Bi-Level Optimization of the Energy Recovery System from Internal Combustion Engines of a Cruise Ship

Abstract

1. Introduction

- converting current engines into complex Combined Heat and Power (CHP) or Combined Cooling Heat and Power (CCHP) systems, characterized by extensive energy recovery, which can be carried out through various technological solutions, in particular through the integration of the main engines with bottom thermodynamic cycles: Organic Rankine Cycle (ORC) and/or Stirling (as described hereinafter), Rankine [12], Brayton [13], Brayton and Rankine [14], or Rankine and ORC [15].

2. Case Study and System Model

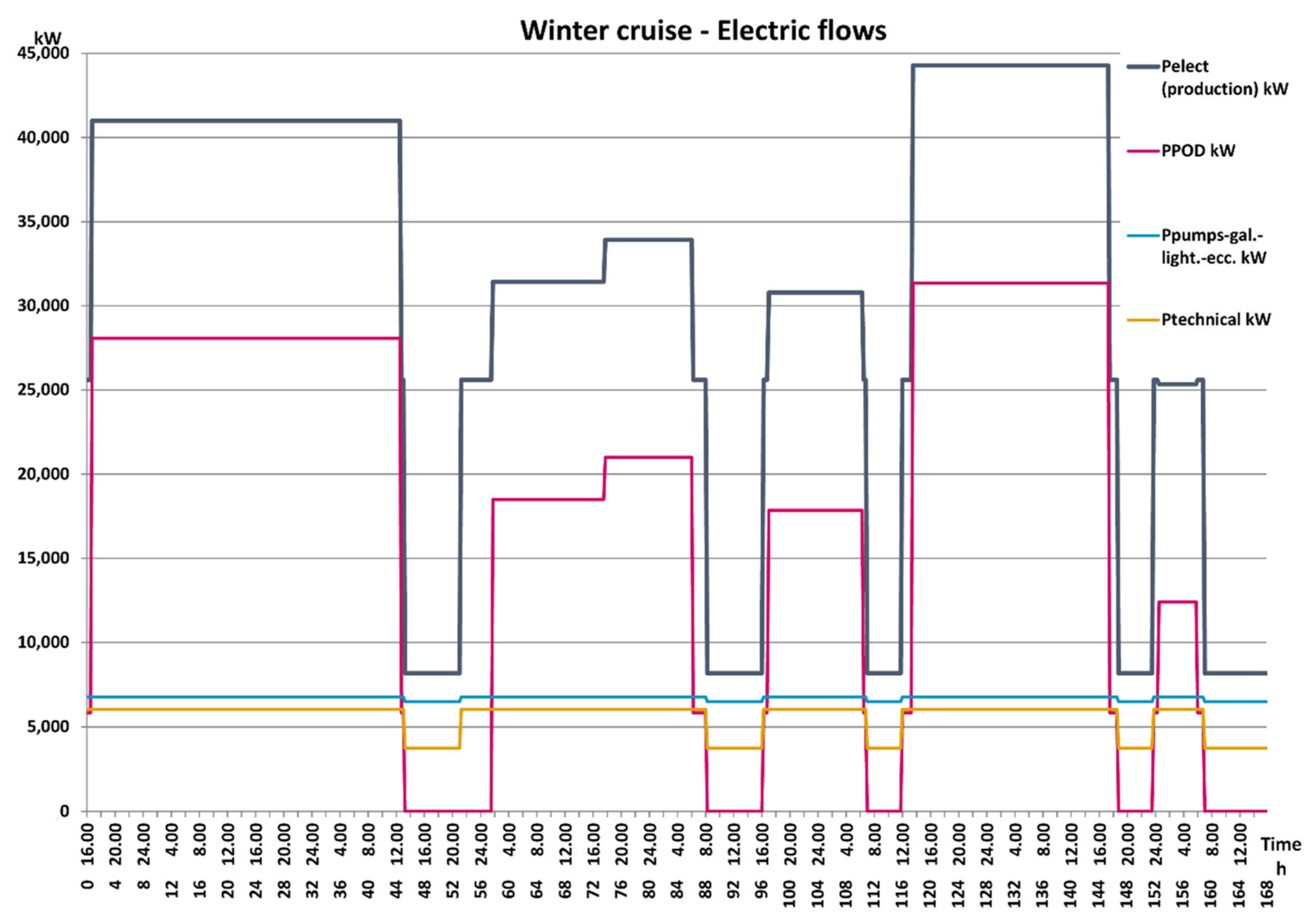

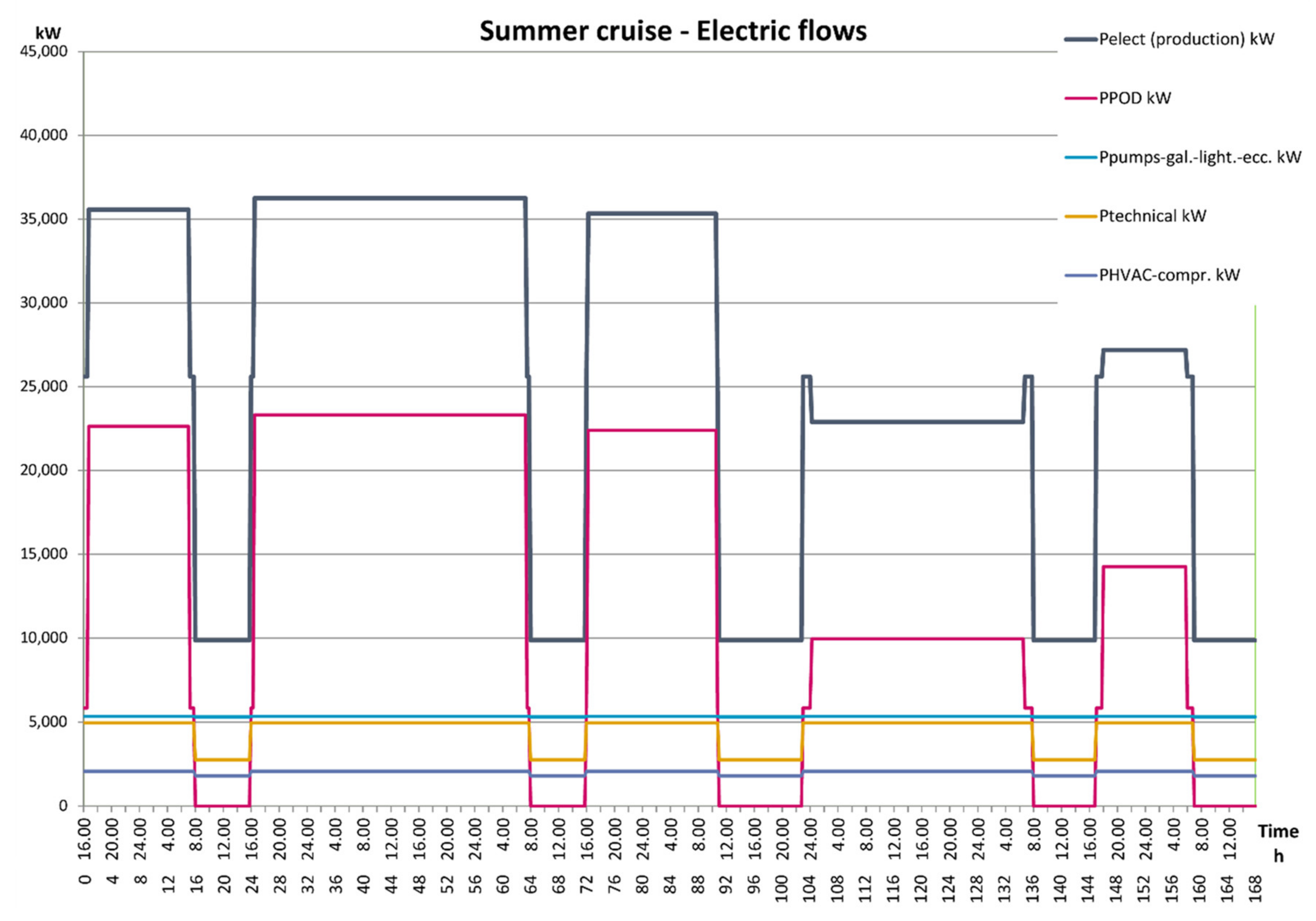

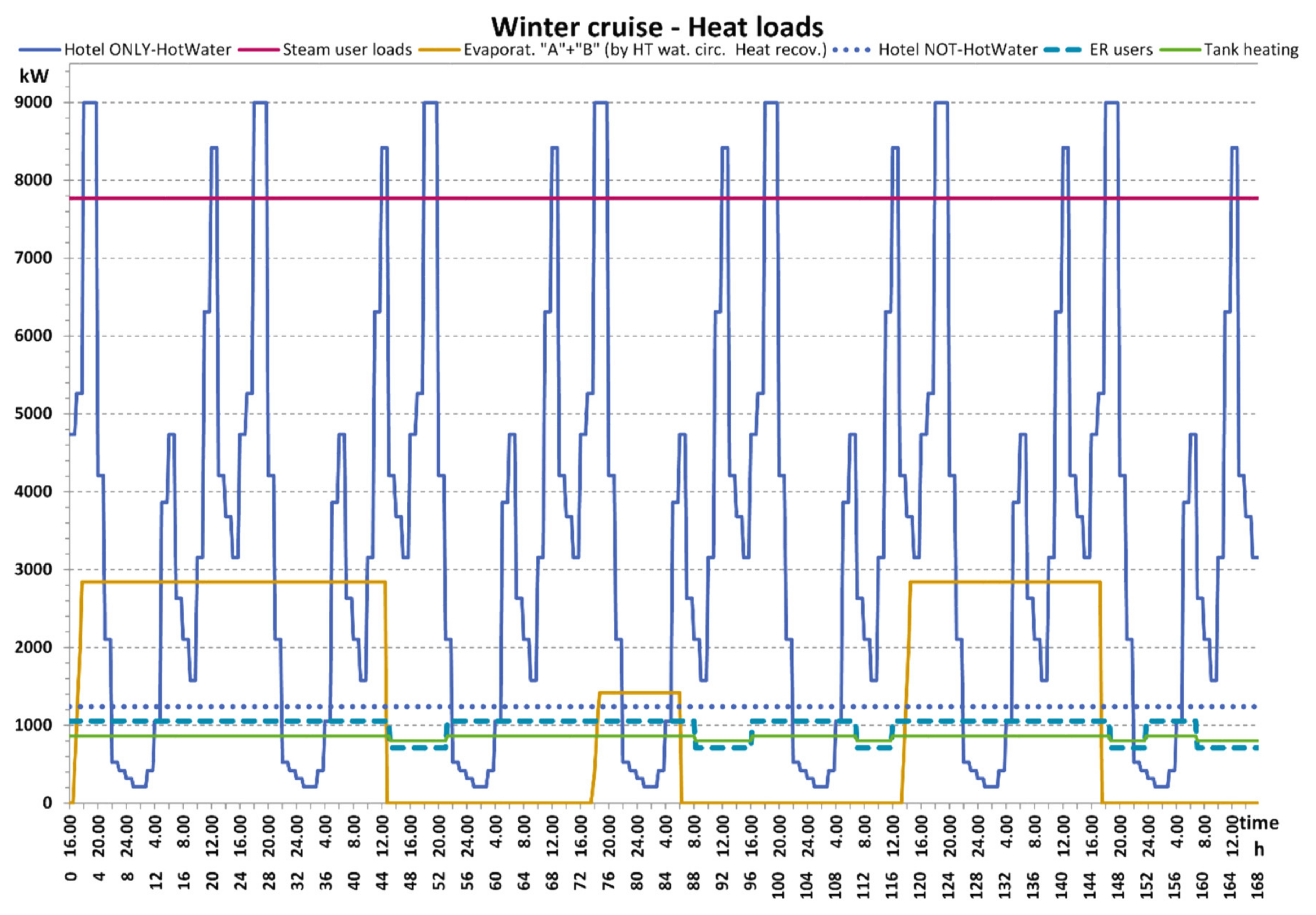

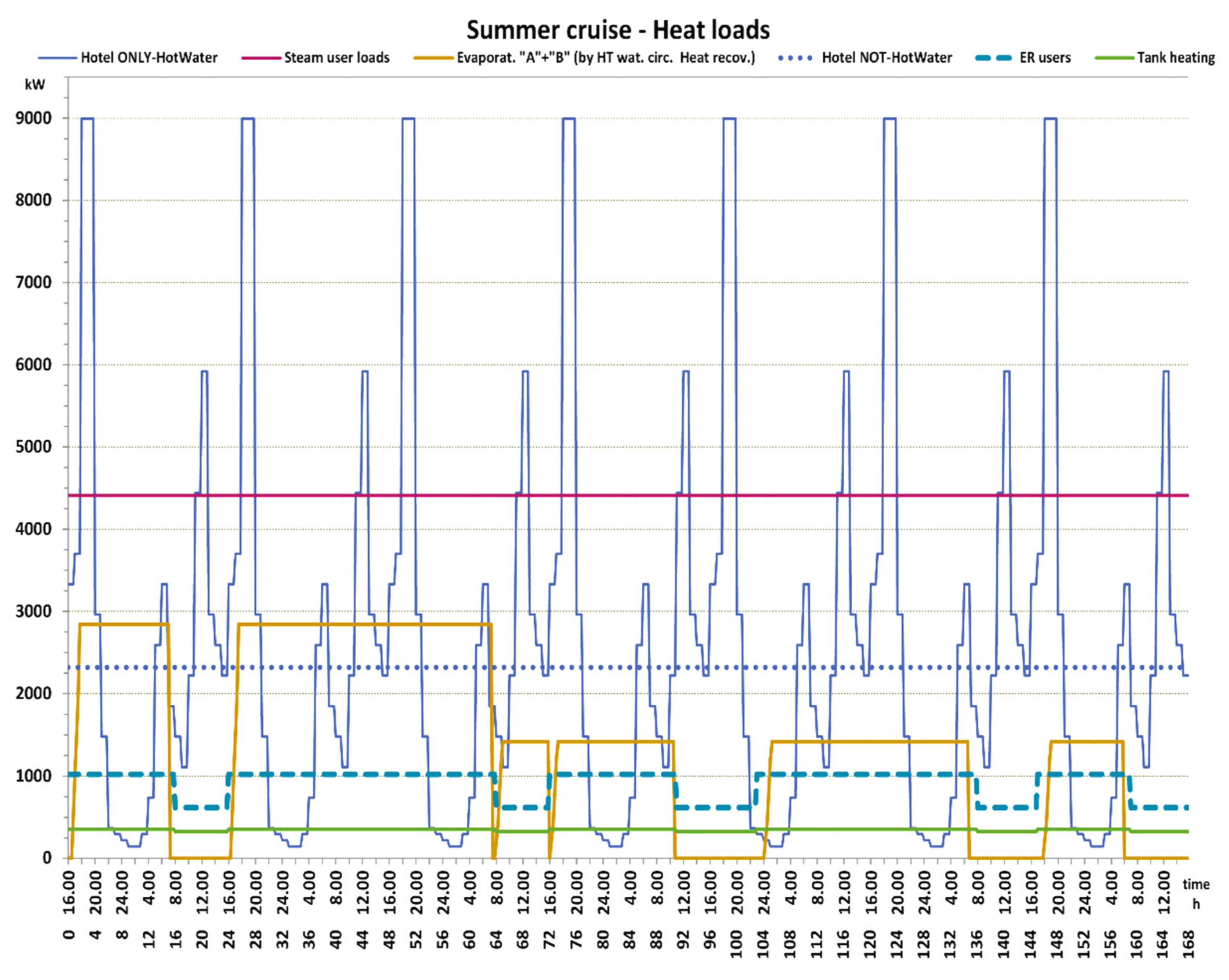

2.1. Thermal and Electrical Energy Demands during the Cruise

- PPOD—power for the pod propulsion system and for the maneuvering propellers;

- P technical—absorbed power for non-propulsive technical uses;

- P pumps—galley—lights, power absorbed for the hotel functions and for the relative systems, excluding that for air conditioning (HVAC);

- P HVAC, absorbed power for air conditioning (during the summer cruise only);

- Thermal request for air conditioning heating;

- Thermal request for galley users, excluding the galley hot water use;

- Hotel only—hot water, for sanitary use, at about 60 °C;

- Hotel not hot water, at about 90 °C (swimming pool heaters and laundry);

- ER users (thermal consumption in the engine rooms) at about 90 °C;

- Tank heating (thermal treatment of fuel, sludge, etc.) at about 50 °C;

- Evaporat. “A” + ”B” (thermal consumption of the evaporation desalinators for producing pure water to be used in engines type “A” and “B”).

- Electric power, RICEL,

- Heat as saturated steam at 10 bar and 180 °C, RICTER_St,

- Hot water at 60–90 °C, RICTER_HTW,

- Chilled water at 8 °C, RICOOL.

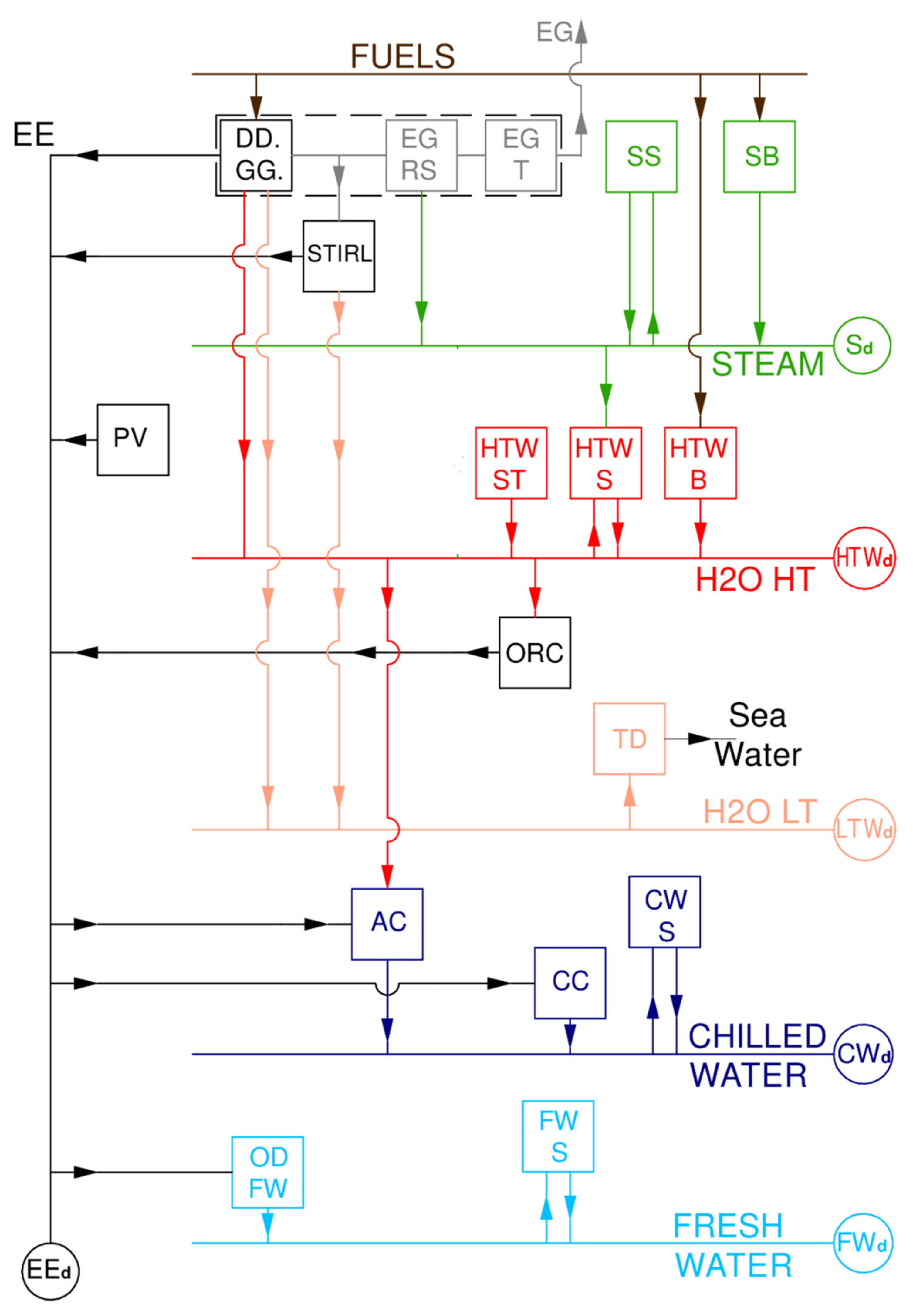

2.2. Model Super-Structure

- Exhaust gases (EG), which directly feed the Stirling engine and the recovery boilers (EGRS), without any connection with other on-board users.

- Electric power (EE) for propulsion, hotel services and all auxiliaries of the on-board energy system; it must meet the electrical energy demand (EEd).

- Steam (STEAM); it must meet the steam demand (Sd).

- Hot water at 85–90 °C (H2O HT); it must meet the hot water demand (HTWd).

- Hot water at about 50 °C (H2O LT); it must meet the low temperature water demand (LTWd), or must be dissipated.

- Chilled water at 8–10 °C (CHILLED WATER); it must meet the for chilled water demand (CWd).

- Fresh water; it must meet the demand for fresh water (FWd); the latter is considered constant for simplicity, regardless of the ship’s operating conditions, and its effect on the whole energy consumption of the ship is limited to the electric energy demand of the reverse osmosis desalinator.

- DD. GG. Main diesel engines. This block is modeled considering the actual individual ICE, allowing the definition of the optimal management of the engines within the solution of the overall system optimization problem. In the case study the block is made up of 5 ICE—2 units of 14,400 kWmecc/600 rpm each (12V) and 3 units of 9600 kWmecc/600 rpm (8L) [53]. This block contains also the required auxiliaries for the engine operation, such as the exhaust gas recovery system (EGRS) and the exhaust gas treatment unit (exhaust gas treatment—EGT).

- Stirl. Stirling units directly powered by the exhaust gases engine [54].

- SB. Steam Boiler. It integrates the heat recovery from the ICE if necessary.

- SS. Steam storage.

- HTW. Boilers, identified accordingly to 3 different types of feeding energy considered—liquid fuel (B), steam taken from the on-board steam carrier (S) and thermal solar panels (ST). The HTW S boilers also possibly has a thermal storage function, at a temperature of 90 °C.

- ORC. Organic Rankine cycle units for the electrical conversion of the heat recovered by the engines.

- TD. Thermal dissipater. It has to dissipate the excess thermal power in the H2O LT line into the seawater.

- AC. Absorption chillers. They can be powered by H2O HT line and, indirectly, also by way of the steam line.

- CC. Compression chillers traditionally present on board the ship, whose size is determined in relation with the introduction of the absorption chillers.

- CWS. Chilled water storage.

- ODFW. Reverse osmosis desalinator.

- FWS. Fresh water storage.

- PV. Photovoltaic solar panels, the overall surface of which is optimized.

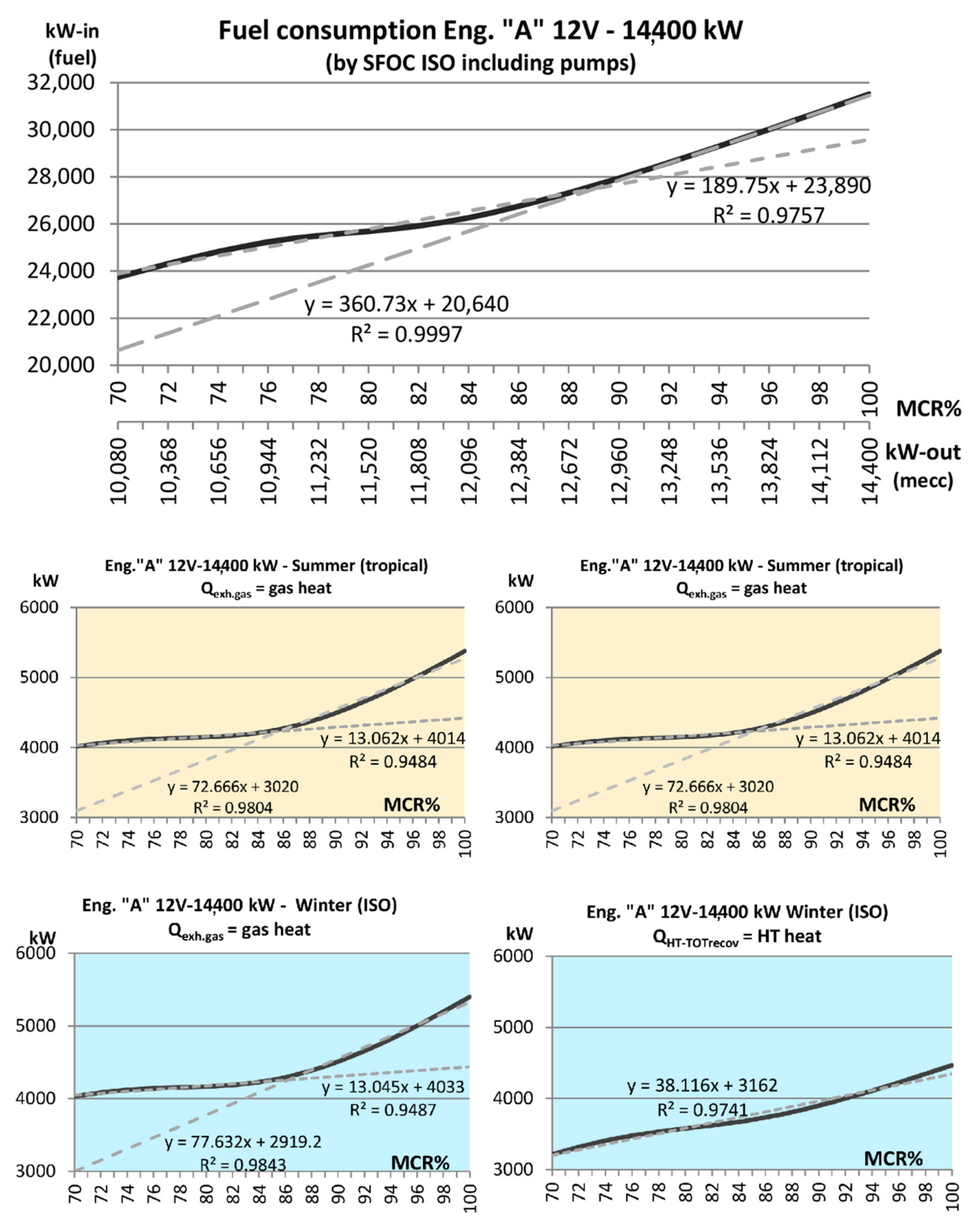

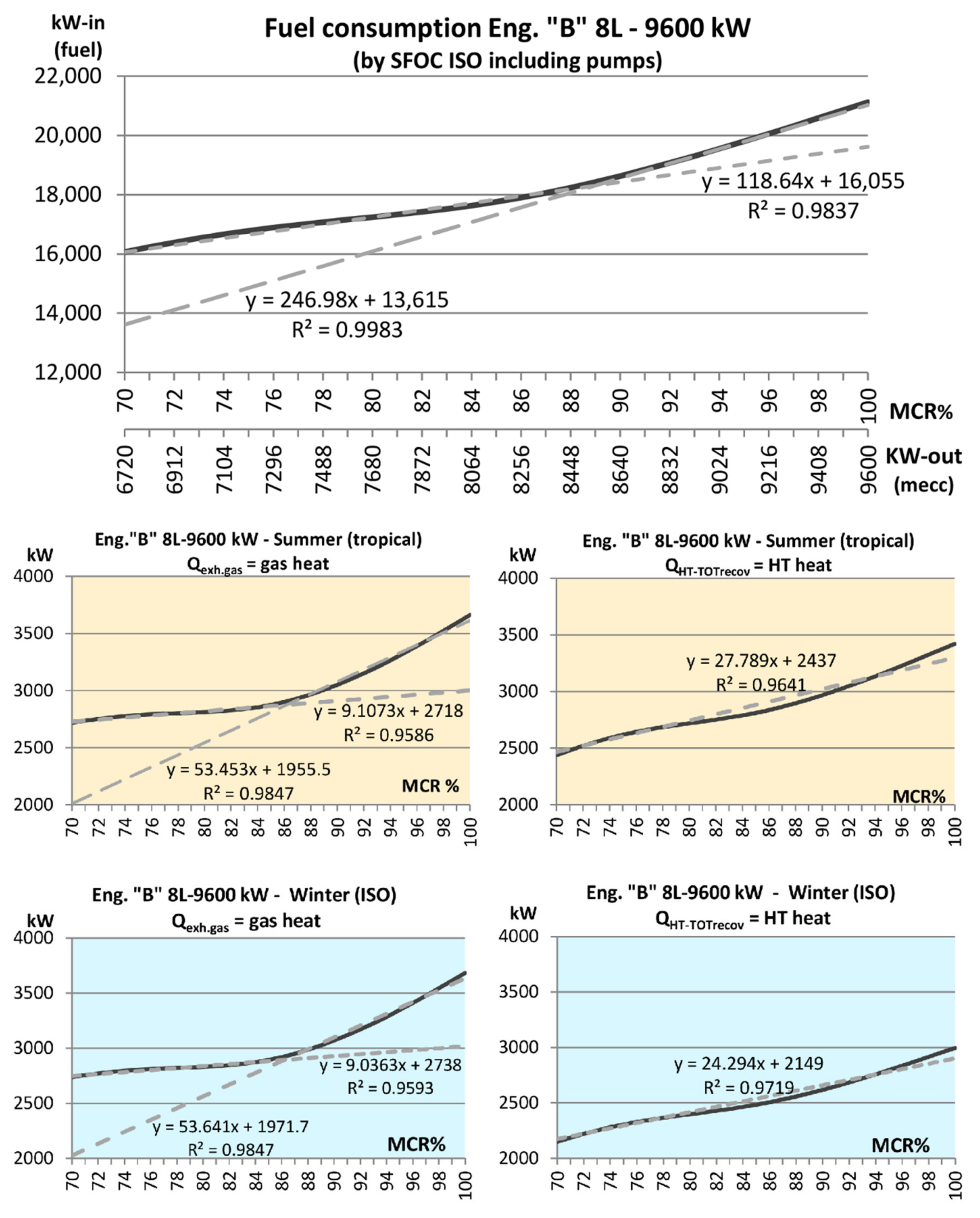

2.3. Linearized Model of the Components

- eta_orc = 7% in the summer cruise, considering an average cooling temperature of 30 °C,

- eta_orc = 10% in the winter cruise, considering an average cooling temperature of 15 °C.

- Pel_str (g,i,j), electrical power produced by each Stirling [kW];

- y_str (g,i,j), ON/OFF condition of each Stirling;

- X_str (j), existence of each Stirling;

- Pel_orc (g,i,j), electrical power produced by each ORC [kW];

- y_orc (g,i,j), ON/OFF condition of each ORC;

- X_orc (j), existence of each ORC.

- SB. Steam generator. It produces the integration heat when the heat recovery from the ICE is not enough. In the linearized model, a constant efficiency of approx. 70% is considered, accordingly to the average value indicated by the ship manufacturer [53].

- SS. Steam storage. Its possible presence and dimensions will be optimized according to the thermal requirements and the overall constraints of the system. Keeping in mind that all the storage will be characterized by a short operating cycle (few hours) the losses due to dispersion have been neglected, as an acceptable approximation.

- HTW. Boilers, divided according to 3 different types of input power considered: liquid fuel (B), on board steam (S) and solar thermal panels (ST). For the latter, it will be necessary to carefully check the definition of a penalty function relating to the dimensions associated with a system of this type. A constant efficiency of 70% for HTW B and 90% for HTW S will be used in the model, accordingly to the indications by the shipbuilder [53], while for the thermal solar panels, the data of a typical vacuum tube collector, like Sunwood SW15 by Sunwood energy solutions (viale del lavoro 18, 37067 Villafranca di Verona, VR, Italy) have been used, for which the optical efficiency and the heat transmission coefficients a1 and a2 are known (Table 1).

- The HTW S has also a thermal storage function, for users at temperature lower than 90 °C. In addition, for this component, heat loss has been neglected as an acceptable approximation.

- TD. Thermal dissipater. It has to dissipate the excess thermal power in the H2O LT line into the seawater. The auxiliary consumptions of the TD are accounted for in the non-propulsive electrical loads, according to the operating data collected for the reference ship. Therefore, the model of this component is not explicitly considered in the balance of energy flows.

- AC. Absorption chiller. They can be powered by the H2O HT network and, indirectly, by the steam network, too. The linearized model of the absorption chiller calculates the thermal consumption and the cooling power produced at different loads, following the performance of a typical water-lithium bromide absorption machine, presented by Joudi and Lafta, in [57]. Their simulations show that the COP remains approximatively constant, if the activation temperature is in the range 85–95 °C. Considering to fed the machine with the hot water carrier at 85–90 °C (H2O HT) a constant prudential value of the COP = 0.6 has been assumed.

- CC. Compression chillers. They are traditionally present on board the ship, whose size will be reduced in relation to the introduction of the absorption chillers. Referring to the data available from the manufacturers [58], a COP = 5.0 has been adopted.

- CWS. Chilled water storage. Considering that all the on board storages are characterized by a short operating cycle (a few hours) the losses due to heat dispersion will be considered null, simply taking into account the maximum accumulated volume.

- ODFW. Reverse osmosis desalinator. The linearized model of the electrical consumption and of the fresh water flow produced refers to the components currently installed on board the ship, whose productivity and electrical consumption are known [53].

- FWS. Fresh water storage. Given that the accumulation of fresh water is currently present on board, its auxiliary consumption is accounted for in the non-propulsive electrical loads. Therefore, the model of this component will not be explicitly considered in the super-structure.

- Cool_abs (g,i), cooling power produced by the absorption chillers [kW];

- Cool_com (g,i), cooling power produced by the compression chillers [kW].

- Lev_St (g,i), energy stored in the steam storage [kWh];

- Input_St (g,i), input power in the steam storage [kW];

- Output_St (g,i), output power in the steam storage [kW];

- Lev_HTW (g,i), energy stored in HTW storage [kWh];

- Input_HTW (g,i), power input into the HTW storage [kW];

- Output_HTW (g,i), output power in the HTW storage [kW];

- y_Input_St (g,i), ON/OFF of the flow entering the steam storage;

- y_Output_St (g,i), ON/OFF of the output stream in the steam storage;

- y_Input_HTW (g,i), ON/OFF of the flow entering the HTW storage;

- y_Output_HTW (g,i), ON/OFF of the output stream in the HTW storage.

- SttoHTW (g,i), thermal power transferred from the steam to the HTW line [kW];

- Apv, Ast, solar photovoltaic panels and thermal collector surfaces [m2].

2.4. Energy Balances and Objective Functions

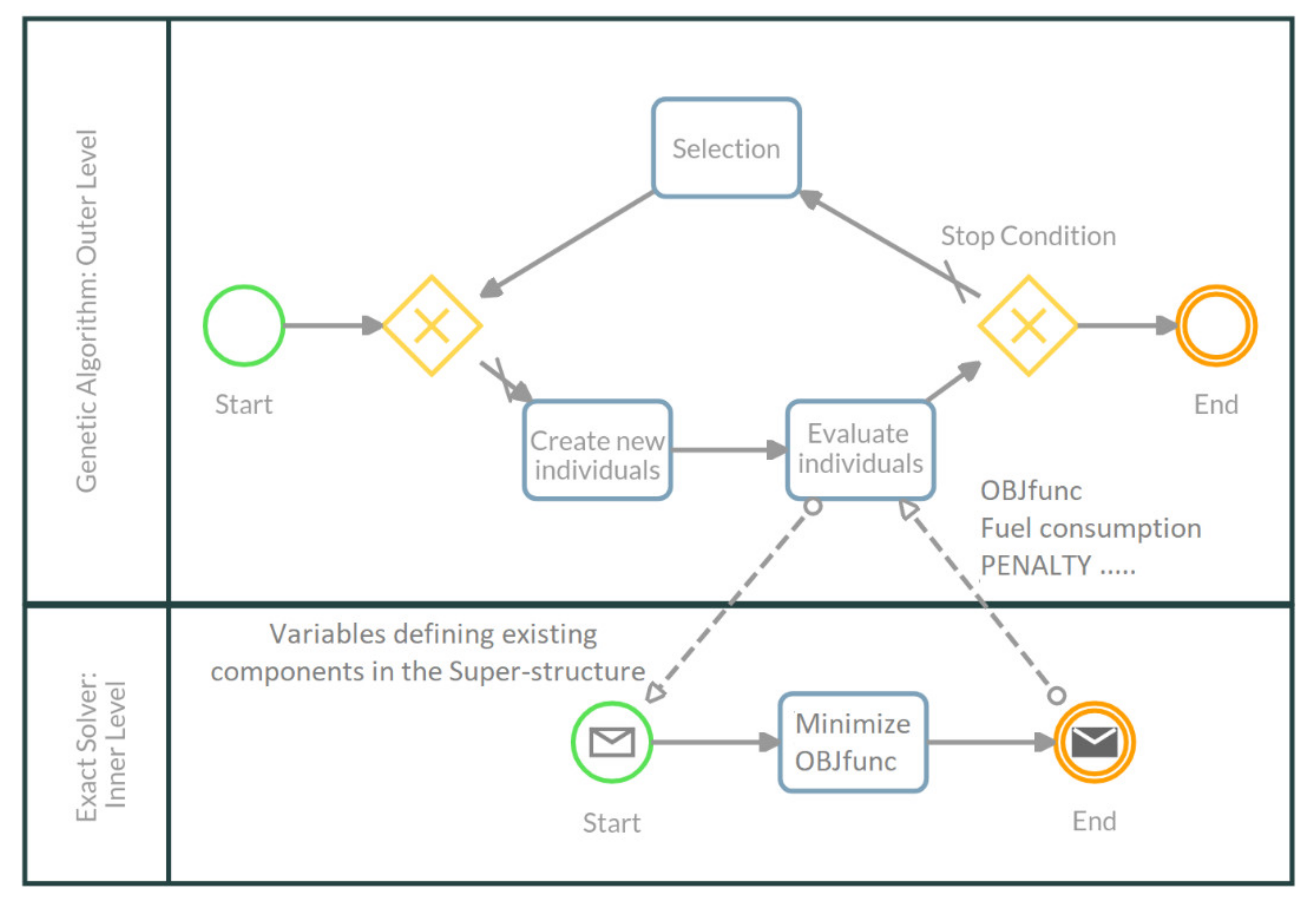

3. Bi-Level Multi-Object Optimization

- X_str (stirling), vector containing the binary variables expressing the presence/absence of each Stirling group;

- X_orc (ORC), vector containing the binary variables expressing the presence/absence of each ORC group;

- Apv, area occupied by photovoltaic solar panels [m2];

- Ast, area occupied by solar thermal collectors [m2];

- Cool_abs_size, absorption chiller size [kW];

- Cool_com_size, compression chiller size [kW];

- Lev_St_size, steam thermal storage size [kWh];

- Lev_HTW_size, hot water thermal storage size [kWh].

4. Results

4.1. Preliminary Optimizations

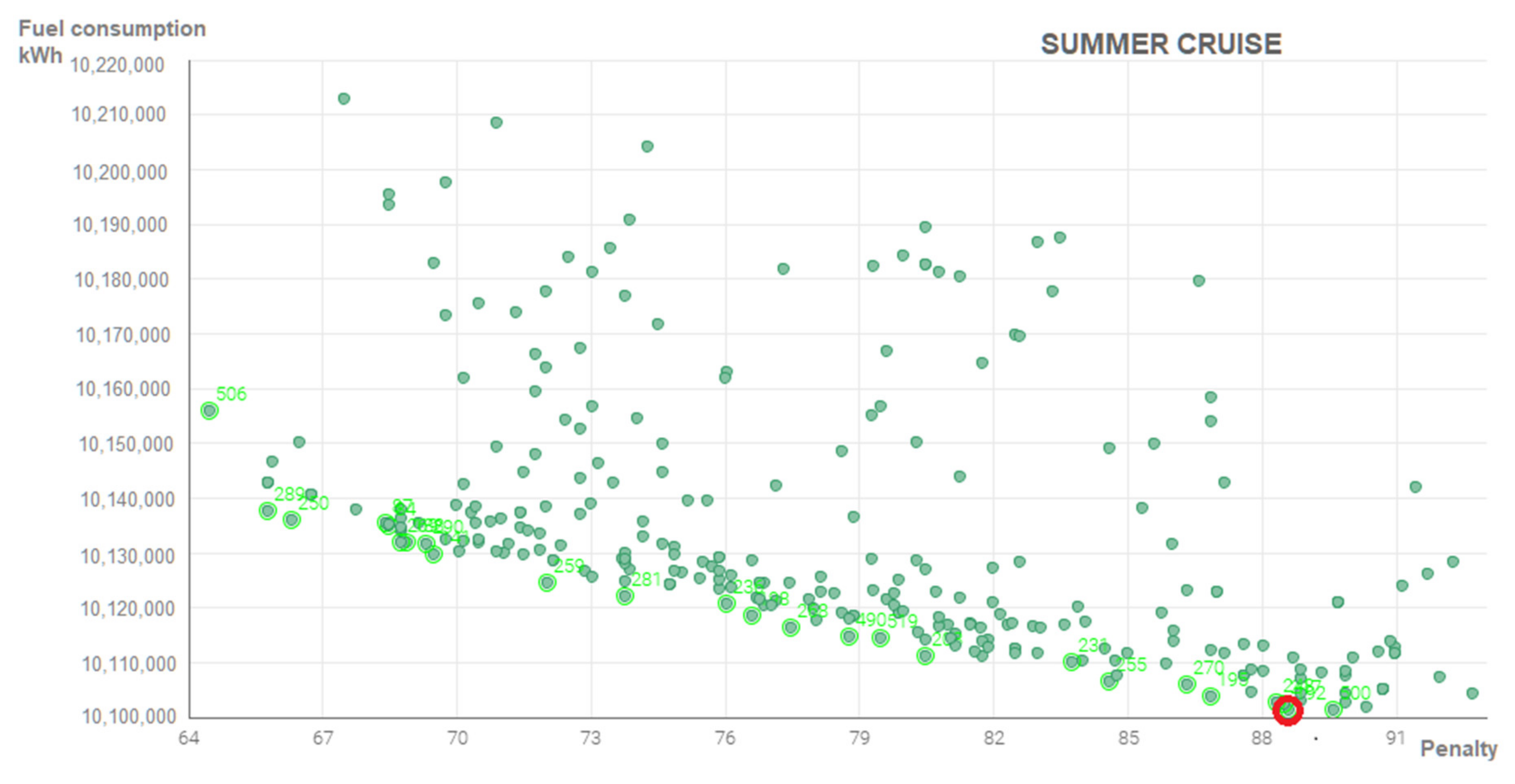

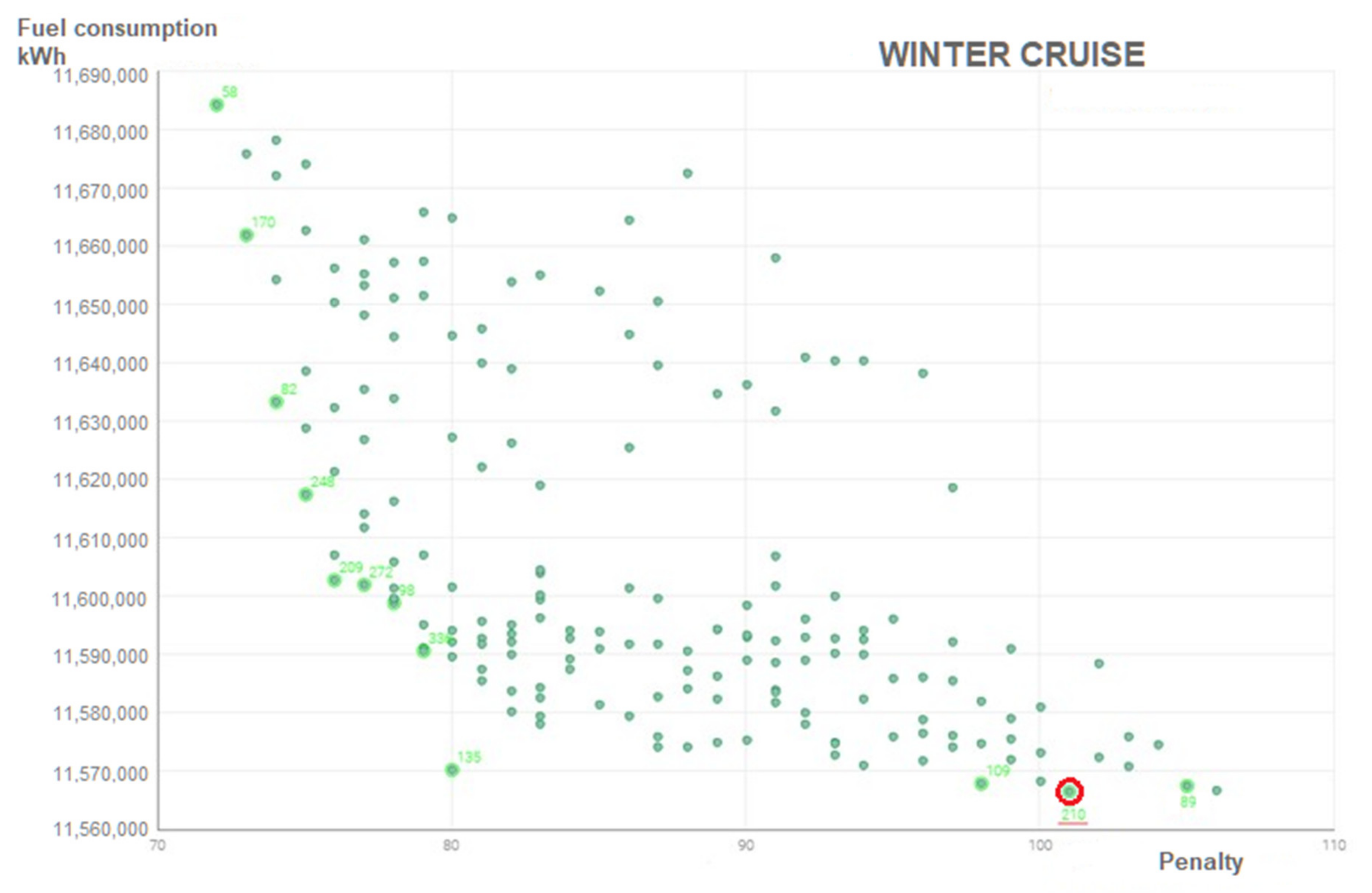

4.2. Pareto Front of the Bi-Level Optimization

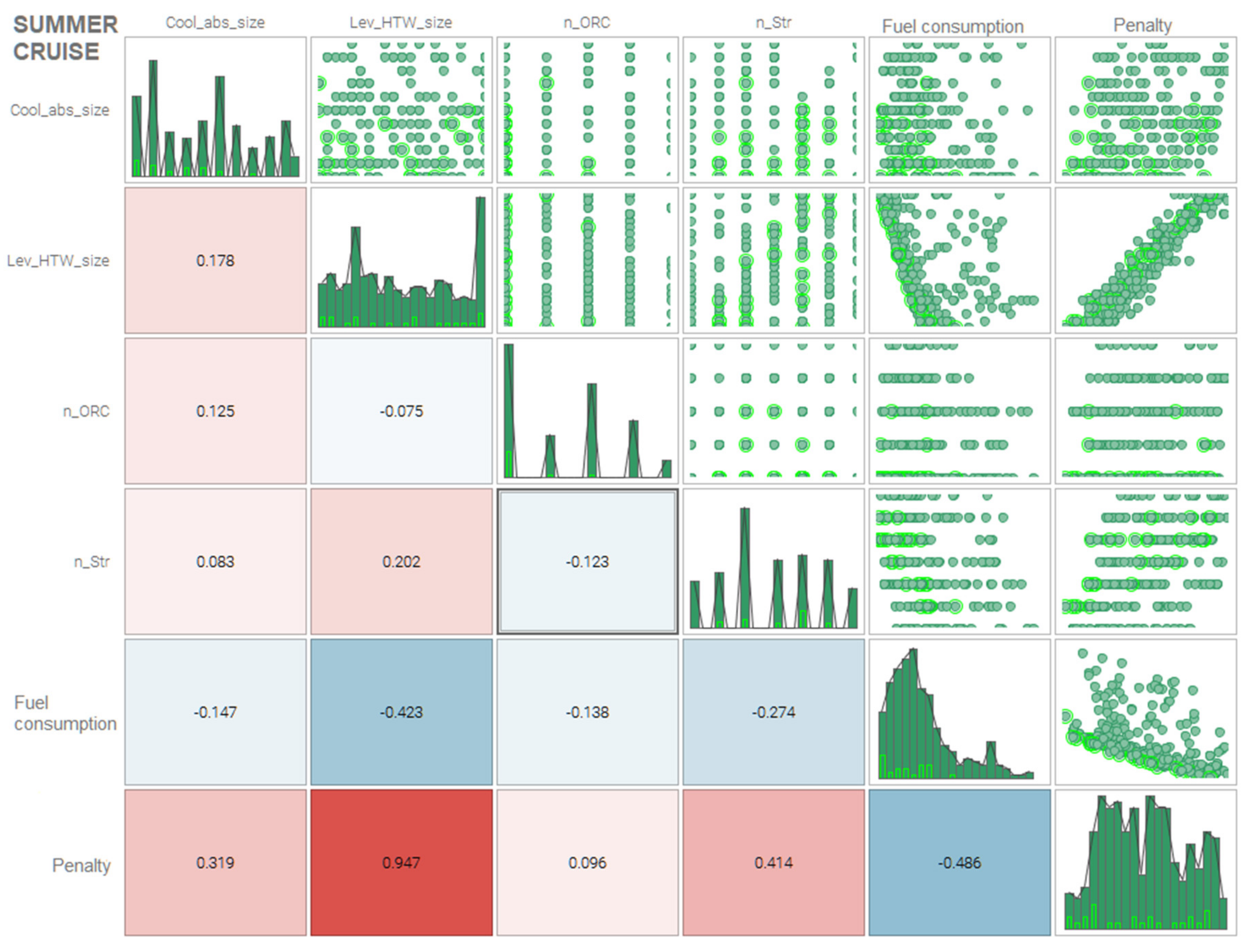

- The size of the HTW thermal storage is the variable that most influences both objectives; it is strictly correlated with the total penalty and rather correlated also with the reduction of the overall fuel consumption.

- The number of ORC groups, on the other hand, does not affect very much both objectives, even if it contributes to the reduction of fuel consumption. The solution with the highest probability density is zero ORC groups.

- The number of Stirling groups is strongly influential on both the objectives. It also contributes to constituting the overall value of the penalty.

- As expected, the two objectives are negatively correlated, in the sense that in most of the designs considered, accepting an increase in the penalty allows a reduction in the fuel consumption. This is no longer true when the penalty value of 89 points is reached, as can be seen from the detail of the Pareto front for the summer case in Figure 11.

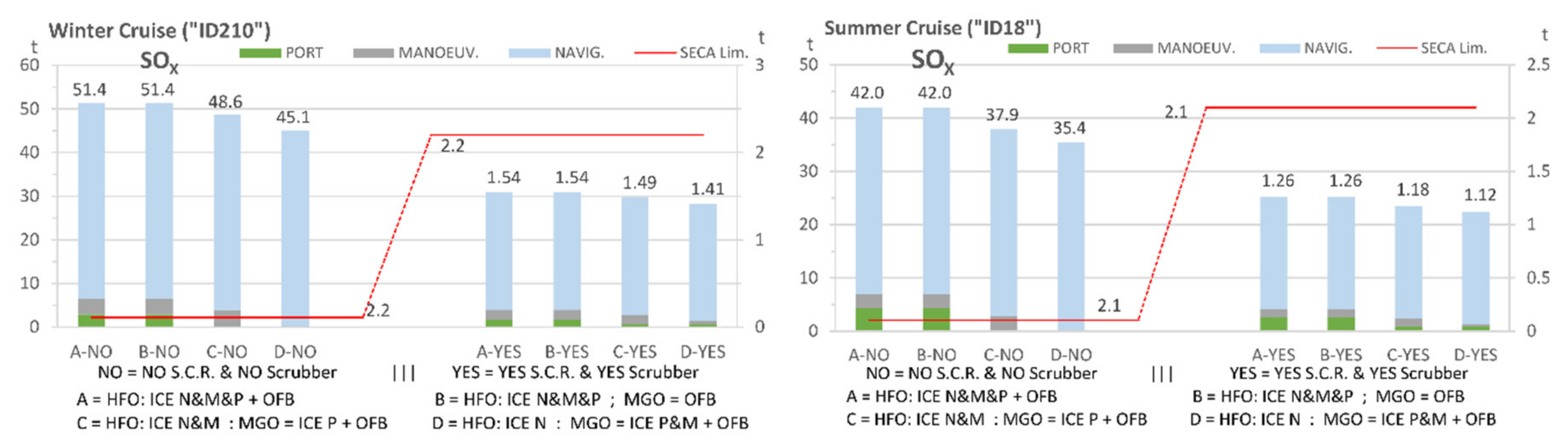

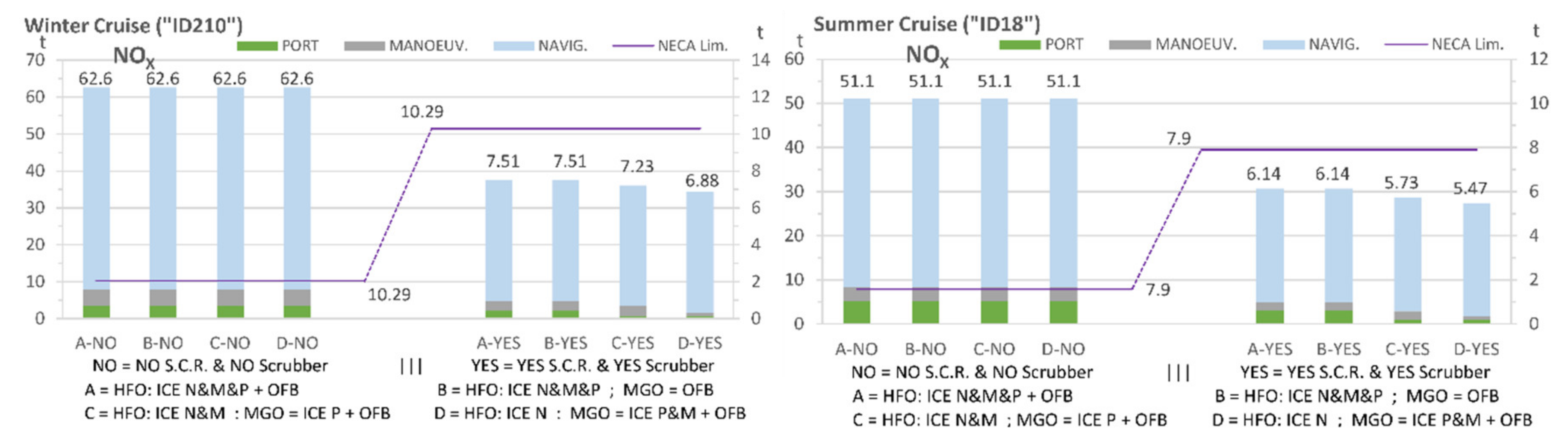

4.3. Pollutant Emissions Evaluation

- A.

- HFO for ICE and boilers in all cruising conditions,

- B.

- HFO for ICE in all cruising conditions and MGO for OFB,

- C.

- HFO for ICE in navigation and maneuvering and MGO for ICE in port and OFB,

- D.

- HFO for ICE in navigation and MGO for ICE in maneuvering and in port and for OFB.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Acronyms | |

| AC | absorption chillers |

| B | liquid fuel |

| BOS | balance of System for the photovoltaic panels |

| CC | compression chillers |

| CHP-CCHP | combined heating and power—combined cooling heating and power |

| CWd | chilled water demand |

| CWS | chilled water storage |

| DD. GG | main diesel engines |

| EG | exhaust gases |

| EGRS | exhaust gases recovery system |

| EGT | exhaust gas treatment |

| EE | electric energy |

| EEd | electric energy demand |

| FWd | fresh water demand |

| FWS | fresh water storage |

| HFO | heavy fuel oil |

| HT | high temperature |

| HTW | hot water boilers |

| HTWd | hot water demand |

| HVAC | Air conditioning |

| ICE | internal combustion engine |

| IMO | International Maritime Organization |

| LNG | liquefied natural gas |

| LT | low temperature |

| LTWd | low temperature water demand |

| MARPOL | short for International Convention for the Prevention of Pollution from Ships |

| MILPMGO | mixed integer linear programmingMarine Gas Oil |

| ODFWOFB | reverse osmosis desalinatorOil Fuel Burner |

| ORC | organic Rankine cycle |

| PV | photovoltaic panels |

| S | stema |

| SB | steam boilers |

| SCR | selective catalytic reduction device |

| Sd | steam demand |

| SECA | sulfur emission control areas |

| SS | steam storage |

| ST | solar thermal collectors |

| Stirl | Stirling unit |

| TD | thermal dissipater |

| TG | gas turbine |

| TS | thermal storages |

| Symbols | ||

| Apv | solar photovoltaic panels surface | [m2] |

| Ast | solar thermal collectors surface | [kW] |

| Cool_abs | absorption chillers cooling power | [kW] |

| Cool_com | compression chillers cooling power | |

| Cool_abs_size | absorption chillers size | [kW] |

| Cool_com_size | compression chillers size | [kW] |

| EFh | generic pollutant emission factor | [gpollutants/kgFuel] |

| EFNOx | NOx emission factor | [gNOx/kgFuel] |

| EFSOx | SOx emission factor | [gSOx/kgFuel] |

| eta_el | electric efficiency | |

| eta_HTW | water boilers integrative thermal efficiency | |

| eta_orc | ORC electrical efficiency | |

| eta_St | steam integrative thermal efficiency | |

| eta_str | Stirling electrical efficiency | |

| ER users | thermal power for engine rooms | [kW] |

| Fuel | engine fuel consumption | [kW] |

| Fuel_BHt | fuel consumption of integrative water boilers | [kW] |

| Fuel_BSt | fuel consumption of integrative steam | [kW] |

| Fuel_TOT | total fuel consumption | [kWh] |

| g | generic day | |

| GNpv | photovoltaic panel data vector | [W/m2] |

| GNst | solar collector data vector | [W/m2] |

| Hexg | heat recovered from the ICE gases | [kW] |

| Hexg_str | thermal input of Stirling groups | [kW] |

| HTh | heat recovered in form of HTW | [kW] |

| HTh_abs | thermal input of absorption chillers | [kW] |

| HTh_orc | thermal input of ORC groups | [kW] |

| Hotel NOT Hot water | thermal power for swimming pool heaters and laundry | [kW] |

| Hotel ONLY- HotWater | thermal power for sanitary use | [kW] |

| i | generic hour | |

| Input_CW | power input in the chilled water storage | [kW] |

| Input_HTW | power input into the HTW storage | [kW] |

| Input_St | power input in the steam storage | [kW] |

| Int_HTW | water boilers integrative thermal power | [kW] |

| Int_St | steam integrative thermal power | [kW] |

| j | generic ICE | |

| Lev_HTW | energy stored in HTW storage | [kWh] |

| Lev_HTW_size | energy stored size in HTW storage | [kWh] |

| Lev_St | energy stored in the steam storage | [kWh] |

| Lev_St_size | energy stored size in the steam storage | [kWh] |

| MCR% | engine load as a percentage of the nominal load | [%] |

| OBJFunc | general objective function | [kWh] |

| Ouput_CW | power output in the chilled water storage | [kW] |

| Output_HTW | power output in the HTW storage | [kW] |

| Output_St | power output in the steam storage | [kW] |

| PEh | generic pollutant emission | [gpollutants] |

| PENOx | NOx emission | [gNOx] |

| PESOx | SOx emission | [gSOx] |

| Pel/Pelect | electrical power | [kW] |

| Pel_com | compression chillers electrical power | [kW] |

| Pel_orc | ORC electrical power | [kW] |

| Pel_str | Stirling electrical power | [kW] |

| PEN_abs | penalty function for absorption chillers | [pt/kW] |

| PENALTY | penalty function | [pt] |

| PENconv | penalty function conversion factor | [kWh/pt] |

| PEN_HTW | penalty function for HTW | [pt/kWh] |

| PEN_orc | penalty function for ORC groups | [pt] |

| PEN_st | penalty function for solar thermal collectors | [pt/m2] |

| PEN_ST | penalty function for steam storage | [pt/kW] |

| PEN_str | penalty function for Stirling groups | [pt] |

| PEN_pv | penalty function for photovoltaic panels | [pt/m2] |

| P HVAC | power for air conditioning | [kW] |

| PPOD | power for the POD propulsion system | [kW] |

| Ppv | solar photovoltaic panels power | [kW] |

| P pumps - galley | lights: power for hotel use and aux systems | [kW] |

| Pst | solar thermal collector power | [kW] |

| P technical | power for non-propulsive technical uses | [kW] |

| Qexh.gas | heat recoverable from the exhaust gases of the ICEs | [kW] |

| QHT-TOTrecov | heat recoverable from the hot water circuit of the ICE | [kW] |

| RICEL | electric power required | [kW] |

| RICCOOL | cooling power required as chilled water at 8 °C | [kW] |

| RICTER_HTW | heat required as hot water at 60–90 °C | [kW] |

| RICTER_St | heat required as saturated steam at 10 bar and 180 °C | [kW] |

| SttoHTW | thermal power from the Steam to the HTW line | [kW] |

| Tank Heating | thermal power for treatment of fuel, sludge, etc. | [kW] |

| X_orc | ORC existence | |

| X_str | Stirling existence | |

| y | ON/OFF condition of ICEs | |

| y_orc | ON/OFF condition of ORC groups | |

| y_Input_HTW | ON/OFF condition of the flow entering the HTW storage | |

| y_Input_St | ON/OFF condition of the flow entering the steam storage | |

| y_Output_HTW | ON/OFF condition of the output stream in the HTW storage | |

| y_Output_St | ON/OFF condition of the output stream in the steam storage | |

| y_str | ON/OFF condition of Stirling groups | |

| ηSCR | SCR abatement efficiency | |

| ηscrubber | scrubber abatement efficiency | |

References

- International Maritime Organization. MARPOL 73/78; Annex VI; International Maritime Organization: London, UK, 1997. [Google Scholar]

- Maragkogianni, A.; Papaefthimiou, S. Evaluating the social cost of cruise ships air emissions in major ports of Greece. Transp. Res. Part. D Transp. Environ. 2015, 36, 10–17. [Google Scholar] [CrossRef]

- Azzara, A.A.; Rutherford, D.; Wang, H. Feasibility of IMO Annex VI Tier III implementation using selective catalytic reduction. Int. Counc. Clean Transp. 2014, 4, 1–9. [Google Scholar]

- Armellini, A.; Daniotti, S.; Pinamonti, P.; Reini, M. Evaluation of Gas Turbines as alternative energy production systems for a large cruise ship to meet new maritime regulations. Appl. Energy 2018, 211, 306–317. [Google Scholar] [CrossRef]

- Armellini, A.; Daniotti, S.; Pinamonti, P.; Reini, M. Reducing the environmental impact of large cruise ships by the adoption of complex cogenerative/trigenerative energy systems. Energy Convers. Manag. 2019, 198, 1–11. [Google Scholar] [CrossRef]

- Haglind, F. A review on the use of gas and steam turbine combined cycles as prime movers for large ships. Part II: Previous work and implications. Energy Convers. Manag. 2008, 49, 3468–3475. [Google Scholar] [CrossRef]

- Geertsma, R.D.; Negenborn, R.R.; Visser, K.; Hopman, J.J. Design and control of hybrid power and propulsion systems for smart ships: A review of developments. Appl. Energy 2017, 194, 30–54. [Google Scholar] [CrossRef]

- Xiao, N.; Zhou, R.; Lin, X. Type selection and design of hybrid propulsion system of ship. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 2016 Second International Conference on Mechanical Engineering and Automation Science (ICMEAS 2016), Singapore, 13–15 October 2016; IOP Publishing: Philadelphia, PA, USA, 2016; Volume 157. [Google Scholar] [CrossRef]

- Lloyd’s Register. LNG-Fuelled Deep Sea Shipping; Lloyd’s Register: London, UK, 2012. [Google Scholar]

- Banawan, A.A.; El Gohary, M.M.; Sadek, I.S. Environmental and economical benefits of changing from marine diesel oil to natural-gas fuel for short-voyage high-power passenger ships. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2010, 224, 103–113. [Google Scholar] [CrossRef]

- Burel, F.; Taccani, R.; Zuliani, N. Improving sustainability of maritime transport through utilization of liquefied natural gas (LNG) for propulsion. Energy 2013, 57, 412–420. [Google Scholar] [CrossRef]

- Ballini, F.; Bozzo, R. Air pollution from ships in ports: The socio-economic benefit of cold-ironing technology. Res. Transp. Bus. Manag. 2015, 17, 92–98. [Google Scholar] [CrossRef]

- Tien, W.K.; Yeh, R.H.; Hong, J.M. Theoretical analysis of cogeneration system for ships. Energy Convers. Manag. 2007, 48, 1965–1974. [Google Scholar] [CrossRef]

- Dzida, M. Possible efficiency increasing of ship propulsion and marine power plant with the system combined of marine diesel engine, gas turbine and steam turbine. Adv. Gas Turbine Technol. 2011, 45–68. [Google Scholar] [CrossRef]

- Nielsen, R.F.; Haglind, F.; Larsen, U. Design and modeling of an advanced marine machinery system including waste heat recovery and removal of sulphur oxides. Energy Convers. Manag. 2014, 85, 687–693. [Google Scholar] [CrossRef]

- Michos, C.N.; Lion, S.; Vlaskos, I.; Taccani, R. Analysis of the backpressure effect of an organic rankine cycle (ORC) evaporator on the exhaust line of a turbocharged heavy duty diesel power generator for marine applications. Energy Convers. Manag. 2017, 132, 347–360. [Google Scholar] [CrossRef]

- Yang, F.; Dong, X.; Zhang, H.; Wang, Z.; Yang, K.; Zhang, J.; Wang, E.; Liu, H.; Zhao, G. Performance analysis of waste heat recovery with a dual loop organic rankine cycle (ORC) system for diesel engine under various operating conditions. Energy Convers. Manag. 2014, 80, 243–255. [Google Scholar] [CrossRef]

- Bonafin, J.; Pinamonti, P.; Reini, M.; Tremuli, P. Performance improving of an internal combustion engine for ship propulsion with a bottom ORC. In Proceedings of the ECOS 2010 ECOS 2010—23rd International Conference on Efficiency, Cost, Optimization, Simulation, and Environmental Impact of Energy Systems, Lausanne, Switzerland, 14–17 June 2010. [Google Scholar]

- Mondejar, M.E.; Ahlgren, F.; Thern, M.; Genrup, M. Quasi-steady state simulation of an organic rankine cycle for waste heat recovery in a passenger vessel. Appl. Energy 2017, 185, 1324–1335. [Google Scholar] [CrossRef]

- Yang, M.H.; Yeh, R.H. Thermodynamic and economic performances optimization of an organic rankine cycle system utilizing exhaust gas of a large marine diesel engine. Appl. Energy 2015, 149, 1–12. [Google Scholar] [CrossRef]

- Rech, S.; Zandarin, S.; Lazzaretto, A.; Frangopoulos, C.A. Design and off-design models of single and two-stage ORC systems on board a LNG carrier for the search of the optimal performance and control strategy. Appl. Energy 2017, 204, 221–241. [Google Scholar] [CrossRef]

- Aladayleh, W.; Alahmer, A. Recovery of exhaust waste heat for ice using the beta type stirling engine. J. Energy 2015, 2015, 1–8. [Google Scholar] [CrossRef]

- Larsen, H.V.; Bøhm, B.; Wigbels, M. A comparison of aggregated models for simulation and operational optimisation of district heating networks. Energy Convers. Manag. 2004, 45, 1119–1139. [Google Scholar] [CrossRef]

- Consonni, S.; Lozza, G.; Macchi, E. Optimization of a cogeneration systems operation Part A: Prime movers modelization. In Proceedings of the ASME Cogen-Turbo ’89, Nice, France, 30 August–1 September 1989; pp. 313–322. [Google Scholar]

- Consonni, S.; Lozza, G.; Macchi, E. Optimization of a cogeneration systems operation Part B: Solution algorithm and examples of optimum operating strategies. In Proceedings of the ASME Cogen-Turbo ’89, Nice, France, 30 August–1 September 1989; pp. 323–331. [Google Scholar]

- Yokoyama, R.; Ito, K. Operational strategy of a cogeneration system under a complex utility rate structure. J. Energy Resour. Technol. 1996, 118, 256–262. [Google Scholar] [CrossRef]

- Yokoyama, R.; Ito, K.; Kamimura, K.; Miyasaja, F. Development of a general purpose optimal operational planning system for energy supply plants. J. Energy Resour. Technol. 1994, 116, 290–296. [Google Scholar] [CrossRef]

- Yokoyama, R.; Ito, K. A revised decomposition method for MILP problems and its application to operational planning of thermal storage systems. J. Energy Resour. Technol. 1996, 118, 277–284. [Google Scholar] [CrossRef]

- Casisi, M.; Pinamonti, P.; Reini, M. Optimal lay-out and operation of CHP distributed generation systems. Energy 2009, 34, 2175–2183. [Google Scholar] [CrossRef]

- Buoro, D.; Casisi, M.; Pinamonti, P.; Reini, M. Optimal lay-out and operation of district heating and cooling distributed trigeneration systems (GT2010-23416). In Proceedings of the AMSE TurboExpo 2010, Glasgow, UK, 14–18 June 2010. [Google Scholar]

- Buoro, D.; Pinamonti, P.; Reini, M. Optimization of a distributed cogeneration system with solar district heating. Appl. Energy 2014, 124, 298–308. [Google Scholar] [CrossRef]

- Casisi, M.; Pinamonti, P.; De Nardi, A.; Reini, M. Effect of different economic support policies on the optimal synthesis and operation of a distributed energy supply system with renewable energy sources for an industrial area. Energy Convers. Manag. 2015, 95, 131–139. [Google Scholar] [CrossRef]

- Steen, D.; Stadler, M.; Cardoso, G.; Groissböck, M.; DeForest, N.; Marnay, C. Modeling of thermal storage systems in MILP distributed energy resource models. Appl. Energy 2015, 137, 782–792. [Google Scholar] [CrossRef]

- Pohekar, S.D.; Ramachandran, M. Application of multi-criteria decision making to sustainable energy planning—A review. Renew. Sustain. Energy Rev. 2004, 8, 365–381. [Google Scholar] [CrossRef]

- Wang, J.J.; Jing, Y.Y.; Zhang, C.F.; Zhao, J.H. Review on multi-criteria decision analysis aid in sustainable energy decision making. Renew. Sustain. Energy Rev. 2009, 13, 2263–2278. [Google Scholar] [CrossRef]

- Alarcón, A.; Ault, G.; Galloway, S. Multi-objective planning of distributed energy resources a review of the state-of-the-art. Renew. Sustain. Energy Rev. 2010, 14, 1353–1366. [Google Scholar] [CrossRef]

- Lazzaretto, A.; Toffolo, A. Energy, economy and environment as objectives in multi-criterion optimization of thermal systems design. Energy 2004, 29, 1139–1157. [Google Scholar] [CrossRef]

- Tsay, M.T. Applying the multi-objective approach for operation strategy of cogeneration systems under environmental constraints. Int. J. Electr. Power Energy Syst. 2003, 25, 219–226. [Google Scholar] [CrossRef]

- Kavvadias, K.C.; Maroulis, Z.B. Multi-objective optimization of a trigeneration plant. Energy Policy 2010, 38, 945–954. [Google Scholar] [CrossRef]

- Buoro, D.; Casisi, M.; De Nardi, A.; Pinamonti, P.; Reini, M. Multicriteria optimization of a distributed energy supply system for an industrial area. Energy 2013, 58, 128–137. [Google Scholar] [CrossRef]

- Ren, H.; Zhou, W.; Nakagami, K.; Gao, W.; Wu, Q. Multi-objective optimization for the operation of distributed energy systems considering economic and environmental aspects. Appl. Energy 2010, 87, 3642–3651. [Google Scholar] [CrossRef]

- Buoro, D.; Casisi, M.; Pinamonti, P.; Reini, M. Optimization of distributed trigeneration system integrated with district heating and cooling micro-grids. Distrib. Gener. Altern. Energy J. 2011, 26, 7–33. [Google Scholar]

- Buoro, D.; Casisi, M.; Pinamonti, P.; Reini, M. A comparison of different district integration for a distributed generation system for heating and cooling in an urban area. Appl. Sci. 2019, 9, 1–40. [Google Scholar]

- Ito, K.; Akagi, S. An optimal planning method for a marine heat and power generation plant by considering its operational problem. Int. J. Energy Res. 1986, 10, 75–85. [Google Scholar] [CrossRef]

- Dai, R.; Mesbahi, M. Optimal power generation and load management for off-grid hybrid power systems with renewable sources via mixed-integer programming. Energy Convers. Manag. 2013, 73, 234–244. [Google Scholar] [CrossRef]

- Trivyza, N.L.; Rentizelas, A.; Theotokatos, G. A novel multi-objective decision support method for ship energy systems synthesis to enhance sustainability. Energy Convers. Manag. 2018, 168, 128–149. [Google Scholar] [CrossRef]

- Skjong, E.; Johansen, T.A.; Molinas, M.; Sørensen, A.J. Approaches to economic energy management in diesel-electric marine vessels. IEEE Trans. Transp. Electrif. 2017, 3, 22–35. [Google Scholar] [CrossRef]

- Dimopoulos, G.G.; Kougioufas, A.V.; Frangopoulos, C.A. Synthesis, design and operation optimization of a marine energy system. Energy 2008, 33, 180–188. [Google Scholar] [CrossRef]

- Gao, D.; Wang, X.; Wang, T.; Wang, Y.; Xu, X. An energy optimization strategy for hybrid power ships under load uncertainty based on load power prediction and improved NSGA-II algorithm. Energies 2018, 11, 1699. [Google Scholar] [CrossRef]

- Baldi, F.; Ahlgren, F.; Van Nguyen, T.; Thern, M.; Andersson, K. Energy and Exergy Analysis of a Cruise Ship. Energies 2018, 11, 2508. [Google Scholar] [CrossRef]

- Yan, Y.; Zhang, H.; Long, Y.; Wang, Y.; Liang, Y.; Song, X.; Yu, J.J.Q. Multi-objective design optimization of combined cooling, heating and power system for cruise ship application. J. Clean. Prod. 2019, 233, 264–279. [Google Scholar] [CrossRef]

- Casisi, M.; Costanzo, S.; Pinamonti, P.; Reini, M. Two-level evolutionary multi-objective optimization of a district heating system with distributed cogeneration. Energies 2019, 12, 114. [Google Scholar] [CrossRef]

- Zentilomo, L. (Fincantieri S.p.A., Trieste, Italy). Personal Communication about ship energy demand. 2019. [Google Scholar]

- EPRI. Stirling Engine Assessment; EPRI: Washington, DC, USA, 2002. [Google Scholar]

- Ballesteros, M.; Pujol, M.; Walsh, F.; Teubner, J. Geothermal Energy Electricity Generation in Australia: Recent Developments and Future Potential; Technical Report; Australian Geothermal Association: Adelaide, Australia, 2019; Available online: https://www.researchgate.net/publication/338384566 (accessed on 1 April 2020).

- Available online: http://www.energiazero.org/solare_termico/curva_efficienza_collettore_solare.pdf (accessed on 1 April 2020).

- Joudi, K.A.; Lafta, A.H. Simulation of a simple absorption refrigeration system. Energy Convers. Manag. 2001, 42, 1575–1606. [Google Scholar] [CrossRef]

- Climaveneta. Water Cooled Liquid Chillers TECS-HF; Climaveneta: Bassano del Grappa, Italy, 2006. [Google Scholar]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Frangopoulos, C.A.; von Spakovsky, M.R.; Sciubba, E. A Brief review of methods for the design and synthesis optimization of energy systems. Int. J. Appl. Thermodyn. 2002, 5, 151–160. [Google Scholar]

- Muñoz, R.J.; von Spakovsky, M.R. A Decomposition Approach for the large scale synthesis/design optimization of highly coupled, highly dynamic energy systems. Int. J. Appl. Thermodyn. 2001, 4, 19–33. [Google Scholar]

- Mueller, L.; Jakobi, G.; Czech, H.; Stengel, B.; Orasche, J.; Arteaga-Salas, J.M.; Karg, E.; Elsasser, M.; Sippula, O.; Streibel, T.; et al. Characteristics and temporal evolution of particulate emissions from a ship diesel engine. Appl. Energy 2015, 155, 204–217. [Google Scholar] [CrossRef]

- Endresen, Ø.; Sørgård, E.; Sundet, J.K.; Dalsøren, J.S.B.; Isaksen, I.S.A.; Berglen, T.F.; Gravir, G. Emission from international sea transportation and environmental impact. J. Geophys. Res. 2003, 108, 1–22. [Google Scholar] [CrossRef]

- Trozzi, C.; De Lauretis, R. EMEP/EEA Air Pollutant Emission Inventory Guidebook 2019; European Environment Agency: Copenhagen, Denmark, 2019. [Google Scholar]

| Optical Efficiency | [%] | 67.9 |

|---|---|---|

| Characteristic Parameter a1 | [W/m2 K] | 1.696 |

| Characteristic Parameter a2 | [W/m2 K2] | 0.0099 |

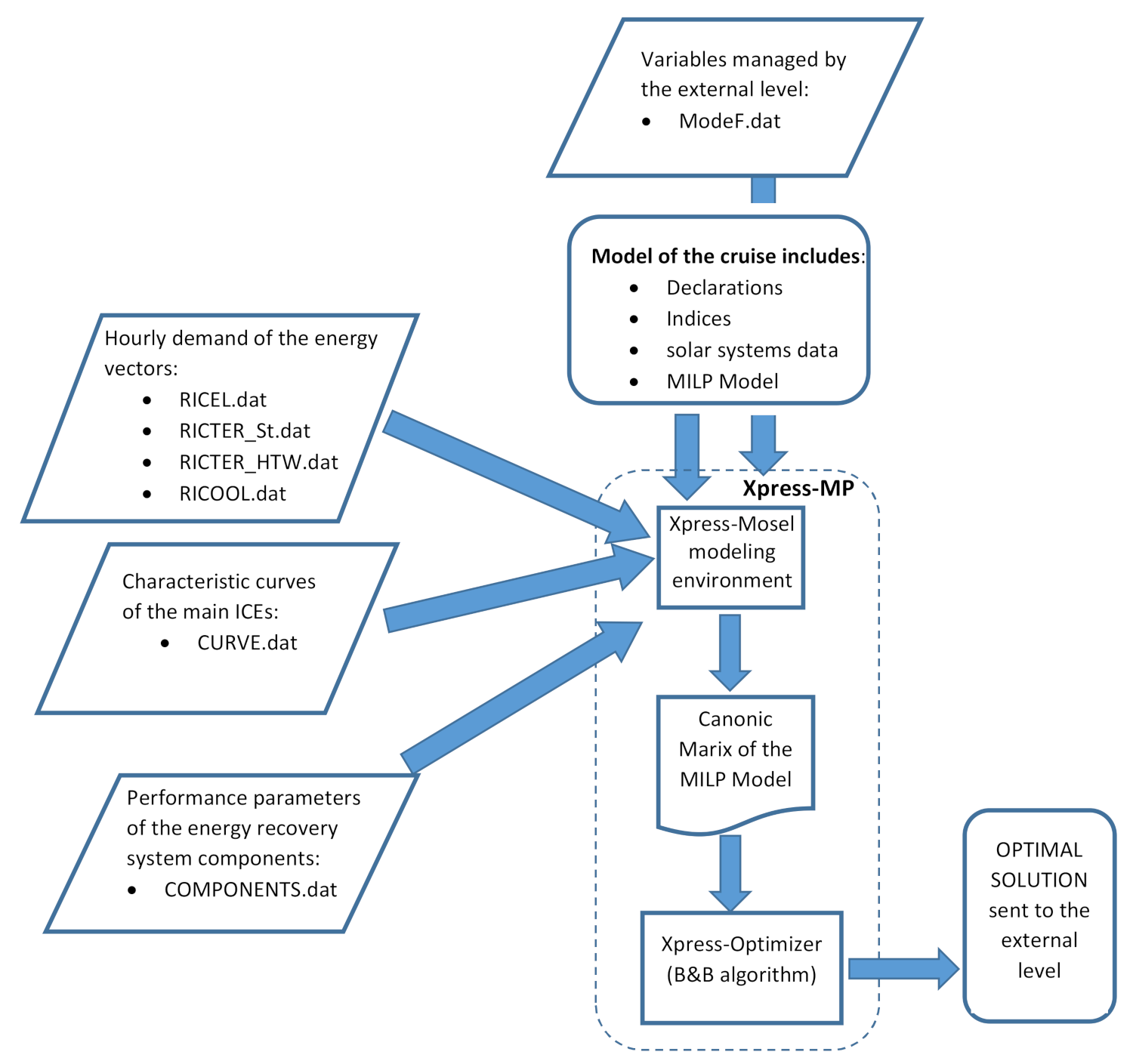

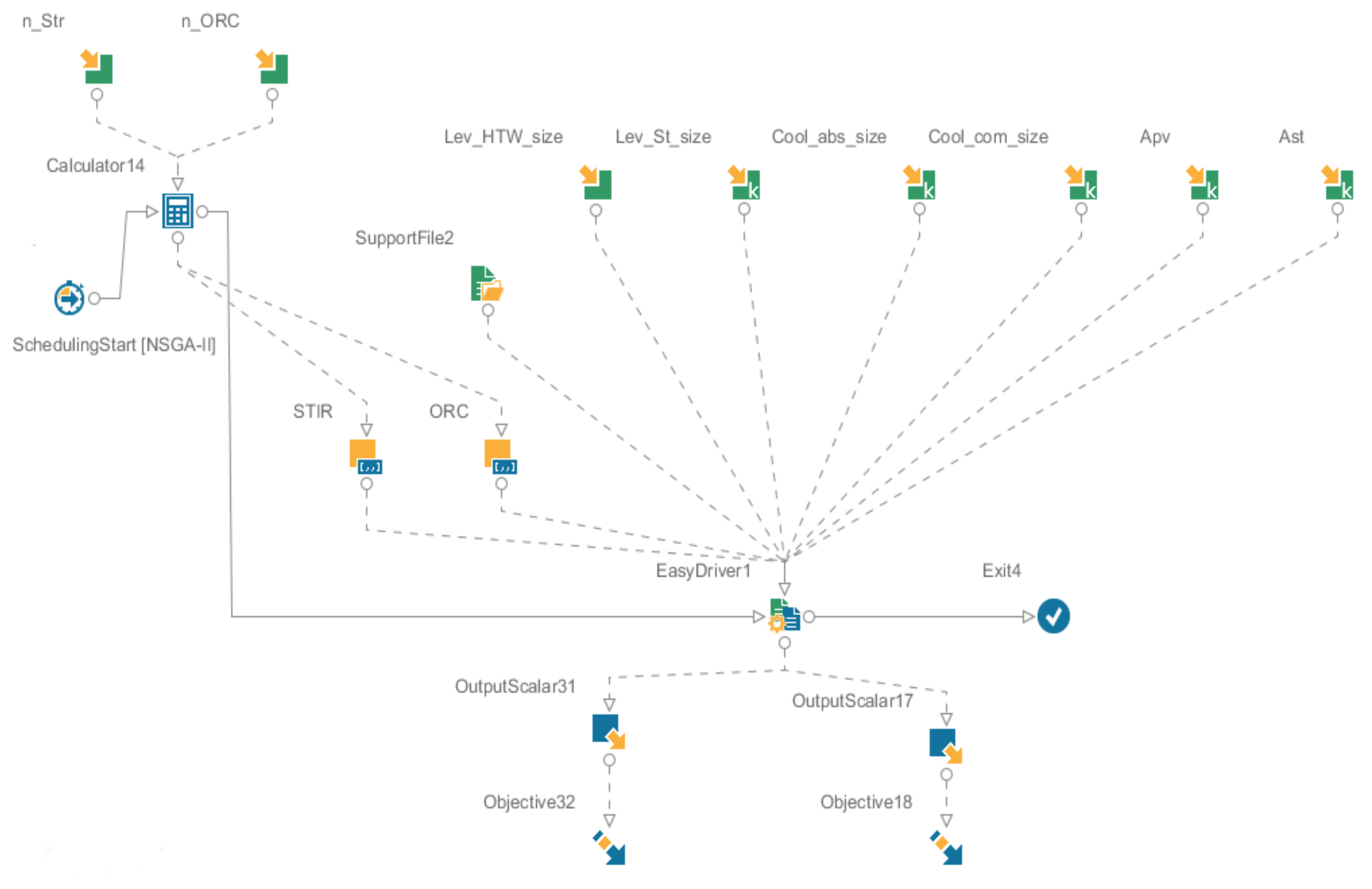

| n_Str; n_ORC | Defining of the variation range for the optimization variables actual number of Stirling groups and actual number of ORC groups. |

| Lev_HTW_size; Lev_St_size; Cool_abs_size; Cool_com_size; Apv; Ast | Defining of the variation range for the other optimization variables, size of HTW thermal storage, size of the steam storage, size of the absorption chiller, size of the compression chiller, area of the solar panels, area of the solar thermal collectors. |

| SchedulingStart | Defining of the optimization algorithm for the external level (NSGA-II) and setting of the parameters for the formulation of the different generations, in particular the number of individuals, the number of generations and the population of the first generation. |

| Calculator 14 | Converting of the number of Stirling groups and of the number of ORC groups into the vectors X_str (stirling) and X_orc (ORC). |

| SupportFile2 | Calling the COMPONENTS.dat (Figure 9) file which contains the characteristics chosen for the components (in particular the efficiencies of the Stirling and ORC groups) and makes it available for the subsequent EasyDriver1 node. |

| STIR; ORC | Containing the vectors X_str (stirling) and X_orc (ORC) produced by the node Calculator 14. |

| EasyDriver1 | It is the main node of the workflow; it defines the modeF.dat file (Figure 9) that can be read by the MILP procedure, launches the genetic procedure and writes the output containing the values of all the variables, calculated internally by the MILP procedure, and of the two objectives for all the individuals, until the end of the procedure. |

| OutputScalar31; OutputScalar17 | Identifying, in the output of the EasyDriver1 node, the two scalar values corresponding to the fuel consumption and to the penalty associated with the choice of variables managed by the external level. |

| Objective32; Objective18 | Identifying the two variables highlighted by nodes OutputScalar31 and OutputScalar17 as objectives to be minimized. |

| Exit4 | Defining the end of the procedure of design evolution, when all the generations set in the SchedulingStart node have been examined. |

| Variables | Ref. Value or Range | Units | Penalty Function | Penalty Ref. Value or Range | Units |

|---|---|---|---|---|---|

| Max number of Stirling | 10–40 | - | PEN_str | 1 | [10 m3] |

| Max number of ORC | 10–25 | - | PEN_orc | 1 | [10 m3] |

| COP_abs | 0,60 | - | - | - | - |

| Pel_strsup | 50 | [kW] | - | - | - |

| Pel_orcsup | 150 | [kW] | - | - | - |

| Cool_abs_max | 10 | [MW] | PENabs | 1/360 | [10 m3/kW] |

| Int_HTW_max | 10 | [MW] | - | - | - |

| Input/Output_HTW_Max | 1–7 | [MW] | PEN_HTW | 0.002 | [10 m3/kW] |

| ApvMax | 1000 | [m2] | PENpv | 1/80–1/320 | [10 m3/m2] |

| AstMax | 500 | [m2] | PENst | 1/50–1/200 | [10 m3/m2] |

| Variation in the Max Number of Stirling Groups | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| n° Stirling max (gap%) | ORC tot_size | Stirling tot_size | Absorber size | HTW storage size | FuelTot | Penalty | Stirling production | ORC production | Boiler integration Steam | Boiler integration HTW | HTW Input to Storage |

| kW | kW | kW | kWh | kWh | 10m3 | kWh | kWh | kWh | kWh | kWh | |

| 10 (1.0) | 600 | 500 | 8000 | 4953 | 10,292,400 | 46.13 | 58,853 | 10,757 | 46,558 | 54,677 | 51,557 |

| 20 (1.0) | 150 | 1000 | 8000 | 4953 | 10,214,600 | 53.13 | 100,791 | 3132 | 59,502 | 56,554 | 52,263 |

| 30 (1.5) | 0 | 1400 | 8000 | 4953 | 10,213,700 | 60.13 | 124,754 | 0 | 58,828 | 50,171 | 57,917 |

| 40 (2.0) | 0 | 1700 | 8000 | 4953 | 10,149,700 | 66.13 | 121,791 | 0 | 57,434 | 51,662 | 56,622 |

| Variation in the max number of ORC groups | |||||||||||

| n° ORC max (gap%) | ORC tot_size | Stirling tot_size | Absorber size | HTW storage size | FuelTot | Penalty | Stirling production | ORC production | Boiler integration Steam | Boiler integration HTW | HTW Input to Storage |

| kW | kW | kW | kWh | kWh | 10m3 | kWh | kWh | kWh | kWh | kWh | |

| 5 (1.0) | 150 | 1000 | 8000 | 4953 | 10,214,600 | 53.13 | 100,791 | 3132 | 59,502 | 56,554 | 52,263 |

| 10 (1.0) | 300 | 1000 | 8000 | 4953 | 10,212,300 | 54.13 | 103,528 | 1043 | 73,204 | 59,832 | 42,410 |

| 15 (1.0) | 300 | 1000 | 8000 | 4715 | 10,216,500 | 53.65 | 101,786 | 3880 | 60,541 | 54,763 | 53,023 |

| 20 (1.0) | 150 | 1000 | 8000 | 4953 | 10,219,100 | 53.13 | 107,468 | 2841 | 76,599 | 56,537 | 54,280 |

| Variation of the max Input/Output flow value of the HTW Storage | |||||||||||

| in/out max (gap%) | ORC tot_size | Stirling tot_size | Absorber size | HTW storage size | FuelTot | Penalty | Stirling production | ORC production | Boiler integration Steam | Boiler integration HTW | HTW Input to Storage |

| kW | kW | kW | kW | kWh | kWh | 10m3 | kWh | kWh | kWh | kWh | kWh |

| 1000 (1.0) | 150 | 1000 | 8000 | 4953 | 10,214,600 | 53.13 | 100,790 | 3132 | 59,502 | 56,554 | 52,264 |

| 3000 (1.0) | 300 | 1000 | 8000 | 9886 | 10,179,700 | 64.00 | 103,380 | 2238 | 74,170 | 37,493 | 101,848 |

| 5000 (1.0) | 300 | 1000 | 8000 | 10,535 | 10,176,400 | 65.30 | 100,234 | 4629 | 56,477 | 31,128 | 164,176 |

| 7000 (1.0) | 300 | 1000 | 8000 | 11,392 | 10,148,300 | 67.01 | 99,468 | 6418 | 55,253 | 30,831 | 233,284 |

| Cruise | Summer | Winter |

|---|---|---|

| Range of Stirling groups | 15–20 | 12–20 |

| Range of ORC groups | 0–3 | 6–12 |

| Solar panel area Apv [m2] | zero | zero |

| Solar thermal collector area Ast [m2] | zero | zero |

| Absorption chiller size, Cool_abs_size [kW] | 7–8000 | zero |

| Compression chiller size, Cool_com_size [kW] | 2000 | 2000 |

| Steam storage size, Lev_St_size [kWh] | zero | zero |

| HTW storage size Lev_HTW_size [kWh] | 15–25,000 | 30–50,000 |

| ID | n° ORC | n° Stirling | Absorber Size | HTW Storage Size | Fuel ICE | Penalty | Stirling Product | ORC Product | Fuel Int. for Steam | Fuel Int. for HTW |

|---|---|---|---|---|---|---|---|---|---|---|

| - | - | [kWh] | [kWh] | [t] | [10 m3] | [kWh] | [kWh] | [t] | [t] | |

| Summer Cruise | ||||||||||

| 18 | 0 | 19 | 7600 | 25,000 | 784.1 | 90.1 | 56,055 | 0 | 8.8 | 58.8 |

| Winter Cruise | ||||||||||

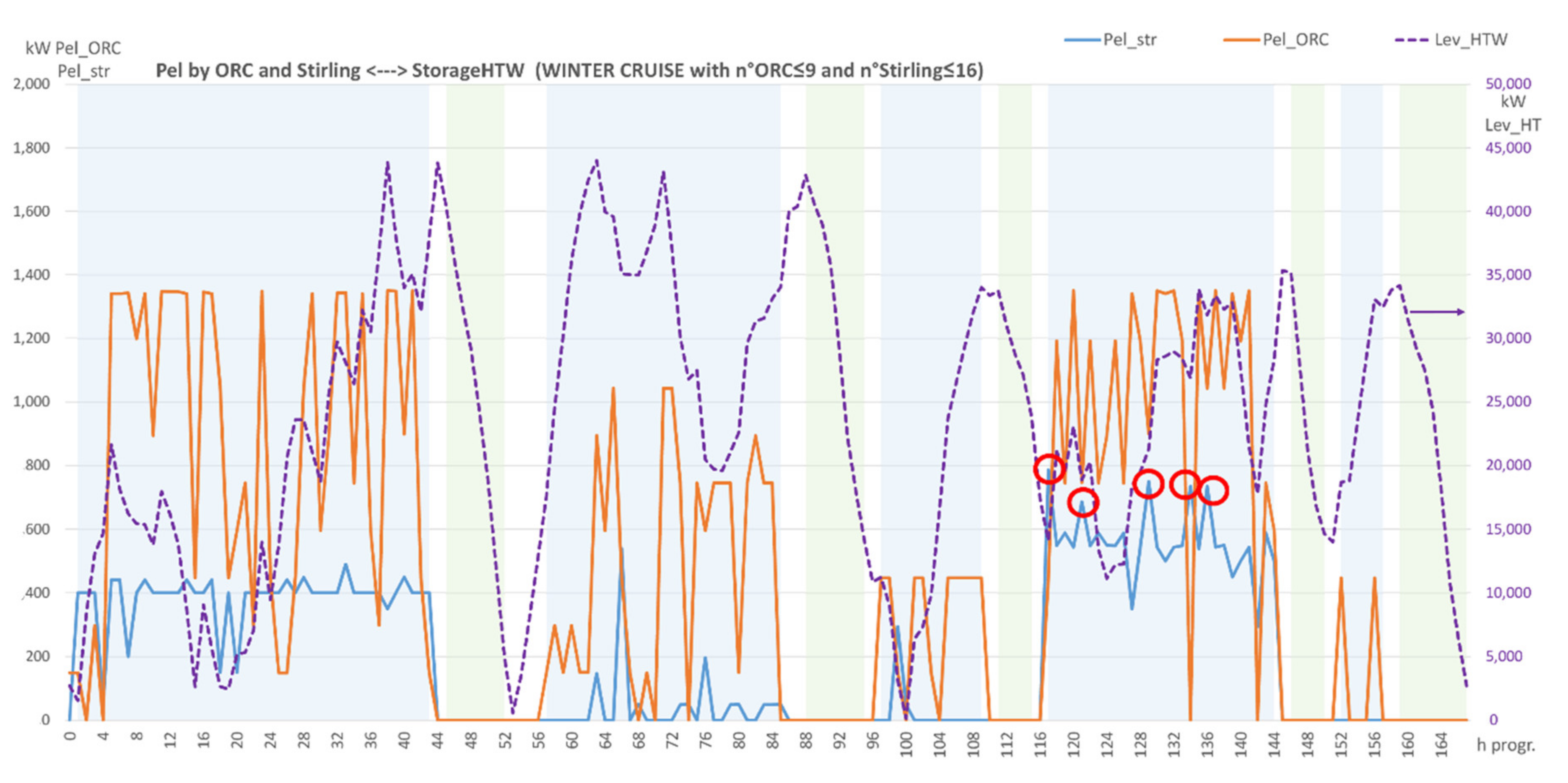

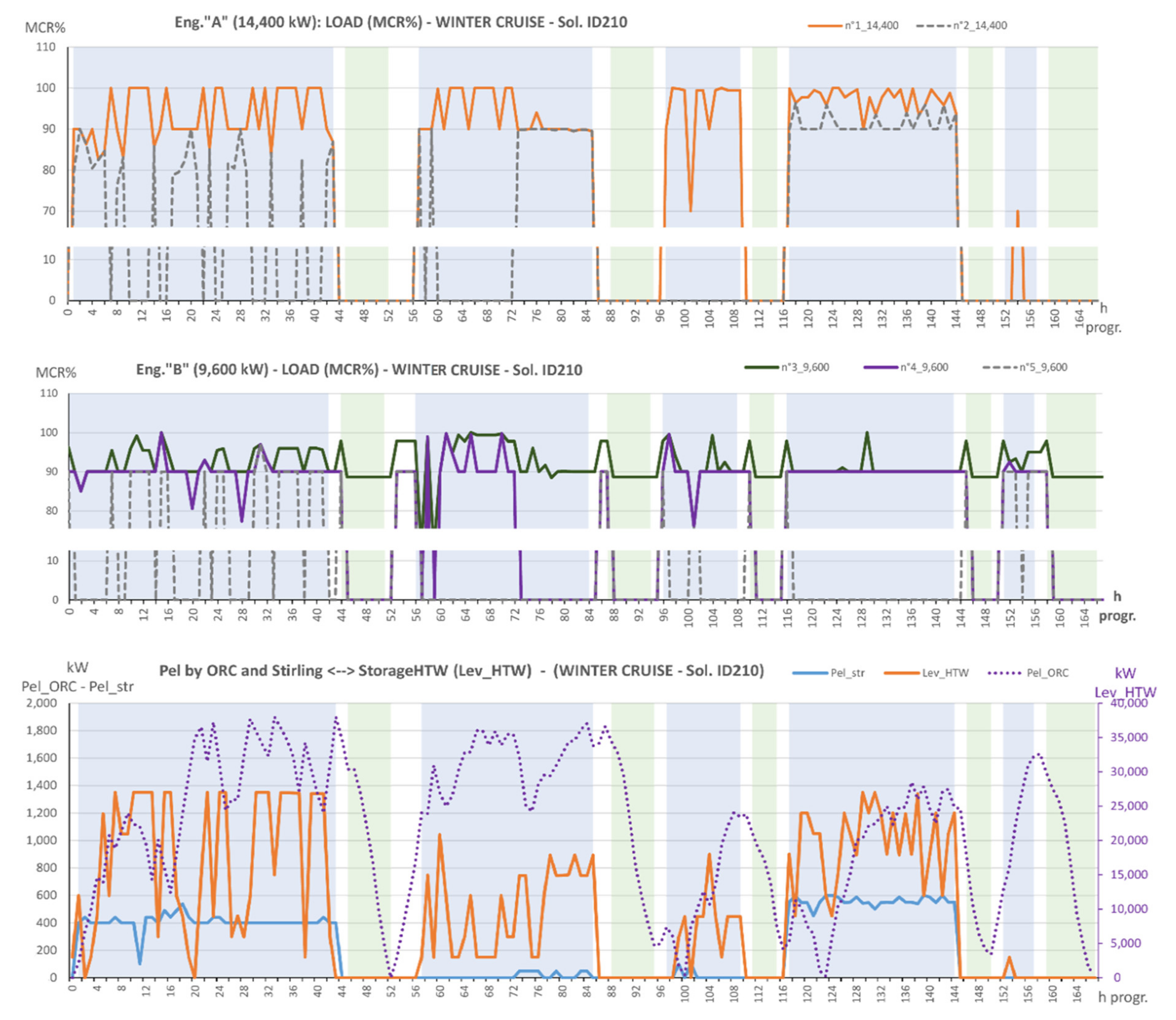

| 210 | 10 | 12 | 0 | 38,000 | 952 | 101.0 | 33,750 | 84,700 | 18.2 | 1.7 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gnes, P.; Pinamonti, P.; Reini, M. Bi-Level Optimization of the Energy Recovery System from Internal Combustion Engines of a Cruise Ship. Appl. Sci. 2020, 10, 6917. https://doi.org/10.3390/app10196917

Gnes P, Pinamonti P, Reini M. Bi-Level Optimization of the Energy Recovery System from Internal Combustion Engines of a Cruise Ship. Applied Sciences. 2020; 10(19):6917. https://doi.org/10.3390/app10196917

Chicago/Turabian StyleGnes, Paolo, Piero Pinamonti, and Mauro Reini. 2020. "Bi-Level Optimization of the Energy Recovery System from Internal Combustion Engines of a Cruise Ship" Applied Sciences 10, no. 19: 6917. https://doi.org/10.3390/app10196917

APA StyleGnes, P., Pinamonti, P., & Reini, M. (2020). Bi-Level Optimization of the Energy Recovery System from Internal Combustion Engines of a Cruise Ship. Applied Sciences, 10(19), 6917. https://doi.org/10.3390/app10196917