Torrefaction of Coffee Husk Flour for the Development of Injection-Molded Green Composite Pieces of Polylactide with High Sustainability

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

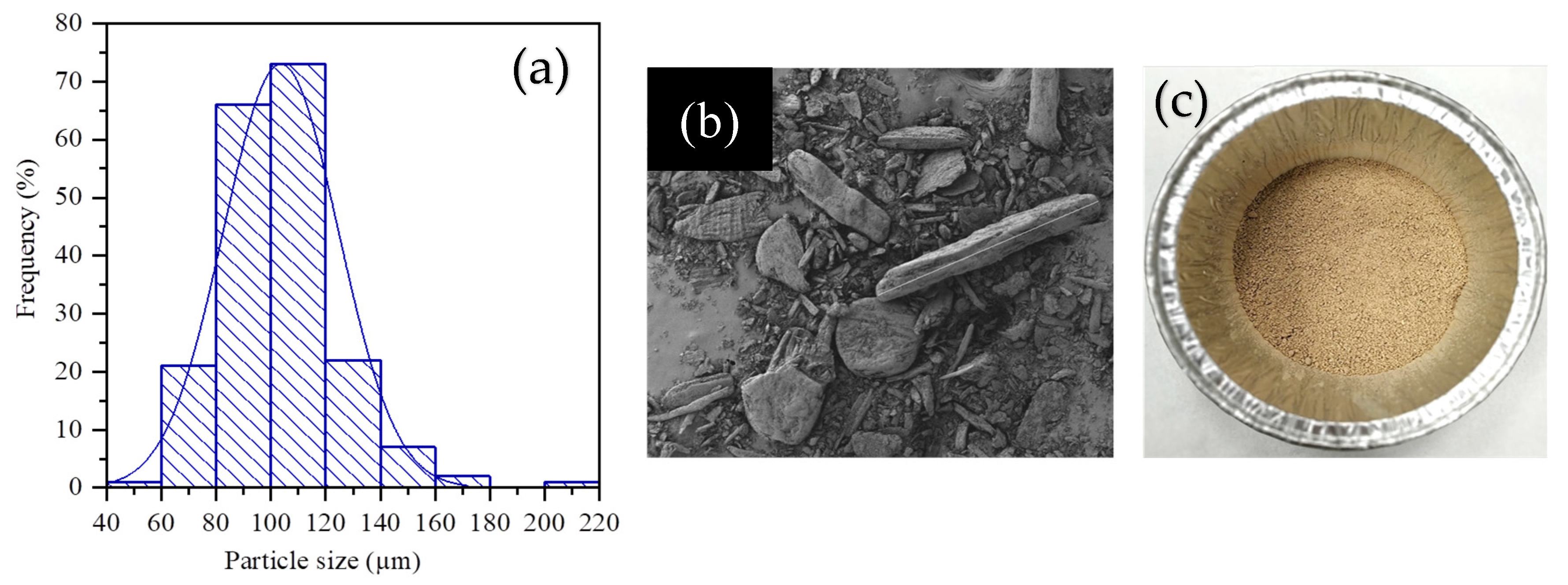

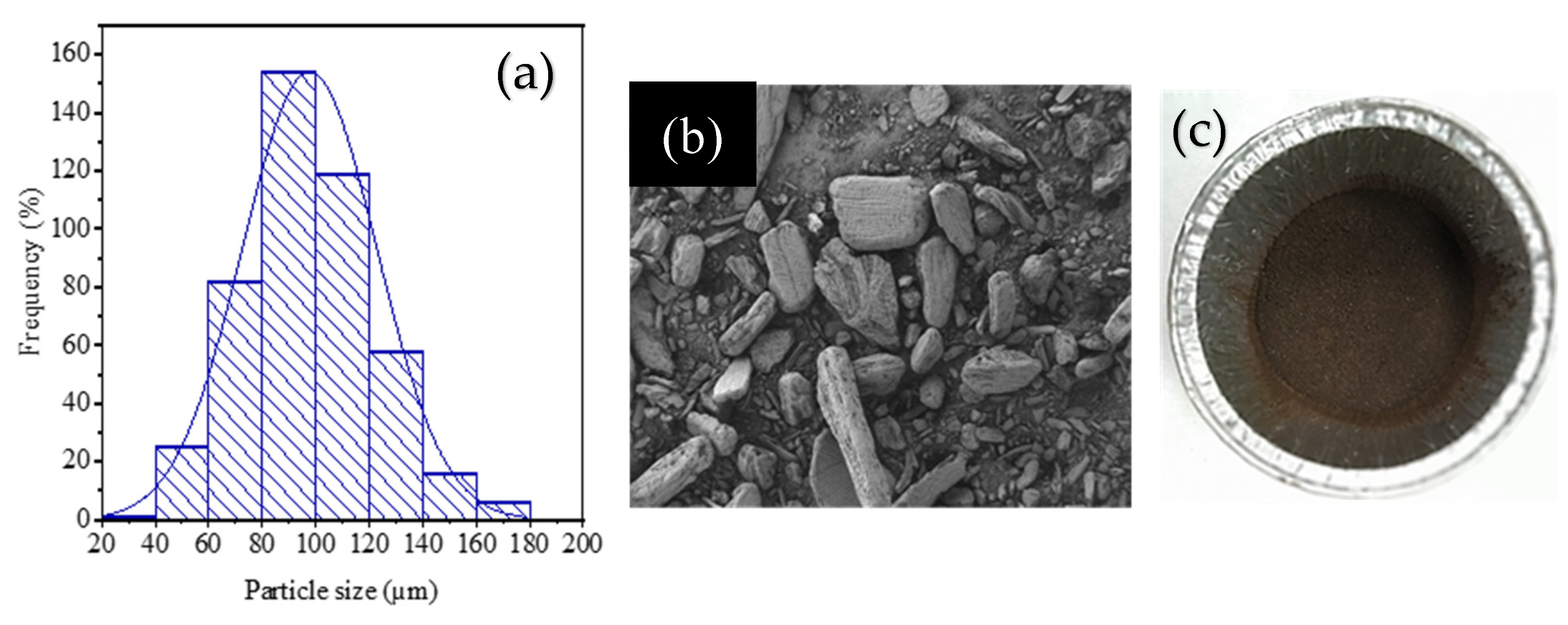

2.1. Materials

2.2. Torrefaction of CHF

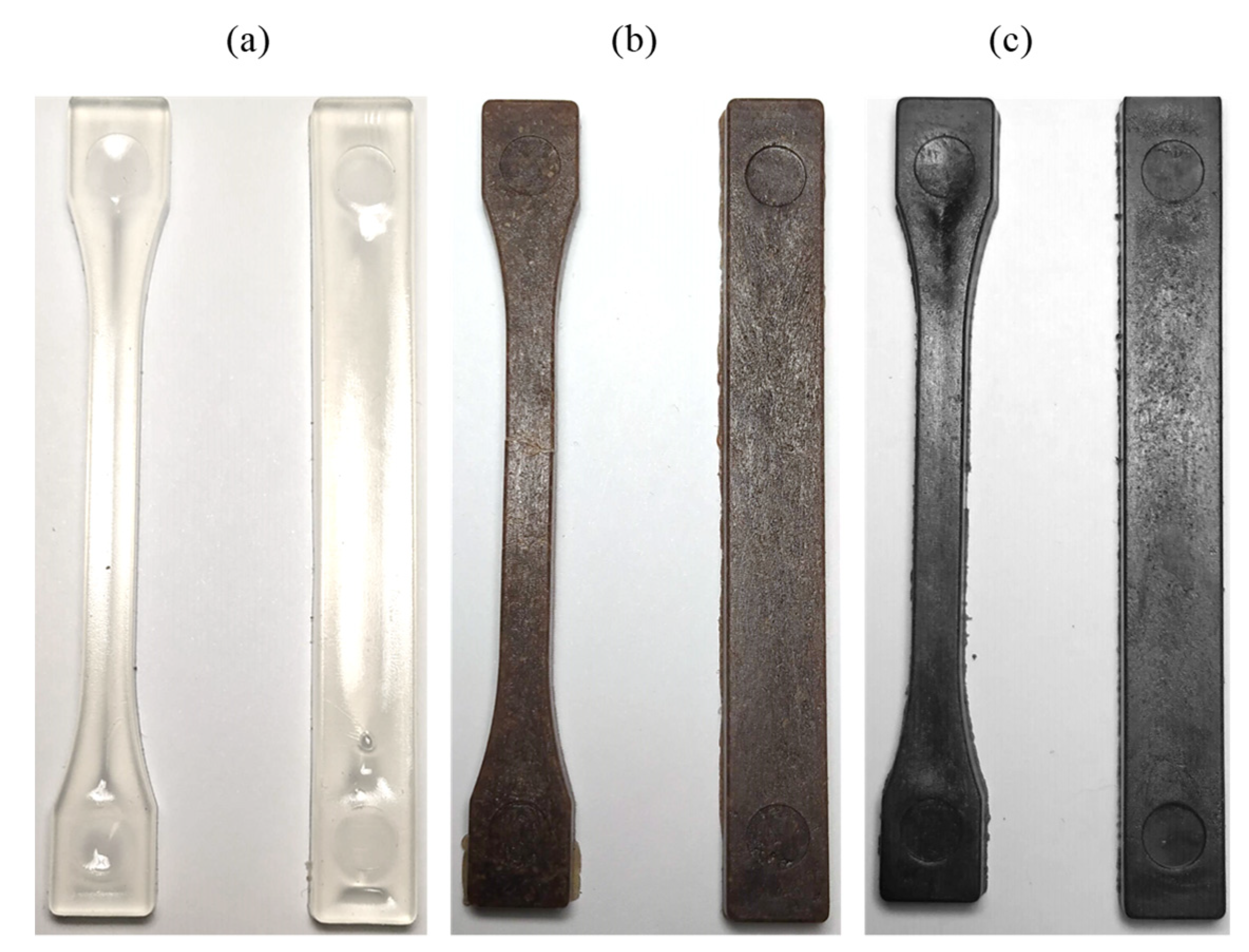

2.3. Preparation of the Green Composite Pieces

2.4. Mechanical Tests

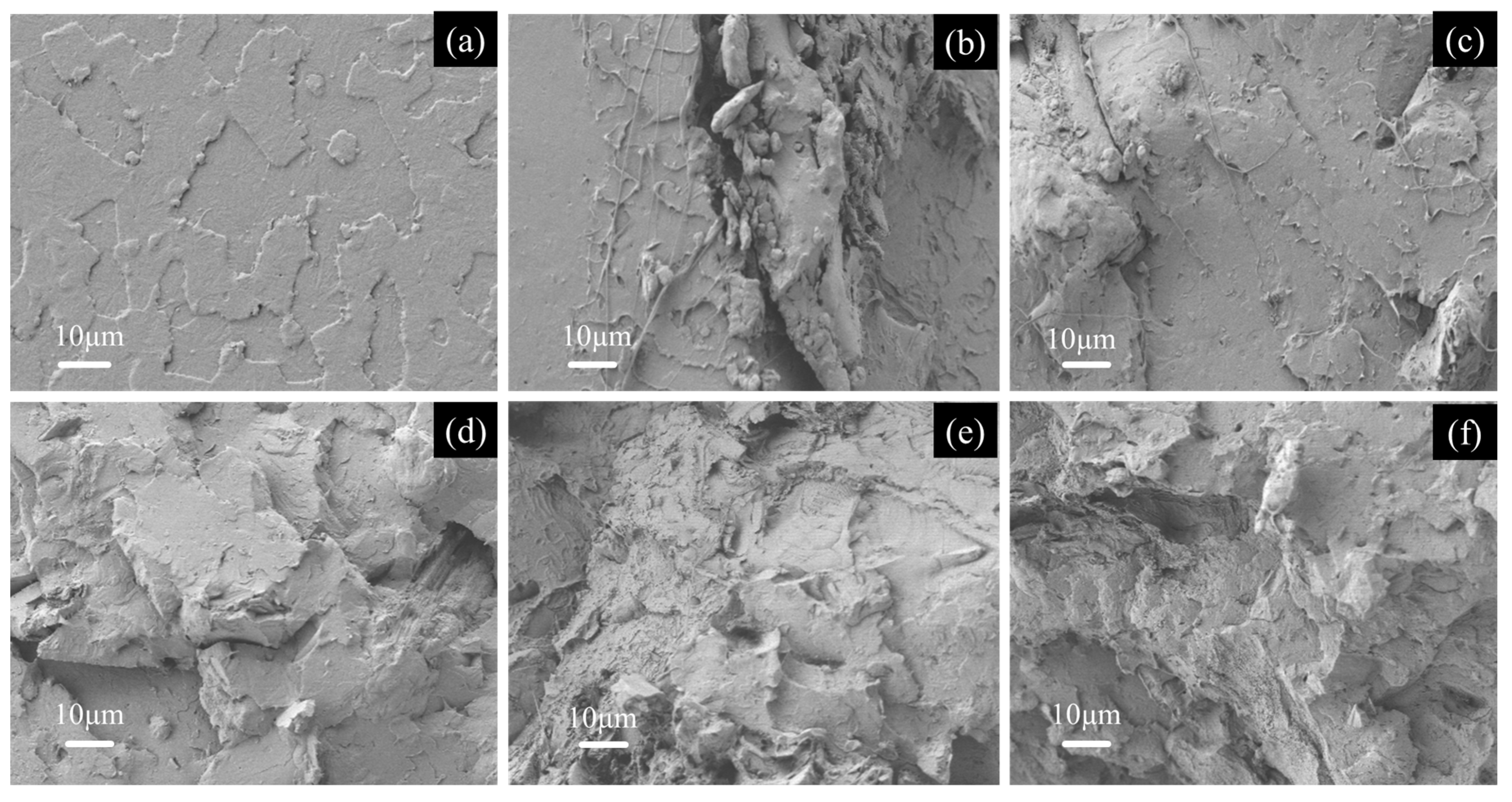

2.5. Microscopy

2.6. Thermal Tests

2.7. Thermomechanical Tests

3. Results

3.1. Mechanical Performance of the Green Composite Pieces

3.2. Aspect and Morphology of the Green Composite Pieces

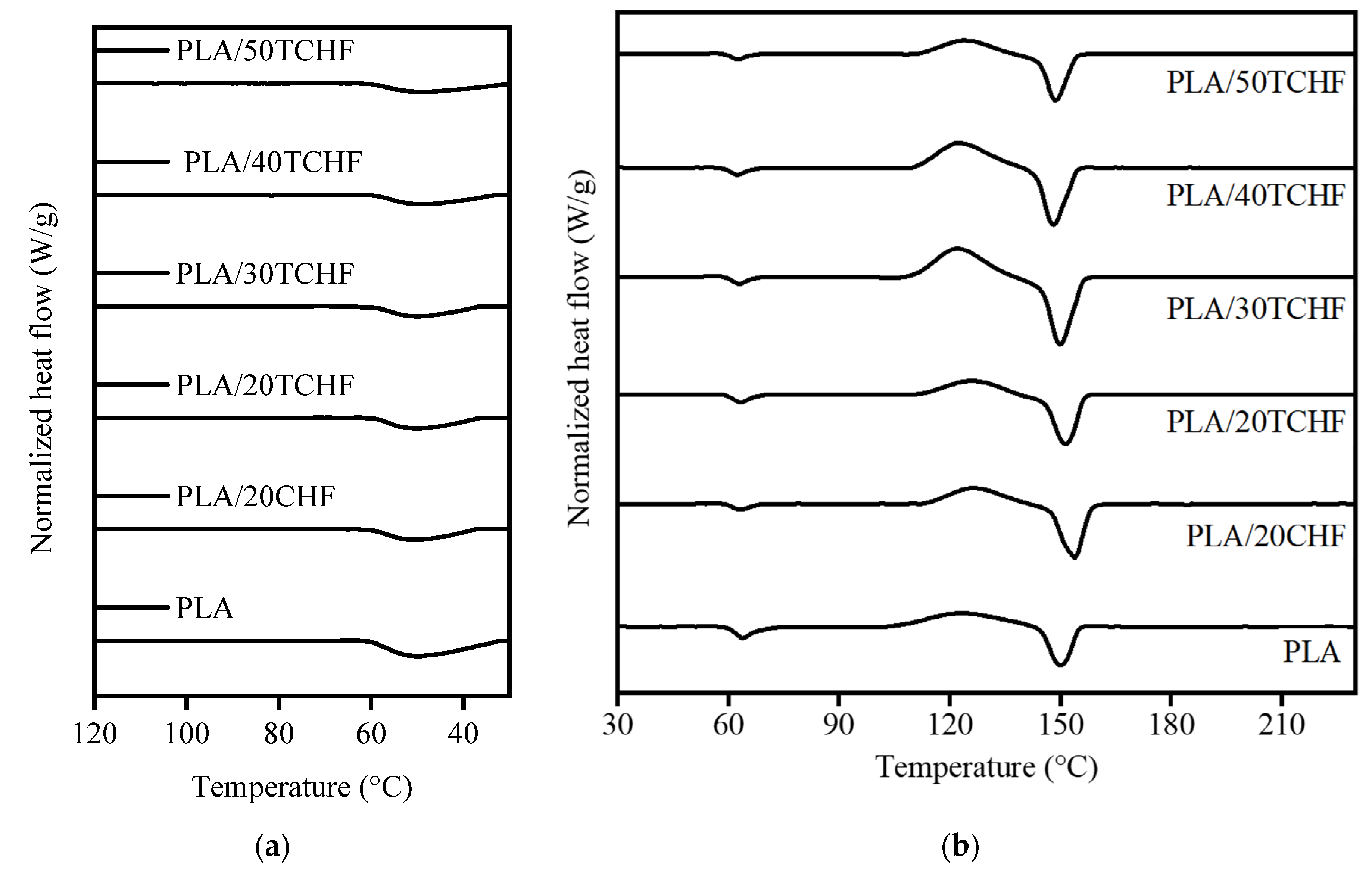

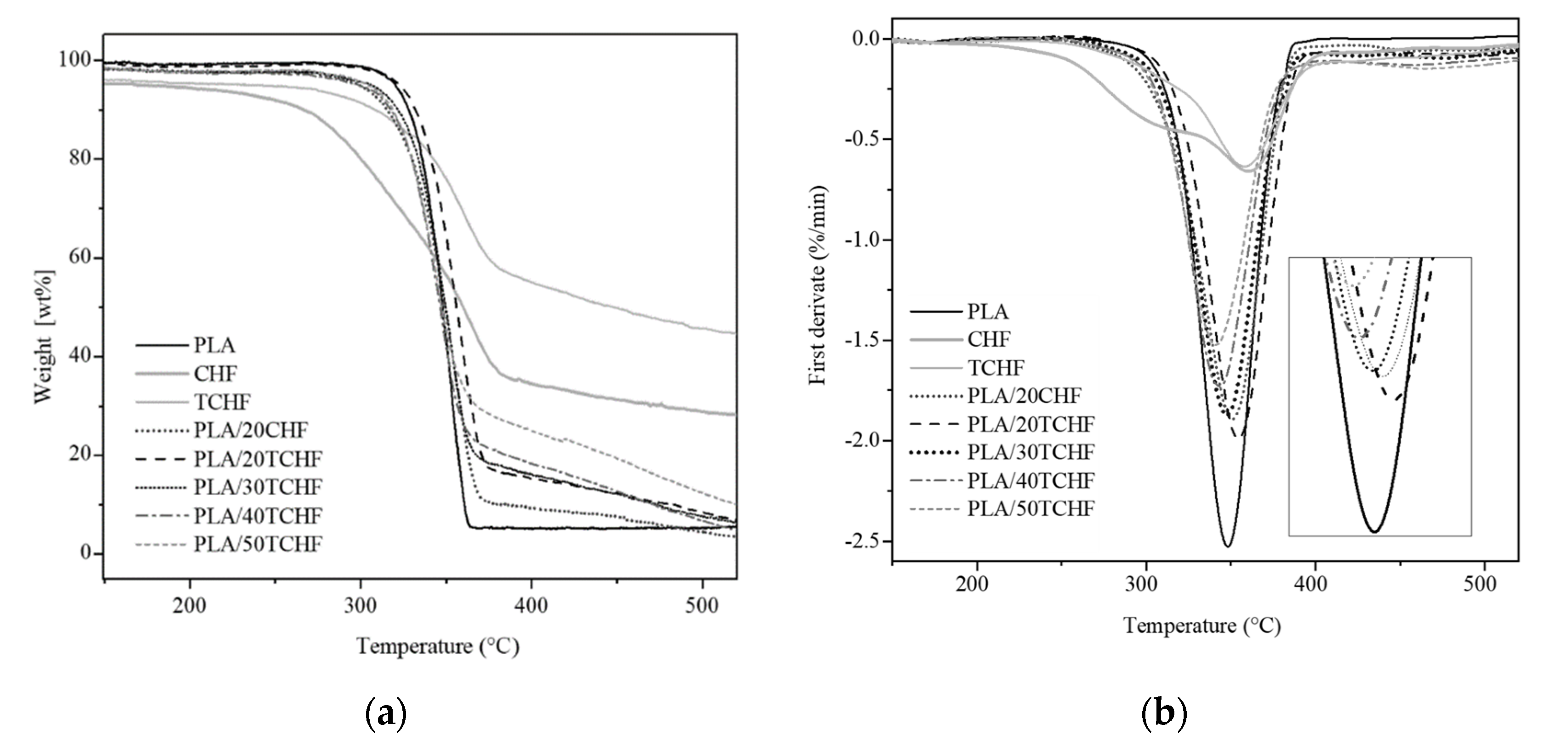

3.3. Thermal Performance of the Green Composite Pieces

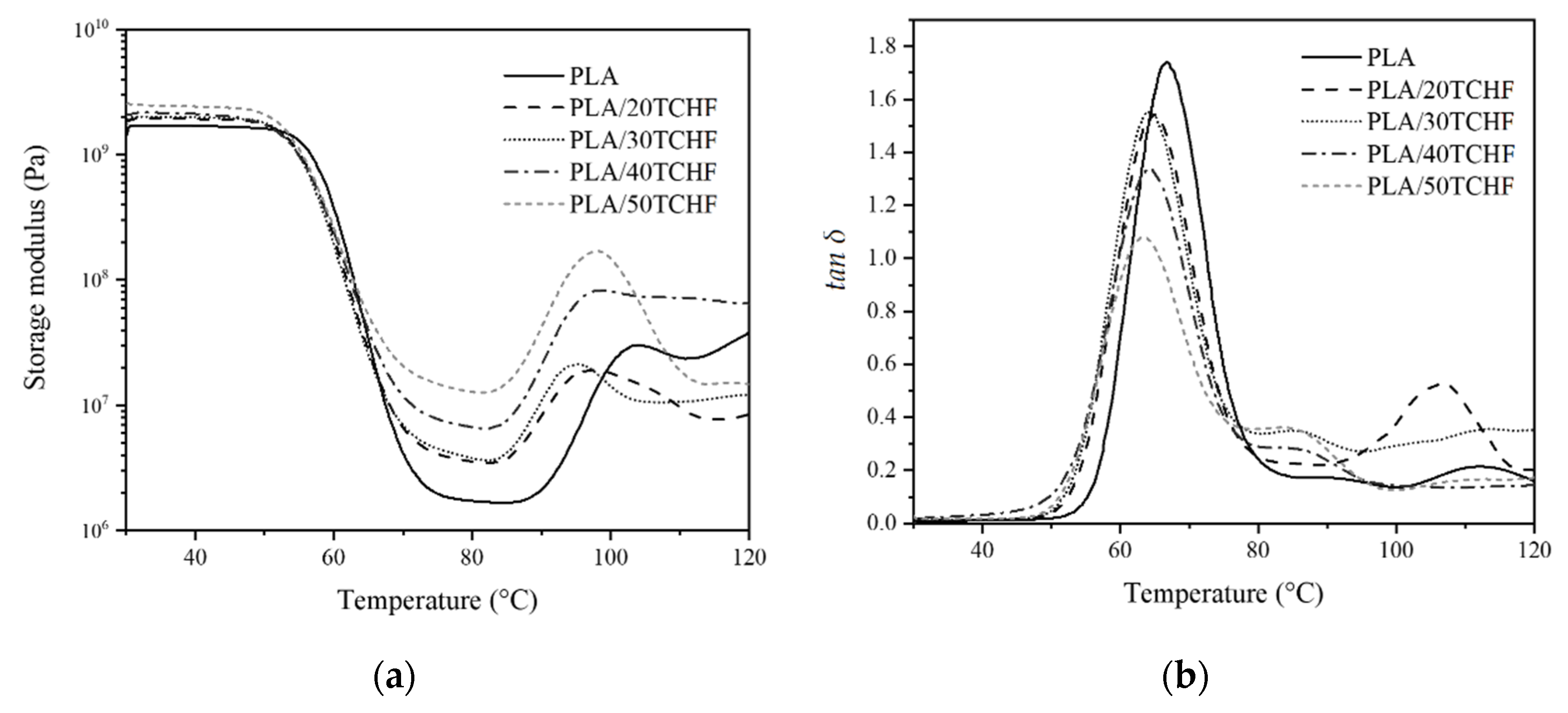

3.4. Thermomechanical Performance of the Green Composite Pieces

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Guillard, V.; Gaucel, S.; Fornaciari, C.; Angellier-Coussy, H.; Buche, P.; Gontard, N. The next generation of sustainable food packaging to preserve our environment in a circular economy context. Front. Nutr. 2018, 5. [Google Scholar] [CrossRef] [PubMed]

- Jurgilevich, A.; Birge, T.; Kentala-Lehtonen, J.; Korhonen-Kurki, K.; Pietikäinen, J.; Saikku, L.; Schösler, H. Transition towards circular economy in the food system. Sustainability 2016, 8, 69. [Google Scholar] [CrossRef]

- Ramesh, M. Flax (Linum usitatissimum L.) fibre reinforced polymer composite materials: A review on preparation, properties and prospects. Prog. Mater. Sci. 2019, 102, 109–166. [Google Scholar] [CrossRef]

- Agüero, A.; Lascano, D.; Garcia-Sanoguera, D.; Fenollar, O.; Torres-Giner, S. Valorization of linen processing by-products for the development of injection-molded green composite pieces of polylactide with improved performance. Sustainability 2020, 12, 652. [Google Scholar] [CrossRef]

- Melendez-Rodriguez, B.; Torres-Giner, S.; Aldureid, A.; Cabedo, L.; Lagaron, J.M. Reactive melt mixing of poly(3-hydroxybutyrate)/rice husk flour composites with purified biosustainably produced poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Materials 2019, 12, 2152. [Google Scholar] [CrossRef]

- Jothibasu, S.; Mohanamurugan, S.; Vijay, R.; Lenin Singaravelu, D.; Vinod, A.; Sanjay, M.R. Investigation on the mechanical behavior of areca sheath fibers/jute fibers/glass fabrics reinforced hybrid composite for light weight applications. J. Ind. Text. 2018, 49, 1036–1060. [Google Scholar] [CrossRef]

- Kumaran, P.; Mohanamurugan, S.; Madhu, S.; Vijay, R.; Lenin Singaravelu, D.; Vinod, A.; Sanjay, M.R.; Siengchin, S. Investigation on thermo-mechanical characteristics of treated/untreated Portunus sanguinolentus shell powder-based jute fabrics reinforced epoxy composites. J. Ind. Text. 2019. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Garcia-Garcia, D.; Carbonell-Verdu, A.; Balart, R.; Torres-Giner, S. Effect of different compatibilizers on injection-molded green composite pieces based on polylactide filled with almond shell flour. Compos. Part B Eng. 2018, 147, 76–85. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Sammon, C.; Balart, R.; Torres-Giner, S. Compatibilization of highly sustainable polylactide/almond shell flour composites by reactive extrusion with maleinized linseed oil. Ind. Crops Prod. 2018, 111, 878–888. [Google Scholar] [CrossRef]

- Montava-Jordà, S.; Quiles-Carrillo, L.; Richart, N.; Torres-Giner, S.; Montanes, N. Enhanced interfacial adhesion of polylactide/poly(ε-caprolactone)/walnut shell flour composites by reactive extrusion with maleinized linseed oil. Polymers 2019, 11, 758. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Lagaron, J.M.; Balart, R.; Torres-Giner, S. On the use of acrylated epoxidized soybean oil as a reactive compatibilizer in injection-molded compostable pieces consisting of polylactide filled with orange peel flour. Polym. Int. 2018, 67, 1341–1351. [Google Scholar] [CrossRef]

- Torres-Giner, S.; Hilliou, L.; Melendez-Rodriguez, B.; Figueroa-Lopez, K.J.; Madalena, D.; Cabedo, L.; Covas, J.A.; Vicente, A.A.; Lagaron, J.M. Melt processability, characterization, and antibacterial activity of compression-molded green composite sheets made of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) reinforced with coconut fibers impregnated with oregano essential oil. Food Packag. Shelf Life 2018, 17, 39–49. [Google Scholar] [CrossRef]

- Chaitanya, S.; Singh, I. Processing of PLA/sisal fiber biocomposites using direct- and extrusion-injection molding. Mater. Manuf. Process. 2017, 32, 468–474. [Google Scholar] [CrossRef]

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural fibers as sustainable and renewable resource for development of eco-friendly composites: A comprehensive review. Front. Mater. 2019, 6. [Google Scholar] [CrossRef]

- Ramesh, M.; Deepa, C.; Kumar, L.R.; Sanjay, M.R.; Siengchin, S. Life-cycle and environmental impact assessments on processing of plant fibres and its bio-composites: A critical review. J. Ind. Text. 2020. [Google Scholar] [CrossRef]

- Adekomaya, O.; Jamiru, T.; Sadiku, R.; Huan, Z. A review on the sustainability of natural fiber in matrix reinforcement – A practical perspective. J. Reinf. Plast. Compos. 2015, 35, 3–7. [Google Scholar] [CrossRef]

- Agüero, Á.; Garcia-Sanoguera, D.; Lascano, D.; Rojas-Lema, S.; Ivorra-Martinez, J.; Fenollar, O.; Torres-Giner, S. Evaluation of different compatibilization strategies to improve the performance of injection-molded green composite pieces made of polylactide reinforced with short flaxseed fibers. Polymers 2020, 12, 821. [Google Scholar] [CrossRef]

- Lachenmeier, D.W.; Teipel, J.; Scharinger, A.; Kuballa, T.; Walch, S.G.; Grosch, F.; Bunzel, M.; Okaru, A.O.; Schwarz, S. Fully automated identification of coffee species and simultaneous quantification of furfuryl alcohol using NMR spectroscopy. J. AOAC Int. 2020, 103, 306–314. [Google Scholar] [CrossRef]

- Murthy, P.S.; Madhava Naidu, M. Sustainable management of coffee industry by-products and value addition—A review. Resour. Conserv. Recycl. 2012, 66, 45–58. [Google Scholar] [CrossRef]

- Janissen, B.; Huynh, T. Chemical composition and value-adding applications of coffee industry by-products: A review. Resour. Conserv. Recycl. 2018, 128, 110–117. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Machado, E.M.S.; Martins, S.; Teixeira, J.A. Production, composition, and application of coffee and its industrial residues. Food Bioprocess Technol. 2011, 4, 661. [Google Scholar] [CrossRef]

- Klingel, T.; Kremer, J.I.; Gottstein, V.; Rajcic de Rezende, T.; Schwarz, S.; Lachenmeier, D.W. A review of coffee by-products including leaf, flower, cherry, husk, silver skin, and spent grounds as novel foods within the European Union. Foods 2020, 9, 665. [Google Scholar] [CrossRef] [PubMed]

- Roussos, S.; de Los Angeles Aquiáhuatl, M.; Del Refugio Trejo-Hernández, M.; Gaime Perraud, I.; Favela, E.; Ramakrishna, M.; Raimbault, M.; Viniegra-González, G. Biotechnological management of coffee pulp—isolation, screening, characterization, selection of caffeine-degrading fungi and natural microflora present in coffee pulp and husk. Appl. Microbiol. Biotechnol. 1995, 42, 756–762. [Google Scholar] [CrossRef]

- Narita, Y.; Inouye, K. Review on utilization and composition of coffee silverskin. Food Res. Int. 2014, 61, 16–22. [Google Scholar] [CrossRef]

- Woldesenbet, A.G.; Woldeyes, B.; Chandravanshi, B.S. Bio-ethanol production from wet coffee processing waste in Ethiopia. SpringerPlus 2016, 5, 1903. [Google Scholar] [CrossRef]

- Mendoza Martinez, C.L.; Alves Rocha, E.P.; Oliveira Carneiro, A.d.C.; Borges Gomes, F.J.; Ribas Batalha, L.A.; Vakkilainen, E.; Cardoso, M. Characterization of residual biomasses from the coffee production chain and assessment the potential for energy purposes. Biomass Bioenergy 2019, 120, 68–76. [Google Scholar] [CrossRef]

- Hachicha, R.; Rekik, O.; Hachicha, S.; Ferchichi, M.; Woodward, S.; Moncef, N.; Cegarra, J.; Mechichi, T. Co-composting of spent coffee ground with olive mill wastewater sludge and poultry manure and effect of Trametes versicolor inoculation on the compost maturity. Chemosphere 2012, 88, 677–682. [Google Scholar] [CrossRef]

- Ballesteros, L.F.; Teixeira, J.A.; Mussatto, S.I. Chemical, functional, and structural properties of spent coffee grounds and coffee silverskin. Food Bioprocess Technol. 2014, 7, 3493–3503. [Google Scholar] [CrossRef]

- Murthy, P.S.; Naidu, M.M. Production and application of xylanase from penicillium sp. utilizing coffee by-products. Food Bioprocess Technol. 2012, 5, 657–664. [Google Scholar] [CrossRef]

- Low, J.H.; Rahman, W.A.W.A.; Jamaluddin, J. Structural elucidation of tannins of spent coffee grounds by CP-MAS 13C NMR and MALDI-TOF MS. Ind. Crops Prod. 2015, 69, 456–461. [Google Scholar] [CrossRef]

- Franklin, G.; Dias, A.C.P. Chlorogenic acid participates in the regulation of shoot, root and root hair development in Hypericum perforatum. Plant Physiol. Biochem. 2011, 49, 835–842. [Google Scholar] [CrossRef]

- García, A.; Gandini, A.; Labidi, J.; Belgacem, N.; Bras, J. Industrial and crop wastes: A new source for nanocellulose biorefinery. Ind. Crops Prod. 2016, 93, 26–38. [Google Scholar] [CrossRef]

- Moustafa, H.; Guizani, C.; Dupont, C.; Martin, V.; Jeguirim, M.; Dufresne, A. Utilization of torrefied coffee grounds as reinforcing agent to produce high-quality biodegradable pbat composites for food packaging applications. ACS Sustain. Chem. Eng. 2017, 5, 1906–1916. [Google Scholar] [CrossRef]

- Wang, Z.; Dadi Bekele, L.; Qiu, Y.; Dai, Y.; Zhu, S.; Sarsaiya, S.; Chen, J. Preparation and characterization of coffee hull fiber for reinforcing application in thermoplastic composites. Bioengineered 2019, 10, 397–408. [Google Scholar] [CrossRef] [PubMed]

- García-García, D.; Carbonell, A.; Samper, M.D.; García-Sanoguera, D.; Balart, R. Green composites based on polypropylene matrix and hydrophobized spend coffee ground (SCG) powder. Compos. Part B Eng. 2015, 78, 256–265. [Google Scholar] [CrossRef]

- Franca, A.S.; Oliveira, L.S. Coffee processing solid wastes: Current uses and future perspectives. In Agricultural Wastes; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2009; pp. 155–190. [Google Scholar]

- Gouvea, B.M.; Torres, C.; Franca, A.S.; Oliveira, L.S.; Oliveira, E.S. Feasibility of ethanol production from coffee husks. Biotechnol. Lett. 2009, 31, 1315–1319. [Google Scholar] [CrossRef]

- Arias, B.; Pevida, C.; Fermoso, J.; Plaza, M.G.; Rubiera, F.; Pis, J.J. Influence of torrefaction on the grindability and reactivity of woody biomass. Fuel Process. Technol. 2008, 89, 169–175. [Google Scholar] [CrossRef]

- Chen, W.-H.; Peng, J.; Bi, X.T. A state-of-the-art review of biomass torrefaction, densification and applications. Renew. Sustain. Energy Rev. 2015, 44, 847–866. [Google Scholar] [CrossRef]

- Ribeiro, J.M.C.; Godina, R.; Matias, J.C.d.O.; Nunes, L.J.R. Future perspectives of biomass torrefaction: Review of the current state-of-the-art and research development. Sustainability 2018, 10, 2323. [Google Scholar] [CrossRef]

- Hamad, K.; Kaseem, M.; Ayyoob, M.; Joo, J.; Deri, F. Polylactic acid blends: The future of green, light and tough. Prog. Polym. Sci. 2018, 85, 83–127. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Pineiro, F.; Jorda-Vilaplana, A.; Torres-Giner, S. Ductility and toughness improvement of injection-molded compostable pieces of polylactide by melt blending with poly(ε-caprolactone) and thermoplastic starch. Materials 2018, 11, 2138. [Google Scholar] [CrossRef]

- Chen, Y.; Geever, L.M.; Killion, J.A.; Lyons, J.G.; Higginbotham, C.L.; Devine, D.M. Review of multifarious applications of poly(lactic acid). Polym. Plast. Technol. Eng. 2016, 55, 1057–1075. [Google Scholar] [CrossRef]

- Risyon, N.P.; Othman, S.H.; Basha, R.K.; Talib, R.A. Characterization of polylactic acid/halloysite nanotubes bionanocomposite films for food packaging. Food Packag. Shelf Life 2020, 23, 100450. [Google Scholar] [CrossRef]

- Cardoso, R.M.; Silva, P.R.L.; Lima, A.P.; Rocha, D.P.; Oliveira, T.C.; do Prado, T.M.; Fava, E.L.; Fatibello-Filho, O.; Richter, E.M.; Muñoz, R.A.A. 3D-Printed graphene/polylactic acid electrode for bioanalysis: Biosensing of glucose and simultaneous determination of uric acid and nitrite in biological fluids. Sens. Actuators B Chem. 2020, 307, 127621. [Google Scholar] [CrossRef]

- Harris, A.M.; Lee, E.C. Heat and humidity performance of injection molded PLA for durable applications. J. Appl. Polym. Sci. 2010, 115, 1380–1389. [Google Scholar] [CrossRef]

- Kumar, S.; Bhatnagar, N.; Ghosh, A.K. Effect of enantiomeric monomeric unit ratio on thermal and mechanical properties of poly(lactide). Polym. Bull. 2016, 73, 2087–2104. [Google Scholar] [CrossRef]

- Rocha, D.B.; de Souza, A.G.; Szostak, M.; Rosa, D.d.S. Polylactic acid/Lignocellulosic residue composites compatibilized through a starch coating. Polym. Compos. 2020. [Google Scholar] [CrossRef]

- Siakeng, R.; Jawaid, M.; Asim, M.; Siengchin, S. Accelerated weathering and soil burial effect on biodegradability, colour and textureof coir/pineapple leaf fibres/pla biocomposites. Polymers 2020, 12, 458. [Google Scholar] [CrossRef] [PubMed]

- Rojas-Lema, S.; Quiles-Carrillo, L.; Garcia-Garcia, D.; Melendez-Rodriguez, B.; Balart, R.; Torres-Giner, S. Tailoring the properties of thermo-compressed polylactide films for food packaging applications by individual and combined additions of lactic acid oligomer and halloysite nanotubes. Molecules 2020, 25, 1976. [Google Scholar] [CrossRef] [PubMed]

- Torres-Giner, S.; Martinez-Abad, A.; Gimeno-Alcañiz, J.V.; Ocio, M.J.; Lagaron, J.M. Controlled delivery of gentamicin antibiotic from bioactive electrospun polylactide-based ultrathin fibers. Adv. Eng. Mater. 2012, 14, B112–B122. [Google Scholar] [CrossRef]

- Huang, L.; Mu, B.; Yi, X.; Li, S.; Wang, Q. Sustainable use of coffee husks for reinforcing polyethylene composites. J. Polym. Environ. 2018, 26, 48–58. [Google Scholar] [CrossRef]

- Berthet, M.A.; Commandré, J.M.; Rouau, X.; Gontard, N.; Angellier-Coussy, H. Torrefaction treatment of lignocellulosic fibres for improving fibre/matrix adhesion in a biocomposite. Mater. Des. 2016, 92, 223–232. [Google Scholar] [CrossRef]

- Lessa, E.F.; Nunes, M.L.; Fajardo, A.R. Chitosan/waste coffee-grounds composite: An efficient and eco-friendly adsorbent for removal of pharmaceutical contaminants from water. Carbohydr. Polym. 2018, 189, 257–266. [Google Scholar] [CrossRef]

- Suaduang, N.; Ross, S.; Ross, G.M.; Pratumshat, S.; Mahasaranon, S. Effect of spent coffee grounds filler on the physical and mechanical properties of poly(lactic acid) bio-composite films. Mater. Today Proc. 2019, 17, 2104–2110. [Google Scholar] [CrossRef]

- Wu, C.-S. Renewable resource-based green composites of surface-treated spent coffee grounds and polylactide: Characterisation and biodegradability. Polym. Degrad. Stab. 2015, 121, 51–59. [Google Scholar] [CrossRef]

- Tsuji, H.; Kawashima, Y.; Takikawa, H.; Tanaka, S. Poly(L-lactide)/nano-structured carbon composites: Conductivity, thermal properties, crystallization, and biodegradation. Polymer 2007, 48, 4213–4225. [Google Scholar] [CrossRef]

- Dominici, F.; García García, D.; Fombuena, V.; Luzi, F.; Puglia, D.; Torre, L.; Balart, R. Bio-polyethylene-based composites reinforced with alkali and palmitoyl chloride-treated coffee silverskin. Molecules 2019, 24, 3113. [Google Scholar] [CrossRef]

- Songtipya, L.; Limchu, T.; Phuttharak, S.; Songtipya, P.; Kalkornsurapranee, E. Poly(lactic acid)-based composites incorporated with spent coffee ground and tea leave for food packaging application: A waste to wealth. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Bali, Indonesia, 30 October–2 November 2018. [Google Scholar]

- Balart, J.F.; García-Sanoguera, D.; Balart, R.; Boronat, T.; Sánchez-Nacher, L. Manufacturing and properties of biobased thermoplastic composites from poly(lactid acid) and hazelnut shell wastes. Polym. Compos. 2018, 39, 848–857. [Google Scholar] [CrossRef]

- Wang, L.; Qiu, J.; Sakai, E.; Wei, X. The relationship between microstructure and mechanical properties of carbon nanotubes/polylactic acid nanocomposites prepared by twin-screw extrusion. Compos. Part A Appl. Sci. Manuf. 2016, 89, 18–25. [Google Scholar] [CrossRef]

- Arbelaiz, A.; Txueka, U.; Mezo, I.; Orue, A. Biocomposites based on poly(lactic acid) matrix and reinforced with lignocellulosic fibers: The effect of fiber type and matrix modification. J. Nat. Fibers 2020, 1–14. [Google Scholar] [CrossRef]

- Johari, A.P.; Mohanty, S.; Kurmvanshi, S.K.; Nayak, S.K. Influence of different treated cellulose fibers on the mechanical and thermal properties of poly(lactic acid). ACS Sustain. Chem. Eng. 2016, 4, 1619–1629. [Google Scholar] [CrossRef]

- Cataldo, V.A.; Cavallaro, G.; Lazzara, G.; Milioto, S.; Parisi, F. Coffee grounds as filler for pectin: Green composites with competitive performances dependent on the UV irradiation. Carbohydr. Polym. 2017, 170, 198–205. [Google Scholar] [CrossRef]

- Arrigo, R.; Jagdale, P.; Bartoli, M.; Tagliaferro, A.; Malucelli, G. Structure–property relationships in polyethylene-based composites filled with biochar derived from waste coffee grounds. Polymers 2019, 11, 1336. [Google Scholar] [CrossRef]

- Cisneros-López, E.O.; Pérez-Fonseca, A.A.; González-García, Y.; Ramírez-Arreola, D.E.; González-Núñez, R.; Rodrigue, D.; Robledo-Ortíz, J.R. Polylactic acid–agave fiber biocomposites produced by rotational molding: A comparative study with compression molding. Adv. Polym. Technol. 2018, 37, 2528–2540. [Google Scholar] [CrossRef]

- Sonseca, A.; Madani, S.; Rodríguez, G.; Hevilla, V.; Echeverría, C.; Fernández-García, M.; Muñoz-Bonilla, A.; Charef, N.; López, D. Multifunctional PLA blends containing chitosan mediated silver nanoparticles: Thermal, mechanical, antibacterial, and degradation properties. Nanomaterials 2020, 10, 22. [Google Scholar] [CrossRef]

- Yaacab, N.D.; Ismail, H.; Ting, S.S. Potential use of paddy straw as filler in poly lactic acid/paddy straw powder biocomposite: Thermal and thermal properties. Procedia Chem. 2016, 19, 757–762. [Google Scholar] [CrossRef]

- Cai, H.; Ba, Z.; Yang, K.; Zhang, Q.; Zhao, K.; Gu, S. Pyrolysis characteristics of typical biomass thermoplastic composites. Results Phys. 2017, 7, 3230–3235. [Google Scholar] [CrossRef]

- De Brito, E.B.; Tienne, L.G.P.; Cordeiro, S.B.; Marques, M.d.F.V. Development of polypropylene composites with green coffee cake fibers subjected to water vapor explosion. Waste Biomass Valorization 2020. [Google Scholar] [CrossRef]

- Totaro, G.; Sisti, L.; Fiorini, M.; Lancellotti, I.; Andreola, F.N.; Saccani, A. Formulation of green particulate composites from pla and pbs matrix and wastes deriving from the coffee production. J. Polym. Environ. 2019, 27, 1488–1496. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Zuorro, A.; Maffei, G.; Lavecchia, R.; Puglia, D.; Dominici, F.; Luzi, F.; Valente, T.; Torre, L. Recycling coffee silverskin in sustainable composites based on a poly(butylene adipate-co-terephthalate)/poly(3-hydroxybutyrate-co-3-hydroxyvalerate) matrix. Ind. Crops Prod. 2018, 118, 311–320. [Google Scholar] [CrossRef]

- Bouzidi, F.; Guessoum, M.; Fois, M.; Haddaoui, N. Viscoelastic, thermo-mechanical and environmental properties of composites based on polypropylene/poly(lactic acid) blend and copper modified nanoclay. J. Adhes. Sci. Technol. 2018, 32, 496–515. [Google Scholar] [CrossRef]

- Kodama, M.; Karino, I. Effects of polar groups of polymer matrix on reinforcement-matrix interaction in kevlar fiber-reinforced composites. J. Appl. Polym. Sci. 1986, 32, 5057–5069. [Google Scholar] [CrossRef]

- Torres-Giner, S.; Montanes, N.; Fenollar, O.; García-Sanoguera, D.; Balart, R. Development and optimization of renewable vinyl plastisol/wood flour composites exposed to ultraviolet radiation. Mater. Des. 2016, 108, 648–658. [Google Scholar] [CrossRef]

| Sample | PLA (wt%) | CHF (wt%) | TCHF (wt%) |

|---|---|---|---|

| PLA | 100 | - | - |

| PLA/20CHF | 80 | 20 | - |

| PLA/20TCHF | 80 | - | 20 |

| PLA/30TCHF | 70 | - | 30 |

| PLA/40TCHF | 60 | - | 40 |

| PLA/50TCHF | 50 | - | 50 |

| Piece | Et (GPa) | σy (MPa) | εb (%) | Ef (GPa) | σf (MPa) | Shore D Hardness | Impact Strength (kJ/m2) |

|---|---|---|---|---|---|---|---|

| PLA | 3.58 ± 0.37 | 49.51 ± 1.92 | 8.91 ± 0.71 | 3.17 ± 0.19 | 98.88 ± 1.18 | 78.65 ± 2.64 | 25.10 ± 2.01 |

| PLA/20CHF | 3.48 ± 0.78 | 39.16 ± 0.69 | 6.98 ± 1.10 | 4.02 ± 0.20 | 84.88 ± 1.35 | 81.04 ± 1.38 | 12.00 ± 0.39 |

| PLA/20TCHF | 3.59 ± 0.53 | 43.29 ± 1.90 | 7.10 ± 0.47 | 4.33 ± 0.19 | 90.96 ± 2.18 | 81.10 ± 2.02 | 12.44 ± 2.17 |

| PLA/30TCHF | 3.66 ± 0.87 | 36.23 ± 1.83 | 5.92 ± 0.36 | 4.48 ± 0.27 | 73.58 ± 1.71 | 82.05 ± 1.80 | 8.85 ± 1.67 |

| PLA/40TCHF | 4.22 ± 1.07 | 30.33 ± 2.16 | 5.59 ± 0.45 | 5.10 ± 0.34 | 71.66 ± 2.21 | 82.10 ± 2.16 | 7.19 ± 0.31 |

| PLA/50TCHF | 4.45 ± 1.04 | 27.81 ± 1.65 | 5.18 ± 0.91 | 5.53 ± 0.40 | 61.42 ± 2.04 | 85.05 ± 1.19 | 7.19 ± 0.97 |

| Piece | Tg (°C) | Tcc (°C) | ΔHcc (J/g) | Tm (°C) | ΔHm (J/g) | XC_max (%) |

|---|---|---|---|---|---|---|

| PLA | 62.3 ± 0.4 | 122.7 ± 1.9 | 4.30 ± 0.35 | 151.3 ± 0.4 | 11.32 ± 0.99 | 12.08 ± 1.80 |

| PLA/20CHF | 61.3 ± 0.3 | 124.7 ± 1.3 | 8.04 ± 0.42 | 153.7 ± 0.5 | 15.17 ± 1.10 | 20.24 ± 1.60 |

| PLA/20TCHF | 61.8 ± 0.4 | 125.9 ± 1.0 | 7.10 ± 0.55 | 152.6 ± 0.3 | 15.92 ± 0.75 | 21.24 ± 2.02 |

| PLA/30TCHF | 61.3 ± 0.4 | 122.1 ± 0.3 | 17.80 ± 0.76 | 150.7 ± 0.6 | 19.59 ± 0.14 | 29.87 ± 2.35 |

| PLA/40TCHF | 61.3 ± 0.8 | 121.8 ± 0.6 | 12.27 ± 0.94 | 149.9 ± 0.5 | 14.35 ± 0.59 | 25.52 ± 1.49 |

| PLA/50TCHF | 60.7 ± 0.5 | 123.2 ± 0.9 | 10.27 ± 0.35 | 149.6 ± 0.4 | 12.05 ± 0.99 | 25.72 ± 0.80 |

| Piece | T5% (°C) | Tdeg (°C) | Residual Mass (%) |

|---|---|---|---|

| CHF | 237.8 ± 1.2 | 360.6 ± 2.2 | 25.2 ± 0.3 |

| TCHF | 252.1 ± 1.3 | 357.8 ± 1.3 | 39.6 ± 0.3 |

| PLA | 320.4 ± 2.3 | 347.4 ± 1.4 | 5.6 ± 0.3 |

| PLA/20CHF | 298.9 ± 1.6 | 351.1 ± 2.2 | 3.2 ± 0.6 |

| PLA/20TCHF | 322.4 ± 1.7 | 354.7 ± 2.2 | 5.6 ± 0.5 |

| PLA/30TCHF | 306.0 ± 1.3 | 347.7 ± 1.7 | 8.1 ± 0.4 |

| PLA/40TCHF | 299.8 ± 1.8 | 343.5 ± 1.8 | 9.7 ± 0.7 |

| PLA/50TCHF | 301.1 ± 1.3 | 341.4 ± 1.6 | 10.9 ± 0.8 |

| Piece | VST (°C) | HDT (°C) |

|---|---|---|

| PLA | 56.6 ± 0.6 | 51.0 ± 0.8 |

| PLA/20TCHF | 57.8 ± 0.8 | 52.3 ± 0.8 |

| PLA/30TCHF | 58.1 ± 0.9 | 52.8 ± 0.9 |

| PLA/40TCHF | 59.4 ± 0.6 | 53.2 ± 0.7 |

| PLA/50TCHF | 59.9 ± 0.3 | 54.1 ± 0.8 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ortiz-Barajas, D.L.; Arévalo-Prada, J.A.; Fenollar, O.; Rueda-Ordóñez, Y.J.; Torres-Giner, S. Torrefaction of Coffee Husk Flour for the Development of Injection-Molded Green Composite Pieces of Polylactide with High Sustainability. Appl. Sci. 2020, 10, 6468. https://doi.org/10.3390/app10186468

Ortiz-Barajas DL, Arévalo-Prada JA, Fenollar O, Rueda-Ordóñez YJ, Torres-Giner S. Torrefaction of Coffee Husk Flour for the Development of Injection-Molded Green Composite Pieces of Polylactide with High Sustainability. Applied Sciences. 2020; 10(18):6468. https://doi.org/10.3390/app10186468

Chicago/Turabian StyleOrtiz-Barajas, Diana L., Johan A. Arévalo-Prada, Octavio Fenollar, Yesid J. Rueda-Ordóñez, and Sergio Torres-Giner. 2020. "Torrefaction of Coffee Husk Flour for the Development of Injection-Molded Green Composite Pieces of Polylactide with High Sustainability" Applied Sciences 10, no. 18: 6468. https://doi.org/10.3390/app10186468

APA StyleOrtiz-Barajas, D. L., Arévalo-Prada, J. A., Fenollar, O., Rueda-Ordóñez, Y. J., & Torres-Giner, S. (2020). Torrefaction of Coffee Husk Flour for the Development of Injection-Molded Green Composite Pieces of Polylactide with High Sustainability. Applied Sciences, 10(18), 6468. https://doi.org/10.3390/app10186468