Robust Design Optimization and Emerging Technologies for Electrical Machines: Challenges and Open Problems

Abstract

1. Introduction

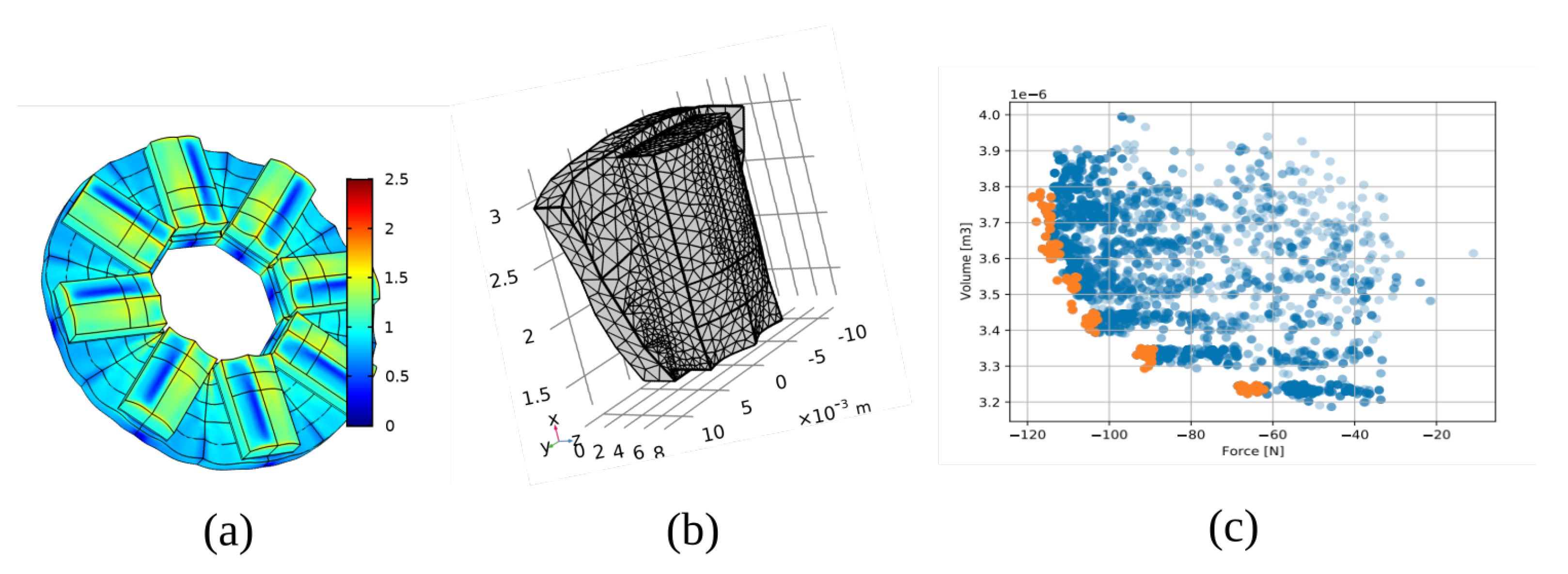

2. Robust Design Optimization Methods and Challenges

2.1. Robustness in Machine Design and Manufacturing

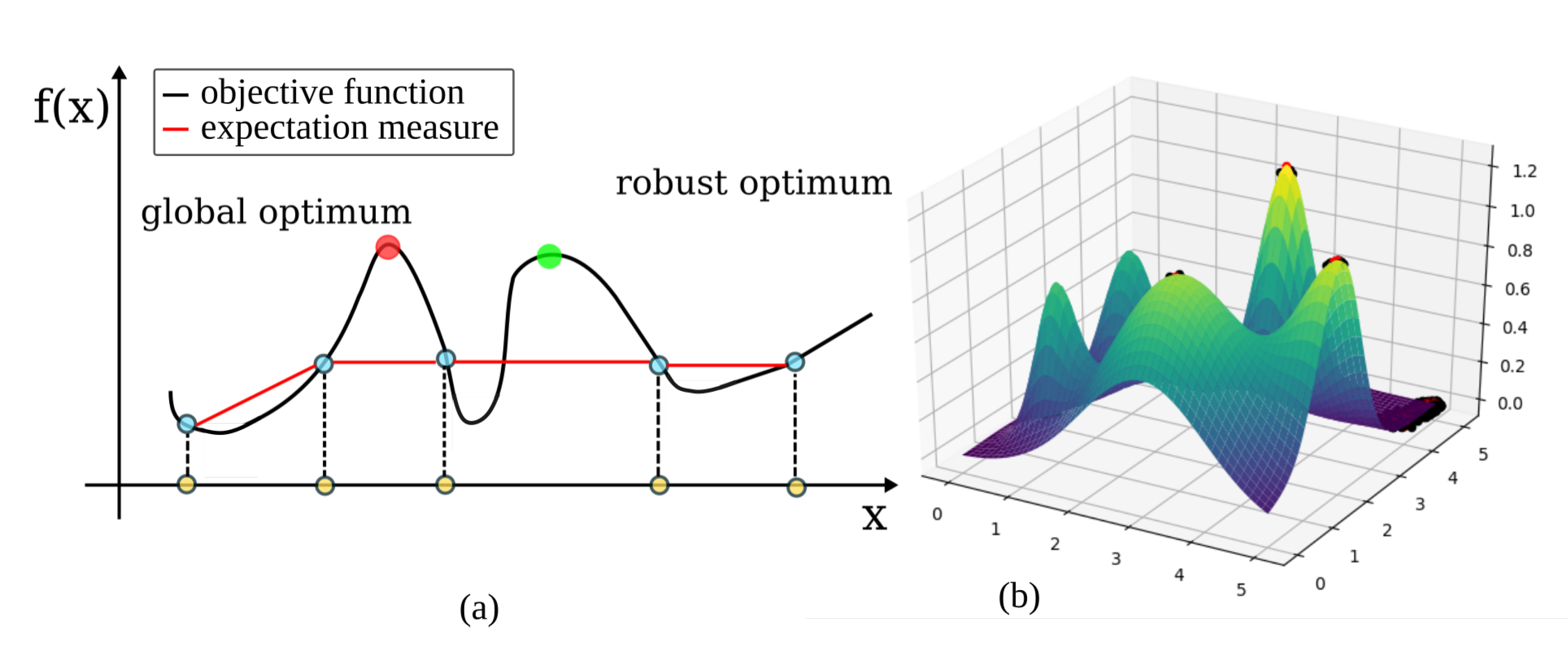

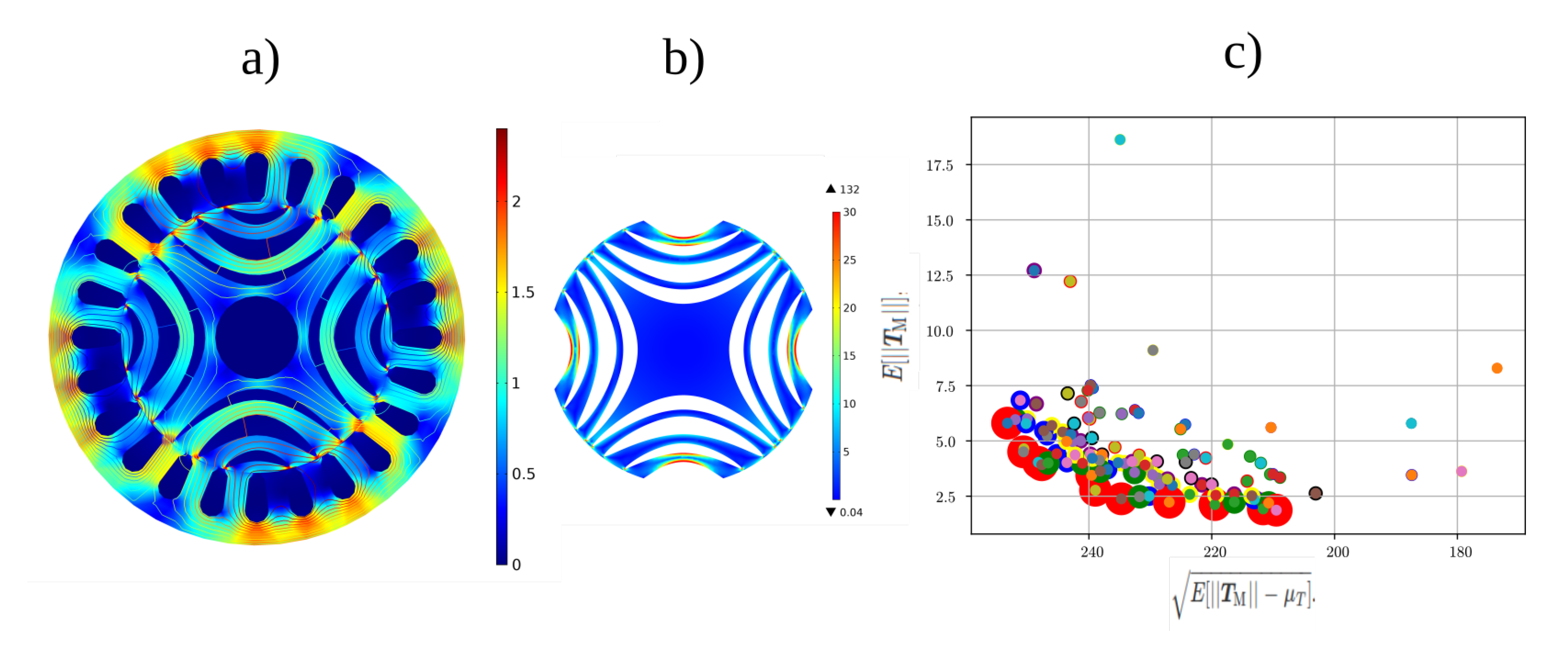

2.2. Robustness Methods and Measures

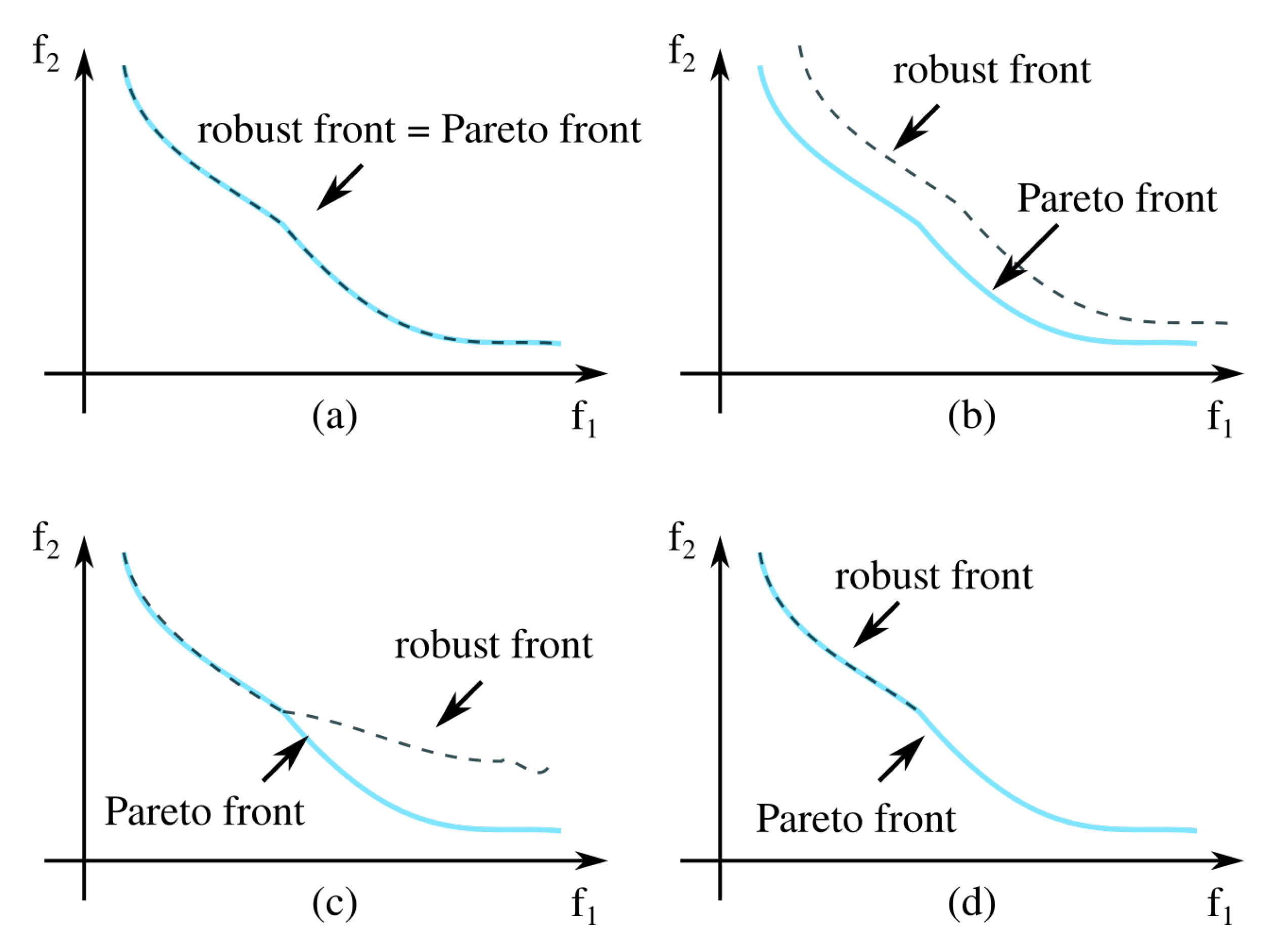

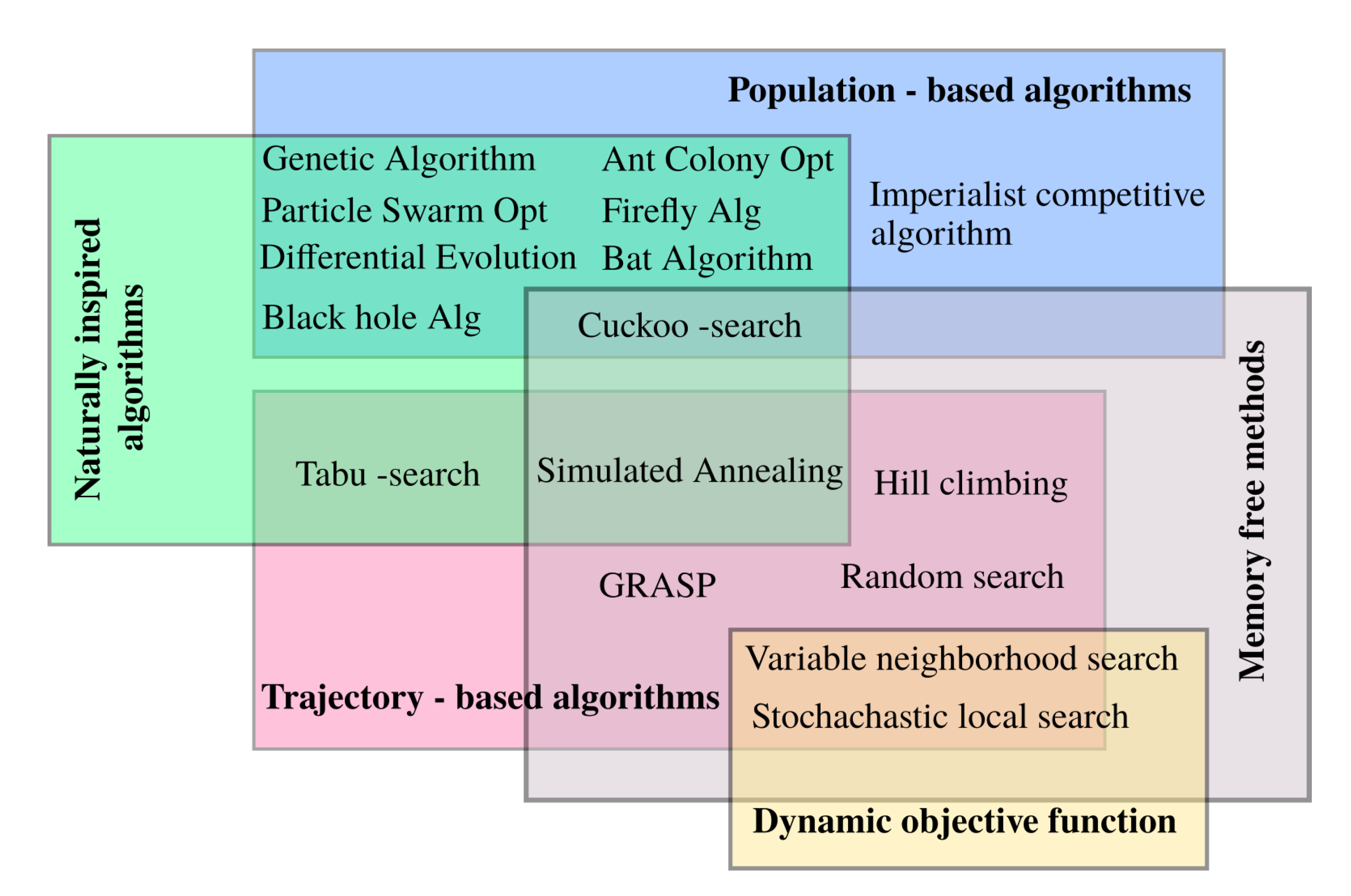

2.3. Multi-Objective Optimization Techniques

2.4. Measures for Evolutionary Algorithms and Uncertainties

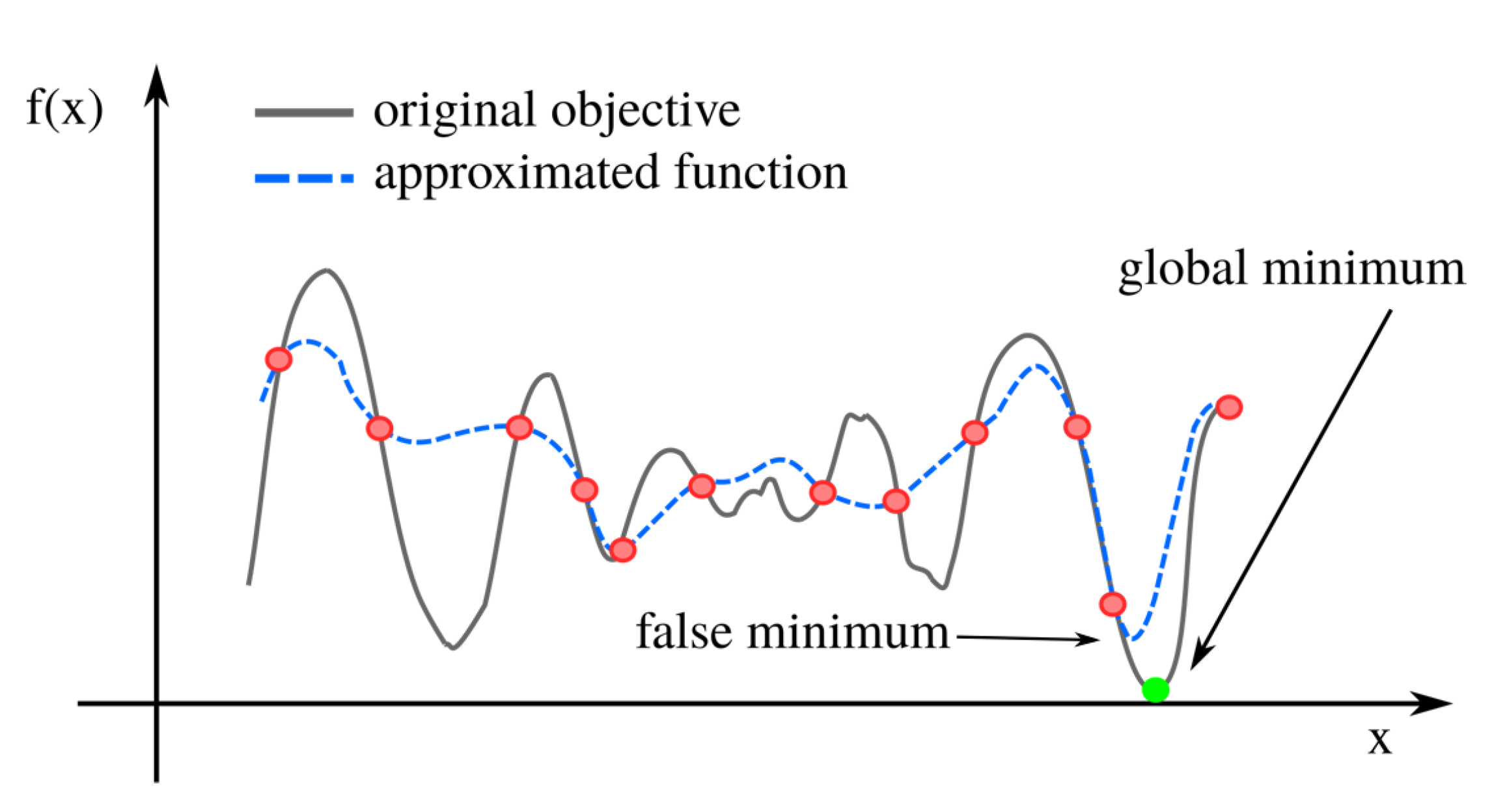

2.5. Methods for Computational Cost Reduction

3. Numerical Modeling and Novel Technologies and Materials

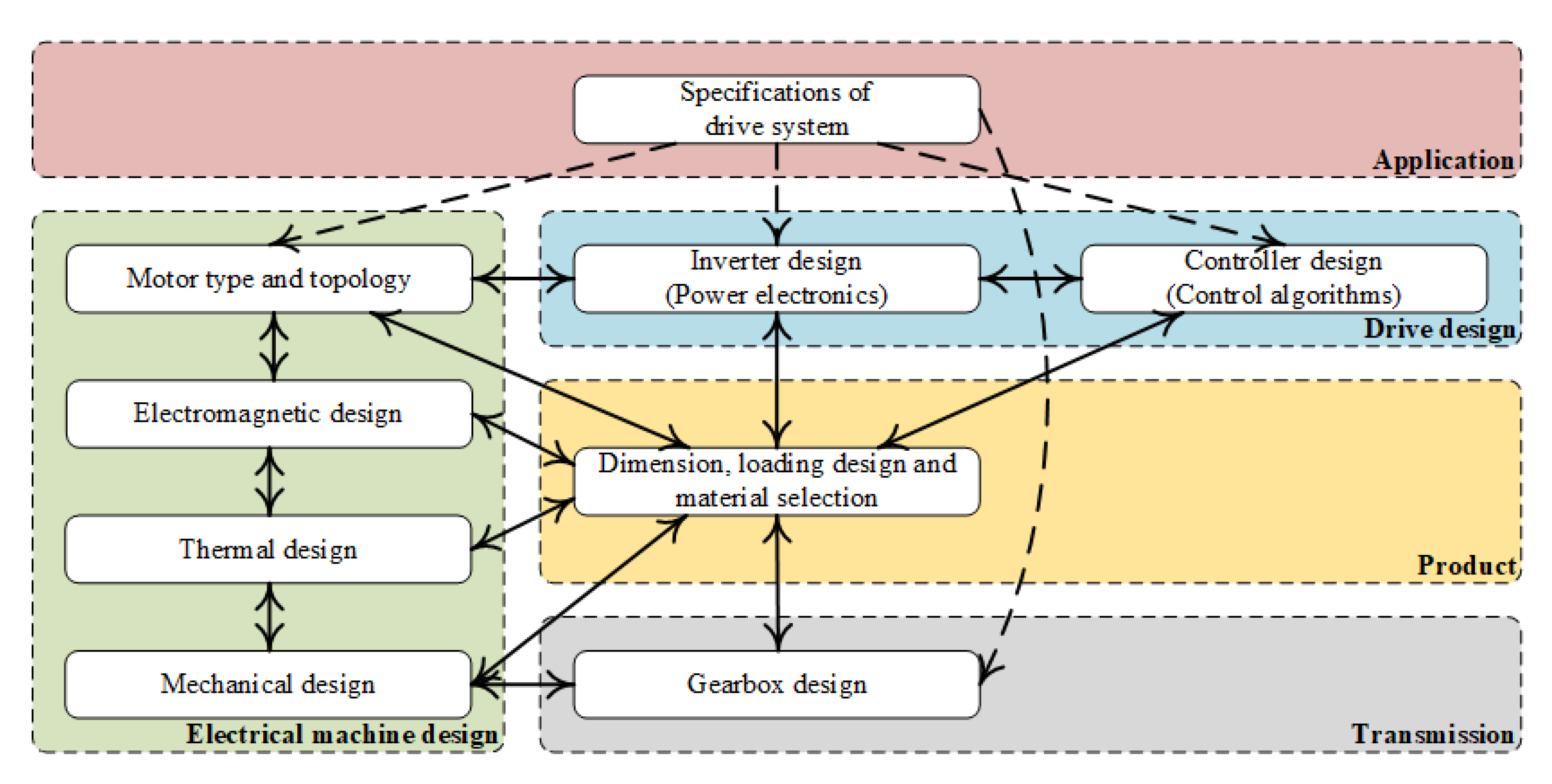

3.1. Drives and Electric Vehicles

- Step 1:

- determination of electrical system requirements (e.g. cost, efficiency, speed range, controllability, power density, electrical machine torque, etc.);

- Step 2:

- topology selection;

- Step 3:

- design of the electrical machine and/or power electronics device;

- Step 4:

- optimization of designed parameters.

- Step 5:

- evaluation of the whole electrical drive system’s performance, including the steady-state performance and dynamic response.

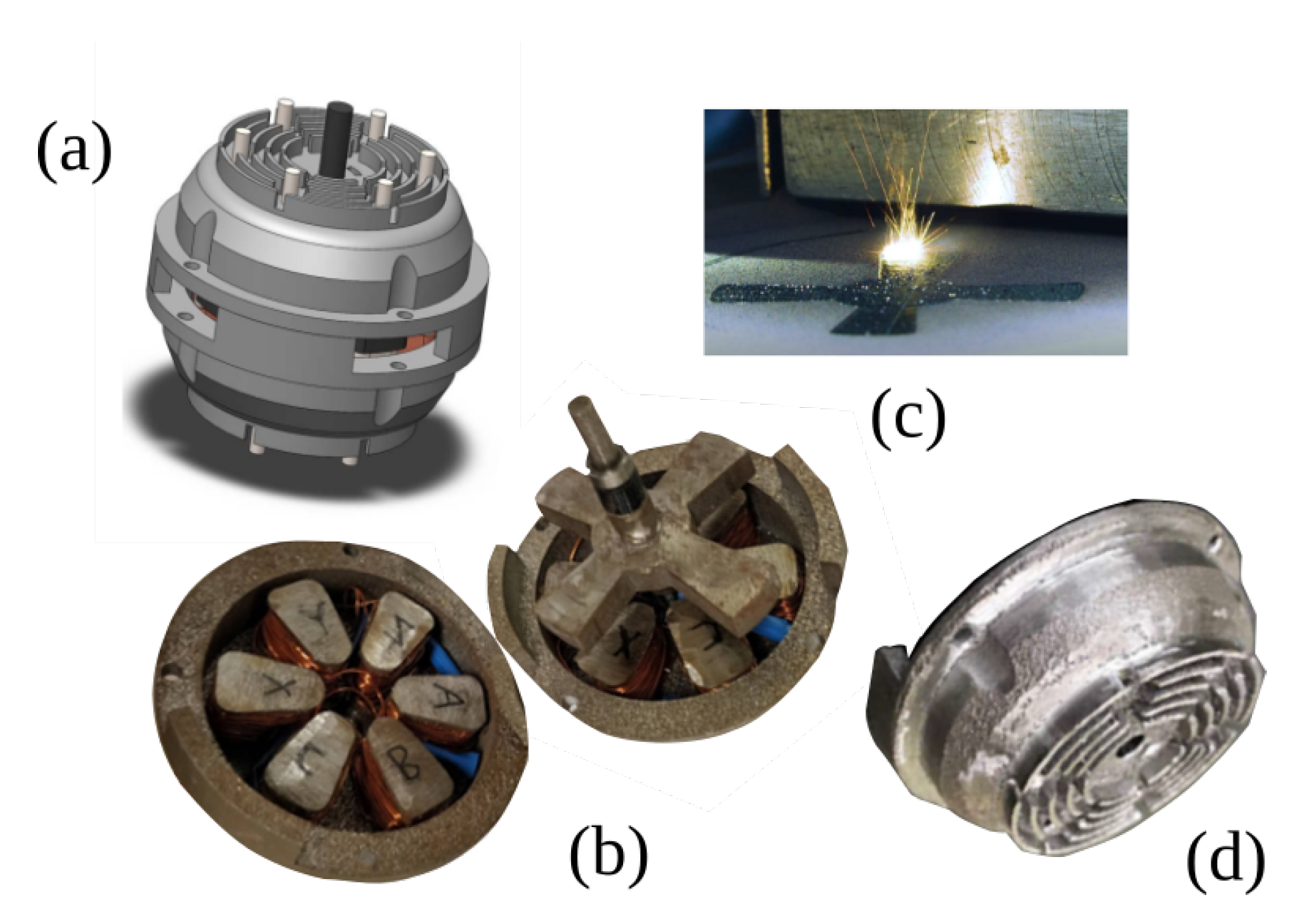

3.2. 3D Printed Electrical Machines

- vat photopolymerization;

- material jetting;

- binder jetting;

- material extrusion;

- powder bed fusion;

- sheet lamination;

- direct energy deposition.

3.3. Superconducting Material Based Electrical Machines

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tenne, Y.; Goh, C.K. Computational Intelligence in Expensive Optimization Problems; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2010; Volume 2. [Google Scholar]

- Darwish, A. Bio-inspired computing: Algorithms review, deep analysis, and the scope of applications. Future Comput. Inform. J. 2018, 3, 231–246. [Google Scholar] [CrossRef]

- Sizov, G.Y.; Ionel, D.M.; Demerdash, N.A.O. A review of efficient FE modeling techniques with applications to PM AC machines. In Proceedings of the 2011 IEEE Power and Energy Society General Meeting, Rhodes, Greece, 15–19 June 2011; pp. 1–6. [Google Scholar] [CrossRef]

- Yilmaz, M.; Krein, P.T. Capabilities of finite element analysis and magnetic equivalent circuits for electrical machine analysis and design. In Proceedings of the 2008 IEEE Power Electronics Specialists Conference, Rhodes, Greece, 15–19 June 2008. [Google Scholar]

- Lei, G.; Zhu, J.; Guo, Y. Multidisciplinary Design Optimization Methods for Electrical Machines and Drive Systems; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Abetti, P.; Cuthbertson, W.; Williams, S. Philosophy of applying digital computers to the design of electric apparatus. Trans. Am. Inst. Electr. Eng. Part I Commun. Electron. 1958, 77, 367–379. [Google Scholar] [CrossRef]

- Del Vecchio, R.; Del Vecchio, R.M.; Poulin, B.; Feghali, P.T.; Shah, D.M.; Ahuja, R. Transformer Design Principles; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Bramerdorfer, G.; Tapia, J.A.; Pyrhönen, J.J.; Cavagnino, A. Modern Electrical Machine Design Optimization: Techniques, Trends, and Best Practices. IEEE Trans. Ind. Electron. 2018, 65, 7672–7684. [Google Scholar] [CrossRef]

- Orosz, T. Evolution and modern approaches of the power transformer cost optimization methods. Periodica Polytech. Electr. Eng. Comput. Sci. 2019, 63, 37–50. [Google Scholar] [CrossRef]

- Sizov, G.Y.; Ionel, D.M.; Demerdash, N.A.O. Modeling and design optimization of PM AC machines using computationally efficient—Finite element analysis. In Proceedings of the 2010 IEEE Energy Conversion Congress and Exposition, Atlanta, GA, USA, 12–16 September 2010. [Google Scholar]

- Devillers, E.; Besnerais, J.L.; Lubin, T.; Hecquet, M.; Lecointe, J.P. A review of subdomain modeling techniques in electrical machines: Performances and applications. In Proceedings of the 2016 XXII International Conference on Electrical Machines (ICEM), Lausanne, Switzerland, 4–7 September 2016; pp. 86–92. [Google Scholar]

- Jurkovic, S.; Rahman, K.M.; Savagian, P.J. Design, optimization and development of electrical machine for traction application in GM battery electric vehicle. In Proceedings of the 2015 IEEE International Electric Machines & Drives Conference (IEMDC), Coeur d’Alene, ID, USA, 10–13 May 2015; pp. 1814–1819. [Google Scholar]

- Ombach, G.; Junak, J. Torque ripple optimization of skewed IPM motor for field weakening operation. In Proceedings of the 2011 International Conference on Electrical Machines and Systems, Beijing, China, 20–23 August 2011; pp. 1–7. [Google Scholar]

- Orosz, T.; Sleisz, Á.; Tamus, Z.Á. Metaheuristic Optimization Preliminary Design Process of Core-Form Autotransformers. IEEE Trans. Magn. 2016, 52, 1–10. [Google Scholar] [CrossRef]

- Boyd, S.; Boyd, S.P.; Vandenberghe, L. Convex Optimization; Cambridge University Press: Cambridge, UK, 2004. [Google Scholar]

- Boules, N. Design optimization of permanent magnet DC motors. IEEE Trans. Ind. Appl. 1990, 26, 786–792. [Google Scholar] [CrossRef]

- Mun, S.J.; Cho, Y.H.; Lee, J.H. Optimum design of synchronous reluctance motors based on torque/volume using finite-element method and sequential unconstrained minimization technique. IEEE Trans. Magn. 2008, 44, 4143–4146. [Google Scholar]

- Mosavi, A.; Salimi, M.; Faizollahzadeh Ardabili, S.; Rabczuk, T.; Shamshirband, S.; Varkonyi-Koczy, A. State of the Art of Machine Learning Models in Energy Systems, a Systematic Review. Energies 2019, 12, 1301. [Google Scholar] [CrossRef]

- Duan, Y.; Ionel, D.M. A Review of Recent Developments in Electrical Machine Design Optimization Methods With a Permanent-Magnet Synchronous Motor Benchmark Study. IEEE Trans. Ind. Appl. 2013, 49, 1268–1275. [Google Scholar] [CrossRef]

- Stipetic, S.; Miebach, W.; Zarko, D. Optimization in design of electrical machines: Methodology and workflow. In Proceedings of the 2015 Intl Aegean Conference on Electrical Machines & Power Electronics (ACEMP), 2015 Intl Conference on Optimization of Electrical & Electronic Equipment (OPTIM) & 2015 Intl Symposium on Advanced Electromechanical Motion Systems (ELECTROMOTION), Side, Turkey, 2–4 September 2015; pp. 441–448. [Google Scholar]

- Duan, Y.; Sun, Q.Y.; Ionel, D.M. Methods for studying the pareto-fronts in multiobjective design optimization problems of electrical machines. In Proceedings of the 2013 IEEE Energy Conversion Congress and Exposition, Denver, CO, USA, 15–19 September 2013; pp. 5013–5018. [Google Scholar]

- Sizov, G.Y. Design Synthesis and Optimization of Permanent Magnet Synchronous Machines Based on Computationally-Efficient Finite Element Analysis. Ph.D. Thesis, Marquette University, Milwaukee, WI, USA, 2013. [Google Scholar]

- Yang, X.S. Nature-inspired optimization algorithms: Challenges and open problems. J. Comput. Sci. 2020, 101104. [Google Scholar] [CrossRef]

- Wolpert, D.H.; Macready, W.G. No free lunch theorems for optimization. IEEE Trans. Evol. Comput. 1997, 1, 67–82. [Google Scholar] [CrossRef]

- Sizov, G.Y.; Ionel, D.M.; Demerdash, N.A.O. Modeling and Parametric Design of Permanent-Magnet AC Machines Using Computationally Efficient Finite-Element Analysis. IEEE Trans. Ind. Electron. 2012, 59, 2403–2413. [Google Scholar] [CrossRef]

- Silvas, E.; Hofman, T.; Murgovski, N.; Etman, L.F.P.; Steinbuch, M. Review of Optimization Strategies for System-Level Design in Hybrid Electric Vehicles. IEEE Trans. Veh. Technol. 2017, 66, 57–70. [Google Scholar] [CrossRef]

- Semidey, S.A.; Duan, Y.; Mayor, J.R.; Harley, R.G.; Habetler, T.G. Optimal Electromagnetic-Thermo- Mechanical Integrated Design Candidate Search and Selection for Surface-Mount Permanent-Magnet Machines Considering Load Profiles. IEEE Trans. Ind. Appl. 2011, 47, 2460–2468. [Google Scholar] [CrossRef]

- Li, M.; Liu, L.; Lin, D. A fast steady-state ε-dominance multiobjective evolutionary algorithm. Comput. Optim. Appl. 2011, 48, 109–138. [Google Scholar] [CrossRef]

- Pánek, D.; Orosz, T.; Karban, P. Artap: Robust design optimization framework for engineering applications. arXiv 2019, arXiv:1912.11550. [Google Scholar]

- Karban, P.; Pánek, D.; Orosz, T.; Petrášová, I.; Doležel, I. FEM based robust design optimization with Agros and Ārtap. Comput. Math. Appl. 2020, in press. [Google Scholar] [CrossRef]

- Pánek, D.; Karban, P.; Orosz, T.; Doležel, I. Comparison of simplified techniques for solving selected coupled electroheat problems. COMPEL-Int. J. Comput. Math. Electr. Electron. Eng. 2020, in press. [Google Scholar]

- Pánek, D.; Orosz, T.; Kropík, P.; Karban, P.; Doležel, I. Reduced-Order Model Based Temperature Control of Induction Brazing Process. In Proceedings of the 2019 Electric Power Quality and Supply Reliability Conference (PQ) 2019 Symposium on Electrical Engineering and Mechatronics (SEEM), Kärdla, Estonia, 12–15 June 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Isfahani, A.H.; Ebrahimi, B.; Lesani, H. Design optimization of a low-speed single-sided linear induction motor for improved efficiency and power factor. IEEE Trans. Magn. 2008, 44, 266–272. [Google Scholar] [CrossRef]

- Ahn, Y.; Park, J.; Lee, C.G.; Kim, J.W.; Jung, S.Y. Novel memetic algorithm implemented with GA (genetic algorithm) and MADS (mesh adaptive direct search) for optimal design of electromagnetic system. IEEE Trans. Magn. 2010, 46, 1982–1985. [Google Scholar] [CrossRef]

- Ārtap - Python Framework for Robust Design Optimization. Available online: http://www.agros2d.org/artap/ (accessed on 16 June 2020).

- Deb, K.; Gupta, H. Introducing Robustness in Multi-Objective Optimization. Evol. Comput. 2006, 14, 463–494. [Google Scholar] [CrossRef] [PubMed]

- Branke, J. Efficient evolutionary algorithms for searching robust solutions. In Evolutionary Design and Manufacture; Springer: Berlin/Heidelberg, Germany, 2000; pp. 275–285. [Google Scholar]

- Mirjalili, S.; Lewis, A. Obstacles and difficulties for robust benchmark problems: A novel penalty based robust optimisation method. Inf. Sci. 2016, 328, 485–509. [Google Scholar] [CrossRef]

- Yang, X.S. Multiobjective firefly algorithm for continuous optimization. Eng. Comput. 2013, 29, 175–184. [Google Scholar] [CrossRef]

- Hu, X.; Shi, Y.; Eberhart, R. Recent advances in particle swarm. In Proceedings of the 2004 Congress on Evolutionary Computation (IEEE Cat. No.04TH8753), Portland, OR, USA, 19–23 June 2004; pp. 90–97. [Google Scholar]

- Branke, J.; Branke, J.; Deb, K.; Miettinen, K.; Slowiński, R. Multiobjective Optimization: Interactive and Evolutionary Approaches; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2008; Volume 5252. [Google Scholar]

- Basili, R.; Zanzotto, F.M. Parsing engineering and empirical robustness. Nat. Lang. Eng. 2002, 8, 97–120. [Google Scholar] [CrossRef]

- Lucía, O.; Maussion, P.; Dede, E.J.; Burdío, J.M. Induction Heating Technology and Its Applications: Past Developments, Current Technology, and Future Challenges. IEEE Trans. Ind. Electron. 2014, 61, 2509–2520. [Google Scholar] [CrossRef]

- Rudnev, V.; Loveless, D.; Cook, R.L. Handbook of Induction Heating; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Pánek, D.; Karban, P.; Doležel, I. Calibration of Numerical Model of Magnetic Induction Brazing. IEEE Trans. Magn. 2019, 55, 1–4. [Google Scholar] [CrossRef]

- Beyer, H.G.; Sendhoff, B. Robust optimization—A comprehensive survey. Comput. Methods Appl. Mech. Eng. 2007, 196, 3190–3218. [Google Scholar] [CrossRef]

- Jin, Y. A comprehensive survey of fitness approximation in evolutionary computation. Soft Comput. 2005, 9, 3–12. [Google Scholar] [CrossRef]

- Jin, Y.; Branke, J. Evolutionary optimization in uncertain environments—A survey. IEEE Trans. Evol. Comput. 2005, 9, 303–317. [Google Scholar] [CrossRef]

- Rakshit, P.; Konar, A.; Das, S. Noisy evolutionary optimization algorithms—A comprehensive survey. Swarm Evol. Comput. 2017, 33, 18–45. [Google Scholar] [CrossRef]

- Chen, W.; Allen, J.K.; Tsui, K.L.; Mistree, F. A procedure for robust design: Minimizing variations caused by noise factors and control factors. Mech. Des. 1996, 118, 478–485. [Google Scholar] [CrossRef]

- Bramerdorfer, G.; Lanser, S.; Amrhein, W. Multi-Harmonic Design and Optimization of PMSMs. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; pp. 7049–7056. [Google Scholar]

- Khanali, M.; Jayaram, S.; Cheng, J. Effects of voltages with high-frequency contents on the transformer insulation properties. In Proceedings of the 2013 IEEE Electrical Insulation Conference (EIC), Ottawa, ON, Canada, 2–5 June 2013; pp. 235–238. [Google Scholar]

- Zhou, P.; Lin, D.; Xiao, Y.; Lambert, N.; Rahman, M. Temperature-dependent demagnetization model of permanent magnets for finite element analysis. IEEE Trans. Magn. 2012, 48, 1031–1034. [Google Scholar] [CrossRef]

- Takahashi, Y.; Fujiwara, K.; Iwashita, T.; Nakashima, H. Parallel Finite-Element Method Based on Space–Time Domain Decomposition for Magnetic Field Analysis of Electric Machines. IEEE Trans. Magn. 2019, 55, 1–4. [Google Scholar] [CrossRef]

- Friedhoff, S.; Hahne, J.; Schöps, S. Multigrid-reduction-in-time for Eddy Current problems. PAMM 2019, 19, e201900262. [Google Scholar] [CrossRef]

- Bast, D.; Kulchytska-Ruchka, I.; Schöps, S.; Rain, O. Accelerated steady-state torque computation for induction machines using parallel-in-time algorithms. IEEE Trans. Magn. 2020, 56, 1–9. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, F.; Cheng, Z.; Yan, W.; Liu, L.; Zhang, J.; Fan, Y. Measurements and Calculation of Core-Based BH Curve and Magnetizing Current in DC-Biased Transformers. IEEE Trans. Appl. Supercond. 2010, 20, 1131–1134. [Google Scholar] [CrossRef]

- Ruoho, S. Demagnetisation of Permanent Magnets in Electrical Machines; OH Presentation, Helsinki University: Helsinki, Finland, 2006. [Google Scholar]

- Song, S.; Chen, S.; Lin, Y.; Zhang, M.; Liu, W. Characteristic and performance analysis of SRM with actual BH curve of electrical steel. Int. J. Appl. Electromagn. Mech. 2017, 53, 435–449. [Google Scholar] [CrossRef]

- Taguchi, G.; Phadke, M.S. Quality engineering through design optimization. In Quality Control, Robust Design, and the Taguchi Method; Springer: Berlin/Heidelberg, Germany, 1989; pp. 77–96. [Google Scholar]

- Condra, L. Reliability Improvement with Design of Experiment; CRC Press: Boca Raton, FL, USA, 2001. [Google Scholar]

- Park, G.J.; Lee, T.H.; Lee, K.H.; Hwang, K.H. Robust design: An overview. AIAA J. 2006, 44, 181–191. [Google Scholar] [CrossRef]

- Vining, G.G.; Myers, R.H. Combining Taguchi and response surface philosophies: A dual response approach. J. Qual. Technol. 1990, 22, 38–45. [Google Scholar] [CrossRef]

- Lee, K.H.; Eom, I.S.; Park, G.J.; Lee, W.I. Robust design for unconstrained optimization problems using the Taguchi method. AIAA J. 1996, 34, 1059–1063. [Google Scholar] [CrossRef]

- Dehnad, K. Quality Control, Robust Design, and the Taguchi Method; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Box, G. Signal-to-noise ratios, performance criteria, and transformations. Technometrics 1988, 30, 1–17. [Google Scholar] [CrossRef]

- Ku, K.J.; Rao, S.S.; Chen, L. Taguchi-aided search method for design optimization of engineering systems. Eng. Optim. 1998, 30, 1–23. [Google Scholar] [CrossRef]

- Nair, V.N.; Abraham, B.; MacKay, J.; Box, G.; Kacker, R.N.; Lorenzen, T.J.; Lucas, J.M.; Myers, R.H.; Vining, G.G.; Nelder, J.A.; et al. Taguchi’s parameter design: A panel discussion. Technometrics 1992, 34, 127–161. [Google Scholar] [CrossRef]

- Krishnan, R.; Bharadwaj, A.S. A review of parameter sensitivity and adaptation in indirect vector controlled induction motor drive systems. IEEE Trans. Power Electron. 1991, 6, 695–703. [Google Scholar] [CrossRef]

- D’Arco, S.; Suul, J.A.; Fosso, O.B. Small-signal modeling and parametric sensitivity of a virtual synchronous machine in islanded operation. Int. J. Electr. Power Energy Syst. 2015, 72, 3–15. [Google Scholar] [CrossRef]

- Offermann, P.; Mac, H.; Nguyen, T.T.; Clénet, S.; De Gersem, H.; Hameyer, K. Uncertainty quantification and sensitivity analysis in electrical machines with stochastically varying machine parameters. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Robyns, B.; Sente, P.A.; Buyse, H.A.; Labrique, F. Influence of digital current control strategy on the sensitivity to electrical parameter uncertainties of induction motor indirect field-oriented control. IEEE Trans. Power Electron. 1999, 14, 690–699. [Google Scholar] [CrossRef]

- Semail, E.; Kestelyn, X.; Bouscayrol, A. Sensitivity of a 5-phase brushless DC machine to the 7th harmonic of the back-electromotive force. In Proceedings of the 2004 IEEE 35th Annual Power Electronics Specialists Conference (IEEE Cat. No.04CH37551), Aachen, Germany, 20–25 June 2004; pp. 4564–4570. [Google Scholar]

- D’Arco, S.; Suul, J.A.; Fosso, O.B. Small-signal modeling and parametric sensitivity of a virtual synchronous machine. In Proceedings of the IEEE 2014 Power Systems Computation Conference(PSCC 2014), Wrocław, Poland, 18–22 August 2014; pp. 1–9. [Google Scholar]

- Le Guyadec, M.; Gerbaud, L.; Vinot, E.; Delinchant, B. Sensitivity analysis using Sobol indices for the thermal modeling of an electrical machine for sizing by optimization. COMPEL-Int. J. Comput. Math. Electr. Electron. Eng. 2019, 38, 965–976. [Google Scholar] [CrossRef]

- Taha, K. Methods That Optimize Multi-Objective Problems: A Survey and Experimental Evaluation. IEEE Access 2020, 8, 80855–80878. [Google Scholar] [CrossRef]

- Tsutsui, S.; Ghosh, A. Genetic algorithms with a robust solution searching scheme. IEEE Trans. Evol. Comput. 1997, 1, 201–208. [Google Scholar] [CrossRef]

- Jeong, D.H.; Lee, B.C. Development of an Optimization Technique for Robust Design of Mechanical Structures. Trans. Korean Soc. Mech. Eng. A 2000, 24, 215–224. [Google Scholar]

- Belegundu, A.D.; Zhang, S. Robust mechanical design through minimum sensitivity. Adv. Des. Autom. 1989, 233–239. [Google Scholar]

- Han, J.S.; Kwak, B.M. Robust optimal design of a vibratory microgyroscope considering fabrication errors. J. Micromech. Microeng. 2001, 11, 662. [Google Scholar] [CrossRef]

- Jin, R.; Du, X.; Chen, W. The use of metamodeling techniques for optimization under uncertainty. Struct. Multidiscip. Optim. 2003, 25, 99–116. [Google Scholar] [CrossRef]

- Du, X.; Chen, W. Efficient uncertainty analysis methods for multidisciplinary robust design. AIAA J. 2002, 40, 545–552. [Google Scholar] [CrossRef]

- Barrico, C.; Antunes, C.H. Robustness analysis in multiobjective optimization using a degree of robustness concept. In Proceedings of the 2006 IEEE International Conference on Evolutionary Computation, Vancouver, BC, Canada, 16–21 July 2006; pp. 1887–1892. [Google Scholar]

- Gaspar-Cunha, A.; Covas, J.A. Robustness in multiobjective optimization using evolutionary algorithms. Comput. Optim. Appl. 2008, 39, 75–96. [Google Scholar] [CrossRef]

- Barrico, C.; Antunes, C.H. A new approach to robustness analysis in multiobjective optimization. In Proceedings of the 7th International Conference on Multi-Objective Programming and Goal Programming (MOPGP 2006), Loire Valley, City of Tours, France, 12–14 June 2006; Springer: New York, USA, 2006; pp. 565–582. [Google Scholar]

- Wiesmann, D.; Hammel, U.; Back, T. Robust design of multilayer optical coatings by means of evolutionary algorithms. IEEE Trans. Evol. Comput. 1998, 2, 162–167. [Google Scholar] [CrossRef]

- Jin, Y.; Sendhoff, B. Trade-off between performance and robustness: An evolutionary multiobjective approach. In International Conference on Evolutionary Multi-Criterion Optimization; Springer: Berlin/Heidelberg, Germany, 2003; pp. 237–251. [Google Scholar]

- Bacelli, G.; Coe, R.G.; Patterson, D.; Wilson, D. System identification of a heaving point absorber: Design of experiment and device modeling. Energies 2017, 10, 472. [Google Scholar] [CrossRef]

- Kushner, H.; Yin, G.G. Stochastic Approximation and Recursive Algorithms and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2003; Volume 35. [Google Scholar]

- Andradottir, S. A review of simulation optimization techniques. In Proceedings of the 1998 Winter Simulation Conference. Proceedings (Cat. No.98CH36274), Washington, DC, USA, 13–16 December 1998; pp. 151–158. [Google Scholar]

- Duchi, J.; Glynn, P.; Namkoong, H. Statistics of Robust Optimization: A Generalized Empirical Likelihood Approach. 2016. Available online: http://xxx.lanl.gov/abs/1610.03425 (accessed on 18 September 2020).

- Robbins, H.; Monro, S. A stochastic approximation method. Ann. Math. Stat. 1951, 22, 400–407. [Google Scholar] [CrossRef]

- Ruppert, D. Efficient Estimations from a Slowly Convergent Robbins-Monro Process; Technical Report; Cornell University Operations Research and Industrial Engineering: New York, NY, USA, 1988. [Google Scholar]

- Tripuraneni, N.; Flammarion, N.; Bach, F.; Jordan, M.I. Averaging stochastic gradient descent on Riemannian manifolds. arXiv 2018, arXiv:1802.09128. [Google Scholar]

- Mou, W.; Li, C.J.; Wainwright, M.J.; Bartlett, P.L.; Jordan, M.I. On Linear Stochastic Approximation: Fine-grained Polyak-Ruppert and Non-Asymptotic Concentration. 2020. Available online: http://xxx.lanl.gov/abs/2004.04719 (accessed on 9 April 2020).

- Shamir, O. Without-replacement sampling for stochastic gradient methods. In Proceedings of the Advances in Neural Information Processing Systems 29 (NIPS 2016), Barcelona, Spain, 5–10 December 2016; pp. 46–54. [Google Scholar]

- Amoiralis, E.I.; Tsili, M.A.; Georgilakis, P.S. The state of the art in engineering methods for transformer design and optimization: A survey. J. Optoelectron. Adv. Mater. 2008, 10, 1149. [Google Scholar]

- Amoiralis, E.I.; Georgilakis, P.S.; Tsili, M.A.; Kladas, A.G. Global transformer optimization method using evolutionary design and numerical field computation. IEEE Trans. Magn. 2009, 45, 1720–1723. [Google Scholar] [CrossRef]

- Manchala, D.; Palazzolo, A.; Kascak, A.; Montague, G.; Brown, G. Constrained quadratic programming, active control of rotating mass imbalance. J. Sound Vib. 1997, 205, 561–580. [Google Scholar] [CrossRef]

- Hashimoto, H. Optimum design of high-speed, short journal bearings by mathematical programming. Tribol. Trans. 1997, 40, 283–293. [Google Scholar] [CrossRef]

- Escande, A.; Mansard, N.; Wieber, P.B. Hierarchical quadratic programming: Fast online humanoid-robot motion generation. Int. J. Robot. Res. 2014, 33, 1006–1028. [Google Scholar] [CrossRef]

- Orosz, T.; Sleisz, Á.; Vajda, I. Core-form transformer design optimization with branch and bound search and geometric programming. In Proceedings of the 2014 55th International Scientific Conference on Power and Electrical Engineering of Riga Technical University (RTUCON), Riga, Latvia, 14 October 2014; pp. 17–21. [Google Scholar]

- Park, J.; Boyd, S. General heuristics for nonconvex quadratically constrained quadratic programming. arXiv 2017, arXiv:1703.07870. [Google Scholar]

- Avriel, M. Advances in Geometric Programming; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; Volume 21. [Google Scholar]

- Boyd, S.; Kim, S.J.; Vandenberghe, L.; Hassibi, A. A tutorial on geometric programming. Optim. Eng. 2007, 8, 67–127. [Google Scholar] [CrossRef]

- Deb, K. Multi-objective optimization. In Search Methodologies; Springer: Berlin/Heidelberg, Germany, 2014; pp. 403–449. [Google Scholar]

- Mashwani, W.K.; Salhi, A.; Jan, M.; Khanum, R.; Suliaman, M. Evolutionary algorithms based on decomposition and indicator functions: State-of-the-art survey. Adv. Comput. Sci. Appl. (IJACSA) 2016, 7, 583–593. [Google Scholar]

- V. Pareto, “Cours d’économie Politique, Volume I and II,” F. Rouge, Lausanne, 1896, 97. Available online: https://journals.sagepub.com/doi/abs/10.1177/000271629700900314?journalCode=anna (accessed on 18 March 2020).

- Ma, Q.; Chen, H.; El-Refaie, A.; Sun, Y. A Review of Electrical Machine Optimization Medthods with Emphasis on Computational Time. In Proceedings of the 2019 IEEE International Electric Machines & Drives Conference (IEMDC), San Diego, CA, USA, 11–15 May 2019; pp. 1895–1902. [Google Scholar]

- Fodorean, D.; Idoumghar, L.; Szabó, L. Motorization for an electric scooter by using permanent-magnet machines optimized based on a hybrid metaheuristic algorithm. IEEE Trans. Veh. Technol. 2012, 62, 39–49. [Google Scholar] [CrossRef]

- Balamurali, A.; Mollaeian, A.; Sangdehi, S.M.; Kar, N.C. Parameter identification of permanent magnet synchronous machine based on metaheuristic optimization. In Proceedings of the 2015 IEEE International Electric Machines & Drives Conference (IEMDC), Coeur d’Alene, ID, USA, 10–13 May 2015; pp. 1729–1734. [Google Scholar]

- Thangaraj, R.; Raj, C.T.; Bouvry, P.; Pant, M.; Abraham, A. Optimal design of induction motor for a spinning machine using population based metaheuristics. In Proceedings of the 2010 International Conference on Computer Information Systems and Industrial Management Applications (CISIM), Krackow, Poland, 8–10 October 2010; pp. 341–346. [Google Scholar]

- Hemmati, R.; Rahideh, A. Optimal design of slotless tubular linear brushless PM machines using metaheuristic optimization techniques. J. Intell. Fuzzy Syst. 2017, 32, 351–362. [Google Scholar] [CrossRef]

- Gutierrez-Reina, D.; Barrero, F.; Riveros, J.; Gonzalez-Prieto, I.; Toral, S.L.; Duran, M.J. Interest and Applicability of Meta-Heuristic Algorithms in the Electrical Parameter Identification of Multiphase Machines. Energies 2019, 12, 314. [Google Scholar] [CrossRef]

- Tang, W.; Wu, Q. Evolutionary computation. In Condition Monitoring and Assessment of Power Transformers Using Computational Intelligence; Springer: Berlin/Heidelberg, Germany, 2011; pp. 15–36. [Google Scholar]

- De León-Aldaco, S.E.; Calleja, H.; Alquicira, J.A. Metaheuristic optimization methods applied to power converters: A review. IEEE Trans. Power Electron. 2015, 30, 6791–6803. [Google Scholar] [CrossRef]

- Torrent-Fontbona, F. Optimisation Methods Meet the Smart Grid. New Methods for Solving Location and Allocation Problems under the Smart grid Paradigm. Ph.D. Thesis, University of Girona, Girona, Spain, 23 June 2015. [Google Scholar]

- López, B.; Munoz, V.; Murillo, J.; Barber, F.; Salido, M.A.; Abril, M.; Cervantes, M.; Caro, L.F.; Villaret, M. Experimental analysis of optimization techniques on the road passenger transportation problem. Eng. Appl. Artif. Intell. 2009, 22, 374–388. [Google Scholar] [CrossRef][Green Version]

- Mahdavi, S.; Shiri, M.E.; Rahnamayan, S. Metaheuristics in large-scale global continues optimization: A survey. Inf. Sci. 2015, 295, 407–428. [Google Scholar] [CrossRef]

- Campbell, S.D.; Sell, D.; Jenkins, R.P.; Whiting, E.B.; Fan, J.A.; Werner, D.H. Review of numerical optimization techniques for meta-device design. Opt. Mater. Express 2019, 9, 1842–1863. [Google Scholar] [CrossRef]

- Holland, J.H. Genetic algorithms. Sci. Am. 1992, 267, 66–73. [Google Scholar] [CrossRef]

- Tamaki, H.; Kita, H.; Kobayashi, S. Multi-objective optimization by genetic algorithms: A review. In Proceedings of the IEEE International Conference on Evolutionary Computation, Vancouver, BC, Canada, 24–29 July 2016; pp. 517–522. [Google Scholar]

- Mirjalili, S.; Dong, J.S.; Sadiq, A.S.; Faris, H. Genetic algorithm: Theory, literature review, and application in image reconstruction. In Nature-Inspired Optimizers; Springer: Berlin/Heidelberg, Germany, 2020; pp. 69–85. [Google Scholar]

- Eberhart, R.; Kennedy, J. Particle swarm optimization. In Proceedings of the IEEE International Conference on Neural Networks, Perth, Australia, 27 November–1 December 1995; pp. 1942–1948. [Google Scholar]

- Storn, R.; Price, K. Differential evolution–a simple and efficient heuristic for global optimization over continuous spaces. J. Glob. Optim. 1997, 11, 341–359. [Google Scholar] [CrossRef]

- Price, K.V. Differential evolution. In Handbook of Optimization; Springer: Berlin/Heidelberg, Germany, 2013; pp. 187–214. [Google Scholar]

- Liang, Y.; Wang, X.; Zhao, H.; Han, T.; Wei, Z.; Li, Y. A covariance matrix adaptation evolution strategy variant and its engineering application. Appl. Soft Comput. 2019, 83, 105680. [Google Scholar] [CrossRef]

- Yang, X.S.; He, X. Firefly algorithm: Recent advances and applications. Int. J. Swarm Intell. 2013, 1, 36–50. [Google Scholar] [CrossRef]

- Fister, I.; Fister, I., Jr.; Yang, X.S.; Brest, J. A comprehensive review of firefly algorithms. Swarm Evol. Comput. 2013, 13, 34–46. [Google Scholar] [CrossRef]

- Yang, X.S.; Deb, S. Cuckoo search: Recent advances and applications. Neural Comput. Appl. 2014, 24, 169–174. [Google Scholar] [CrossRef]

- Coello, C.A.C. A comprehensive survey of evolutionary based multiobjective optimization techniques. Knowl. Inf. Syst. 1999, 1, 269–308. [Google Scholar] [CrossRef]

- Parsopoulos, K.E.; Vrahatis, M.N. Multi-objective particles swarm optimization approaches. In Multi-objective Optimization in Computational Intelligence: Theory and Practice; IGI Global: New York, NY, USA, 2008; pp. 20–42. [Google Scholar]

- Mostaghim, S.; Teich, J. Strategies for finding good local guides in multiobjective particle swarm optimization (MOPSO). In Proceedings of the 2003 IEEE Swarm Intelligence Symposium, SIS’03 (Cat. No. 03EX706), Indianapolis, IN, USA, 26 April 2003; pp. 26–33. [Google Scholar]

- Nebro, A.J.; Durillo, J.J.; Garcia-Nieto, J.; Coello, C.C.; Luna, F.; Alba, E. SMPSO: A new PSO based metaheuristic for multiobjective optimization. In Proceedings of the 2009 IEEE Symposium on Computational Intelligence in Multi-Criteria Decision-Making (MCDM), Nashville, TN, USA, 30 March–2 April 2009; pp. 66–73. [Google Scholar]

- Godinez, A.C.; Espinosa, L.E.M.; Montes, E.M. An experimental comparison of multiobjective algorithms: NSGA-II and OMOPSO. In Proceedings of the 2010 IEEE Electronics, Robotics and Automotive Mechanics Conference, Morelos, Mexico, 28 September–1 October 2010; pp. 28–33. [Google Scholar]

- Parsopoulos, K.E.; Vrahatis, M.N. Particle swarm optimization method in multiobjective problems. In Proceedings of the 2002 ACM Symposium on Applied Computing, Madrid, Spain, 10–14 March 2002; pp. 603–607. [Google Scholar]

- Zitzler, E. Evolutionary algorithms for multiobjective optimization. In Proceedings of the EUROGEN2001 Conference; Publisher International Center for Numerical Methods in Engineering (CIMNE): Athens, Greece, 2002; pp. 19–26. [Google Scholar]

- Varga, T.; Király, A.; Abonyi, J. Improvement of PSO Algorithm by Memory-Based Gradient Search—Application in Inventory Management. In Swarm Intelligence and Bio-Inspired Computation; Elsevier: Amsterdam, The Netherlands, 2013; pp. 403–422. [Google Scholar]

- Sengupta, S.; Basak, S.; Peters, R.A. Particle Swarm Optimization: A survey of historical and recent developments with hybridization perspectives. Mach. Learn. Knowl. Extr. 2019, 1, 157–191. [Google Scholar] [CrossRef]

- Bramerdorfer, G.; Zavoianu, A.C.; Silber, S.; Lughofer, E.; Amrhein, W. Speed improvements for the optimization of electrical machines—A survey. In Proceedings of the 2015 IEEE International Electric Machines & Drives Conference (IEMDC), Coeur d’Alene, ID, USA, 10–13 May 2015; pp. 1748–1754. [Google Scholar]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Ciro, G.C.; Dugardin, F.; Yalaoui, F.; Kelly, R. A NSGA-II and NSGA-III comparison for solving an open shop scheduling problem with resource constraints. IFAC-PapersOnLine 2016, 49, 1272–1277. [Google Scholar] [CrossRef]

- Deb, K.; Mohan, M.; Mishra, S. Evaluating the ε-domination based multiobjective evolutionary algorithm for a quick computation of Pareto-optimal solutions. Evol. Comput. 2005, 13, 501–525. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, H. MOEA/D: A multiobjective evolutionary algorithm based on decomposition. IEEE Trans. Evol. Comput. 2007, 11, 712–731. [Google Scholar] [CrossRef]

- Kukkonen, S.; Lampinen, J. GDE3: The third evolution step of generalized differential evolution. In Proceedings of the 2005 IEEE Congress on Evolutionary Computation, Edinburgh, Scotland, UK, 2–5 September 2005; Volume 1, pp. 443–450. [Google Scholar]

- Knowles, J.; Corne, D. Properties of an adaptive archiving algorithm for storing non-dominated vectors. IEEE Trans. Evol. Comput. 2003, 7, 100–116. [Google Scholar] [CrossRef]

- Corne, D.W.; Jerram, N.R.; Knowles, J.D.; Oates, M.J. PESA-II: Region based selection in evolutionary multiobjective optimization. In Proceedings of the 3rd Annual Conference on Genetic and Evolutionary Computation, San Francisco, CA, USA, 7–11 July 2001; pp. 283–290. [Google Scholar]

- Onaka, J.H.D.; de Lima, A.S.; da Silva Kataoka, V.; Bezerra, U.H.; de Lima Tostes, M.E.; Vieira, J.P.A.; Carvalho, C.M. Comparing NSGA-II and SPEA2 metaheuristics in solving the problem of optimal capacitor banks placement and sizing in distribution grids considering harmonic distortion restrictions. In Proceedings of the 2016 17th International Conference on Harmonics and Quality of Power (ICHQP), Belo Horizonte, Brazil, 16–19 October 2016; pp. 77–82. [Google Scholar]

- Zitzler, E.; Künzli, S. Indicator based selection in multiobjective search. In International Conference on Parallel Problem Solving from Nature; Springer: Berlin/Heidelberg, Germany, 2004; pp. 832–842. [Google Scholar]

- Rostami, S.; Shenfield, A. Cma-paes: Pareto archived evolution strategy using covariance matrix adaptation for multiobjective optimisation. In Proceedings of the IEEE 2012 12th UK Workshop on Computational Intelligence (UKCI), Edinburgh, UK, 5–7 September 2012; pp. 1–8. [Google Scholar]

- Zitzler, E.; Laumanns, M.; Thiele, L. SPEA2: Improving the strength Pareto evolutionary algorithm. TIK-Report 2001, 103, 1–21. [Google Scholar]

- Jiang, S.; Zhang, J.; Ong, Y.; Zhang, A.N.; Tan, P.S. A Simple and Fast Hypervolume Indicator-Based Multiobjective Evolutionary Algorithm. IEEE Trans. Cybern. 2015, 45, 2202–2213. [Google Scholar] [CrossRef]

- Sun, Y.; Yen, G.G.; Yi, Z. IGD indicator based evolutionary algorithm for many-objective optimization problems. IEEE Trans. Evol. Comput. 2018, 23, 173–187. [Google Scholar] [CrossRef]

- Li, M.; Yang, S.; Liu, X. Diversity Comparison of Pareto Front Approximations in Many-Objective Optimization. IEEE Trans. Cybern. 2014, 44, 2568–2584. [Google Scholar] [CrossRef] [PubMed]

- Gandibleux, X.; Mezdaoui, N.; Fréville, A. A tabu search procedure to solve multiobjective combinatorial optimization problems. In Advances in Multiple Objective and Goal Programming; Springer: Berlin/Heidelberg, Germany, 1997; pp. 291–300. [Google Scholar]

- Tuyttens, D.; Teghem, J.; Fortemps, P.; Van Nieuwenhuyze, K. Performance of the MOSA method for the bicriteria assignment problem. J. Heuristics 2000, 6, 295–310. [Google Scholar] [CrossRef]

- Yusoff, Y.; Ngadiman, M.S.; Zain, A.M. Overview of NSGA-II for optimizing machining process parameters. Procedia Eng. 2011, 15, 3978–3983. [Google Scholar] [CrossRef]

- Zhang, X.; Tian, Y.; Cheng, R.; Jin, Y. An efficient approach to non-dominated sorting for evolutionary multiobjective optimization. IEEE Trans. Evol. Comput. 2014, 19, 201–213. [Google Scholar] [CrossRef]

- Deb, K.; Jain, H. Handling many-objective problems using an improved NSGA-II procedure. In Proceedings of the 2012 IEEE Congress on Evolutionary Computation, Brisbane, Australia, 10–15 June 2012; pp. 1–8. [Google Scholar]

- D’Souza, R.G.; Sekaran, K.C.; Kandasamy, A. Improved NSGA-II based on a novel ranking scheme. arXiv 2010, arXiv:1002.4005. [Google Scholar]

- Blank, J.; Deb, K. pymoo: Multi-objective Optimization in Python. IEEE Access 2020, 8, 89497–89509. [Google Scholar] [CrossRef]

- Fortin, F.A.; De Rainville, F.M.; Gardner, M.A.G.; Parizeau, M.; Gagné, C. DEAP: Evolutionary algorithms made easy. J. Mach. Learn. Res. 2012, 13, 2171–2175. [Google Scholar]

- Garrett, A. Inspyred: A Framework for Creating Bio-Inspired Computational Intelligence Algorithms in Python. 2017 Software. Available online: https://aarongarrett.github.io/inspyred (accessed on 18 September 2020).

- Hadka, D. Platypus-Multiobjective Optimization in Python, Software. Available online: https://platypus.readthedocs.io (accessed on 18 September 2020).

- Pagmo and pygmo, Software. Available online: https://esa.github.io/pagmo2/index.html (accessed on 18 September 2020).

- Durillo, J.J.; Nebro, A.J. jMetal: A Java framework for multiobjective optimization. Adv. Eng. Softw. 2011, 42, 760–771. [Google Scholar] [CrossRef]

- Lei, G.; Zhu, J.; Guo, Y.; Liu, C.; Ma, B. A review of design optimization methods for electrical machines. Energies 2017, 10, 1962. [Google Scholar] [CrossRef]

- Wolpert, D.H.; Macready, W.G. Coevolutionary free lunches. IEEE Trans. Evol. Comput. 2005, 9, 721–735. [Google Scholar] [CrossRef]

- Di Barba, P.; Forzan, M.; Sieni, E. Multiobjective design optimization of an induction heating device: A benchmark problem. Int. J. Appl. Electromagn. Mech. 2015, 47, 1003–1013. [Google Scholar] [CrossRef]

- Di Barba, P.; Dughiero, F.; Forzan, M.; Sieni, E. Improved solution to a multiobjective benchmark problem of inverse induction heating. Int. J. Appl. Electromagn. Mech. 2015, 49, 279–288. [Google Scholar] [CrossRef]

- Karban, P.; Pánek, D.; Orosz, T.; Doležel, I. Semi-Analytical Solution for a Multi-Objective TEAM Benchmark Problem. Period. Polytech. Electr. Eng. Comput. Sci. in press.

- Mirjalili, S.; Lewis, A. Hindrances for robust multiobjective test problems. Appl. Soft Comput. 2015, 35, 333–348. [Google Scholar] [CrossRef]

- Jamil, M.; Yang, X.S. A literature survey of benchmark functions for global optimisation problems. Int. J. Math. Model. Numer. Optim. 2013, 4, 150–194. [Google Scholar] [CrossRef]

- CEC - Benchmarks for Evaluation of Evolutionary Algorithms. Available online: https://www.ntu.edu.sg/home/epnsugan/index_files/cec-benchmarking.htm (accessed on 18 September 2020).

- Biswas, S.; Das, S.; Suganthan, P.N.; Coello, C.A.C. Evolutionary multiobjective optimization in dynamic environments: A set of novel benchmark functions. In Proceedings of the 2014 IEEE Congress on Evolutionary Computation (CEC), Beijing, China, 6–11 July 2014; pp. 3192–3199. [Google Scholar]

- Ong, Y.S.; Nair, P.B.; Lum, K.Y. Max-min surrogate-assisted evolutionary algorithm for robust design. IEEE Trans. Evol. Comput. 2006, 10, 392–404. [Google Scholar]

- Mirjalili, S.; Lewis, A.; Dong, J.S. Confidence based robust optimisation using multiobjective meta-heuristics. Swarm Evol. Comput. 2018, 43, 109–126. [Google Scholar] [CrossRef]

- Lei, G.; Liu, C.; Jafari, M.; Zhu, J.; Guo, Y. Multilevel Robust Design Optimization of a Superconducting Magnetic Energy Storage Based on a Benchmark Study. IEEE Trans. Appl. Supercond. 2016, 26, 1–5. [Google Scholar] [CrossRef]

- Soares, G.L.; Adriano, R.L.; Maia, C.A.; Jaulin, L.; Vasconcelos, J.A. Robust multiobjective TEAM 22 problem: A case study of uncertainties in design optimization. IEEE Trans. Magn. 2009, 45, 1028–1031. [Google Scholar] [CrossRef]

- Lyu, Z.; Kenway, G.K.; Martins, J.R. Aerodynamic shape optimization investigations of the common research model wing benchmark. AIAA J. 2015, 53, 968–985. [Google Scholar] [CrossRef]

- Branke, J. Creating robust solutions by means of evolutionary algorithms. In International Conference on Parallel Problem Solving from Nature; Springer: Berlin/Heidelberg, Germany, 1998; pp. 119–128. [Google Scholar]

- Parmee, I.; Johnson, M.; Burt, S. Techniquesto aid global search in engineering design. In Proceedings of the 7th International Conference on Industrial and Engineering Applications of Artificial Intelligence and Expert Systems; CRC Press: Boca Raton, FL, USA, 1994; p. 377. [Google Scholar]

- Parmee, I.C.; Bonham, C. The maintenance of search diversity for effective design space decomposition using cluster oriented genetic algorithms (COGAs) and multi-agent strategies (GAANT). In Proceedings of the ACEDC; University of Plymouth: Plymouth, UK, 1996. [Google Scholar]

- Aizawa, A.N.; Wah, B.W. Dynamic control of genetic algorithms in a noisy environment. rn 1993, 2, 1. [Google Scholar]

- Aizawa, A.N.; Wah, B.W. Scheduling of genetic algorithms in a noisy environment. Evol. Comput. 1994, 2, 97–122. [Google Scholar] [CrossRef]

- Miller, B.L.; Goldberg, D.E. Genetic algorithms, selection schemes, and the varying effects of noise. Evol. Comput. 1996, 4, 113–131. [Google Scholar] [CrossRef]

- Miller, B.L. Noise, sampling, and efficient genetic algorithms. IlliGAL Rep. 1997, 91. [Google Scholar]

- Rakshit, P.; Konar, A. Non-dominated Sorting Bee Colony optimization in the presence of noise. Soft Comput. 2016, 20, 1139–1159. [Google Scholar] [CrossRef]

- Markon, S.; Arnold, D.V.; Back, T.; Beielstein, T.; Beyer, H.G. Thresholding-a selection operator for noisy ES. In Proceedings of the 2001 Congress on Evolutionary Computation (IEEE Cat. No. 01TH8546), Seoul, Korea, 27–30 May 2001; pp. 465–472. [Google Scholar]

- Neri, F.; Caponio, A. A differential evolution for optimisation in noisy environment. Int. J. Bio-Inspired Comput. 2010, 2, 152–168. [Google Scholar] [CrossRef]

- Branke, J.; Schmidt, C. Selection in the presence of noise. In Genetic and Evolutionary Computation Conference; Springer: Berlin/Heidelberg, Germany, 2003; pp. 766–777. [Google Scholar]

- Gutjahr, W.J.; Pflug, G.C. Simulated annealing for noisy cost functions. J. Glob. Optim. 1996, 8, 1–13. [Google Scholar] [CrossRef]

- Rakshit, P.; Konar, A. Noisy Multi-objective Optimization for Multi-robot Box-Pushing Application. In Principles in Noisy Optimization; Springer: Berlin/Heidelberg, Germany, 2018; pp. 243–305. [Google Scholar]

- Hughes, E.J. Evolutionary multiobjective ranking with uncertainty and noise. In International Conference on Evolutionary Multi-Criterion Optimization; Springer: Berlin/Heidelberg, Germany, 2001; pp. 329–343. [Google Scholar]

- Teich, J. Pareto-front exploration with uncertain objectives. In International Conference on Evolutionary Multi-Criterion Optimization; Springer: Berlin/Heidelberg, Germany, 2001; pp. 314–328. [Google Scholar]

- Sudret, B.; Marelli, S.; Wiart, J. Surrogate models for uncertainty quantification: An overview. In Proceedings of the IEEE 2017 11th European Conference on Antennas and Propagation (EUCAP), Paris, France, 19–24 March 2017; pp. 793–797. [Google Scholar]

- Schöbi, R. Surrogate models for uncertainty quantification in the context of imprecise probability modeling. IBK Bericht 2019, 505. [Google Scholar]

- Oduguwa, V.; Roy, R. Multi-objective optimisation of rolling rod product design using meta-modeling approach. In Proceedings of the 4th Annual Conference on Genetic and Evolutionary Computation, New York, NY, USA, 9–13 July 2002; pp. 1164–1171. [Google Scholar]

- Rasheed, K.; Hirsh, H. Informed operators: Speeding up genetic-algorithm based design optimization using reduced models. In Proceedings of the 2nd Annual Conference on Genetic and Evolutionary Computation, Las Vegas, NV, USA, 12 July 2000; pp. 628–635. [Google Scholar]

- Hong, Y.S.; Lee, H.; Tahk, M.J. Acceleration of the convergence speed of evolutionary algorithms using multi-layer neural networks. Eng. Optim. 2003, 35, 91–102. [Google Scholar] [CrossRef]

- Jin, Y.; Olhofer, M.; Sendhoff, B. On Evolutionary Optimization with Approximate Fitness Functions. In Proceedings of the Genetic and Evolutionary Computation Conference, Las Vegas, NV, USA, 8–12 July 2000; pp. 786–793. [Google Scholar]

- Jin, Y.; Sendhoff, B. Fitness approximation in evolutionary computation—A survey. In Proceedings of the 4th Annual Conference on Genetic and Evolutionary Computation, New York, NY, USA, 9–13 July 2002; pp. 1105–1112. [Google Scholar]

- Pierret, S.; Van den Braembussche, R. Turbomachinery blade design using a Navier–Stokes solver and artificial neural network. J. Turbomach. 1999, 121, 326–332. [Google Scholar] [CrossRef]

- Ong, Y.S.; Nair, P.B.; Keane, A.J. Evolutionary optimization of computationally expensive problems via surrogate modeling. AIAA J. 2003, 41, 687–696. [Google Scholar] [CrossRef]

- Ulmer, H.; Streichert, F.; Zell, A. Model-assisted steady-state evolution strategies. In Genetic and Evolutionary Computation Conference; Springer: Berlin/Heidelberg, Germany, 2003; pp. 610–621. [Google Scholar]

- Simpson, T.W.; Mauery, T.M.; Korte, J.J.; Mistree, F. Kriging models for global approximation in simulation based multidisciplinary design optimization. AIAA J. 2001, 39, 2233–2241. [Google Scholar] [CrossRef]

- Mazumdar, A.; Chugh, T.; Miettinen, K.; López-Ibáñez, M. On dealing with uncertainties from kriging models in offline data-driven evolutionary multiobjective optimization. In International Conference on Evolutionary Multi-Criterion Optimization; Springer: Berlin/Heidelberg, Germany, 2019; pp. 463–474. [Google Scholar]

- Matthews, A.G.d.G.; Rowland, M.; Hron, J.; Turner, R.E.; Ghahramani, Z. Gaussian process behaviour in wide deep neural networks. arXiv 2018, arXiv:1804.11271. [Google Scholar]

- Suthaharan, S. Support vector machine. In Machine Learning Models and Algorithms for Big Data Classification; Springer: Berlin/Heidelberg, Germany, 2016; pp. 207–235. [Google Scholar]

- Poyhonen, S.; Negrea, M.; Arkkio, A.; Hyotyniemi, H.; Koivo, H. Fault diagnostics of an electrical machine with multiple support vector classifiers. In Proceedings of the IEEE Internatinal Symposium on Intelligent Control, Vancouver, BC, Canada, 30 October 2002; pp. 373–378. [Google Scholar]

- Vas, P. Artificial-Intelligence-Based Electrical Machines and Drives: Application of Fuzzy, Neural, Fuzzy-Neural, and Genetic-Algorithm-Based Techniques; Oxford University Press: Oxford, UK, 1999; Volume 45. [Google Scholar]

- Awadallah, M.A.; Morcos, M.M. Application of AI tools in fault diagnosis of electrical machines and drives-an overview. IEEE Trans. Energy Convers. 2003, 18, 245–251. [Google Scholar] [CrossRef]

- Duchaud, J.L.; Hlioui, S.; Louf, F.; Gabsi, M. Electrical machine optimization using a kriging predictor. In Proceedings of the IEEE 2014 17th International Conference on Electrical Machines and Systems (ICEMS), Hangzhou, China, 22–25 October 2014; pp. 3476–3481. [Google Scholar]

- Woo, D.K.; Kim, I.W.; Jung, H.K. Optimal rotor structure design of interior permanent magnet synchronous machine based on efficient genetic algorithm using Kriging model. J. Electr. Eng. Technol. 2012, 7, 530–537. [Google Scholar] [CrossRef]

- Hong, S.K.; Ro, J.S.; Jung, H.K. Optimal design of a novel permanent magnetic actuator using evolutionary strategy algorithm and kriging meta-model. J. Electr. Eng. Technol. 2014, 9, 471–477. [Google Scholar] [CrossRef]

- Liu, X.; Li, X.; Huang, S. Parameters Optimization of the Permanent Magnet Linear Synchronous Machine Using Kriging based Genetic Algorithm. In Proceedings of the IEEE 2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019; pp. 1–6. [Google Scholar]

- Bittner, F.; Hahn, I. Kriging-assisted multiobjective particle swarm optimization of permanent magnet synchronous machine for hybrid and electric cars. In Proceedings of the IEEE 2013 International Electric Machines & Drives Conference, Chicago, IL, USA, 12–15 May 2013; pp. 15–22. [Google Scholar]

- Woo, D.K.; Lim, D.K.; Ali, M.; Jung, H.K. Optimal rotor structure design of interior permanent magnet synchronous machine based on accelerating evolution algorithm using the Kriging metamodel. Int. J. Appl. Electromagn. Mech. 2011, 36, 317–325. [Google Scholar] [CrossRef]

- Wiak, S.; Xiao, S.; Rotaru, M.; Sykulski, J.K. Exploration versus exploitation using kriging surrogate modeling in electromagnetic design. COMPEL- Int. J. Comput. Math. Electr. Electron. Eng. 2012, 31, 1541–1551. [Google Scholar]

- Rassõlkin, A.; Kallaste, A.; Orlova, S.; Gevorkov, L.; Vaimann, T.; Belahcen, A. Re-Use and Recycling of Different Electrical Machines. Latvian J. Phys. Tech. Sci. 2018, 55, 13–23. [Google Scholar] [CrossRef]

- Ferreira, F.J.; De Almeida, A.T. Reducing energy costs in electric-motor-driven systems. IEEE Ind. Appl. Mag. 2018, 24, 84–97. [Google Scholar] [CrossRef]

- Lei, G.; Wang, T.; Zhu, J.; Guo, Y.; Wang, S. System-Level Design Optimization Method for Electrical Drive Systems - Robust Approach. IEEE Trans. Ind. Electron. 2015, 62, 4702–4713. [Google Scholar] [CrossRef]

- Rassõlkin, A.; Heidari, H.; Kallaste, A.; Acedo, J.P.; Romero-cadaval, E. Efficiency Map Comparison of Induction and Synchronous Reluctance Motors. In Proceedings of the 26th International Workshop on Electric Drives: Improvement in Efficiency of Electric Drives (IWED), Moscow, Russia, 30 January–2 February 2019; pp. 4–7. [Google Scholar] [CrossRef]

- Kalt, S.; Bronner, M.; Lienkamp, M. Application based design of electrical machines for new vehicle concepts in developing countries. In Proceedings of the 2019 14th International Conference on Ecological Vehicles and Renewable Energies, EVER 2019, Monte-Carlo, Monaco, 8–10 May 2019. [Google Scholar] [CrossRef]

- Lei, G.; Guo, Y.G.; Zhu, J.G.; Wang, T.S.; Chen, X.M.; Shao, K.R. System level six sigma robust optimization of a drive system with PM transverse flux machine. IEEE Trans. Magn. 2012, 48, 923–926. [Google Scholar] [CrossRef]

- Zhu, J.G.; Lei, G.; Guo, Y.G.; Wang, T.S.; Ma, B. A robust design optimization method for manufacturing SMC-PMSMs and drive systems of six sigma quality. In Proceedings of the 2017 7th International Conference on Power Electronics Systems and Applications—Smart Mobility, Power Transfer and Security, Hong Kong, China, 12–14 December 2017; pp. 1–7. [Google Scholar] [CrossRef]

- Lei, G.; Zhu, J.; Liu, C.; Ma, B. Robust design optimization of electrical machines and drive systems for high quality mass production. In Proceedings of the 2016 6th International Electric Drives Production Conference, EDPC 2016, Nuremberg, Germany, 30 November 2016. [Google Scholar] [CrossRef]

- Degano, M.; Carraro, E.; Bianchi, N. Robust optimization of a traction PMASR motor according to given driving cycles. In Proceedings of the 2014 International Conference on Electrical Machines, ICEM 2014, Berlin, Germany, 2–5 September 2014; pp. 270–276. [Google Scholar] [CrossRef]

- D’Angelo, L.A.; Bontinck, Z.; Schöps, S.; De Gersem, H. Robust Optimization of a Permanent-Magnet Synchronous Machine Considering Uncertain Driving Cycles. IEEE Trans. Magn. 2020, 56, 1–5. [Google Scholar] [CrossRef]

- Rassõlkin, A.; Sell, R.; Leier, M. Development case study of the first estonian self-driving car, iseauto. Electr. Control Commun. Eng. 2018, 14, 81–88. [Google Scholar] [CrossRef]

- Ma, C.; Hao, W.; He, R.; Jia, X.; Pan, F.; Fan, J.; Xiong, R. Distribution path robust optimization of electric vehicle with multiple distribution centers. PLoS ONE 2018, 13, e0193789. [Google Scholar] [CrossRef]

- Fontana, M.W. Optimal Routes for Electric Vehicles Facing Uncertainty, Congestion, and Energy Constraints. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2013. [Google Scholar]

- Soroudi, A.; Keane, A. Robust optimization based EV charging. In Proceedings of the 2014 IEEE International Electric Vehicle Conference, IEVC 2014, Florence, Italy, 15–17 December 2015; pp. 2–7. [Google Scholar] [CrossRef]

- Rassõlkin, A.; Vaimann, T.; Kallaste, A.; Kuts, V. Digital twin for propulsion drive of autonomous electric vehicle. In Proceedings of the 2019 IEEE 60th International Scientific Conference on Power and Electrical Engineering of Riga Technical University (RTUCON), Riga, Latvia, 7–9 October 2019; pp. 1–4. [Google Scholar]

- El Saddik, A. Digital twins: The convergence of multimedia technologies. IEEE MultiMedia 2018, 25, 87–92. [Google Scholar] [CrossRef]

- Vaimann, T.; Rassõlkin, A.; Kallaste, A.; Pomarnacki, R.; Belahcen, A. Artificial Intelligence in Monitoring and Diagnostics of Electrical Energy Conversion Systems. In Proceedings of the 2020 27th International Workshop on Electric Drives: MPEI Department of Electric Drives 90th Anniversary (IWED), Moscow, Russia, 27–30 January 2020; pp. 1–4. [Google Scholar]

- Rassõlkin, A.; Belahcen, A.; Kallaste, A.; Vaimann, T.; Lukichev, D.V.; Orlova, S.; Heidari, H.; Asad, B.; Acedo, J.P. Life cycle analysis of electrical motor-drive system based on electrical machine type. Proc. Est. Acad. Sci. 2020, 69, 162–177. [Google Scholar] [CrossRef]

- Standard Terminology for Additive Manufacturing Technologies, (Withdrawn 2015); ASTM International: West Conshohocken, PA, USA, 2012; Available online: http://www.astm.org/cgi-bin/resolver.cgi?F2792 (accessed on 18 September 2020).

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The role of additive manufacturing in the era of industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Tiismus, H.; Kallaste, A.; Vaimann, T.; Rassõlkin, A.; Belahcen, A. Electrical Resistivity of Additively Manufactured Silicon Steel for Electrical Machine Fabrication. In Proceedings of the 2019 Electric Power Quality and Supply Reliability Conference (PQ) & 2019 Symposium on Electrical Engineering and Mechatronics (SEEM), Kärdla, Estonia, 12–15 June 2019; pp. 1–4. [Google Scholar]

- Kang, N.; El Mansori, M.; Guittonneau, F.; Liao, H.; Fu, Y.; Aubry, E. Controllable mesostructure, magnetic properties of soft magnetic Fe-Ni-Si by using selective laser melting from nickel coated high silicon steel powder. Appl. Surf. Sci. 2018, 455, 736–741. [Google Scholar] [CrossRef]

- Garibaldi, M.; Gerada, C.; Hague, R. Laser Additive Manufacturing of Soft Magnetic Cores for Rotating Electrical Machinery: Materials Development and Part Design. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2018. [Google Scholar]

- Garibaldi, M.; Ashcroft, I.; Simonelli, M.; Hague, R. Metallurgy of high-silicon steel parts produced using Selective Laser Melting. Acta Materialia 2016, 110, 207–216. [Google Scholar] [CrossRef]

- Urbanek, S.; Ponick, B. Surface Eddy Current Loss Reduction in Additively Manufactured Permanent Magnet Rotor Active Parts. In Proceedings of the 2018 XIII International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018; pp. 1317–1322. [Google Scholar]

- Kaska, J.; Orosz, T.; Karban, P.; Doležel, I.; Pechánek, R.; Pánek, D. Optimization of Reluctance Motor with Printed Rotor. In Proceedings of the 2019 22nd International Conference on the Computation of Electromagnetic Fields (COMPUMAG), Paris, France, 15–19 July 2019; pp. 1–4. [Google Scholar]

- Krings, A.; Boglietti, A.; Cavagnino, A.; Sprague, S. Soft Magnetic Material Status and Trends in Electric Machines. IEEE Trans. Ind. Electron. 2017, 64, 2405–2414. [Google Scholar] [CrossRef]

- Billah, K.M.M.; Coronel, J.L.; Halbig, M.C.; Wicker, R.B.; Espalin, D. Electrical and thermal characterization of 3D printed thermoplastic parts with embedded wires for high current-carrying applications. IEEE Access 2019, 7, 18799–18810. [Google Scholar] [CrossRef]

- Simpson, N.; Tighe, C.; Mellor, P. Design of High Performance Shaped Profile Windings for Additive Manufacture. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; pp. 761–768. [Google Scholar]

- Lorenz, F.; Rudolph, J.; Wemer, R. Design of 3D printed High Performance Windings for switched reluctance machines. In Proceedings of the 2018 XIII International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018; pp. 2451–2457. [Google Scholar]

- Wu, F.; El-Refaie, A.M. Towards fully additively-manufactured permanent magnet synchronous machines: Opportunities and challenges. In Proceedings of the 2019 IEEE International Electric Machines & Drives Conference (IEMDC), San Diego, CA, USA, 11–15 May 2019; pp. 2225–2232. [Google Scholar]

- Aguilera, E.; Ramos, J.; Espalin, D.; Cedillos, F.; Muse, D.; Wicker, R.; MacDonald, E. 3D printing of electro mechanical systems. In Proceedings of the Solid Freeform Fabrication Symposium, Washington, DC, USA, 12–14 August 2013; pp. 950–961. [Google Scholar]

- Ellery, A. Universal construction based on 3D printing electric motors: Steps towards self-replicating robots to transform space exploration. In Proceedings of the 2017 IEEE International Symposium on Robotics and Intelligent Sensors (IRIS), Ottawa, ON, Canada, 5–7 October 2017; pp. 81–85. [Google Scholar]

- Wrobel, R.; Scholes, B.; Mustaffer, A.; Ullah, S.; Reay, D.; Mecrow, B.; Hussein, A. Design and Experimental Characterisation of an Additively Manufactured Heat Exchanger for the Electric Propulsion Unit of a High-Altitude Solar Aircraft. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; pp. 753–760. [Google Scholar]

- Additive Manufacturing Moves TUfast. Available online: tps://additivenews.com/additive-manufacturing-moves-tufast/ (accessed on 9 April 2020).

- Improved Cooling Thanks to Aluminum Jacket with Internal Helix. Available online: https://www.eos.info/press/customer_case_studies/additive-manufacturing-of-water-cooled-electric-motor-component (accessed on 9 April 2020).

- Vialva, T. Trumpf Introduces Precious Metal and Copper 3D Printing Powered by Green Laser. 3D Printing Industry. 2018. Available online: https://3dprintingindustry.com/news/trumpf-introduces-precious-metal-and-copper-3d-printing-powered-by-green-laser-143689/ (accessed on 18 September 2020).

- Sixel, W.; Liu, M.; Nellis, G.; Sarlioglu, B. Cooling of windings in electrical machines via 3D printed heat exchanger. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 September 2018; pp. 229–235. [Google Scholar]

- Sixel, W.; Liu, M.; Nellis, G.; Sarlioglu, B. Ceramic 3D Printed Direct Winding Heat Exchangers for Improving Electric Machine Thermal Management. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; pp. 769–776. [Google Scholar]

- Tseng, G.M.; Jhong, K.J.; Tsai, M.C.; Huang, P.W.; Lee, W.H. Application of additive manufacturing for low torque ripple of 6/4 switched reluctance motor. In Proceedings of the 2016 19th International Conference on Electrical Machines and Systems (ICEMS), Makuhari, Chiba, Japan, 13–16 November 2016; pp. 1–4. [Google Scholar]

- Lammers, S.; Adam, G.; Schmid, H.J.; Mrozek, R.; Oberacker, R.; Hoffmann, M.J.; Quattrone, F.; Ponick, B. Additive Manufacturing of a lightweight rotor for a permanent magnet synchronous machine. In Proceedings of the 2016 6th International Electric Drives Production Conference (EDPC), Nuremberg, Germany, 30 November–1 December 2016; pp. 41–45. [Google Scholar]

- Andriushchenko, E.; Kaska, J.; Kallaste, A.; Vaimann, T.; Belahcen, A.; Rassõlkin, A. Design Optimization of a 3D Printed Permanent Magnet Clutch with Ārtap Framework. Periodica Polytech. Electr. Eng. Comput. Sci. 2020, in press. [Google Scholar]

- Pippuri, J.; Metsä-Kortelainen, S.; Lindroos, T.; Savolainen, M.; Jokinen, A.; Revuelta, A.; Pasanen, A.; Ruusuvuori, K. 3D Printing of Soft Magnetic Cores for Electrical Machines. In Proceedings of the 1st Annual SMACC Research Seminar 2016; Tampere University of Technology: Tampere, Finland, 2016. [Google Scholar]

- Silbernagel, C. Investigation of the Design, Manufacture and Testing of Additively Manufactured Coils for Electric Motor Applications. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2019. [Google Scholar]

- Simpson, N.; North, D.; Collins, S.; Mellor, P. Additive manufacturing of shaped profile windings for minimal AC loss in electrical machines. IEEE Trans. Ind. Appl. 2020, 56, 2510–2519. [Google Scholar] [CrossRef]

- Jee, Y.A.; Kim, C.J.; Sung, T.H.; Hong, G.W. Top-seeded melt growth of Y-Ba-Cu-O superconductor with multiseeding. Supercond. Sci. Technol. 2000, 13, 195–201. [Google Scholar] [CrossRef]

- Kim, C.J.; Jee, Y.A.; Hong, G.W. Variables affecting the fabrication of single grain YBa2Cu3O7-y superconductors by the top-seeded melt growth process. Supercond. Sci. Technol. 2000, 13, 709. [Google Scholar] [CrossRef]

- Pina, J.M.; Pereira, P.; Valadas, D.; Ceballos, J.; Álvarez, A. Sand pile modeling of multiseeded HTS bulk superconductors: Current densities identification by genetic algorithms. IEEE Trans. Appl. Supercond. 2012, 23, 8000804. [Google Scholar] [CrossRef]

- Seidel, P. Applied Superconductivity: Handbook on Devices and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Song, H.; Brownsey, P.; Zhang, Y.; Waterman, J.; Fukushima, T.; Hazelton, D. 2G HTS coil technology development at SuperPower. IEEE Trans. Appl. Supercond. 2012, 23, 4600806. [Google Scholar] [CrossRef]

- Hazelton, D.W.; Selvamanickam, V.; Duval, J.M.; Larbalestier, D.C.; Markiewicz, W.D.; Weijers, H.W.; Holtz, R.L. Recent developments in 2G HTS coil technology. IEEE Trans. Appl. Supercond. 2009, 19, 2218–2222. [Google Scholar] [CrossRef]

- Zhang, Y.; Lehner, T.F.; Fukushima, T.; Sakamoto, H.; Hazelton, D.W. Progress in production and performance of second generation (2G) HTS wire for practical applications. IEEE Trans. Appl. Supercond. 2014, 24, 1–5. [Google Scholar]

- Nagamatsu, J.; Nakagawa, N.; Muranaka, T.; Zenitani, Y.; Akimitsu, J. Superconductivity at 39 K in magnesium diboride. Nature 2001, 410, 63–64. [Google Scholar] [CrossRef]

- Mackinnon, I.D.; Winnett, A.; Alarco, J.A.; Talbot, P.C. Synthesis of MgB2 at low temperature and autogenous pressure. Materials 2014, 7, 3901–3918. [Google Scholar] [CrossRef]

- Tixador, P. Development of superconducting power devices in Europe. Phys. C Supercond. Appl. 2010, 470, 971–979. [Google Scholar] [CrossRef]

- Grilli, F. Numerical modeling of HTS applications. IEEE Trans. Appl. Supercond. 2016, 26, 1–8. [Google Scholar] [CrossRef]

- Kim, B.; Jin, L.; Jeong, S. Investigation on AC losses in a superconducting linear motor. Cryogenics 2019, 102, 22–27. [Google Scholar] [CrossRef]

- Balachandran, T.; Lee, D.; Haran, K.S. Optimal Design of a Fully Superconducting Machine for 10-MW Offshore Wind Turbines. In Proceedings of the 2019 IEEE International Electric Machines & Drives Conference (IEMDC), San Diego, CA, USA, 11–15 May 2019; pp. 1903–1909. [Google Scholar]

- Borghi, C.A.; Fabbri, M.; Ribani, P.L. Design optimization of a microsuperconducting magnetic energy storage system. IEEE Trans. Magn. 1999, 35, 4275–4284. [Google Scholar] [CrossRef]

- Schiferl, R.; Flory, A.; Livoti, W.C.; Umans, S.D. High temperature superconducting synchronous motors: Economic issues for industrial applications. In Proceedings of the 2006 Record of Conference Papers-IEEE Industry Applications Society 53rd Annual Petroleum and Chemical Industry Conference, Philadelphia, PA, USA, 11–15 September 2006; pp. 1–9. [Google Scholar]

- Brambilla, R.; Grilli, F.; Martini, L.; Bocchi, M.; Angeli, G. A finite-element method framework for modeling rotating machines with superconducting windings. IEEE Trans. Appl. Supercond. 2018, 28, 1–11. [Google Scholar] [CrossRef]

- Lee, J.Y.; Kim, S.I.; Hong, J.P.; Jo, Y.S.; Sohn, M.H.; Baik, S.K.; Kwon, Y.K. Optimal design of superconducting motor to improve power density using 3D EMCN and response surface methodology. IEEE Trans. Appl. Supercond. 2006, 16, 1819–1822. [Google Scholar] [CrossRef]

- Karban, P.; Mach, F.; Kus, P.; Pánek, D.; Doležel, I. Numerical solution of coupled problems using code Agros2D. Computing 2013, 95, 381–408. [Google Scholar] [CrossRef]

- Šolın, P.; Demkowicz, L. Goal-oriented hp-adaptivity for elliptic problems. Comput. Methods Appl. Mech. Eng. 2004, 193, 449–468. [Google Scholar] [CrossRef]

| Technique | Name | Description |

|---|---|---|

| NSGA-II | Non-dominated Sorting Genetic Algorithm II | It is a widely used optimization method. It uses the elitist strategy with the crowding distance operator to preserve diversity and the efficient non-dominated sorting operator to select the Pareto-dominant solutions [141]. |

| NSGA-III | Reference point based Non-dominated Sorting Genetic Algorithm | This algorithm is designed for many-objective problems (more than two). It uses similar operators, like NSGA-II with reference points and the niche preservation operator, where the reference point can be associated with some solutions, and it keeps the solutions that are close to the reference point [142]. |

| -MOEA | -dominance based Multiobjective Evolutionary Algorithm | It uses the epsilon-dominance concept with an epsilon archiving strategy for limiting and sorting the Pareto-dominant solutions, which can be faster than the non-dominated sorting, and it can be advantageous in many cases. However, the sorting time is not relevant in most cases of numerically expensive electrical machine design problems [143]. |

| MOEA/D | Multiobjective Evolutionary Algorithm with Decomposition | This algorithm explicitly decomposes the problem into scalar optimization subproblems. It solves these subproblems simultaneously. At each generation, the population is composed of the best solution found so far for each subproblem. This algorithm can significantly reduce the computational complexity compared to NSGA-II [144]. |

| GDE3 | Generalized Differential Evolution | GDE3 uses the weak-dominance concept to select the Pareto-dominant solutions and an improved crowding distance operator and non-dominated sorting for the results [145]. |

| PAES | Pareto Archived Evolution Strategy | It uses a non-dominated bounded archive to maintain the Pareto-optimal solutions. There are three main versions: (1+1), (1+), and (+)-PAES [146], where (1+1)-ES means that during each iteration, one mutant is created from one parent, and their union is used in the selection. |

| PESA2 | Pareto Envelope based Selection Algorithm | It uses a region based selection operator, instead of individual based ones, like NSGA-II. It requires only comparisons for every hyperbox [147]. |

| SPEA2 | Strength based Evolutionary Algorithm | SPEA-2 uses the strength based diversity operator, the calculation and sorting time of which are more expensive than the case of NSGA-II; however, the diversity and convergence of the results can be better, which can be advantageous in the case of expensive optimization problems [148]. |

| IBEA | Indicator Based Evolutionary Algorithm | It uses a flexible integration of preference information. Therefore, an arbitrary performance indicator can be used for the search. It does not need any diversity preservation techniques; moreover, the population size can be arbitrary [149]. |

| MO-CMA-ES | Covariance Matrix Adaption Evolution Strategy | The adaptive grid archiving strategy, which was presented in PAES, is merged with the covariance matrix adaption evolutionary strategy. In contrast to most other evolutionary algorithms, the CMA-ES is quasi-parameter-free [150]. |

| SMPSO | Speed-constrained Multiobjective Particle Swarm Optimization | It is very similar to the OMOPSO algorithm, and there are only three differences: the usage of the speed constriction factor and the polynomial mutation operator and velocity handling at the borders of the search space [134]. |

| NSPSO | Non-dominated Sorting based multiobjective Particle Swarm Optimization | It uses the main mechanisms of NSGA-II (crowding distance, non-dominated sorting), and the global leader is selected randomly from the leaders’ archive. OMOPSO and SMPSO clearly outperform this variant [134]. |

| AMOPSO | Another Multiobjective Particle Swarm Optimization | It selects leaders from a non-dominated external archive. Three different selection are techniques used: Roundsby to preserve diversity, calledRandom to promote convergence, and called Prob, a weighted probability method [132]. OMOPSO and SMPSO outperform this method. |

| MOFA | Multiobjective Firefly Algorithm | Uses random weights to select the best from the Pareto-optimal solutions. Very quickly converges to the solution; however, it contains usually more than one function evaluation in every iteration step because the selected firefly makes one step with a new evaluation of a dominating one. This is a disadvantage in the case of expensive optimization problems [39]. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Orosz, T.; Rassõlkin, A.; Kallaste, A.; Arsénio, P.; Pánek, D.; Kaska, J.; Karban, P. Robust Design Optimization and Emerging Technologies for Electrical Machines: Challenges and Open Problems. Appl. Sci. 2020, 10, 6653. https://doi.org/10.3390/app10196653

Orosz T, Rassõlkin A, Kallaste A, Arsénio P, Pánek D, Kaska J, Karban P. Robust Design Optimization and Emerging Technologies for Electrical Machines: Challenges and Open Problems. Applied Sciences. 2020; 10(19):6653. https://doi.org/10.3390/app10196653

Chicago/Turabian StyleOrosz, Tamás, Anton Rassõlkin, Ants Kallaste, Pedro Arsénio, David Pánek, Jan Kaska, and Pavel Karban. 2020. "Robust Design Optimization and Emerging Technologies for Electrical Machines: Challenges and Open Problems" Applied Sciences 10, no. 19: 6653. https://doi.org/10.3390/app10196653

APA StyleOrosz, T., Rassõlkin, A., Kallaste, A., Arsénio, P., Pánek, D., Kaska, J., & Karban, P. (2020). Robust Design Optimization and Emerging Technologies for Electrical Machines: Challenges and Open Problems. Applied Sciences, 10(19), 6653. https://doi.org/10.3390/app10196653