Experimental Study of Forced Convective Heat Transfer in a Coiled Flow Inverter Using TiO2–Water Nanofluids

Abstract

1. Introduction

2. Experimental Methodology

2.1. Preparation of the Nanofluids

2.2. Characterization of the Nanofluids

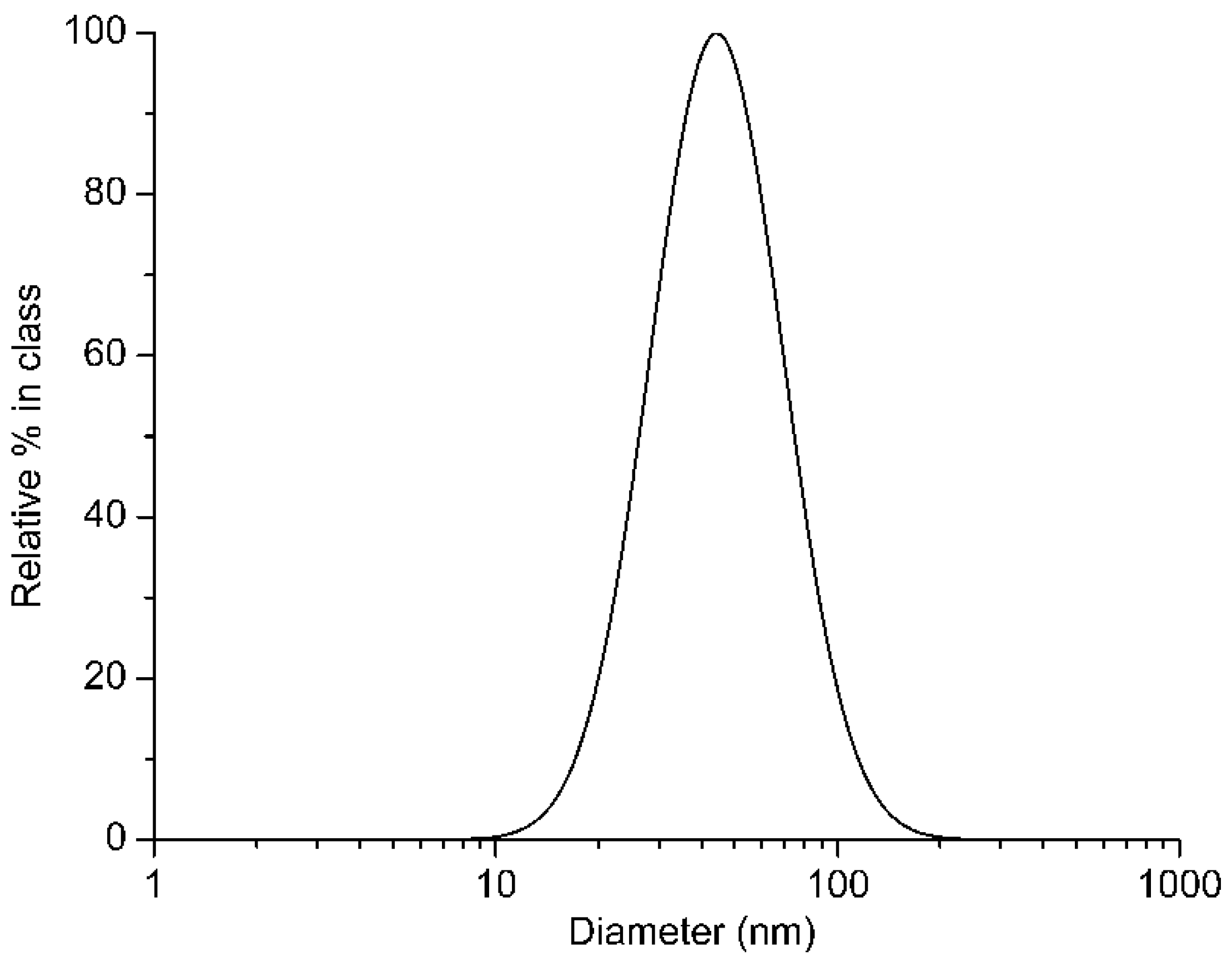

2.3. Characterization of the Nanoparticles

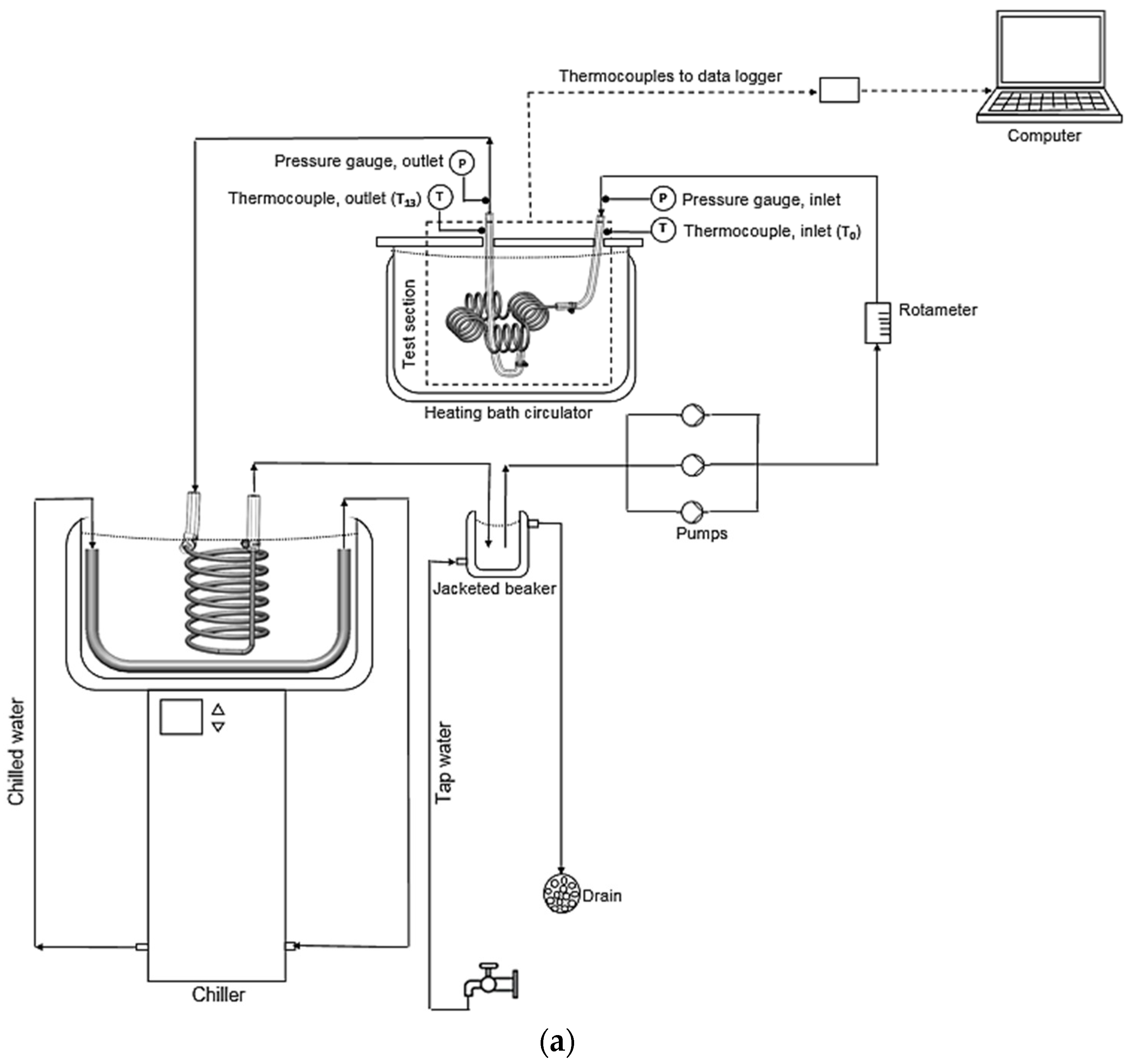

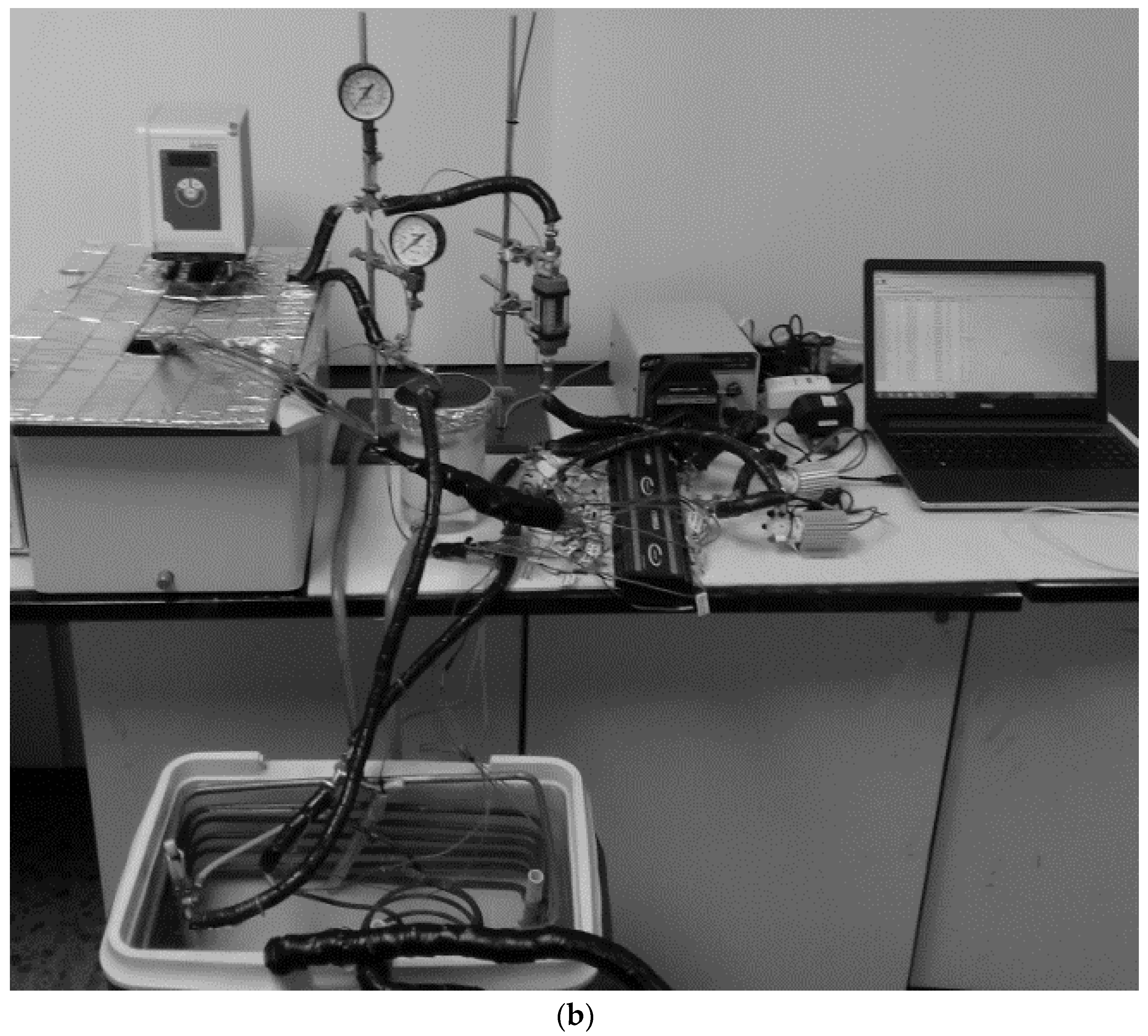

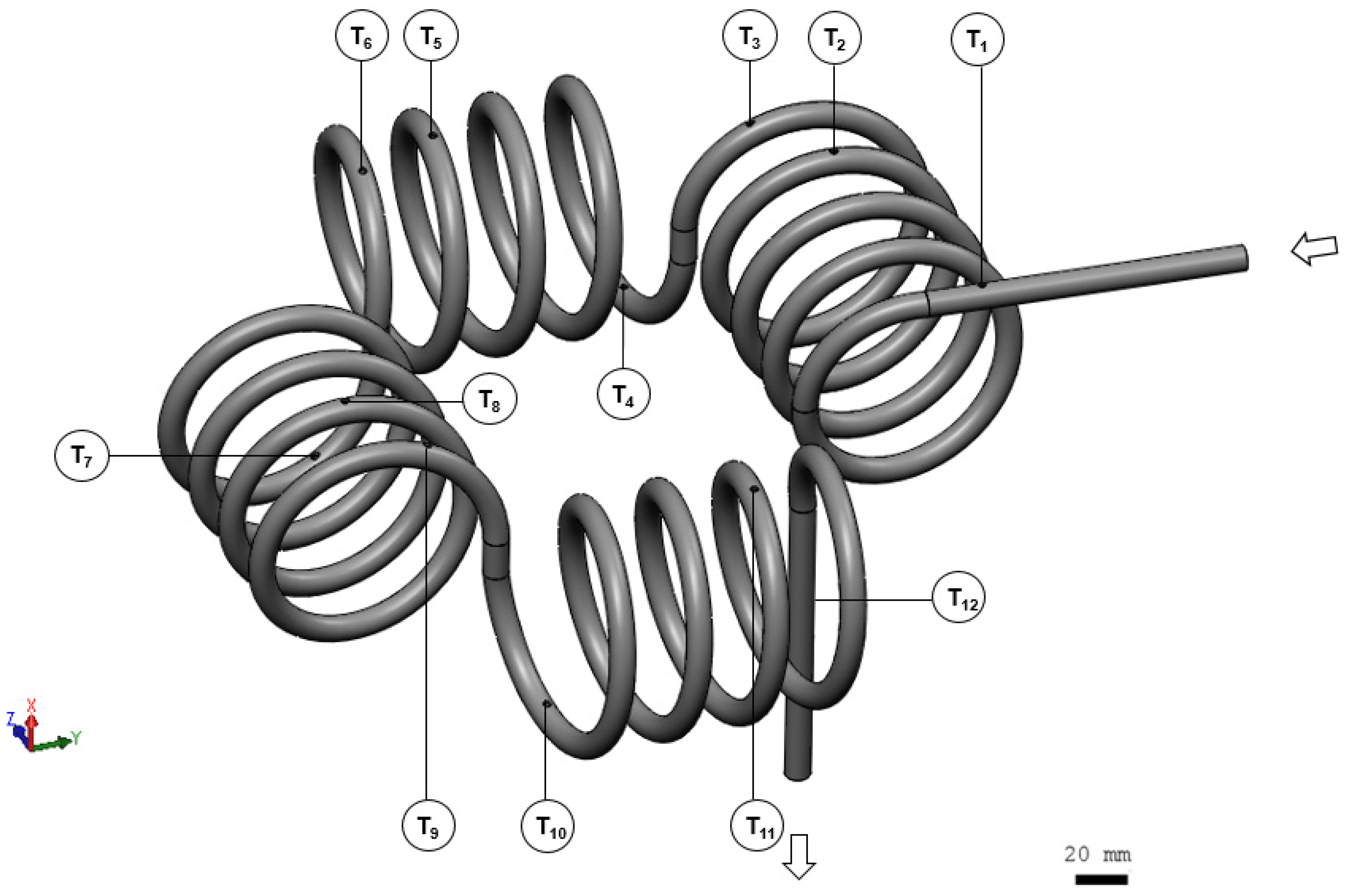

2.4. Measurements of the Convective Heat Transfer Coefficient

3. Calculations

4. Results and Discussion

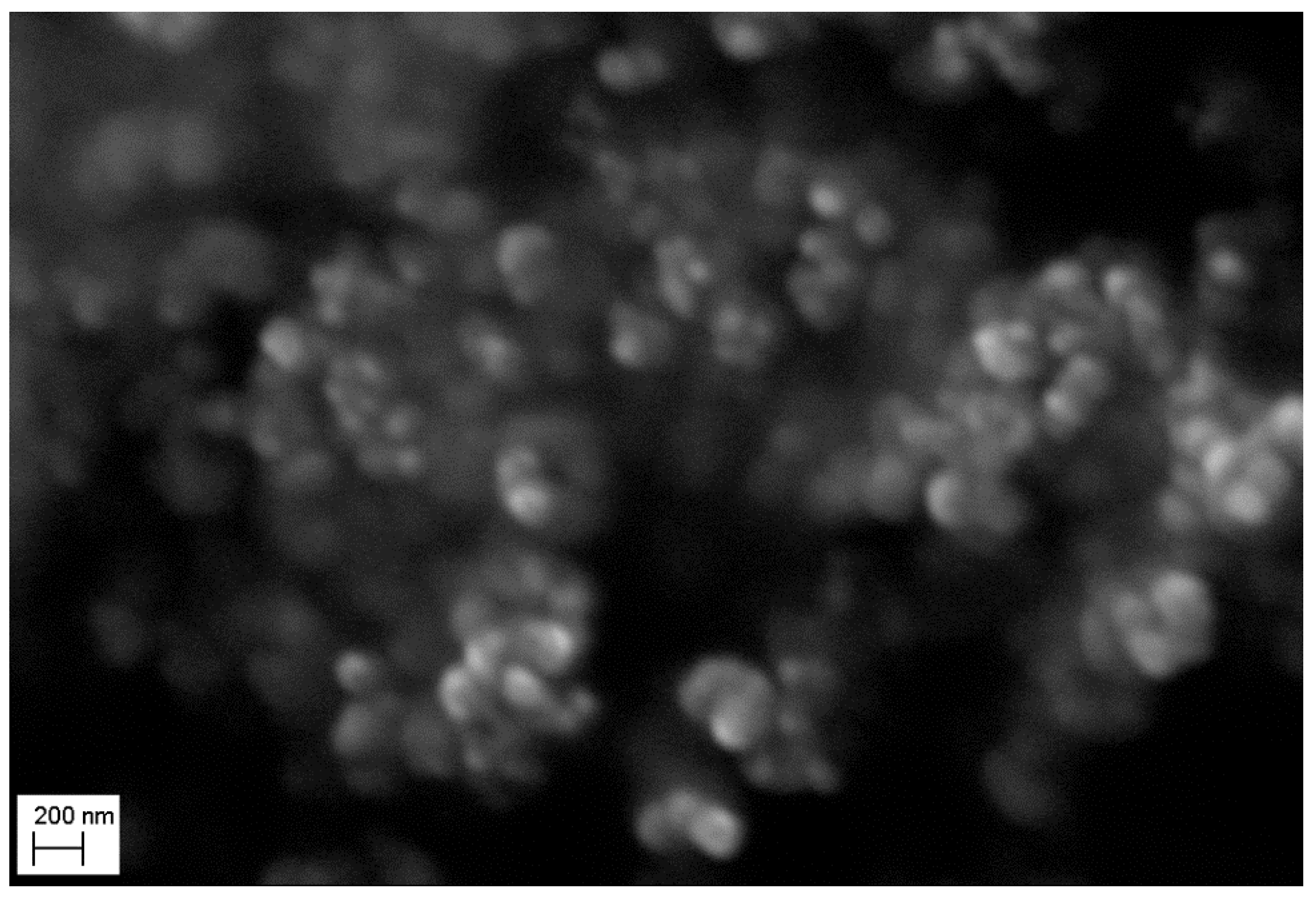

4.1. Nanoparticle Characterization by DLS, XRD, and SEM Analysis

4.2. Nanofluid Characterization

4.2.1. The Thermal Conductivity of the Nanofluids

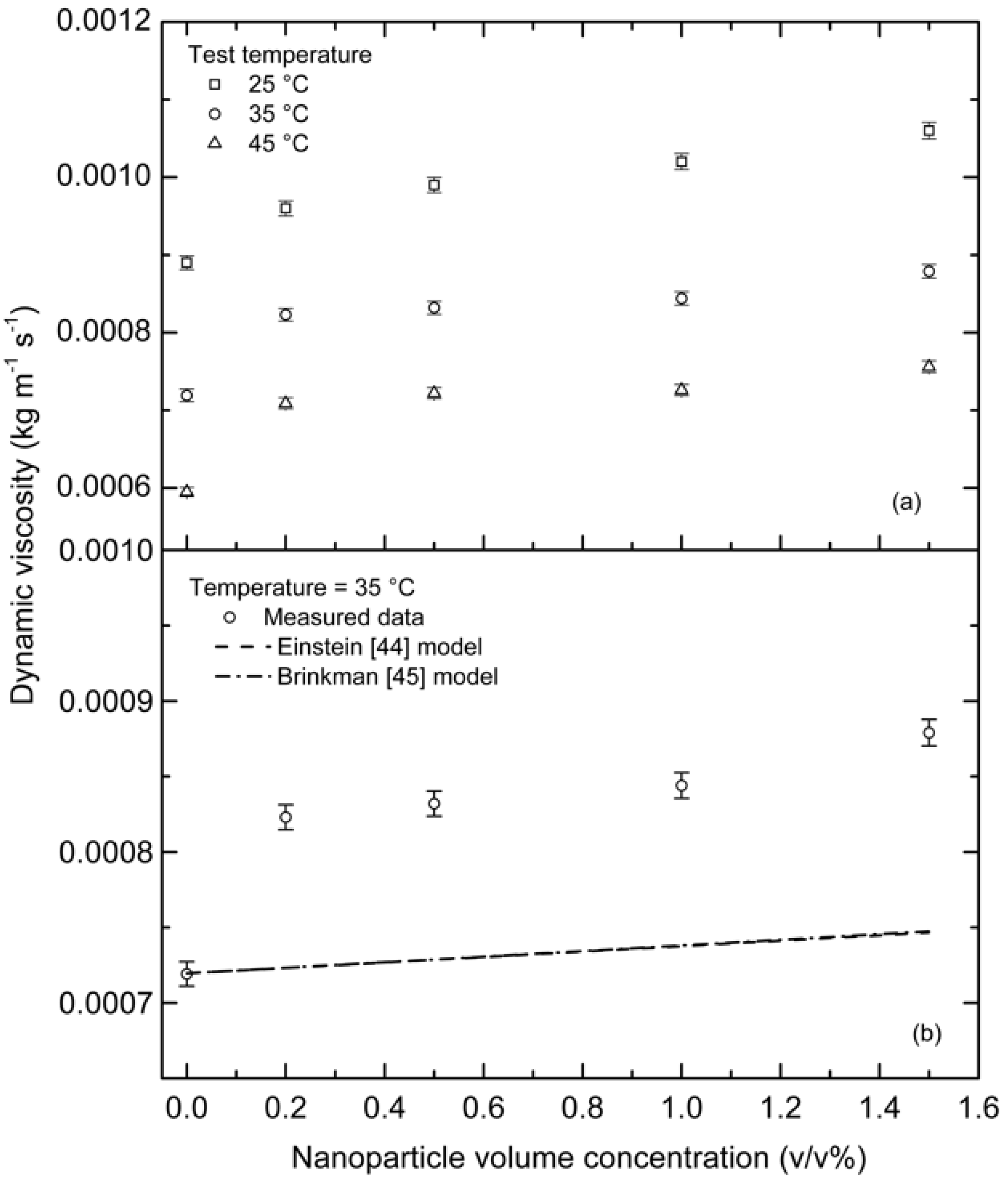

4.2.2. The Dynamic Viscosity of the Nanofluids

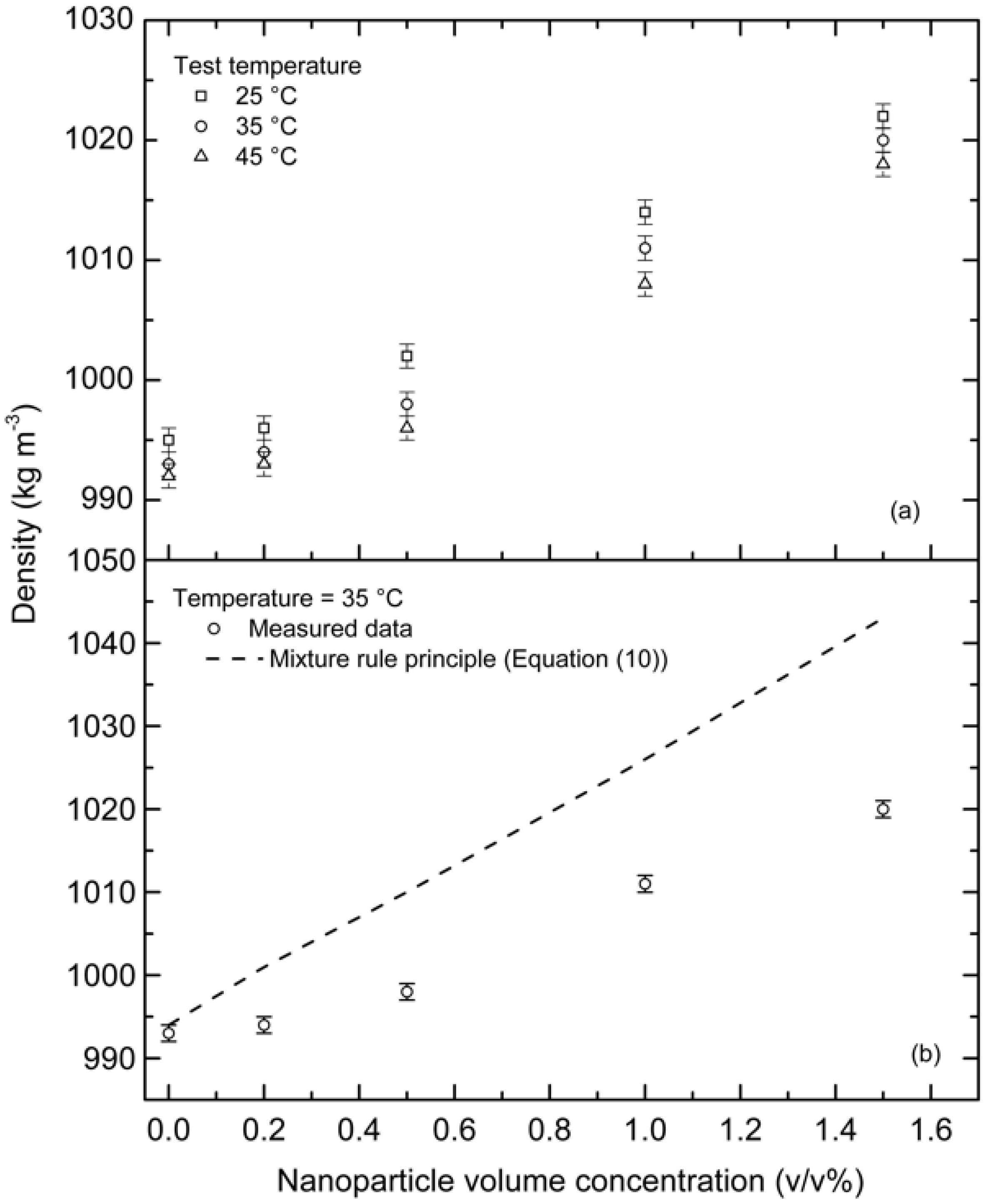

4.2.3. The Density of the Nanofluids

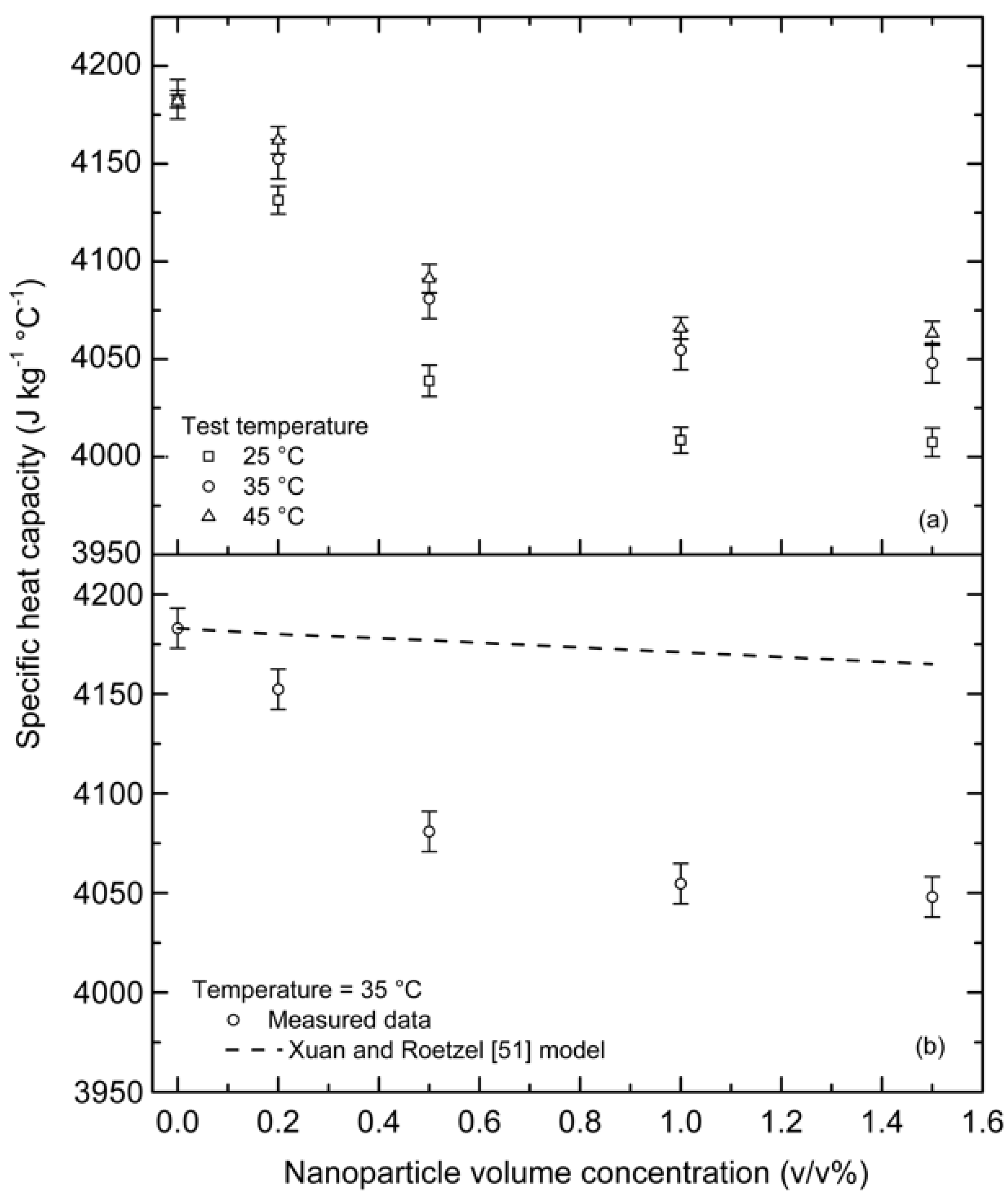

4.2.4. The Specific Heat Capacity of the Nanofluids

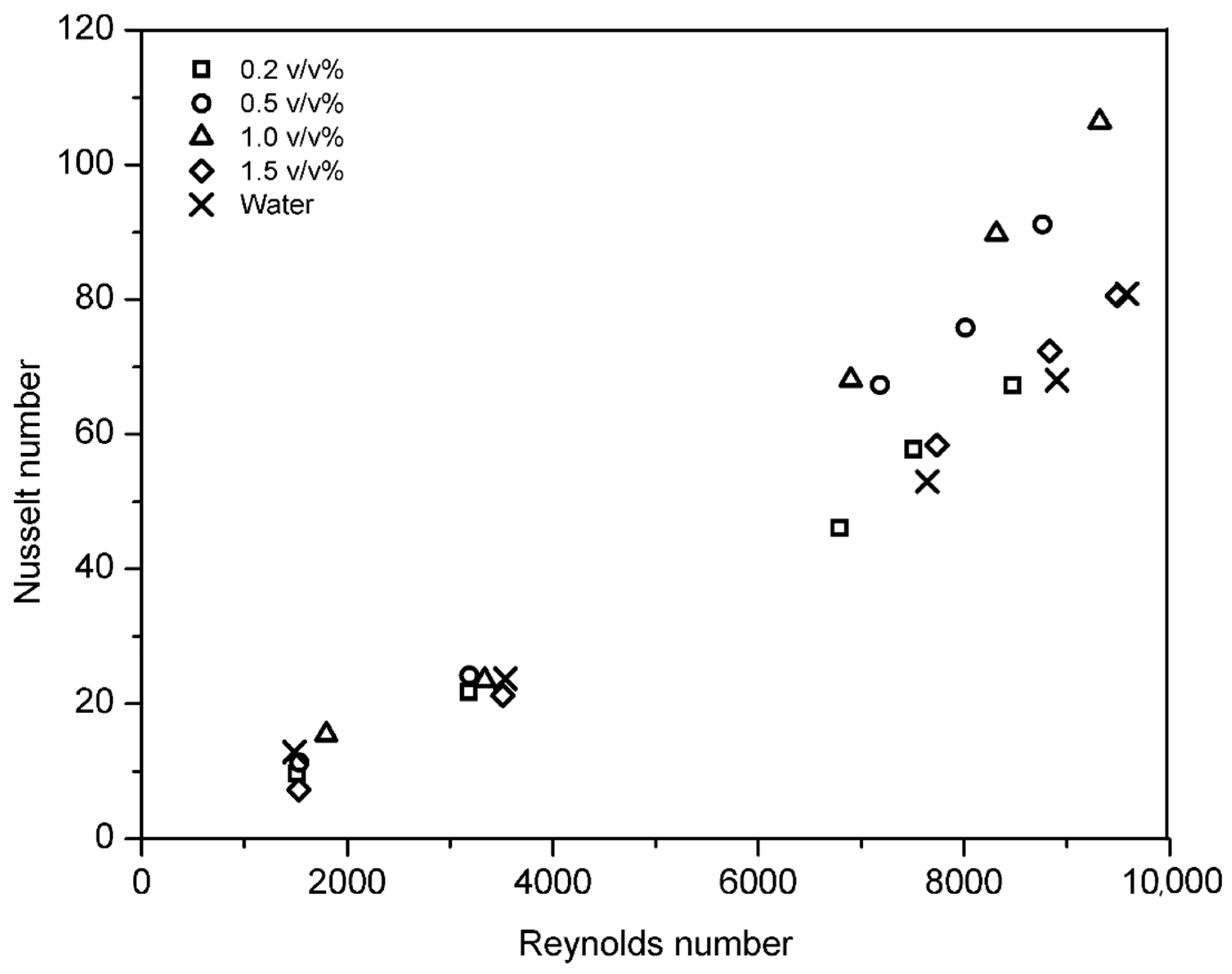

4.3. Forced Convective Heat Transfer Study

4.4. Uncertainty Analysis

5. Conclusions

- ○

- Over particular ranges of NP volume concentrations and Reynolds numbers, the heat transfer was considerably higher in the proposed system than in the base fluid (i.e., water) flowing through the CFI and potentially superior than in water flowing in a helical coiled tube and TiO2–W NFs in a straight tube.

- ○

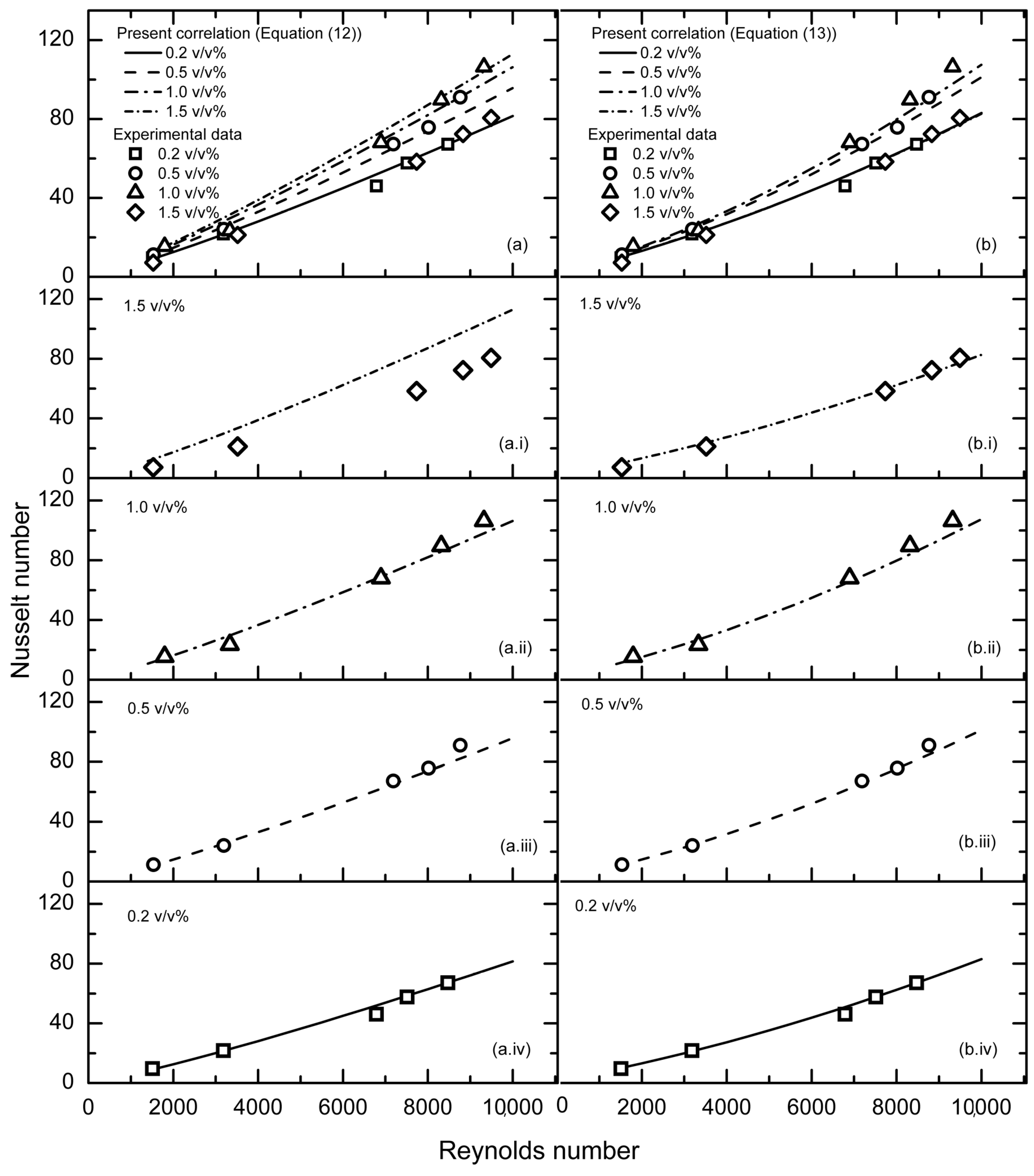

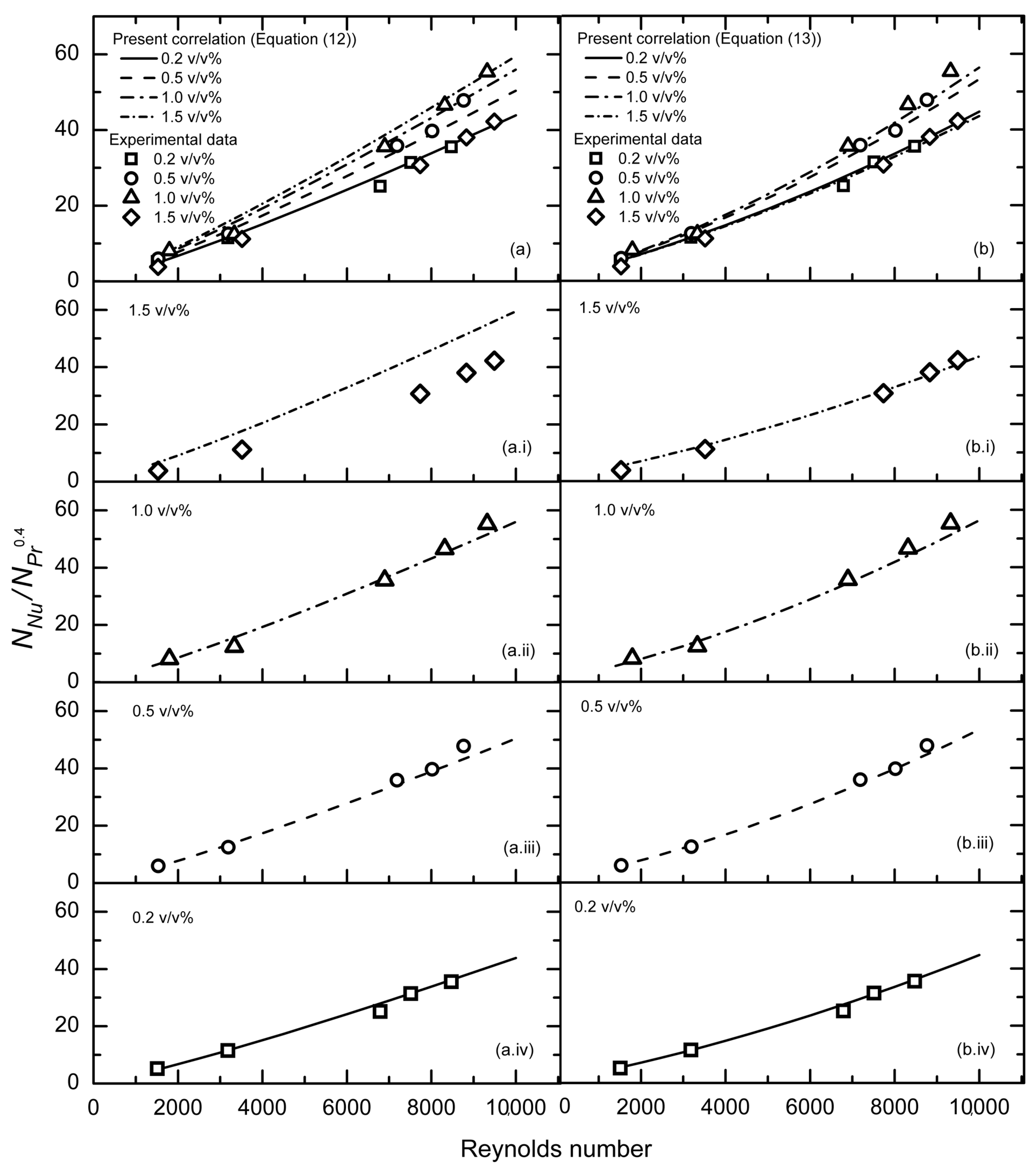

- NP volume concentrations of 0.2, 0.5, 1.0, and 1.5 v/v% were studied at Reynolds numbers ranging from 1400 to 9500. The heat transfer was enhanced in the 6000 ≤ ≤ 9500 and at all NP concentrations, except for 1.5 v/v%. At the latter concentration, it is theorized that the higher viscosity of the NF than that of the base fluid outweighed the thermal conductivity advantage of the NF.

- ○

- The most significant increase of the NF in the CFI was 41–52% relative to water, obtained for the 1.0 v/v% NF in the higher Reynolds number range (i.e., 6000 ≤ ≤ 9500). At lower Reynolds numbers (i.e., 1400 ≤ < 6000), the CFI geometry failed to enhance the heat transfer of the NFs (relative to water) at any concentration.

- ○

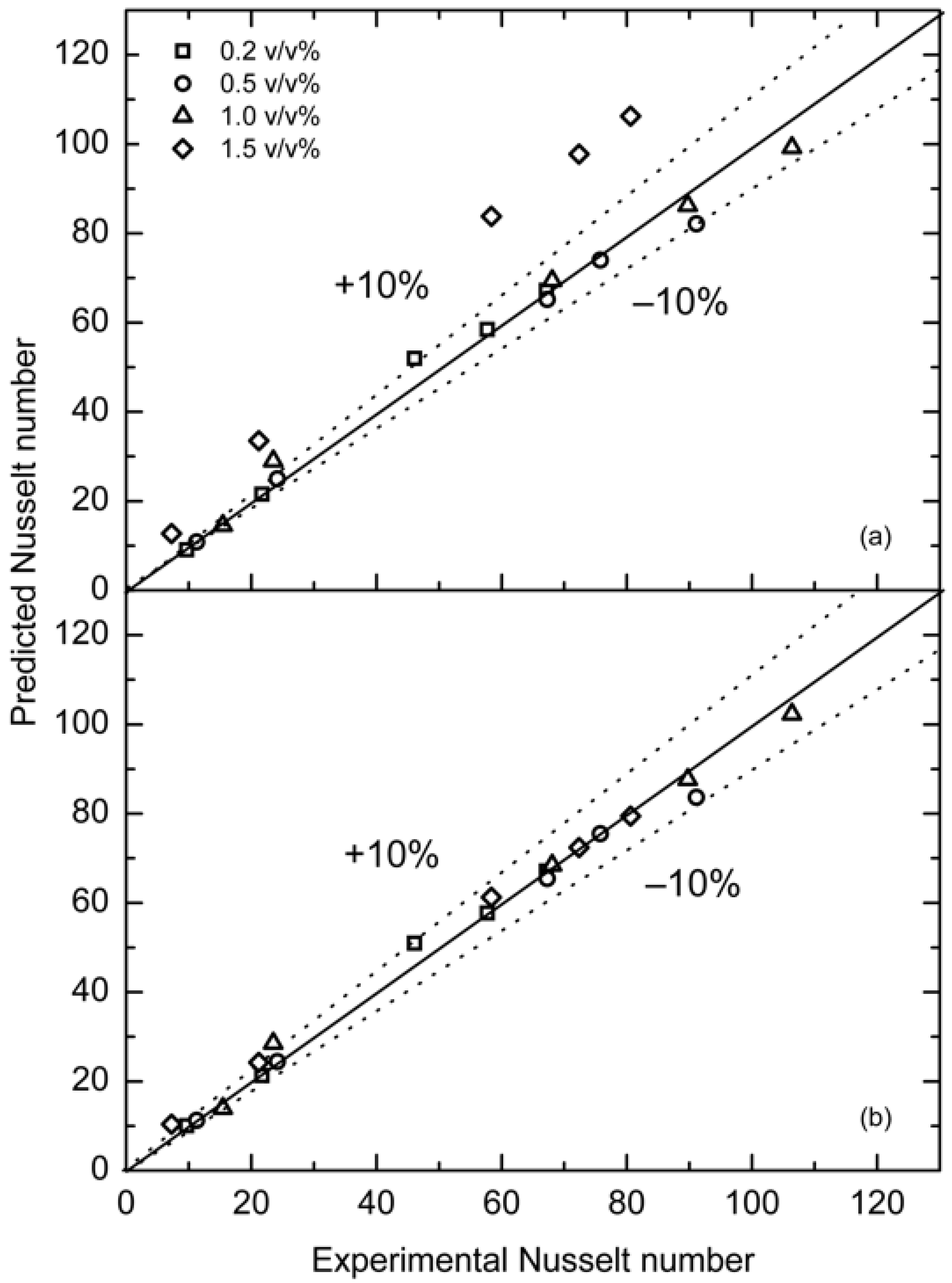

- From the experimental results of the TiO2–W NFs in the CFI, two new empirical equations for prediction were proposed. The correlations are valid in the 1400 ≤ ≤ 9500 range of Reynolds numbers, the 4.5 ≤ ≤ 5.2 range of Prandtl numbers, and NP volume fractions of 0.002 ≤ ϕ ≤ 0.010 and 0.002 ≤ ϕ ≤ 0.015. The latter was built using previous theoretical findings for CFI, and the enhancement was added considering the limiting effect of having excess NPs.

- ○

- The physical and transport properties of the TiO2–W NFs were measured experimentally in the concentration domain of 0.2–1.5 v/v% and with temperature varied from 25 to 45 °C. The experimental results indicated that the classical theoretical models to estimate the thermophysical properties of NFs do not accurately predict the data for the TiO2–W NFs used in this study.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| external surface area of heat exchange (m2) | |

| specific heat capacity (of working fluid) (J kg−1 °C−1) | |

| inner diameter of the tube (m) | |

| outer diameter of the tube (m) | |

| coil diameter (m) | |

| convective heat transfer coefficient (W m−2 °C−1) | |

| thermal conductivity (of working fluid) (W m−1 °C−1) | |

| thermal conductivity of the tube in the test section (W m−1 °C−1) | |

| length of the tube in the test section (m) | |

| mass flow rate of working fluid (kg s−1) | |

| empirical shape factor of nanoparticles | |

| Dean number | |

| Nusselt number | |

| Peclet number | |

| Prandtl number | |

| Reynolds number | |

| ppm | parts per million |

| heat transfer rate (W) | |

| bulk fluid temperature at the inlet (°C) | |

| – | bulk fluid temperatures at the intermediate points along the test section (°C) |

| bulk fluid temperature at the outlet (°C) | |

| temperature of the heating bath water (°C) | |

| temperature difference at the inlet (°C) | |

| temperature difference at the outlet (°C) | |

| logarithmic mean temperature difference (°C) | |

| overall heat transfer coefficient (W m−2 °C−1) | |

| uncertainty in a calculated quantity | |

| inlet velocity (m s−1) | |

| v/v% | volume percent concentration (%) |

| w/w% | weight percent concentration (%) |

| a measured quantity for Equation (16) | |

| uncertainty in a measured quantity |

Subscripts

| base fluid | |

| inner | |

| nanofluid | |

| nanoparticle | |

| outer |

Greek Symbols

| ,, | constants in Equation (13) |

| λ | curvature ratio |

| dynamic viscosity (kg m−1 s−1) | |

| density (kg m−3) | |

| ϕ | volume fraction of nanoparticles |

| nanoparticles volume fraction enhancement limit for the present study ( = 0.015) | |

| sphericity of nanoparticle |

Acronyms

| CFI | coiled flow inverter |

| DLS | dynamic light scattering |

| EG | ethylene glycol |

| GNP | graphene nanoplate |

| HVAC-R | heating, ventilation, air conditioning, and refrigeration |

| ICSD | inorganic crystal structure database |

| LPM | liters per minute |

| MWCNT | multi-walled carbon nanotube |

| NF(s) | nanofluid(s) |

| NP(s) | nanoparticle(s) |

| PALS | phase analysis light scattering |

| PHE | plate and frame heat exchanger |

| PTFE | polytetrafluoroethylene |

| PVC | polyvinyl chloride |

| SEM | scanning electronic microscopy |

| STHE | shell and tube heat exchanger |

| XRD | X-ray diffraction |

| W | water |

References

- Bergles, A.E. Techniques to enhance heat transfer. In Handbook of Heat Transfer, 3rd ed.; McGraw-Hill: New York, NY, USA, 1998; pp. 11.1–11.76. [Google Scholar]

- Sheikholeslami, M.; Gorji-Bandpy, M.; Ganji, D. Review of heat transfer enhancement methods: Focus on passive methods using swirl flow devices. Renew. Sustain. Energy Rev. 2015, 49, 444–469. [Google Scholar] [CrossRef]

- Choi, S.U.S. Enhancing thermal conductivity of fluid with nanoparticles. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, ASME, San Francisco, CA, USA, 12–17 November 1995; pp. 99–105. [Google Scholar]

- Yu, W.; France, D.M.; Routbort, J.L.; Choi, S.U.S. Review and Comparison of Nanofluid Thermal Conductivity and Heat Transfer Enhancements. Heat Transf. Eng. 2008, 29, 432–460. [Google Scholar] [CrossRef]

- Fotukian, S.M.; Esfahany, M.N. Experimental investigation of turbulent convective heat transfer of dilute γ-Al2O3/water nanofluid inside a circular tube. Int. J. Heat Fluid Flow 2010, 31, 606–612. [Google Scholar] [CrossRef]

- Ravi Kumar, N.T.; Bhramara, P.; Addis, B.M.; Sundar, L.S.; Singh, M.K.; Sousa, A.C.M. Heat transfer, friction factor and effectiveness analysis of Fe3O4/water nanofluid flow in a double pipe heat exchanger with return bend. Int. Commun. Heat Mass Transf. 2017, 81, 155–163. [Google Scholar] [CrossRef]

- Qi, C.; Luo, T.; Liu, M.; Fan, F.; Yan, Y. Experimental study on the flow and heat transfer characteristics of nanofluids in double-tube heat exchangers based on thermal efficiency assessment. Energy Convers. Manag. 2019, 197, 111877. [Google Scholar] [CrossRef]

- Kumar, N.; Sonawane, S.S. Experimental study of Fe2O3/water and Fe2O3/ethylene glycol nanofluid heat transfer enhancement in a shell and tube heat exchanger. Int. Commun. Heat Mass Transf. 2016, 78, 277–284. [Google Scholar] [CrossRef]

- Shahrul, I.M.; Mahbubul, I.M.; Saidur, R.; Khaleduzzaman, S.S.; Sabri, M.F.M.; Rahman, M.M. Effectiveness Study of a Shell and Tube Heat Exchanger Operated with Nanofluids at Different Mass Flow Rates. Numer. Heat Transfer Part A Appl. 2014, 65, 699–713. [Google Scholar] [CrossRef]

- Kumar, V.; Tiwari, A.K.; Ghosh, S.K. Effect of variable spacing on performance of plate heat exchanger using nanofluids. Energy 2016, 114, 1107–1119. [Google Scholar] [CrossRef]

- Behrangzade, A.; Heyhat, M. The effect of using nano-silver dispersed water based nanofluid as a passive method for energy efficiency enhancement in a plate heat exchanger. Appl. Therm. Eng. 2016, 102, 311–317. [Google Scholar] [CrossRef]

- Khoshvaght-Aliabadi, M.; Jafari, A.; Sartipzadeh, O.; Salami, M. Thermal–hydraulic performance of wavy plate-fin heat exchanger using passive techniques: Perforations, winglets, and nanofluids. Int. Commun. Heat Mass Transf. 2016, 78, 231–240. [Google Scholar] [CrossRef]

- Strandberg, R.; Das, D.K. Finned tube performance evaluation with nanofluids and conventional heat transfer fluids. Int. J. Therm. Sci. 2010, 49, 580–588. [Google Scholar] [CrossRef]

- Li, J.; Kleinstreuer, C. Thermal performance of nanofluid flow in microchannels. Int. J. Heat Fluid Flow 2008, 29, 1221–1232. [Google Scholar] [CrossRef]

- Osman, S.; Sharifpur, M.; Meyer, J.P. International Journal of Heat and Mass Transfer Experimental investigation of convection heat transfer in the transition flow regime of aluminium oxide-water nanofluids in a rectangular channel. Int. J. Heat Mass Transf. 2019, 133, 895–902. [Google Scholar] [CrossRef]

- Rainieri, S.; Bozzoli, F.; Cattani, L.; Pagliarini, G. Compound convective heat transfer enhancement in helically coiled wall corrugated tubes. Int. J. Heat Mass Transf. 2013, 59, 353–362. [Google Scholar] [CrossRef]

- Srinivas, T.; Vinod, A.V. Heat transfer intensification in a shell and helical coil heat exchanger using water-based nanofluids. Chem. Eng. Process. Process Intensif. 2016, 102, 1–8. [Google Scholar] [CrossRef]

- Bahrehmand, S.; Abbassi, A.; Bahremand, H. Heat transfer and performance analysis of nanofluid flow in helically coiled tube heat exchangers. Chem. Eng. Res. Des. 2016, 109, 628–637. [Google Scholar] [CrossRef]

- Mokrani, A.; Castelain, C.; Peerhossaini, H. The effects of chaotic advection on heat transfer. Int. J. Heat Mass Transf. 1997, 40, 3089–3104. [Google Scholar] [CrossRef]

- Acharya, N.; Sen, M.; Hsueh-Chia, C. Heat transfer enhancement in coiled tubes by chaotic mixing. Int. J. Heat Mass Transf. 1992, 35, 2475–2489. [Google Scholar] [CrossRef]

- Saxena, A.K.; Nigam, K.D.P. Coiled configuration for flow inversion and its effect on residence time distribution. AIChE J. 1984, 30, 363–368. [Google Scholar] [CrossRef]

- Kumar, V.; Mridha, M.; Gupta, A.; Nigam, K.D. Coiled flow inverter as a heat exchanger. Chem. Eng. Sci. 2007, 62, 2386–2396. [Google Scholar] [CrossRef]

- Mandal, M.; Kumar, V.; Nigam, K. Augmentation of heat transfer performance in coiled flow inverter vis-à-vis conventional heat exchanger. Chem. Eng. Sci. 2010, 65, 999–1007. [Google Scholar] [CrossRef]

- Singh, J.; Nigam, K. Pilot plant study for effective heat transfer area of coiled flow inverter. Chem. Eng. Process. Process Intensif. 2016, 102, 219–228. [Google Scholar] [CrossRef]

- Kumar, V.; Nigam, K. Numerical simulation of steady flow fields in coiled flow inverter. Int. J. Heat Mass Transf. 2005, 48, 4811–4828. [Google Scholar] [CrossRef]

- Kumar, V.; Nigam, K. Laminar convective heat transfer in chaotic configuration. Int. J. Heat Mass Transf. 2007, 50, 2469–2479. [Google Scholar] [CrossRef]

- Mridha, M.; Nigam, K. Numerical study of turbulent forced convection in coiled flow inverter. Chem. Eng. Process. Process Intensif. 2008, 47, 893–905. [Google Scholar] [CrossRef]

- Singh, J.; Choudhary, N.; Nigam, K.D. The thermal and transport characteristics of nanofluids in a novel three-dimensional device. Can. J. Chem. Eng. 2014, 92, 2185–2201. [Google Scholar] [CrossRef]

- Tohidi, A.; Ghaffari, H.; Nasibi, H.; Mujumdar, A. Heat transfer enhancement by combination of chaotic advection and nanofluids flow in helically coiled tube. Appl. Therm. Eng. 2015, 86, 91–105. [Google Scholar] [CrossRef]

- Bashirnezhad, K.; Ghavami, M.; Alrashed, A.A. Experimental investigations of nanofluids convective heat transfer in different flow regimes: A review. J. Mol. Liq. 2017, 244, 309–321. [Google Scholar] [CrossRef]

- Yang, L.; Hu, Y. Toward TiO2 Nanofluids—Part 1: Preparation and Properties. Nanoscale Res. Lett. 2017, 12, 417. [Google Scholar] [CrossRef]

- ASTM E1269-11. Standard Test Method for Determining Specific Heat Capacity by Differential Scanning Calorimetry; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Vashisth, S.; Nigam, K. Experimental investigation of void fraction and flow patterns in coiled flow inverter. Chem. Eng. Process. Process. Intensif. 2008, 47, 1281–1297. [Google Scholar] [CrossRef]

- White, F.M. Heat Transfer, 1st ed.; Addison-Wesley Publishing Company Inc.: New York, NY, USA, 1984. [Google Scholar]

- Kakac, S.; Yener, Y.; Pramuanjaroenkij, A. Enhancement of Convective Heat Transfer with Nanofluids. In Convective Heat Transfer, 3rd ed.; Taylor & Francis Group; CRC Press: Boca Raton, FL, USA, 2014; pp. 517–560. [Google Scholar]

- Qiu, L.; Zhu, N.; Feng, Y.; Michaelides, E.E.; Żyła, G.; Jing, D.; Zhang, X.; Norris, P.M.; Markides, C.N.; Mahian, O. A review of recent advances in thermophysical properties at the nanoscale: From solid state to colloids. Phys. Rep. 2020, 843, 1–81. [Google Scholar] [CrossRef]

- Viswanatha, K.; Seshu, S.; Vandrangi, K.; Snoussi, L. Influence of nanofluid properties on turbulent forced convection heat transfer in different base liquids. Math. Methods Appl. Sci. 2020, 1–22. [Google Scholar] [CrossRef]

- Maxwell, J.C. A Treatise on Electricity and Magnetism, 2nd ed.; Oxford Univ. Press: Oxford, UK, 1904. [Google Scholar]

- Hamilton, R.L.; Crosser, O.K. Thermal Conductivity of Heterogeneous Two-Component Systems. Ind. Eng. Chem. Fundam. 1962, 1, 187–191. [Google Scholar] [CrossRef]

- Wasp, E.J. Solid-Liquid Flow Slurry Pipeline Transportation; Trans. Tech Publications: Berlin, Germany, 1977. [Google Scholar]

- Bruggeman, D.A.G. Berechnung verschiedener physikalischer kkonstanten von heterogenen ssubstanzen. Ann. Phys. 1935, 24, 636–664. [Google Scholar] [CrossRef]

- Timofeeva, E.V.; Gavrilov, A.N.; McCloskey, J.M.; Tolmachev, Y.; Sprunt, S.; Lopatina, L.M.; Selinger, J.V. Thermal conductivity and particle agglomeration in alumina nanofluids: Experiment and theory. Phys. Rev. E 2007, 76, 061203. [Google Scholar] [CrossRef] [PubMed]

- Murshed, S.M.S.; Leong, K.C.; Yang, C. Enhanced thermal conductivity of TiO2—Water based nanofluids. Int. J. Therm. Sci. 2005, 44, 367–373. [Google Scholar] [CrossRef]

- Einstein, A. Calculation of the viscosity-coefficient of a liquid in which a large number of small spheres are suspended in irregular distribution. Ann. Phys. 1906, 324, 289–306. [Google Scholar] [CrossRef]

- Brinkman, H. The viscosity of concentrated suspensions and solutions. J. Chem. Phys. 1952, 20, 571–581. [Google Scholar] [CrossRef]

- He, Y.; Jin, Y.; Chen, H.; Ding, Y.; Cang, D.; Lu, H. Heat transfer and flow behaviour of aqueous suspensions of TiO2 nanoparticles (nanofluids) flowing upward through a vertical pipe. Int. J. Heat Mass Transf. 2007, 50, 2272–2281. [Google Scholar] [CrossRef]

- Murshed, S.M.S.; Leong, K.; Yang, C. Investigations of thermal conductivity and viscosity of nanofluids. Int. J. Therm. Sci. 2008, 47, 560–568. [Google Scholar] [CrossRef]

- Khanafer, K.; Vafai, K. A critical synthesis of thermophysical characteristics of nanofluids. Int. J. Heat Mass Transf. 2011, 54, 4410–4428. [Google Scholar] [CrossRef]

- Said, Z.M.; Sajid, H.; Kamyar, A.; Saidur, R. Experimental investigation on the stability and density of TiO2, Al2O3, SiO2 and TiSiO4. In Proceedings of the IOP Conference Series: Earth and Environmental Science (16), IOP Publishing Ltd., Putrajaya, Malaysia, 5–6 March 2013; p. 012002. [Google Scholar]

- Vajjha, R.; Das, K. Specific Heat Measurement of Three Nanofluids and Development of New Correlations. J. Heat Transf. 2009, 131, 071601. [Google Scholar] [CrossRef]

- Xuan, Y.; Roetzel, W. Conceptions for heat transfer correlation of nanofluids. Int. J. Heat Mass Transf. 2000, 43, 3701–3707. [Google Scholar] [CrossRef]

- Saeedinia, M.; Akhavan-Behabadi, M.A.; Razi, P. Thermal and rheological characteristics of CuO–Base oil nanofluid flow inside a circular tube. Int. Commun. Heat Mass Transf. 2012, 39, 152–159. [Google Scholar] [CrossRef]

- Akilu, S.; Baheta, A.T.; Sharma, K.V.; Said, M.A. Experimental determination of nanofluid specific heat with SiO2 nanoparticles in different base fluids. In Proceedings of the AIP Conference Proceedings (1877), American Institute of Physics Inc., Langkawi, Malaysia, 9–11 November 2016. 090001. [Google Scholar]

- Duangthongsuk, W.; Wongwises, S. An experimental study on the heat transfer performance and pressure drop of TiO2-water nanofluids flowing under a turbulent flow regime. Int. J. Heat Mass Transf. 2010, 53, 334–344. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Z.G.; Grulke, E.A.; Anderson, W.B.; Wu, G. Heat transfer properties of nanoparticle-in-fluid dispersions (nanofluids) in laminar flow. Int. J. Heat Mass Transf. 2005, 48, 1107–1116. [Google Scholar] [CrossRef]

- Shchukin, V.K. Correlation for experimental data on heat transfer in curved pipes. Therm. Eng. 1969, 16, 72–76. [Google Scholar]

- Taylor, B.N.; Kuyatt, C.E. Guidelines for Evaluating and Expressing the Uncertainty of NIST Measurement Results; National Institute of Standards and Technology Technical Note 1297; National Institute of Standards and Technology: Gaithersburg, MD, USA, 1994.

| Parameters | Value |

|---|---|

| TiO2 volume concentration (v/v%) | 0.2–1.5 |

| Reynolds number range | 1400–9500 |

| Working fluid inlet temperature (°C) | 18–32 |

| Heating bath water (°C) | 70 |

| NP Volume Concentration in TiO2–W NFs | Constants | ||

|---|---|---|---|

| 0.002 ≤ ϕ ≤ 0.015 | |||

| 0.000783 | 0.8933 | 0.24 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arevalo-Torres, B.; Lopez-Salinas, J.L.; García-Cuéllar, A.J. Experimental Study of Forced Convective Heat Transfer in a Coiled Flow Inverter Using TiO2–Water Nanofluids. Appl. Sci. 2020, 10, 5225. https://doi.org/10.3390/app10155225

Arevalo-Torres B, Lopez-Salinas JL, García-Cuéllar AJ. Experimental Study of Forced Convective Heat Transfer in a Coiled Flow Inverter Using TiO2–Water Nanofluids. Applied Sciences. 2020; 10(15):5225. https://doi.org/10.3390/app10155225

Chicago/Turabian StyleArevalo-Torres, Barbara, Jose L. Lopez-Salinas, and Alejandro J. García-Cuéllar. 2020. "Experimental Study of Forced Convective Heat Transfer in a Coiled Flow Inverter Using TiO2–Water Nanofluids" Applied Sciences 10, no. 15: 5225. https://doi.org/10.3390/app10155225

APA StyleArevalo-Torres, B., Lopez-Salinas, J. L., & García-Cuéllar, A. J. (2020). Experimental Study of Forced Convective Heat Transfer in a Coiled Flow Inverter Using TiO2–Water Nanofluids. Applied Sciences, 10(15), 5225. https://doi.org/10.3390/app10155225