Carbon Dioxide Uptake by Mortars and Concretes Made with Portuguese Cements

Abstract

Featured Application

Abstract

1. Introduction

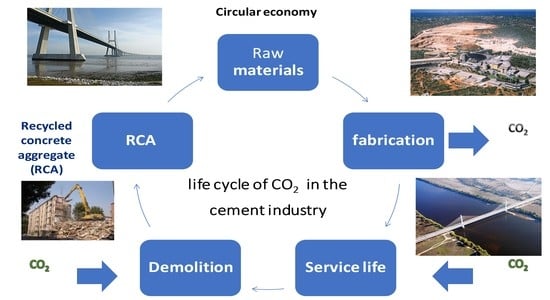

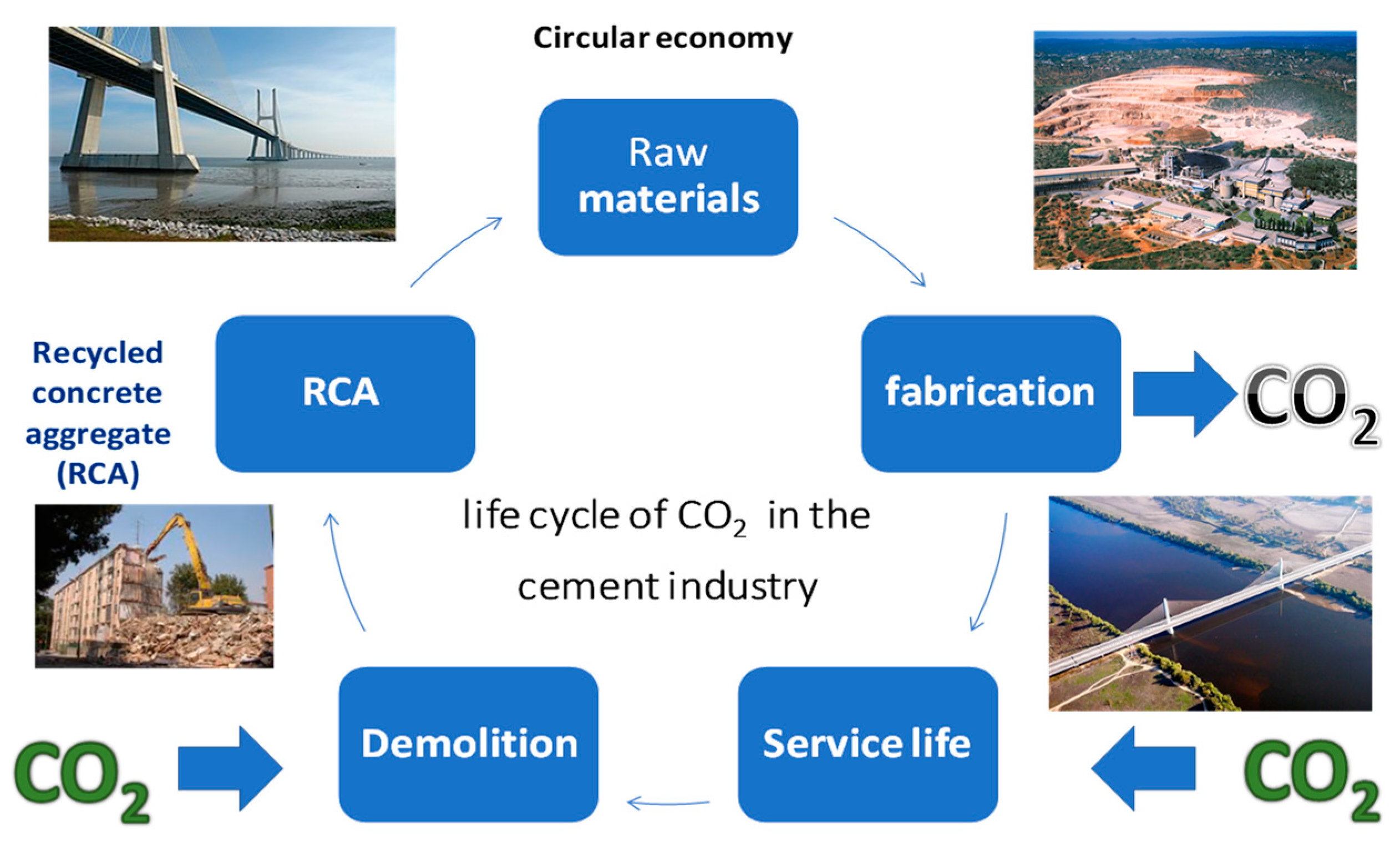

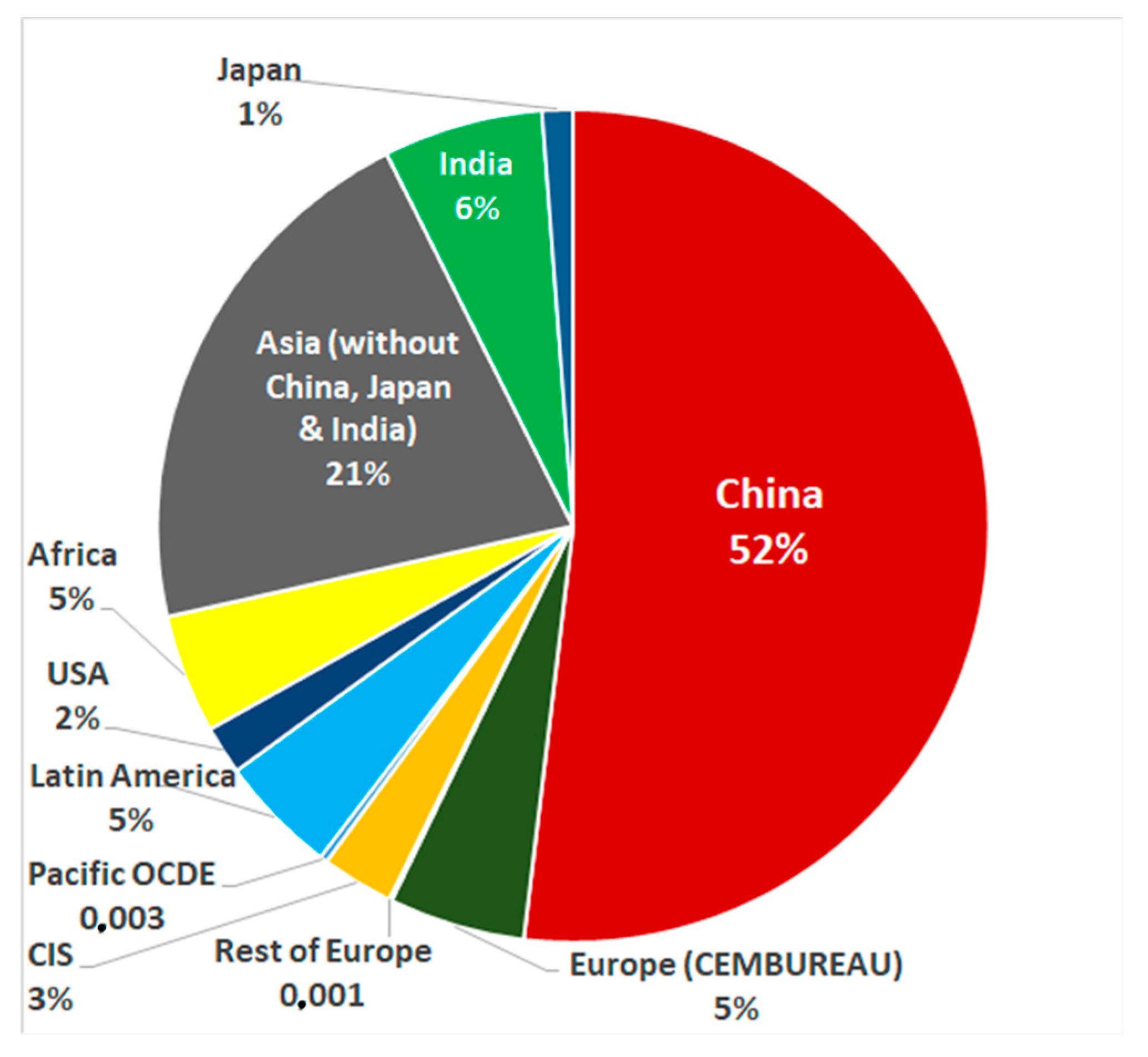

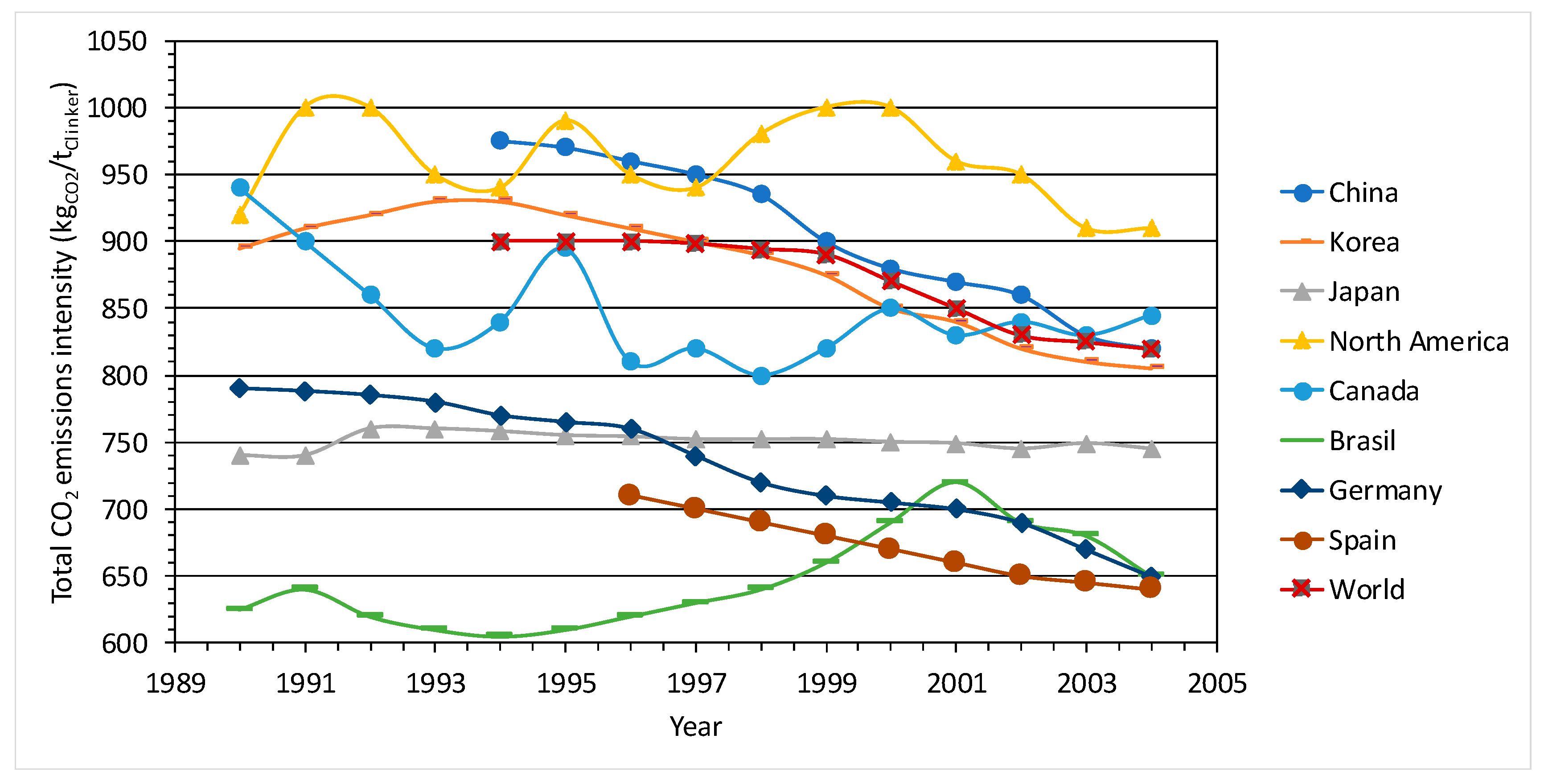

2. CO2 Emissions by the Cement Sector

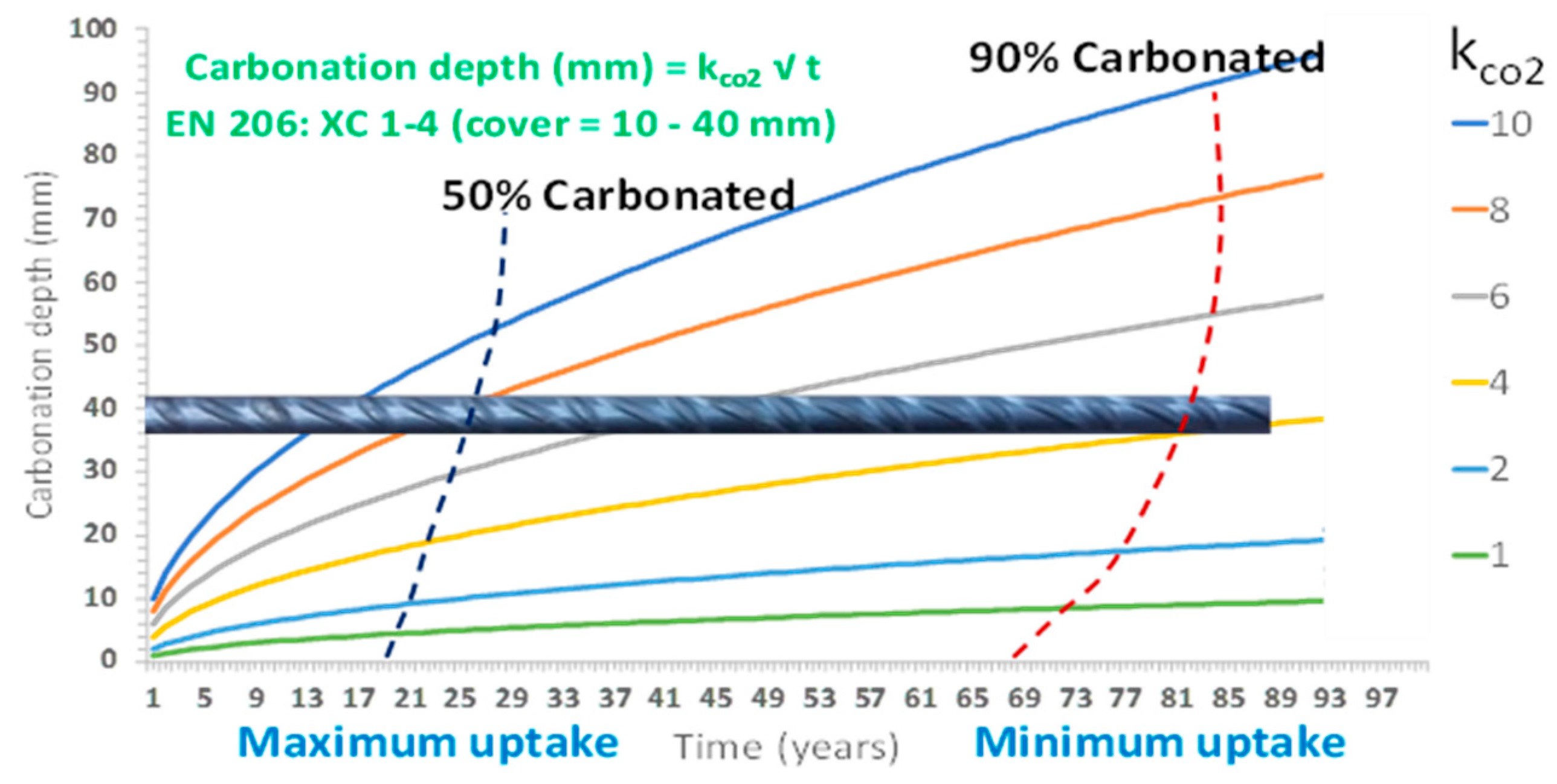

3. CO2 Uptake of Concrete

- XC1: dry or permanently wet

- XC2: wet or rarely dry

- XC3: moderate humidity

- XC4: cyclic wet and dry

4. Methodology

4.1. Calculation of CO2 Uptake of Concretes and Mortars Following the Simplified Method (Tier 1)

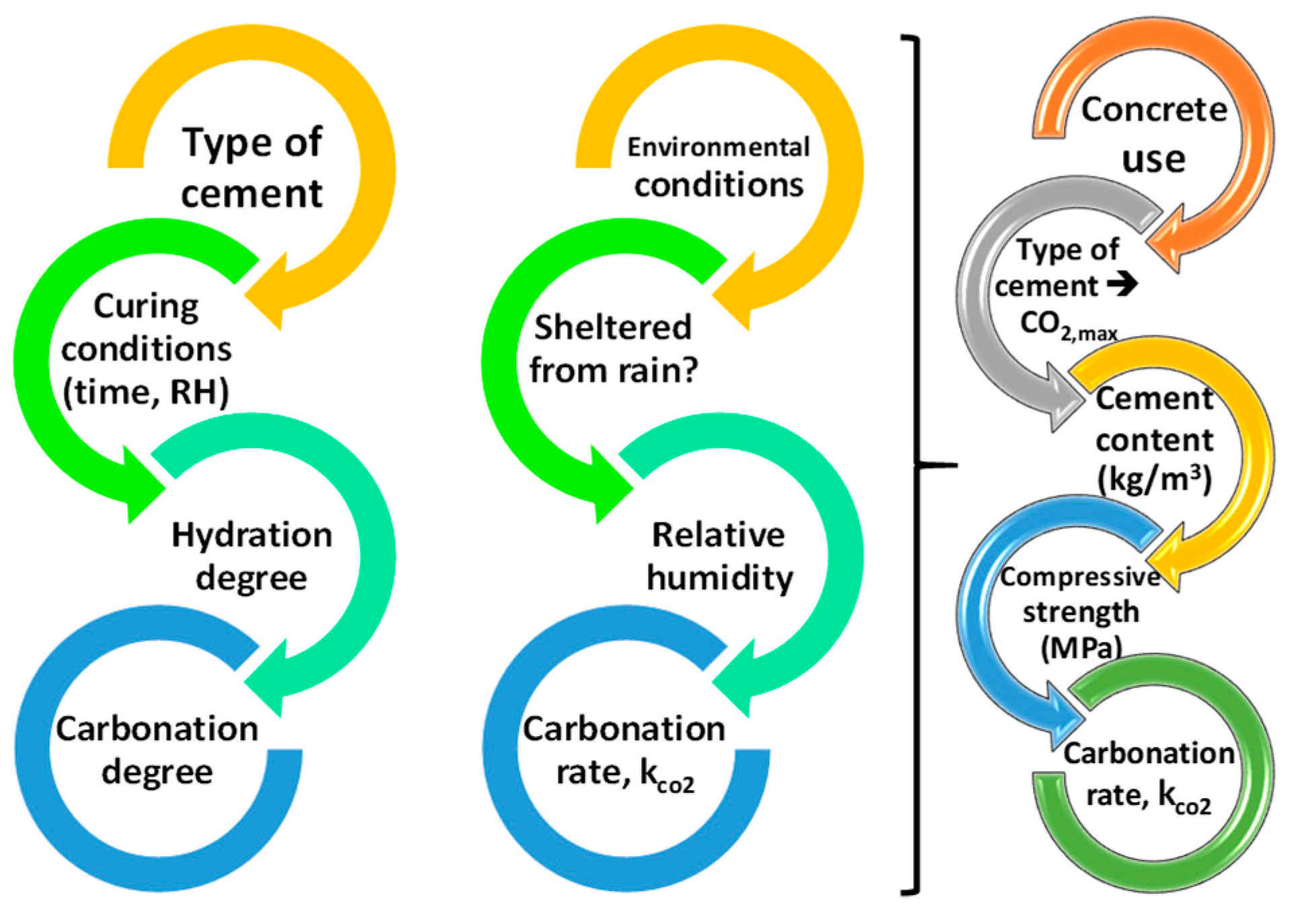

4.2. Calculation of CO2 Uptake of Concretes and Mortars Following the Advanced Method (Tier 2)

- (CO2)uptake: carbon dioxide content uptake, kg CO2.

- C: cement manufactured, kg cement.

- CO2,max: maximum carbon dioxide content able to be uptake, kg CO2/kg cement.

- DoC: carbonation degree, dimensionless. In this study was 0.6576.

- kco2: carbonation rate, mm/year0.5.

- t: time, years.

- S/V: surface per volume ratio, m2/m3.

5. Results

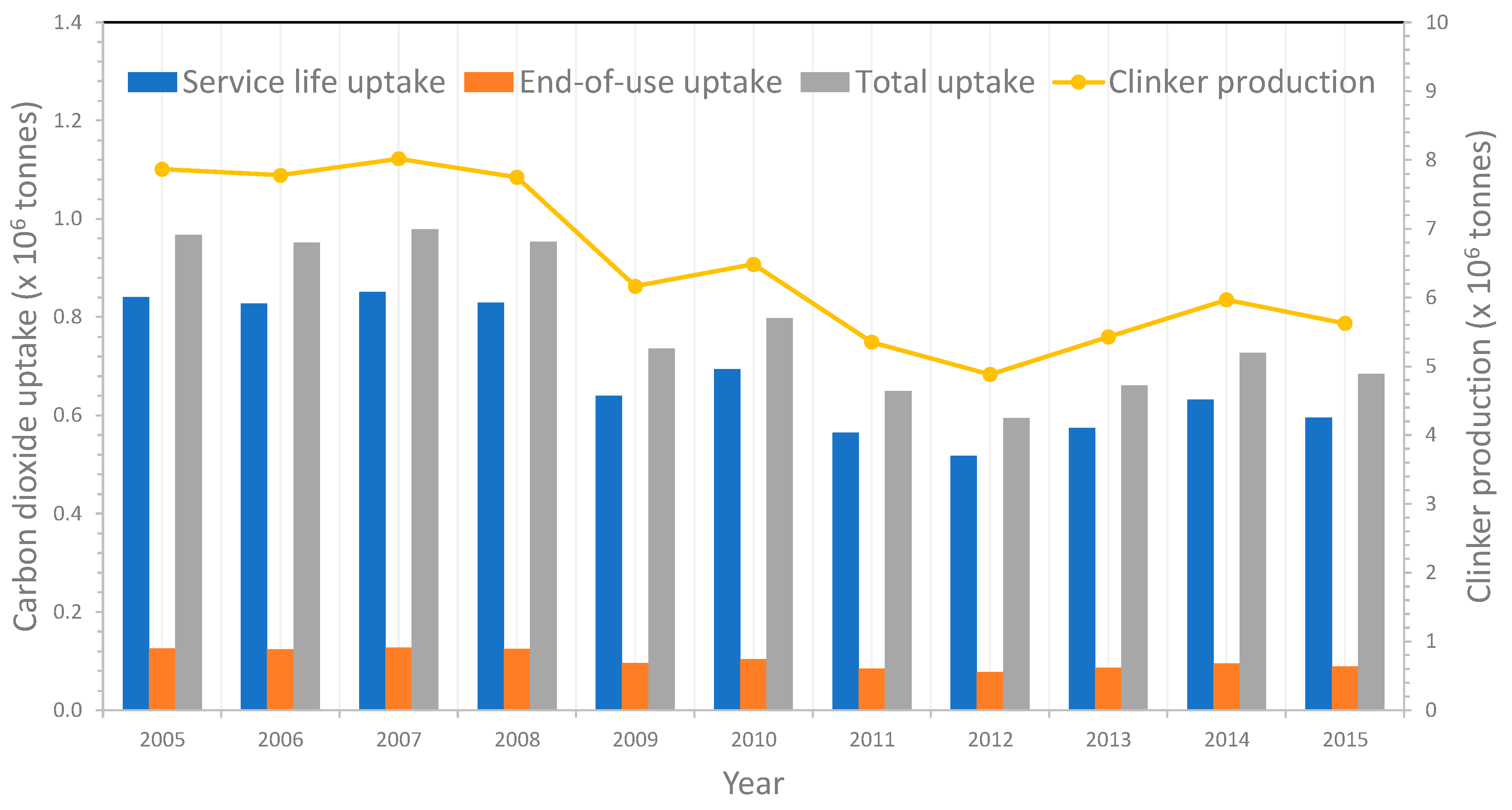

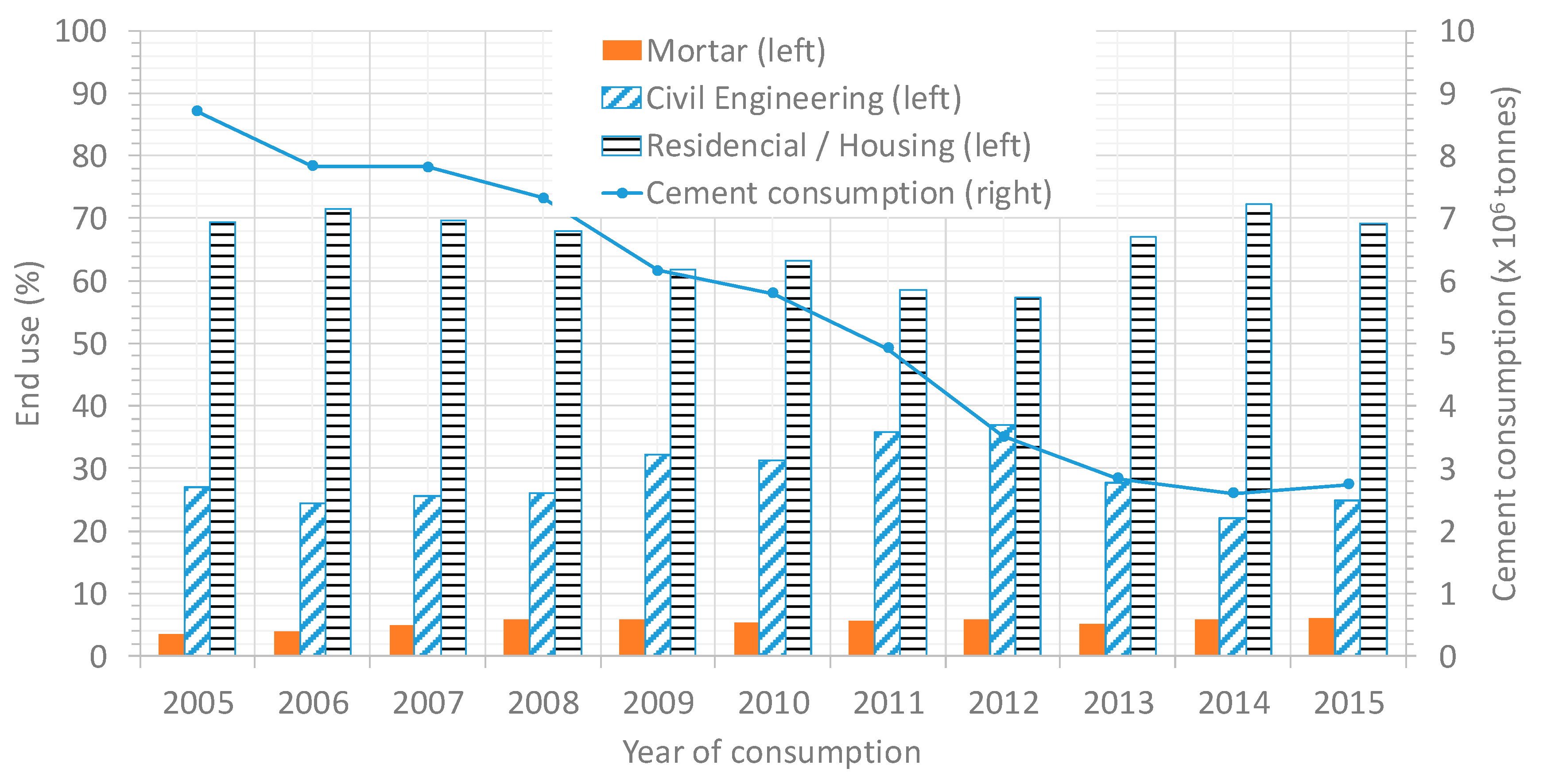

5.1. CO2 Uptake of Concretes Manufactured with Portuguese Cements Following the Simplified Method

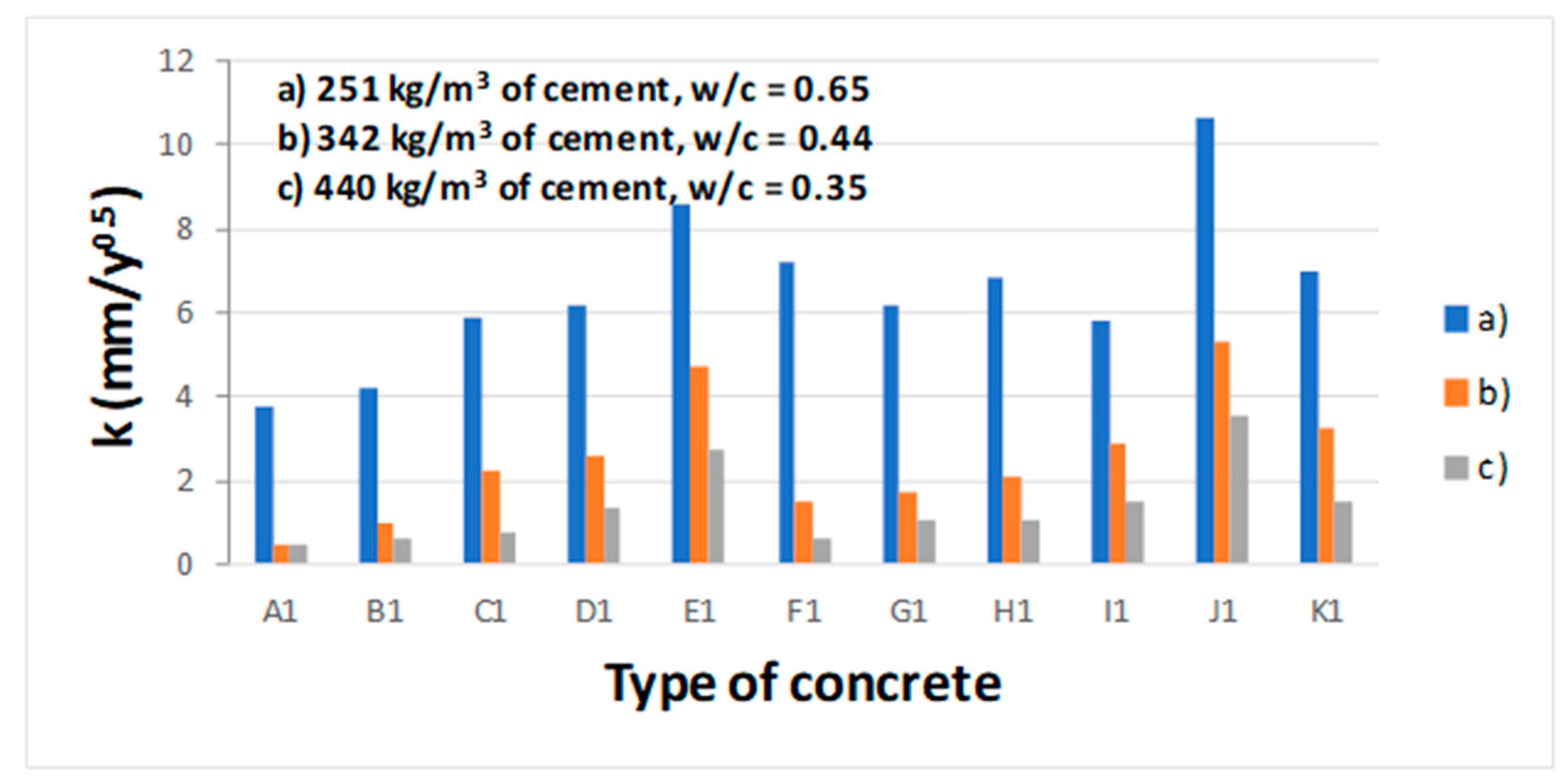

5.2. CO2 Uptake of Concretes Manufactured with Portuguese Cements Following the Advanced Method

- B = carbonation coefficient (mm/y0.5).

- x = carbonation depth (mm).

- t = time of natural carbonation (years).

- CO2,max: maximum amount of carbon dioxide that can be absorbed, kg CO2/kg cement.

- CaOreactive: kg CaO/kg binder × 100. This value is taken as 65%.

- Binder: Amount of cement (kg).

- MCO2: 44.0 g/mol.

- MCaO: 56.1 g/mol.

6. Conclusions

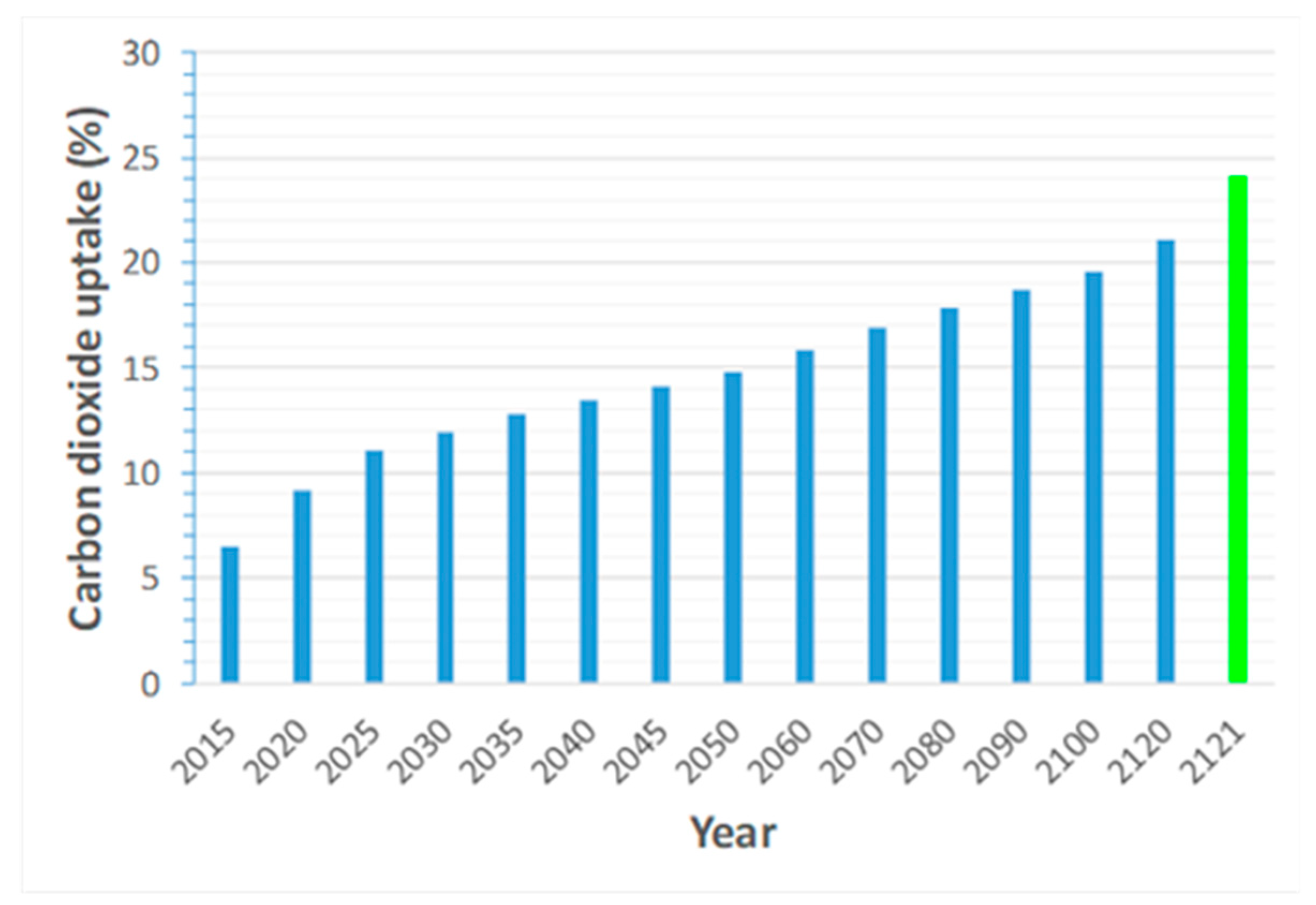

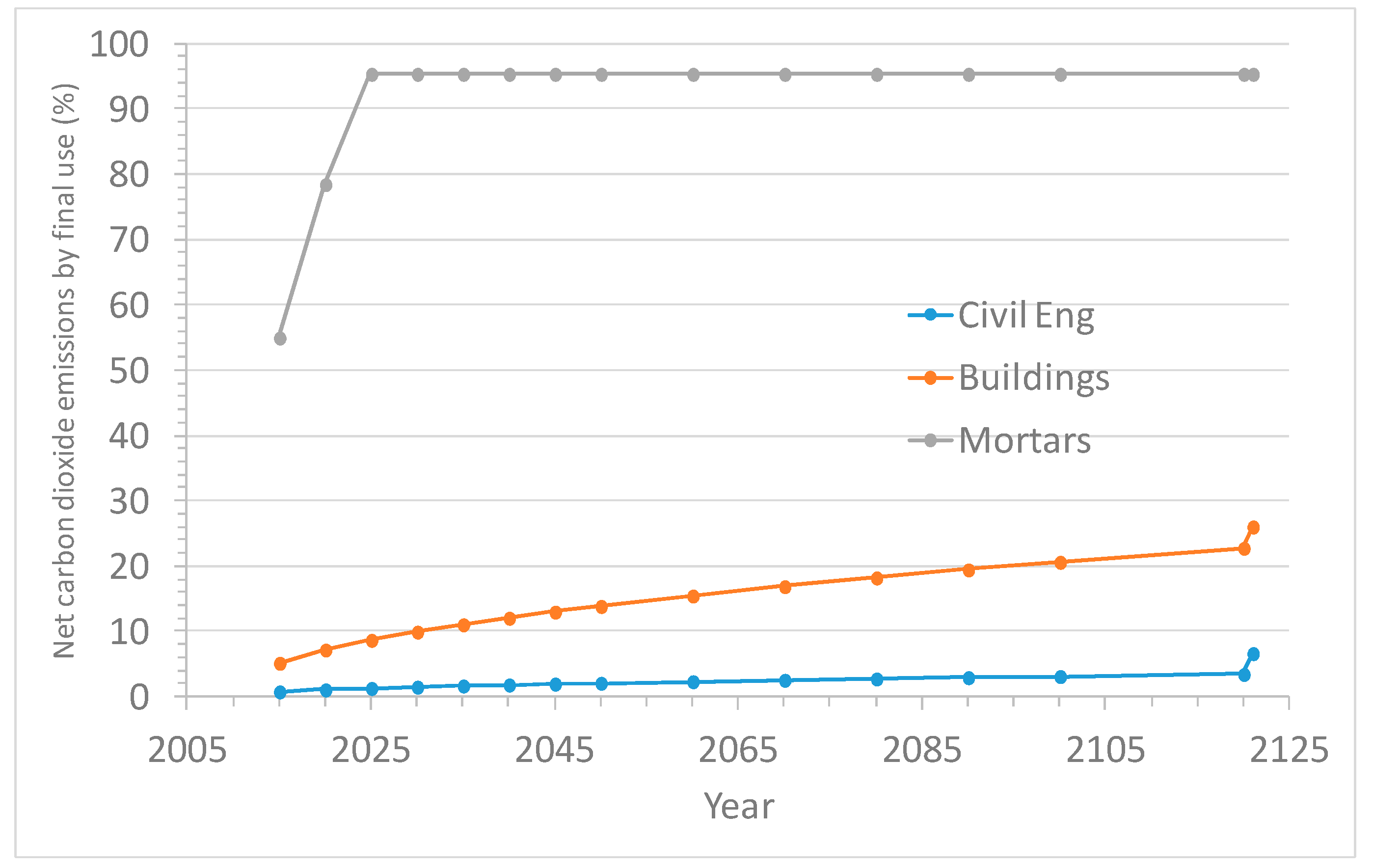

- The total amount of carbon dioxide that can be absorbed by concretes and mortars made with Portuguese cements, consumed from 2005 to 2015, was found to go from 5.6 to 7.4 million tons from 2050 to 2100 when considering the surface/volume ratios of three for civil engineering works, eight for buildings, and 20 for mortars. Thus, the percentage of carbon dioxide uptake, considering the absolute gross process CO2 emissions, is in the range between 14.8% and 19.6%. Consequently, the simplified method agrees with the carbon dioxide uptake from the origin considered in the present study until the year 2100. Nevertheless, 9.1 million tons of carbon dioxide will be uptake in the year 2121 (24.2%), when 3% of the absolute gross process CO2 emissions due to the end-of-life stage is added to the carbon dioxide uptake reached in 2021.

- In the period of 2005–2015, CO2 absorption from Portuguese cements was estimated at 8.7 million tons of CO2 when using the simplified methodology and applying a factor of 0.23 (20% for service life and 3% for the end-of-life plus secondary usage stage), which is what is proposed in the IVL simplified methodology.

- Mortar’s carbon dioxide uptake was about 95% in ten years. However, civil works and building concretes only reached 6.6% and 26.0% after one hundred years of carbonation, respectively.

- As expected, short carbonation periods provide a low carbon dioxide uptake. Therefore, actual service-life periods should be considered in order to assess the whole process. In addition, the great influence of the S/V ratio on carbon dioxide uptake make this a key factor in this advanced methodology

- In regard to the shortcomings in the current climate models, which do not consider the net carbon dioxide emission (released by the calcination process in the clinker fabrication minus concrete carbonation) attributed to the Portland cement clinker production, IPCC authors are strongly encouraged to improve their climate models adding the aforementioned net carbon dioxide emissions.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sanjuan, M.A.; Estévez, E.; Argiz, C.; Del Barrio, D. Effect of curing time on granulated blast-furnace slag cement mortars carbonation. Cem. Concr. Compos. 2018, 90, 257–265. [Google Scholar] [CrossRef]

- The Intergovernmental Panel on Climate Change. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC Guidelines Volume 3. Chapter 3 Industrial Processes. In IPCC Good Practice Guidance and Uncertainty Management in National Greenhouse Gas Inventories 3.1; Eggleston, H.S., Buendia, L., Miwa, K., Ngara, T., Tanabe, K., Eds.; IGES: Hayama, Japan, 2006; Available online: https://www.ipcc-nggip.iges.or.jp/public/gp/english/3_Industry.pdf (accessed on 2 December 2019).

- Stripple, H.; Ljungkrantz, C.; Gustafsson, T. CO2 Uptake in Cement-Containing Products. Background and Calculation Models for IPCC Implementation, 1st ed.; Report Number: B 2309; IVL Swedish Environmental Research Institute: Stockholm, Sweden, 2018; pp. 20–30. [Google Scholar]

- Andrade, C.; Sanjuán, M.A. Updating Carbon Storage Capacity of Spanish Cements. Sustainability 2018, 10, 4806. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). CO2 Emissions from Fuel Combustion 2019: HIGHLIGHTS; IEA Publications: Paris, France, 2018; p. 156. Available online: http://data.iea.org/payment/products/115-co2-emissions-from-fuel-combustion.aspx (accessed on 2 December 2019).

- Sevelsted, T.F.; Skibsted, J. Carbonation of C–S–H and C–A–S–H samples studied by 13C, 27Al and 29Si MAS NMR spectroscopy. Cem. Concr. Res. 2015, 71, 56–65. [Google Scholar] [CrossRef]

- Zhou, Q.; Glasser, F. Kinetics and mechanism of the carbonation of ettringite. Adv. Cem. Res. 2000, 12, 131–136. [Google Scholar] [CrossRef]

- Morandeau, A.; Thiery, M.; Dangla, P. Investigation of the carbonation mechanism of CH and CSH in terms of kinetics, microstructure changes and moisture properties. Cem. Concr. Res. 2014, 56, 153–170. [Google Scholar] [CrossRef]

- World Business Council for Sustainable Development (WBCSD)—Cement Sustainability Initiative’s (CSI). Getting the Numbers Right (GNR) Project, 1st ed.; World Business Council for Sustainable Development: Geneva, Switzerland; Available online: http://www.wbcsdcement.org/index.php/key-issues/climate-protection/gnr-database (accessed on 10 September 2019).

- The European Cement Association (CEMBUREAU). Activity Report, 1st ed.; CEMBUREAU: Brussels, Belgium, 2017; pp. 1–42. Available online: https://cembureau.eu/media/1716/activity-report-2017.pdf (accessed on 2 December 2019).

- Hoenig, V.; Hoppe, H.; Emberger, B. Carbon Capture Technology—Options and Potentials for the Cement Industry, 1st ed.; European Cement Research Academy: Düsseldorf, Germany, 2007; pp. 1–96. [Google Scholar]

- International Energy Agency (IEA). Energy Technology Perspectives. Scenarios & Strategies to 2050, 1st ed.; IEA/OECD: Paris, France, 2006. [Google Scholar]

- UN General Assembly. Transforming Our World: The 2030 Agenda for Sustainable Development, 1st ed.; United Nations: New York, NY, USA, 2015. [Google Scholar]

- Eurostat. Sustainable Development in the European Union. Overview of Progress towards the SDGs in an EU Context, 1st ed.; Publications Office of the European Union: Luxembourg, 2017; pp. 1–37. [Google Scholar]

- EN 206: 2013—Concrete—Specification, Performance, Production and Conformity; European Committee for Standardization (CEN): Brussels, Belgium, 2013.

- EN 1992-1-1. Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings; European Committee for Standardization (CEN): Brussels, Belgium, 2004. [Google Scholar]

- Bettencourt Ribeiro, A.; Santos, T.; Gonçalves, A. Performance of concrete exposed to natural carbonation: Use of the k-value concept. Constr. Build. Mater. 2018, 175, 360–370. [Google Scholar] [CrossRef]

- Monteiro, I.; Branco, F.A.; de Brito, J.; Neves, R. Statistical analysis of the carbonation coefficient in open air concrete structures. Constr. Build. Mater. 2012, 29, 263–269. [Google Scholar] [CrossRef]

- Sanjuán, M.A.; Argiz, C. The new European standard on common cements specifications, EN-197-1:2011. Mater. Construcc. 2012, 62, 425–430. [Google Scholar] [CrossRef]

- EN 16757:2016. Sustainability of Construction Works—Environmental Product Declarations—Product Category Rules for Concrete and Concrete Elements. Annex BB (Informative). CO2 Uptake by Carbonation—Guidance on Calculation; European Committee for Standardization (CEN): Brussels, Belgium, 2016. [Google Scholar]

- Sanjuán, M.Á.; Estévez, E.; Argiz, C. Carbon Dioxide Absorption by Blast-Furnace Slag Mortars in Function of the Curing Intensity. Energies 2019, 12, 2346. [Google Scholar] [CrossRef]

- Galán, I.; Andrade, C.; Mora, P.; Sanjuán, M.A. Sequestration of CO2 by Concrete Carbonation. Environ. Sci. Technol. 2010, 44, 3181–3186. [Google Scholar] [CrossRef] [PubMed]

- Sanjuán, M.A.; Andrade, C.; Mora, P.; Zaragoza, A. Carbon Dioxide Uptake by Cement-Based Materials: A Spanish Case Study. Appl. Sci. 2020, 10, 339. [Google Scholar] [CrossRef]

| Environmental Requirement for Minimum Concrete Cover (mm) | Structural Class | |||||

|---|---|---|---|---|---|---|

| Exposure Class: Corrosion Induced by Carbonation | S1 | S2 | S3 | S4 | S5 | S6 |

| XC1—dry or permanently wet | 10 | 10 | 10 | 15 | 20 | 25 |

| XC2—wet or rarely dry | 10 | 15 | 20 | 25 | 30 | 35 |

| XC3—moderate humidity | 10 | 15 | 20 | 25 | 30 | 35 |

| XC4—cyclic wet and dry | 15 | 20 | 25 | 30 | 35 | 40 |

| Year | 2005 | 2006 | 2007 | 2008 | 2009 | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Clinker annual production (kilotons) | 7865 | 7777 | 8018 | 7748 | 6164 | 6484 | 5351 | 4882 | 5427 | 5968 | 5626 |

| Total Absolute Gross CO2 Emissions (kilotons) (without biomass emissions) | 6722 | 6640 | 6811 | 6524 | 5075 | 5458 | 4455 | 4015 | 4393 | 4904 | 4621 |

| Absolute Gross Process CO2 Emissions (kilotons) | 4206 | 4141 | 4256 | 4146 | 3200 | 3471 | 2825 | 2588 | 2872 | 3162 | 2978 |

| Main Types | Type Name | Type Notation | K 1 | MAC 2 | Factor (Kcement/KCEM I) | Factor (Kcement/KCEM I) | CO2,max |

|---|---|---|---|---|---|---|---|

| kg CO2/kg Cement | |||||||

| CEM I | Portland cement | CEM I | 95–100 | 0–5 | 95/95 = 1 | 1 | 0.49 |

| CEM II | Portland-slag cement | CEM II/A-S | 80–88 | 0–5 | 80/95–94/95 | 0.84–0.99 | 0.41–0.48 |

| CEM II/B-S | 65–79 | 0–5 | 65/95–79/95 | 0.68–0.83 | 0.34–0.41 | ||

| Portland-silica fume cement | CEM II/A-D | 90–94 | 0–5 | 90/95–94/95 | 0.95–0.99 | 0.46–0.48 | |

| Portland-pozzolana cement | CEM II/A-P | 80–94 | 0–5 | 80/95–94/95 | 0.84–0.99 | 0.41–0.48 | |

| CEM II/B-P | 65–79 | 0–5 | 65/95–79/95 | 0.68–0.83 | 0.34–0.41 | ||

| CEM II/A-Q | 80–94 | 0–5 | 80/95–94/95 | 0.84–0.99 | 0.41–0.48 | ||

| CEM II/B-Q | 65–79 | 0–5 | 65/95–79/95 | 0.68–0.83 | 0.34–0.41 | ||

| Portland-fly ash cement | CEM II/A-V | 80–94 | 0–5 | 80/95–94/95 | 0.84–0.99 | 0.41–0.48 | |

| CEM II/B-V | 65–79 | 0–5 | 65/95–79/95 | 0.68–0.83 | 0.34–0.41 | ||

| CEM II/A-W | 80–94 | 0–5 | 80/95–94/95 | 0.84–0.99 | 0.41–0.48 | ||

| CEM II/B-W | 65–79 | 0–5 | 65/95–79/95 | 0.68–0.83 | 0.34–0.41 | ||

| Portland-burnt shale cement | CEM II/A-T | 80–94 | 0–5 | 80/95–94/95 | 0.84–0.99 | 0.41–0.48 | |

| CEM II/B-T | 65–79 | 0–5 | 65/95–79/95 | 0.68–0.83 | 0.34–0.41 | ||

| Portland-limestone cement | CEM II/A-L | 80–94 | 0–5 | 80/95–94/95 | 0.84–0.99 | 0.41–0.48 | |

| CEM II/B-L | 65–79 | 0–5 | 65/95–79/95 | 0.68–0.83 | 0.34–0.41 | ||

| CEM II/A-LL | 80–94 | 0–5 | 80/95–94/95 | 0.84–0.99 | 0.41–0.48 | ||

| CEM II/B-LL | 65–79 | 0–5 | 65/95–79/95 | 0.68–0.83 | 0.34–0.41 | ||

| Portland-composite cement | CEM II/A-M | 80–88 | 0–5 | 80/95–94/95 | 0.84–0.99 | 0.41–0.48 | |

| CEM II/B-M | 65–79 | 0–5 | 65/95–79/95 | 0.68–0.83 | 0.34–0.41 | ||

| CEM III | Blast furnace cement | CEM III/A | 35–64 | 0–5 | 35/95–64/95 | 0.37–0.67 | 0.18–0.33 |

| CEM III/B | 20–34 | 0–5 | 20/95–34/95 | 0.21–0.36 | 0.10–0.18 | ||

| CEM III/C | 5–19 | 0–5 | 5/95–19/95 | 0.05–0.20 | 0.03–0.10 | ||

| CEM IV | Pozzolanic cement | CEM IV/A | 65–89 | 0–5 | 65/95–89/95 | 0.68–0.94 | 0.34–0.46 |

| CEM IV/B | 45–64 | 0–5 | 45/95–64/95 | 0.47–0.67 | 0.23–0.33 | ||

| CEM V | Composite cement | CEM V/A | 40–64 | 0–5 | 40/95–64/95 | 0.42–0.67 | 0.21–0.33 |

| CEM V/B | 20–38 | 0–5 | 20/95–38/95 | 0.21–0.40 | 0.10–0.20 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanjuán, M.Á.; Andrade, C.; Mora, P.; Zaragoza, A. Carbon Dioxide Uptake by Mortars and Concretes Made with Portuguese Cements. Appl. Sci. 2020, 10, 646. https://doi.org/10.3390/app10020646

Sanjuán MÁ, Andrade C, Mora P, Zaragoza A. Carbon Dioxide Uptake by Mortars and Concretes Made with Portuguese Cements. Applied Sciences. 2020; 10(2):646. https://doi.org/10.3390/app10020646

Chicago/Turabian StyleSanjuán, Miguel Ángel, Carmen Andrade, Pedro Mora, and Aniceto Zaragoza. 2020. "Carbon Dioxide Uptake by Mortars and Concretes Made with Portuguese Cements" Applied Sciences 10, no. 2: 646. https://doi.org/10.3390/app10020646

APA StyleSanjuán, M. Á., Andrade, C., Mora, P., & Zaragoza, A. (2020). Carbon Dioxide Uptake by Mortars and Concretes Made with Portuguese Cements. Applied Sciences, 10(2), 646. https://doi.org/10.3390/app10020646