Investigation and Enhancement of the Detectability of Flaws with a Coarse Measuring Grid and Air Coupled Ultrasound for NDT of Panel Materials Using the Re-Radiation Method

Abstract

1. Introduction

2. Materials and Methods

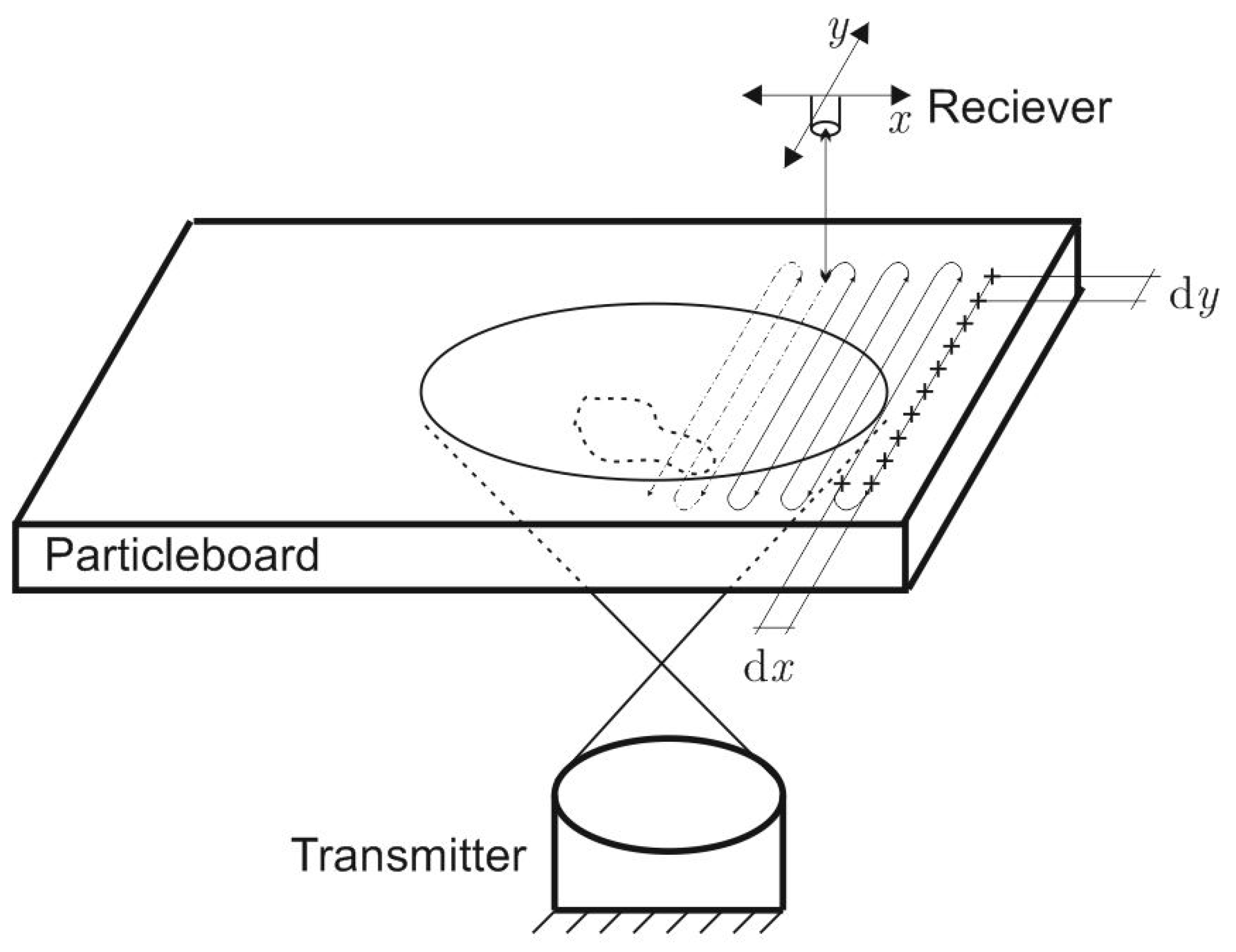

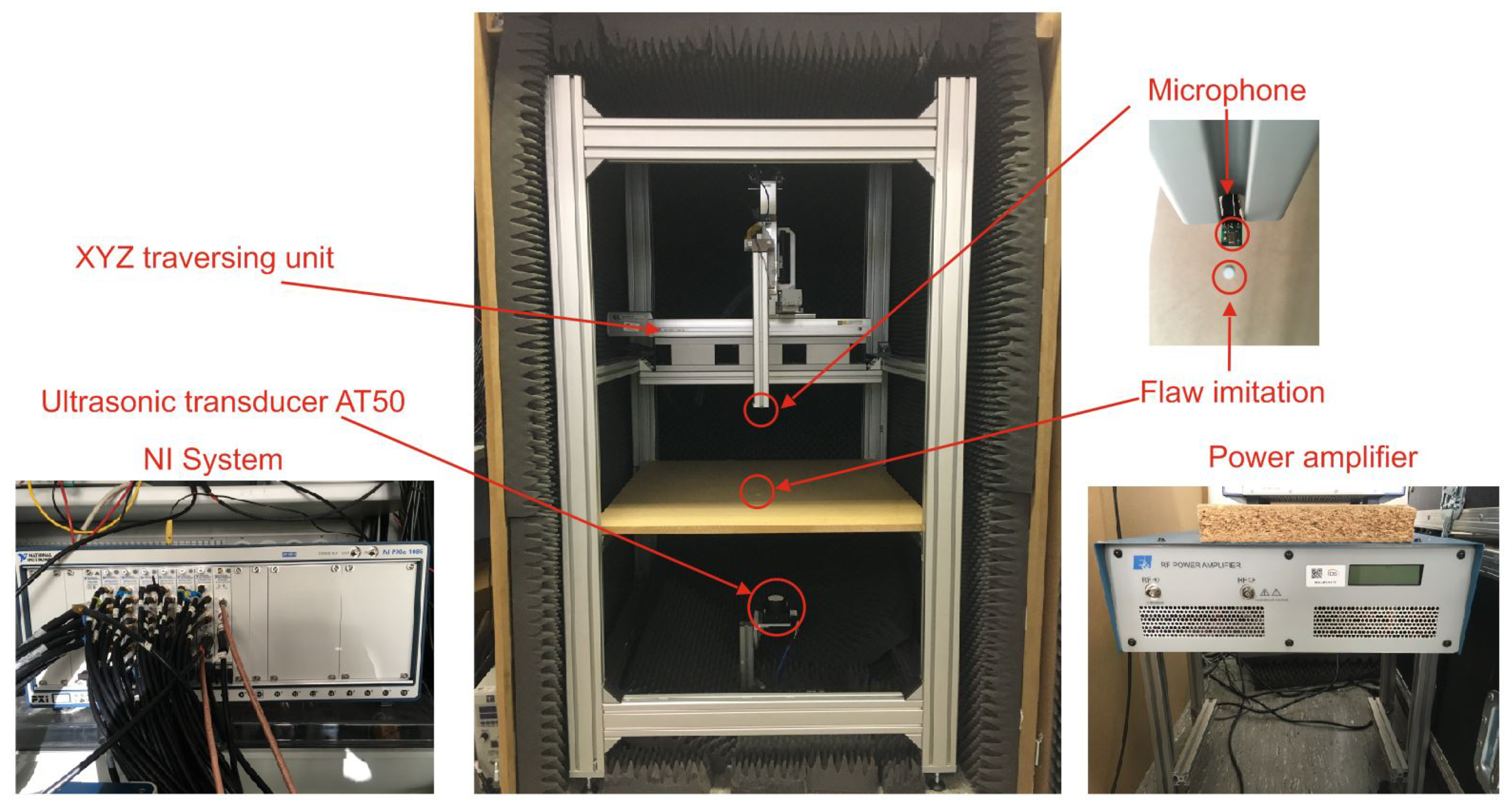

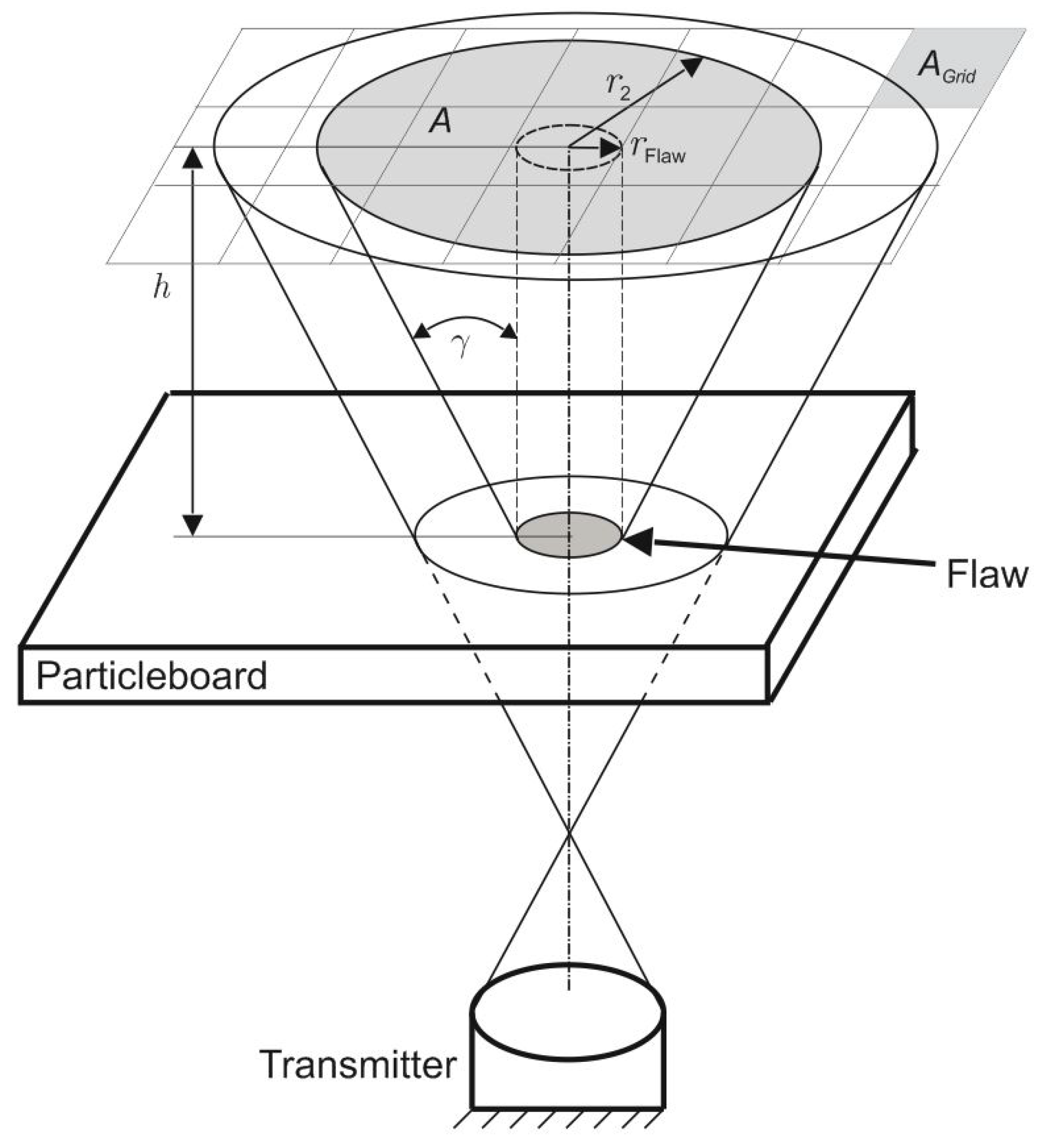

2.1. Experimental Setup

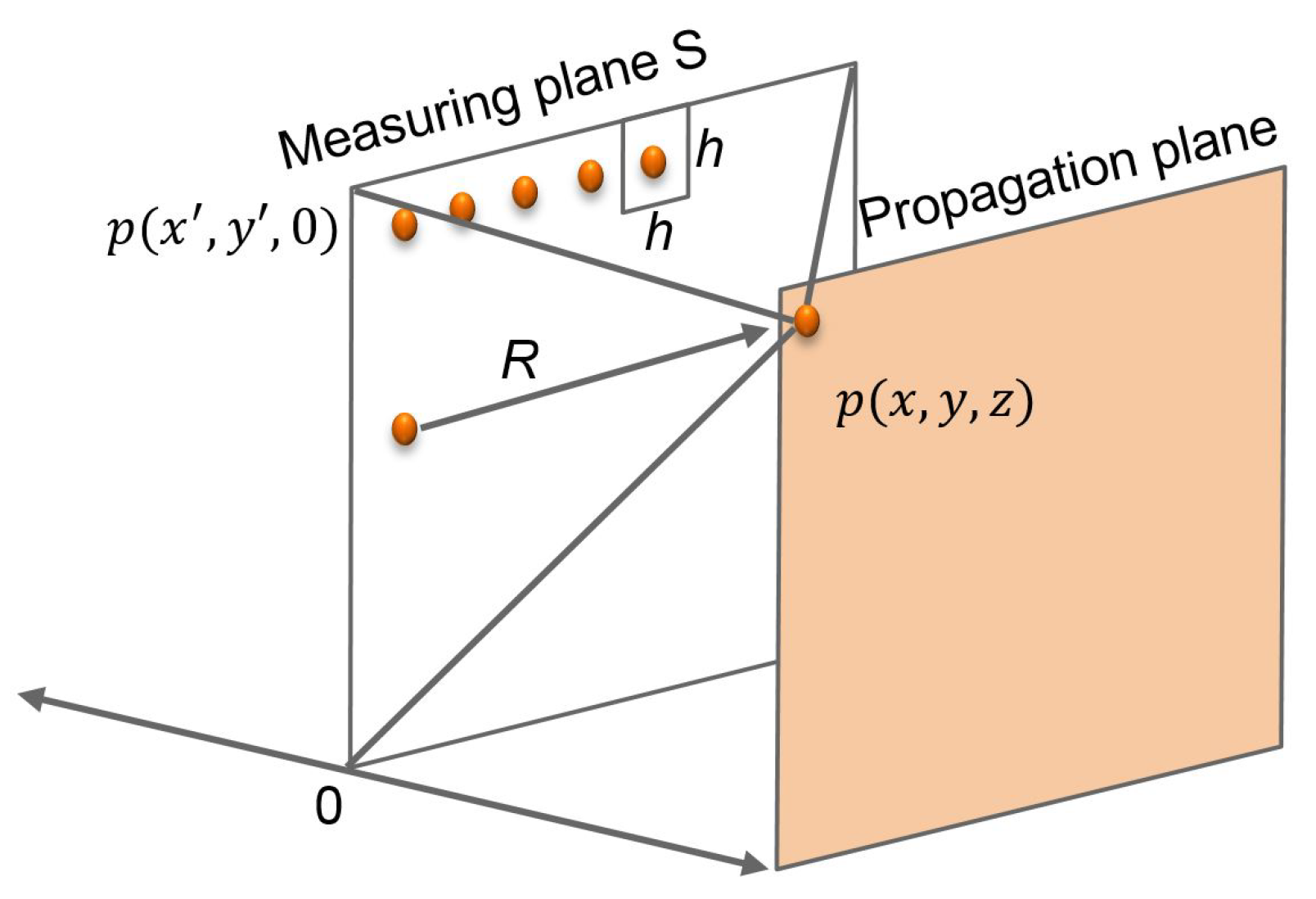

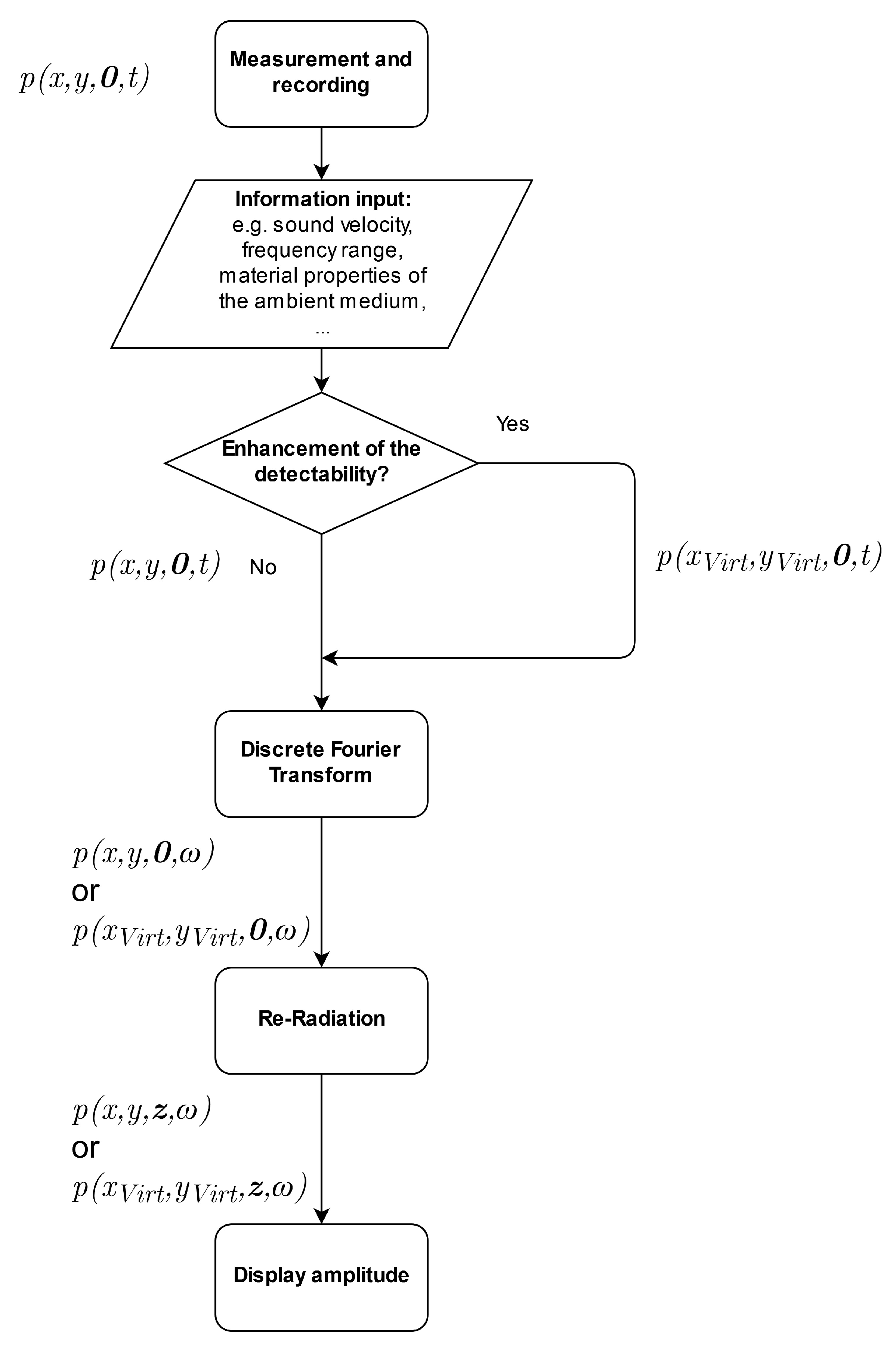

2.2. Mathematical Methods

2.2.1. Re-Radiation

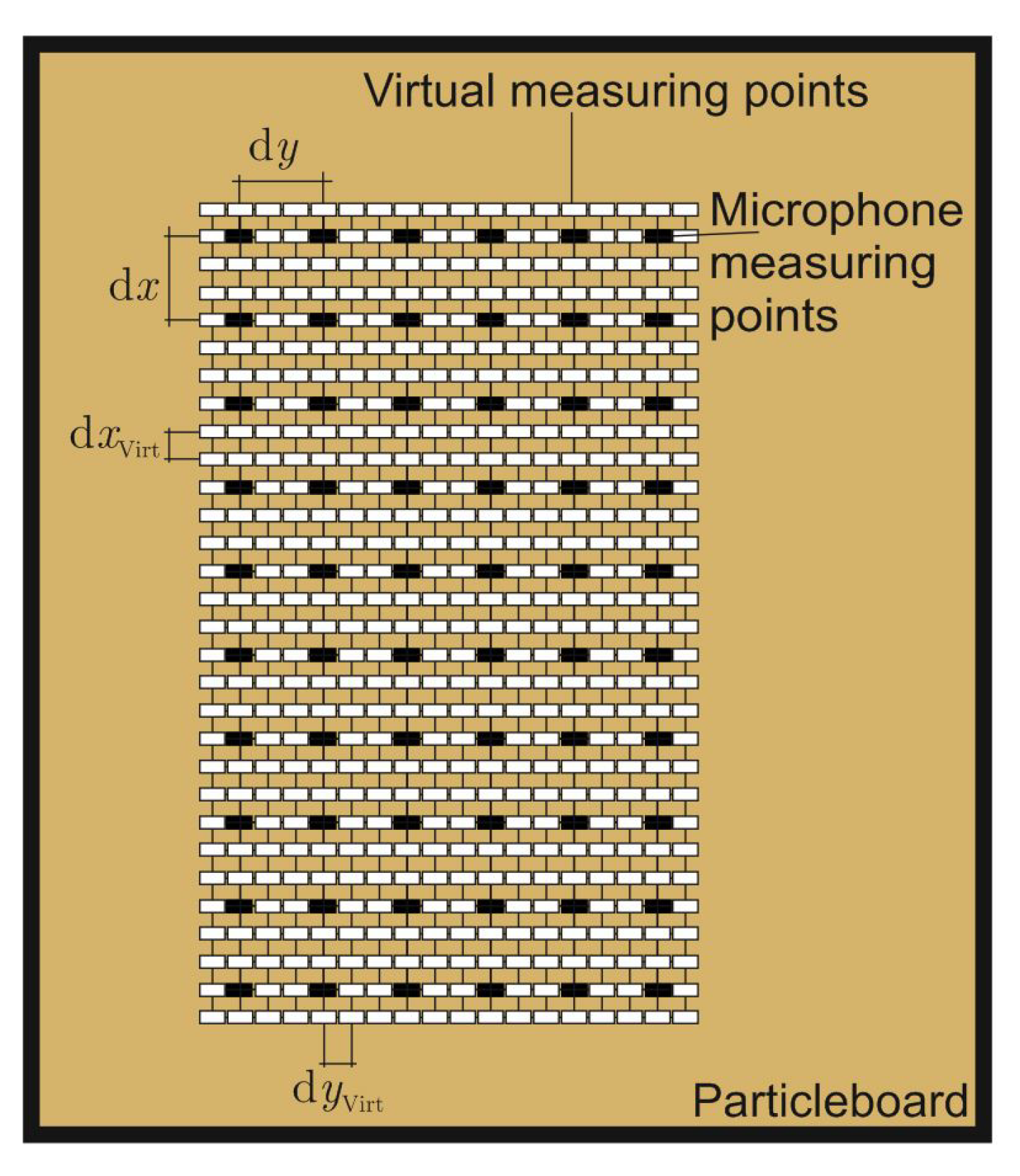

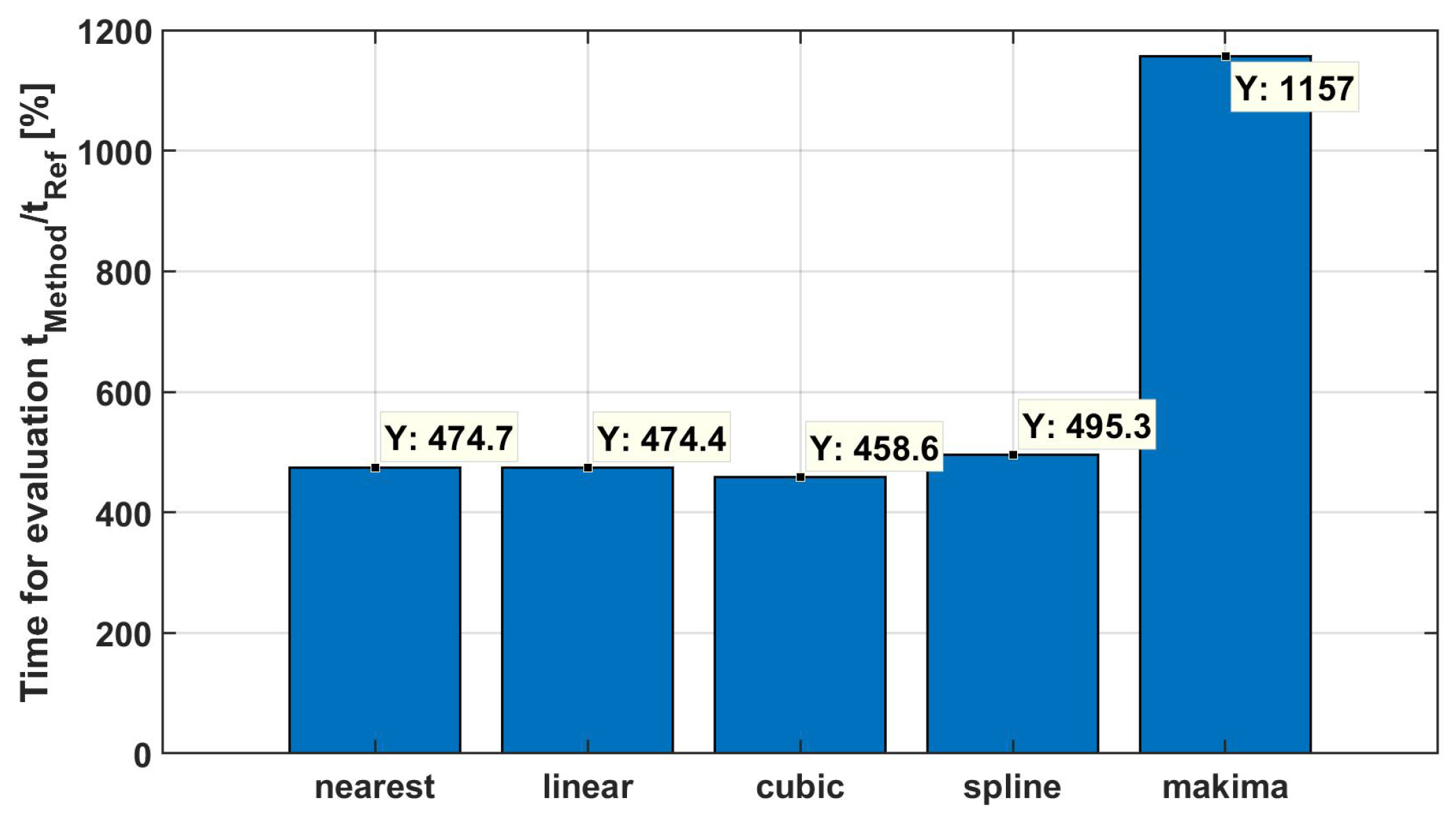

2.2.2. Virtual Refinement

3. Results

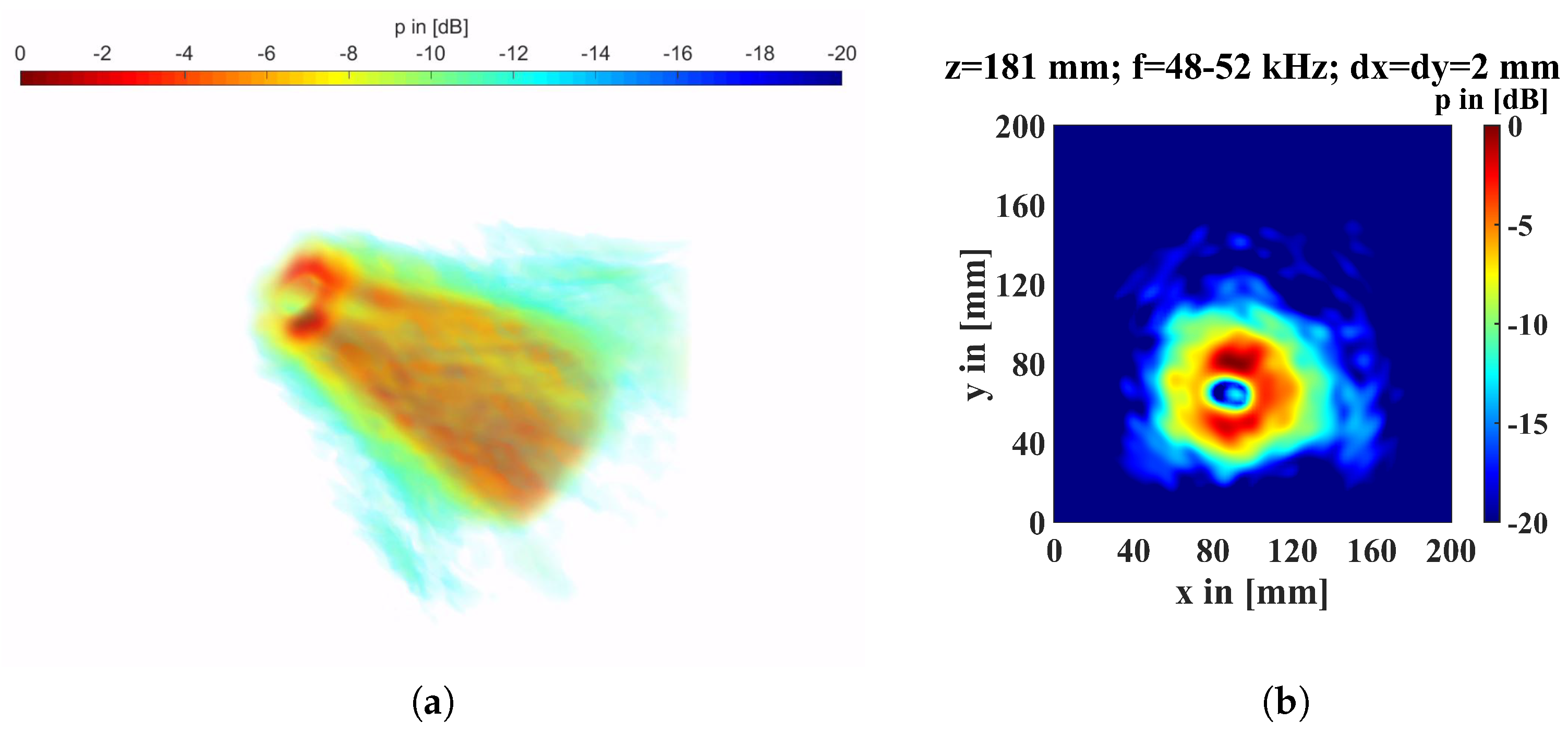

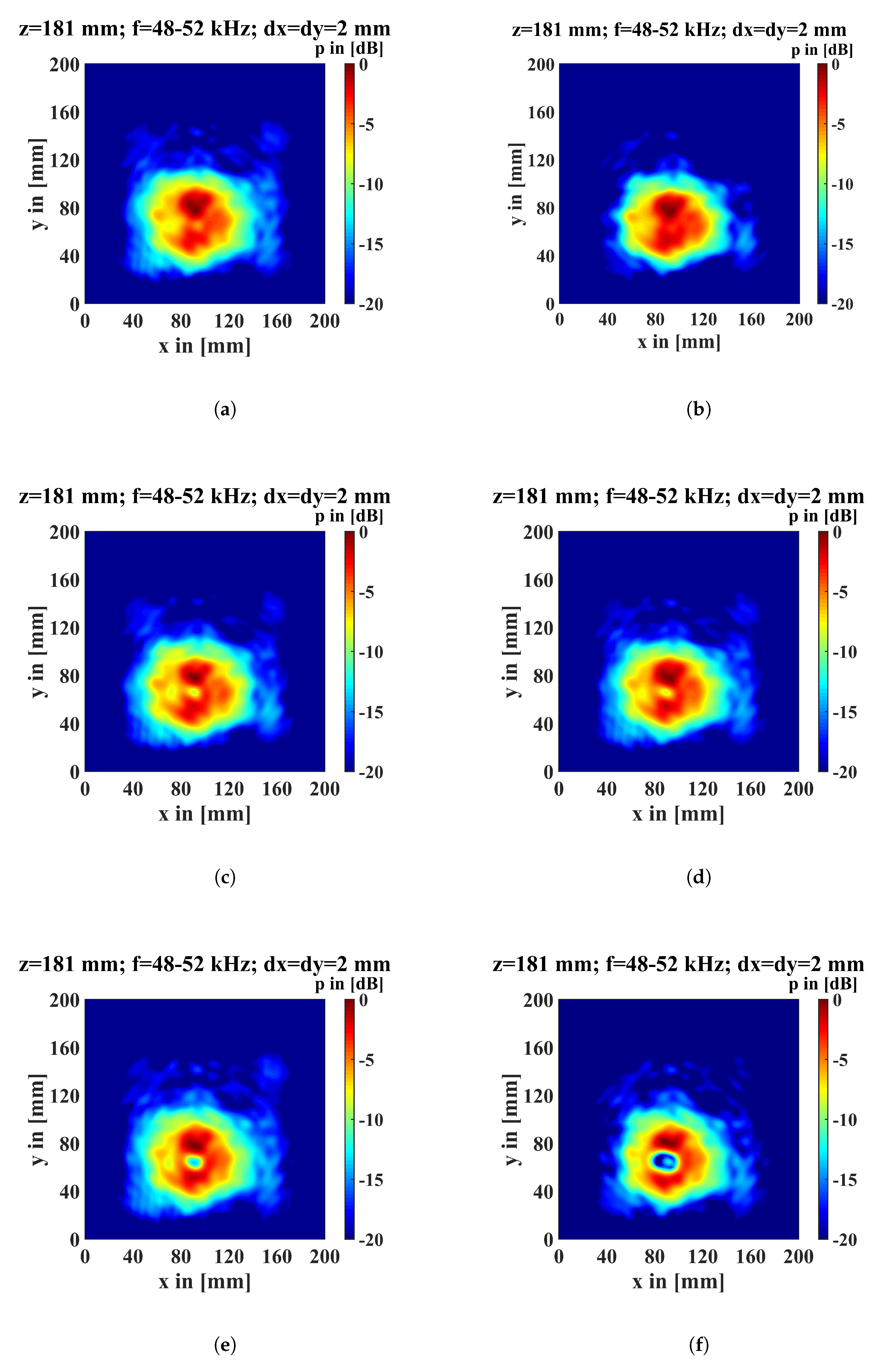

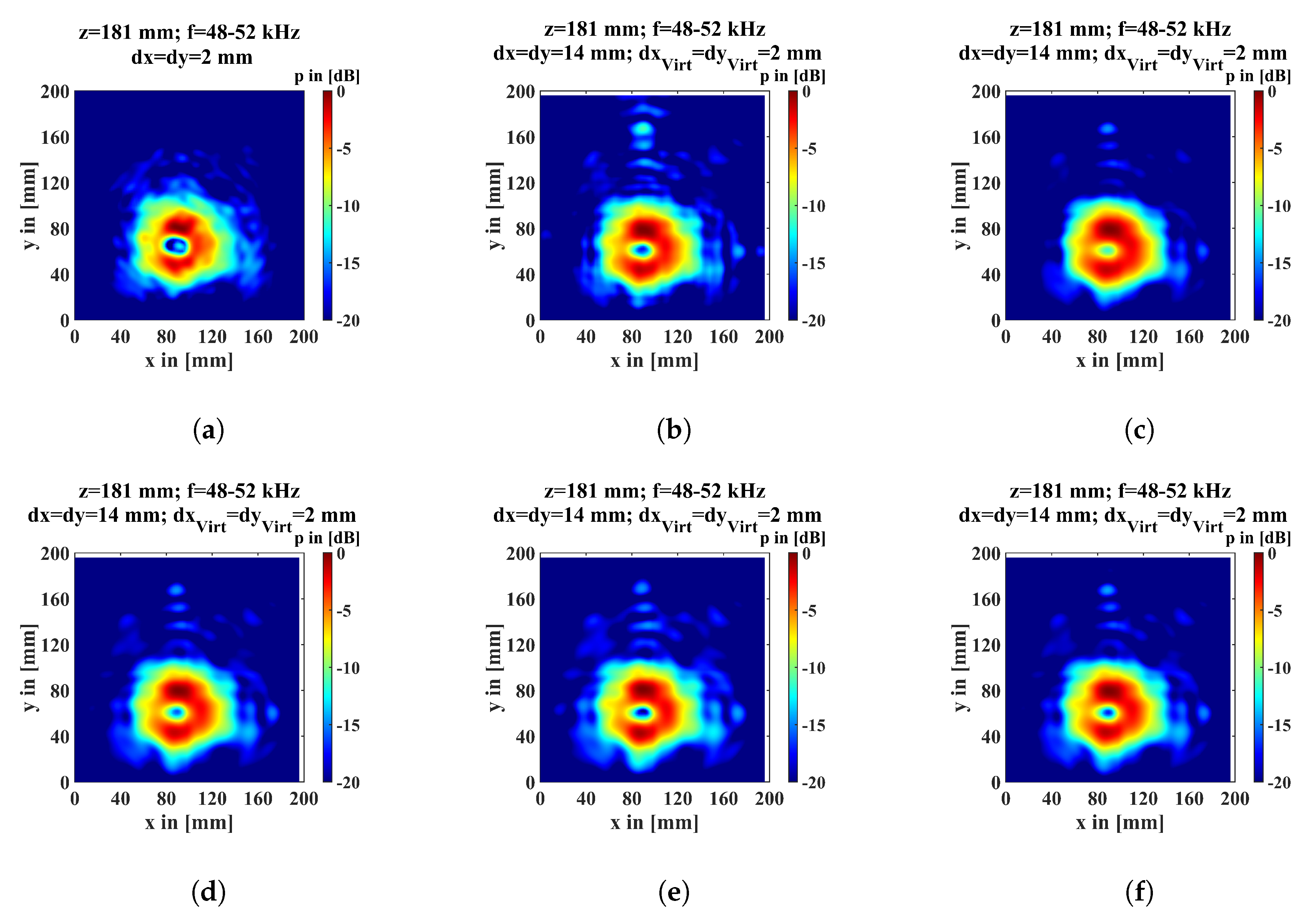

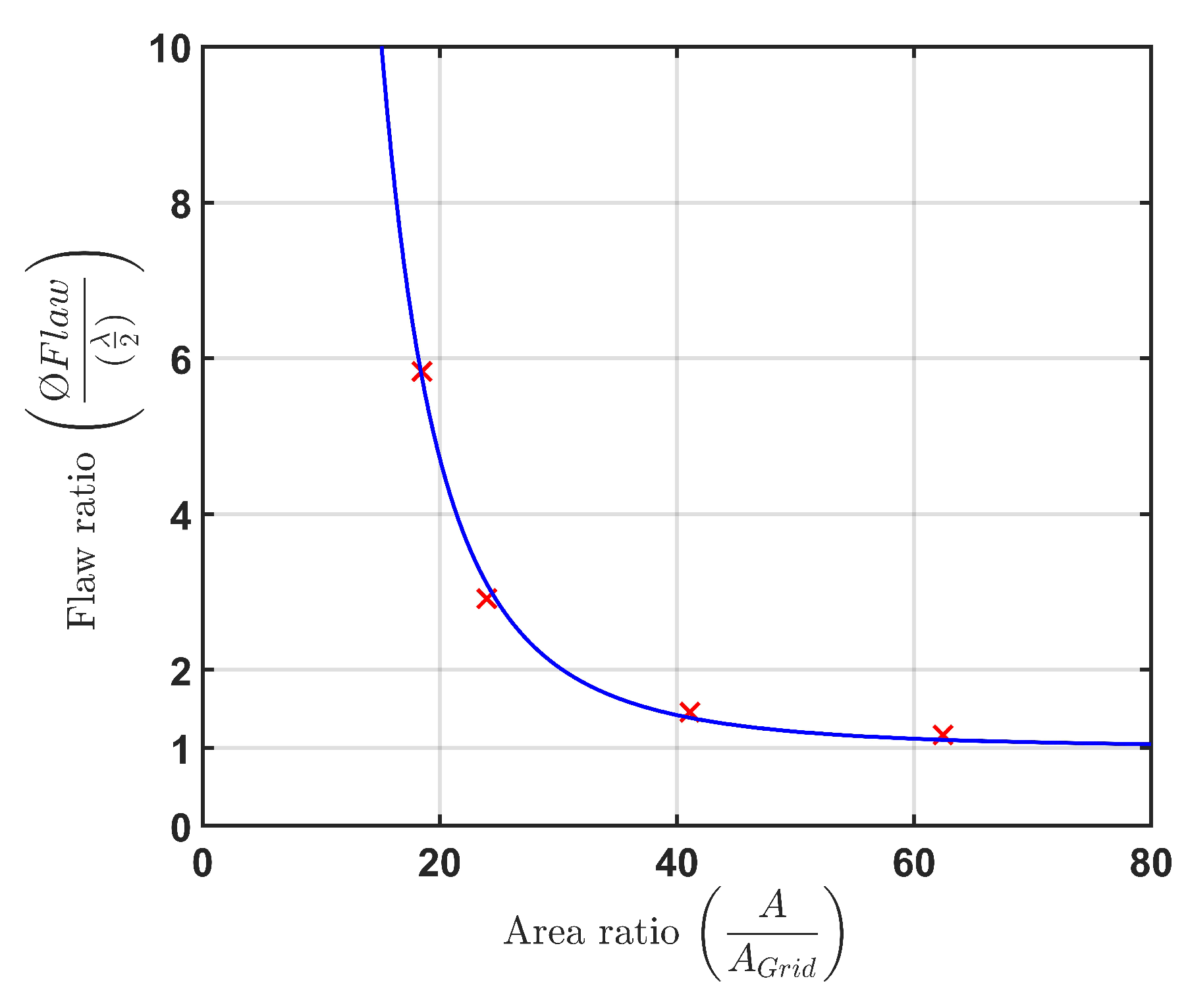

3.1. Detectability Enhancement with Coarse Measurement Grid

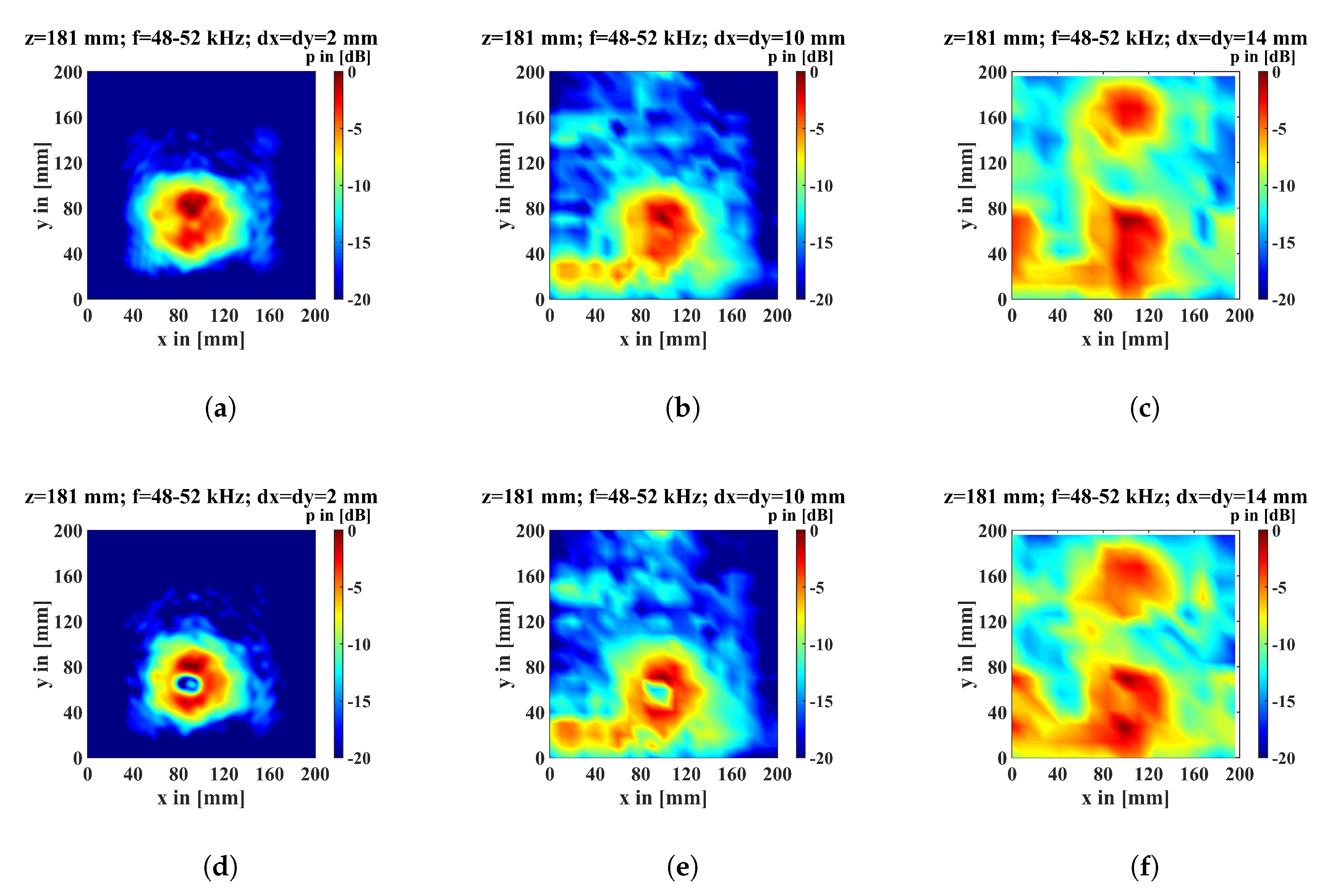

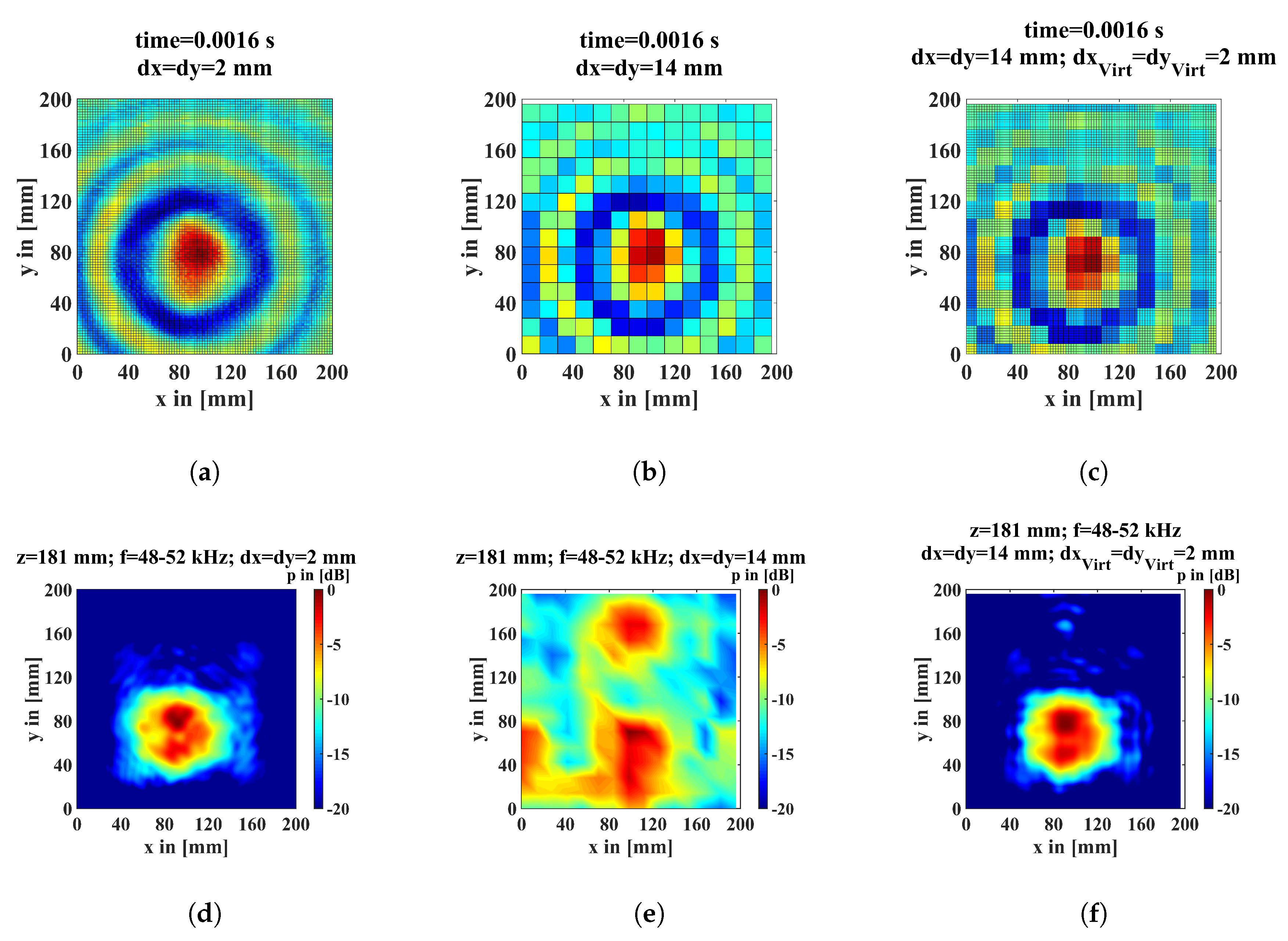

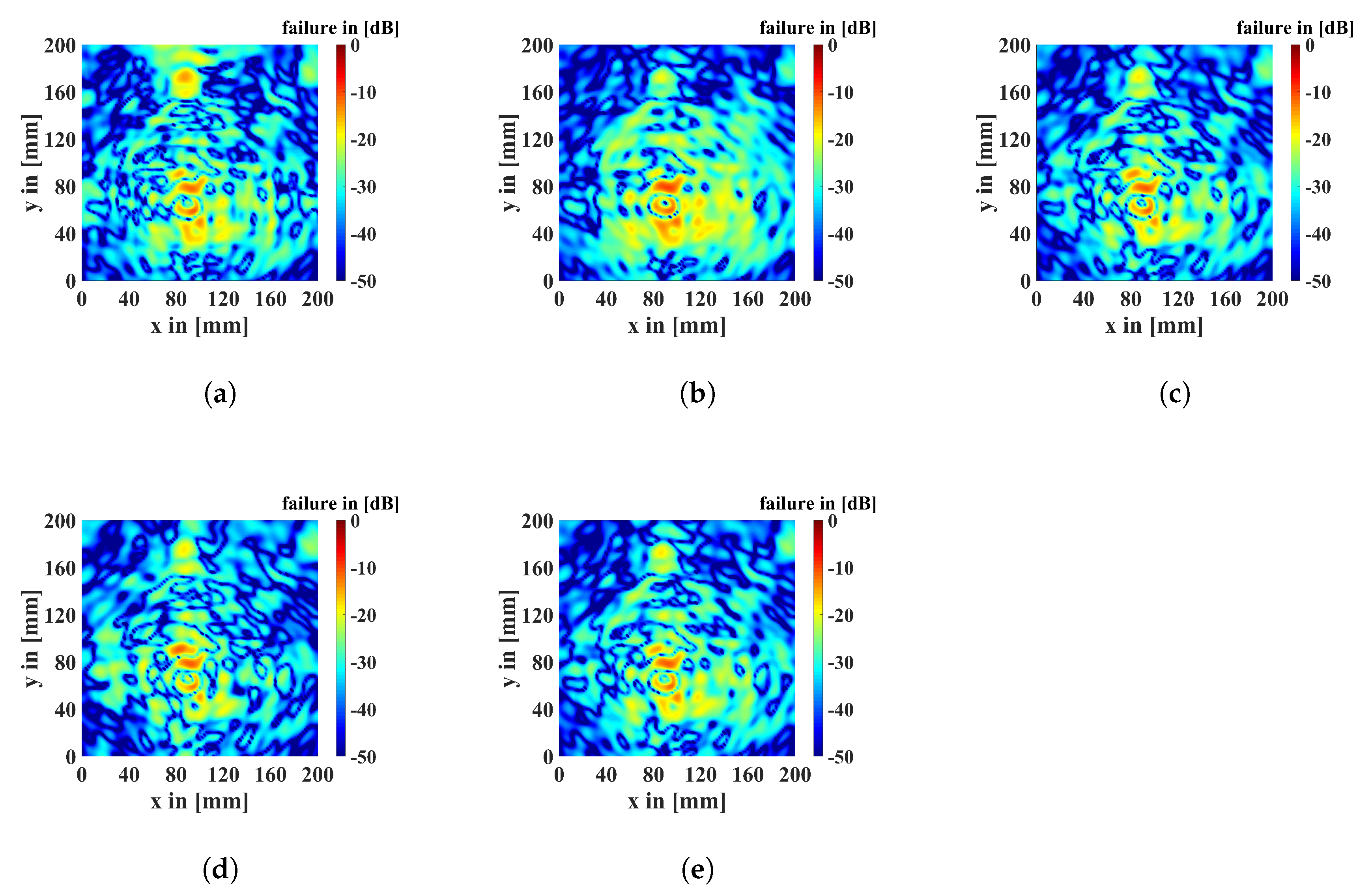

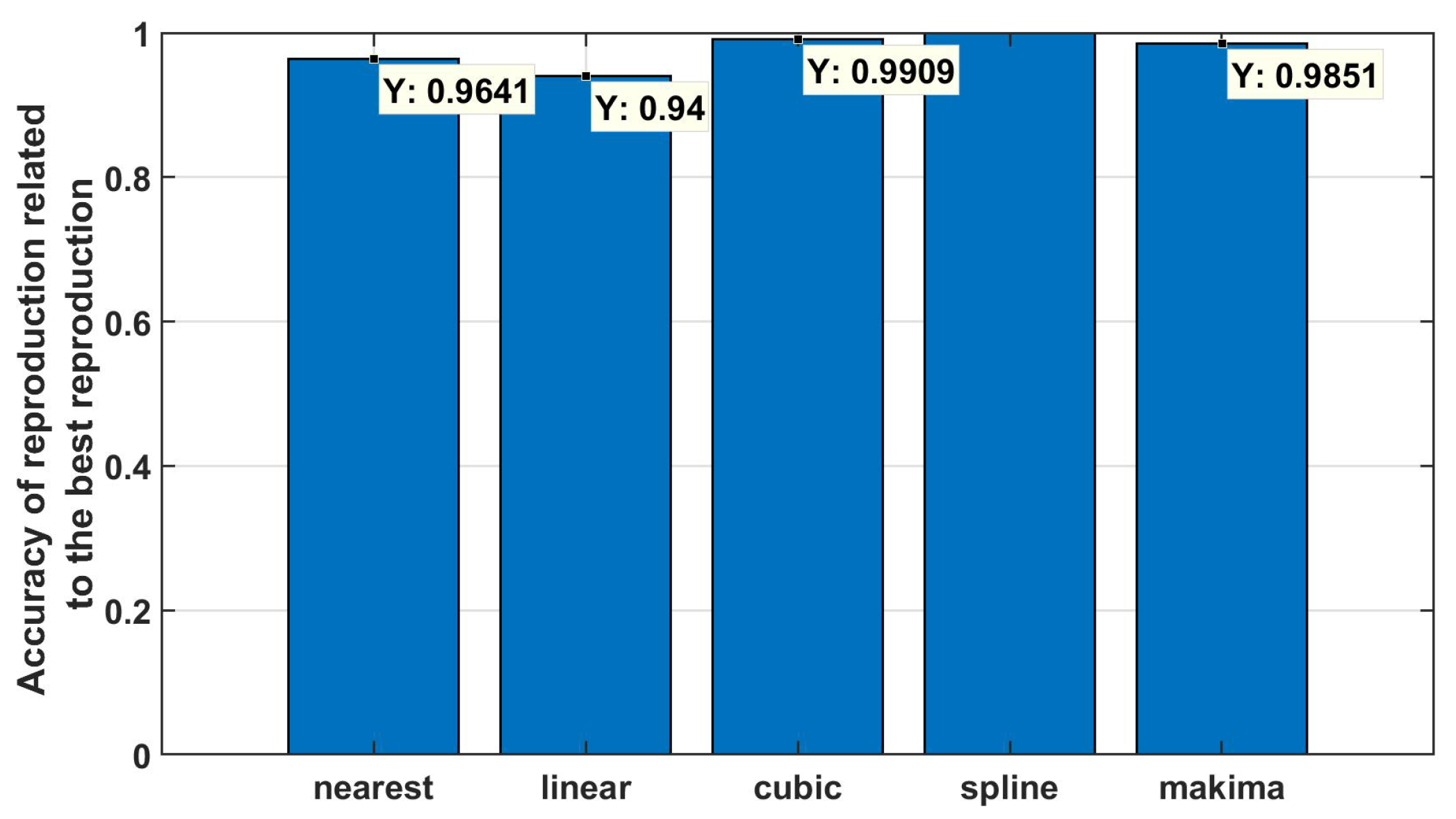

3.2. Sensitivity of the Measurement Grid Point Distance in Respect to the Identification of the Flaw with a Refined Grid

- The opening angle of the sound field of the main lobe does not change.

- The flaw located behind the sound field shows its influence only in the sound field considering the opening angle of the main lobe.

4. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| NDT | Non destructive testing |

| ACU | Air-coupled Ultrasound |

| MDF | Medium-density fiberboard |

| CFRP | Carbon fiber reinforced polymer |

| GFRP | Glass fiber reinforced polymer |

| NI | National Instruments |

References

- Sokolov, S.Y. On the problem of the propagation of ultrasonic oscillations in various bodies. Elek. Nachr. Tech. 1929, 6, 454–460. [Google Scholar]

- Fleming, M.R.; Bhardwaj, M.C.; Janowiak, J.J.; Shield, E.J.; Roy, R.; Agrawal, D.K.; Bauer, L.S.; Miller, D.L.; Hoover, K. Noncontact ultrasound detection of exotic insects in wood packing materials. For. Prod. J. 2005, 55, 33–37. [Google Scholar]

- Chimenti, D.E. Review of air-coupled ultrasonic materials characterization. Ultrasonics 2014, 54, 1804–1816. [Google Scholar] [CrossRef] [PubMed]

- Hillger, W.; Bühling, L.; Ilse, D. Review 0f 30 years ultrasonic systems and developments for the future. In Proceedings of the 11th European Conference on Non-Destructive Testing (ECNDT 2014), Prague, Czech Republic, 6–10 October 2014. [Google Scholar]

- Dunky, D.; Niemz, P. Theorie und Grundlagen der Verleimung und der Prüfung von Holzwerkstoffen. In Holzwerkstoffe und Leime; Springer: Berlin/Heidelberg, Germany, 2002; pp. 615–644. ISBN 978-3-642-62754-5. [Google Scholar]

- Schiebold, K. Zerstörungsfreie Werkstoffprüfung—Ultraschallprüfung; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 978-3-662-44699-7. [Google Scholar]

- Stößel, R. Air-Coupled Ultrasound Inspection as a New Non-Destructive Testing Tool for Quality Assurance. Ph.D. Thesis, Universität Stuttgart, Stuttgart, Germany, 2003. [Google Scholar]

- Dahmen, S.; Ketata, H.; Ghozlen, M.H.B.; Hosten, B. Elastic constants measurement of anisotropic Olivier wood plates using air-coupled transducers generated Lamb wave and ultrasonic bulk waves. Ultrasonics 2010, 50, 502–507. [Google Scholar] [CrossRef] [PubMed]

- Fang, Y.; Lin, L.; Feng, H.; Lu, Z.; Emms, G.W. Review of the use of air-coupled ultrasonic technologies for nondestructive testing of wood and wood products. Comput. Electron. Agric. 2017, 137, 79–87. [Google Scholar] [CrossRef]

- Bucur, V. Delamination detection in wood—Based composites, a methodological review. In Proceedings of the 20th International Congress on Acoustics (ICA 2010), Cape Town, South Africa, 7–12 March 2010; pp. 835–843, ISBN 978-1-61782-745-7. [Google Scholar]

- Döring, D. Luftgekoppelter Ultraschall und Geführte Wellen für die Anwendung in der Zerstörungsfreien Werkstoffprüfung. Ph.D. Thesis, Universität Stuttgart, Stuttgart, Germany, 2011. [Google Scholar]

- Matthies, K.; Gohlke, D. Der Ultraschall-Volumenscan als Werkzeug zur Prüfung komplizierter Geometrien und komplexer Gefüge. In Proceedings of the DGZfP—Jahrestagung, Fürth, Germany, 14–16 May 2007; Volume 57, ISBN 978-3-931381-98-1. [Google Scholar]

- Krautkrämer, J.; Krautkrämer, H. Bild und rekonstruktionsverfahren. In Werkstoffprüfungen mit ultraschall; Springer: Berlin/Heidelberg, Germany, 1986; Volume 5, pp. 262–288. [Google Scholar]

- Hoffmann, M.; Unger, A.; Ho, M.-C.; Park, K.K.; Khuri-Yakub, B.T.; Kupnik, M. Volumetric characterization of ultrasonic transducers for gas flow metering. In Proceedings of the 2013 IEEE International Ultrasonics Symposium (IUS), Prague, Czech Republic, 21–25 July 2013; pp. 1315–1318. [Google Scholar] [CrossRef]

- Neild, A.; Hutchins, D.A.; Robertson, T.J.; Davis, L.A.J.; Billson, D.R. The radiated fields of focussing air-coupled ultrasonic phased arrays. Ultrasonics 2005, 43, 183–195. [Google Scholar] [CrossRef] [PubMed]

- Marhenke, T.; Sanabria, S.J.; Chintada, B.R.; Furrer, R.; Neuenschwander, J.; Goksel, O. Acoustic field characterization of medical array transducers based on unfocused transmits and single-plane hydrophone measurements. Sensors 2019, 19, 863. [Google Scholar] [CrossRef] [PubMed]

- Marhenke, T.; Sanabria, S.J.; Twiefel, J.; Furrer, R.; Neuenschwander, J.; Wallaschek, J. Three dimensional sound field computation and optimization of the delamination detection based on the re-radiation. In Proceedings of the 12th European Conference on Non-destructive Testing (12th ECNDT), Gothenburg, Sweden, 11–15 June 2018; ISBN 978-91-639-6217-2. [Google Scholar]

- Sanabria, S.J.; Marhenke, T.; Furrer, R.; Neuenschwander, J. Calculation of volumetric sound field of pulsed air-coupled ultrasound transducers based on single-plane measurements. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2018, 65, 72–84. [Google Scholar] [CrossRef] [PubMed]

- Schmelt, A.S.; Marhenke, T.; Twiefel, J. Identifying objects in a 2D-space utilizing a novel combination of a re-radiation based method and of a difference-image-method. In Proceedings of the 23rd International Congress on Acoustics (ICA 2019), Aachen, Germany, 9–13 September 2019; ISBN 978-3-939296-15-7. [Google Scholar]

- Tsysar, S.A.; Sapozhnikov, O.A. Ultrasonic holography of 3D objects. In Proceedings of the IEEE International Ultrasonics Symposium (2009 IEEE IUS), Roma, Italy, 20–23 September 2009; pp. 737–740. [Google Scholar]

- Schmerr, L.W.; Song, S.-J. A Rayleigh–Sommerfeld Integral Transducer Model. In Ultrasonic Nondestructive Evaluation Systems—Models and Measurements; Springer: New York, NY, USA, 2007; pp. 134–137. [Google Scholar]

- Marhenke, T.; Neuenschwander, J.; Furrer, R.; Zolliker, P.; Twiefel, J.; Hasener, J.; Wallaschek, J.; Sanabria, S. Air-coupled ultrasound time reversal (ACU-TR) for subwavelength non-destructive imaging. IEEE Trans. Ultrason. Ferroelectr. Freq. Contr. 2019. [Google Scholar] [CrossRef] [PubMed]

- Sommerfeld, A. Optics: Lectures on Theoretical Physics. In Optics: Lectures on Theoretical Physics; Academic: New York, NY, USA, 1964; p. 197. [Google Scholar]

- Delen, N.; Hooker, B. Free-space beam propagation between arbitrarily oriented planes based on full diffraction theory: A fast Fourier transform approach. J. Opt. Soc. Am. A 1998, 15, 857–867. [Google Scholar] [CrossRef]

- Simonetti, F. Multiple scattering: The key to unravel the subwavelength world from the far-field pattern of a scattered wave. Phys. Rev. 2006, 73, 036619-1–036619-13. [Google Scholar] [CrossRef] [PubMed]

- Wolf, E. Three-dimensional structure determination of semi-transparent objects from holographic data. Opt. Commun. 1969, 1, 153–156. [Google Scholar] [CrossRef]

- Cramer, O. The variation of the specific heat ratio and the speed of sound in air with temperature, pressure, humidity, and CO2 concentration. J. Acoust. Soc. Am. 1993, 93, 2510–2516. [Google Scholar] [CrossRef]

- Krautkrämer, J.; Krautkrämer, H. Schallfeld des ebenen, kreisförmigen Kolbenschwingers. In Werkstoffprüfungen mit ultraschall; Springer: Berlin/Heidelberg, Germany, 1986; Volume 5, pp. 73–80. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schmelt, A.S.; Marhenke, T.; Hasener, J.; Twiefel, J. Investigation and Enhancement of the Detectability of Flaws with a Coarse Measuring Grid and Air Coupled Ultrasound for NDT of Panel Materials Using the Re-Radiation Method. Appl. Sci. 2020, 10, 1155. https://doi.org/10.3390/app10031155

Schmelt AS, Marhenke T, Hasener J, Twiefel J. Investigation and Enhancement of the Detectability of Flaws with a Coarse Measuring Grid and Air Coupled Ultrasound for NDT of Panel Materials Using the Re-Radiation Method. Applied Sciences. 2020; 10(3):1155. https://doi.org/10.3390/app10031155

Chicago/Turabian StyleSchmelt, Andreas Sebastian, Torben Marhenke, Jörg Hasener, and Jens Twiefel. 2020. "Investigation and Enhancement of the Detectability of Flaws with a Coarse Measuring Grid and Air Coupled Ultrasound for NDT of Panel Materials Using the Re-Radiation Method" Applied Sciences 10, no. 3: 1155. https://doi.org/10.3390/app10031155

APA StyleSchmelt, A. S., Marhenke, T., Hasener, J., & Twiefel, J. (2020). Investigation and Enhancement of the Detectability of Flaws with a Coarse Measuring Grid and Air Coupled Ultrasound for NDT of Panel Materials Using the Re-Radiation Method. Applied Sciences, 10(3), 1155. https://doi.org/10.3390/app10031155