Abstract

A novel design of a vibration energy absorbing mechanism (VEAM) that is based on multi-physics (magnetic spring, hydraulic system, structural dynamics, etc.) for cable vibration is proposed. The minimum working force of the hydraulic cylinder has been exploited in this design in order to combine a non-linear stiffness vibration isolation module that is composed of permanent magnetic springs with hydraulic viscous vibration damping modules. In response to different environmental vibration impacts, VEAM can automatically switch the vibration control modes without an electronic mechanism. Additionally, the non-contact design effectively reduces the wear that is induced by the reciprocating motion of the small amplitude of the hydraulic viscous dampers. The proposed mechanism is explained and a theoretical model is established. The transmissibility of the two modules at a single degree of freedom is derived using the harmonic balance method. After that, a series of variable control numerical simulations were performed for each important parameter. Empirical rules for designing the system were created by comparing the influence of each parameter on the vibration isolation performance of the entire system.

1. Introduction

Cables are widely used in construction, cable cars, traction, and other fields due to their extremely high tensile strength, long-distance capabilities, and low cost. This article will conduct research that is based on the cable-stayed bridge, which is the most representative and technically demanding application of cables, and illustrate a novel vibration energy absorbing mechanism that effectively responds to common vibration that is caused by environmental impacts with the automatic switching modes of the non-stiffness vibration isolators with the hydraulic viscous dampers.

In recent years, the cable-stayed bridge design has gained popularity as the design of choice for the construction of long-span bridges. This can be attributed to its simple and beautiful design, and its ability to span longer distances at relatively low construction costs [1]. From 2016 to 2019, a total of 20 cable stayed bridges with spans over 500 m were built around the world. Currently, the longest span cable-stayed bridge in the world is the Russky Bridge built over the Eastern Bosphorous in Russia, which has a span of 1104 m. Although the span of this bridge is quite short when compared to suspension bridges, the trend in construction seems to be moving towards an increasing number and spans of cable-stayed bridges. The cable-stayed bridge is mainly composed of bridge pylons, cables, and decks. The cables connect the decks to the pylons directly, so that the pylons carry the entire load. Like all structures, cable-stayed bridges are also subjected to vibration resulting from such exogenous factors, such as wind, rain, temperature change, and the movement of pedestrians and vehicles. These vibrations are transmitted to pylons and decks by the cables [2]. If the excitation frequency is close to a natural frequency of the bridge system, resonance will occur. Resonance is regarded as one of the main causes of bridge damage leading to fatigue and shortened life [3,4,5,6,7]. Therefore, a great amount of effort has been undertaken to develop methods for avoiding/mitigating the effects of vibration on cable-stayed bridge structures. Increasing the damping between the cable and the bridge deck is one of the key methods used to improve the robustness of cable-stayed bridges by preventing the occurrence of resonance.

Various types of vibration control systems are used in a wide variety of fields, such as automotive, aerospace, and structural engineering. According to their working mechanisms, vibration control systems for cable-stayed bridges can be divided into: (1) high-damping rubber (HDR) dampers, (2) viscous dampers, (3) magneto-rheological (MR) dampers, and (4) friction dampers.

Rubber dampers are the oldest type of damping systems used in cable-stayed bridges. These dampers dissipate vibration energy via hysteretic losses. Nakamura et al. [8] proposed an external high-damping rubber (HDR) damper for cable-stayed bridges and experimentally evaluated its performance against dynamic vibration. Cu et al. [9,10] formulated a complex eigen value problem in order to address the different damping effects of a single HDR damper and two attached HDR dampers under different installation conditions and material loss factors. Their work provides a strong theoretical basis for the design of HDR dampers. The damping performance of the HDR damper is highly dependent on the damping characteristics of its material, e.g., rubber. However, rubber materials have a limited energy consumption performance and they are easily affected by environmental factors, such as temperature.

The viscous damper category is mainly comprised of hydraulic cylinder type dampers that dissipate the vibration energy through the friction between the hydraulic fluid and their orifice(s). The maximum damping ratio of a viscous damper has a relationship with the relative distance between the support and the damper. This was proposed by Pacheco et al. [11], who also derived an optimal damping constant for viscous dampers with low modes of vibration. A later study by Krenk [12] optimized the modal damping values of the lowest five modes of vibration. Sawka [13] experimentally studied the total pressures of viscous dampers as a function of time after excitation by a mass impact. This work showed that viscous dampers show better damping performance against large dynamic vibrations, but they are not sensitive enough to small amplitude vibrations. Tomski and Kukla et al. [14] confirmed these results through numerical simulations. Viscous dampers are susceptible to reduction in load capacity due to load misalignment. In order to explore this further, Gamez-Montero et al. [15] performed a buckling analysis on hydraulic cylinders, while Niu et al. [16] proposed an oil damper with variable stiffness (ODVS). In their designs, the orifice size of the variable overflow valve can be changed to achieve a variable damping ratio according to different hydraulic loads. Viscous dampers are also susceptible to leakage due to thermal deformation and aging of the seal ring due to frequent reciprocating movements that are mostly associated with low amplitude vibrations. To overcome the problem of leakage, Zhan et al. [17] proposed the design of a third-generation hydraulic cylinder with a special lip shape at the piston periphery that varies the clearance between the piston and the cylinder according to the change in hydraulic pressure. A common method for evaluating the isolation performance of dampers is to calculate their transmissibility. Tao et al. [18] established a mathematical model for calculating the damped power transmissibility of a vibration isolation system. Guo et al. [19] analyzed a single degree of freedom (SDOF) displacement vibration isolation system (DVIS) and a forced vibration isolation system (FVIS) with a nonlinear viscous damper; simulations of system transmissibility were obtained. It has been noted that the non-linear viscous damper can significantly improve the damping performance across a wide range of frequencies. However, the problem of wear has not yet been solved due to frequent reciprocating movements.

Magneto-rheological (MR) fluid is a force transmission fluid that can be precisely controlled while using a magnetic field. Therefore, it is widely used in controllable damping systems. Wu et al. [20] proposed a tuned mass damper magneto-rheological (TMD-MR) design, which showed good damping performance in all modes during experimental verification. Macháček et al. [21] incorporated an elastic metal bellows in the spring-MR damper, which significantly improved the vibration absorption over the entire frequency range. MR dampers require the employment of an active feedback control system in order to operate properly. The controller senses the input vibration parameters and accordingly modulates the electrical signal that influences the MR fluid characteristics. This requires the use of complex electronic equipment and a constant supply of electrical power. These requirements increase the system complexity and costs related to installation, operation, and maintenance. They may also increase the chances of system failure due to a variety of causes including electrical failure.

Friction dampers use friction to dissipate vibration energy. Using a mathematical model, Nguyen et al. [22] analyzed the damping performance of two friction dampers on a stay cable and proposed the best design and installation method for friction dampers. However, friction dampers have some limitations, such as their inability to dampen low amplitude vibrations and the use of consumable friction materials that need to be replaced regularly, which serves to increase the system’s operating and maintenance costs.

With the development of industrial technology, the requirements for high vibration isolation performance are also increasing [23,24,25]. It is apparent from the preceding discussion that there is a need for the development of a vibration damping system. Moreover, a vibration damping system is needed that can handle both high and low amplitude vibrations without requiring complex hardware, continuous power supply, and frequent maintenance. One approach that offers promise is non-linear damping technology that has attracted a great amount of attention from researchers in recent years [26,27,28]. The existing literature shows that the natural frequency of an isolation system can be decreased by introducing a non-linear stiffness [29,30,31]. This means that the introduction of non-linear stiffness is an effective method for broadening the isolation bandwidth of a damping system. Carrella et al. [32] proposed a quasi-zero-stiffness (QZS) vibration isolation system with non-linear stiffness consisting of a positive stiffness spring and two negative stiffness springs. The high-static-low-dynamic-stiffness (HSLDS) vibration isolation characteristic of their system was confirmed by calculating its transmissibility. Numerous innovative QZS designs have been proposed and applied in various fields due to the desirable performance of QZS vibration isolation [33,34,35,36]. Permanent magnets (PM), when placed in an opposing repulsive manner, can generate a non-linear stiffness. This characteristic of PMs has resulted in their wide usage in the design of QZS vibration isolators in recent years. A large number of studies have shown that vibration isolators that are composed of PMs have better vibration isolation performance than linear vibration isolators [37,38,39]. Yan et al. [40,41] proposed the design of a vari-stiffness nonlinear isolator (VSNI) and a bi-state nonlinear vibration isolator (BS-NVI). In their designs, the nonlinear stiffness is controlled through the manipulation of the magnetic fields. This means that the isolation performance of the system is controlled by changing the distance and included angle between the PMs. Thus, the transmissibility models established were verified through experiments.

Matsumoto et al., through field observations and wind tunnel tests, conducted in-depth evaluation and analysis of the influence of rain and wind induced vibrations on a cable bridge [42,43,44,45,46]. Ma et al. [47] and Du et al. [48] used wind tunnel tests and digital imaging techniques to study the dynamic characteristics of cable-stayed bridges. These studies confirmed that the amplitude of rain, wind, and traffic induced vibrations at the installation position of the damping system is usually very small. Large amplitude vibrations only occur under special circumstances and are, thus, less frequent. Hence, cable-stayed bridges can greatly benefit from the design of a vibration damping system that does not require external power supply and can handle small amplitude vibrations with minimal wear while also being able to cater to larger amplitude vibrations.

Consequently, this paper proposes a hybrid damping system design that combines a PM based non-linear stiffness vibration isolator and a hydraulic viscous damper. In the proposed design, when the amplitude of vibration in the cable is less than a preset threshold value, the non-linear stiffness isolator damps the vibration transmitted to the deck and the viscous damper is not actuated. This will help to increase the overall system life, as it protects the viscous damper from thermal deformation and excessive wear of the seal ring due to its high frequency reciprocating motion that is associated with low amplitude vibrations. When the vibration amplitude becomes greater than the threshold value, the PMs travel until there is a minimum relative distance between them and then the viscous dampers are actuated to further dissipate the vibration energy. Thus, the presented system, which we have called a vibration energy absorbing mechanism (VEAM), is developed to meet three objectives: (1) reduce the wear due to inefficient working conditions of the viscous dampers used in the system. (2) Provide a non-contact link between the viscous damper and the cable so that shear damage to the damper due to multi-directional cable motion can be avoided. (3) Achieve damping of a wide range of vibration amplitudes without using complex electronic components, such as sensors and controllers. The detailed design of the VEAM and validation through simulations are presented in this paper.

2. Mechanism of the VEAM

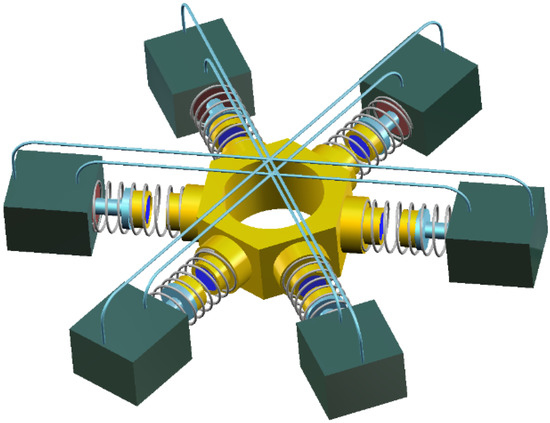

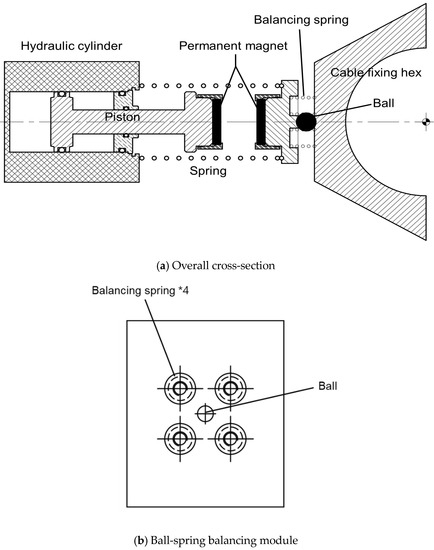

Figure 1 presents the 3D model of VEAM. The cable passing through the center is supported on six sides by the developed multi-physic dampers, which are in turn connected to the bridge deck. Traditional viscous damper systems usually adopt a three damper arrangement [16]. In contrast, the VEAM adopts an arrangement of three opposing pairs of dampers resulting in a six-directional cable support system. This has been done to better counter the randomness of stay cable vibration. Figure 2a shows the internal configuration of the VEAM. Because the system is symmetrically constructed using six identical modules, we will only use one of those modules to illustrate the design principles. The complete system is fitted to the cable via a central hex piece that is divided into two parts which are assembled using long through bolts. The six damper assemblies are attached to this hex piece, one on each side. The damper assemblies consist mainly of a ball-joint connected to the hex piece, a PM based non-linear stiffness isolator, a viscous damper, and a rotary mount to allow the rotation of the damper assembly about an axis perpendicular to the damper’s axis of travel. The vibration of the stay cable moves the magnets, which dampen it due to non-linear stiffness. The vibration force is transmitted to the viscous damper through repulsion between the PMs placed with like poles facing each other. If the force magnitude is greater than the minimum force required to actuate the viscous damper, then the damper starts moving and dissipates the vibration energy through viscous drag.

Figure 1.

Three-dimensional (3D) model of the vibration energy absorbing mechanism (VEAM).

Figure 2.

Internal configuration of 1/6 piece of VEAM.

The thrust force applied to the piston should be aligned with the cylinder axis and should have no radial component in order to keep the viscous damper moving smoothly with minimal amount of wear. In the proposed system, the source of this thrust force is the PM based isolator attached to the end of the hydraulic piston. Thus, the necessary conditions for the smooth operation of the hydraulic cylinder can only be guaranteed if the force applied to the PM assembly has no radial component. However, in reality, the direction of vibration is not always aligned with the center axis of the damper assembly. Therefore, a compliant attachment between the damper assembly and the cable is required to ensure that only axial forces are transmitted to the damper assembly. In the proposed design, a ball joint is added between the hex and the PM side of the damper assembly in order to allow for the cable fixing hex to change angles with respect to the damper assembly. This joint, as shown in Figure 2b, consists of a ball at the center with four retaining springs around it to prevent excessive movement and damage to the joint. At the other end of the damper assembly, the cylinder of the viscous damper is connected to the system frame using a ball bearing based rotary joint shown in Figure 2c that allows for rotation of the damper assembly around an axis perpendicular to the cylinder axis. The addition of these two joints ensures that the two PMs are always coaxial and only axial loads are applied to the viscous damper. Furthermore, to provide structural damping while keeping the PMs in parallel [49,50], the design also includes a spring connecting the hex side PM and the viscous damper cylinder.

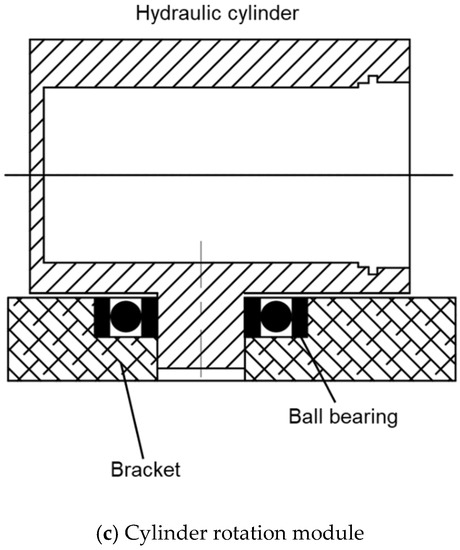

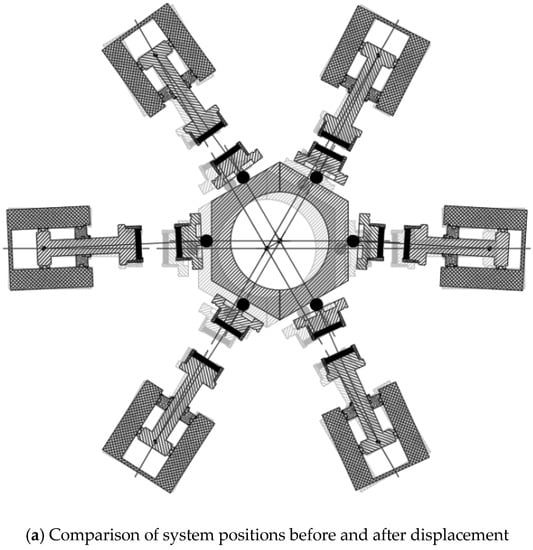

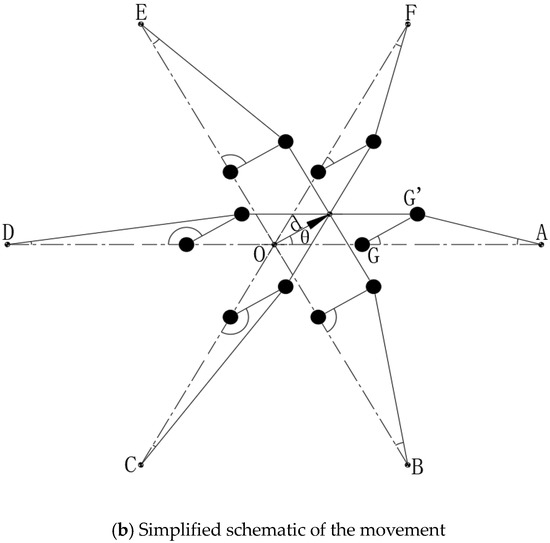

It can be seen from Figure 3a that when the hex moves due to cable movement, the six damper assemblies rotate to different angles to compensate for this displacement. However, the PMs and viscous damper always remain aligned with each other. The rotation angle of each damper assembly can be derived while using the geometric relationship between the key elements. Figure 3b shows the simplified schematic diagram of this scenario. In this figure, points A, B, C, D, E, and F represent the rotating centers of the bearings between the hydraulic cylinders and the system structure, while d and ∠θ represent the magnitude and angle (acute angle with respect to the horizontal) of displacement of the center point of the cable fixing hex. Circles with black solid hatching represent the joint balls. G is a ball in the initial (default) position and G’ is the final position of ball G after the displacement.

Figure 3.

Kinematic response of the VEAM to cable displacement.

It can be observed that the displacement GG′ is equal to d and the angle ∠ is equal to ∠θ. The distances from the cable fixing hex center to the ball and to the rotating center of the bearing at the initial position are known. Thus, the distance between the ball at position G and the bearing rotating center at the initial position is GA = OA − OG.

According to the law of cosines, G′A can be deduced as:

Here, we assume that the radial deformation of the spring is zero, which means that it can only perform telescopic movement along the axial direction. Through the law of sines, the rotation angle of the hydraulic cylinder can be expressed as:

From the geometric relationship, it can be seen that the rotation angle of the cable fixing hex side magnet around the ball center and the rotation angle of the hydraulic cylinder are alternate interior angles. Thus, combining Equations (1) and (2), the ∠A can be rewritten as:

The rotation angles of the other hydraulic cylinders can also be calculated with Equations (4)–(8):

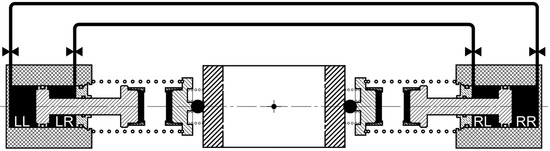

A conventional viscous damper forms a hydraulic circuit by connecting the two hydraulic chambers cut off by the piston by opening an orifice in the piston itself. In this case, mainly the friction between the hydraulic oil and the orifice provides the damping effect. However, because the orifice is inside the hydraulic cylinder, it is difficult to change the orifice size after assembly. In order to facilitate the adjustment of the damping ratio, this proposed design utilizes an external circuit design, as shown in Figure 4. The double triangle marks in the figure indicate the orifice regulating valves, while LL, LR, RL, and RR represent the hydraulic chambers divided by the pistons. When the cable fixing hex is in the default position, the left and right subsystems of the VEAM are in a balanced state and the pistons on both sides are positioned in the middle of their respective hydraulic cylinders with equal pressures on both sides of the pistons. The LL chamber is connected to the RR chamber and the LR chamber is connected to the RL chamber. The purpose of this inter-connection is to ensure the continuity of the damping process. Assuming that the repulsive force between the PMs is large enough, when the cable fixing hex moves leftwards the magnet pushes the left side piston, reducing the LL chamber volume and increasing its internal pressure. Therefore, the hydraulic oil in the LL chamber flows through the orifice and the piping to the RR chamber, which is at a relatively lower pressure. At the same time, the pressure in the LR chamber is reduced, which sucks in the hydraulic oil from the RL chamber. This creates a pressure difference between the RL and RR chambers that causes the right side piston to move out. This mechanism ensures that when the cable fixing hex moves, the pistons on both sides simultaneously move in the same direction. In this way, when the hex moves to the maximum amplitude in one direction and then moves in the opposite direction, the two PMs on the opposite side will be close enough to generate a repulsive force form the movement onset, thus preventing the occurrence of sudden cable movement or the jumping phenomenon. Because the damper assemblies are designed to move, the hydraulic lines used in the prototype have been coiled to reduce the stress at coupling points. Conventional viscous dampers usually use internal or external springs to restore the piston to its default position. Because of the design of the cable-stayed bridge, the cables are always in tension and so always tend to return to their default position. The VEAM design exploits this characteristic and uses the cable movement to automatically restore the hydraulic dampers to their default positions, thus doing away with the need for an additional spring.

Figure 4.

Schematic diagram of the hydraulic connection between opposing cylinders.

3. Theoretical Modeling of the VEAM

The VEAM is composed of six identical damper assemblies, where each pair of opposing damper assemblies is connected through a hydraulic circuit to form a sub-system. Thus, each sub-system is composed of two magnetic non-linear stiffness modules and two hydraulic viscous damping modules. The isolation and damping performance of the VEAM can be evaluated by calculating its transmissibility [51]. The harmonic balance method (HBM) is an efficient method for modeling periodic problems and it is widely used to derive transmissibility [41]. Therefore, in this paper, HBM is used to establish theoretical models for the non-linear stiffness and the viscous damping modules. In this section, a mathematical model for the mechanism of a subsystem of VEAM in a single degree of freedom is established.

3.1. Automatic Switching Between Non-Linear Stiffness and Viscous Damping Modules

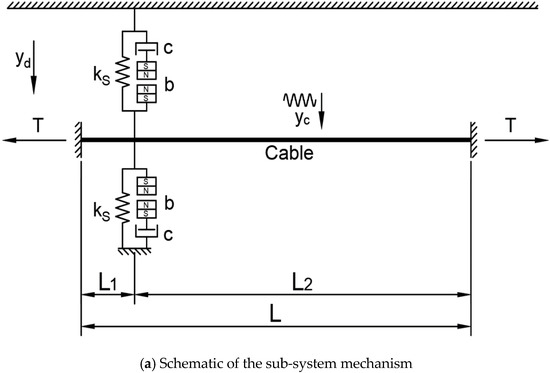

Figure 5a presents a simplified single degree of freedom theoretical model of a subsystem of the VEAM along the direction of its central axis. The thick line in the middle indicates the cable, with its two ends fixed between the deck and the pylon under a tensile force (T) acting at each end. The total length of the cable is L. The VEAM is fixed at a distance L1 from the deck. The cable fixing hex is connected to the cable and the damping system structure is fixed to the deck. In the figure, represents the excitation of the stay cable and represents the absolute displacement of the deck. As we are only considering the single degree of freedom case, the role of the ball joint and the rotary joint of the hydraulic cylinder is not considered. Hence, VEAM is simplified as a model in which the magnetic force that is generated by the PMs is connected in series with the hydraulic cylinder and then in parallel with the spring.

Figure 5.

Simplified theoretical model of the VEAM.

The minimum working pressure of the hydraulic cylinder is mainly caused by the friction of the piston seal, which is mostly dependent on the manufacturing and assembly accuracies, etc. In recent years, in order to improve the efficiency of hydraulic cylinders, researchers have tried to minimize this minimum working pressure through various methods, but static friction that is caused by seals is inevitable. With the development of industrial technology, it is not difficult to maintain the minimum working pressure at a fixed value by controlling the precision of machining and seal manufacturing. This minimum working pressure can be easily determined through experiments. The VEAM realizes automatic switching between the non-linear vibration isolator and the hydraulic viscous damper based on the minimum working pressure of the hydraulic cylinder.

For each subsystem, it can be observed from Figure 2 and Figure 4 that one PM is fixed on the piston rod and the other is connected to the vibration excitation side, such that like the poles of the two PMs are opposite to each other. When a large amplitude vibration occurs at the excitation side, the distance between the PMs becomes small and the repulsive force increases. This repulsive force is transmitted to the piston rod as a thrust force (). When this thrust force is less than the minimum working force () of the hydraulic cylinder only the non-linear vibration isolator works. Conversely, only the hydraulic viscous damper works when the thrust force is greater than the minimum working force of the hydraulic cylinder. Yamakawa et al. [52] proposed that the repulsive force between two PMs is inversely proportional to the nth power of the distance between them. The two magnets that are discussed in this article are identical and, therefore, satisfy the conditions for the application of this relationship. Thus, the repulsive force between the two PMs can be taken as,

where, a (Unit: Nm−n) is the equivalence coefficient of the repulsive force, denotes the characteristic index, l (Unit: m) represents the preset distance between the PMs, and y (Unit: m) denotes the relative displacement between the cable and ground. When only the magnetic non-linear stiffness module works, the inequality exists. Substituting Equation (9) into this inequality, we get the relationship between the preset distance of the two PMs and the excitation amplitude:

3.2. Nonlinear Stiffness Isolator Model

In the VEAM sub-system, there is a set of mutually exclusive PMs at each end of the cable fixing hex, these two sets of PMs form a magnetic spring. The force exerted on the cable fixing hex by the repulsion of the magnetic spring can be expressed as the following Duffing type cubic polynomial equation [40,41].

where, represents the resultant force provided by the magnetic spring and and represent the equivalent linear and non-linear stiffness coefficients, respectively.

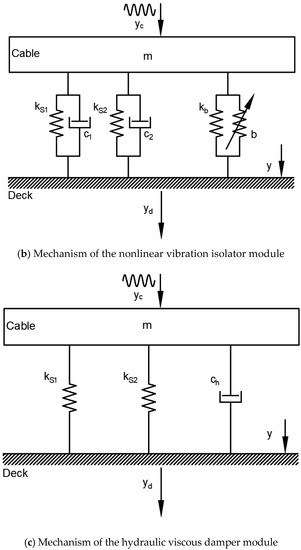

When , the hydraulic cylinder does not work, and the PM at the end of the hydraulic piston rod can be assumed as grounded. The theoretical model of the non-linear stiffness isolator module of the VEAM can be established as a system composed of; (1) the mass (), (2) the linear stiffness of the coil spring (, ), (3) the structural damping from the two coil springs on each side of the sub-system (which is simplified as Rayleigh damping in this study) (, ), and (4) the equivalent linear and non-linear stiffness due to the magnetic spring (), as shown in Figure 5b. The linear stiffness coefficient of the VEAM subsystem can be integrated as .

To simplify the calculations, the vibration excitation from the stay cable is calculated as the following sine function:

where, is the vibration amplitude, ϖ is the angular frequency, t is the time, and φ is the phase shift. Thus, the displacement of the VEAM subsystem (), which is the relative displacement between the stay cable and the deck, can be expressed as:

When the VEAM sub-system receives the vibration transmitted from the stay cable and enters a steady state, the equation of motion of the sub-system according to the HBM can be written as the following Duffing type equation [53,54]:

Because the same springs are used on both sides of the sub-system, we assume that their structural damping coefficients are equal, i.e., .

Substituting Equations (12) and (13) into Equation (14) and deriving the time, the following equation is obtained.

The cubic term in this equation can be broken down as: . The non-harmonic high frequency term that, in general, does not simply decay with time can be omitted and the constant terms with and can be integrated as:

and

The absolute displacement of the deck is the sum of the vibration excitation of the stay cable and the relative displacement between the stay cable and the deck:

Therefore, the displacement transmissibility of the VEAM sub-system can be sorted as:

Substituting Equation (16) into Equation (19), we get:

3.3. Hydraulic Viscous Damper Model

When is less than , the PM pushes the piston and the hydraulic viscous damper begins to work. The damping due to the hydraulic cylinder is much greater than that due to the structural damping of the coil springs. Therefore, the structural damping is neglected in the theoretical model. The VEAM sub-system can be simplified as an SDOF model, as shown in Figure 5c. The figure graphically shows that the damping of the hydraulic cylinder () is connected in parallel with the stiffness of the two coil springs (). Thus, the equation of motion of the VEAM sub-system can be expressed as:

The derivation process to get the displacement transmissibility is similar to that described in Section 3.2. Thus, the equation is obtained, as follows:

4. Numerical Simulation

VEAM is a multi-physics system composed of a non-linear permanent magnet vibration isolator module and a hydraulic viscous damping module. The vibration isolation or damping performance of the VEAM may be greatly influenced by the different design factors. It is necessary to explore the influence of each design factor on system performance in order to design the VEAM system, so that it meets the highest requirements for cable-stayed bridges. In this section, we use the control variates method to change each of the key parameter values to observe and discuss its impact on the overall system performance. Table 1 lists the default parameters used in the simulation. In each simulation, one of these values is changed, while the rest remain constant. The simulations were coded using Python 3.7 and processed on a workstation with a 3.6 GHz Intel Xeon processor and 16GB RAM. The non-linear equations were solved using the newton_krylov method in the scipyoptimize module [55]. Section 4.1 discusses the relationship between the required distance between PMs and the starting force of the hydraulic cylinder with respect to different magnetic factors. Section 4.2 shows the simulation and discussions addressing the characteristics of the non-linear stiffness magnetic isolation module when the parameters of the coil spring and magnet are varied. In Section 4.3, the characteristics of hydraulic viscous damper under different design parameters are reported.

Table 1.

Default parameters for simulation.

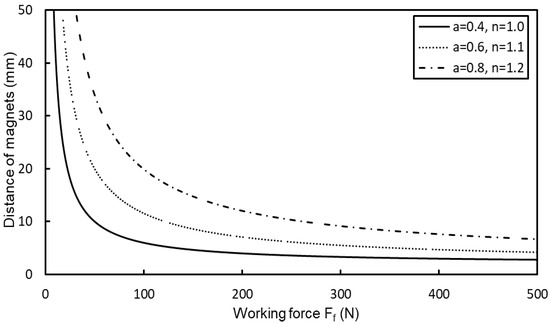

4.1. Preset Distance of Magnet

In Section 3.1, we mentioned that the automatic switching of the non-linear stiffness vibration isolator and hydraulic viscous damper is mainly determined by the distance between the magnets () and the minimum working force () of the hydraulic cylinder. However, different permanent magnets exhibit different magnetic repulsive force characteristics. We must understand the effect of the hydraulic cylinder working force on the distance between PMs under different PM parameters in order to design a VEAM that can switch modes when the input vibration amplitude is above the specified value. In order to evaluate this, we set the mode switching amplitude as 0.002 m in this simulation.

Figure 6 presents the relationship between the designed distance between the PMs and the minimum working force of the hydraulic cylinder according to Equation (10). We performed simulations that are based on three kinds of PMs with different magnetic repulsive force characteristics. The solid line represents the curve obtained using the PMs with a = 0.4 and n = 1.0, where a and n are consistent with Equation (9). The dotted line and the dash-dot-dash line represent the curves for when a = 0.6, n = 1.1, and a = 0.8, n = 1.2, respectively. Because the magnet calculation formula involves the power function calculation that may get an infinite value, the ordinate is only taken to an effective distance of 0.05 m.

Figure 6.

Graph showing the relationship between the preset distance between Permanent magnets (PMs) and the working force of the hydraulic cylinder.

It can be observed that the three curves show an exponential downward trend as the minimum working force required by the hydraulic cylinder increases, which also reflects the characteristics of the magnet repulsive force. We can also observe that, for the curve with a larger magnetic repulsion factor, the allowable distance between PMs is also greater. Assuming that the minimum working force of the hydraulic cylinder is 200 N, the curve obtained using the magnet repulsive force factor of a = 0.4 and n = 1.0 shows a distance of 0.004 m, which is very close to the preset amplitude value. The reciprocating motion that is caused by vibration is likely to cause the PMs to collide with each other, which may cause damage to the magnet or other components of the VEAM. During the design stage, the allowable distance between PMs should be greater than the preset amplitude to ensure the safety of the system. At the same minimum working force, the allowable distance on the dash-dot-dash curve with a strong magnetic repulsive force is 0.012 m, which is two times higher than the solid curve. Even so, when considering the limitations of geometry and safety factor in actual application, the allowable distance between PMs provided by the simple structural Neodymium magnets (Nd2Fe14B) cannot fully guarantee the safety of the system. However, this work only provides a basis for the design optimization of the VEAM. Based on these methods, we can devise a safer system using stronger magnets in the future by possibly utilizing some sort of motion limiting mechanism or collision prevention buffers between the magnets.

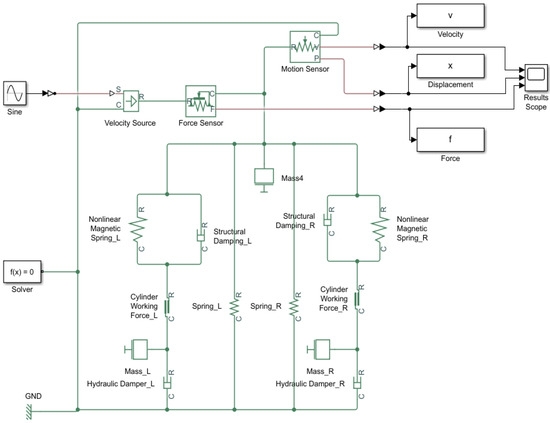

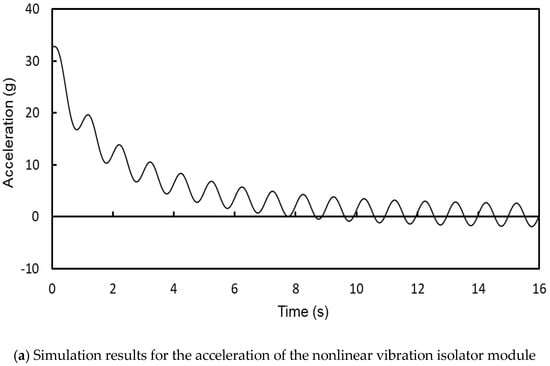

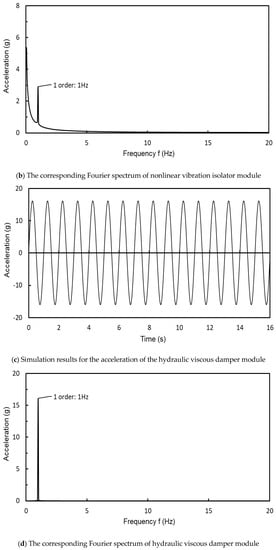

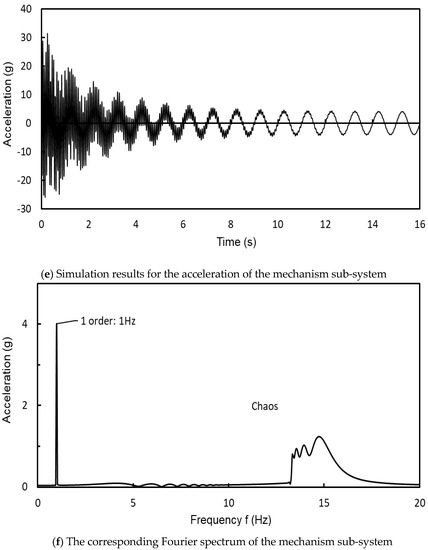

A Simulink model is established using the Simscape module available in Matlab 2019, which is a special numerical simulation software for solving multi-physical problems, in order to verify the automatic switching function between the nonlinear vibration isolator and the hydraulic viscous damper modules. Figure 7 shows the Simulink model of the entire VEAM subsystem. Table 1 shows the default parameter values used in this simulation. The nonlinear stiffness isolator module, hydraulic viscous damper module, and the entire VEAM subsystem are simulated separately in order to discuss whether the developed model is valid. In the simulation of the nonlinear stiffness isolator module, the input amplitude and frequency are set at 0.001 m and 1 Hz. In the simulations of hydraulic viscous damper module and the entire VEAM subsystem, the input amplitude and frequency are set at 0.005 m and 1 Hz, respectively. In order to reduce the calculation time, the symmetrically connected hydraulic cylinders are simplified as general viscous damping and the simulation is performed using ode23t solver. No errors or warnings were reported during the entire simulation processes, which shows that each mechanism can operate normally, and that the nonlinear vibration isolator and hydraulic viscous damper can be switched without any problems. Figure 8 shows the simulation results for the acceleration and the corresponding Fourier spectrum of each mechanism. As shown in Figure 8a, due to the nonlinear preloading force, the acceleration is relatively large at the beginning, and it tends to gradually reduce to a steady state. It can be seen from the corresponding Fourier spectrum (Figure 8b) that the acceleration presents a non-linear decreasing curve over the entire bandwidth. When the nonlinear stiffness isolation module is removed and only the hydraulic damping module is operating, the output becomes a familiar damped simple harmonic motion form, this simulation result is shown in Figure 8c,d. It can be seen from Figure 8e that the high-frequency harmonics appear at the beginning of the bandwidth and their period cannot be clearly distinguished when the entire VEAM is in a state where the nonlinear stiffness isolation module and the hydraulic damping module operate together. This may be attributed to the nonlinear dynamics of the magnetic force that is generated by the permanent magnets. Figure 8f plots the corresponding Fourier spectrum implies the visible chaotic phenomenon in the continuous band.

Figure 7.

Simscape model of the VEAM.

Figure 8.

Simulation results for the acceleration and the corresponding Fourier spectrum of the VEAM.

4.2. Non-Linear Stiffness Isolator

When the magnetic repulsive force is less than the minimum working force of the hydraulic cylinder, only the non-linear stiffness vibration isolator composed of the magnetic springs works. In this section, we will individually alter the key parameters of the coil springs and PMs used in the non-linear vibration isolator in order to observe the influence of the parameters , , , and ζ on the vibration isolation performance of the system and summarize the design experience.

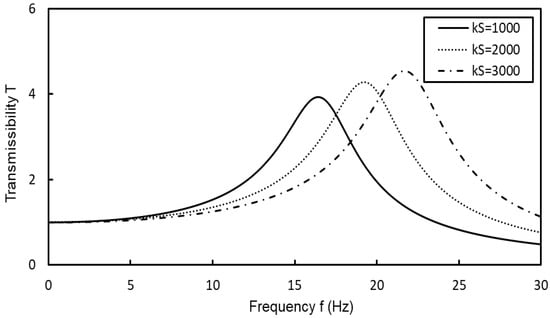

In the first case, the linear stiffness of the coil springs is set as 1000 Nm−1, 2000 Nm−1, and 3000 Nm−1, while the other parameters are kept at the default values that are shown in Table 1, and the displacement transmissibility of the non-linear stiffness isolator module is observed. The simulation results are shown in Figure 9. It can be observed that the simulated transmissibility curve moves to the high frequency region with the increase in linear stiffness of the spring. This is accompanied by an increase in the peak value of transmissibility. When the stiffness is 1000 Nm−1, the maximum displacement transmissibility of 3.9 occurs at a frequency of 16.5 Hz. When the stiffness is 3000 Nm−1, the maximum displacement transmissibility of 4.5 occurs at a frequency of 21.7 Hz. This shows that increasing the linear stiffness of the spring in the VEAM can effectively reduce the displacement transmissibility in the low frequency region. This means that the vibration isolation performance of the VEAM at a tuning frequency can be optimized using springs with higher stiffness values.

Figure 9.

Transmissibility of the non-linear stiffness isolator module of VEAM with varying values of .

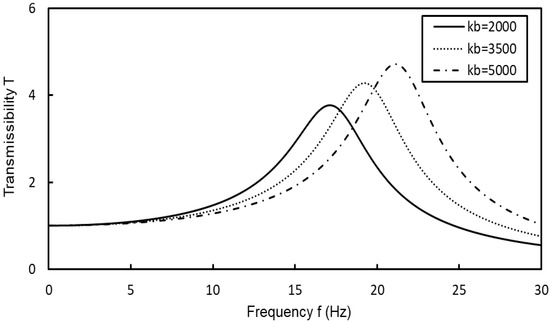

The results of the second case are presented in Figure 10, which shows the effect of different equivalent linear stiffness obtained using different magnetic springs on the displacement transmissibility of the VEAM. The solid, dotted, and dash-dot-dash curves represent the magnetic spring equivalent linear stiffness values of 2000 Nm−1, 3500 Nm−1, and 5000 Nm−1, respectively. It can be seen that the shifting of the transmissibility curve is similar to that observed while varying the linear stiffness of the spring; i.e., as the equivalent linear stiffness increases the curve shifts to the high frequency region. At frequencies below 18.5 Hz, the VEAM sub-system with a value of 5000 Nm−1 has a lower transmissibility than that of the sub-system with a value of 2000 Nm−1. At 18.5 Hz, the transmissibility in both cases is equal with a value of 3.2. Beyond this frequency, the transmissibility with a value of 5000 Nm−1 becomes higher than that with a value of 2000 Nm−1. Therefore, according to these results the VEAM sub-system with larger value will have better vibration isolation performance in the low frequency range, but it will not work satisfactorily in the high frequency range.

Figure 10.

Transmissibility of the non-linear stiffness isolator module of VEAM with varying values of .

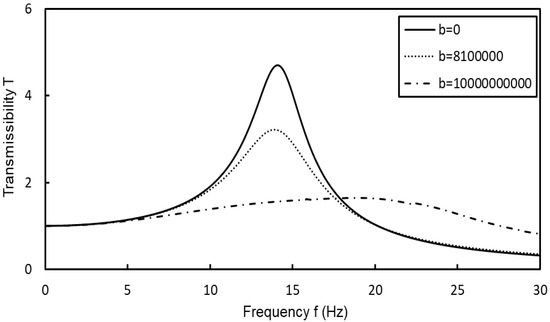

b is the only non-linear stiffness parameter in the VEAM system, so it is necessary to consider its influence on the vibration isolation performance of the whole sub-system. The solid, dotted, and dash-dot-dash curves in Figure 11 indicate the simulated transmissibility of the VEAM sub-system with respect to b values of 0 (no non-linear stiffness component in the system), default value (8.1 × 106), and 10 × 109 (an ideal value chosen in order to clearly see the effect of increasing the value), respectively. It can be observed that, as the value of b increases, the peak value of the transmissibility decreases and shifts towards the high-frequency region. However, the curve appears to bend to the right and, as the value of b gets larger, the amount of bending also becomes greater (as shown in the dash-do-dash curve). A similar sort of transmissibility curve bending towards the high frequency region has also been reported in other works [40,41]. We speculate that the excessive curve bending caused by the large b value will cause multiple transmissibility values to exist in a part of the frequency range, which means that there will be a multiple states phenomenon. This may cause the dynamics of the system to become complicated with the change in amplitude and frequency of excitation and chaotic motion may occur, as shown in Figure 8b.

Figure 11.

Transmissibility of the non-linear stiffness isolator module of VEAM with varying values of .

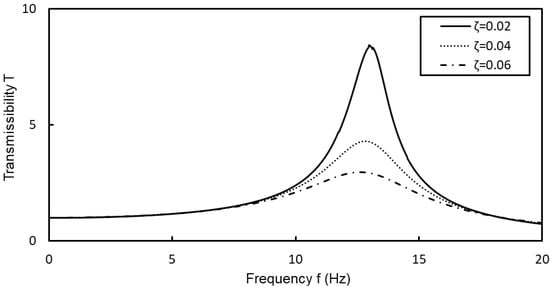

In the non-linear stiffness isolator module consisting of a magnetic spring, there is no additional damping, except for the structural damping of the springs. We simulated the transmissibility of the VEAM sub-system with spring structural damping ratios of 0.02, 0.04, and 0.06. Figure 12 shows the results of these simulations. It can be observed that, the larger the structural damping ratio, the smaller the transmissibility of the VEAM sub-system. It is also apparent that the structural damping has almost no effect on the change of the frequency domain of the peak transmissibility value. When the frequency is 13.0 Hz, the maximum transmissibility of the sub-system with a spring structural damping ratio of 0.06 is 65.2% lower than that with a structural damping ratio of 0.02. This result shows that structural damping has a considerable effect on the overall vibration damping characteristic of the system.

Figure 12.

Transmissibility of the non-linear stiffness isolator module of VEAM with varying values of ζ.

4.3. Hydraulic Damper

Under normal conditions, the stay cable vibration has a small amplitude. However, under special environmental impacts, such as earthquakes and typhoons, the amplitude of the stay cable vibration can become large. The VEAM incorporates hydraulic viscous dampers in its design to dampen such large amplitude vibrations by exploiting their high damping performance. This section explores the effects of damping and spring stiffness on the performance of this damper module. In this section, the excitation amplitude is set as 0.005 m.

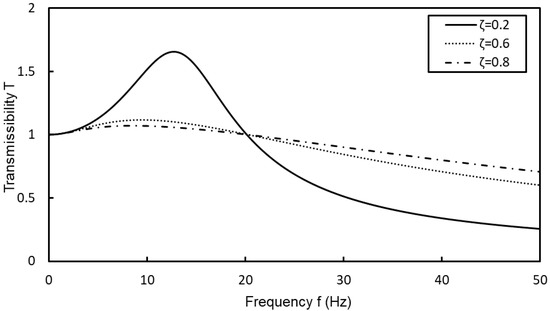

In practical applications, the damping ratio of the hydraulic damper used in VEAM can be adjusted by changing the size of the orifice in the flow path. To make performance comparisons, we set the damping ratios of the hydraulic cylinders at 0.2, 0.6, and 0.8. Figure 13 shows the simulated transmissibility results of the VEAM sub-system. It can be seen that the higher the damping ratio of the hydraulic cylinder the lower the peak value of the transmissibility. However, although the curve with the lowest damping ratio of 0.2 has a higher transmissibility in the low-frequency region (region of amplification) within a characteristic frequency, the frequency region after this frequency, which is called the “isolation region”, shows better vibration isolation performance.

Figure 13.

Transmissibility of the hydraulic viscous damper module of VEAM with varying values of .

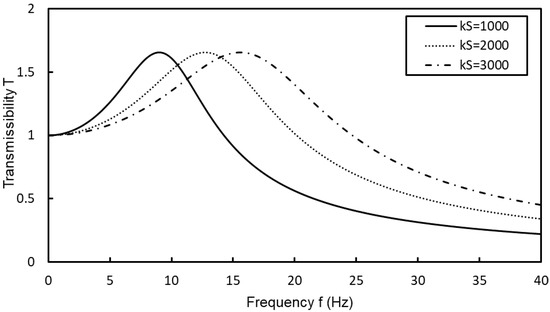

Figure 14 shows a comparison of the simulated transmissibility with varying values of . Similar to Figure 9, the frequency domain of the peak wave of transmissibility curve becomes wider as the value of increases, and the maximum transmissibility occurs at a higher frequency. However, the difference between the two figures is that the peak value of the transmissibility is not affected by the change in the value of . This is because, when the hydraulic shock absorber is in operation, the magnetic spring stops working, and the equivalent stiffness of the entire system no longer changes due to the nonlinear stiffness. Thus, for the damping module, the spring with a lower value shows better isolation performance in the high frequency region.

Figure 14.

Transmissibility of the hydraulic viscous damper module of VEAM with varying .

5. Conclusions

This study has proposed a novel damper design for cable stayed bridges that can respond to different vibration amplitudes that are caused by different environmental phenomena. It is a hybrid system that combines non-linear stiffness vibration isolation modules and hydraulic viscous damper modules. The VEAM proposes a novel way to utilize the minimum working force of the hydraulic cylinders, which is an unavoidable characteristic that can be leveraged to combine the two modules together to form a hybrid system that is able to automatically switch the module in operation based on the input vibration amplitude. This paper presented the mechanism design and theoretical model of the VEAM. Multiple numerical case studies were performed in order to observe the influence of various factors on the vibration isolation and damping performance of the entire system. The key findings of this research are as follows:

- VEAM mechanism, through the combined action of hydraulic cylinder bearings, ball joints, and springs, can maintain the alignment of PMs at all times, and will not cause vibration force transmission instability due to tangential shift.

- The external hydraulic circuit connecting the opposing damper pairs can maintain motion synchrony to avoid the jumping phenomenon, thus preventing system damage. This method can also easily make adjustments of the orifice regulating valves to achieve a variable damping ratio. Through the Simscape simulation of the entire VEAM subsystem, the design theory of the automatic switching mechanism was tested. The results showed that, when the whole system is working, due to the non-linear stiffness, chaotic output is observed in the high frequency bandwidth. The implications of this behavior need to be verified in future experiments with the real system.

- We can use strong repulsive magnets to ensure the maintenance of a safe distance between the PM pairs. The use of magnets with stronger linear stiffness will reduce the transmissibility of the nonlinear stiffness module in the low frequency region, but it will increase the transmissibility in the high frequency region. However, magnets with stronger nonlinear stiffness can effectively reduce the peak of transmissibility. In the design stage, according to the needs of the actual situation, the selection of PMs of appropriate magnetic strength can ensure a high performing safe design, while also ensuring a safe distance. However, during prototype manufacturing, we found that, due to space constraints, it is difficult to only use the magnetic force between the two PMs to actuate the hydraulic cylinder. Accordingly, it may be necessary to use crash pads between the magnets to achieve rigid transmission of force. The magnetic resistance of the surrounding environment and design involving stronger PMs will be considered in future studies.

- In the low-frequency region, the greater the spring linear stiffness, the lower will be the transmissibility of both the non-linear stiffness vibration isolation module and the hydraulic damper module, i.e., there will be better vibration isolation performance. However, in the high-frequency region, the stiffness of the spring will affect the vibration isolation performance when only the nonlinear stiffness vibration isolator is in operation. Therefore, the common effect of both modules must be considered when selecting the spring stiffness.

- The structural damping of the spring will undoubtedly provide good isolation performance when the non-linear stiffness module is working. However, the viscous damping of the hydraulic cylinder is different. Excessive viscous damping will affect the vibration isolation performance of the VEAM and increase the possibility of structural damage. On the other hand, small viscous damping has a large area of the isolation region, which can improve the poor vibration isolation that is caused by the shift towards the high frequency region of the transmissibility caused by excessive spring stiffness.

Author Contributions

Z.Q. and Y.-T.W. contributed equally. Conceptualization, Z.Q. and Y.-T.W.; methodology, A.H.; software, Z.Q. and Y.-T.W.; validation, Z.Q., Y.-T.W. and A.H.; formal analysis, S.K.L.; investigation, Y.-T.W.; resources, S.-K.L.; data curation, Z.Q., Y.-T.W. and A.H.; writing—original draft preparation, Z.Q. and Y.-T.W.; writing—review and editing, A.H., S.-K.L. and J.W.S.; visualization, Z.Q.; supervision, Y.-T.W.; project administration, S.-K.L.; funding acquisition, S.-K.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Regional Leading Research Center of NRF and MOCIE (NRF- 2019R1A5A808320112).

Conflicts of Interest

The authors declared that they have no conflict of interest to this work.

References

- Chen, W.-L.; Gao, D.; Laima, S.; Li, H. A Field Investigation on Vortex-Induced Vibrations of Stay Cables in a Cable-Stayed Bridge. Appl. Sci. 2019, 9, 4556. [Google Scholar] [CrossRef]

- Xu, Y.; Zeng, Z.; Cui, C.; Zeng, S. Practical Design Method of Yielding Steel Dampers in Concrete Cable-Stayed Bridges. Appl. Sci. 2019, 9, 2857. [Google Scholar] [CrossRef]

- Qin, Z.; Wu, Y.T.; Eizad, A.; Lee, K.H.; Lyu, S.K. Design and evaluation of two-stage planetary gearbox for special-purpose industrial machinery. J. Mech. Sci. Technol. 2019, 33, 5943–5950. [Google Scholar] [CrossRef]

- Qin, Z.; Zhang, Q.; Wu, Y.T.; Eizad, A.; Lyu, S.K. Experimentally Validated Geometry Modification Simulation for Improving Noise Performance of CVT Gearbox for Vehicles. Int. J. Precis. Eng. Manuf. 2019, 20, 1969–1977. [Google Scholar] [CrossRef]

- Qin, Z.; Wu, Y.T.; Eizad, A.; Jeon, N.S.; Kim, D.S.; Lyu, S.K. A Study on Simulation Based Validation of Optimized Design of High Precision Rotating Unit for Processing Machinery. Int. J. Precis. Eng. Manuf. 2019, 20, 1601–1609. [Google Scholar] [CrossRef]

- Qin, Z.; Son, H.I.; Lyu, S.K. Design of anti-vibration mounting for 140A class alternator for vehicles. J. Mech. Sci. Technol. 2018, 32, 5233–5239. [Google Scholar] [CrossRef]

- Qin, Z.; Wu, Y.T.; Lyu, S.K. A Review of Recent Advances in Design Optimization of Gearbox. Int. J. Precis. Eng. Manuf. 2018, 19, 1753–1762. [Google Scholar] [CrossRef]

- Nakamura, A.; Kasuga, A.; Arai, H. The effects of mechanical dampers on stay cables with high-damping rubber. Constr. Build. Mater. 1998, 12, 115–123. [Google Scholar] [CrossRef]

- Cu, V.H.; Han, B. High-damping rubber damper for taut cable vibration reduction. Aust. J. Struct. Eng. 2015, 16, 283–291. [Google Scholar] [CrossRef]

- Cu, V.H.; Han, B.; Wang, F. Damping of a taut cable with two attached high damping rubber dampers. Struct. Eng. Mech. 2015, 55, 1261–1278. [Google Scholar] [CrossRef]

- Pacheco, B.M.; Fujino, Y.; Sulekh, A. Estimation curve for modal damping in stay cables with viscous damper. J. Struct. Eng. 1993, 119, 1961–1979. [Google Scholar] [CrossRef]

- Krenk, S. Vibrations of a taut cable with an external damper. J. Appl. Mech. Trans. ASME 2000, 67, 772–776. [Google Scholar] [CrossRef]

- Sawka, B. Experiments on dynamic response of hydraulic props. Report of GIG Chief Mining Institute; Główny Instytut Górnictwa (GIG): Katowice, Poland, 1973. [Google Scholar]

- Tomski, L.; Kukla, S. Dynamical response of bar-fluid-shell system simulating hydraulic cylinder subjected to arbitrary axial excitation. J. Sound Vib. 1984, 92, 273–284. [Google Scholar] [CrossRef]

- Gamez-Montero, P.J.; Salazar, E.; Castilla, R.; Freire, J.; Khamashta, M.; Codina, E. Misalignment effects on the load capacity of a hydraulic cylinder. Int. J. Mech. Sci. 2009, 51, 105–113. [Google Scholar] [CrossRef]

- Niu, J.; Ding, Y.; Shi, Y.; Li, Z. Oil damper with variable stiffness for the seismic mitigation of cable-stayed bridge in transverse direction. Soil Dyn. Earthq. Eng. 2019, 125, 105719. [Google Scholar] [CrossRef]

- Zhan, C.; Deng, J.; Chen, K. Research on low-friction and high-response hydraulic cylinder with variable clearance. Jixie Gongcheng Xuebao 2015, 51, 161–167. [Google Scholar] [CrossRef]

- Tao, J.; Mak, C.M. Effect of viscous damping on power transmissibility for the vibration isolation of building services equipment. Appl. Acoust. 2006, 67, 733–742. [Google Scholar] [CrossRef]

- Guo, P.F.; Lang, Z.Q.; Peng, Z.K. Analysis and design of the force and displacement transmissibility of nonlinear viscous damper based vibration isolation systems. Nonlinear Dyn. 2012, 67, 2671–2687. [Google Scholar] [CrossRef]

- Wu, W.J.; Cai, C.S. Theoretical exploration of a taut cable and a TMD system. Eng. Struct. 2007, 29, 962–972. [Google Scholar] [CrossRef]

- Macháček, O.; Kubík, M.; Strecker, Z.; Roupec, J.; Mazůrek, I. Design of a frictionless magnetorheological damper with a high dynamic force range. Adv. Mech. Eng. 2019, 11, 1–8. [Google Scholar] [CrossRef]

- Nguyen, D.T.; Vo, D.H. A Study on Combination of Two Friction Dampers to Control Stayed-Cable Vibration Under Considering its Bending Stiffness. In CIGOS 2019, Innovation for Sustainable Infrastructure 2020; Springer: Singapore, 2019; pp. 87–92. [Google Scholar]

- Huang, X.; Liu, X.; Sun, J.; Zhang, Z.; Hua, H. Effect of the system imperfections on the dynamic response of a high-static-low-dynamic stiffness vibration isolator. Nonlinear Dyn. 2014, 76, 1157–1167. [Google Scholar] [CrossRef]

- Han, L.; Wei, H.; Wang, F. Study on the Vibration Isolation Performance of Composite Subgrade Structure in Seasonal Frozen Regions. Appl. Sci. 2020, 10, 3597. [Google Scholar] [CrossRef]

- Hao, Z.; Cao, Q.; Wiercigroch, M. Nonlinear dynamics of the quasi-zero-stiffness SD oscillator based upon the local and global bifurcation analyses. Nonlinear Dyn. 2017, 87, 987–1014. [Google Scholar] [CrossRef]

- Ding, H.; Ji, J.; Chen, L. Nonlinear vibration isolation for fluid-conveying pipes using quasi-zero stiffness characteristics. Mech. Syst. Signal Process. 2019, 121, 675–688. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, J.; Xu, D.; Ouyang, H.; Duan, Y. Force transmissibility of a two-stage vibration isolation system with quasi-zero stiffness. Nonlinear Dyn. 2017, 87, 633–646. [Google Scholar] [CrossRef]

- Liu, C.; Yu, K. A high-static–low-dynamic-stiffness vibration isolator with the auxiliary system. Nonlinear Dyn. 2018, 94, 1549–1567. [Google Scholar] [CrossRef]

- Virgin, L.N.; Santillan, S.T.; Plaut, R.H. Vibration isolation using extreme geometric nonlinearity. J. Sound Vib. 2008, 315, 721–731. [Google Scholar] [CrossRef]

- Wang, Y.; Li, S.; Neild, S.A.; Jiang, J.Z. Comparison of the dynamic performance of nonlinear one and two degree-of-freedom vibration isolators with quasi-zero stiffness. Nonlinear Dyn. 2017, 88, 635–654. [Google Scholar] [CrossRef]

- Sun, M.; Dong, Z.; Song, G.; Sun, X.; Liu, W. A Vibration Isolation System Using the Negative Stiffness Corrector Formed by Cam-Roller Mechanisms with Quadratic Polynomial Trajectory. Appl. Sci. 2020, 10, 3573. [Google Scholar] [CrossRef]

- Carrella, A.; Brennan, M.J.; Waters, T.P. Static analysis of a passive vibration isolator with quasi-zero-stiffness characteristic. J. Sound Vib. 2007, 301, 678–689. [Google Scholar] [CrossRef]

- Lan, C.C.; Yang, S.A.; Wu, Y. Design and experiment of a compact quasi-zero-stiffness isolator capable of a wide range of loads. J. Sound Vib. 2014, 333, 4843–4858. [Google Scholar] [CrossRef]

- Araki, Y.; Asai, T.; Kimura, K.; Maezawa, K.; Masui, T. Nonlinear vibration isolator with adjustable restoring force. J. Sound Vib. 2013, 332, 6063–6077. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, X.; Xu, D.; Bishop, S. Nonlinear dynamic characteristics of a quasi-zero stiffness vibration isolator with cam-roller-spring mechanisms. J. Sound Vib. 2015, 346, 53–69. [Google Scholar] [CrossRef]

- Zhou, J.; Xu, D.; Bishop, S. A torsion quasi-zero stiffness vibration isolator. J. Sound Vib. 2015, 338, 121–133. [Google Scholar] [CrossRef]

- Zhou, N.; Liu, K. A tunable high-static-low-dynamic stiffness vibration isolator. J. Sound Vib. 2010, 329, 1254–1273. [Google Scholar] [CrossRef]

- Wu, W.; Chen, X.; Shan, Y. Analysis and experiment of a vibration isolator using a novel magnetic spring with negative stiffness. J. Sound Vib. 2014, 333, 2958–2970. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, X.; Luo, Y.; Yan, B.; Ma, C. Design and experiment of a high-static-low-dynamic stiffness isolator using a negative stiffness magnetic spring. J. Sound Vib. 2016, 360, 31–52. [Google Scholar] [CrossRef]

- Yan, B.; Ma, H.; Zhao, C.; Wu, C.; Wang, K.; Wang, P. A vari-stiffness nonlinear isolator with magnetic effects: Theoretical modeling and experimental verification. Int. J. Mech. Sci. 2018, 148, 745–755. [Google Scholar] [CrossRef]

- Yan, B.; Ma, H.; Jian, B.; Wang, K.; Wu, C. Nonlinear dynamics analysis of a bi-state nonlinear vibration isolator with symmetric permanent magnets. Nonlinear Dyn. 2019, 97, 2499–2519. [Google Scholar] [CrossRef]

- Matsumoto, M.; Shiraishi, N.; Kitazawa, M.; Knisely, C.; Shirato, H.; Kim, Y.; Tsujii, M. Aerodynamic behavior of inclined circular cylinders-cable aerodynamics. J. Wind Eng. Ind. Aerodyn. 1990, 33, 63–72. [Google Scholar] [CrossRef]

- Matsumoto, M.; Saitoh, T.; Kitazawa, M.; Shirato, H.; Nishizaki, T. Response characteristics of rain-wind induced vibration of stay-cables of cable-stayed bridges. J. Wind Eng. Ind. Aerodyn. 1995, 57, 323–333. [Google Scholar] [CrossRef]

- Matsumoto, M.; Daito, Y.; Kanamura, T.; Shigemura, Y.; Sakuma, S.; Ishizaki, H. Wind-induced vibration of cables of cable-stayed bridges. J. Wind Eng. Ind. Aerodyn. 1998, 74, 1015–1027. [Google Scholar] [CrossRef]

- Matsumoto, M.; Yagi, T.; Shigemura, Y.; Tsushima, D. Vortex-induced cable vibration of cable-stayed bridges at high reduced wind velocity. J. Wind Eng. Ind. Aerodyn. 2001, 89, 633–647. [Google Scholar] [CrossRef]

- Matsumoto, M.; Shiraishi, N.; Shirato, H. Rain-wind induced vibration of cables of cable-stayed bridges. J. Wind Eng. Ind. Aerodyn. 1992, 43, 2011–2022. [Google Scholar] [CrossRef]

- Ma, C.M.; Duan, Q.S.; Liao, H.L. Experimental investigation on aerodynamic behavior of a long span cable-stayed bridge under construction. KSCE J. Civ. Eng. 2017, 22, 2492–2501. [Google Scholar] [CrossRef]

- Du, W.; Lei, D.; Bai, P.; Zhu, F.; Huang, Z. Dynamic measurement of stay-cable force using digital image techniques. Meas. J. Int. Meas. Confed. 2020, 151, 107211. [Google Scholar] [CrossRef]

- Barton, M.A.; Kuroda, K. Ultralow frequency oscillator using a pendulum with crossed suspension wires. Rev. Sci. Instrum. 1994, 65, 3775–3779. [Google Scholar] [CrossRef][Green Version]

- Barton, M.A.; Kanda, N.; Kuroda, K. A low-frequency vibration isolation table using multiple crossed-wire suspensions. Rev. Sci. Instrum. 1996, 67, 3994–3999. [Google Scholar] [CrossRef]

- Carrella, A.; Brennan, M.J.; Waters, T.P.; Lopes, V., Jr. Force and displacement transmissibility of a nonlinear isolator with high-static-low-dynamic-stiffness. Int. J. Mech. Sci. 2012, 55, 22–29. [Google Scholar] [CrossRef]

- Yamakawa, I.; Takeda, S.; Kojima, H. Behavior of a New Type Dynamic Vibration Absorber Consisting of Three Permanent Magnets. Bull. JSME 1977, 20, 947–954. [Google Scholar] [CrossRef]

- He, J.; Cai, J. Dynamic Analysis of Modified Duffing System via Intermittent External Force and Its Application. Appl. Sci. 2019, 9, 4683. [Google Scholar] [CrossRef]

- Fathi, M.F.; Bakhshinejad, A.; Baghaie, A.; D’Souza, R.M. Dynamic Denoising and Gappy Data Reconstruction Based on Dynamic Mode Decomposition and Discrete Cosine Transform. Appl. Sci. 2018, 8, 1515. [Google Scholar] [CrossRef]

- Knoll, D.A.; Keyes, D.E. Jacobian-free Newton–Krylov methods: A survey of approaches and applications. J. Comput. Phys. 2004, 193, 357–397. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).