1. Introduction

Experimental data on droplets behavior in high-speed flows is often required for such applications as combustion of liquid fuels, especially in ramjets, liquid atomization in airblast nozzles and many others. In general, the atomization of liquid droplets due to aerodynamic forces is a complex process that involves various physical mechanisms. Through the last several decades, a large number of experimental works aimed at revealing of influencing parameters, better understanding of breakup evolution and morphology, systematization of acquired data were performed.

A widely-adopted breakup morphology classification was proposed in the paper by Pilch and Erdman [

1]. Since this publication, a lot of attention was paid to the physical phenomena, governing the droplets morphology and transition between regimes. Some of the results were summarized in the works by Gel’ fand [

2] and Guildenbecher et al. [

3]. The proposed classification was expanded, and the role of different phenomena was revised through a series of works summarized in the paper of Theofanous [

4].

Generally, it is considered that Weber number (

We), Ohnesorge number (

Oh) and Eötvös or Bond number (

Bo) govern the behavior of liquid drops in the flow, while an effect of Reynolds number (

Re) is less apparent. The dimensionless parameters mentioned are expressed as:

In these equations, ρg is the gas, Δv is the droplet-to-gas relative velocity, d is the initial droplet size (diameter), ρd, σ and µd are the density, surface tension and the dynamic viscosity of the liquid, respectively.

The Weber number is generally considered the most important parameter. In connection with the classification of breakup regimes introduced in [

1], Weber number ranges are often referred to as “low”—

We < 100, “medium” (100 <

We < 350) and “high” (

We > 350). Ohnesorge number expresses the measure of viscosity effect in breakup processes. Usually, transitional Weber numbers, demarking the breakup regimes, are considered stable for

Oh < 0.1, while for a higher

Oh increase in transitional

We are typically observed (see [

5]). At low Ohnesorge numbers, several breakup regimes are usually demarked according to

We range: bag breakup for

We > 12, multimode (multi-bag) or bag and stamen breakup for 30 <

We < 80, sheet (or shear) stripping regime in the range of 80 <

We < 350 and catastrophic regime at

We > 350.

A droplet flattening into the ellipsoid form precedes any breakup regime. Hsiang and Faeth [

6] provided an approximation for the maximum deformation of a droplet.

where

dy_c is the major axis of the ellipse (flattened droplet). Hsiang and Faeth also found, that for low

Oh, total breakup time almost does not vary over the wide range of

We and may be approximated as

where

t* is a characteristic time of breakup initiation

t*, proposed by Ranger and Nichols [

7].

Other approximations taking into account

tb dependence on

We for different breakup regimes were also provided in [

1].

According to [

3,

8], and many other papers, an effect of viscous shear stress, and therefore, Reynolds number, plays no significant role in the transition between breakup regimes. Some numerical studies suggest that

Re, although not governing the breakup mode, has an effect on the shape of the droplet during the breakup. For example, studies performed by Han, and Tryggvason [

9,

10], showed that the liquid film surface area is correlated with

Re. A similar conclusion can be drawn from the numerical investigation by Kekesi et al. [

11].

The most common approaches to the experimental study of liquid drops deformation and breakup processes can be roughly divided into two categories: shock-tube experiments and experiments in continuous flows. Shock-tubes provide supersonic flow speed and controllable conditions, though instant aerodynamic loads can alter the behavior of the droplets comparing to the gradual acceleration case. Shock-tube approach was adopted, for example, in the works [

12,

13], and many others. Experiments with droplets in the continuous flow often provide more close resemblance to the practical application cases but also introduce additional parameters and effects to consider [

14,

15,

16]. For example, in the paper by Wierzba [

14] experiments on the bag type breakup of 2.2–3.9 mm size droplets in the continuous flow at near-critical

We were reported. The main aim was to accurately determine the critical conditions necessary to complete the bag breakup. The author reported that five significantly different modes of droplet deformation and breakup were observed within the range of 11 ~< We ~< 14. Wierzba concluded that breakup of droplets at nearly critical

We is very sensitive to fluctuations of the flow conditions. Similarly, in the review [

3], the authors concluded that the transition between breakup regimes is a continuous process, while a single transitional

We is an over-simplification.

The paper by Liu and Reitz [

15] covered many issues, including droplets trajectory prediction and droplets morphology at different stages of a breakup for the bag, shear stripping and catastrophic regimes. Through scaling down the size of the droplet from 200 µm to 70 µm while preserving

We, the authors showed that similar bag breakup regime occurred in both cases. Interesting to note, that in [

15] authors observed the bag breakup regime at

We = 56, while multimode or bag and stamen regime is considered to occur at such

We numbers.

The physical mechanisms behind the bag and multimode breakup regimes are still a matter of discussion that primarily provides two different explanations. The first one attributes the bag breakup purely to the aerodynamic effects, while the second assumes that the bag breakup occurs due to the initial disturbance of the flattened droplet’s surface, caused by Rayleigh–Taylor (RT) instability. The work by Theofanous et al. [

17] showed, among other results, that the second theory neatly explains the transition from bag to multimode breakup.

In the majority of the papers, droplets of size about 1 mm and larger are considered (see, for example, reviews [

2,

3]). For such droplets, low and medium Weber numbers at normal ambient conditions are achieved only at low, strongly subsonic gas velocities. At the same time, droplets of smaller size, usually produced in a primary jet, liquid film or a large droplet breakup at the atomizer, are also subjected to considerable aerodynamic loads in high-speed flow. While relative gas and droplets’ velocity can be high, up to supersonic, the Weber number for small droplets remains in the moderate or low range, resulting in a combination of dimensionless parameters, significantly different from those observed in experiments with large droplets. Another aspect is the change of flow conditions—rapid acceleration of small droplets, as well as the rapid change of velocity and density in supersonic flow—may lead to multiple switching of the

We number range associated with specific breakup modes.

Examples of works in which the breakup of small droplets in high-speed continuous flows is considered are few, some of those being [

18,

19]. In both works droplets in a converging–divergent nozzle were investigated. Other examples are [

8,

20], in which high-speed vaporizing droplets of the size of about 200 µm, injected into the cross-flow, were studied. The work by Sommerfeld [

18] did not provide insight into the processes of droplets’ breakup. Still, it showed that the final size distribution, in general, conforms to the expected one, derived from the existing breakup models.

Results provided by Kim and Hermanson [

19] and further developed in [

21], showed that under supersonic and overheating conditions, droplets exhibit breakup stages and morphology in some aspects different from commonly adopted. In the work [

19], authors investigated a dynamics, breakup and vaporization of single volatile (overheated) and non-volatile small droplets in the underexpanded jet at supersonic gas-to-droplets relative Mach numbers. Droplet’s maximum Weber number in this experiment varied from 200 to 280 for different liquids, covering

We range, typically associated with sheet-stripping breakup regime. One of the important features of this experiment was that droplets’

We number varied significantly during acceleration in the air flow: in the initial acceleration region,

We remained in the low range but quickly increased to the values of We > 100.

One of the main conclusions brought by the authors was that for different test liquids droplet breakup followed a similar pattern that included four subsequent stages: the initial deformation of the droplet, sheet stripping, ‘primary breakup’ and a catastrophic breakup. Although not mentioned by the authors, the primary breakup could arguably be regarded as the transition phase from sheet stripping to the catastrophic regime. Authors also noted that the We at which the mentioned breakup regimes occur are generally higher than those reported previously for shock-tube experiments, and the total breakup times are an order of magnitude shorter than would be expected in shock-tube flows for similar Weber numbers.

In the present paper, a study of dynamics and breakup of submillimeter droplets, resulting from the primary breakup of the liquid jet, in a flow accelerating from subsonic to supersonic speed in a converging–diverging nozzle is reported. The work is focused on the deformation and breakup of small droplets and related flow characteristics at different regions of the flow. The motivation for the work was to bridge the gap in the experimental data for small droplets behavior at low, near-critical We numbers in continuous accelerating flow.

2. Materials and Methods

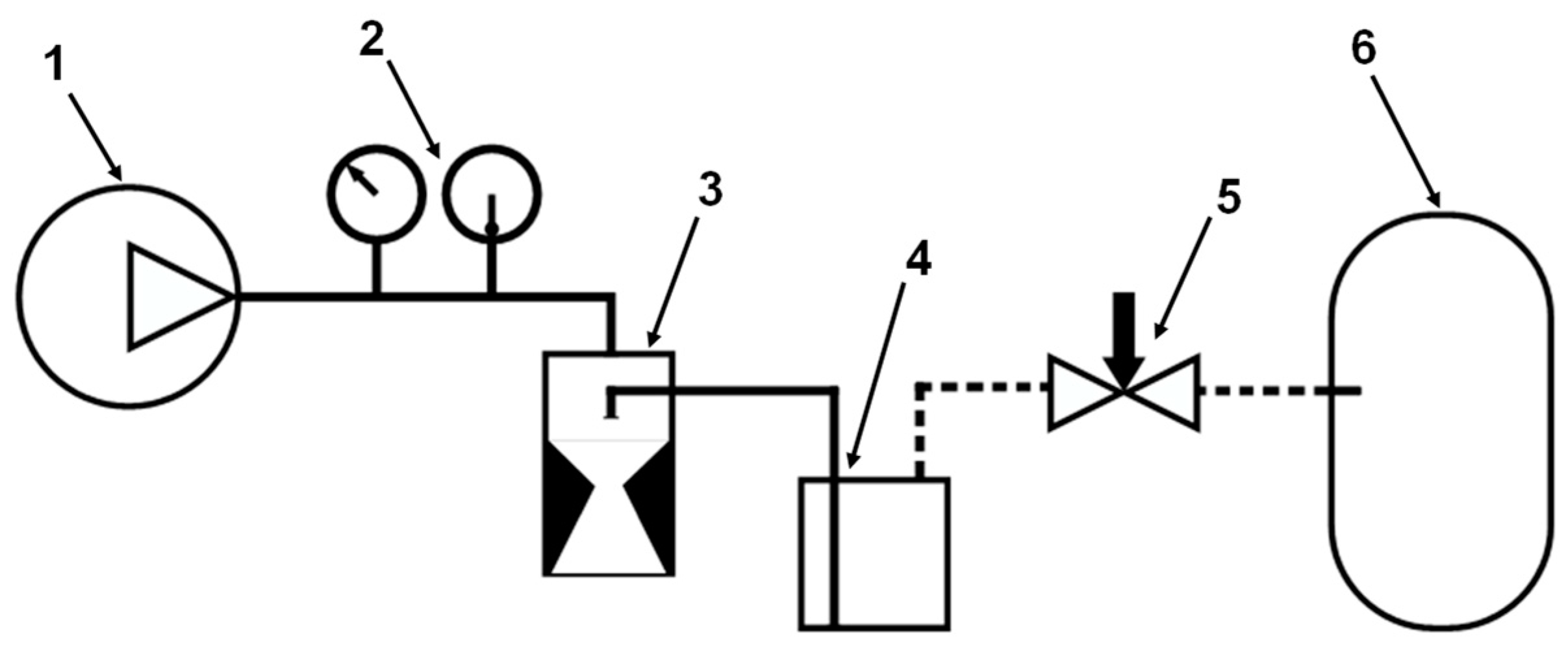

The behavior of liquid drops introduced into a gradually accelerating air flow in a converging–diverging nozzle was investigated. A converging–diverging nozzle with a rectangular cross-section and a throat size of 8 × 10 mm was employed for the study. Optical access to the measurement area was provided by transparent flat side walls of the nozzle. A compressor supplied constant airflow through the air supply line at the rate of 36 L/s. Air flow temperature and pressure were measured in the settling chamber preceding the converging part of the nozzle. The nozzle was operated in a choked regime with the formation of a Mach disk inside the divergent part of the nozzle, at a distance of 11.5 mm from the nozzle throat.

Droplets were introduced into the flow by atomization of the coaxial liquid jet of distilled water issued from the tube with an inner diameter of 0.5 mm. The exit of the tube was fixed in the settling chamber at a distance of 35 mm upstream of the nozzle throat. A fiber atomization regime of the round jet, described, e.g., in the review by Lasheras and Hopfinger [

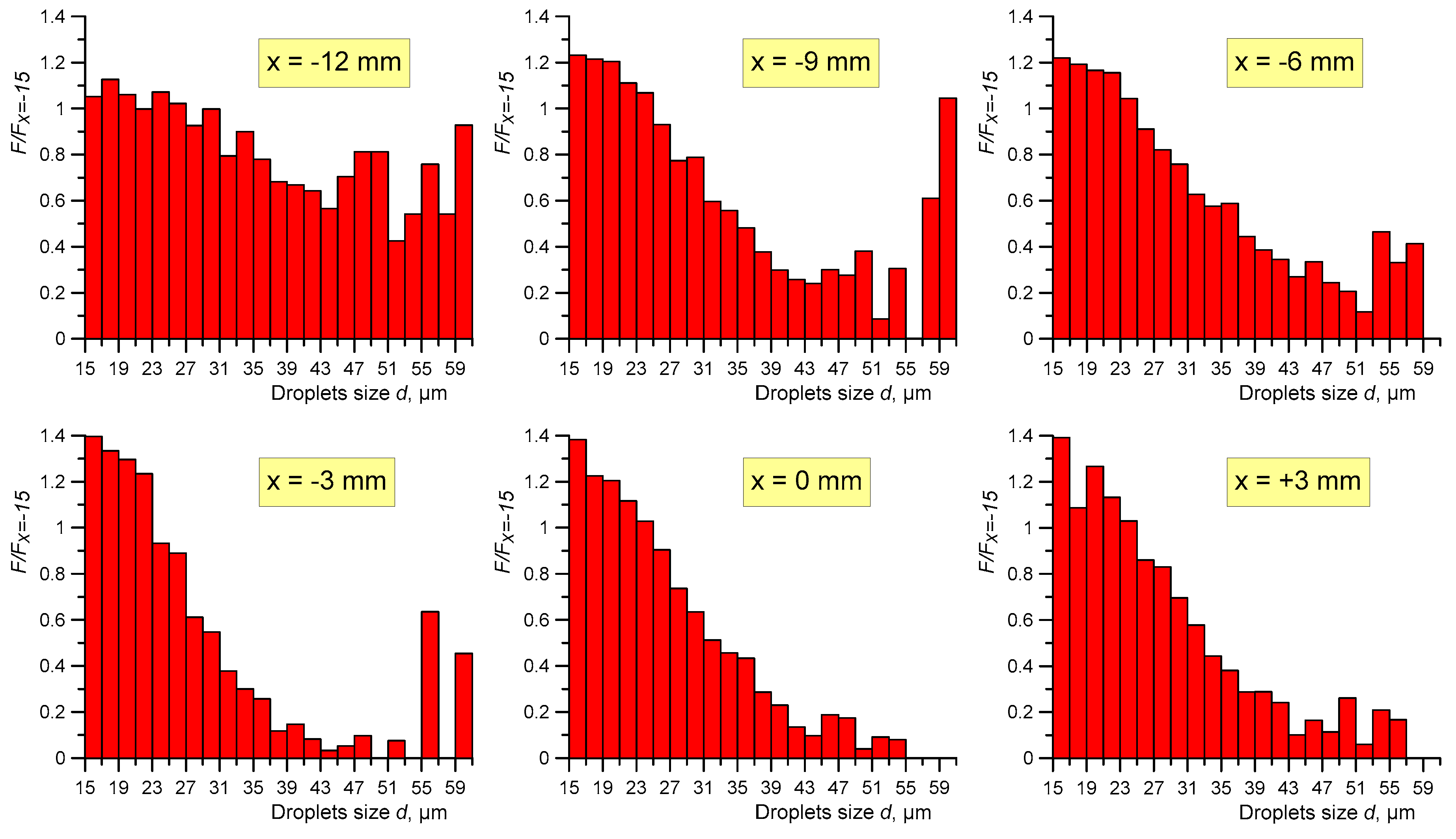

22], was observed at the exit of the tube. Large liquid clusters formed at the distance of 3–5 mm from the tube exit. Primary atomization was generally finished at the distance of 10–12 mm, the size of resulting drops mainly varied in the range from 10 to 100 µm. A scheme of the setup and the flow inside the nozzle is shown in

Figure 1 and

Figure 2, respectively.

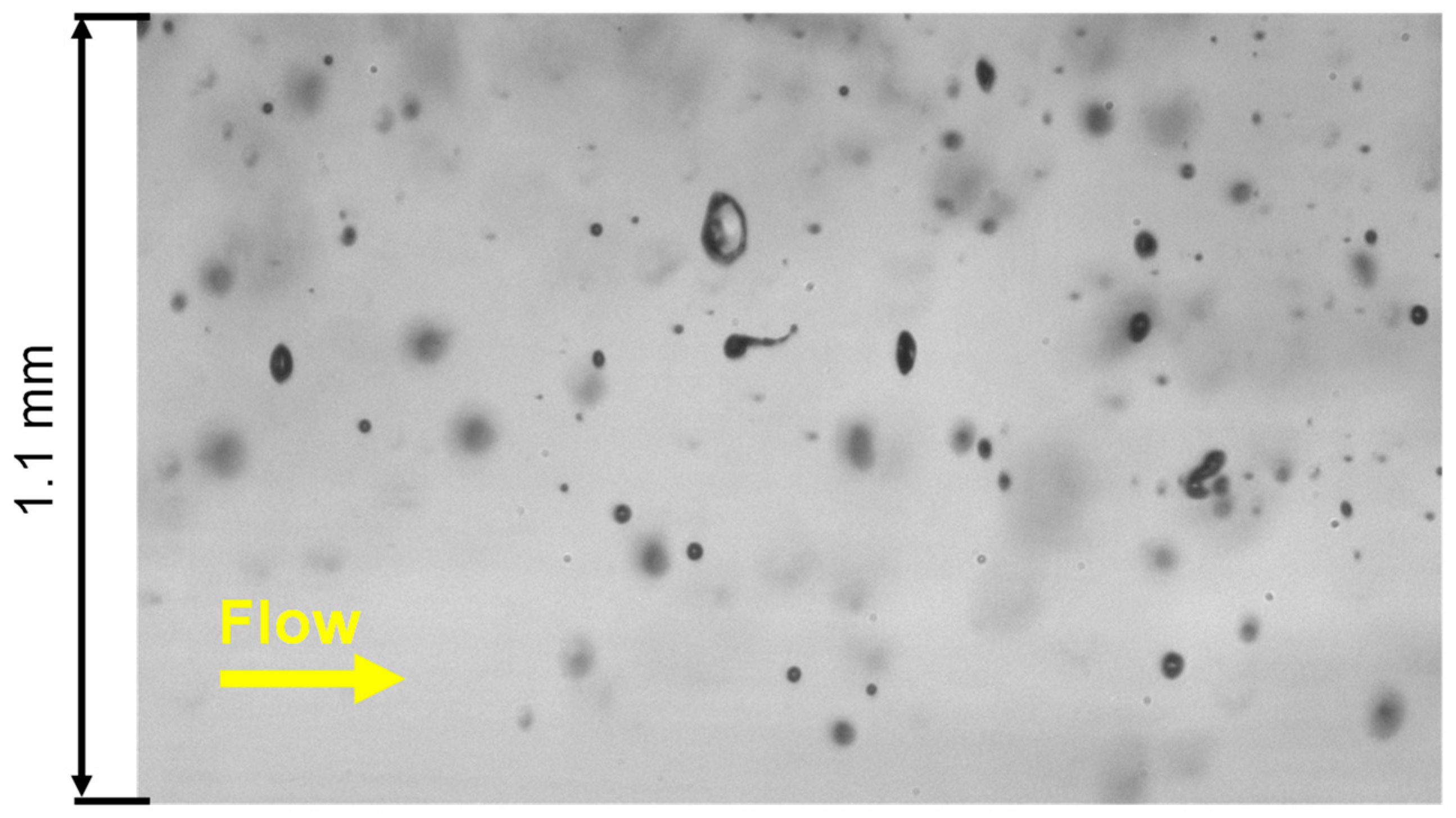

Direct visualization of droplet’s behavior in the flow using shadow photography (SP) played a key role in the work. To acquire a sharp image of a small-scale droplet in a supersonic flow, a high spatial resolution and short exposure are required. In the present work, short exposure was provided by a Rhodamine-B fluorescent background screen (thin cuvette filled with dyed ethanol), excited by 5–7 ns duration Nd:YAG laser (Quantel Evergreen EVG00200, Lannion, France) pulses. The fluorescent screen provided background lighting without speckles, which allowed visual analysis of small droplets. Images were captured by a CCD-camera (Bobcat B2020, Imperx, Boca Raton, FL, USA) with an Infinity K2/SC long-distance microscope (Infinity photo-optical, Centennial, CO, USA) with the optical magnification of 4.6:1, which is 1.6 µm/pix. An example of the SP image is shown in

Figure 3.

The spatial resolution of the images was enough to measure the size of droplets larger than 15 µm and to qualitatively analyze the morphology of droplets in the state of the breakup. At the same time, fine details and small droplets remained unresolved. An increase in spatial resolution could be useful for such tasks as the estimation of the breakup products’ size distribution and analysis of the droplets’ surface shape in the state of the breakup. An increase in resolution in future works can be achieved through the employment of cameras with smaller pixel size and employment of higher magnification optics, although considerations for the optics diffraction limit should be taken into account.

During the exposure time, droplets’ displacement was less than one pixel, and the motion blur of the droplets’ images was negligible. The use of a dual-head laser and a CCD-camera in double-frame exposure mode allowed capturing pairs of images with a short interframe delay (down to 300 ns), fetching not only instant images but also an evolution of the droplets over two frames. A small depth-of-field (DOF) of the microscope, which was about a few hundreds of micrometers, allowed to localize the measurement region in the central plane of the nozzle. At the same time, out-of-focus droplets significantly hindered the evaluation.

Automatic and manual processing of shadow images was employed for different purposes. Images of droplets in the state of the breakup were extracted and analyzed manually. Automatic processing was used to detect non-disrupting droplets in the images and to aggregate the statistical data for such droplets. The automatic image processing procedure was implemented using Python 3.6 programming language with Numpy 1.13.3 and OpenCV 3.3 open-source libraries. The processing procedure consisted of several steps. In the first step, a custom local variance filter [

23] was applied to detect edges in the image. After that, a blob detector method from the OpenCV kit was employed to find contours (connected areas) in the image. The blob detector method performs multiple threshold binarization of images and extracts connected areas (contours) from each binary image using the border traversal algorithm implemented by the FindContours class of the OpenCV module. The blob detection procedure yielded a center of mass, the area and perimeter length of each detected contour. Variance filter and blob detector processing parameters were fine-tuned to detect only sharp contours of the droplets. No DOF correction method [

24] was employed in the experiments, but, as the processing parameters were tuned specifically to reject even slightly blurred out-of-focus droplets, and the droplets’ size range was rather small, the statistical bias due to DOF effect could be ignored.

Additional filtering was applied to the extracted contours. Contours with the area smaller than 30 pixels2 (corresponding to the area of the droplet with equivalent sphere diameter d of 10 µm) were filtered out. Lower size threshold was set because smaller droplets were not expected to feature breakup or significant deformation.

The second filter employed the isoperimetric quotient

Q of the contour as the parameter:

where

S is the area of the contour, and

P is the perimeter of the contour. Isoperimetric quotient shows a ratio of the contour’s area to the area of a circle with the same boundary length. Contours with

Q < 0.6 were rejected. Such filtering passed elongated or slightly deformed droplets, but reliably rejected fibers, ligaments and droplets in the state of breakup. The filter with the threshold of

Q = 0.6 passed the droplets with

dmax/d < 1.8, considering a deformed droplet as an ellipse.

The processing method was tested on generated images and experimentally on the images of monodisperse glass microspheres (Whitehouse Scientific Ltd., Waverton, Cheshire, UK) of d = 25.6 µm and d = 84.3 µm, and yielded an RMS error of about 1.7 µm in the conditions similar to the present experiments.

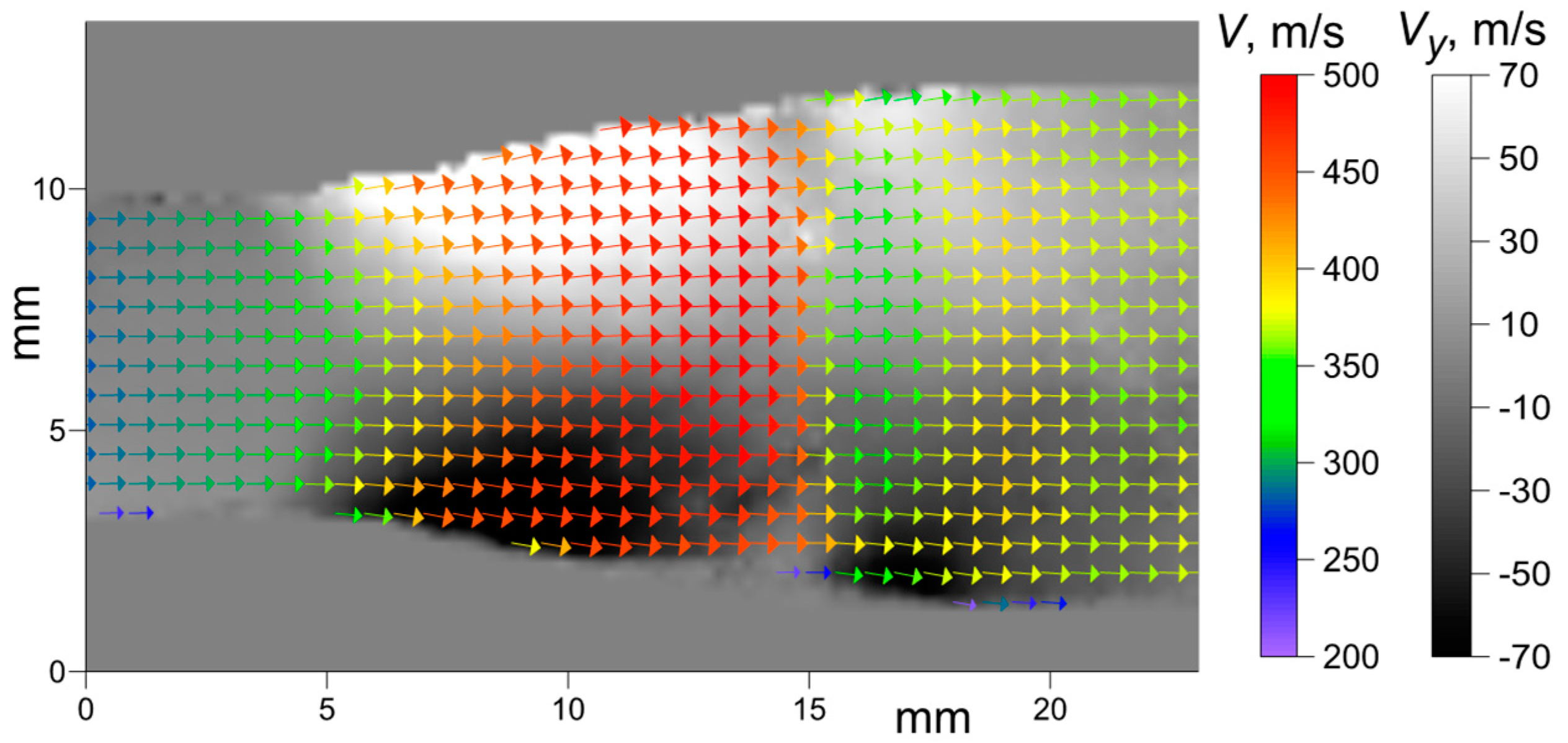

Additionally, particle image velocimetry (PIV) and particle tracking velocimetry (PTV) techniques were used to assess the gas and droplets’ velocity fields in the nozzle. Water-glycerol tracing particles of the size of about one µm were produced by the Laskin-nozzle type aerosol generator and were introduced into the air supply line immediately after the outlet of the compressor. Gas and droplets velocities were acquired in separate experiments. Gas velocity distribution was measured in the flow without droplets, as droplets’ images, which are much brighter than the images of tracer particles, made a proper evaluation of PIV data impossible. It is important to note for further consideration, that PIV tracer’s response to the abrupt deceleration of the flow after the shock wave front is not instant because of the tracer’s inertia. In the described experimental conditions. Relaxation length of the tracers after the shock wave (SW) front was about 2 mm, and the gas velocity data in this region were overestimated. A gas velocity distribution in a central plane of the nozzle is shown in

Figure 4. Measured velocity pulsations near the axis of symmetry of the nozzle were in the range of ±2% of the mean gas velocity over the whole measurement area, excluding the region of ±1.5 mm from the average shock wave front position, within which a shock wave front oscillations occurred.

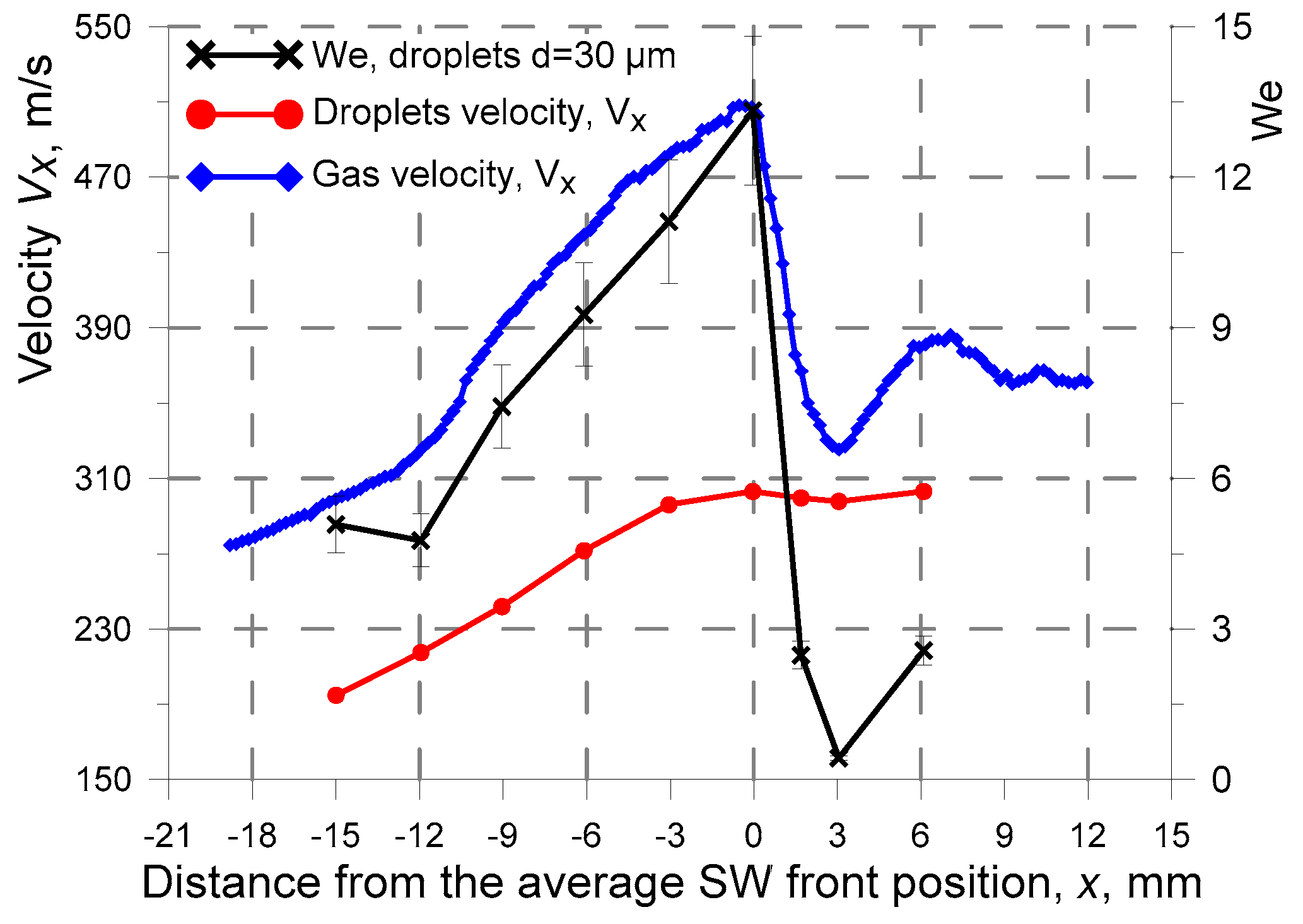

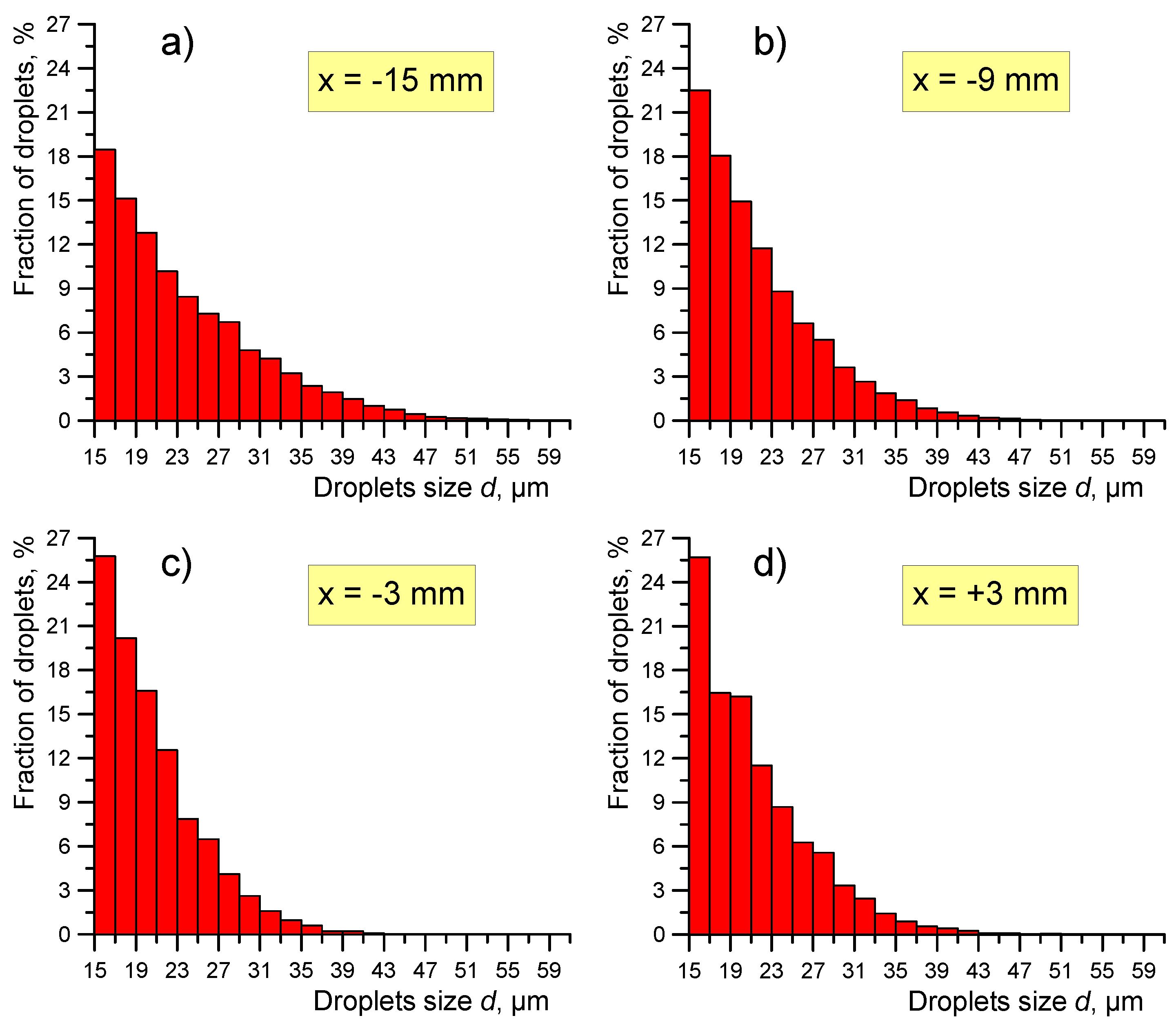

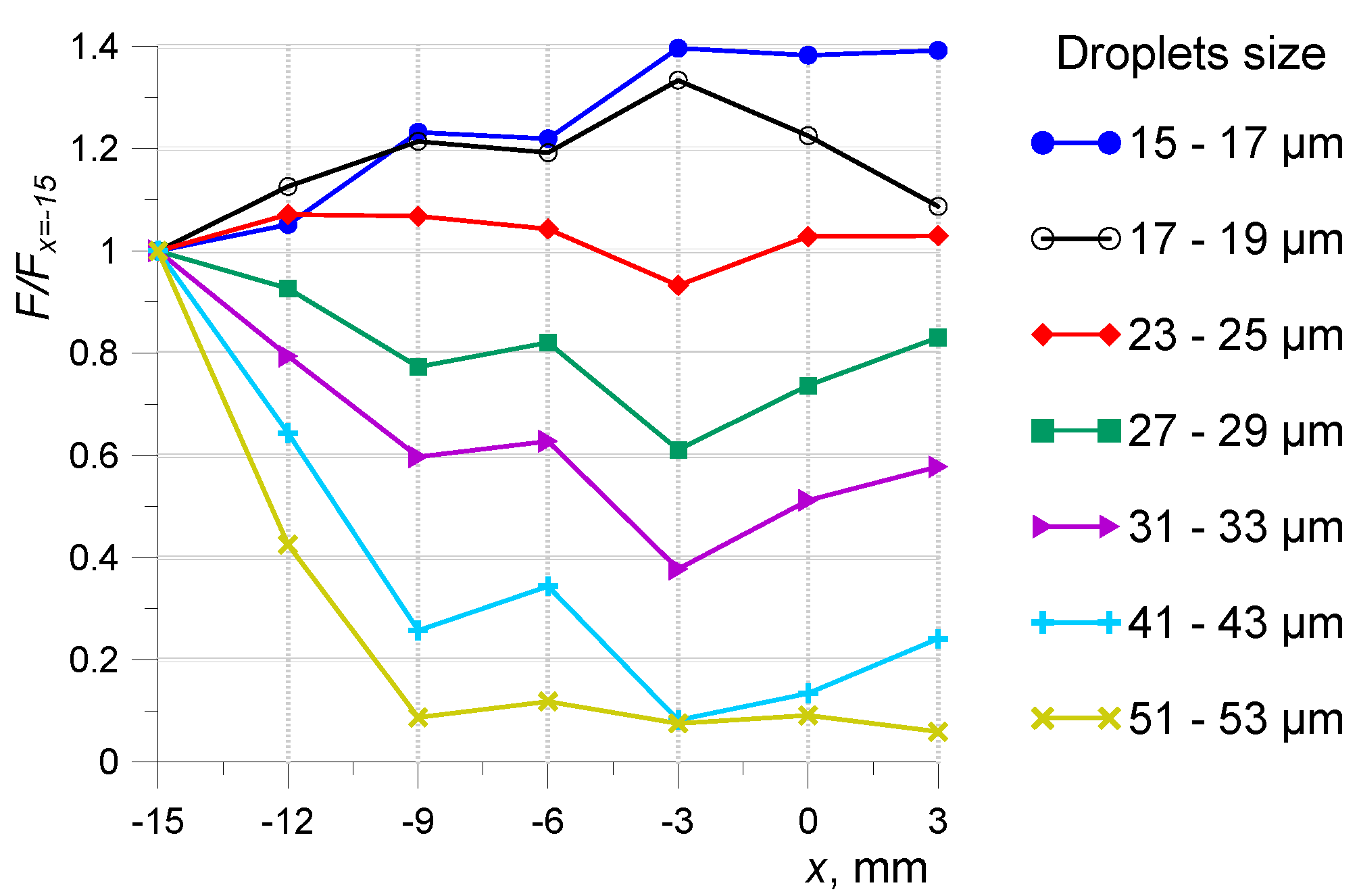

For the liquid phase (droplets), a PTV image processing algorithm was employed instead of PIV, as it was more suitable for measuring the average droplets’ velocity. In these measurements, no droplets’ size separation was made, and thus only average liquid phase velocity was measured. Gas and droplets’ velocity profiles are presented in

Figure 5. As droplets’ acceleration depends on their size, manual evaluation of velocity for droplets of different sizes in shadow images was performed. At the distance of 3 mm upstream of the average SW front position, the average velocity of 45 µm droplets was 275 m/s, while for 15 µm droplets, it amounted to 305 m/s. Therefore, an error introduced in the estimation of local

We by neglecting the difference in velocity for droplets of different size was less than 10%.

As dimensionless parameters, including

We, depend on the gas density, its variation along the nozzle should be taken into account. Initially, the gas density was evaluated through the isentropic gas flow equations at the point in the converging part of the nozzle, where pressure measurements were taken. After that, a density distribution along the axis of symmetry of the nozzle was estimated through the law of the mass flow rate conservation along the streamtube using density at the initial point and the gas velocity distribution from the PIV measurements. Error in density estimation was within ±6% of the value, considering the velocity measurement error and the precision of pressure and temperature sensors. Measured droplets and gas velocities combined with the evaluated gas density profile allowed to assess a Weber number variation along the axis of the nozzle with relative error within 11% of the value, assuming that the exact size of the droplet is known (

Figure 5). As the droplets’ visualization region’s transverse size was quite small, about 3.5 mm, and was always centered at the axis of symmetry of the nozzle, the velocity and We data at the axis were used as a reference for all of the considerations about droplets behavior.

4. Conclusions

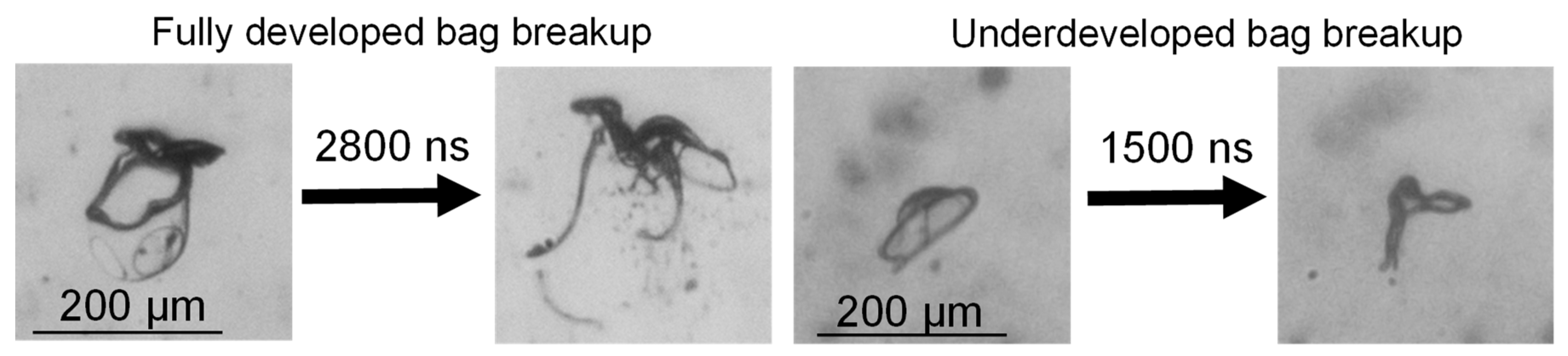

A behavior of submillimeter-scale water droplets produced by a liquid jet breakup in the flow in a converging–diverging nozzle was investigated using a set of optical techniques. Flow configuration, including gas velocity and density distributions, were evaluated from point-wise and planar measurements. Shadow photography allowed to specify velocity ranges for different droplet sizes and to visualize droplets dynamics and breakup modes.

No evidence of systematic droplets’ breakup at the Weber numbers below 12 was detected, while for higher Weber numbers, the bag and multi-bag breakup regimes were dominant. In general, small-scale droplets in the range of low We numbers feature the same breakup processes and thus are governed by similar physical mechanisms, as large (size of a millimeter) droplets.

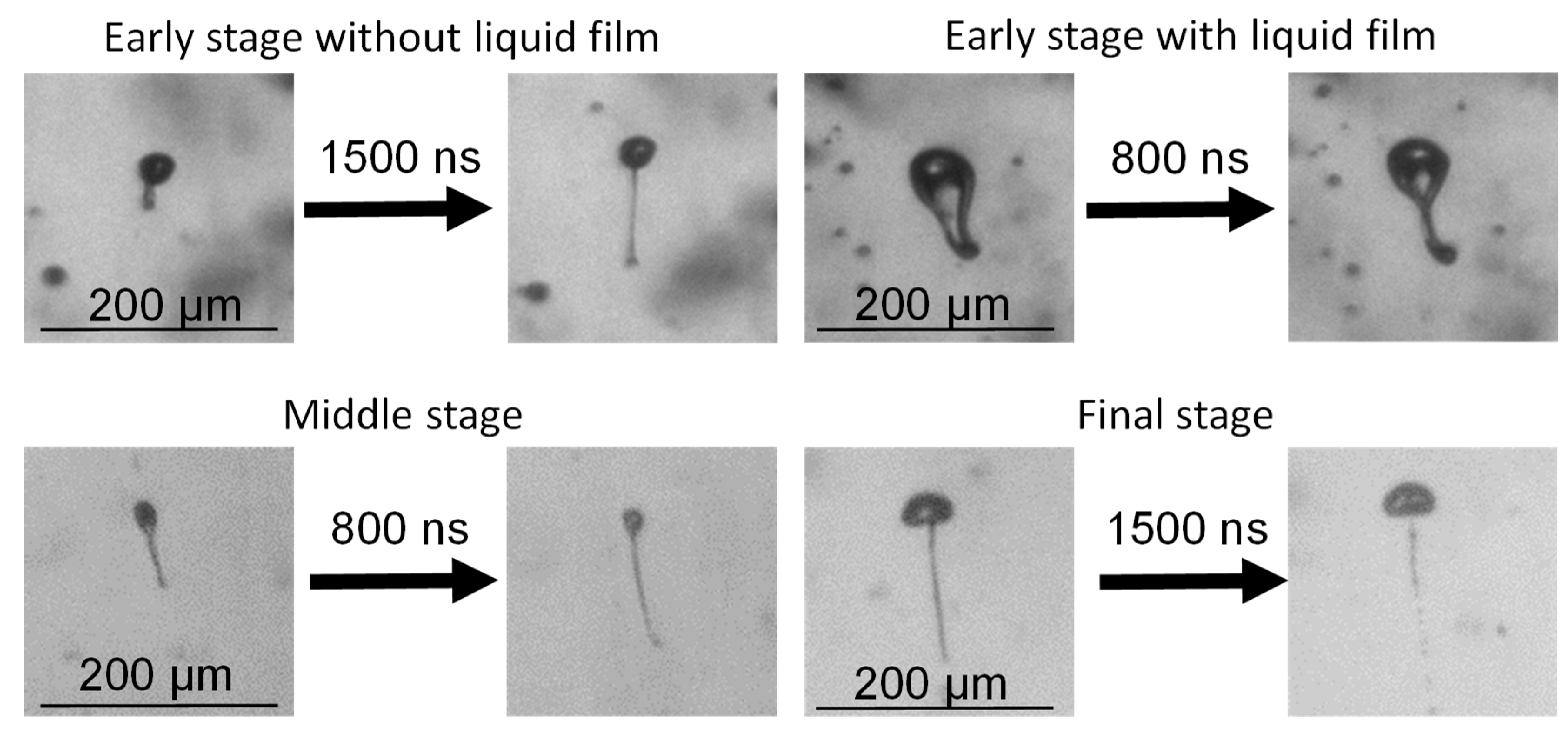

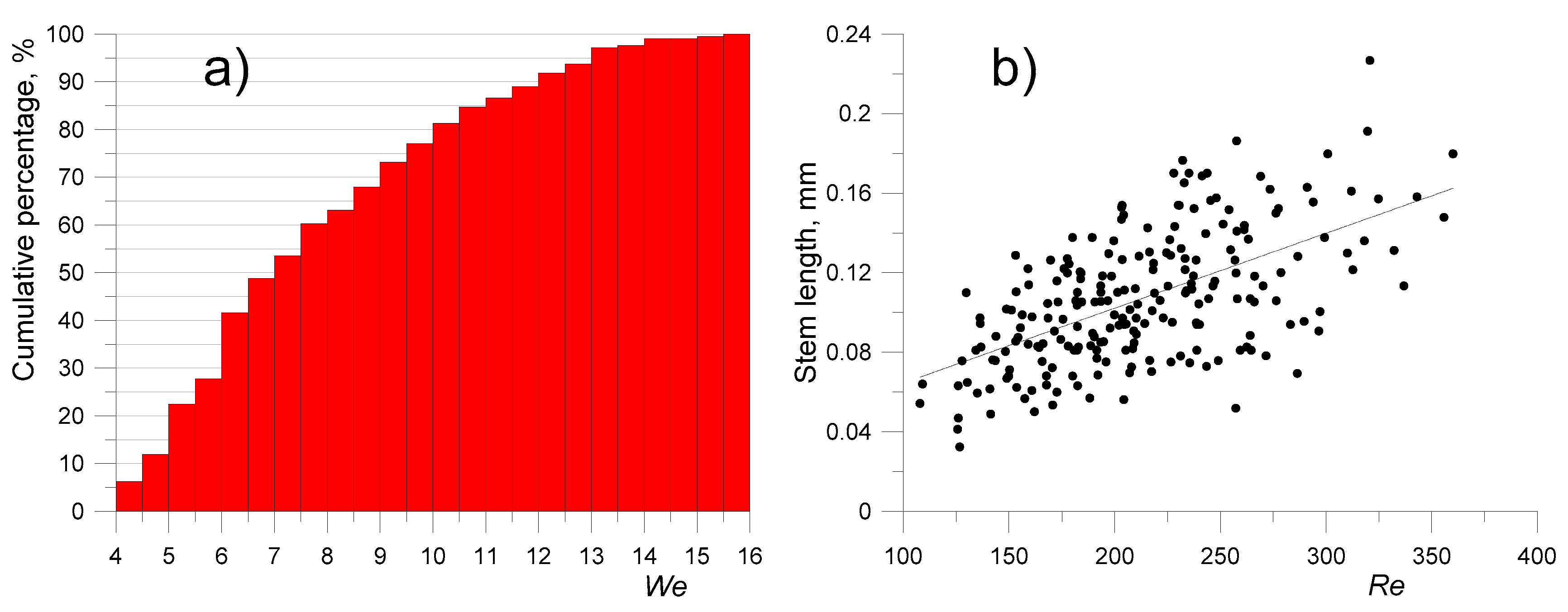

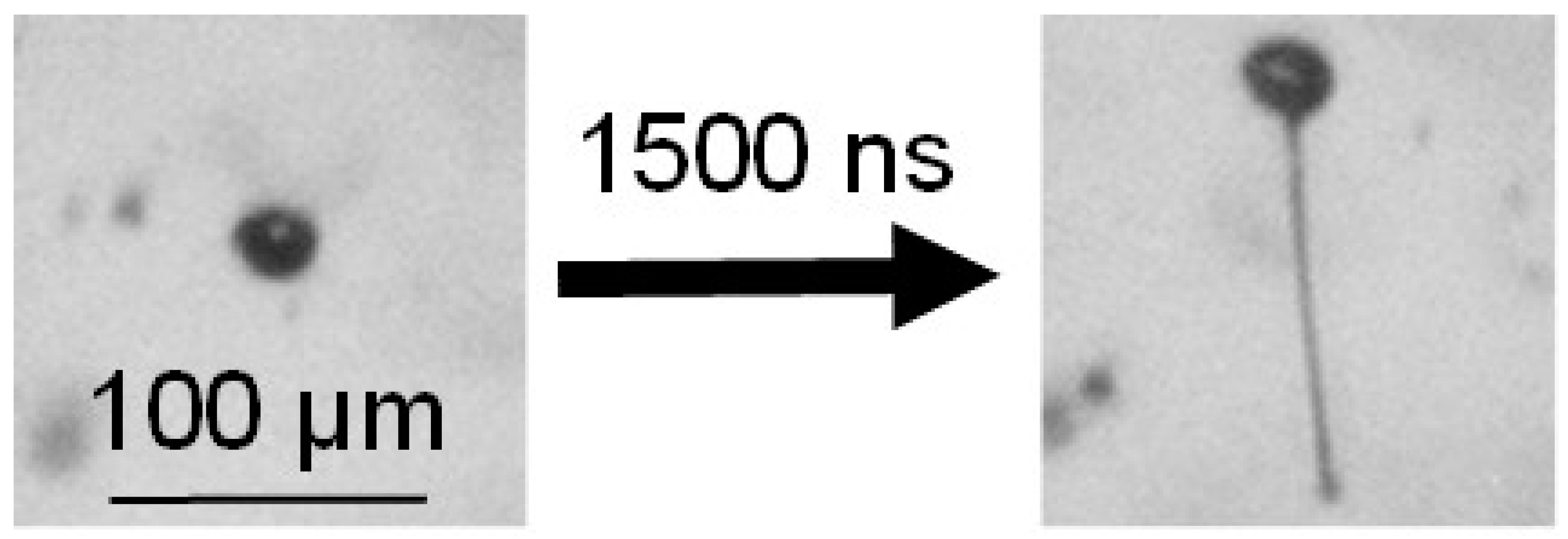

A qualitative description of pulling breakup regime, detected at low Weber numbers, ranging from 4 to 14, is given. In this regime, a stem emerges from a droplet, and smaller droplets are produced through disruption of the stem, presumably through fluid thread breakup. It was noted that the length of the stem has a positive correlation with the local Reynolds number (Re) and size of the initial drop. An additional consideration, explaining the manifestation of pulling breakup regime in smaller droplets through shear stress, is provided. The proposed explanation suggests that with a particular combination of flow parameters, shear stress can play a significant role in the atomization process.

The studies reported, and the results obtained are of certain practical importance. In the first place, they can be used to refine the methods and models for the prediction of final atomization products in applied problems.