Abstract

Enhanced quality and reduced on-site construction time are the basic features of prefabricated bridge elements and systems. Prefabricated lightweight bridge decks have already started finding their place in accelerated bridge construction (ABC). Therefore, the development of deck panels using high strength and high performance concrete has become an active area of research. Further optimization in such deck systems is possible using prestressing or replacement of raw materials with sustainable and recyclable materials. This research involves experimental evaluation of six full-depth precast prestressed high strength fiber-reinforced concrete (HSFRC) and six partial-depth sustainable ultra-high performance concrete (sUHPC) composite bridge deck panels. The composite panels comprise UHPC prepared with ground granulated blast furnace slag (GGBS) with the replacement of 30% cement content overlaid by recycled aggregate concrete made with replacement of 30% of coarse aggregates with recycled aggregates. The experimental variables for six HSFRC panels were depth, level of prestressing, and shear reinforcement. The six sUHPC panels were prepared with different shear and flexural reinforcements and sUHPC-normal/recycled aggregate concrete interface. Experimental results exhibit the promise of both systems to serve as an alternative to conventional bridge deck systems.

1. Introduction

Replacement of traditional cast-in-place concrete bridge decks is time demanding and causes long delays in traffic movement [1,2]. Such constraints make the decisions of replacing the worn-out decks more difficult and cause loss of interest in the expansion of bridges [3]. This problem is more pronounced in densely populated urban areas. Therefore, there is a need to develop such deck systems, which can make the process of replacement and new construction quick and safe. Such systems should satisfy not only the strength requirements but also have the flexibility to fit in the existing bridge superstructures.

Prefabricated bridge deck panels are becoming increasingly popular because of their accelerated construction, reduced requirement of on-site labor, and shorter traffic disruption. For example, over 10 years, the application of prefabricated bridge decking in the United States increased by 25% with 49,043 bridges in 2007 to 61,416 bridges in 2016 [4]. Several researchers like Saleem et al. [5], Ghasemi et al. [6], Al-Ramahee et al. [3] have proposed precast bridge systems developed with ultra-high performance concrete (UHPC), high strength steel (HSS), and fiber-reinforced polymers (FRP). First developed in France in the 1990s [7], UHPC comprises of steel fibers, silica fumes, ground quartz, and superplasticizer, in addition to cement and sand [8,9]. It has no coarse aggregate. In comparison to regular concrete, UHPC has high flowability, high resistance to cracking, very low permeability, and low shrinkage/creep properties [10]. The minimum compressive strength is more than 150 MPa, and good tensile strength exceeds 5 MPa. The modulus of elasticity crosses 46 GPa [11,12]. A low-profile asymmetric waffle deck system was developed by Saleem et al. [5] using UHPC and HSS. The self-weight of this system was 1.55 kN/m2, which was further optimized to 1.0 kN/m2 by Ghasemi et al. [6]. These systems were tested with single and multiple ribs, both in simple-span and two-span configurations. Static and dynamic testing proved their potential and feasibility to replace the conventional bridge decks for fixed and moveable bridges. Ghasemi et al. [13], for the first time, combined UHPC with carbon fiber reinforced polymer (CFRP) rebars to develop waffle bridge deck panels. The idea was to offset the brittle behavior of CFRP with the ductile nature of UHPC. The study confirmed that with only 102 mm overall depth and self-weight of 0.9 kN/m2, the deck panels meet the strength and serviceability requirements for a stringer spacing of 1.2 m. Al-Ramahee et al. [3] developed precast deck panels by combining UHPC with FRP laminates. No reinforcement in the form of rebars was used. With an overall depth of 127 mm and self-weight of 0.5–0.6 kN/m2, the system met the strength and serviceability requirement (∆all = L/800) of AASHTO LRFD [14]. UHPC materials have also been used in other bridge-related applications, such as serving as the bonding material for precast prestressed concrete bridge girders [15]. It was concluded that UHPC connections with short, straight rebar provided considerable resistance to separation and transferred the load effectively under seismic condition. In another study, UHPC material was used to provide the longitudinal connection between lightweight bridge decks and steel beams to form composite bridge girder [16]. The T-shape connections proved to perform better than the traditional connection due to the better control of crack width.

Attempts have also been made to introduce environmentally friendly materials in bridge deck applications. For instance, Venancio [17] tested half-scale partial-depth precast bridge deck panels developed with sustainable UHPC. Quartz powder as a whole and a fraction of fine sand content were replaced with ground granulated blast furnace slag (GGBS). UHPC panels were tested in flexure and shear, and comparison was made with reinforced concrete control panels. Panels were prepared with 51 and 76 mm depths. UHPC with conventional mild-steel reinforcement achieved the highest ultimate load. UHPC panels tested under shear configuration also failed in flexure, demonstrating excellent performance under shear force.

Another way to increase the sustainability of UHPC material is by introducing coarse aggregates. Coarse aggregates have been used in various concretes to enhance the economic and technical advantages of the cementitious products [18,19,20], and their long-term performance has been verified [21]. Prior research also demonstrated that the UHPC material with coarse aggregate and 2% volume fraction of steel fiber could provide as much as 5.5 times of shear resistance of the conventional RC beams with the same size and configuration [22]. The flexural failure of beams made of UHPC with coarse aggregate failed in a ductile manner, and it was found out that the maximum aggregate size of 5 or 8 mm has no significant impact on its structural behavior. At the same time, the longitudinal reinforcement ratios control the stiffness and ultimate strength of the beam [23]. Using recycled aggregate to produce sustainable ultra-high-performance concrete (sUHPC) can further enhance the sustainability of the material. Recycled aggregates have been used for paving blocks to enhance sustainability [20]. It was proved that using RCA can reduce the strength of the concrete block, and adding GGBS can help partially recover the strength loss. Introducing recycled aggregate in UHPC material can help reduce both the usage of cement and virgin aggregate.

Optimization in design is another aspect of precast deck panels, which can lead to improved service. One way to achieve this is to use prestressing. This combination of high-strength or fiber reinforced concrete with prestressing has excellent potential in bridge deck applications because not only can it decrease the self-weight of the deck system by reducing the thickness, but also offers other advantages such as less maintenance, improved durability, reduced crack width, and high tensile strength.

Limited research is available on the application of combining prestressing with the application of sustainable high strength fiber reinforced concrete in the development of bridge deck panels. With this background, the primary objective of this research was to develop and characterize different configurations of full-depth precast prestressed high strength concrete—with and without fibers—bridge deck panels, and partial-depth precast sustainable ultra-high performance concrete (sUHPC)-normal/recycled aggregate concrete bridge deck panels. The collective efforts aimed to explore different optimization methods considering reduced self-weight and increased sustainability while focusing first on their conformation to the existing design standards.

2. Experimental Work

Experimental work was carried out in two phases. The first phase consisted of testing six prestressed deck panels and the second phase consisted of testing of six partial-depth precast non-prestressed sUHPC deck panels. Table 1 presents the test matrix of the entire stock of specimens, as well as some specimens from prior research programmes.

Table 1.

Test matrix and specimen details.

Five types of reinforcement were listed in Table 1: Type A is high strength steel rebar with yielding strength of 690 MPa and ultimate strength 1030 MPa; Type B and Type C are #10 and #13 carbon fiber reinforced plastic rebar, respectively, with ultimate tensile strength equal 2172 and 2068 MPa. Type D is the prestressing steel strand with yielding strength of 416 MPa and ultimate strength of 1380 MPa; Type E is the normal strength steel rebar with yielding strength of 250 MPa.

Prestressed deck panels were divided into three groups, with two identical specimens in each group. The first group consisted of two high strength concrete (HSC) panels, which had no steel fibers and coarse aggregates but included conventional shear reinforcement (#10-s:75 mm c/c). The flexural reinforcement comprised of 5.5 mm dia. high-strength steel wires. The second group consisted of prestressed high strength fiber reinforced concrete (HSFRC) deck panels with no shear reinforcement and having 2% steel fibers by volume. The third group was optimized prestressed HSFRC (O-HSFRC) panels. Optimization was carried out by modifying the thickness of panels and prestressing force. Depth of panels for the first two groups was 127 mm, and for the optimized panels, the depth was reduced to 102 mm. Width for all the panels was fixed as 457 mm. The span length was 1.22 m with prestressing carried out in the direction perpendicular to traffic.

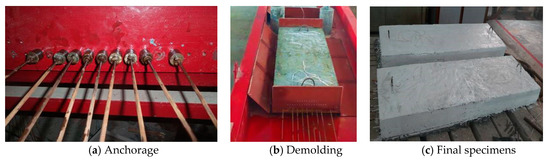

Design of HSFRC deck panels was carried out following the Precast/Prestressed Concrete Institute (PCI) recommended guidelines [24]. Prestressing was carried out using the method of pre-tensioning. Force transfer was carried out on the 28th day of casting, and then the panels were moved to the lab to perform the test, within a week after force transferring. Average concrete strength was 69 MPa with a standard deviation of 4.42 MPa. The ultimate tensile strength of prestressing wires was 1380 MPa. An initial prestressing of 965 MPa was applied. Prestress losses were assumed to be 25% at the preliminary design stage. Deck panel sections were designed to satisfy the allowable stress limits for concrete and steel, both at the mid-span and support sections. The ultimate condition was also checked for the sections. The compressive strength of HSC/HSFRC was obtained by testing three 100 × 200 mm cylinders for each batch. Figure 1 presents some details of specimen preparations.

Figure 1.

Preparation of high strength concrete (HSC)/high strength fiber-reinforced concrete (HSFRC) prestressed deck panels.

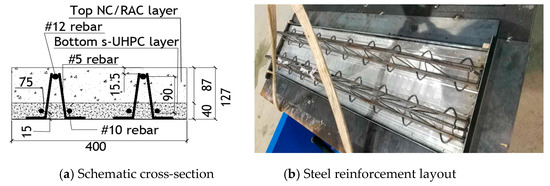

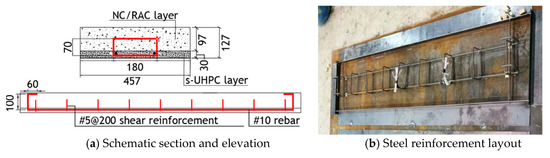

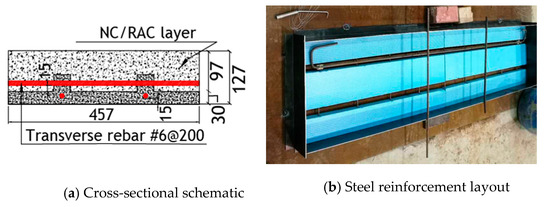

Panels tested in the second phase were also divided into three groups. In each group, one panel had normal aggregate (NA) concrete as the top layer, whereas the other panel had recycled aggregate (RA) concrete as the top layer. All of these panels had an overall depth of 127 mm and a span of 1.52 m. Widths of panels varied between 0.41 and 0.46 m, depending on the reinforcement configurations. The designate Type A-NA represents deck type A with natural aggregate concrete on top of sUHPC. Similarly, Type A-RA denotes deck type A with recycled aggregate concrete on top. Details of geometry, steel fibers volume fraction and reinforcement are provided in Table 1. The cross-sectional and longitudinal configurations of the three types of panels are shown in Figure 2, Figure 3 and Figure 4. Design of sUHPC panels was experimental because no specific guidelines are available for such type of composite concrete deck panels. For deck type A (as shown in Figure 2), the bottom steel plate is stay-in-place welded with the bottom tension reinforcement, inclined continuous shear reinforcement, and compression reinforcement. Conventional shear reinforcement was used in deck type B (as shown in Figure 3). Deck type C as shown in Figure 4 had two 40 × 40 mm sUHPC ribs running in the longitudinal direction. Transverse reinforcement along the width at regular intervals was passed through the ribs to develop the composite connection between two discrete concrete layers. Rebars with the yield strength of 250 MPa were used in all specimens. Compressive strength was determined by testing three 150 × 300 mm cylinders for each concrete type and is reported in Table 1. Reference mix design for UHPC by Graybeal [25] was adopted for the preparation of sUHPC, except that 30% of the cement content was replaced with GGBS. Similarly, in RA concrete, 30% of natural/virgin coarse aggregates were replaced with recycled aggregate. Physical properties of materials for sUHPC are presented in Table 2. Table 3 shows the mix designs for sUHPC, NA/RA concrete.

Figure 2.

Details of deck type A (units in mm).

Figure 3.

Details of deck type B (units in mm).

Figure 4.

Details of deck type C (units in mm).

Table 2.

Constituent material properties for sustainable ultra-high performance concrete (sUHPC).

Table 3.

Mix designs for sUHPC, normal aggregate (NA), and recycled aggregate (RA) concrete.

During casting, sUHPC was introduced from one end of the formwork and was allowed to flow to the other end. Whenever more material was required, it was introduced behind the leading edge of the flowing material. The same casting method was used for all the specimens to maintain similar fiber distribution. The traditional method of moist curing was used. Specimens were sealed with plastic sheets for 28 days to prevent the loss of moisture.

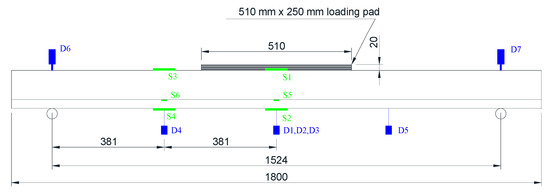

All the deck panels were tested as simple-span against AASHTO HS-20 truck dual-tire wheel with a footprint measuring 510 × 250 mm [14], which was applied using a neoprene pad with the longer side placed perpendicular to traffic direction. A steel plate with size in 50 mm excess on all four sides was placed on top of a neoprene pad to distribute the load over the pad uniformly (Figure 5). Linear variable displacement transducers (LVDT) and strain gauges were installed at strategic locations to acquire the deflection and strain data as shown in Figure 6, in which D and S represent LVDT and strain gauge, respectively. Loading was applied in displacement control mode at a rate of 1 mm/min. All instruments were connected to a high-speed data acquisition system which recorded the data at a frequency of 1 Hz. Tests were stopped at 25% load drop unless preceded by excessive cracking or deflection, which could make the test setup unstable.

Figure 5.

Test setups.

Figure 6.

Instrumentation plan.

3. Sectional Analyses

Sectional analyses were performed to predict the critical moment of the composite section for sUHPC decks. The modulus of elasticity of normal strength concrete (either with or without recycled aggregates) and s-UHPC are estimated to be 20 and 45 GPa, respectively. The compressive strength of normal concrete and sUHPC are assumed to be 26 and 150 MPa, respectively. The modulus of elasticity of steel rebar is set to be 200 GPa, with yielding strength of 250 MPa while the ultimate tensile strength of sUHPC is 10 MPa. By using the material properties and geometries of three types of decks, the location of the neutral axis and the second moment of inertia can be calculated, as shown in Table 4. Based on the elastic analyses, the critical moment corresponding to curvature when the concrete start to crush, the rebar starts to yield, and the sUHPC reaching ultimate tensile strength can be predicted. Plastic section analyses lead to another set of results on the plastic moment by considering the yielding of rebar as the only source of sectional tensile force or consider the contribution from both the rebar and sUHPC. It was found out that the tensile strength of sUHPC makes a big difference regarding the plastic sectional moment, which increases from 8.1 to 22.5 kN·m for deck type A. The summary of the results is listed in Table 4.

Table 4.

Summary of sectional analyses.

4. Results and Discussion

4.1. Summary of the Load Demand and Capacity

Based on the approximate methods of analyses specified in the AASHTO bridge design specification [14], the width of the equivalent interior strip (W) can be calculated based on the spacing of the supporting components (S) as shown in the following Equation (1). For deck strip specimens in phases 1 and 2, the spacings are 1.22 and 1.52 m, respectively, which lead to the equivalent width of W equal to 1331 and 1496 mm. It is assumed that the deck strip with equivalent width will sustain full wheel load under “Strength I” and “Service I” limit states. Therefore, with the wheel load of 71.2 kN, the service load demand is 92.6 after considering the dynamic impact factor of 0.3 and the ultimate load demand is 162.0 kN with same impact factor and the load factor equals 1.75. By dividing the service and ultimate load by the effective width (W), the capacity demand of the unit width of the deck slab can be calculated. Table 5 summarizes the experiment results of deck strips available in the literature as well as those presented in this paper. The deflections under service and ultimate load levels are identified. Experimental ultimate load capacities of each deck strip were compared to the target load demand to calculate the capacity versus demand ratio. The unified capacity versus demand ratio based on the self-weight is also listed as the last column for an intuitive indicator of the effectiveness of the design.

Table 5.

Summary of testing results.

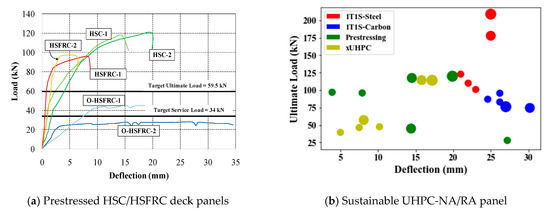

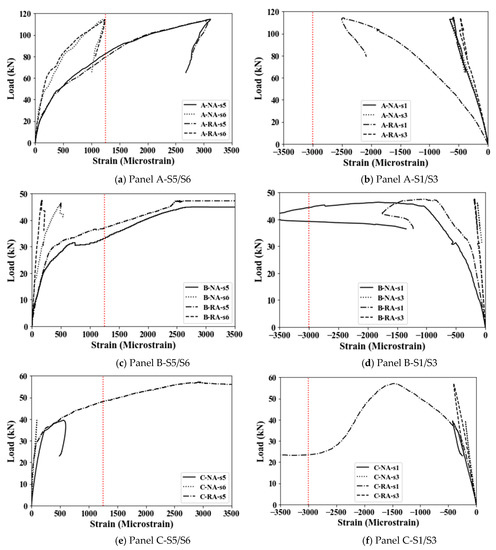

The load versus deflection curves for various prestressed deck strips tested in this research is shown in Figure 7a. Figure 7b provides a clear comparison between test and literature results. While the deck strip features a UHPC layer and high strength steel rebar (1T1S-Steel) reaches the highest ultimate load, the deck with prestressing strands and composite sUHPC deck can reach a similar level of capacity to demand ratio, which is denoted by the size of the marker in the Figure 7b. The deck strips with polymer rebars also exhibit excellent efficiency. However, generally speaking, they have more significant deflection at ultimate load under the reported configuration. The experiment observations and results of prestressed HSC/HSFRC deck and sUHPC deck will be discussed in the following sections.

Figure 7.

Load deflection responses of prestressed deck panels.

4.2. Prestressed HSC/HSFRC Deck Panels

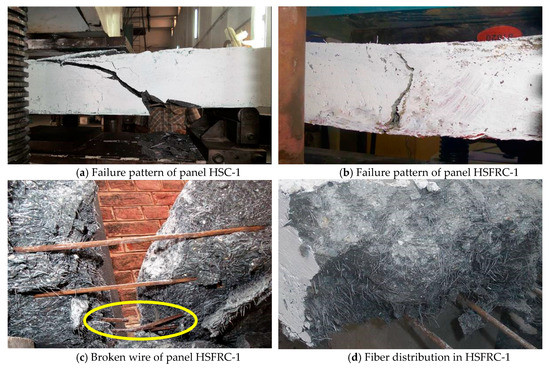

It was found out that the capacity to demand ratios of panels HSC-1 and HSC-2 are less than the single-span specimens tested by Saleem et al. [5] but are comparable to the panels tested by Ghasemi [6,13]. Both panels achieved the ultimate loads, double the target load, which shows the benefit of introducing prestressing. These two panels did not have steel fibers but only minimum conventional shear reinforcement (#10-s:75mm c/c). Deflection in panel HSC-1 at the service load was 0.97 mm, which is less than the limiting deflection of 1.53 mm (span/800) as recommended by AASHTO LRFD [14]. Deflection at the ultimate load was 14.5 mm (Table 4), which is 15 times more than the service load deflection. Load-deflection responses and failure pattern of both HSC deck panels are shown in Figure 7a and Figure 8, respectively. The first flexural crack in the panel HSC-1 appeared at the load of 47.5 kN. This crack was at the mid-span followed by several other flexure and shear cracks under and around loading patch. The failure occurred at the peak load of 117.5 kN due to shear compression mode of failure, as shown in Figure 8a. This failure was sudden, as can be seen in the load-deflection response. However, this should not be a matter of concern because the failure load is double the target load and significantly high deflection (meaning ductility) at the ultimate load. Saleem et at. [5] and Ghasemi [6,13] also observed shear failure for similar span and load patch. However, their failure was more ductile because of the presence of steel fibers. First flexural cracking panel HSC-2 was noted at 42.5 kN, followed by several other flexure cracks. The failure occurred at a peak load of 120 kN due to rupture of prestressing wire with the complete opening of the flexural crack along the width of the panel. At 103 kN, the second prestressing wire ruptured with a loud noise and load dropped rapidly to 90 kN. No crushing of concrete or large shear cracks were observed in this case. Deflection of panel HSC-2 at the service load was 1.8 mm, which is little more than limiting value of deflection. This panel also had the capacity to demand ratio of 2.0 and a very high deflection of 19.9 mm at the ultimate load.

Figure 8.

Failure pattern and forensics of prestressed panels.

The panels HSFRC-1 and 2 had no conventional shear stirrups but 2% steel fiber by volume of concrete. Both the identical panels exhibited a capacity to demand ratio of 1.6, which is less than the HSC panels and comparable to UHPC-CFRP deck panels tested by Ghasemi et al. [6]. Load-deflection responses are shown in Figure 7a. The first flexural crack in the panel HSFRC-1 was observed at 70 kN after which the load-deflection curve started to flatten and then dropped suddenly after achieving a peak load of 96 kN. The reason behind the sudden drop was the rupture of the prestressing wire, as shown in Figure 8c. No other flexural crack followed the first crack until the final failure. This flexural crack opened to a width of 4 mm throughout the width of the panel, as shown in Figure 8b. No crushing in compression or shear cracks were observed in this panel. Deflection at the service load was 0.51 mm, which is well below the limiting deflection. For deck panel HSFRC-2, the first flexural crack appeared at a load of 75 kN near the mid-span and continued to grow in an upward direction until the panel reached a peak load of 97 kN. The panel continued to yield at the peak load for 3 mm until the loud bursting of prestressing wire dropped the load to 82 kN. The behavior of panels HSFRC-1 and HSFRC-2 was similar except that this panel had a higher service load deflection of 0.97 mm.

In comparison to HSC panels, HSFRC panels demonstrated higher stiffness throughout the loading. However, their capacity to demand ratio was smaller, but still acceptable. The panel HSFRC-1 was broken down after the test to reveal the distribution of fibers across the depth (Figure 8d). Based on visual observations, it is evident that fibers, under the effect of gravity, concentrated more on the lower part of the panel. However, this should not be a matter of concern because these panels are proposed to be simply supported, and concrete on the top will be in compression and fibers do not significantly contribute to compressive strength.

The optimized high strength fiber reinforced concrete (O-HSFRC) panels had reduced depth of 102 mm, which was intended to decrease the self-weight. Figure 7a presents the load-deflection responses of O-HSFRC panels. Panel O-HSFRC-1 reached the peak load of 28 kN with 24 kN as first crack load. The panel failed in flexure with the crack appearing at the location of the joint between two concrete batches. Three prestressing wires also ruptured before the test was stopped at a deflection of 35 mm. For panel O-HSFRC-2, the first flexural crack was observed at a load level of 39 kN. The peak load of 45 kN was reached, followed by flexural failure. Rupturing of two prestressing wires was also observed before the test was stopped at a deflection of around 20 mm. Both panels could not achieve the target load. However, this should not lead to the conclusion that they do not have the potential to meet the target load. The main reason behind lower failure load could be a lower quality of concrete due to high environmental temperature, error in following proper mixing regime, and joint formation due to delay in successive batches. With better quality control and casting the whole specimen with one batch will surely increase the failure load to meet the target.

4.3. Sustainable UHPC-NA/RA Deck Panels

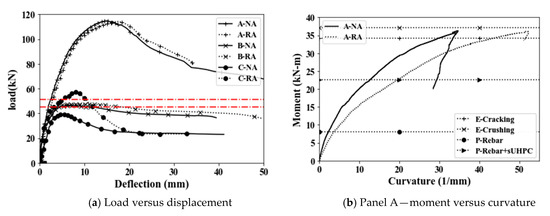

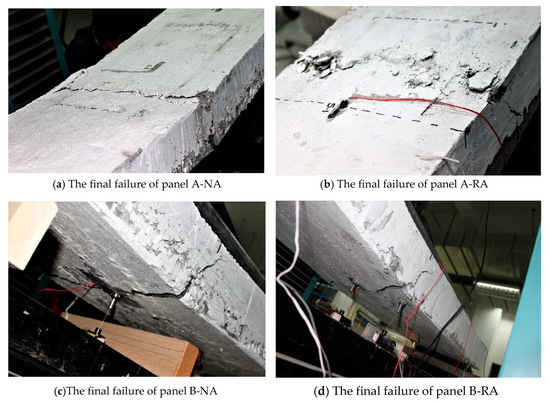

Load-deflection curves for all the deck panels tested in phase 2 are presented in Figure 9a while the moment versus curvature plot for deck types A, B, and C are shown in Figure 9b–d, respectively. The moments were calculated based on the recorded load value and an assumed uniform distribution in the load patch area. The curvature was calculated based on the strain recording S1 and S5, which are the strain of top concrete and strain of the rebar. Moment predictions from the sectional analyses are also presented for comparisons.

Figure 9.

Load deflection responses of composite deck panels.

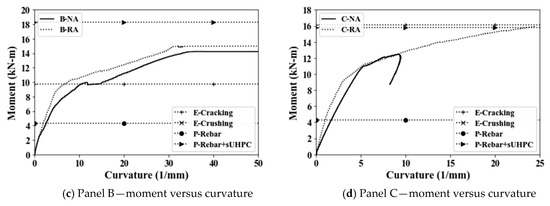

The failure pattern of composite deck Type A and Type B are shown in Figure 10. For panel A-NA having the top layer prepared with regular concrete, the first flexural crack was seen on the side surface at 53 kN, followed by delamination of bottom steel plate. The peak load of 114.4 kN was recorded. Crushing of concrete was not observed. However, the main steel bar at the bottom yielded, as shown in Figure 11a at the 83 kN, making it a ductile failure, as shown in Figure 10a. Mid-span tensile strain at the peak load in the bottom UHPC layer was recorded as 0.0062. At the failure stage, the flexural crack reached to the top, and the bottom steel plate got detached significantly under the loading area, as shown in Figure 10a. Deflection at the peak load was 15 mm beyond which the panel deflected another 45 mm and the test was stopped due to safety concerns. The ductile behavior can be attributed to dowel action of the longitudinal bars and the fiber pullout mechanism of the bottom UHPC layer. Deflection at the service load was 0.98 mm, which is well below the AASHTO LRFD [14] limit. Capacity to demand ratio was 2.5, indicating the provision of optimization through a reduction in thickness.

Figure 10.

Failure patterns of composite deck panels.

Figure 11.

Load–strain responses for the composite deck panels.

For the deck type A-RA, the first flexural cracking load was noted as 47.5 kN. After the appearance of two flexural cracks, one near the edge of the neoprene pad and other close to the mid-span, failure occurred at a load-level of 114.18 kN. At the failure, the flexural crack had reached the compression face, as shown in Figure 10b. Compressive strain in concrete at the failure load was recorded as 0.0026, which is close to the crushing strain of 0.003. Some chipping-off at the top was observed in concrete directly under the load patch. Strain in steel at the mid-span at peak load was recorded as 0.003, and the yield strain was reached at around 80 kN, as shown in Figure 11b. Service load-deflection was 0.98 mm, and the capacity to demand ratio was 2.5.

Panels A-NA and A-RA behaved very similarly, both in the pre-peak and post-peak regions. Type A deck panels not only exceeded the target load (45.4 kN) by far but also exhibited higher stiffness compared to the rest of the panels tested in this phase. The sectional moment passed the predicted plastic moment, indicating good composite action that leads to a more evenly distributed stress along with the section height. The ultimate sectional moment was close to the predicted values for elastic failure due to concrete cracking and crushing, as shown in Figure 11b, which leads to more efficient use of materials. The yielding of the steel rebar provides sufficient ductility; however, based on the analyses, the contribution of sUHPC regarding the tensile forces are significant. The welded connection between the bottom, top, inclined shear reinforcement, and bottom steel plate is effective in controlling the cracking development. This developed outstanding composite behavior leading to higher load capacity and stiffness.

For the deck panel, B-NA failure load was observed as 46.4 kN, and failure mode was flexural, caused by the rupture of steel reinforcement. From Figure 11c,d, it is clear that the bottom rebar yielded at a load level around 32 kN while concrete was crushed when approaching the ultimate load. The stress distribution of the section at the ultimate load level led to the ultimate moment close to the fully plastic sectional moment, as shown in Figure 9c. The ultimate moment falls short of the prediction due to the cracking opening at the middle span and reduction of the contribution from sUHPC. Deflection at the service load was recorded as 2.68 mm, which is more than the AASHTO LRFD limit. Demand to capacity ratio was 0.9. This panel is 10% short of the target load and failed by breaking for bottom rebar (No. 10). This problem can be solved by using one size bigger rebar (No. 13) as the primary reinforcement or increasing the grade of steel. This will also increase the stiffness leading to smaller service load deflection. The provided shear stirrups are effective as no shear cracks were observed. The stirrups also act as shear connectors between the layers of UHPC and regular concrete, leading to better composite behavior and enhanced flexural capacity. However, the widening of the flexural cracks, especially those at the middle span is not constrained. The post-peak response of this panel is more ductile compared to both panels of type A, and load drop was much more gradual, as can be seen in Figure 9a, because the failure is mainly due to the plastic deformation of steel rebar rather than the crushing of the top concrete. The test was stopped at a deflection of 43 mm due to safety concerns.

For the panel, B-RA first flexural crack was observed at a load of 32 kN while failure occurred at a load of 47.5 kN. The test was stopped at a deflection of 50 mm. Strain in steel reinforcement at peak load was recorded as 0.0025, which is twice the yield strain (0.00125) for 250-grade steel. Yielding of steel bars was reached at a load level of 37 kN while the concrete strain on compression face at that stage is around 500 microstrain, which is way less than the crushing strain of concrete. Compressive strain at peak load was recorded as 0.0012, which is half the value of crushing strain for concrete. Deflection at the service load was 2.67 mm, and the capacity to demand ratio was 0.9. The usage of concrete containing recycled aggregates did not cause a drastic change in either the pre-peak or post-peak behaviors.

Deck panel C-NA got damaged during transportation. Therefore, it failed at a much smaller load of 39.5 kN. Failure was flexural with significant post-peak deflection (43 mm) till the stoppage of the test. For the panel, C-RA first flexural crack appeared near the edge of loading pad at a load of 40 kN followed by a series of other flexural cracks near the mid-span. Ultimate failure load was recorded at 57.20 kN with the flexural mode of failure at a mid-span deflection of 8 mm. The deck panel offered sufficient ductility as the panel continued to take load till a deflection of 37 mm when the test was stopped. As can be seen from Figure 9d, specimen C-NA has a premature failure due to the pre-damage while specimen C-RA presents the typical performance for this type and is discussed. Steel reinforcement was recorded to yield at a load level of 48 kN when the compressive strain at the top surface was only 0.0008, as shown in Figure 11e,f. Concrete strain at the ultimate load was recorded as 0.0015 while it approached the crushing strain of 0.003 as the crack entered the top surface of recycled aggregate concrete. Deflection at the service load was 2.12 mm, which is more than the limiting deflection. Capacity to demand ratio was 1.1. The drop of load for this panel was much quicker than the type B panels (Figure 9a). The post-peak capacity of this panel is almost half of the type B panels. This can be attributed to reduced composite action between the two layers of concrete, leading to the conclusion that UHPC ribs and horizontal transverse rebars are not as effective as shear stirrups in developing composite action, as observed in type B panels.

5. Conclusions and Recommendations

This research work focused on developing low-profile precast bridge deck panels for accelerated bridge construction using a combination of prestressing, high-strength, and ultra-high strength concrete, and recycled aggregate concrete. Use of prestressing and high strength materials enables a design with an overall depth of 102 and 127 mm, which are significantly less than the conventional deck thicknesses of 200–250 mm. In total, 12 deck panels were tested: six prestressed panels prepared with high strength/fiber reinforced concrete and six composite deck panels made of sustainable UHPC overlaid with normal or recycled aggregate concrete. In the light of experimental work, the following conclusions may be drawn:

The prestressed concrete deck panels with/without steel fibers exceeded the loading conditions expected from the HS20 truck and met the serviceability requirements as well. The capacity to demand ratios of HSC and HSFRC panels are comparable to those tested by Ghasemi [6,13]. By steel fiber, cracking load of HSFRC panels increased by 60%, on average, in comparison with HSC panels. This leads to the conclusion that replacing shear stirrups with steel fibers significantly improved the stiffness of the system. However, the optimized panels (O-HSFRC) could not meet the requirements but demonstrated potential. With a slight improvement in design and preparation, these panels should be able to meet the strength and stiffness demand. The governing mode of failure in the prestressed HSC panels was a sudden shear failure, as can be seen in the load-deflection responses. The HSFRC and O-HSFRC panels, however, failed in flexure having a plateau before the rupture of wire. Especially, the O-HSFRC panels exhibited significant deflection beyond the peak load, indicating substantial ductility and warning before failure.

Deck panels A-NA and A-RA behaved identically. Both exceeded the demand by 2.5 times. Service load deflections and first crack loads were also similar and well within limits. Significantly high post-peak deflections were observed. Replacement of conventional constituents of concrete with sustainable materials displayed satisfactory performance with no detrimental effect on the mechanical behavior of the deck panels. Welded connection of steel (flexure and shear) and bottom plate proved very effective in achieving the high capacity to demand ratio. This design can be optimized further to reduce the self-weight. Panels B-NA and B-RA fell slightly short of meeting the strength and serviceability requirements. However, this design is relatively simple and has exhibited a long post-peak plateau pointing towards ductile behavior. With a slight improvement in design, these panels should able to meet the desired load and serviceability needs. Panel C-NA met the load demand but not the deflection limit. The first flexural crack, however, appeared after service load. The design needs modification to improve composite action between the two layers of concrete, which will enhance stiffness and will thus help in meeting the deflection limit.

The sUHPC A-NA/RA deck panels offered the highest capacity to demand ratio (2.5) among the entire stock of 12 specimens and their deflection was the lowest of the tested specimens. When the test was stopped at 60 mm, panel A-NA was still holding more load than the load target, and a similar case was also observed for panel A-RA. Hence, the sustainable UHPC NA/RA composite deck panels may be the most suitable alternative for replacing the conventional bridge deck systems, especially for the situations when self-weight is a concern, for instance, moveable bridges.

Although the proposed deck designs show great promise, further studies are still needed before any field implementation: (1) more precise measurement of the prestressing losses that help lead to more accurate design; (2) optimization of design by decreasing the self-weight; (3) design of connections with girders and adjacent deck panels; (4) testing of full-scale panels (multi-unit, multi-span) with the connection under static and dynamic effects of moving wheel load to assess the long-term behavior; (5) implementation of prestressing in the sUHPC-NA/RA deck panels.

Author Contributions

All authors have read and agree to the published version of the manuscript. Conceptualization, M.A.S. and J.X.; methodology, M.A.S. and J.X.; formal analysis, M.N.Z.; investigation, M.N.Z. and M.M.S.; writing—original draft preparation, M.N.Z.; writing—review and editing, M.A.S. and J.X.; visualization, M.M.S.; supervision, J.X.; project administration, M.A.S.; funding acquisition, M.A.S. and J.X.

Funding

This research study was jointly funded by Bridge Engineering Lab. at the Department of Civil Engineering, UET Lahore, Pakistan and Department of Civil Engineering, Xi’an Jiaotong-Liverpool University (XJTLU), Suzhou, China (funding # RDS10120190072).

Acknowledgments

Raw material sponsorship from Imporient Chemicals® Ltd., SIKA Pakistan® and Lahore Ceramics Pvt. Ltd. is highly acknowledged.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Keller, T.; Rothe, J.; Castro, J.; de Osei-Antwi, M. GFRP-Balsa Sandwich Bridge Deck: Concept, Design, and Experimental Validation. J. Compos. Constr. 2014, 18, 04013043. [Google Scholar] [CrossRef]

- Manalo, A.; Aravinthan, T.; Fam, A.; Benmokrane, B. State-of-the-Art Review on FRP Sandwich Systems for Lightweight Civil Infrastructure. J. Compos. Constr. 2017, 21, 04016068. [Google Scholar] [CrossRef]

- Al-Ramahee, M.; Chan, T.; Mackie, K.R.; Ghasemi, S.; Mirmiran, A. Lightweight UHPC-FRP Composite Deck System. J. Bridg. Eng. 2017, 22, 04017022. [Google Scholar] [CrossRef]

- Federal Highway Administration, U.S.; Department of Transportation. FHWA: Tables of Frequently Requested NBI Data [Internet]. 2017. Available online: http://www.fhwa.dot.gov/bridge/britab.htm (accessed on 5 February 2020).

- Saleem, M.A.; Mirmiran, A.; Xia, J.; Mackie, K.R. Ultra-High-Performance Concrete Bridge Deck Reinforced with High-Strength Steel. ACI Struct. J. 2011, 108. [Google Scholar] [CrossRef]

- Ghasemi, S.; Mirmiran, A.; Xiao, Y.; Mackie, K.R. Novel UHPC-CFRP Waffle Deck Panel System for Accelerated Bridge Construction. J. Compos. Constr. 2016, 20, 04015042. [Google Scholar] [CrossRef]

- Keierleber, B.; Bierwagen, D.; Wipf, T.; Abu-Hawash, A. Design Of Buchanan County, Iowa, Bridge, Using Ultra High-Performance Concrete And Pi Beam Cross Section. In Proceedings of the Mid-Continent Transportation Research Symposium, Ames, IA, USA, 15–16 August 2007. [Google Scholar]

- Habel, K.; Viviani, M.; Denarié, E.; Brühwiler, E. Development of the mechanical properties of an Ultra-High Performance Fiber Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2006, 36, 1362–1370. [Google Scholar] [CrossRef]

- Graybeal, B.A. Compressive Behavior of Ultra-High-Performance Fiber-Reinforced Concrete. ACI Mater. J. 2007, 104, 146–152. [Google Scholar]

- Graybeal, B.A. Structural Behavior of Ultra-High Performance Concrete Prestressed I-Girders Final Report; Federal Highway Administration: McLean, VA, USA, 2006. [Google Scholar]

- Graybeal, B.A. Characterization of the Behavior of Ultrahigh Performance; University of Maryland: College Park, MD, USA, 2005. [Google Scholar]

- Ahlborn, T.M.; Peuse, E.J.; Misson, D.L. Concrete For Michigan Bridges Material Performance—Phase I Final Report; Michigan Department of Transportation: Lansing, MI, USA, 2008. [Google Scholar]

- Ghasemi, S.; Zohrevand, P.; Mirmiran, A.; Xiao, Y.; Mackie, K.R. A super lightweight UHPC–HSS deck panel for movable bridges. Eng. Struct. 2016, 113, 186–193. [Google Scholar] [CrossRef]

- Watts, R.; Mills, R.W.; Fish, R. The Highway Coalition Revisited: Using the Advocacy Coalition Framework to Explore the Content of the American Association of State Highway and Transportation Officials’ Daily Transportation Update. Public Voices 2016, 13, 79. [Google Scholar] [CrossRef]

- Huang, C.; Song, J.; Zhang, N.; Lee, G.C. Seismic Performance of Precast Prestressed Concrete Bridge Girders Using Field-Cast Ultrahigh-Performance Concrete Connections. J. Bridg. Eng. 2019, 24, 04019046. [Google Scholar] [CrossRef]

- Deng, S.; Shao, X.; Yan, B.; Wang, Y.; Li, H. On Flexural Performance of Girder-To-Girder Wet Joint for Lightweight Steel-UHPC Composite Bridge. Appl. Sci. 2020, 10, 1335. [Google Scholar] [CrossRef]

- Venancio, V.G. Behavior of Ultra-High Performance Concrete Bridge Deck Panels Compared to Conventional Stay-In-Place Deck Panels in Partial Fulfillment of the Requirements for the Degree; Missouri University of Science and Technology: Rolla, MO, USA, 2016. [Google Scholar]

- Containing, A.; Sludge, M. Properties of Concrete with Recycled Concrete Aggregate Containing Metallurgical Sludge Waste. Materials 2020, 13, 1448. [Google Scholar]

- Duarte, G.; Gomes, R.C.; de Brito, J.; Bravo, M.; Nobre, J. Economic and Technical Viability of Using Shotcrete with Coarse Recycled Concrete Aggregates in Deep Tunnels. Appl. Sci. 2020, 10, 2697. [Google Scholar] [CrossRef]

- Wang, X.; Chin, C.S.; Xia, J. Material Characterization for Sustainable Concrete Paving Blocks. Appl. Sci. 2019, 9, 1197. [Google Scholar] [CrossRef]

- Tam, V.W.; Kotrayothar, D.; Xiao, J. Long-term deformation behaviour of recycled aggregate concrete. Constr. Build. Mater. 2015, 100, 262–272. [Google Scholar] [CrossRef]

- Qi, J.; Wang, J.; Feng, Y. Shear performance of an innovative UHPFRC deck of composite bridge with coarse aggregate Shear performance of an innovative UHPFRC deck of composite bridge with coarse aggregate. Adv. Concr. Constr. 2019, 7, 219–229. [Google Scholar]

- Feng, Y.; Qi, J.; Wang, J.; Liu, J.; Liu, J. Flexural Behavior of the Innovative CA-UHPC Slabs with High and Low Reinforcement Ratios. Adv. Mater. Sci. Eng. 2019, 2019, 1–14. [Google Scholar] [CrossRef]

- PCI Industry Handbook Committee. PCI Design Handbook, 7th ed.; Precast/Prestressed Concrete Institute PCI: Chicago, IL, USA, 2010; 226p. [Google Scholar]

- Graybeal, B.A. Material Property Characterization of Ultra-High Performance Concrete No. FHWA-HRT-06-103; Federal Highway Administration: Washington, DC, USA, 2006. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).