Abstract

There is a constant increase in the attention being paid to food quality and the effects of food on human health among consumers. Vegetable milk is among the foods whose consumption worldwide has increased because, when compared to animal-derived milk, it offers numerous benefits for human health. The aim of this research work was to use vegetable milk to obtain yogurt-like products enriched with different concentrations of carob seed flour, which has a double function: to modify, and thus perfect, the rheological characteristics of vegetable-milk-based yogurt-like samples and to increase their nutritional value. The rheological parameters of the obtained samples were studied both in static and dynamic conditions, confirming that carob seed flour, especially at the highest used concentrations (0.75%; 1%), allows one to obtain products characterized by a good stability and suitable rheological characteristics. The obtained yogurt-like products may also be consumed by celiac subjects, since carob seed flour is a gluten-free flour, and allow celiac consumers to combine a gluten-free diet with a diet free of animal derivatives. Furthermore, the addition of carob flour allows one to obtain a tasty product thanks to the sweet taste of the carob seed flour.

1. Introduction

Celiac disease is an autoimmune disorder, which leads to mild or severe symptoms, especially at the gastrointestinal level. Its clinical signs occur in a genetically predisposed subject following gluten intake. For a person who is genetically predisposed to a celiac disease, the only way to avoid the manifestation of this pathology is to consume exclusively gluten-free food and beverages [1]. In the last few years, among the consumers, there is an increase in the consumption of products derived from plants as there are numerous studies in literature in which it has been shown that the vegetarian diet decreases the risk of dangerous diseases for humans, such as obesity and coronary heart disease [2]. In addition, plant-based diets could reduce healthcare costs [3]. For all these reasons, an increase in the demand for plant-derived products was recorded.

In particular, there is an increase in the demand for vegetable-milk-derived products because it is known that there may be a relationship between vegetable-based diet and the reduction of the risk of pathology such as cancer and cardiovascular diseases [4]. Soy, almond and coconut milk are among the most consumed vegetable milks [4]. Soymilk, without lactose and cholesterol and rich in protein and other important compounds, can be useful to prevent cardiovascular disease [3,5]; the coagulation of soy protein can be promoted by adding starter cultures, which allow us to obtain yogurt-like product [6]. Moreover, the products obtained from coconut milk are as follows: it is lactose free, cholesterol free and contains a low amount of saturated fatty acids; furthermore, coconut milk showed greater antioxidant properties compared with goat and cow’s milk [7].

Recently, there is also an increase in the consumption of non-dairy products derived from plants [8] for its peculiar characteristic compared with milk of animal origin. For example, it has been demonstrated by Jambazian et al. that the almond milk consumption led to a reduction of cholesterol blood levels and, at the same time, an increase of α-tocopherol (vitamin E), a strong antioxidant compound [9].

Yogurt is one of the main milk-derived products; it is obtained from milk fermentation by starter cultures such as Lactobacillus bulgaricus, Streptococcus thermophilus [10], and lactic acid bacteria [11], which induce carbohydrates’ fermentation [12]. Thanks to the possibility to prepare different types of yogurt, such as low-fat yogurt [13] and lactose-free yogurt [14], that meet the health needs of all types of consumer, yogurt is one of the most globally required products. Furthermore, yogurt is considered a healthy food due to its probiotics content and for the possibility to add important elements for to human health, for example fibers [15,16]. Yogurt obtained precisely from vegetable milk has become very popular among consumers. Unfortunately, yogurt made from plant-based milk showed problems with texture and stability. Different hydrocolloids are used to solve these problems [17].

Different types of thickeners, such as pectin or xantan gum, are added to milk-derived products in order to improve their stability and to modify their rheological parameters, for example, their viscosity [18]. Carob (Ceratonia siliqua L.) is a typical leguminous tree of the Mediterranean area and carob seed flour, rich in dietary fibers [19], is produced from the seeds of the fruit. Due to its content of gum, carob seed flour is used in the food industry as a thickener and stabilizing agent [20]. Recently, there has been an increase in the interest in the use of carob seed flour in food field due to also its nutritional and antioxidant properties; in particular, antioxidant properties can be attributed to the polyphenols and lignans contents [21].

In a recent experimental work, Fidan and collaborators demonstrated that carob seeds possess important nutritional and functional properties and considered the use of carob seed in food industry as a “value-added” component in the production of functional foods [22]. Caroubin is a protein contained in carob seed flour. This protein possesses properties similar to gluten, but caroubin is characterized by a greater hydrophilicity [23]. Experimental studies have shown that caroubin possesses viscoelastic properties [21,23]. In fact, hydrated caroubin forms a viscoelastic structure [24] that will affect the final rheological properties of the product [25,26].

Carob flour was used to improve the nutritional, rheological and chemico-physical characteristics of gluten-free doughs [26,27,28]. In particular, carob flour is considered a pseudocereal characterized by a high content of dietary fiber, micronutrients and protein, and its content is able to enhance the nutritional value of the gluten-free products [27]. Carob flour is used in the food industry for the preparation of several products, as beverages, bakery products, noodles and more, thanks to its ability to enhance viscosity already jet at low concentrations and to stabilize the resulting product [29]. Moreover, Romàn et al. demonstrated that the incorporation of carob flour in confectionary doughs was useful to increase the solid elastic-like behavior of products as cookie doughs, highlighting a strong interaction between carob flour and their formula ingredients [30].

The aim of this research was to use carob seed flour as a functional gluten-free thickener to obtain a good yogurt-like structure in terms of texture and palatability using three vegetables milks: almond milk, soy milk and coconut milk. The change of the rheological parameters of selected vegetable milks during the fermentation process mediated by starter culture of Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus were monitored.

2. Materials and Methods

Carob seed flour (Di Sano S.r.l., Milano, Italy), soy milk (3.3 g/100 mL protein; 1.8 g/100 mL fat; 0.3 g/100 mL carbohydrate) (Alpro, Wevelgem, Belgium), almond milk (0.5 g/100 mL protein; 1.1 g/100 mL fat; 3.0 g/100 mL carbohydrate) (Alpro, Wevelgem, Belgium) and coconut milk (0.1 g/100 mL protein; 0.9 g/100 mL fat; 2.7 g/100 mL carbohydrate) (Alpro, Wevelgem, Belgium) were purchased from a local market. Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus (FD-DVS YC-380-Yo-Flex, Chr. Hansen) were used as a starter culture following the manufacturer’s instruction.

2.1. Yogurt Production

Yogurt samples were produced as follows: a total volume of 100 mL of milk was distributed in five different beakers (20 mL of milk in each beaker). These beakers were heated in a water bath at 80 °C for 30 min. Then, carob seed flour was added to the milk at different percentages w/w: 0.25%, 0.5%, 0.75%, 1%; one milk sample was left as a control (without carob seed flour). All the samples were left in the water bath at 80 °C for 1 h and then they were vortex-mixed at 700 rpm (Vortex, VELP Scientifica, Usmate (MB), Italy) for 5 min to facilitate the solubilization of carob seed flour inside the milk. When the flour solubilization was completed, the samples were quickly cooled down to 45 °C in a water bath and the starter coulter was added in each of the five samples at the concentration of 0.2 U/L (units per liter) according to the manufacturer’s indication. Finally, each sample was put in a cylindrical glass vial (20 mm diameter) and placed in the chambers of the Rheolaser MasterTM (Formulaction, I’Union, Toulouse, France) previously set to the temperature of 45 °C in order to follow all the fermentation process.

At the end of the fermentation process, the samples were homogenized by using an Ultra-Turrax T 25 equipped with an S25 N-8G homogenizing probe (IKA-WERKE) at 25,000 rpm for 3 min and then they were stored at 4 °C before any other analysis. By using this technique, the samples were prepared in three replicates.

2.2. Microrheological Analysis

The microrheological parameters of yogurt-like samples were evaluated by using Rheolaser MasterTM (Formulaction, I’Union, Toulouse, France). The measuring principle of this instrument is multi-speckle diffusing wave spectroscopy (MS-DWS). The Brownian motion of the particles is measured as the particles’ mean squared displacement (MSD) versus time. The MSD is strictly dependent on the viscoelastic properties of the sample. Data were analyzed by RheoSoft Master® 1.4.0.0 software. Starting from an MSD curve, it was possible to obtain viscoelastic properties of the sample expressed as solid–liquid balance (SLB), macroscopic viscosity index (MVI) and elasticity index (EI). Rheolaser MasterTM instrument allowed for the analysis of microrheological parameters without applying any kind of stress on the studied sample. Immediately after adding the starter culture, the samples were vortexed and were put in the chambers of the instrument that was set at 45 °C. The microrheological analyses were performed for 6 h to follow the fermentation process. The starter culture caused milk gelation. The gel point as a function of the time and at a constant temperature (45 °C) was calculated by using the time cure superposition method [31,32]. At the end of the fermentation process, the samples were stored at 4 °C and Rheolaser MasterTM measurements were performed on the yogurt samples after 24 h, 48 h and 5 days in order to understand if storage conditions can modify microrheological parameters.

2.3. Dynamic Rheological Characterization of Yogurt-Like Samples

Kinexus Pro+ rotational rheometer (Malvern Instruments Ltd. Worchestershire, UK), equipped with cone-plate geometries (40 mm diameter; 2° angle), was used to evaluate the rheological behavior of the samples when they are somehow solicited. In particular, a dynamic oscillatory test was applied to measure the viscoelastic properties, with a frequency sweep ranging 0.1–10 Hz at controlled stress (1 Pa) [33]. The dynamic rheological properties, in terms of complex viscosity (ɳ*) and storage modulus (G′), were evaluated at 0, 1, 2 and 5 days of storage. All runs were carried out at 25.00 ± 0.01 °C. A fixed gap between the geometries was pre-set to 1 mm and the excess sample was removed.

2.4. pH Values Evaluation

The pH values of three different types of milk and of the yogurt-like samples were evaluated by using a digital pH instrument (Seven Compact Duo meter, Mettler Toledo, Columbus, OH, USA).

2.5. Statistical Analysis

Statistical analysis of all results was carried out by using one-way ANOVA. A p value < 0.001 was considered statistically significant. All experiments were repeated three times.

3. Results and Discussion

3.1. Microrheological Parameters During Fermentation Process

The exact gel-point time of each sample was measured using time-cure superposition (TCS) method; gel point values are reported in Table 1. As can be seen from the obtained results, there is no correlation between carob seed flour (CSF) amount and gel point time; so, we can suppose that the flour amount does not affect the gelation time. This trend can be observed for all three types of milk.

Table 1.

Gel point time for different milk samples in function of carob seed flour (CSF).

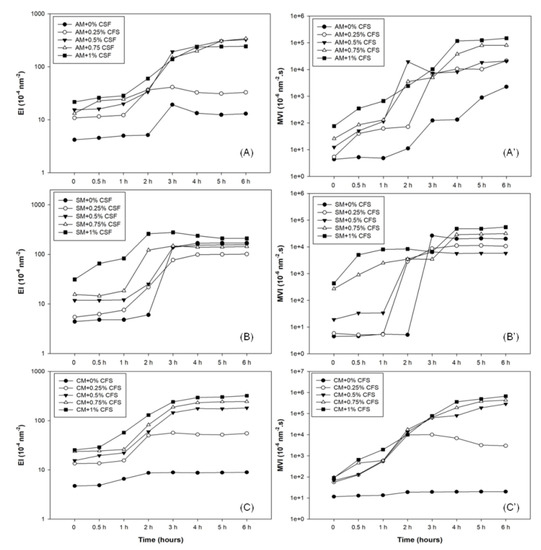

As can be seen in the graph (Figure 1), MVI and EI values during the fermentation process increased until they reach a plateau; both the MVI and EI values are higher as the amount of carob seed flour was higher; in particular, after gel point time, these values increase for all the samples, indicating an increase in the macroscopic viscosity index and elastic properties of the samples. These results probably are due to the fact that, after reaching the gel point, gel-like structure are formed.

Figure 1.

Elasticity index (EI) and macroscopic viscosity index (MVI) values for almond milk (A,A’), soy milk (B,B’) and coconut milk (C,C’) during the fermentation process. The results are the mean of three experiments.

Solid–Liquid Balance (SLB) is a parameter that allows for determining if the sample has solid-like or liquid-like behavior; it is directly proportional to the viscoelasticity of the sample. For all the studied samples, before fermentation, SLB values between 0.5 and 1, indicating that the liquid behavior was predominant, while, after the fermentation process, these values decreased to between 0 and 0.5, indicating a solid-like behavior [34] of the samples and thus confirming the formation of yogurt-like products. In Table 2, SLB values before and after fermentation are reported. All samples show a SLB value lower than 0.5 after fermentation, confirming that the protocol used in this study is suitable for obtaining the yogurt-like structures. Moreover, these finding confirmed again that the presence of different carob seed flour concentrations did not affect the fermentation process.

Table 2.

Solid–liquid balance (SLB) before and after fermentation process. The results are the mean of three experiments ± standard deviation. (* p value < 0.05; ** p value < 0.001).

After the end of the fermentation process, the samples were stored at 4 °C and other microrheological parameters were measured with Rheolaser MasterTM after 24 h, 48 h and 5 days of storage. The macroscopic viscosity index is an important parameter to evaluate the viscosity of the studied sample, while elasticity index values give information about the sample recovery after a solicitation.

As can be seen from the results, both MVI (see Table 3) and EI (see Table 4) values are maintained during the storage at 4 °C after 5 days, for almost all samples with the highest percentages of carob seed flour, thus demonstrating that the obtained samples were stable.

Table 3.

MVI (nm−2.s) values obtained at the end of fermentation and after 24 h, 48 h and 5 days of storage at 4 °C. The results are the mean of three experiments ± standard deviation. (* p < 0.05; ** p < 0.001 of milk-based yogurt-like structure with respect to the same storage time of samples without CSF).

Table 4.

EI (nm−2) values obtained at the end of fermentation and after 24h, 48h and 5 days of storage at 4 °C. The results are the mean of three experiments ± standard deviation. (* p < 0.05; ** p < 0.001 of milk-based yogurt-like structure with respect to the same storage time of samples without CSF).

Furthermore, as already mentioned, MVI increased as the amount of the carob seed flour increased; therefore, a higher content of carob seed flour allows one to obtain yogurt-like products with more suitable macroscopic viscosity values to be consumed by man. These results are in agreement with a recent work of Turfani and collaborators in which carob flour added to wheat bread dough caused an increase in the viscosity, which was probably caused by the water absorption of the caroubin, which led to the formation of a gel structure [21].

It is interesting to notice that the MVI (Table 3) and EI values (Table 4) of almond milk without carob seed flour after 5 days of storage are not shown because this sample has lost its characteristics undergoing a phase separation. On the other hand, almond-milk-based yogurt-like products with 0.25%, 0.5%, 0.75% and 1% (% w/w) of carob seed flour showed very similar MVI values after 24 h, 48 h and 5 days storage, thus demonstrating that carob seed flour at these percentages increased the stability of the samples. Probably, the carob seed flour induces the formation of a three-dimensional network able to support the yogurt structures and prevent destabilization phenomena such as sedimentation, coalescence or phase separation. In the case of soy-milk-derived yogurt-like structure, without and with 0.25% carob seed flour, MVI values decreased during storage time, thus demonstrating that the samples without and with the lowest concentration of carob seed flour (0.25% w/w) were not stable. On the contrary, MVI and EI values increased after 5 days of storage for the samples containing 0.5%, 0.75%, 1% of carob seed flour; these amounts were able to increase the MVI of the samples during storage time.

For coconut-milk-based yogurt-like products, the obtained results are similar to those obtained for almond-milk-based yogurt-like products.

In Table 4, EI values are reported. In accordance with previously reported findings in a research work of Tsatsaragkou and collaborators, the addition of carob seed flour increased the elastic properties of the sample [35]. In fact, the obtained results suggest that EI values increased as the amount of carob seed flour increased, independently of used vegetal milk. Probably, as previously hypothesized for the MVI values, the increase of the EI values was also due to the viscoelastic properties possessed by caroubins [21]. The carob seed flour-free samples showed the lowest EI values, thus confirming, once again, that the elastic properties of the samples were to be attributed to the presence of caroubins.

Almond-milk-based and coconut-milk-based yogurt-like structures showed the same behavior and their EI values were maintained during storage condition; for almond milk without carob seed flour, EI values were not reported, since, as already mentioned, we had a phase separation after 5 days of storage.

In case of soy milk without and containing 0.25% of carob seed flour, a reduction in EI values over time was observed. On the contrary, for samples containing 0.5%, 0.75%, 1% of 0.25%, EI values were almost constant during storage time. The higher concentrations of carob seed flour allowed us to obtain products with higher elasticity index, for all three types of milk.

According to the results obtained, it is possible to establish that the addition of carob flour allows one to obtain more compact and stable products: the firmness of the samples increases at the increasing of the amount of carob flour [29]. In a recent work by Moreira and collaborators, carob flour was used to prepare yogurt with low lactose level [36].

Based on these results, it is possible to conclude that the presence of carob seed flour is important not only to stabilize the yogurt-like structures but also to increase the elastic properties and the macroscopic viscosity index of vegetable-milk-based yogurt-like products, making them more acceptable to the consumers in terms of consistency, viscosity and stability during storage conditions.

Finally, as recently demonstrated by Moreira and collaborators, the addition of carob flour to yogurt allowed them to obtain a product highly appreciated by consumers, especially for the sweetening power of carob flour and for its taste similar to cocoa [36].

The addition of carob seed flour allows one not only to obtain yogurt-like products rich in fibers [27] but also with a taste similar to chocolate.

3.2. Dynamic Rheological Study of Yogurt Samples

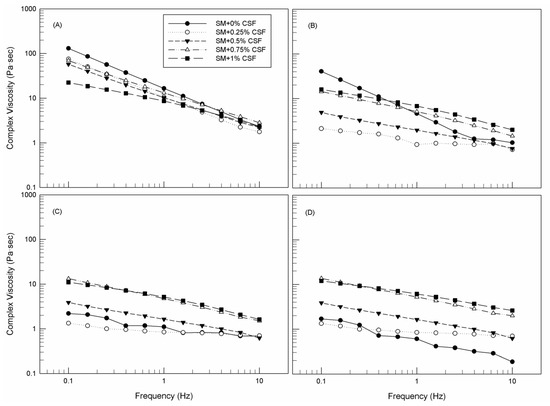

The microrheological characterization reported above allowed us to effectively analyze the rheological behavior of the samples at rest and the phase transition from milk to a yogurt-like structure, without altering the analyzed samples. Unfortunately, this particular method is not suitable to describe the rheological behavior of the samples when they are manipulated. Samples such as yogurt-like structures are handled during storage, transport and consumption by the consumer, and these manipulations could modify the structure and the texture of samples, risking to be no longer pleasant. For this reason, we chose to associate the microrheological characterization with dynamic rheological studies. Thanks to Kinexus Pro+ rotational rheometer, the rheological parameters (G′ and complex viscosity) of yogurt-like structures made with different vegetal milk and different amount of carob seed flour were obtained in function of frequency and storage time. In general, the complex viscosity (ɳ*) corresponds to the total resistance of a sample to flow as a function of frequency [37] and we wanted to evaluate the effect of carob seed flour on the sample’s ability to resist or change following the induced oscillation.

Figure 2 shows the rheological results of the samples in terms of frequency dependence of the complex viscosity. Generally, the viscosity decreased as a function of an increasing frequency when the sample moved faster with applied force, and the reduction in viscosity was a consequence of a reduction in interactions between the components of sample [38]. Observing Figure 2, we can note that, independent of storage time, all samples prepared with soy milk and with or without carob seed flour respond to the applied force with a reduction in their viscosity, highlighting a pseudoplastic fluid nature, as already demonstrated by Mei et al. [39]. In our study, immediately after preparation (time 0 of storage), the viscosity of soy-milk-based yogurt-like structure sample prepared without any concentration of carob seed flour was characterized by a starting complex viscosity at low frequency higher than the sample containing 1% of carob seed flour; the slope of the sample without the carob seed flour curve is visibly the steepest of the other samples, indicating that the interactions between the components of this sample of soy-milk-based yogurt-like structure. During the following days of storage of soy-milk-based yogurt-like structures, carob seed flour seems to stabilize the network. In the presence of a high amount of carob seed flour (0.75% and SM + 1% respectively), the complex viscosity did not change when samples were subjected to a variation of oscillation frequency, thanks to the viscoelastic properties of caroubin [22]; on the contrary, the sample without carob seed flour underwent a considerable reduction in viscosity values during the rheological test, resulting in it being much more sensitive to rheological stresses. In fact, the difference in terms of complex viscosity data between SM + 0% and CSF samples became statistically significant after 2 days of storage and at high CSF concentration (p < 0.001). These findings can be due to the entrapment of soy milk proteins between the meshes of the network, and, when carob seed flour amount is increased, probably, the meshes become narrower, and complex viscosity is not affected by the applied stress.

Figure 2.

Complex viscosity (Pa·sec) versus frequency (Hz) for yogurt-like structures made of soy milk and increasing concentration of carob seed flour. The samples were analyzed at time 0 (A), 24 h (B), 48 h (C) and 5 (D) days of storage. The illustrated results were representative of three independent experiments.

Soy milk is characterized by high protein content (3.3 g/100 mL) in respect to almond (0.5 g/100 mL) and coconut (0.1 g/100 mL) milks. These data, reported on the label of the used vegetal products, could explain the different rheological behavior and the different complex viscosity values of almond- and coconut-derived yogurt-like structure samples, in respect to soy-derived products.

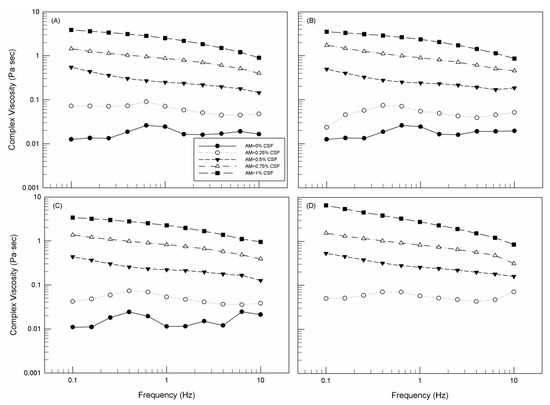

Figure 3 reported the rheological behavior of almond-milk-based yogurt-like structures as complex viscosity curves vs frequency. Observing the figure, we can see that the presence of high carob seed flour concentrations permitted the stabilization of yogurt-like structures. In fact, the complex viscosity of almond milk containing a decreasing amount of carob seed flour (1%, 0.75% and 0.5% carob seed flour) was not affected by storage time and it was maintained almost constant during 5 days. These findings are in agreement with Rheolaser Master™ results. Moreover, we can observe that the slope of the complex viscosity curves of almond-milk-based samples is much less marked when the frequency of oscillation is increased, in respect to the slope of soy-milk-based yogurt-like structures curves. These results showed that the samples responded to the applied stress by modifying its complex viscosity only slightly. We can affirm that carob seed flour does not lead to a marked increase in complex viscosity but it permits to obtain a three dimensional network more resistant to applied stress, compared to what happens with soy milk. In any case, the complex viscosity data of AM + 0% are significantly lower (p < 0.001) than the values obtained for samples prepared with increasing concentration of CSF.

Figure 3.

Complex viscosity (Pa·sec) versus frequency (Hz) for yogurt-like structures made of almond milk and increasing concentration of carob seed flour. The samples were analyzed at time 0 (A), 24 h (B), 48 h (C) and 5 (D) days of storage. The illustrated results were representative of three independent experiments.

In the case of almond-based yogurt-like structures, the importance of carob seed flour for obtaining a good product was confirmed after 5 days of storage. As we can see, in Figure 3D, the complex viscosity curve of the sample containing almond milk without carob seed flour is missing, because the sample after 5 days of storage showed an evident phase separation, as already mentioned, and, for this reason, the rheological characterization of this sample was not carried out. The absence of carob seed flour does not permit the construction of a solid three-dimensional network that stabilizes the yogurt-like structures.

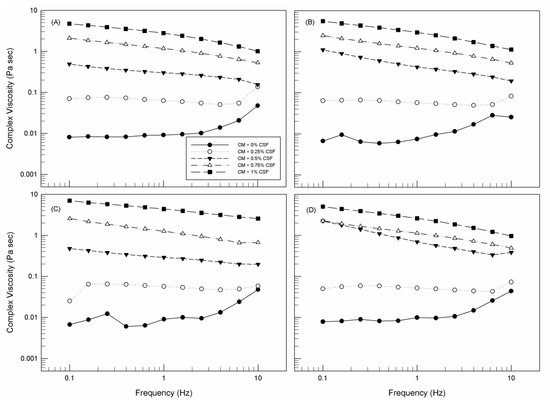

The rheological characterization of coconut-based yogurt-like structures obtained using increasing carob seed flour concentrations gave similar results to those of the almond-based samples. In fact, the starting complex viscosity of all coconut-milk-based samples was near to the starting complex viscosity values of almond-milk-based samples. Moreover, their rheological behavior highlights a slight dependence of complex viscosity on frequency variation; in fact, we can see in Figure 4 that the slope of complex viscosity curves is reduced when compared to the complex viscosity curves of the soy-milk-based samples. Moreover, in the case of coconut-milk-based samples, the complex viscosity data obtained for CM + 0% CSF are statistically significant with respect to the samples prepared with CSF (p < 0.001), independently of time storage and CSF concentration. We supposed that the similarity of results given by almond-milk- and coconut-milk-based yogurt-like structures was due to the similar protein content of both vegetal milks.

Figure 4.

Complex viscosity (Pa·sec) versus frequency (Hz) for yogurt-like structures made of coconut milk and increasing concentration of carob seed flour. The samples were analyzed at time 0 (A), 24 h (B), 48 h (C) and 5 (D) days of storage. The illustrated results were representative of three independent experiments.

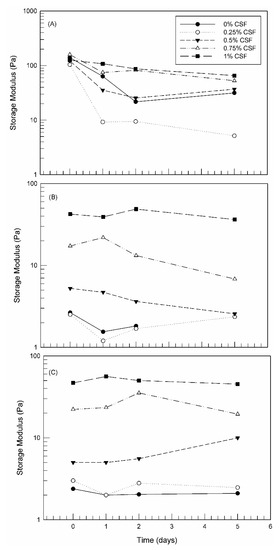

Changes in G′ values (storage modulus, Pa) of different vegetal-milk-based yogurt-like structures during storage for a period of 5 days are reported in Figure 5. G′ is a rheological parameter that represents the elastic behavior of the sample. It corresponds to a measure of deformation energy stored in the sample during shear process [34,40].

Figure 5.

Changes in the storage modulus of yogurt-like structure samples composed by soy milk (A), almond milk (B) and coconut milk (C) (at frequency of 10 Hz) with storage time. The illustrated results were representative of three independent experiments.

Once again, we have shown how carob seed flour is able to stabilize the obtained yogurt-like structures during storage time. This effect is particularly evident in Figure 5A, which reported G′ values of soy-milk-based yogurt-like structures at a frequency of 10 Hz in the function of storage time. We can see that, in the absence or presence of low carob seed flour concentrations, a reduction in G′ values occurs during the time, while, for soy milk samples containing 0.75% and 1% of carob seed flour, the elastic behavior is maintained for 5 days of storage.

The stability of yogurt-like structures induced by carob seed flour was also evident for almond milk- and coconut-milk-based samples. As demonstrated by complex viscosity curves versus frequency, the solid behavior of samples and the strength of the three-dimensional network seem to be dependent on carob seed flour concentrations. The difference in G′ values of almond milk and coconut milk without and with increasing amount of carob seed flour is reported in Figure 5B,C, respectively.

The results reported in Figure 5 confirmed that carob seed flour is a gluten-free thickener, useful to obtain a stable vegetable-milk-based yogurt-like-structure product. Moreover, these rheological findings confirm that the addition of gelling agents has a significant impact on the rheological properties of yogurt-like structures and on the maintenance of their appreciable texture characteristics over the storage time [41].

4. pH Results

In Table 5, we reported the results of the obtained yogurt-like structures compared with that of raw vegetal milk from which they were prepared. As previously obtained by Yaakob and collaborators, the pH values of yogurt-like product obtained from the coconut milk range are around 5 [42], while the pH values of yogurt-like product obtained from almond milk are around 4 (between 4.43 and 4.84) [43]. Moreover, for soy milk yogurt-like products, pH values are around 4 [44]. As can be seen from the values shown in the table below, the values of the yoghurt-like products obtained from the fermentation of milk are significantly lower than the pH of the milk from which they derive (p < 0.001); this happens because the organic acids produced from carbohydrate metabolism during fermentation process cause a reduction in the pH values [45]. On the contrary, yogurt-like structures containing CSF are characterized by pH values not statistically significant compared to CSF unloaded samples. These results confirm that carob seed flour did not prevent the fermentation or the formation of yogurt-like structures. In fact, the presence of the thickener did not interfere with the reduction in pH values, that is a symptom of occurred fermentation.

Table 5.

pH measurements results. The values are the mean of three experiments ± standard deviation.

5. Conclusions

In this experimental work, carob seed flour, a gluten-free flour, was used at different amounts in order to obtain a yogurt-like structure from almond milk, coconut milk and soy milk. The obtained products not only have the advantages derived from the use of vegetable milk but also the advantages derived from the use of carob seed flour, which acts as a thickener. Moreover, carob seed flour allows one to obtain products rich in all the nutritional properties possessed by the flour itself. In fact, carob seed flour represents a good thickener, a source of antioxidant molecules and fibers. The yogurt-like structures obtained and studied in this research work were found to be stabilized by the addition of carob seed flour. In particular, this kind of thickener permits one to maintain the rheological characteristics and the viscosity of yogurt-like structures up to 5 days of storage, both in a state of rest and following stress. The samples made up by vegetal milk, such as milk derived from soy, almond or coconut, will win the favor of the consumer with celiac diseases and people who want to follow a lactose-free, cholesterol-free, and vegetal-based diet. The use of carob seed flour, in addition to improving the technological and nutritional characteristics, could also improve the taste of the products obtained thanks to its sweetening power. Finally, further experiments could be performed to evaluate the sensory characteristics of the obtained samples and to prepare a new yogurt-like product using other types of vegetable milk.

Author Contributions

Methodology, M.I.; investigation, F.F. and M.C.C.; writing—original draft preparation, F.F. and M.C.C.; writing—review and editing, A.M.; supervision, D.P.; project administration, D.P. All authors have read and agreed to the published version of the manuscript.

Funding

The research activity of Maria Chiara Cristiano was supported by the European Commission, FESR FSE 2014-2020 and the final sponsorship of Calabria Region.

Acknowledgments

The authors are very grateful to Betty P. Udongo for her revision of the language of this manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Caio, G.; Volta, U.; Sapone, A.; Leffler, D.A.; De Giorgio, R.; Catassi, C.; Fasano, A. Celiac disease: A comprehensive current review. BMC Med. 2019, 17, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Kahleova, H.; Levin, S.; Barnard, N. Cardio-metabolic benefits of plant-based diets. Nutrients 2017, 9, 848. [Google Scholar] [CrossRef] [PubMed]

- Kahleova, H.; Katz, D.L. Vegetarian Dietary Patterns in the Prevention and Treatment of Disease. Front. Nutr. 2020, 7, 92. [Google Scholar] [CrossRef] [PubMed]

- Bernat, N.; Cháfer, M.; Chiralt, A.; González-Martínez, C. Vegetable milks and their fermented derivative products. Int. J. Food Stud. 2014, 3. [Google Scholar] [CrossRef]

- Sirtori, C.R.; Lovati, M.R. Soy proteins and cardiovascular disease. Curr. Atheroscler. Rep. 2001, 3, 47–53. [Google Scholar] [CrossRef]

- Rui, X.; Zhang, Q.; Huang, J.; Li, W.; Chen, X.; Jiang, M.; Dong, M. Does lactic fermentation influence soy yogurt protein digestibility: A comparative study between soymilk and soy yogurt at different pH. J. Sci. Food Agric. 2019, 99, 861–867. [Google Scholar] [CrossRef]

- Alyaqoubi, S.; Abdullah, A.; Samudi, M.; Abdullah, N.; Addai, Z.R.; Musa, K.H. Study of antioxidant activity and physicochemical properties of coconut milk (Pati santan) in Malaysia. J. Chem. Pharm. Res. 2015, 7, 967–9736. [Google Scholar]

- Ellis, D.; Lieb, J. Hyperoxaluria and genitourinary disorders in children ingesting almond milk products. J. Pediatr. 2015, 167, 1155–1158. [Google Scholar] [CrossRef]

- Jambazian, P.R.; Haddad, E.; Rajaram, S.; Tanzman, J.; Sabaté, J. Almonds in the diet simultaneously improve plasma α-tocopherol concentrations and reduce plasma lipids. J. Am. Diet. Assoc. 2005, 105, 449–454. [Google Scholar] [CrossRef]

- Yadav, A.; Jaiswal, P.; Jaiswal, M.; Kumar, N.; Sharma, R.; Raghuwanshi, S.; Prasad, G.B.K.S.; Bisen, P.S. Concise Review: Importance of probiotics yogurt for human health improvement. IOSR J. Environ. Sci. Toxicol. Food Technol. 2015, 9, 25–30. [Google Scholar] [CrossRef]

- Somkuti, G.A.; Steinberg, D.H. Pediocin production in milk by Pediococcus acidilactici in co-culture with Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus. J. Ind. Microbiol. Biotechnol. 2010, 37, 65–69. [Google Scholar] [CrossRef] [PubMed]

- Donkor, O.N.; Henriksson, A.; Vasiljevic, T.; Shah, N.P. α-Galactosidase and proteolytic activities of selected probiotic and dairy cultures in fermented soymilk. Food Chem. 2007, 104, 10–20. [Google Scholar] [CrossRef]

- Nikitina, E.; Riyanto, R.A.; Vafina, A.; Yurtaeva, T.; Tsyganov, M.; Ezhkova, G. Effect of fermented modified potato starches to low-fat yogurt. J. Food Nut. Res. 2019, 7, 549–553. [Google Scholar] [CrossRef]

- Skryplonek, K.; Henriques, M.; Gomes, D.; Viegas, J.; Fonseca, C.; Pereira, C.; Dmytrów, I.; Mituniewicz-Małek, A. Characteristics of lactose-free frozen yogurt with κ-carrageenan and corn starch as stabilizers. J. Dairy Sci. 2019, 102, 7838–7848. [Google Scholar] [CrossRef] [PubMed]

- Hashim, I.B.; Khalil, A.H.; Afifi, H.S. Quality characteristics and consumer acceptance of yogurt fortified with date fiber. J. Dairy Sci. 2009, 92, 5403–5407. [Google Scholar] [CrossRef]

- Denkova, R.; Goranov, B.; Denkova, Z.; Teneva, D.; Kostov, G. Enhancing yogurt health benefits: Development of starters for dairy and non-dairy yogurt. In Functional Foods: Sources, Health Effects and Future Perspectives, 1st ed.; Nelson, N., Ed.; Nova Sciences Publishers: Hauppauge, NY, USA, 2017; Chapter 7. [Google Scholar]

- Grasso, N.; Alonso-Miravalles, L.; O’Mahony, J.A. Composition, physicochemical and sensorial properties of commercial plant-based yogurts. Foods 2020, 9, 252. [Google Scholar] [CrossRef]

- Matia-Merino, L.; Lau, K.; Dickinson, E. Effects of low-methoxyl amidated pectin and ionic calcium on rheology and microstructure of acid-induced sodium caseinate gels. Food Hydrocoll. 2004, 18, 271–281. [Google Scholar] [CrossRef]

- Durazzo, A.; Turfani, V.; Narducci, V.; Azzini, E.; Maiani, G.; Carcea, M. Nutritional characterisation and bioactive components of commercial carobs flours. Food Chem. 2014, 153, 109–113. [Google Scholar] [CrossRef]

- Petkova, N.; Petrova, I.; Ivanov, I.; Mihov, R.; Hadjikinova, R.; Ognyanov, M.; Nikolova, V. Nutritional and antioxidant potential of carob (Ceratonia siliqua) flour and evaluation of functional properties of its polysaccharide fraction. J. Pharm. Sci. Res. 2017, 9, 2189–2195. [Google Scholar]

- Turfani, V.; Narducci, V.; Durazzo, A.; Galli, V.; Carcea, M. Technological, nutritional and functional properties of wheat bread enriched with lentil or carob flours. LWT 2017, 78, 361–366. [Google Scholar] [CrossRef]

- Fidan, H.; Stankov, S.; Petkova, N.; Petkova, Z.; Iliev, A.; Stoyanova, M.; Ivanova, T.; Zhelyazkov, N.; Ibrahim, S.; Stoyanova, A.; et al. Evaluation of chemical composition, antioxidant potential and functional properties of carob (Ceratonia siliqua L.) seeds. J. Food Sci. Technol. 2020, 57, 2404–2413. [Google Scholar] [CrossRef] [PubMed]

- Smith, B.M.; Bean, S.R.; Schober, T.J.; Tilley, M.; Herald, T.J.; Aramouni, F. Composition and molecular weight distribution of carob germ protein fractions. J. Agric. Food Chem. 2010, 58, 7794–7800. [Google Scholar] [CrossRef] [PubMed]

- Feillet, P.; Roulland, T.M. Caroubin: A gluten-like protein isolated from carob bean germ. Cereal Chem. 1998, 75, 488–492. [Google Scholar] [CrossRef]

- Bengoechea, C.; Puppo, M.C.; Romero, A.; Cordobes, F.; Guerrero, A. Linear and non-linear viscoelasticity of emulsions containing carob protein as emulsifier. J. Food Eng. 2008, 87, 124–135. [Google Scholar] [CrossRef]

- Miñarro, B.; Albanell, E.; Aguilar, N.; Guamis, B.; Capellas, M. Effect of legume flours on baking characteristics of gluten-free bread. J. Cereal Sci. 2012, 56, 476–481. [Google Scholar] [CrossRef]

- Tsatsaragkou, K.; Gounaropoulos, G.; Mandala, I. Development of gluten free bread containing carob flour and resistant starch. LWT Food Sci. Technol. 2014, 58, 124–129. [Google Scholar] [CrossRef]

- Tsatsaragkou, K.; Kara, T.; Ritzoulis, C.; Mandala, I.; Rosell, C.M. Improving carob flour performance for making gluten-free breads by particle size fractionation and jet milling. Food Bioprocess Technol. 2017, 10, 831–841. [Google Scholar] [CrossRef]

- Benković, M.; Bosiljkov, T.; Semić, A.; Ježek, D.; Srečec, S. Influence of carob flour and carob bean gum on rheological properties of cocoa and carob pastry fillings. Foods 2019, 8, 66. [Google Scholar] [CrossRef]

- Román, L.; González, A.; Espina, T.; Gómez, M. Degree of roasting of carob flour affecting the properties of gluten-free cakes and cookies. J. Food Sci. Technol. 2017, 54, 2094–2103. [Google Scholar] [CrossRef]

- Ceniti, C.; Froiio, F.; Gagliardi, A.; Britti, D.; Paolino, D.; Costanzo, N. Observations on passive microrheology for monitoring the fermentation process in yoghurt. Int. Dairy J. 2020, 102, 104604. [Google Scholar] [CrossRef]

- Jiang, D.; Huang, J.; Shao, H.; Hu, X.; Song, L.; Zhang, Y. Characterization of bladder acellular matrix hydrogel with inherent bioactive factors. Mater. Sci. Eng. C 2017, 77, 184–189. [Google Scholar] [CrossRef] [PubMed]

- Cristiano, M.C.; Froiio, F.; Costanzo, N.; Poerio, A.; Lugli, M.; Fresta, M.; Britti, D.; Paolino, D. Effects of flour mean particle size, size distribution and water content on rheological properties of wheat flour doughs. Eur. Food Res. Technol. 2019, 245, 2053–2062. [Google Scholar] [CrossRef]

- Cristiano, M.C.; Froiio, F.; Mancuso, A.; De Gaetano, F.; Ventura, C.A.; Fresta, M.; Paolino, D. The Rheolaser Master™ and Kinexus Rotational Rheometer® to Evaluate the Influence of Topical Drug Delivery Systems on Rheological Features of Topical Poloxamer Gel. Molecules 2020, 25, 1979. [Google Scholar] [CrossRef] [PubMed]

- Tsatsaragkou, K.; Yiannopoulos, S.; Kontogiorgi, A.; Poulli, E.; Krokida, M.; Mandala, I. Effect of carob flour addition on the rheological properties of gluten-free breads. Food Bioprocess Technol. 2014, 7, 868–876. [Google Scholar] [CrossRef]

- Moreira, T.C.; da Silva, A.T.; Fagundes, C.; Ferreira, S.M.R.; Cândido, L.M.B.; Passos, M.; Krüger, C.C.H. Elaboration of yogurt with reduced level of lactose added of carob (Ceratonia siliqua L.). LWT Food Sci. Technol. 2017, 76, 326–329. [Google Scholar] [CrossRef]

- Larson, R.G. The Structure and Rheology of Complex Fluids; Oxford University Press: New York, NY, USA, 1999; Volume 150. [Google Scholar]

- Khali, U.; Haider, S.; Khan, M.S.; Haider, A.; Khan, R.; Alghyamah, A.A.; Almasry, W.A.; Bououdina, M. Synthesis of novel copper nanoparticles/ternary polymer blend nanocomposites and their structural, thermal and rheological properties and AC impedance. Polym. Int. 2017, 66, 1182–1189. [Google Scholar] [CrossRef]

- Mei, J.; Feng, F.; Li, Y. Effective of different homogeneous methods on physicochemical, textural and sensory characteristics of soybean (Glycine max L.) yogurt. CyTA-J. Food 2017, 15, 21–26. [Google Scholar] [CrossRef]

- Mason, T.G.; Gang, H.; Weitz, D.A. Rheology of complex fluids measured by dynamic light scattering. J. Mol. Struct. 1996, 383, 81–90. [Google Scholar] [CrossRef]

- Nazir, A.; Asghar, A.; Aslam Maan, A. Food Gels: Gelling Process and New Applications. In Advances in Food Rheology and Its Applications; Ahmed, J., Ed.; Woodhead Publishing: Duxford, UK, 2017; pp. 335–353. [Google Scholar] [CrossRef]

- Yaakob, H.; Ahmed, N.R.; Daud, S.K.; Abd Malek, R.; Rahman, R.A. Optimization of ingredient and processing levels for the production of coconut yogurt using response surface methodology. Food Sci. Biotechnol. 2012, 21, 933–940. [Google Scholar] [CrossRef]

- Bernat, N.; Cháfer, M.; Chiralt, A.; González-Martínez, C. Development of a non-dairy probiotic fermented product based on almond milk and inulin. Food Sci. Technol. Int. 2015, 21, 440–453. [Google Scholar] [CrossRef]

- Granata, L.A.; Morr, C.V. Improved acid, flavor and volatile compound production in a high protein and fiber soymilk yogurt-like product. J. Food Sci. 1996, 61, 331–336. [Google Scholar] [CrossRef]

- Widyastuti, Y.; Febrisiantosa, A. The role of lactic acid bacteria in milk fermentation. Food Nutr. Sci. 2014. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).