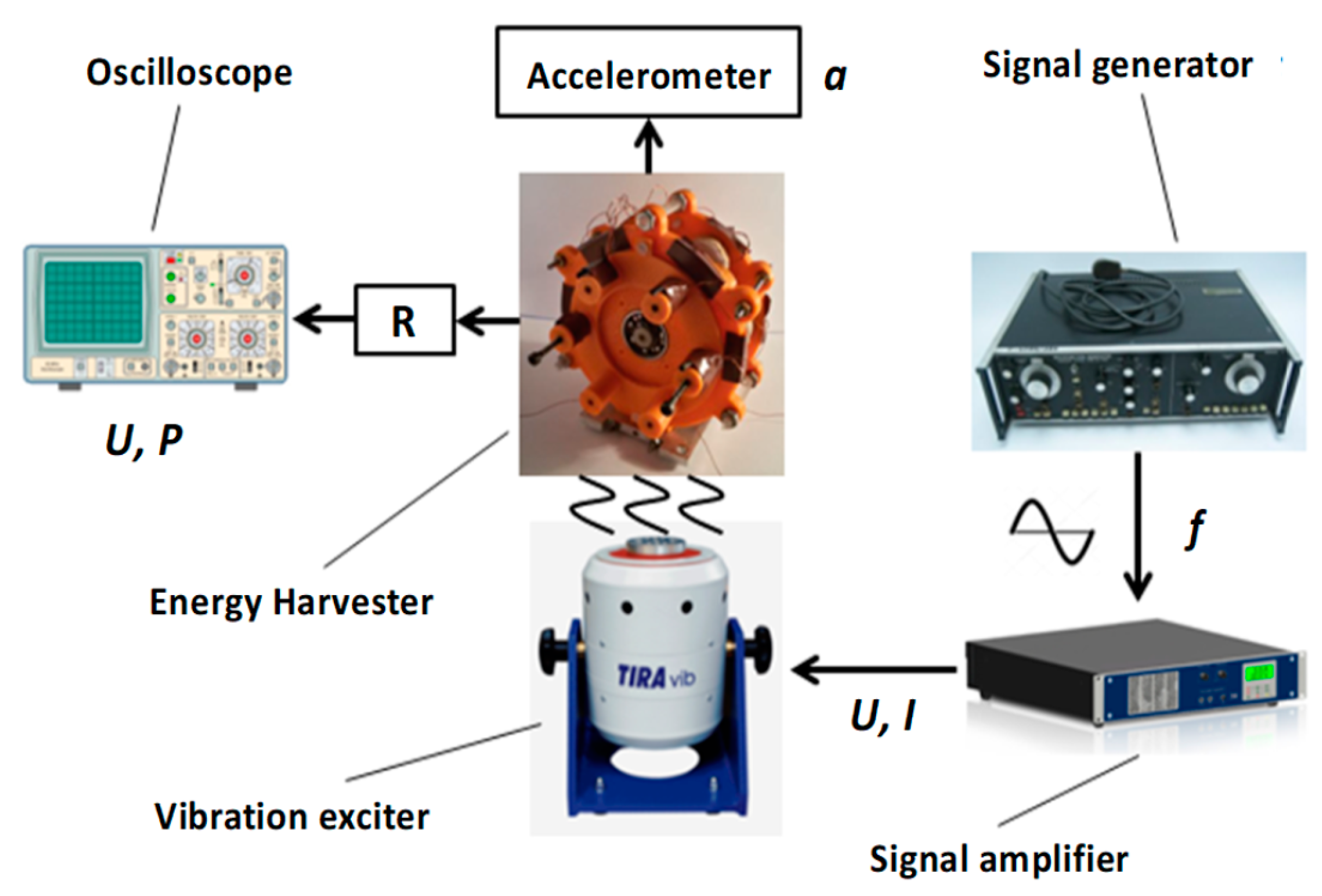

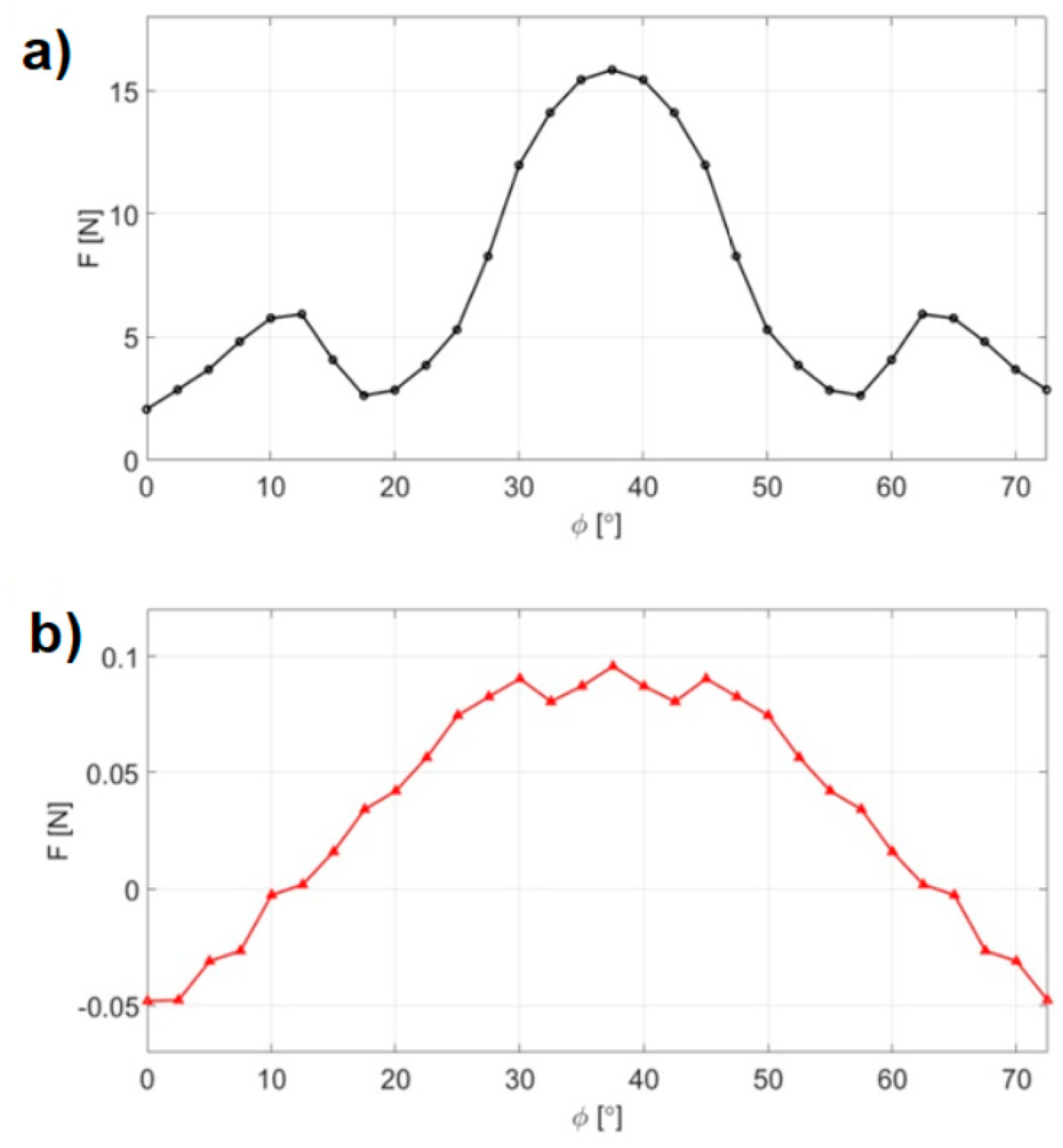

2.1. Prototype and Physical Experiment

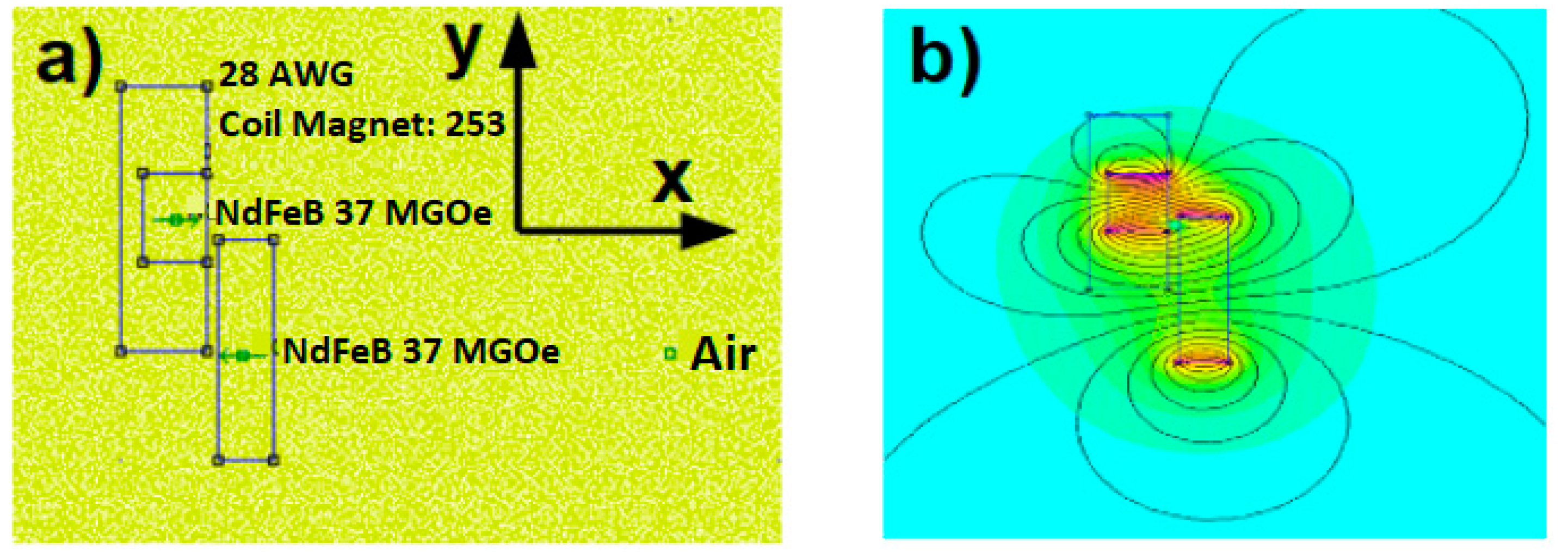

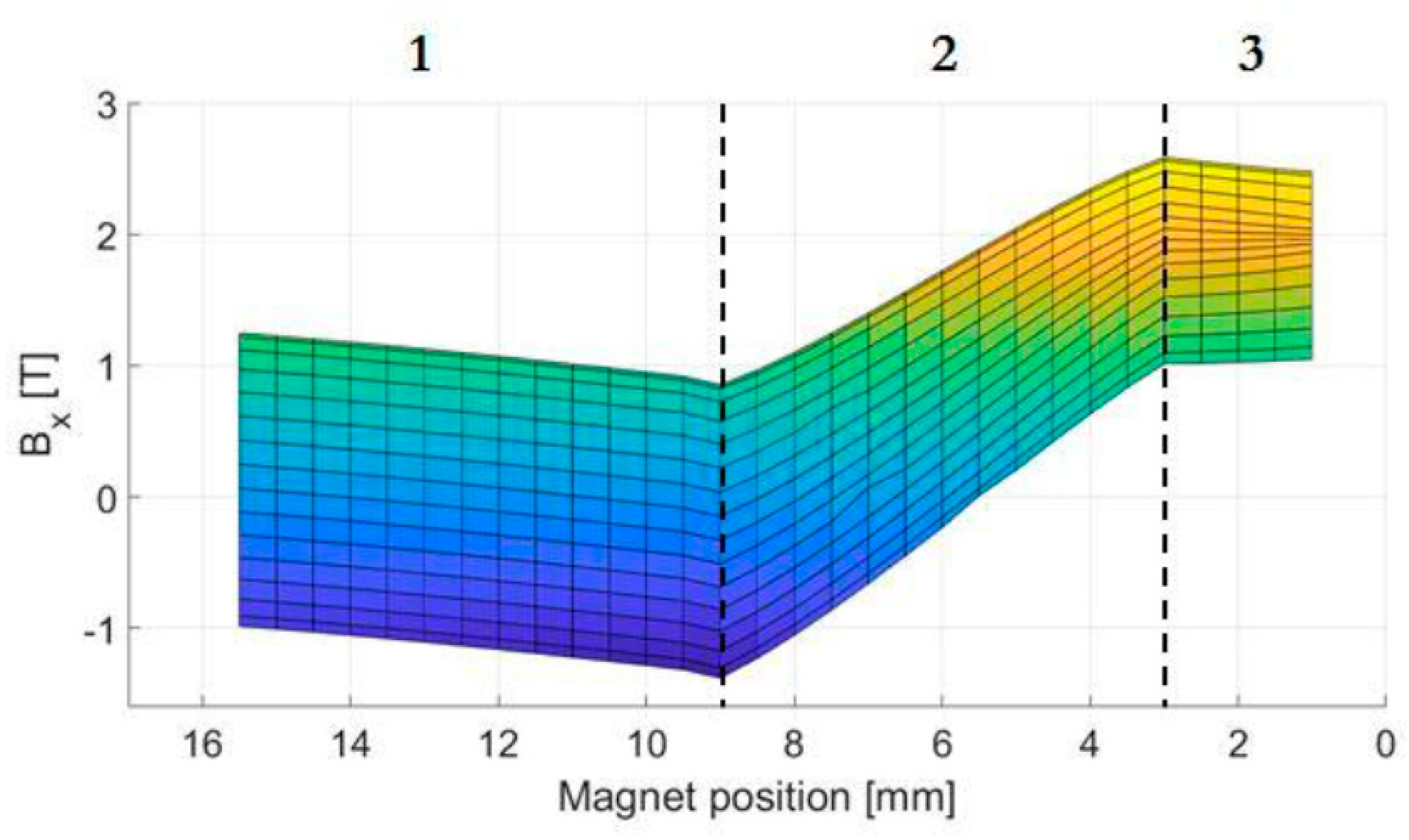

2.2. Numerical Simulations

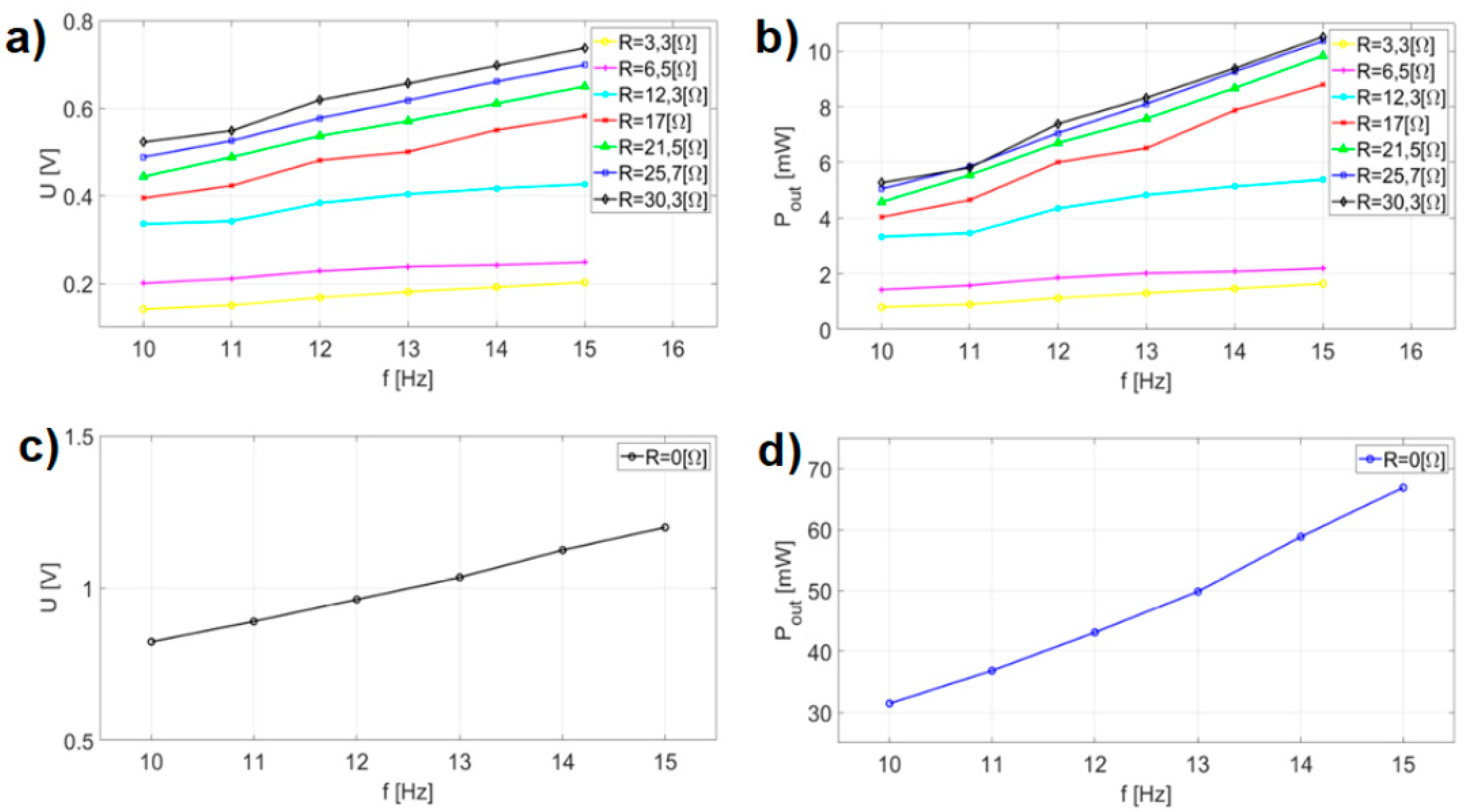

3. Experimental Results

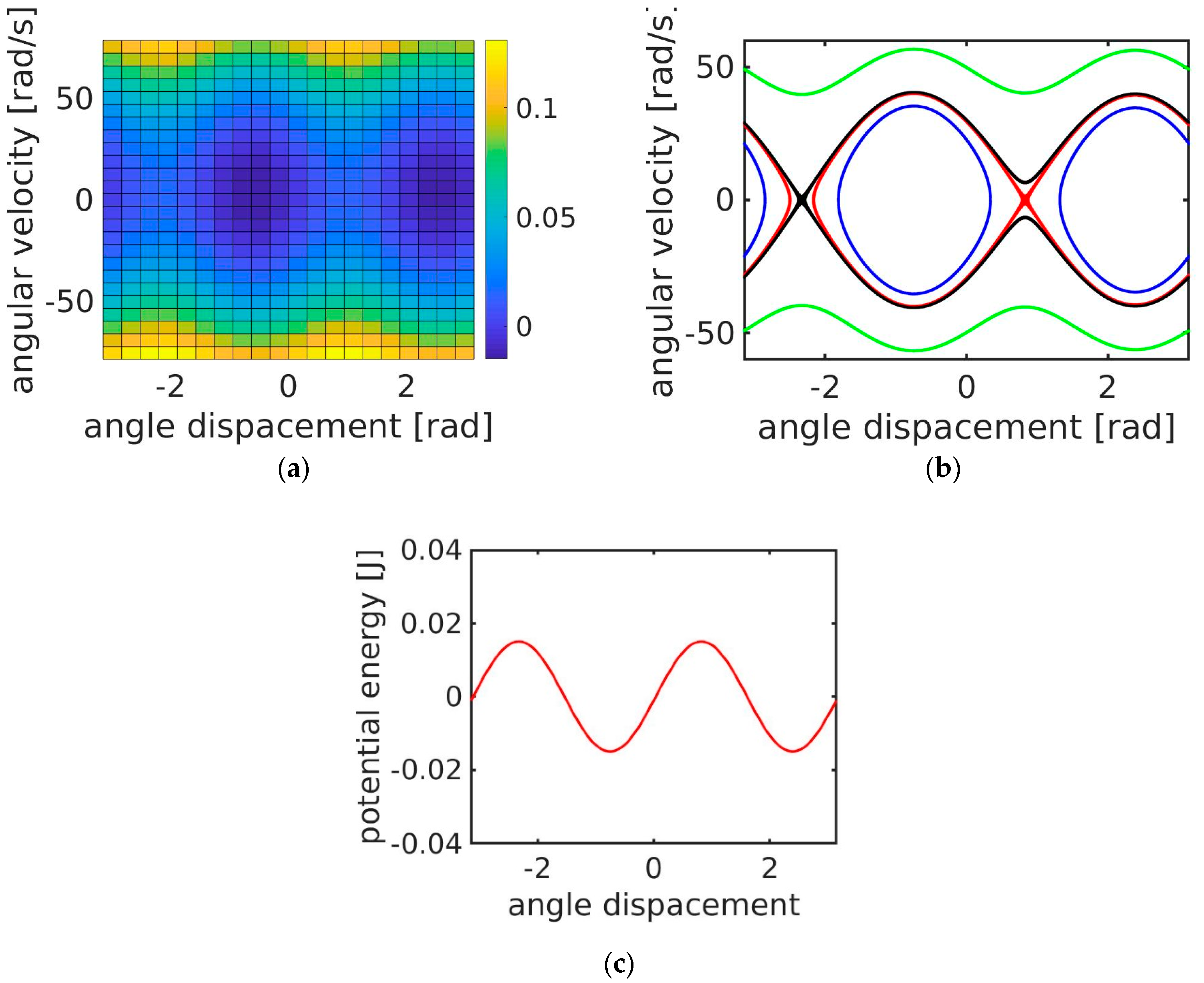

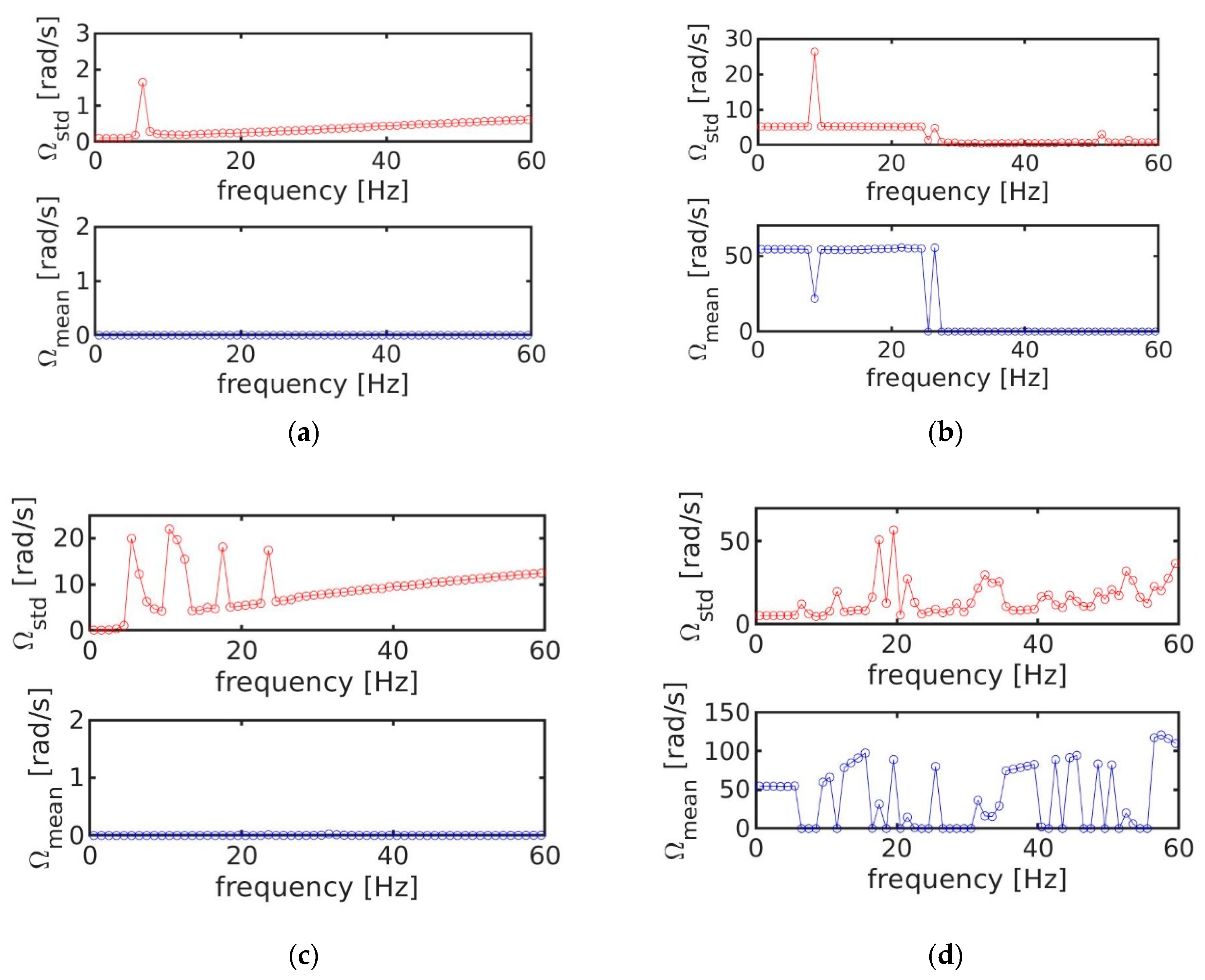

4. Mechanical Model of the Mechanical Resonator and a Broadband Effect

5. Conclusions

Author Contributions

Funding

| This publication was supported by the program of the Polish Ministry of Science and Higher Education under the project DIALOG 0019/DLG/2019/10 in the years 2019–2021. |

Conflicts of Interest

References

- Maurya, D.; Kumar, P.; Khaleghian, S.; Sriramdas, R.; Kang, M.G.; Kishore, R.A.; Kumar, V.; Song, H.C.; Park, J.M.; Taheri, S.; et al. Energy harvesting and strain sensing in smart tire for next generation autonomous vehicles. Appl. Energy 2018, 232, 312–322. [Google Scholar] [CrossRef]

- Shaikh, K.; Zeadally, S. Energy harvesting in wireless sensor networks: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 55, 1041–1054. [Google Scholar] [CrossRef]

- Dong, L.; Wen, C.; Liu, Y.; Closson, A.B.; Han, X.; Escobar, G.L.; Oglesby, M.; Feldman, M.; Chen, Z.; Zhang, J.X.J. Piezoelectric Buckled Beam Array on a Pacemaker Lead for Energy Harvesting. Adv. Mater. Technol. 2019, 4. [Google Scholar] [CrossRef]

- Balguvhar, S.; Bhalla, S. Evaluation of power extraction circuits on piezo-transducers operating under low-frequency vibration-induced strains in bridges. Strain 2019, 55, e12303. [Google Scholar] [CrossRef]

- Priya, S.; Inman, D.J. Energy Harvesting Technologies; Springer: Blacksburg, VA, USA, 2009. [Google Scholar]

- Kaźmierski, T.J.; Beeby, S. Energy Harvesting Systems, Principles, Modelling and Applications; Springer: New York, NY, USA, 2011. [Google Scholar]

- Sarker, M.R.; Julai, S.; Sabri, M.F.M.; Said, S.M.; Islam, M.M.; Tahir, M. Review of piezoelectric energy harvesting system and application of optimization techniques to enhance the performance of the harvesting system. Sens. Actuators A 2019, 300, 111634. [Google Scholar] [CrossRef]

- Tarelho, J.P.G.; Soares dos Santos, M.P.; Ferreira, J.A.F.; Ramos, A.; Kopyl, S.; Kim, S.O.; Hong, S.; Kholkin, A. Graphene-based materials and structures for energy harvesting with fluids—A review. Mater. Today 2018, 21, 1019–1041. [Google Scholar] [CrossRef]

- Dai, F.; Pan, D. Piezoelectric Energy Harvesting Based on Bi-Stable Composite Laminate. In Energy Harvesting; Manyala, R., Ed.; IntechOpen: London, UK, 2018; pp. 63–82. [Google Scholar]

- Koszewnik, A. Analytical modeling and experimental validation of an energy harvesting system for the smart plate with an integrated piezo-harvester. Sensors 2019, 19, 812. [Google Scholar] [CrossRef] [PubMed]

- Spreeman, D.; Manoli, Y. Electromagnetic Vibration Energy Harvesting Devices: Architectures, Design, Modelling and Optimization; Springer: Berlin, Germany, 2012. [Google Scholar]

- Erturk, A.; Hoffmann, J.; Inman, D.J. A piezomagnetoelastic structure for broadband vibration energy harvesting. Appl. Phys. Lett. 2009, 94, 254102. [Google Scholar] [CrossRef]

- Cottone, F.; Vocca, H.; Gammaitoni, L. Nonlinear energy harvesting. Phys. Rev. Lett. 2009, 102. [Google Scholar] [CrossRef] [PubMed]

- Litak, G.; Friswell, M.I.; Adhikari, S. Magnetopiezoelastic energy harvesting driven by random excitations. Appl. Phys. Lett. 2010, 96, 214103. [Google Scholar] [CrossRef]

- Ando, B.; Baglio, S.; Marletta, V.; Pergolizzi, E.; Ferrari, V.; Ferrari, M.; Bulsara, A.R. Nonlinear Snap-Through-Buckling Devices for Energy Harvesting from Vibrations. Sensors 2015, 319, 409–413. [Google Scholar]

- Ferrari, M.; Ferrari, V.; Guizzetti, M.; Ando, B.; Baglio, S.; Trigona, C. Improved energy harvesting from wideband vibrations by nonlinear piezoelectric converters. Sens. Actuators A 2010, 162, 425–431. [Google Scholar] [CrossRef]

- Friswell, M.I.; Ali, S.F.; Adhikari, S.; Lees, A.W.; Bilgen, O.; Litak, G. Nonlinear piezoelectric vibration energy harvesting from a vertical cantilever beam with tip mass. J. Intell. Mater. Syst. Struct. 2012, 23, 1505–1521. [Google Scholar] [CrossRef]

- Huang, D.; Zhou, S.; Litak, G. Theoretical analysis of multi-stable energy harvesters with high-order stiffness terms. Commun. Nonlinear Sci. Numer. Simul. 2019, 69, 270–286. [Google Scholar] [CrossRef]

- Malaji, P.V.; Faruque Ali, S. Analysis and experiment of magneto-mechanically coupled harvesters. Mech. Syst. Signal Process. 2018, 108, 304–316. [Google Scholar] [CrossRef]

- Kumar, R.; Gupta, S.; Faruque Ali, S. Energy harvesting from chaos in base excited double pendulum. Mech. Syst. Signal Process. 2019, 124, 49–64. [Google Scholar] [CrossRef]

- Daqaq, M.F.; Masana, R.; Erturk, A.; Quinn, D.D. On the role of nonlinearities in vibratory energy harvesting: A critical review and discussion. Appl. Mech. Rev. 2014, 66. [Google Scholar] [CrossRef]

- Coccolo, M.; Litak, G.; Seoane, J.M.; Sanjuan, M.A.F. Optimizing the electrical power in an energy harvesting system. Int. J. Bifurc. Chaos 2015, 25, 1550171. [Google Scholar] [CrossRef]

- Łygas, K.; Wolszczak, P.; Litak, G.; Stączek, P. Complex response of an oscillating vertical cantilever with clearance. Meccanica 2019, 54, 1689–1702. [Google Scholar] [CrossRef]

- Wolszczak, P.; Litak, G.; Łygas, K. Analysis of dynamics of a vertical cantilever in rotary coupling to the moving frame with movement limiters. In Proceedings of the International Conference on Structural Nonlinear Dynamics and Diagnosis, Tangier, Morocco, 25–27 June 2018; Volume 241. [Google Scholar]

- Łygas, K.; Wolszczak, P.; Stączek, P.; Litak, G. Energy harvesting from an oscillating vertical piezoelectric cantilever with clearance. In Energy Harvesting for Wireless Sensor Networks; Kanoun, O., Ed.; De Gruyter Oldenbourg: Chemnitz, Germany, 2018; pp. 125–135. [Google Scholar]

- Izadgoshasb, I.; Lim, Y.Y.; Padilla, R.V.; Sedighi, M.; Novak, J.P. Performance Enhancement of a Multiresonant Piezoelectric Energy Harvester for Low Frequency Vibrations. Energies 2019, 12, 2770. [Google Scholar] [CrossRef]

- De Paula, A.S.; Savi, M.A.; Wiercigroch, M.; Pavlovskaia, E. Chaos Control Methods Applied to Avoid Bifurcations in Pendulum Dynamics; IUTAM Bookseries; IUTAM: Aberdeen, UK, 2013; Volume 32, pp. 387–395. [Google Scholar]

- Najdecka, A.; Kapitaniak, T.; Wiercigroch, M. Synchronous rotational motion of parametric pendulums. Int. J. Non-Linear Mech. 2013, 70, 84–94. [Google Scholar] [CrossRef]

- Dostal, L.; Pick, M.A. Theoretical and experimental study of a pendulum excited by random loads. Eur. J. Appl. Math. 2019, 30, 912–927. [Google Scholar] [CrossRef]

- Teh, S.H.; Woo, K.C.; Demrdash, H. Rotating orbits of pendulum in stochastic excitation. J. Theor. Appl. Mech. 2016, 54, 717–730. [Google Scholar] [CrossRef][Green Version]

- Teh, S.H.; Woo, K.C.; Demrdash, H. Rotations of pendulum when its pivot oscillates chaotically. J. Comput. Nonlinear Dyn. 2018, 13. [Google Scholar] [CrossRef]

- Ding, W.; Cao, H.; Zhang, B.; Wang, K. A low frequency tunable miniature inertial pendulum energy harvester. J. Appl. Phys. 2018, 124, 164506. [Google Scholar] [CrossRef]

- Ylli, K.; Hoffmann, D.; Willmann, A.; Folkmer, B.; Manoli, Y. Investigation of Pendulum Structures for Rotational Energy Harvesting from Human Motion. J. Phys. Conf. Ser. 2015, 660. [Google Scholar] [CrossRef]

- Halim, M.A.; Rantz, R.; Zhang, Q.; Gu, L.; Yang, K.; Roundy, S. Electromagnetic energy harvesting from swing-arm motion using rotational eccentric mass structure. In Proceedings of the 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems, Kaohsiung, Taiwan, 18–22 June 2017; pp. 1863–1866. [Google Scholar]

- Halim, M.A.; Rantz, R.; Zhang, Q.; Gu, L.; Yang, K.; Roundy, S. An electromagnetic rotational energy harvester using sprung eccentric rotor driven by pseudo-walking motion. Appl. Energy 2018, 217, 66–74. [Google Scholar] [CrossRef]

- Hou, C.; Chen, T.; Li, Y.; Huang, M.; Shi, Q.; Liu, H.; Sun, L.; Lee, C. A rotational pendulum based electromagnetic/triboelectric hybrid-generator for ultra-low-frequency vibrations aiming at human motion and blue energy applications. Nano Energy 2019, 63, 103871. [Google Scholar] [CrossRef]

- Izadgoshasb, I.; Lim, Y.Y.; Tang, L.; Padilla, R.V.; Tang, Z.S.; Sedighi, M. Improving efficiency of piezoelectric based energy harvesting from human motions using double pendulum system. Energy Convers. Manag. 2019, 184, 559–570. [Google Scholar] [CrossRef]

- Payne, O.R.; Moss, S.D. Rotational energy harvesting from a drive shaft for structural health monitoring. In Proceedings of the 8th Australian Congress on Applied Mechanics, Melbourne, Australia, 23–26 November 2014; pp. 834–841. [Google Scholar]

- Dotti, F.E.; Reguera, F.; Machado, S.P. Rotations of the parametric pendulum excited by a reciprocating motion with a view on energy harvesting. Lect. Notes Mech. Eng. 2018, 6, 385–397. [Google Scholar]

- Rubes, O.; Smilek, J.; Hadas, Z. Development of vibration energy harvester fabricated by rapid prototyping technology. In Proceedings of the 16th International Conference on Mechatronics Mechatronika, Brno, Czech Republic, 3–5 December 2014. [Google Scholar]

- De Vlieger, J.; Vanoost, D.; Peuteman, J.; Verbrugge, S.; De Gersem, H.; Pissoort, D. Design, simulation and use of energy harvester based on permanent magnet synchronous generator. In Proceedings of the 2016 IEEE International Power Electronics and Motion Control Conference (PEMC), Varna, Bulgaria, 25–28 September 2016; pp. 557–562. [Google Scholar]

- Zhang, Y.; Cao, J.; Liao, W.H.; Zhao, L.; Lin, J. Theoretical modelling and experimental verification of circular Halbach electromagnetic energy harvesters for performance enhancement. Smart Mater. Struct. 2018, 27. [Google Scholar] [CrossRef]

- Moghaddam, R.R.; Sandulescu, P.; Tenca, P.; Zanuso, G. Efficient and accurate fully coenergy-based inductance-less FEM model of electrical machines for modern control and identification purposes. In Proceedings of the 2016 XXII International Conference on Electrical Machines (ICEM), Lausanne, Switzerland, 4–7 September 2016; pp. 299–305. [Google Scholar]

- Rysak, A.; Gregorczyk, M.; Chwełatiuk, K.; Gąska, D. Study of the High-Amplitude Solutions in the System of Magnetic Sliding Oscillator with many degrees of freedom. In Dynamical Systems Theory and Applications; Springer Proceedings in Mathematics & Statistics; Springer: Łódź, Poland, 2018; Volume 248, pp. 295–310. [Google Scholar]

- Kęcik, K. Assessment of energy harvesting and vibration mitigation of pendulum dynamic absorber. Mech. Syst. Signal Process. 2018, 106, 198–209. [Google Scholar] [CrossRef]

- Koszewnik, A.; Grześ, P.; Walendziuk, W. Mechanical and electrical impedance matching in a piezoelectric beam for Energy Harvesting. Eur. Phys. J. Spec. Top. 2015, 224, 2719–2731. [Google Scholar] [CrossRef]

- Li, Z.; Zuo, L.; Luhrs, G.; Lin, L.; Qin, Y.X. Electromagnetic energy-harvesting shock absorbers: Design, modelling, and road tests. IEEE Trans. Veh. Technol. 2013, 62, 1065–1074. [Google Scholar] [CrossRef]

- Kim, H.S.; Kim, J.H.; Kim, J. A review of piezoelectric energy harvesting based on vibration. Int. J. Precis. Eng. Manuf. 2011, 12, 1129–1141. [Google Scholar] [CrossRef]

- Masana, R.; Daqaq, M.F. Electromechanical modeling and nonlinear analysis of axially loaded energy harvesters. J. Vib. Acoust. 2011, 133. [Google Scholar] [CrossRef]

- Marszal, M.; Witkowski, B.; Jankowski, K.; Perlikowski, P.; Kapitaniak, T. Energy harvesting from pendulum oscillations. Int. J. Non-Linear Mech. 2017, 94, 251–256. [Google Scholar] [CrossRef]

- Marszal, M.; Jankowski, K.; Perlikowski, P.; Kapitaniak, T. Bifurcations of Oscillatory and Rotational Solutions of Double Pendulum with Parametric Vertical Excitation. Math. Probl. Eng. 2014. [Google Scholar] [CrossRef]

- Witkowski, B.; Perlikowski, P.; Prasad, A.; Kapitaniak, T. The dynamics of co- and counter rotating spherical pendula. Eur. Phys. J. Spec. Top. 2014, 223, 707–720. [Google Scholar] [CrossRef][Green Version]

- Huguet, T.; Badel, A.; Druet, O.; Lallart, M. Drastic bandwidth enhancement of bistable energy harvesters: Study of subharmonic behaviors and their stability robustness. Appl. Energy 2018, 226, 607–617. [Google Scholar] [CrossRef]

- Syta, A.; Litak, G.; Friswell, M.I.; Adhikari, S. Multiple solutions and corresponding power output of a nonlinear bistable piezoelectric energy harvester. Eur. Phys. J. 2016, 89, 99. [Google Scholar] [CrossRef]

- Zhou, S.; Junyi, C.; Litak, G.; Jing, L. Numerical analysis and experimental verification of broadband tristable energy harvesters. Tm-Tech. Mess. 2018, 85, 521–532. [Google Scholar] [CrossRef]

| Feature | Value |

|---|---|

| Rated peak force [N] | 100 |

| Frequency range [Hz] | 2–7000 |

| Max. rated travel [mm] Pk-Pk | 13 |

| Max. velocity [m/s] sine | 1.5 |

| Max. acceleration [g] sine | 45 |

| Feature | Value |

|---|---|

| Operating voltage [V] | 2.5–5.0 |

| Supply current [mA] | 6 |

| Output format | I2C |

| Sensitivity range [g] | ±2, ±4, ±6, ±8, ±10 |

| Test Feature | Input Data |

|---|---|

| Operational frequencies [Hz] | 10; 11; 12; 13; 14; 15 |

| Internal resistance of the system [Ω] | 21.5 |

| Additional resistance [Ω] | 3.3; 6.5; 12.3; 17; 21.5; 25.7; 30.3 |

| Sampling rate per channel [S/s] | 100,000 |

| System Parameters | Values [Unit] |

|---|---|

| h | 0.03325 [m] |

| c | 0.000003 [N s/(kg m2)] |

| g | 9.81 [m/s2] |

| m | 0.00186 [kg] |

| Fm | 0.03 [N] |

| I | 0.0000377 [kg m2] |

| A | 0.002 or 0.05 [m] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ambrożkiewicz, B.; Litak, G.; Wolszczak, P. Modelling of Electromagnetic Energy Harvester with Rotational Pendulum Using Mechanical Vibrations to Scavenge Electrical Energy. Appl. Sci. 2020, 10, 671. https://doi.org/10.3390/app10020671

Ambrożkiewicz B, Litak G, Wolszczak P. Modelling of Electromagnetic Energy Harvester with Rotational Pendulum Using Mechanical Vibrations to Scavenge Electrical Energy. Applied Sciences. 2020; 10(2):671. https://doi.org/10.3390/app10020671

Chicago/Turabian StyleAmbrożkiewicz, Bartłomiej, Grzegorz Litak, and Piotr Wolszczak. 2020. "Modelling of Electromagnetic Energy Harvester with Rotational Pendulum Using Mechanical Vibrations to Scavenge Electrical Energy" Applied Sciences 10, no. 2: 671. https://doi.org/10.3390/app10020671

APA StyleAmbrożkiewicz, B., Litak, G., & Wolszczak, P. (2020). Modelling of Electromagnetic Energy Harvester with Rotational Pendulum Using Mechanical Vibrations to Scavenge Electrical Energy. Applied Sciences, 10(2), 671. https://doi.org/10.3390/app10020671