A Study of Waterproof Reinforcement Layers for the Post-Cracking Behavior of Fiber Reinforced Concrete

Abstract

Featured Application

Abstract

1. Introduction

2. Experimental Program

2.1. Materials

2.1.1. Concrete Reinforcing Fiber

2.1.2. Protective Materials

2.1.3. Experimental Composition

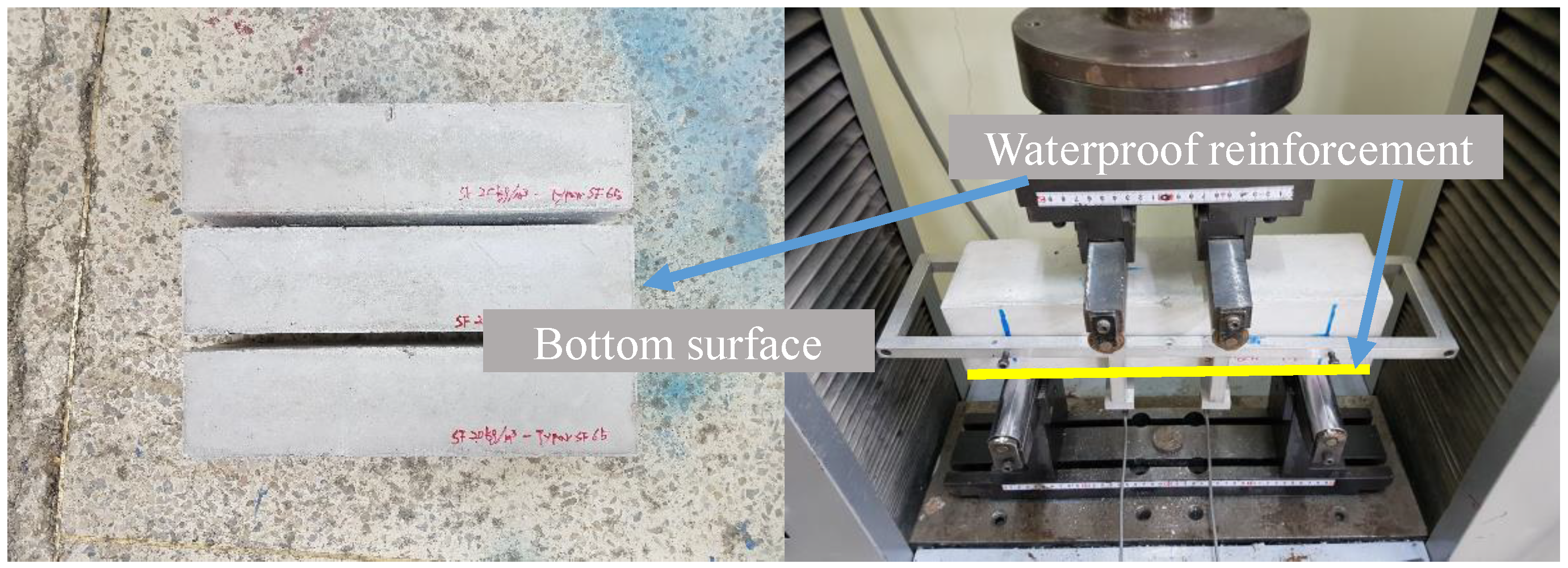

2.2. Specimen Preparation

Mixing Proportion

3. Test Methods

3.1. Test Specimen

3.2. Compressive Test

3.3. Crack Growth Resistance with Flexural Test

4. Test Results

4.1. Compressive Strength

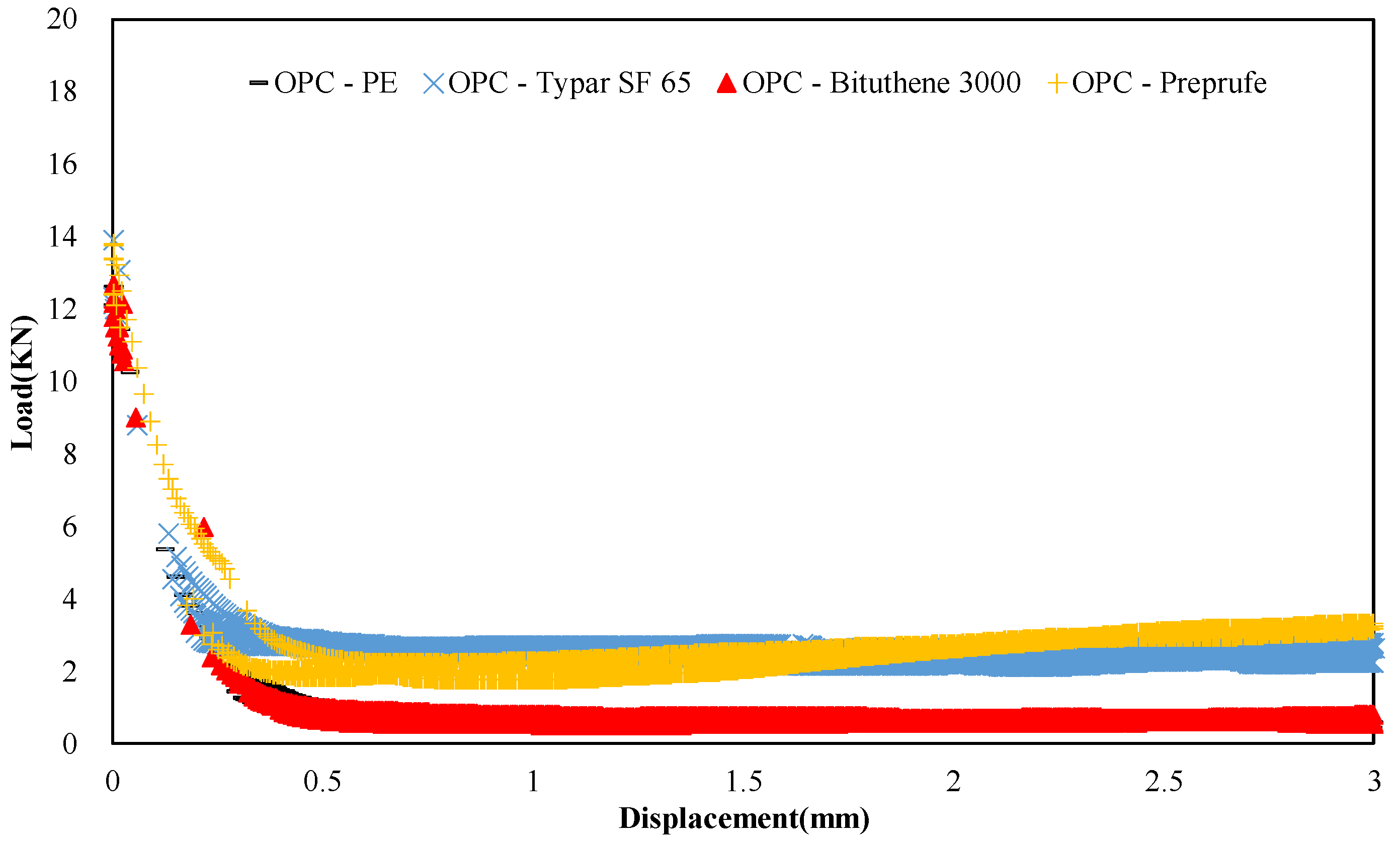

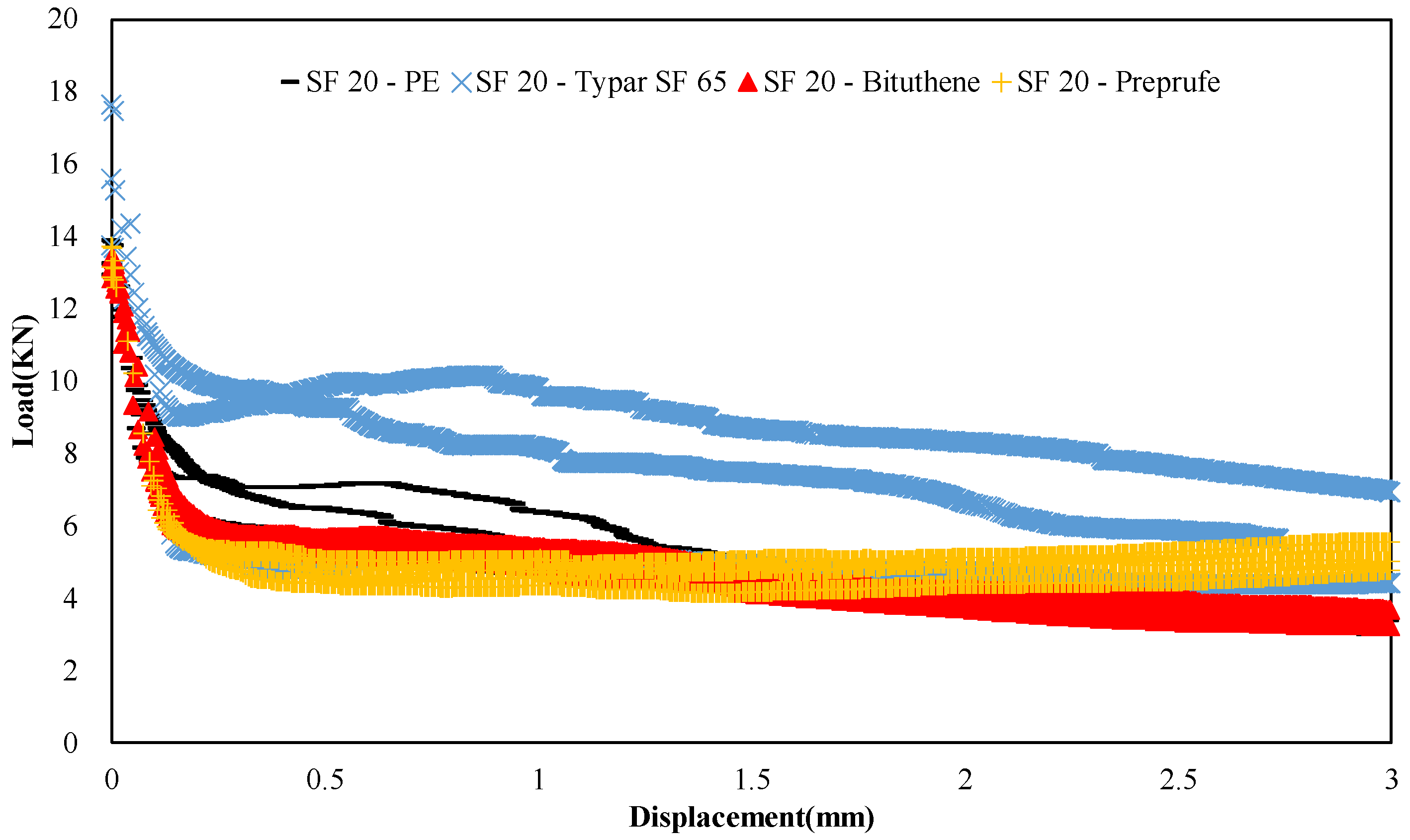

4.2. Flexural Test Results

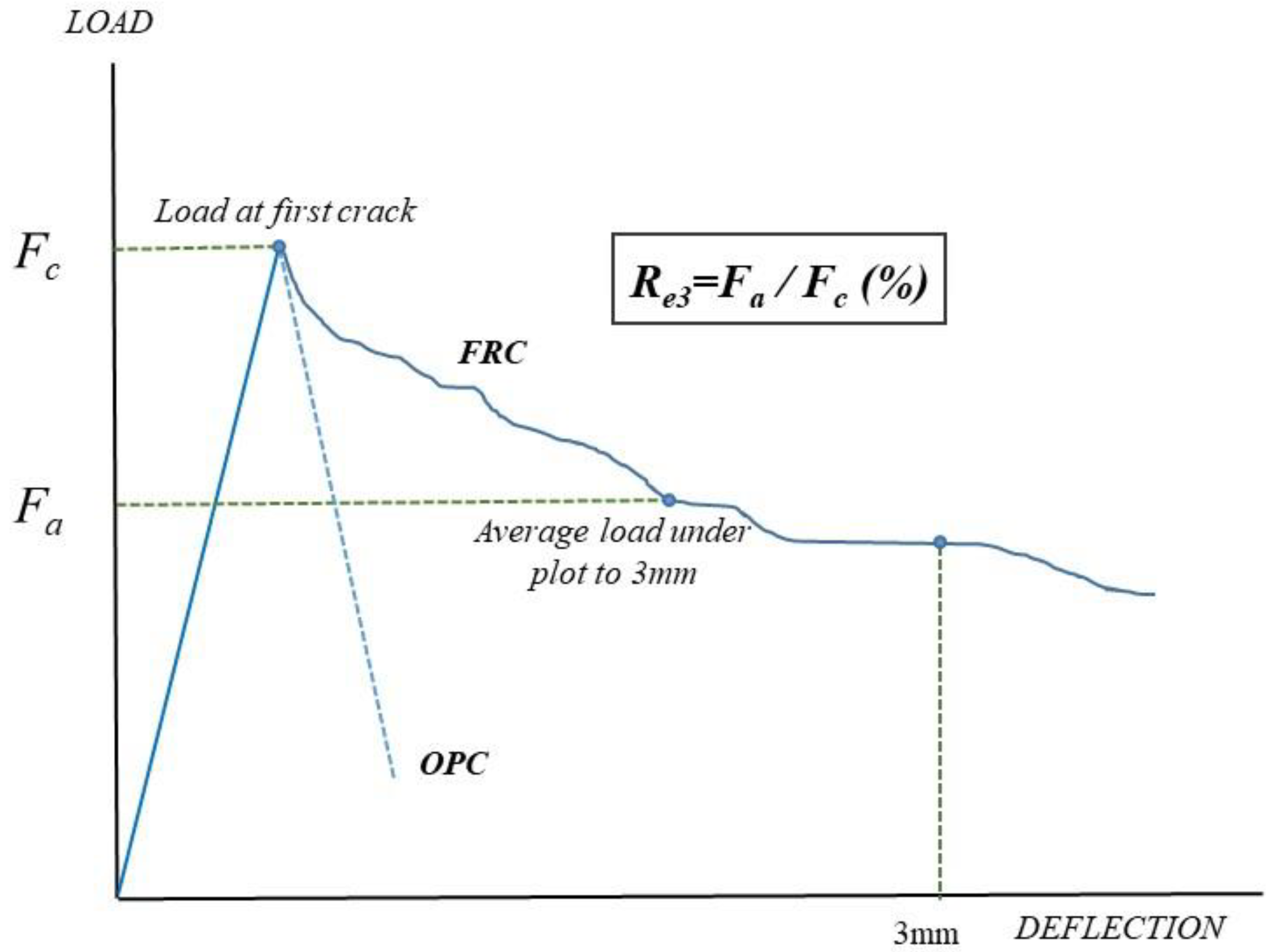

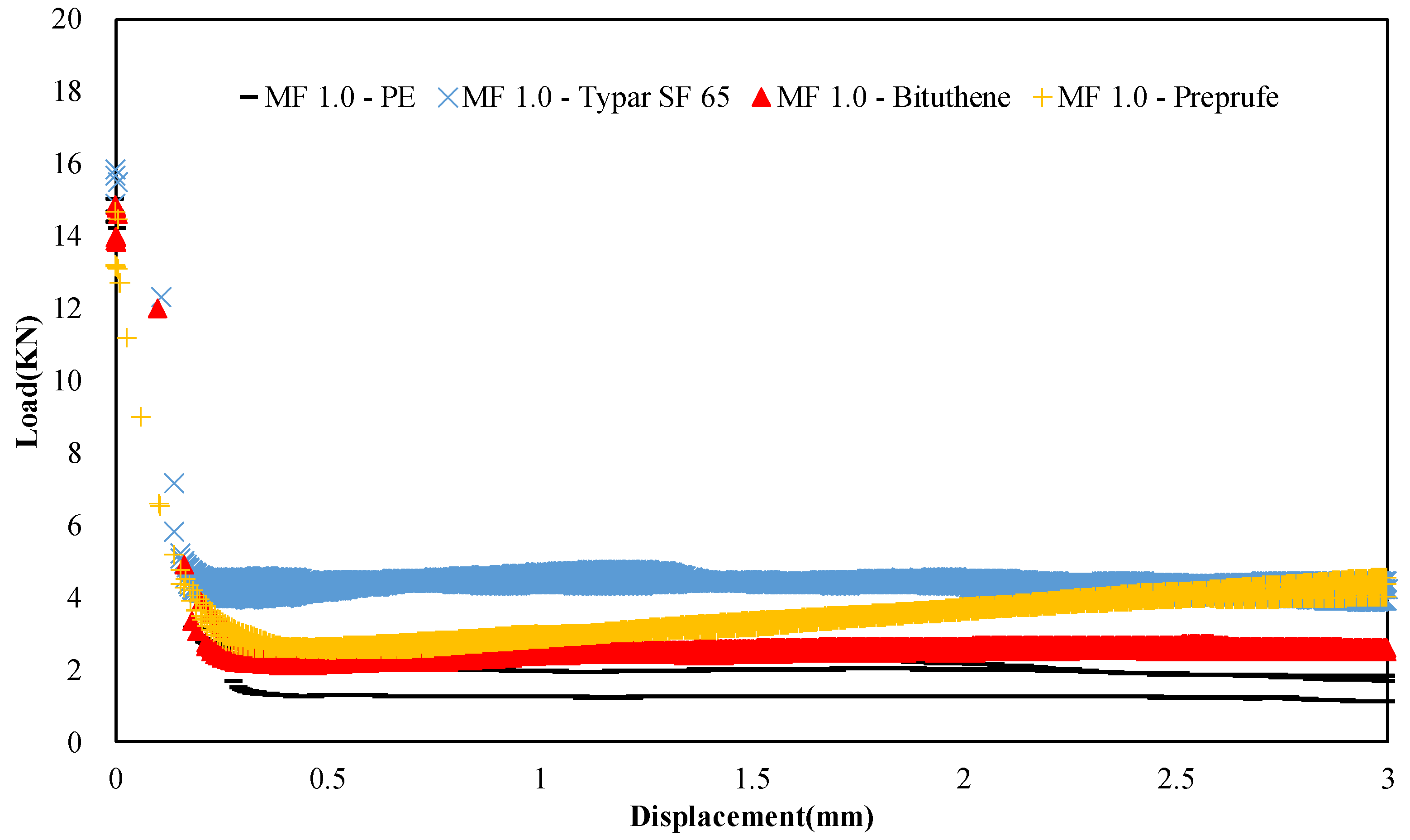

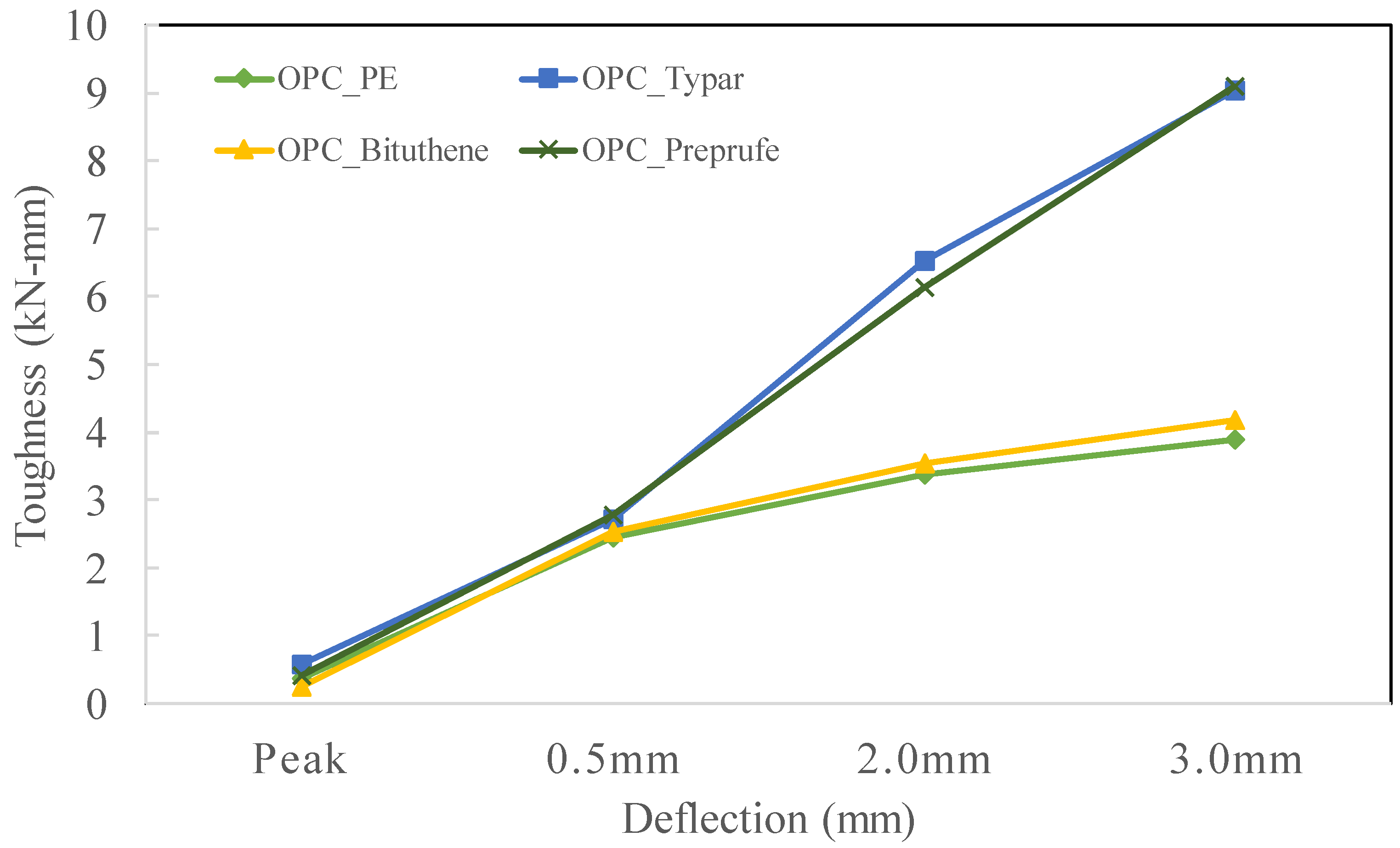

4.3. Flexural Test Performance

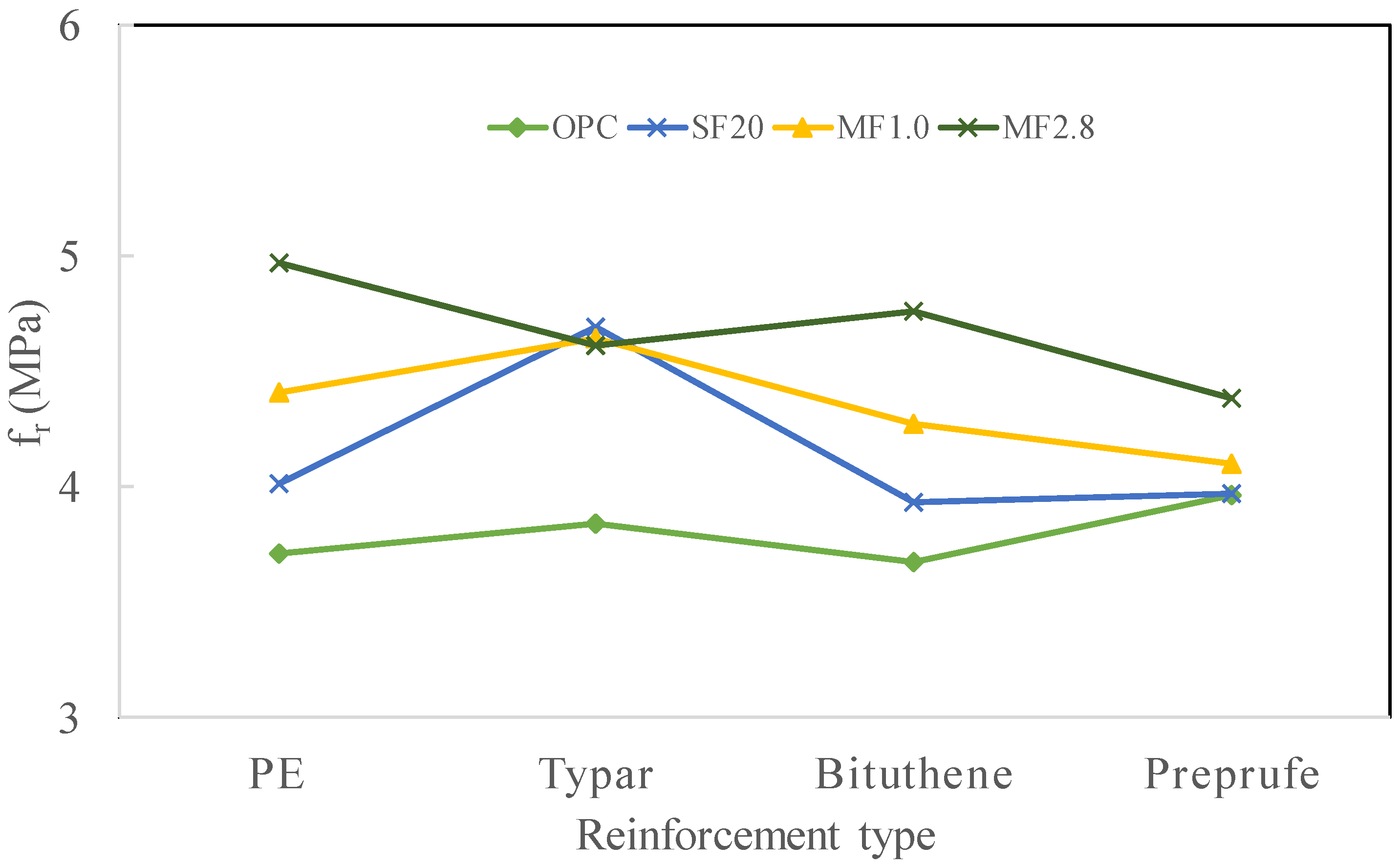

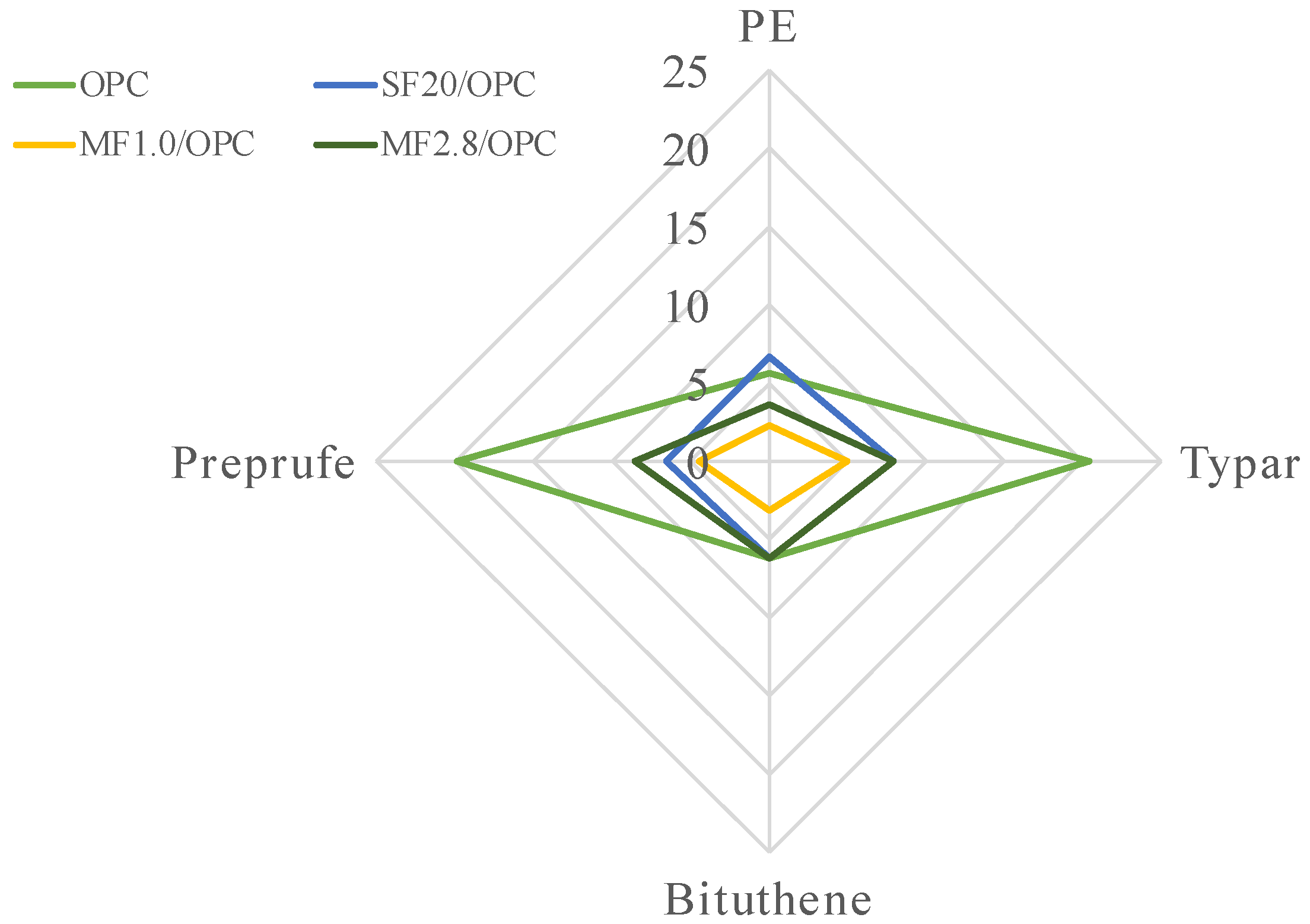

4.4. Residual Stress

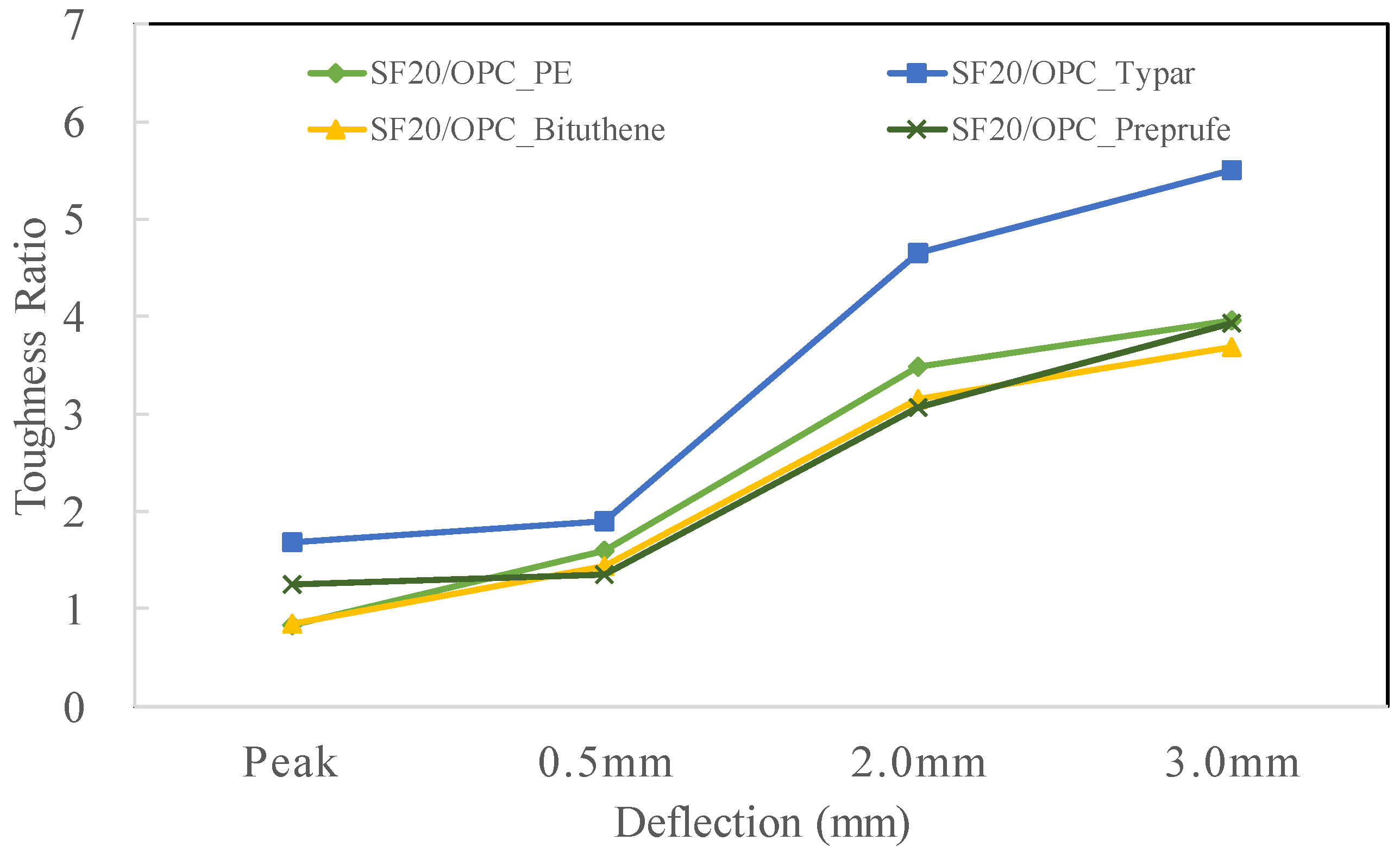

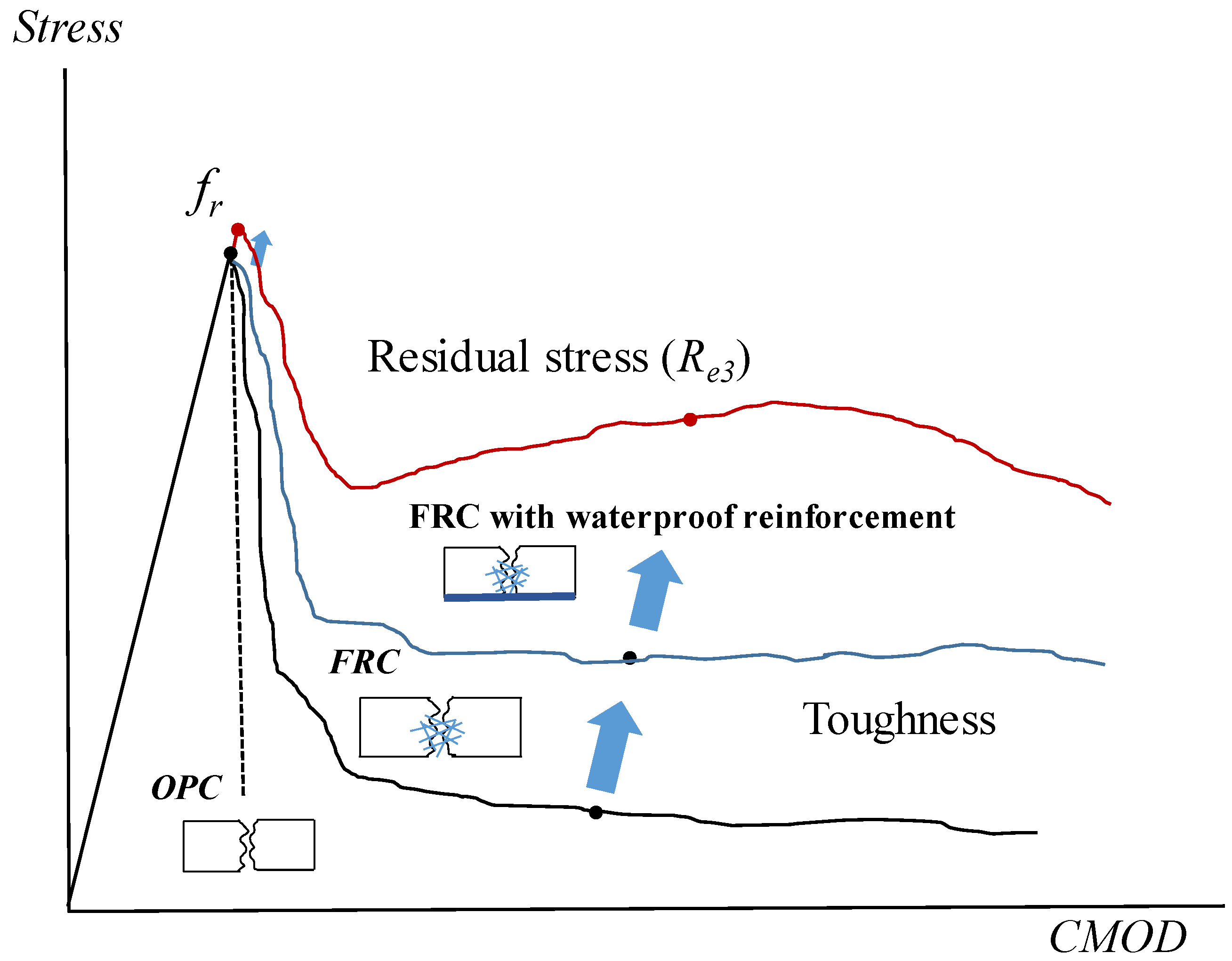

5. Resistance Ability of Waterproof Reinforcement for Flexural Failure

6. Conclusions

- The flexural strength of four types of waterproof reinforcement was improved by about 10–48%. The flexural strength improvement of the test specimen reinforced with Typar and Prepurf was the best among all the specimens, and the increase in flexural strength due to the combination of the steel fiber (SF20) and organic fiber (MF2.8) and the reinforcing material was apparent. In particular, the SF20 + Typar and MF2.8 + Preprufe test specimens showed results of improved flexural strength of 45 and 48%, respectively.

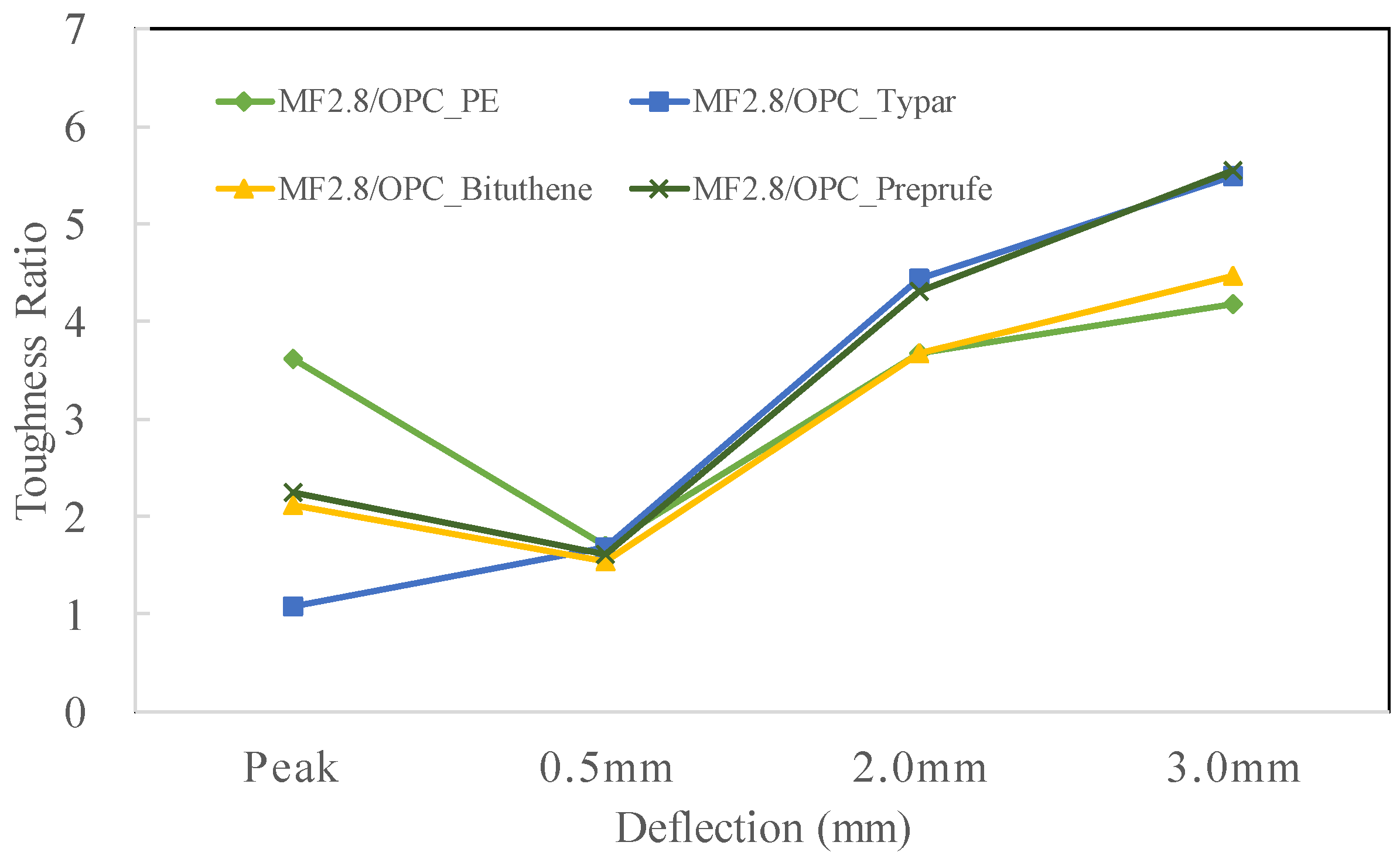

- The change in toughness showed a marked improvement in all specimens due to the combination of fiber and waterproof reinforcement. After the concrete matrix cracking, the toughness due to the fiber pull-out resistance and the increase in the reaction force of waterproof reinforcement showed a continuous increase in toughness in the specimen reinforced with the steel fiber. Toughness due to organic fiber mixing showed stable toughness improvements after an unstable toughness change from a maximum load to 0.5 mm. The test specimen reinforced with Typar showed the best crack resistance regardless of fiber type.

- The crack transfer mechanism in the concrete floor layer due to fiber mixing and water-reinforcing reinforcement decreases the crack length (l) as the load due to the fiber pull-out resistance and the reaction force generation of the reinforcing material decreases immediately after the cracking of the concrete matrix, thereby protecting the fiber bridging zone (lf). Afterwards, it is judged that the residual stress rises, maintains, and slows, as the resistance of the fiber pullout and the effect of the reinforcement is combined.

Author Contributions

Funding

Conflicts of Interest

Abbreviations and Acronyms

| OPC | Ordinary Plain Concrete |

| FA | Fine Aggregate |

| CA | Coarse Aggregate |

| SP | Super Plasticizer |

| SF | 20 Steel Fiber 20 kg/m3 |

| MF | 1.0 Micro Fiber 1 kg/m3 |

| MF | 2.8 Micro Fiber 2.8 kg/m3 |

| Re3 | Residual Stress |

| Lf | Fiber Bridging Zone |

| LVDT | Linear Variable Differential Transformer |

| PE | Polyethylene |

| fr | Flexural Strength |

| CMOD | Crack Mouth Opening Displacement |

References

- Meyer, C. The greening of the concrete industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Mehta, P.K. Global concrete industry sustainability. Concr. Int. 2009, 31, 45–48. [Google Scholar]

- Sealey, B.J.; Philips, P.S.; Hill, G.J. Waste management issues for the UK ready-mixed concrete industry. Resour. Conserv. Recycl. 2001, 32, 321–331. [Google Scholar] [CrossRef]

- Holton, I.; Glass, J.; Price, A.D.F. Managing for sustainability: Findings from four company case studies in the UK precast concrete industry. J. Clean. Prod. 2010, 18, 152–160. [Google Scholar] [CrossRef]

- Ahn, D.S.; Oh, K.H.; Park, J.S.; Oh, S.-K. Viscosity and Waterproofing Performance Evaluation of Synthetic Polymerized Rubber Gel (SPRG) after Screw Mixing. Appl. Sci. 2018, 8, 1989. [Google Scholar] [CrossRef]

- Oh, S.-K.; Shim, J.-S. Maintenance for Leakage due to Cracking in Concrete Structures-Guidelines for Repair of Water-Leakage Cracks in Concrete Structures. J. Korea Concr. Inst. 2011, 23, 47–52. [Google Scholar]

- Chen, X.; Zhu, Y.; Cai, D.; Xu, G.; Dong, T. Investigation on Interface Damage between Cement Concrete Base Plate and Asphalt Concrete Waterproofing Layer under Temperature Load in Ballastless Track. Appl. Sci. 2020, 10, 2654. [Google Scholar] [CrossRef]

- Hoła, J.; Sadowski, Ł.; Nowacki, A. Analysis of the causes of cracks in marble slabs in a large-surface floor of a representative commercial facility. Eng. Fail. Anal. 2019, 97, 1–9. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 3rd ed.; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

- Ismail, M.; Ohtsu, M. Corrosion rate of ordinary and high-performance concrete subjected to chloride attack by AC impedance spectroscopy. Constr. Build. Mater. 2006, 20, 458–469. [Google Scholar] [CrossRef]

- Glass, G.K.; Buenfeld, N.R. The influence of chloride binding on the chloride induced corrosion risk in reinforced concrete. Corros. Sci. 2000, 42, 329–344. [Google Scholar] [CrossRef]

- Jensen, O.M.; Hansen, P.F.; Coats, A.M.; Glasser, F.P. Chloride ingress in cement paste and mortar. Cem. Concr. Res. 1999, 29, 1497–1504. [Google Scholar] [CrossRef]

- Sakai, Y. Relationship between pore structure and chloride diffusion in cementitious materials. Constr. Build. Mater. 2019, 229, 116868. [Google Scholar] [CrossRef]

- Alberti, M.G.; Enfedaque, A.; Gálvez, J.C. On the mechanical properties and fracture behavior of polyefin fiber-reinforced self-compacting concrete. Constr. Build. Mater. 2014, 55, 274–288. [Google Scholar] [CrossRef]

- Lee, J.; Lee, T. Influences of Chemical Composition and Fineness on the Development of Concrete Strength by Curing Conditions. Materials 2019, 12, 4061. [Google Scholar] [CrossRef] [PubMed]

- Kumar, M.P.; Mini, K.M.; Rangarajan, M. Ultrafine GGBS and calcium nitrate as concrete admixtures for improved mechanical properties and corrosion resistance. Constr. Build. Mater. 2018, 182, 249–257. [Google Scholar] [CrossRef]

- Luo, R.; Cai, Y.; Wang, C.; Huang, X. Study of chloride binding and diffusion in GGBS concrete. Cem. Concr. Res. 2003, 33, 1–7. [Google Scholar] [CrossRef]

- Mohan, A.; Mini, K.M. Strength and durability studies of SCC incorporating silica fume and ultra fine GGBS. Constr. Build. Mater. 2018, 171, 919–928. [Google Scholar] [CrossRef]

- Özbay, E.; Erdemir, M.; Durmuş, H.I. Utilization and efficiency of ground granulated blast furnace slag on concrete properties—A review. Constr. Build. Mater. 2016, 105, 423–434. [Google Scholar] [CrossRef]

- Chunxiang, Q.; Patnaikuni, I. Properties of high-strength steel fiber-reinforced concrete beams in bending. Cem. Concr. Compos. 1999, 21, 73–81. [Google Scholar] [CrossRef]

- Zollo, R.F. Fiber-refinforced concrete: An overview after 30 years of development. Cem. Concr. Compos. 1997, 19, 107–122. [Google Scholar] [CrossRef]

- Sovják, R.; Máca, P.; Imlauf, T. Effect of fibere length on the fracture energy of UHPFRC. Procedia Eng. 2017, 193, 74–79. [Google Scholar] [CrossRef]

- Tang, K.; Wilkinson, S. Corrosion resistance of electrified railway tunnels made of steel fibre reinforced concrete. Constr. Build. Mater. 2020, 230, 117006. [Google Scholar] [CrossRef]

- Rashid, M.U. Experimental investigation on durability characteristics of steel and polypropylene fiber reinforced concrete exposed to natural weathering action. Constr. Build. Mater. 2020, 250, 118910. [Google Scholar] [CrossRef]

- Ede, A.N.; Ige, A. Optimal polypropylene fibre content for improved compressive and flexural strength of concrete. IOSR J. Mech. Civ. Eng. (IOSR-JMCE) 2014, 11, 129–135. [Google Scholar]

- Nehme, S.G.; László, R.; Mir, A.E. Mechanical Performance of Steel Fiber Reinforced Self-compacting Concrete in Panels. Procedia Eng. 2017, 196, 90–96. [Google Scholar] [CrossRef]

- Hannant, P.J. Fibre Cements and Fibre Concretes; John Wiley: New York, NY, USA, 1978. [Google Scholar]

- Banthia, N.; Zanotti, C.; Sappakittipakorn, M. Sustainable fiber reinforced concrete for repair applications. Constr. Build. Mater. 2014, 67, 405–412. [Google Scholar] [CrossRef]

- Han, Y.-J.; Oh, S.-K.; Kim, B. Effect of Load Transfer Section to Toughness for Steel Fiber-Reinforced Concrete. Appl. Sci. 2017, 7, 549. [Google Scholar] [CrossRef]

- Kim, B.-I.; Han, Y.-J. Flexural Performance of Transparent Plastic Bar Reinforced Concrete. Appl. Sci. 2018, 8, 325. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, C. Investigation on the relationship between the steel fibre distribution and the post-cracking behavior of SFRC. Constr. Build. Mater. 2019, 200, 539–550. [Google Scholar] [CrossRef]

- KS F 2402-07. Slump Test Method of Concrete; Korea Industrial Standards: Seoul, Korea, 2007. [Google Scholar]

- KS F 2461-06. Air Volume Test Method of Fresh Concrete by Pressure Method; Korea Industrial Standards: Seoul, Korea, 2006. [Google Scholar]

- KS F 2403-14. Method of Fabricating Test Pieces for Concrete Strength Test; Korea Industrial Standards: Seoul, Korea, 2014. [Google Scholar]

- KS F 2405-10. Test Method of Concrete Compressive Strength; Korea Industrial Standards: Seoul, Korea, 2010. [Google Scholar]

- RILEM TC 162-TDF. Test and design methods for steel fiber reinforced concrete: Bending test. Mater. Struct. 2002, 35, 262–278. [Google Scholar] [CrossRef]

- The Concrete Society. Concrete Industrial Ground Floors: A Guide to Their Design and Construction; TR 34 Third Edition; The Concrete Society: Camberley, UK, 2003. [Google Scholar]

- JSCE-SF4. Methods of Tests for Flexural Toughness of Steel Fiber Reinforced Concrete; Japanese Society of Civil Engineers: Tokyo, Japan, 1985. [Google Scholar]

- Beaudoin, J.J. Handbook of Fiber-Reinforced Concrete: Principles, Properties, Developments and Applications; Noyes: Park Ridge, NJ, USA, 1990; pp. 1–41. [Google Scholar]

- Ding, C.; Guo, L.; Chen, B. Orientation distribution of polyvinyl alcohol fibers and its influence on bridging capacity and mechanical performances for high ductility cementitious composites. Constr. Build. Mater. 2020, 247, 118491. [Google Scholar] [CrossRef]

- Lu, C.; Li, V.C.; Leung, C.K.Y. Flaw characterization and correlation with cracking strength in Engineered Cementitious Composites (ECC). Cem. Concr. Res. 2018, 107, 64–74. [Google Scholar] [CrossRef]

- Lu, C.; Yu, J.; Leung, C.K. Tensile performance and impact resistance of strain hardening cementitious composites (SHCC) with recycled fibers. Constr. Build. Mater. 2018, 171, 566–576. [Google Scholar] [CrossRef]

- Wecharatana, M.; Shah, S.P. Experimental Methods to Determine Fracture Parameters for Concrete; Technological Institute. Northwestern University: Evanston, IL, USA, 1982; p. 18. [Google Scholar]

| Fiber Type | Material Property | Reference | |

|---|---|---|---|

| Hookend Steel Fiber (SF) |

|

| corrosion concerns |

| Micro PP Fiber (MF) |

|

| high acid, alkali and salt resistance |

| Type | Material Property | |

|---|---|---|

PE Film |

|

|

| ||

Typar SF 65 |

|

|

Bituthene 3000 |

| |

|

| |

| ||

Preprufe |

|

|

| ||

| Combination of Materials | PE FILM (PE) | Typar SF 65 (Typar) | Bituthene 3000 (Bituthene) | Preprufe |

|---|---|---|---|---|

| Ordinary Plain Concrete (OPC) | OPC-PE | OPC-Typar | OPC-Bituthene | OPC-Preprufe |

| Steel Fiber 20 kg/m3 (SF 20) | SF20-PE | SF20-Typar | SF20-Bituthene | SF20-Bituthene |

| Micro Fiber 1.0 kg/m3 (MF 1.0) | MF1.0-PE | MF1.0-Typar | MF1.0-Bituthene | MF1.0-Bituthene |

| Micro Fiber 2.8 kg/m3 (MF 2.8) | MF2.8-PE | MF2.8-Typar | MF2.8-Bituthene | MF2.8-Bituthene |

| Type | W/C (%) | S/a (%) | Water (kg/m3) | Cement (kg/m3) | FA (kg/m3) | CA (kg/m3) | SP (C × %) | Fiber (%) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| OPC | 42.5 | 47.5 | 165 | 388 | 845 | 973 | 2.72 | - | |

| SF 20 | 42.5 | 47.5 | 165 | 388 | 845 | 973 | 2.72 | 0.84 | Steel Fiber |

| MF 1.0 | 42.5 | 47.5 | 165 | 388 | 845 | 973 | 2.72 | 0.04 | Micro Fiber |

| MF 2.8 | 42.5 | 47.5 | 165 | 388 | 845 | 973 | 2.72 | 0.12 | Micro Fiber |

| Type | OPC | Steel Fiber 20 kg/m3 | Micro Fiber 1.0 kg/m3 | Micro Fiber 2.8 kg/m3 | |

|---|---|---|---|---|---|

| Compressive strength (MPa) | 1 | 46.16 | 47.29 | 41.24 | 41.74 |

| 2 | 45.09 | 45.15 | 42.31 | 42.38 | |

| 3 | 43.70 | 43.83 | 39.98 | 42.31 | |

| Ave. | 44.98 | 45.42 | 41.18 | 42.14 | |

| Type | Toughness (kN-mm) | f’c (MPa) | fr (MPa) | Re3 (%) | ||||

|---|---|---|---|---|---|---|---|---|

| 0–Peak | 0–0.5 mm | 0–2.0 mm | 0–3.0 mm | |||||

| OPC | N/A | - | - | - | - | 44.67 | 3.35 | - |

| PE | 0.364 | 2.445 | 3.374 | 3.880 | 44.98 | 3.71 | 5.67 | |

| Typar | 0.564 | 2.721 | 6.515 | 9.027 | 44.98 | 3.84 | 20.43 | |

| Bituthene | 0.248 | 2.536 | 3.534 | 4.182 | 3.67 | 6.15 | ||

| Preprufe | 0.405 | 2.778 | 6.135 | 9.104 | 3.96 | 19.86 | ||

| SF20 | PE | 0.304 | 3.897 | 11.756 | 15.392 | 45.44 | 4.01 | 37.96 |

| Typar | 0.613 | 4.649 | 15.713 | 21.361 | 4.69 | 44.86 | ||

| Bituthene | 0.309 | 3.522 | 10.638 | 14.297 | 3.93 | 35.07 | ||

| Preprufe | 0.457 | 3.316 | 10.338 | 15.249 | 3.97 | 36.86 | ||

| MF1.0 | PE | 0.986 | 2.852 | 5.776 | 7.464 | 41.18 | 4.41 | 12.87 |

| Typar | 1.463 | 3.462 | 10.151 | 14.450 | 4.64 | 28.47 | ||

| Bituthene | 0.277 | 2.755 | 6.541 | 9.007 | 4.27 | 17.75 | ||

| Preprufe | 0.368 | 2.638 | 7.255 | 11.263 | 4.10 | 25.19 | ||

| MF2.8 | PE | 1.318 | 4.157 | 12.408 | 16.193 | 42.14 | 4.97 | 20.44 |

| Typar | 0.394 | 4.128 | 14.991 | 21.309 | 4.61 | 45.19 | ||

| Bituthene | 0.770 | 3.762 | 12.382 | 17.305 | 4.76 | 35.41 | ||

| Preprufe | 0.818 | 3.937 | 14.543 | 21.519 | 4.38 | 48.26 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-I.; Gong, M.-H.; Song, J.-Y.; Oh, S.-K.; Kim, B. A Study of Waterproof Reinforcement Layers for the Post-Cracking Behavior of Fiber Reinforced Concrete. Appl. Sci. 2020, 10, 5762. https://doi.org/10.3390/app10175762

Kim J-I, Gong M-H, Song J-Y, Oh S-K, Kim B. A Study of Waterproof Reinforcement Layers for the Post-Cracking Behavior of Fiber Reinforced Concrete. Applied Sciences. 2020; 10(17):5762. https://doi.org/10.3390/app10175762

Chicago/Turabian StyleKim, Jung-Il, Min-Ho Gong, Je-Young Song, Sang-Keun Oh, and Byoungil Kim. 2020. "A Study of Waterproof Reinforcement Layers for the Post-Cracking Behavior of Fiber Reinforced Concrete" Applied Sciences 10, no. 17: 5762. https://doi.org/10.3390/app10175762

APA StyleKim, J.-I., Gong, M.-H., Song, J.-Y., Oh, S.-K., & Kim, B. (2020). A Study of Waterproof Reinforcement Layers for the Post-Cracking Behavior of Fiber Reinforced Concrete. Applied Sciences, 10(17), 5762. https://doi.org/10.3390/app10175762