A Clustering-Based Bubble Method for Generating High-Quality Tetrahedral Meshes of Geological Models

Abstract

1. Introduction

- (1)

- We apply the clustering algorithm based on the spatial distribution to divide the surface points for determining the initial bubbles.

- (2)

- A procedure based on the distance of nearby bubbles to determine the initial size of bubbles.

- (3)

- We evaluate the quality of the tetrahedral mesh in the geological model using three indicators.

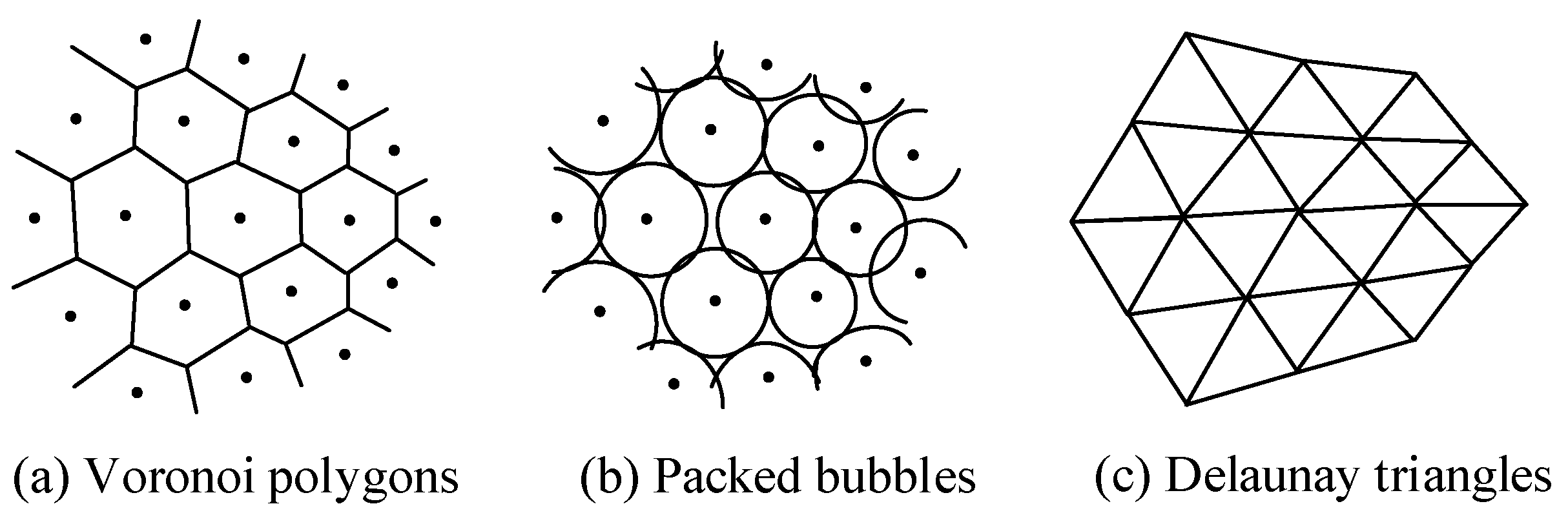

2. Brief Introduction to the Original Bubble Meshing Method

2.1. Initial Bubble Placement

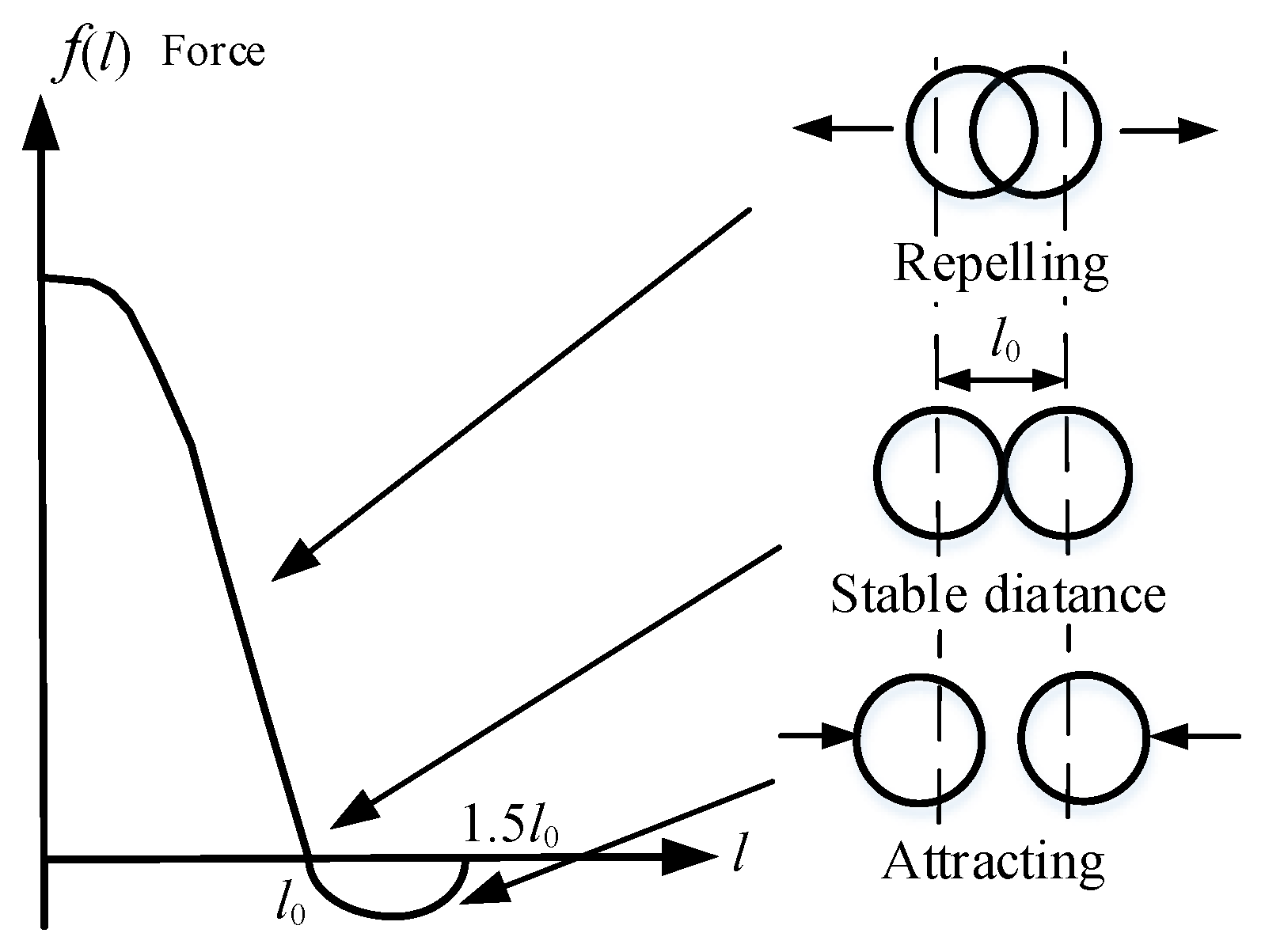

2.2. Interaction Forces

2.3. Physically-Based Relaxation

2.4. Adaptive Population Control

3. The Proposed Clustering-Based Bubble Meshing Method

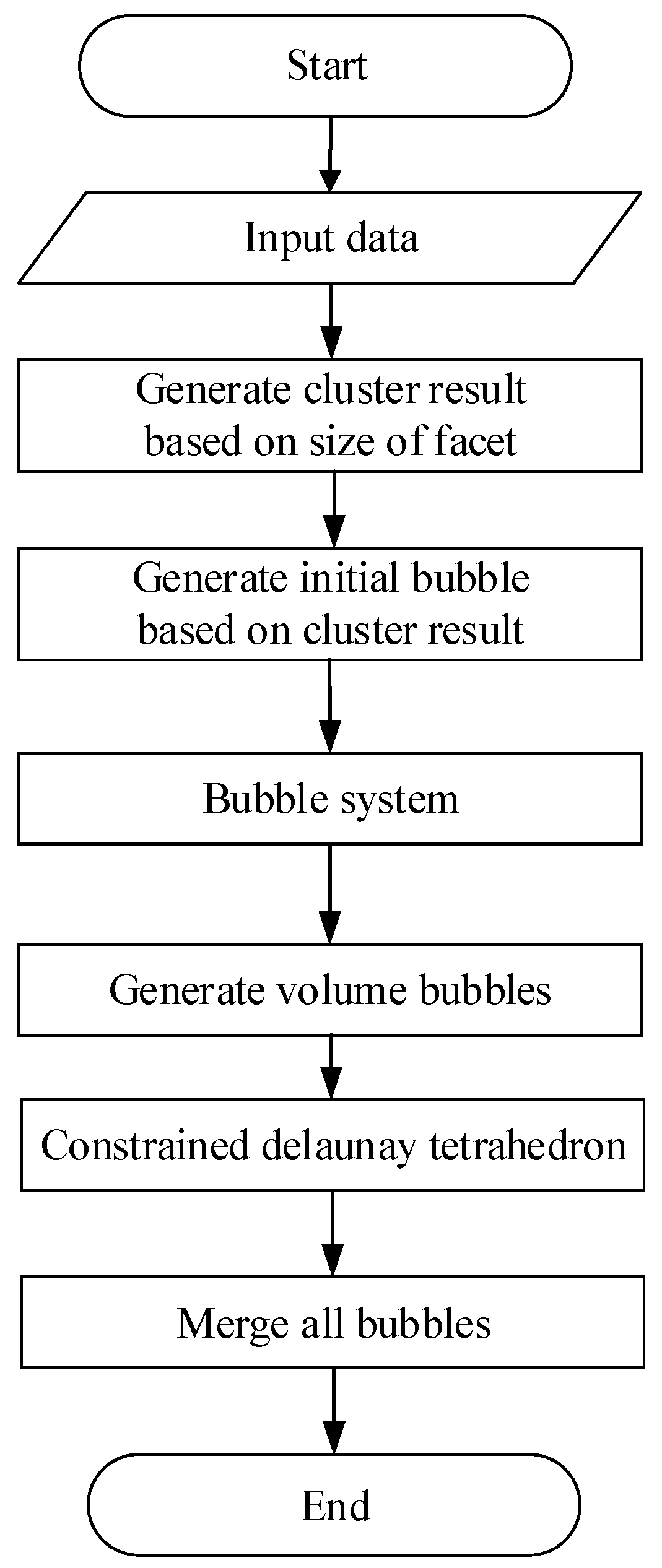

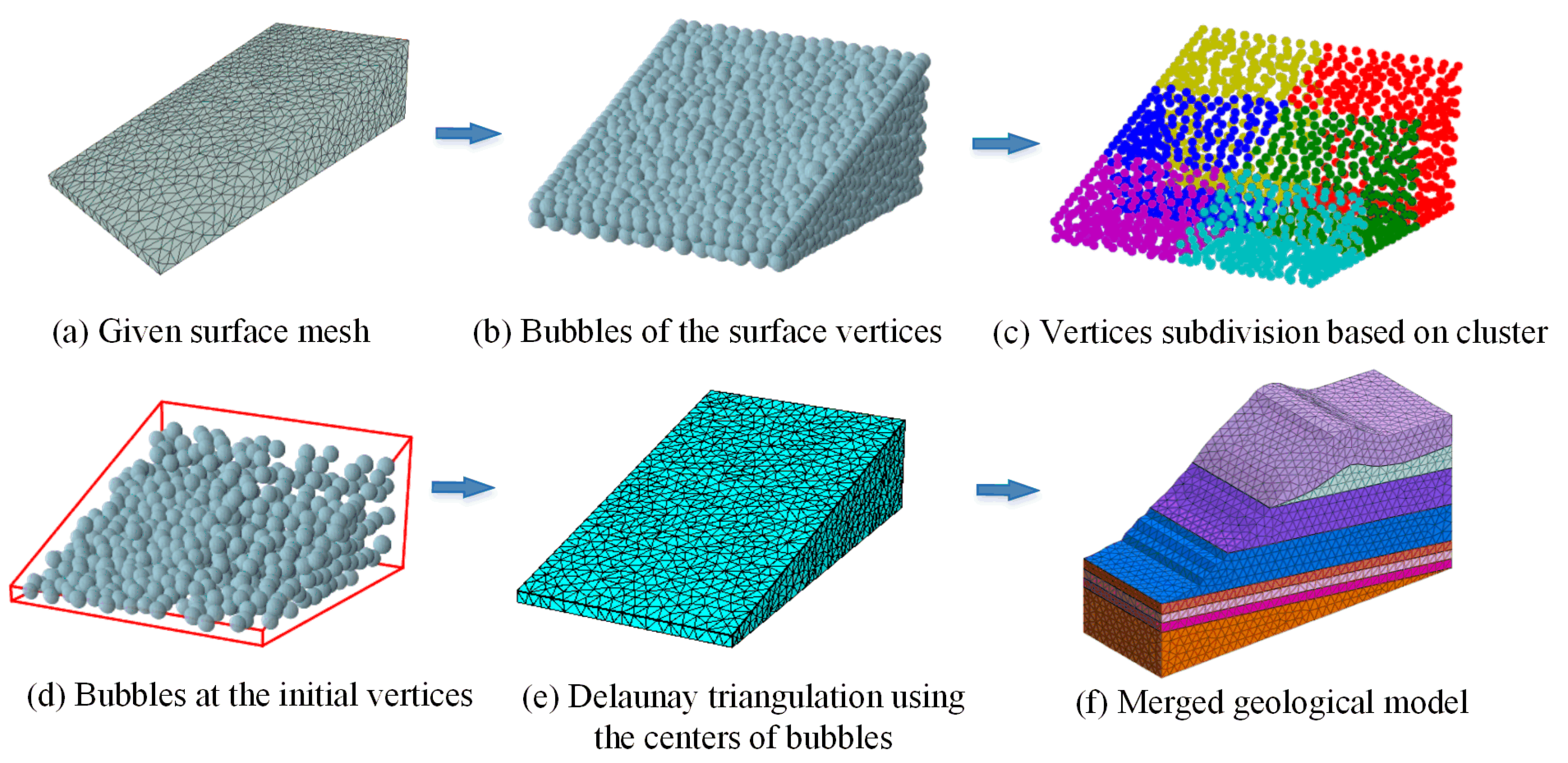

3.1. Overview

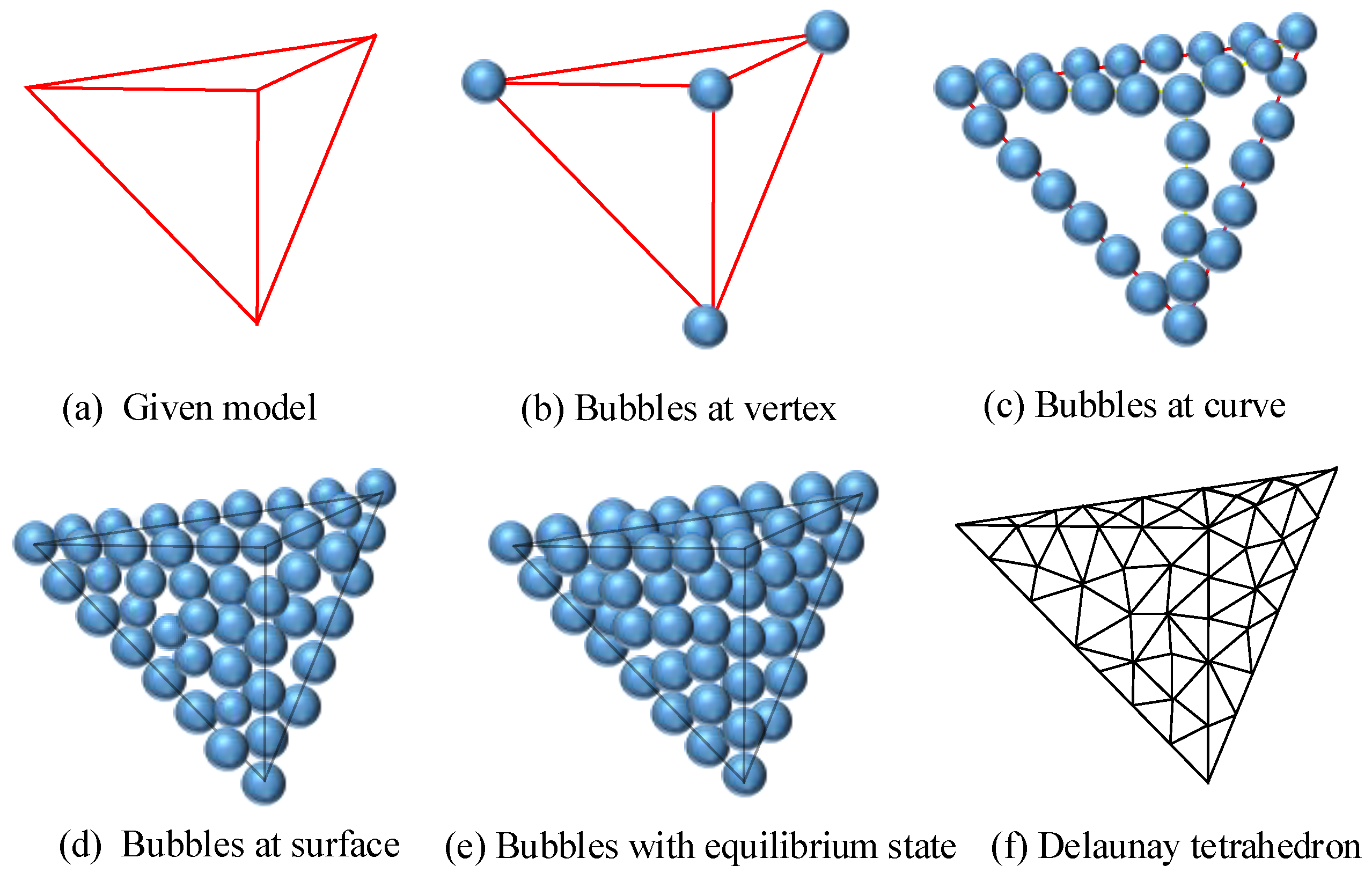

3.2. Procedures of the Proposed Bubble Method

3.2.1. Procedure 1: Inputted Geological Model

3.2.2. Procedure 2: Initial Bubble Placement

3.2.3. Procedure 3: Equation of Motion Control

3.2.4. Procedure 4: Adaptive Population Control

3.2.5. Procedure 5: Obtaining the Final Mesh Model by Merging

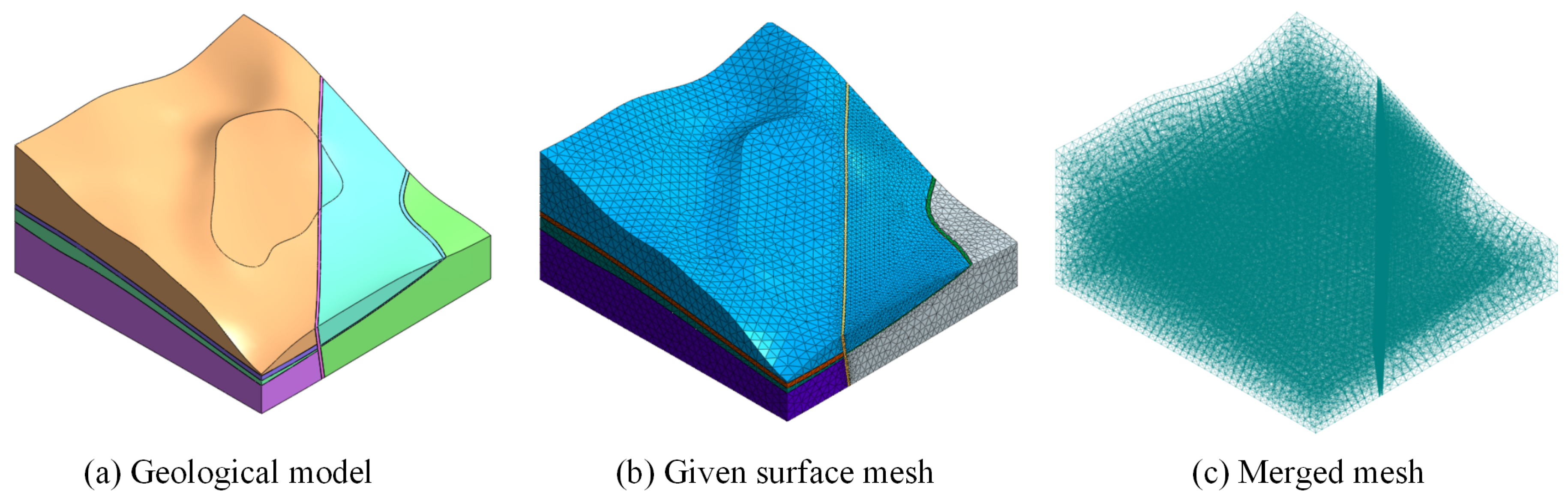

4. Results

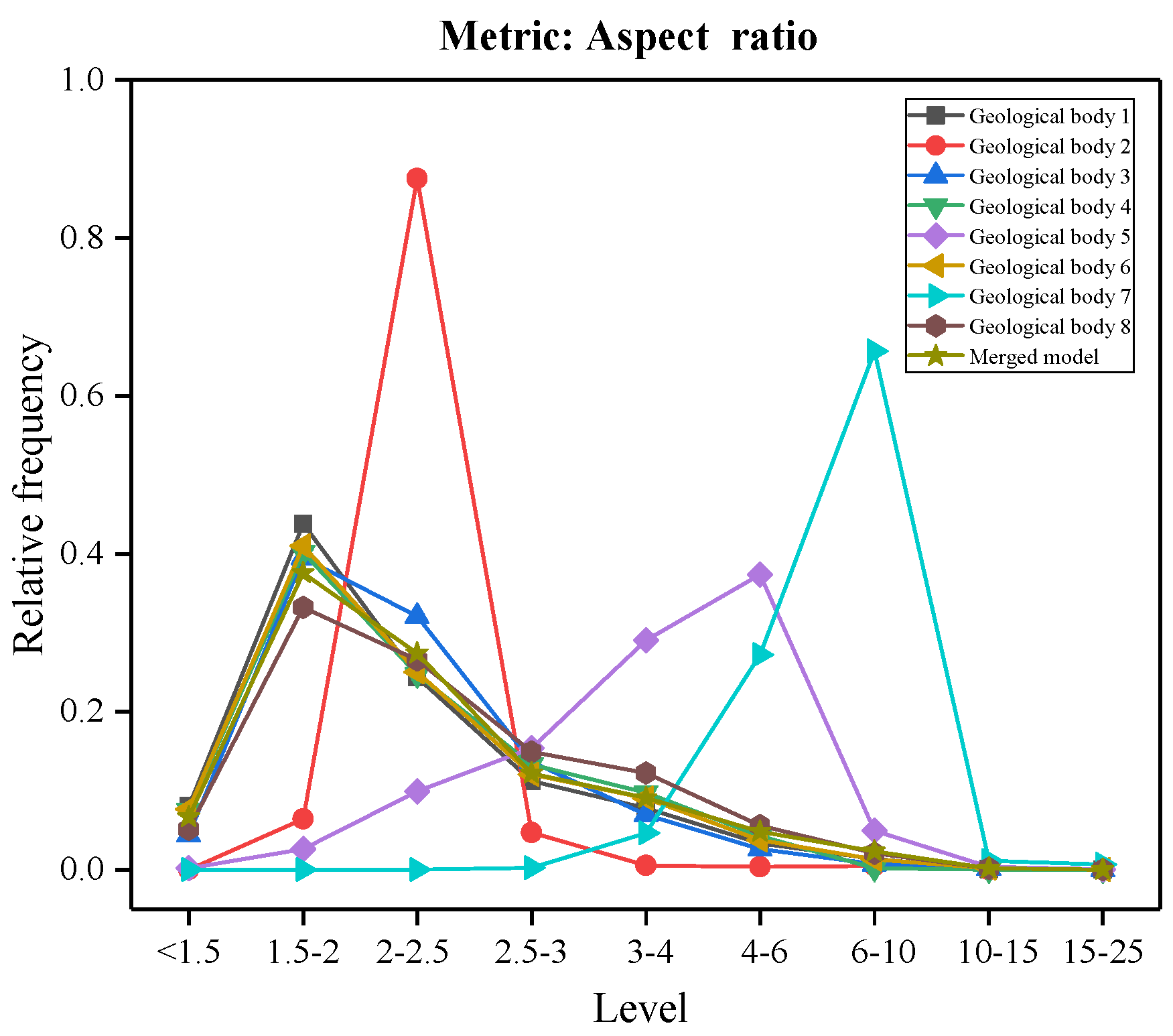

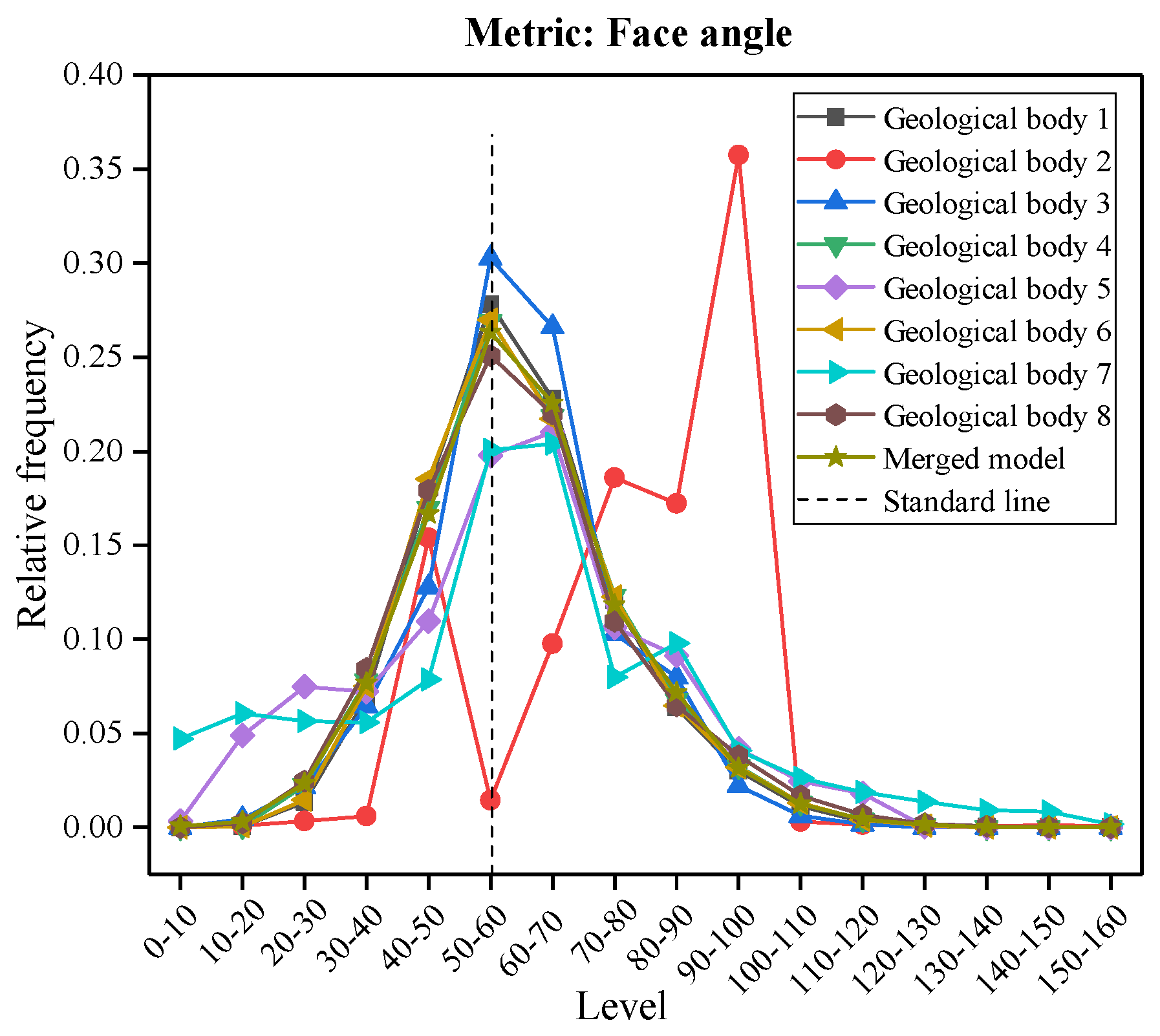

4.1. Mesh Quality Metrics

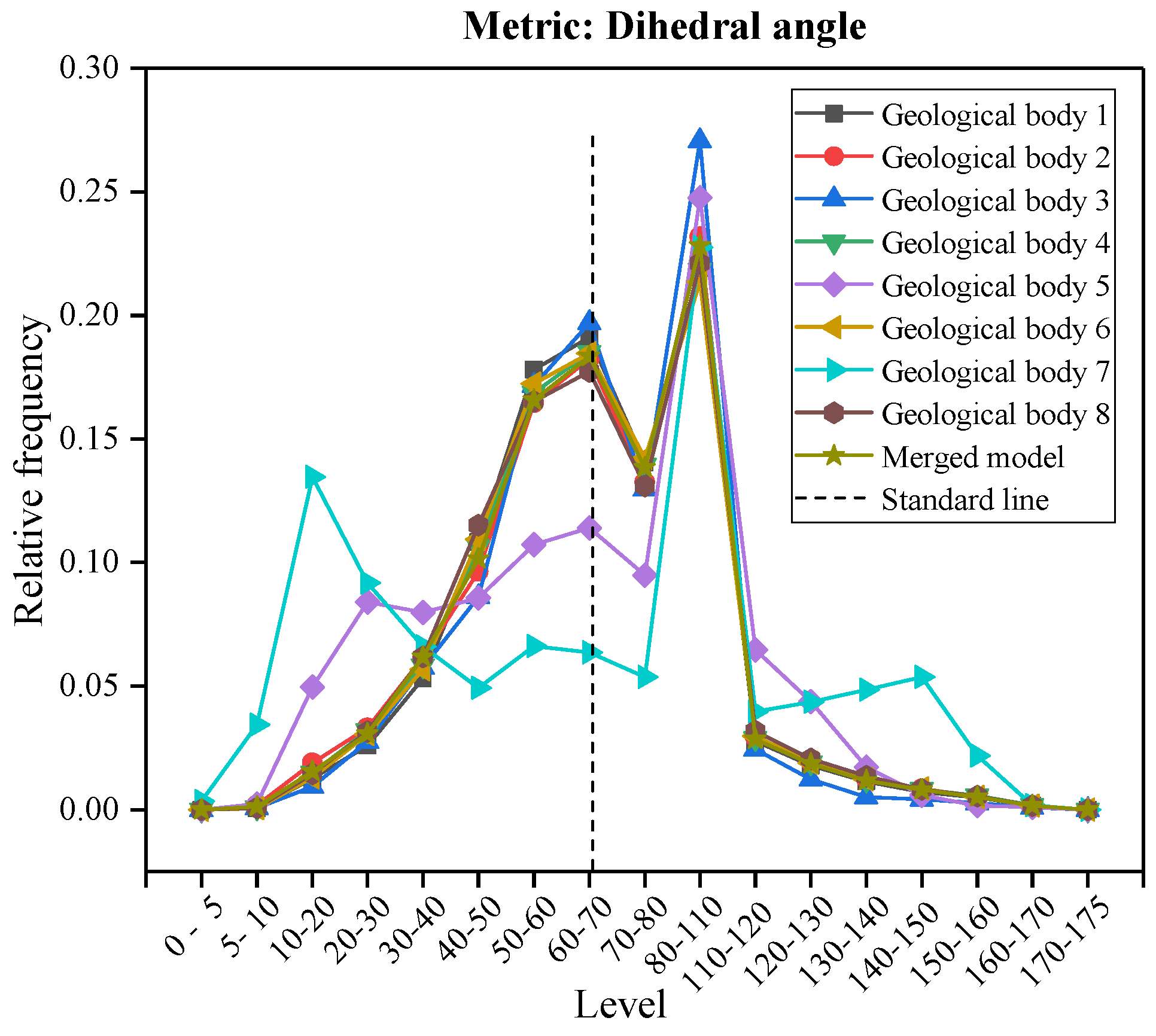

4.2. Statistics of the Mesh Quality

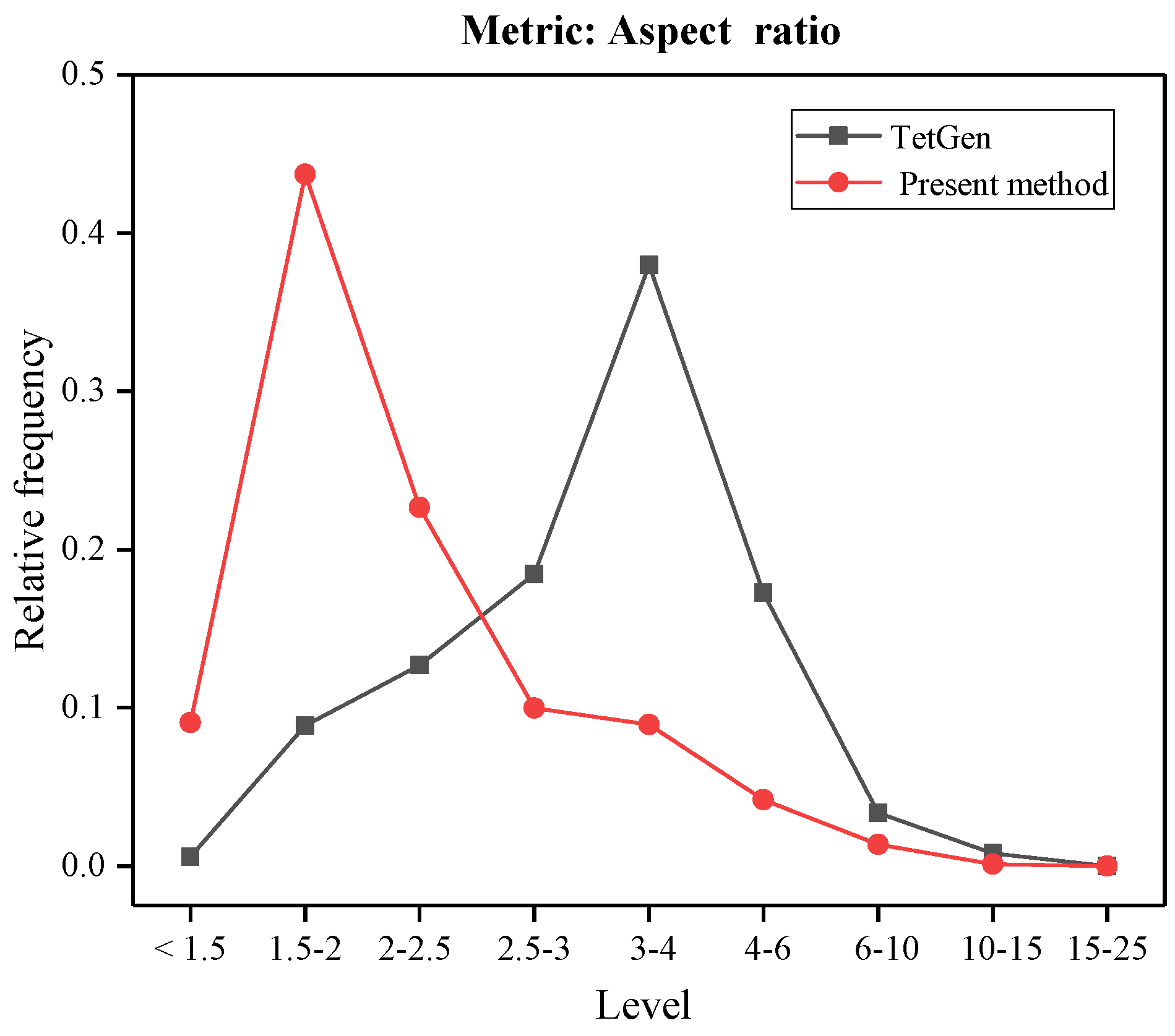

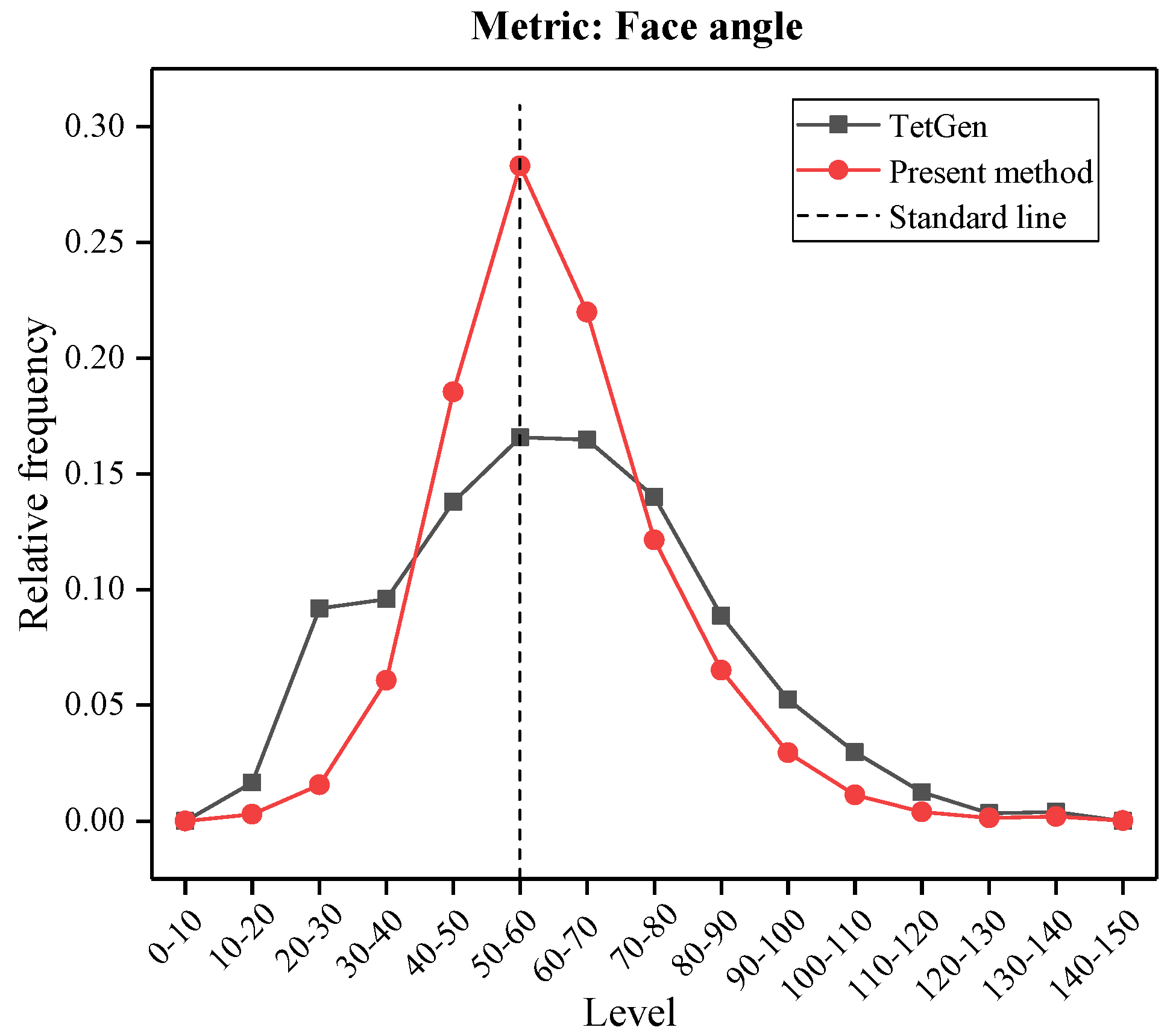

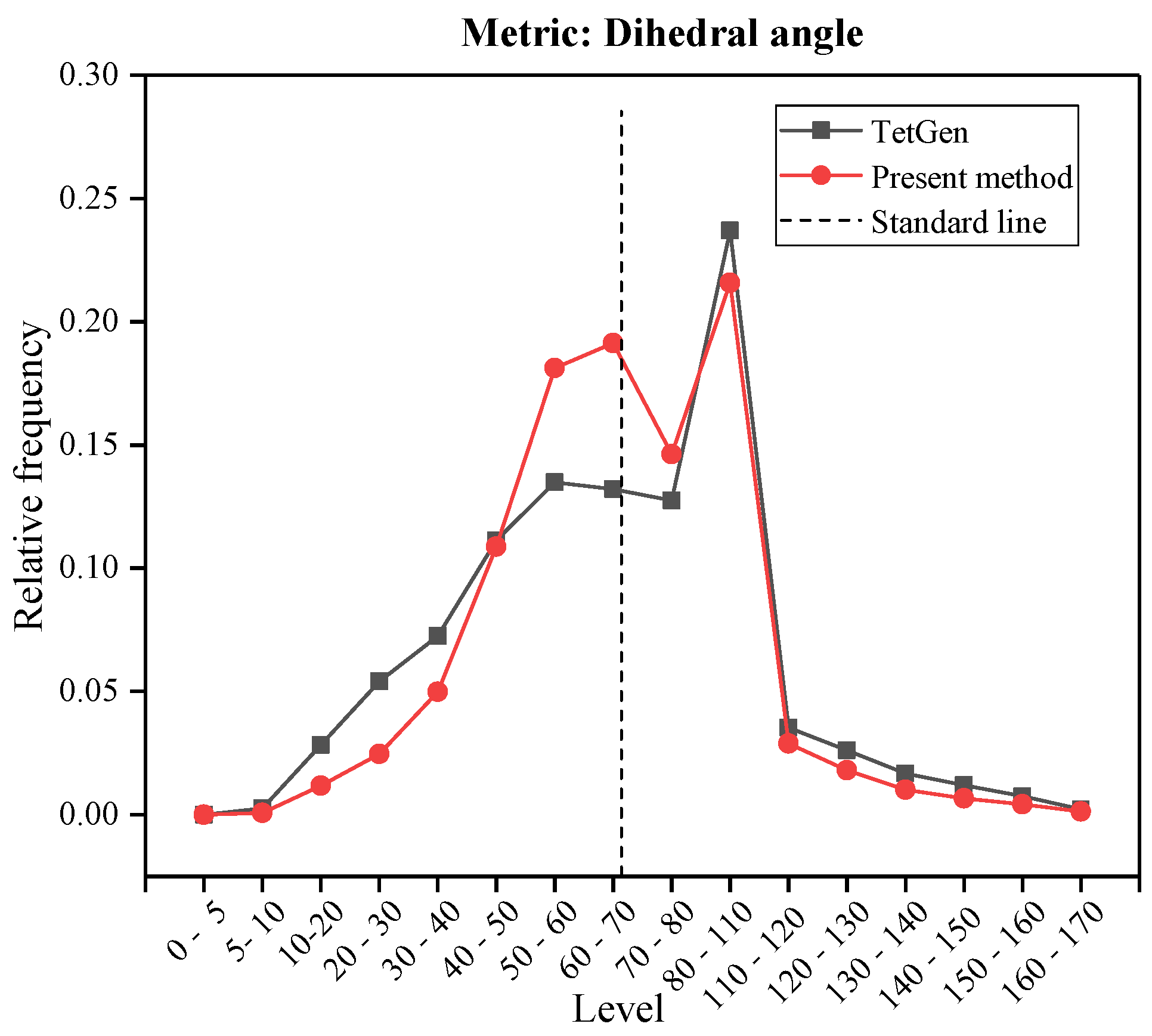

4.3. Comparative Analysis of Mesh Quality

5. Discussion

5.1. Applicability, Advantage and Shortcomings of the Proposed Method

5.2. Outlook and Future Work

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bowyer, A. Computing dirichlet tessellations. Comput. J. 1981, 24, 162–166. [Google Scholar] [CrossRef]

- Watson, D.F. Computing the n-dimensional Delaunay tessellation with application to Voronoi polytopes. Comput. J. 1981, 24, 167–172. [Google Scholar] [CrossRef]

- Wang, B.; Khoo, B.C.; Xie, Z.Q.; Tan, Z.J. Fast centroidal Voronoi Delaunay triangulation for unstructured mesh generation. J. Comput. Appl. Math. 2015, 280, 158–173. [Google Scholar] [CrossRef]

- Muylle, J.; Ivanyi, P.; Topping, B.H.V. A new point creation scheme for uniform Delaunay triangulation. Eng. Comput. 2002, 19, 707–735. [Google Scholar] [CrossRef]

- Lo, S.H. Dynamic grid for mesh generation by the advancing front method. Comput. Struct. 2013, 123, 15–27. [Google Scholar] [CrossRef]

- Cuilliere, J.C. An adaptive method for the automatic triangulation of 3D parametric surfaces. Comput.-Aided Des. 1998, 30, 139–149. [Google Scholar] [CrossRef]

- Tautges, T.J. The generation of hexahedral meshes for assembly geometry: Survey and progress. Int. J. Numer. Methods Eng. 2001, 50, 2617–2642. [Google Scholar] [CrossRef]

- Pei, X.B.; Xu, N.X. Hexahedron-Dominant Mesh Generation for Blocks with Constrained Triangulated Boundary Surfaces; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2014; Volume 580, pp. 2983–2989. [Google Scholar]

- Meng, X.; Zhou, K.; Li, J.; Yang, Q. Triangular framework mesh generation of 3D geological structure. In Proceedings of the Fifth International Conference on Machine Vision (ICMV 2012): Computer Vision, Image Analysis and Processing, Wuhan, China, 20–21 April 2012; International Society for Optics and Photonics: Bellingham, WA, USA, 2012; Volume 8783, p. 87830Z. [Google Scholar]

- Sarrate Ramos, J.; Ruiz-Gironés, E.; Roca Navarro, F.J. Unstructured and semi-structured hexahedral mesh generation methods. Comput. Technol. Rev. 2014, 10, 35–64. [Google Scholar] [CrossRef]

- Sun, L.; Yeh, G.T.; Lin, F.P.; Zhao, G. Automatic quadrilateral mesh generation and quality improvement techniques for an improved combination method. Comput. Geosci. 2015, 19, 371–388. [Google Scholar] [CrossRef]

- Araújo, C.; Celes, W. Quadrilateral mesh generation with deferred constraint insertion. Procedia Eng. 2014, 82, 88–100. [Google Scholar] [CrossRef]

- De Oliveira Miranda, A.C.; Lira, W.W.M.; Marques, R.C.; Pereira, A.M.B.; Cavalcante-Neto, J.B.; Martha, L.F. Finite element mesh generation for subsurface simulation models. Eng. Comput. 2015, 31, 305–324. [Google Scholar] [CrossRef]

- Xing, H.; Liu, Y. Mesh Generation for 3D Geological Reservoirs with Arbitrary Stratigraphic Surface Constraints. Procedia Comput. Sci. 2014, 29, 897–909. [Google Scholar] [CrossRef]

- Borouchaki, H.; Lo, S.H. Fast Delaunay triangulation in three dimensions. Comput. Methods Appl. Mech. Eng. 1995, 128, 153–167. [Google Scholar] [CrossRef]

- Borouchaki, H.; George, P.L.; Lo, S.H. Optimal delaunay point insertion. Int. J. Numer. Methods Eng. 1996, 39, 3407–3437. [Google Scholar] [CrossRef]

- Shimada, K.; Yamada, A.; Itoh, T. Anisotropic triangular meshing of parametric surfaces via close packing of ellipsoidal bubbles. In Proceedings of the 6th International Meshing Roundtable, Park City, UT, USA, 13–15 October 1997; pp. 375–390. [Google Scholar]

- Yokoyama, T.; Cingoski, V.; Kaneda, K.; Yamashita, H. 3-D automatic mesh generation for FEA using dynamic bubble system. Ieee Trans. Magn. 1999, 35, 1318–1321. [Google Scholar] [CrossRef]

- Nagakura, S.; Noguchi, S.; Kaneda, K.; Yamashita, H.; Cingoski, V. Automatic quadrilateral mesh generation for FEM using dynamic bubble system. IEEE Trans. Magn. 2001, 37, 3522–3525. [Google Scholar] [CrossRef][Green Version]

- Zhang, W.; Nie, Y.; Wang, L. Bubble Meshing Method for Two-parametric Surface. Chin. J. Comput. Phys. 2012, 29, 43–50. [Google Scholar]

- Guo, W.; Nie, Y.; Zhang, W. Parallel adaptive mesh refinement method based on bubble-type local mesh generation. J. Parallel Distrib. Comput. 2018, 117, 37–49. [Google Scholar] [CrossRef]

- Guo, W.; Nie, Y.; Zhang, W. Acceleration strategies based on bubble-type adaptive mesh refinement method. Math. Comput. Simul. 2020, 170, 143–163. [Google Scholar] [CrossRef]

- Wang, Q.; Gao, B.; Wu, H. Triangular mesh generation on free-form surfaces based on bubble dynamics simulation. Eng. Comput. 2019, 36, 646–663. [Google Scholar] [CrossRef]

- Kim, J.H.; Kim, H.G.; Lee, B.C.; Im, S. Adaptive mesh generation by bubble packing method. Struct. Eng. Mech. 2003, 15, 135–149. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Z.; Xiong, H.; Gao, X.; Wu, J. Understanding of Internal Clustering Validation Measures. In Proceedings of the 2010 IEEE International Conference on Data Mining, Sydney, NSW, Australia, 13–17 December 2010. [Google Scholar] [CrossRef]

- Jain, A.K.; Dubes, R.C. Algorithms for Clustering Data; Prentice-Hall, Inc.: Upper Saddle River, NJ, USA, 1988; Volume 32, pp. 227–229. [Google Scholar]

- Dalal, M.A.; Harale, N.D.; Kulkarni, U.L. An Iterative Improved k-means Clustering. Int. J. Netw. Secur. 2011, 2. [Google Scholar]

- Calinski, T.; Harabasz, J. A Dendrite Method for Cluster Analysis. Commun. Stat. 1974, 3, 1–27. [Google Scholar]

- Zhu, L.J.; Bing-Xian, M.A.; Zhao, X.Q. Clustering validity analysis based on silhouette coefficient. J. Comput. Appl. 2010, 2, 139–142. [Google Scholar]

- Wu, J.; Hui, X.; Jian, C. Adapting the right measures for K-means clustering. In Proceedings of the 15th ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, Paris, France, 28 June–1 July 2009. [Google Scholar]

- Xiong, H.; Wu, J.; Chen, J. K-Means Clustering Versus Validation Measures: A Data-Distribution Perspective. IEEE Trans. Syst. Man Cybern. Part B 2009, 39, 318–331. [Google Scholar] [CrossRef]

- Yamakawa, S.; Shimada, K. High Quality Anisotropic Tetrahedral Mesh Generation Via Ellipsoidal Bubble Packing. In Proceedings of the IMR 2000, New Orleans, LA, USA, 2–5 October 2000; pp. 263–274. [Google Scholar]

- Shimada, K. Physically-Based Mesh Generation: Automated Triangulation of Surfaces and Volumes via Bubble Packing. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1993. [Google Scholar]

- Shimada, K.; Gossard, D.C. Bubble Mesh: Automated Triangular Meshing of Non-Manifold Geometry by Sphere Packing. In Proceedings of the 3rd Shymposium on Solid Modeling and Applications, Salt Lake City, UT, USA, 17–19 May 1995; pp. 409–419. [Google Scholar]

- Shimada, K.; Gossard, D.C. Automatic triangular mesh generation of trimmed parametric surfaces for finite element analysis. Comput. Aided Geom. Des. 1998, 15, 199–222. [Google Scholar] [CrossRef]

- Mei, G.; Cuomo, S.; Tian, H.; Xu, N.; Peng, L. MeshCleaner: A Generic and Straightforward Algorithm for Cleaning Finite Element Meshes. Int. J. Parallel Program. 2018, 46, 565–583. [Google Scholar] [CrossRef]

- Si, H. TetGen, a Delaunay-Based Quality Tetrahedral Mesh Generator. ACM Trans. Math. Softw. 2015, 41, 1–36. [Google Scholar] [CrossRef]

- Jing, Y.B.; Wang, L.G.; Jia, M.T.; Chen, J.H.J.R.; Mechanics, S. Visual modeling of complex FLAC (3D) model based on TetGen. Rock Soil Mech. 2010, 31, 2655–2660. [Google Scholar]

- Li, M.; Zhong, D.; Qin, Z.; Tong, D.; Liu, J. Refined Modeling for Numerical Simulation of Engineering Rock Mass Structures Based on 3D Geological Model. Chin. J. Rock Mech. Eng. 2007, 26, 1893–1898. [Google Scholar]

- Mei, G.; Xu, N.; Qin, J.; Wang, B.; Qi, P. A Survey of Internet of Things (IoT) for Geo-hazards Prevention: Applications, Technologies, and Challenges. IEEE Internet Things J. 2020, 26, 4371–4386. [Google Scholar] [CrossRef]

- Changjian, D.U.; Qinglin, Y.I.; Zhang, M.; Meng, H.; Wen, K. The numerical simulation on landslide stability to chasm mountain landslide affected by water filling at trailing edge chasm. Chin. J. Geol. Hazard Control 2017, 28, 13–21. [Google Scholar]

- Ventisette, C.D.; Garfagnoli, F.; Ciampalini, A.; Battistini, A.; Casagli, N. Catastrophic debris-flows: Geological hazard and human influence. In Proceedings of the EGU General Assembly 2013, Vienna, Austria, 7–12 April 2013. [Google Scholar]

- Brovelli, M.; Cannata, M. Digital terrain model reconstruction in urban areas from airborne laser scanning data: The method and an example for Pavia (northern Italy). Comput. Geoences 2004, 30, 325–331. [Google Scholar] [CrossRef]

- Miller, C.L.; Laflamme, R.A. The Digital Terrain Model—Theory and Application; M.I.T. Photogrammetry Laboratory: Cambridge, MA, USA, 1958. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Sun, Y.; Xu, N.; Mei, G. A Clustering-Based Bubble Method for Generating High-Quality Tetrahedral Meshes of Geological Models. Appl. Sci. 2020, 10, 5292. https://doi.org/10.3390/app10155292

Wang B, Sun Y, Xu N, Mei G. A Clustering-Based Bubble Method for Generating High-Quality Tetrahedral Meshes of Geological Models. Applied Sciences. 2020; 10(15):5292. https://doi.org/10.3390/app10155292

Chicago/Turabian StyleWang, Bowen, Yingjie Sun, Nengxiong Xu, and Gang Mei. 2020. "A Clustering-Based Bubble Method for Generating High-Quality Tetrahedral Meshes of Geological Models" Applied Sciences 10, no. 15: 5292. https://doi.org/10.3390/app10155292

APA StyleWang, B., Sun, Y., Xu, N., & Mei, G. (2020). A Clustering-Based Bubble Method for Generating High-Quality Tetrahedral Meshes of Geological Models. Applied Sciences, 10(15), 5292. https://doi.org/10.3390/app10155292