Thermal Performance of Concrete with Recycled Concrete Powder as Partial Cement Replacement and Recycled CDW Aggregate

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

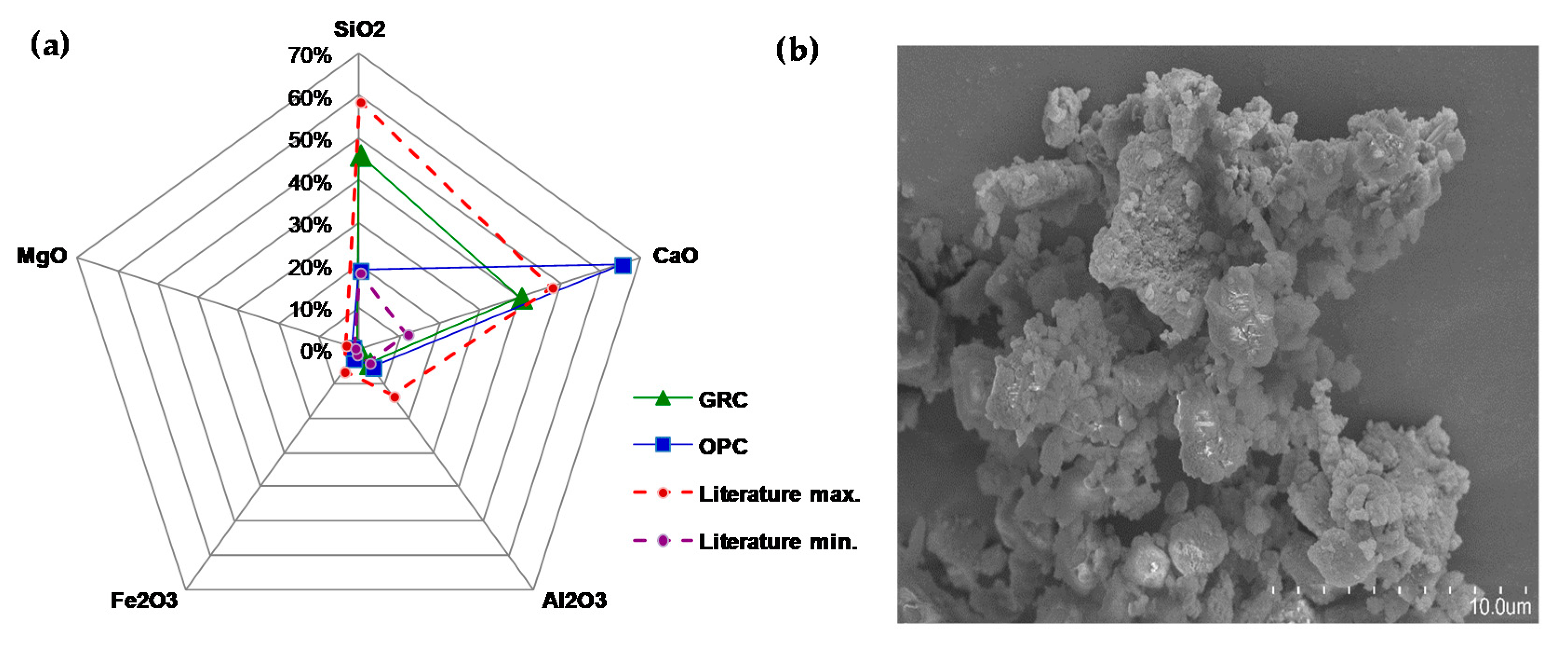

2.1.1. Binders

2.1.2. Aggregates

2.2. Testing and methodology

2.3. Concrete Design

3. Results

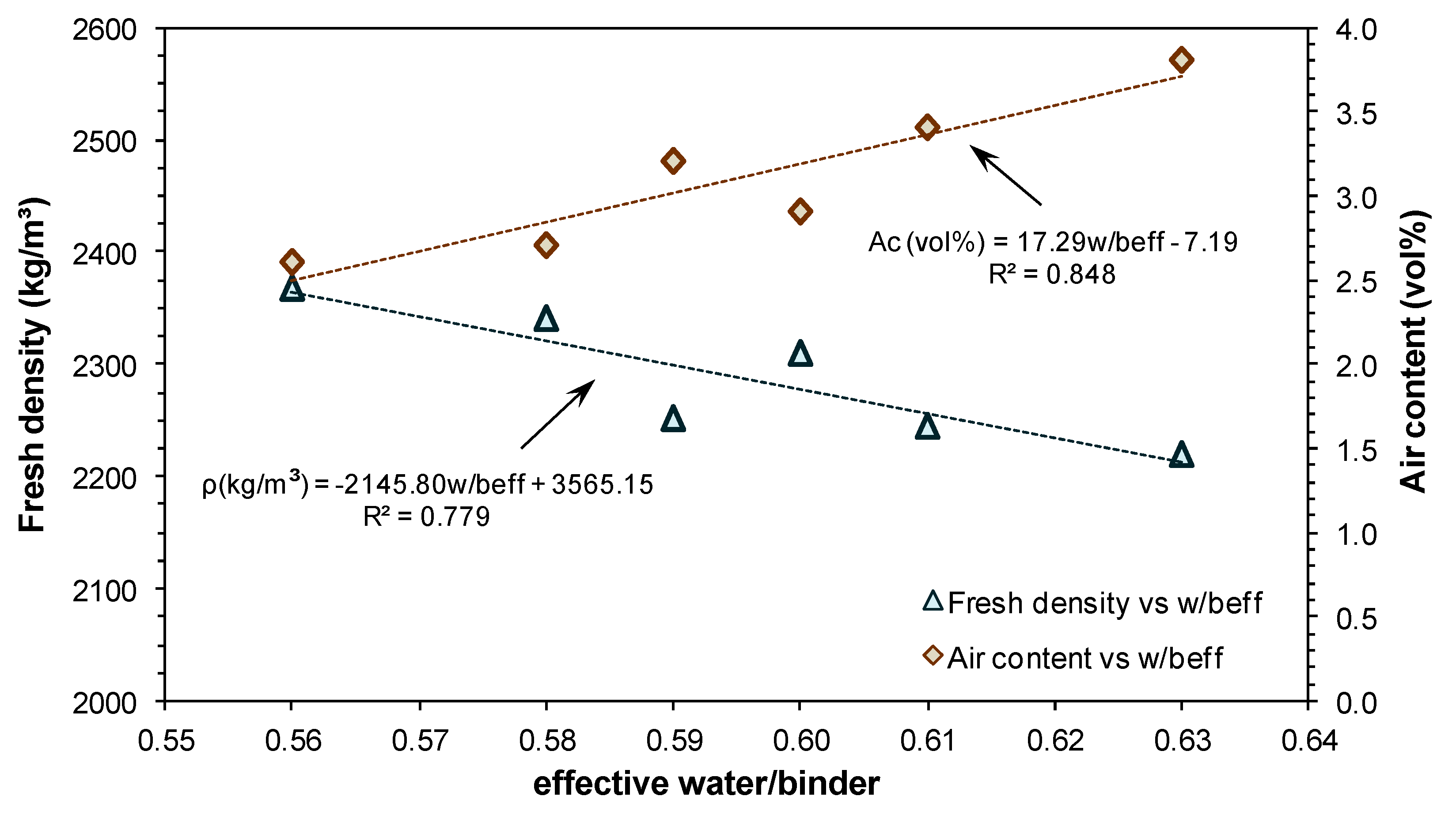

3.1. Fresh Properties

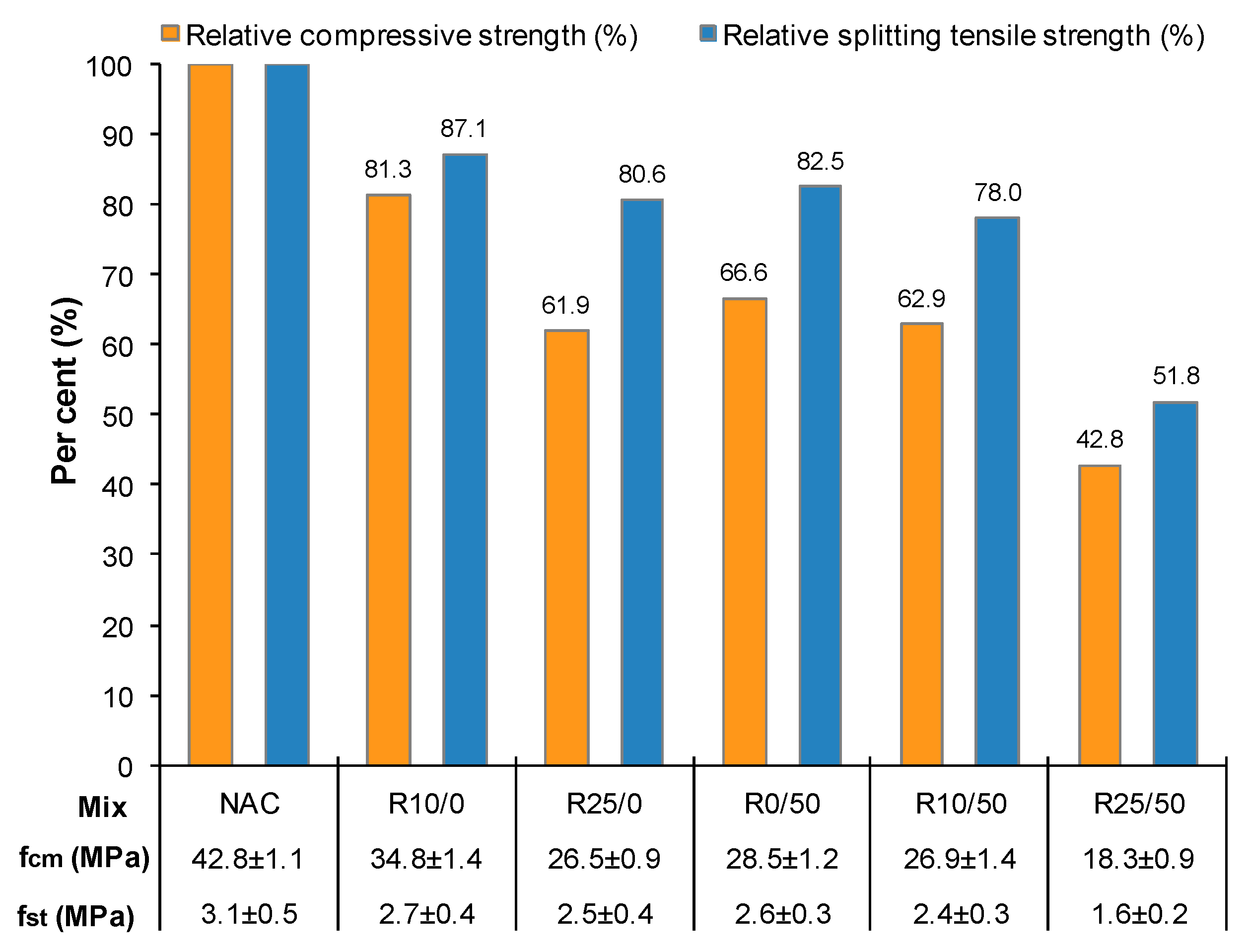

3.2. Mechanical Properties

3.3. Physical Properties

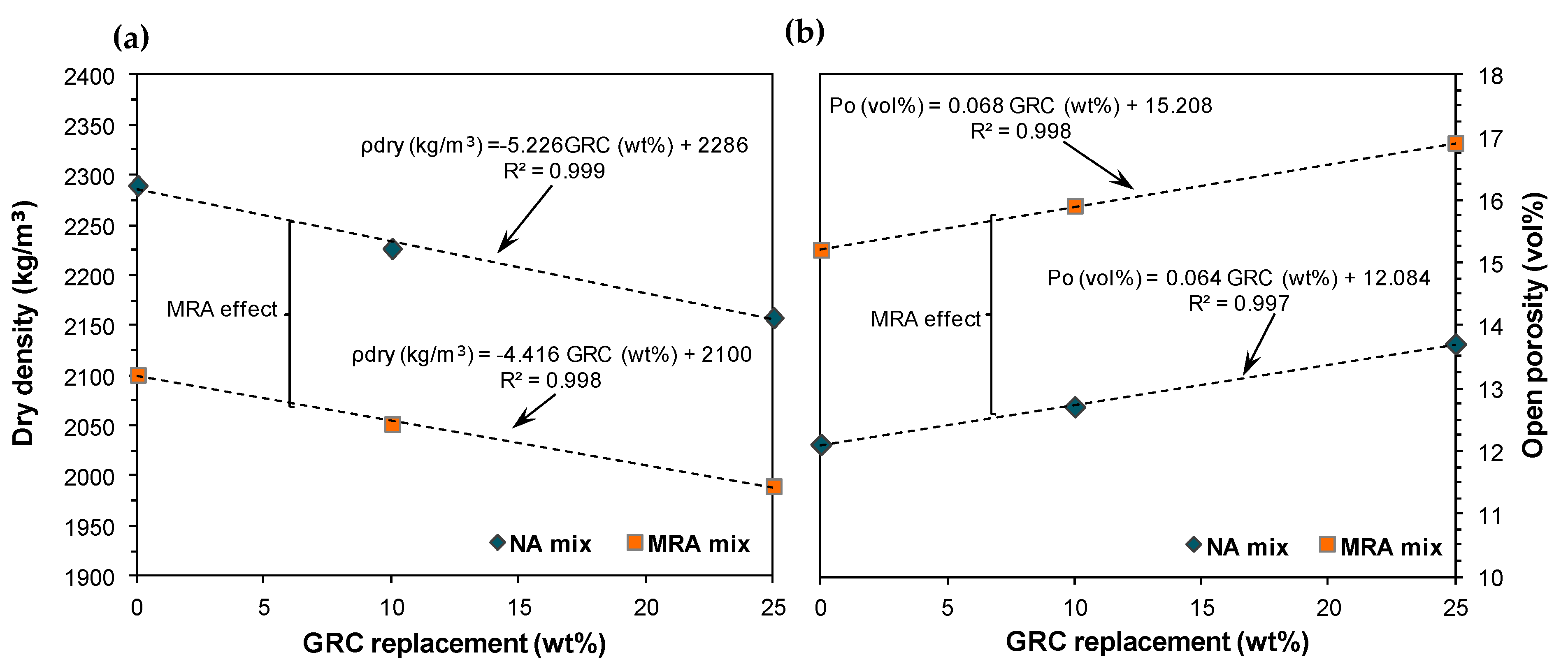

3.3.1. Dry Density

3.3.2. Open Porosity

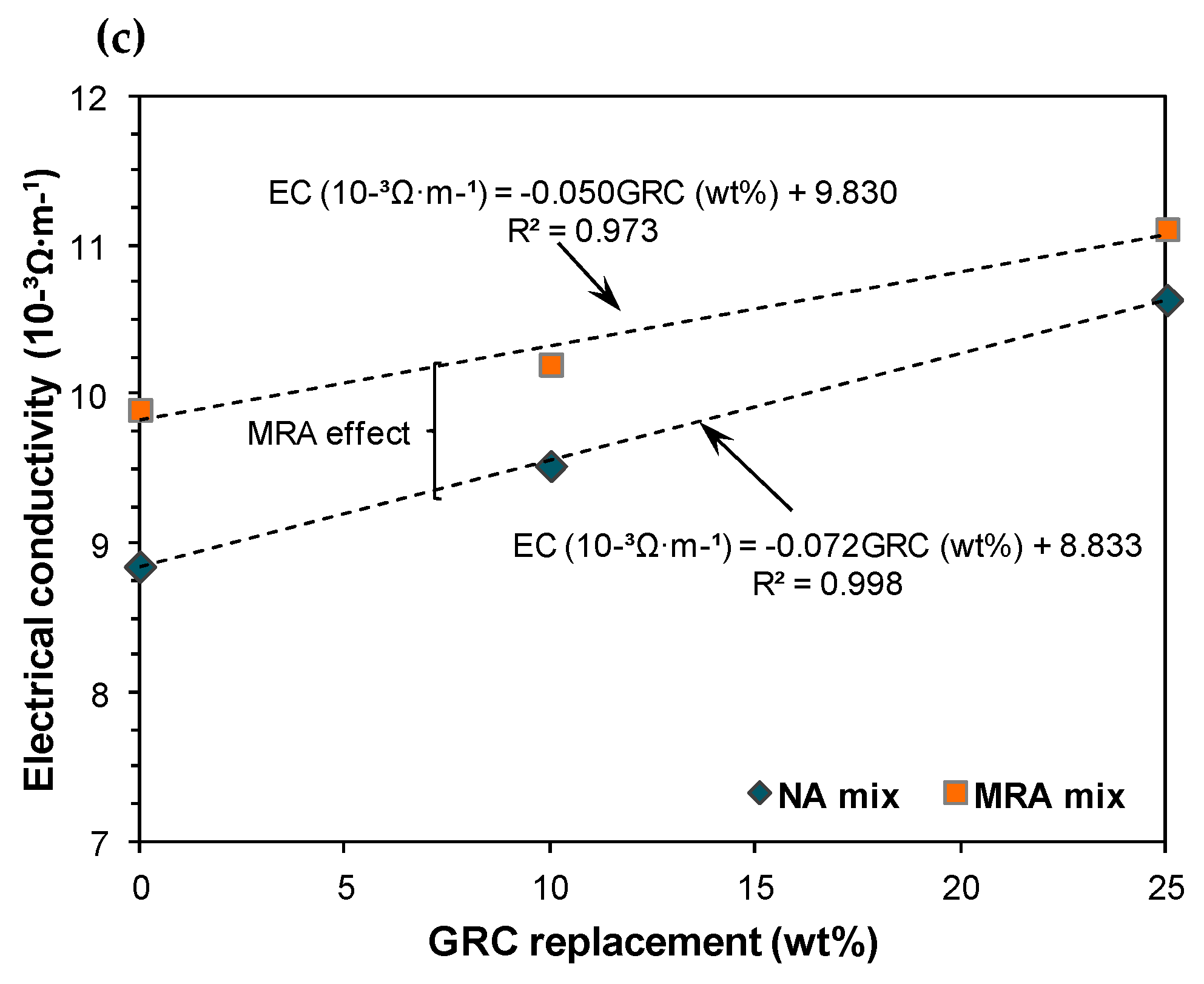

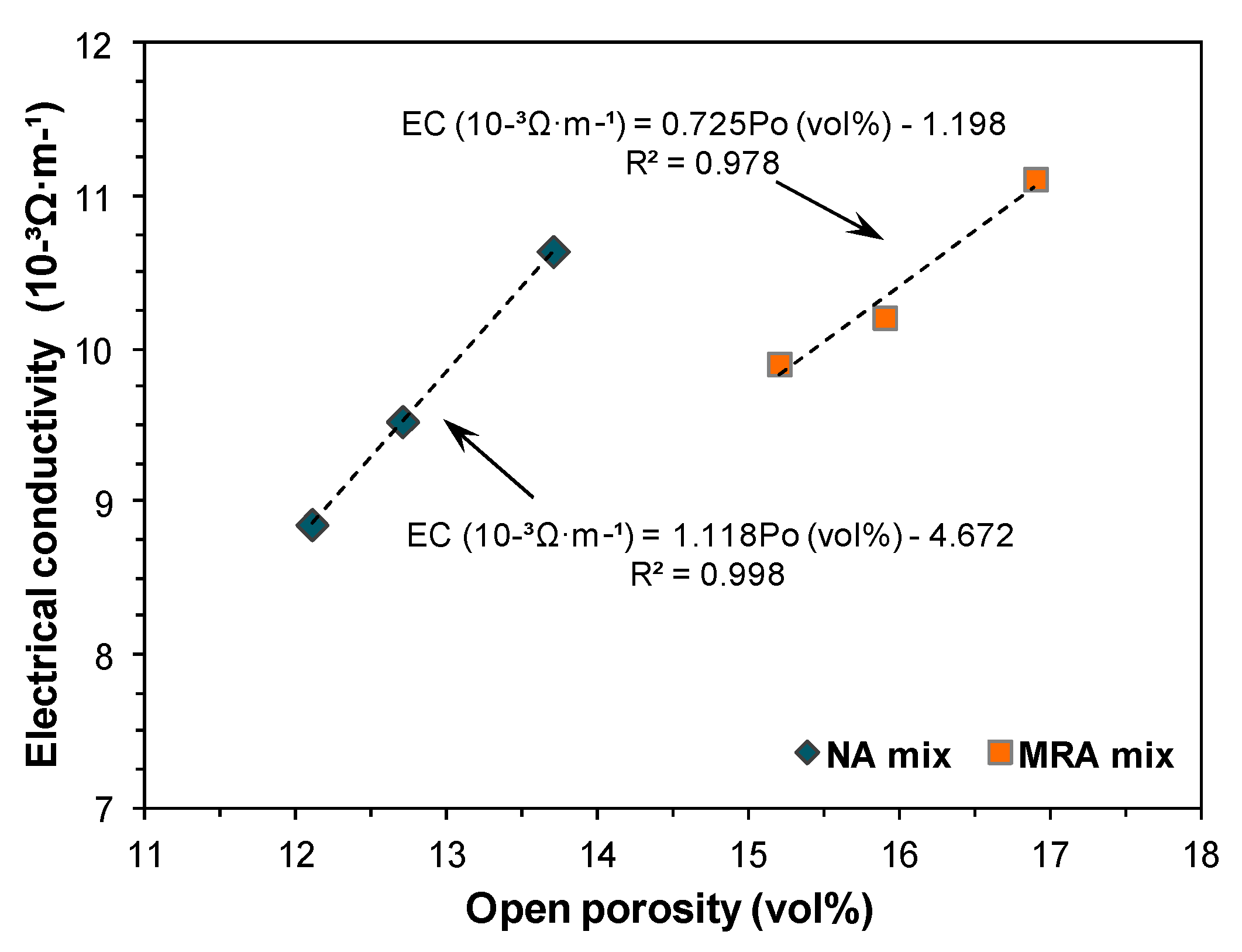

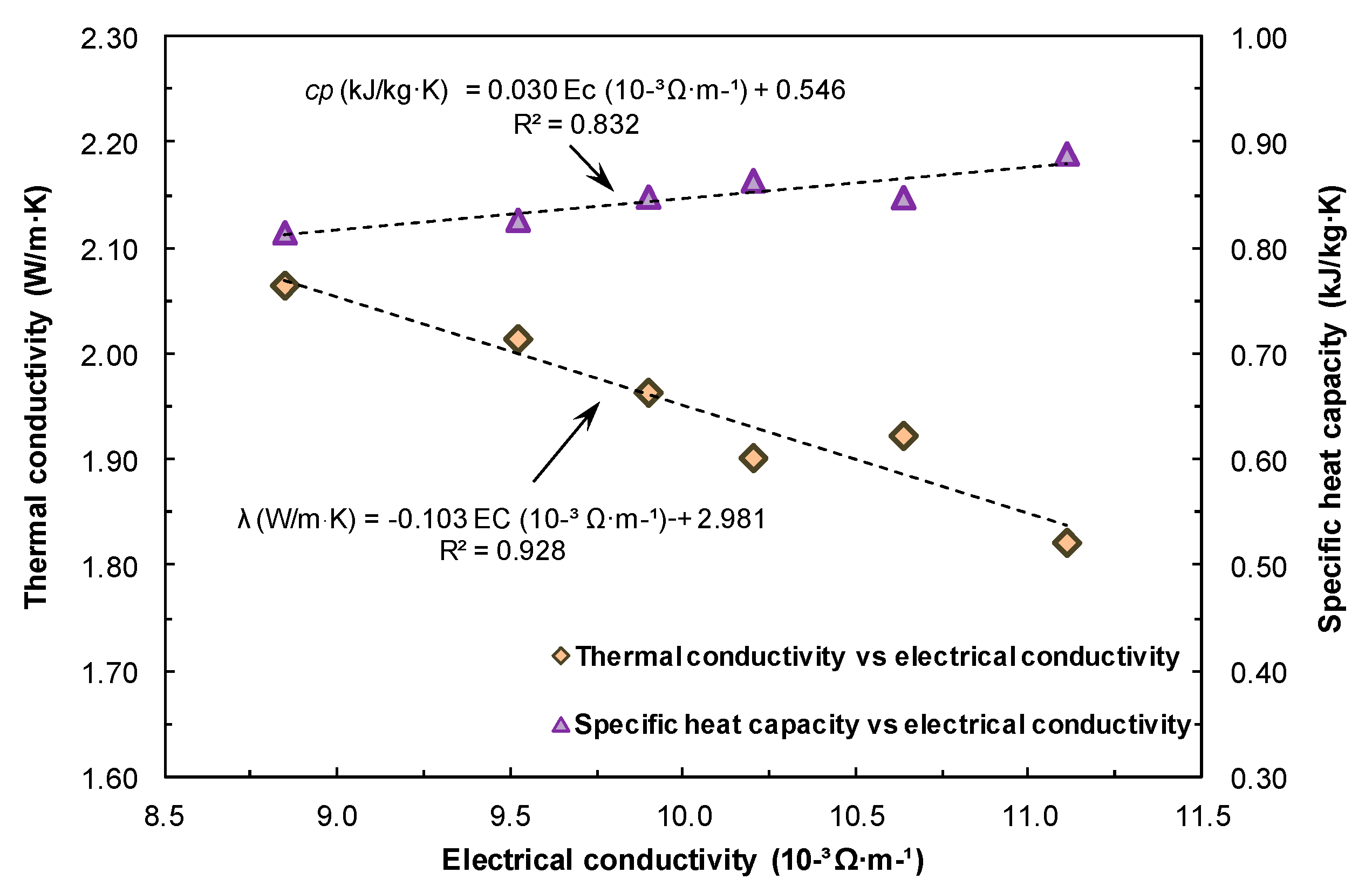

3.3.3. Electrical Conductivity

3.4. Thermal Properties

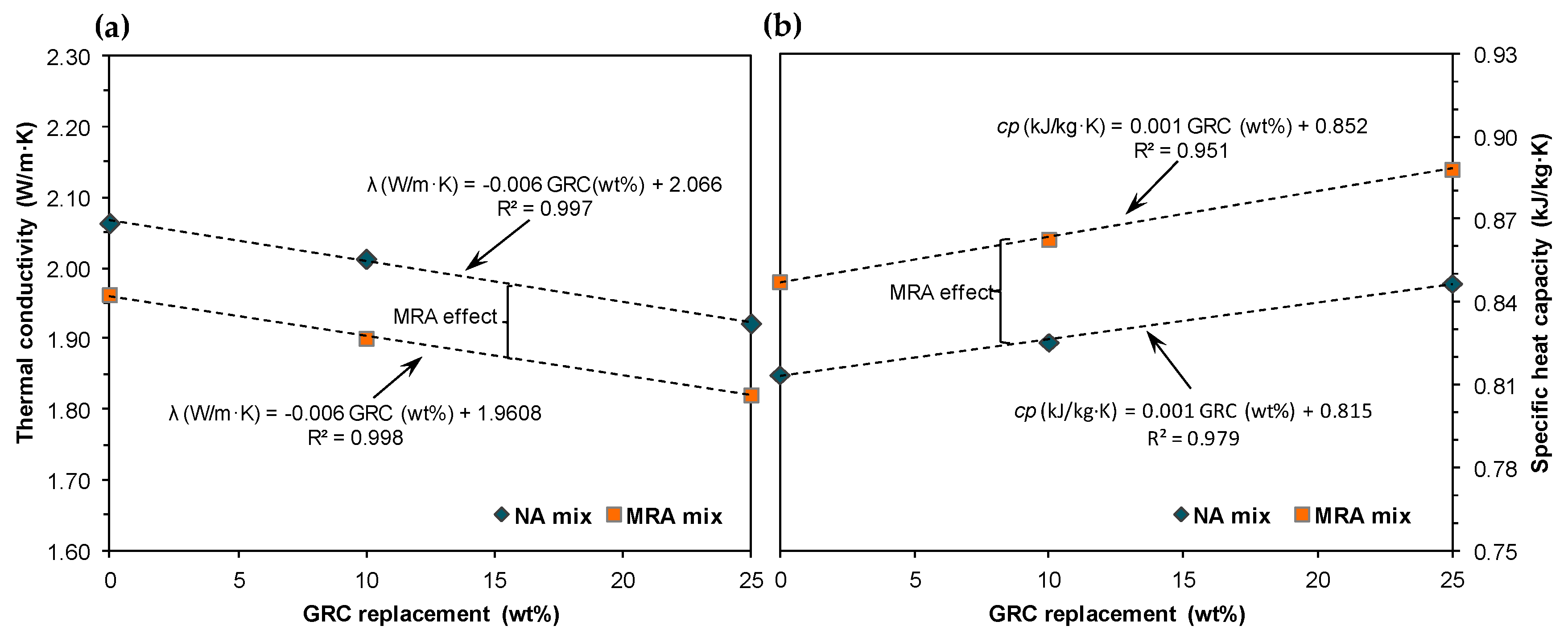

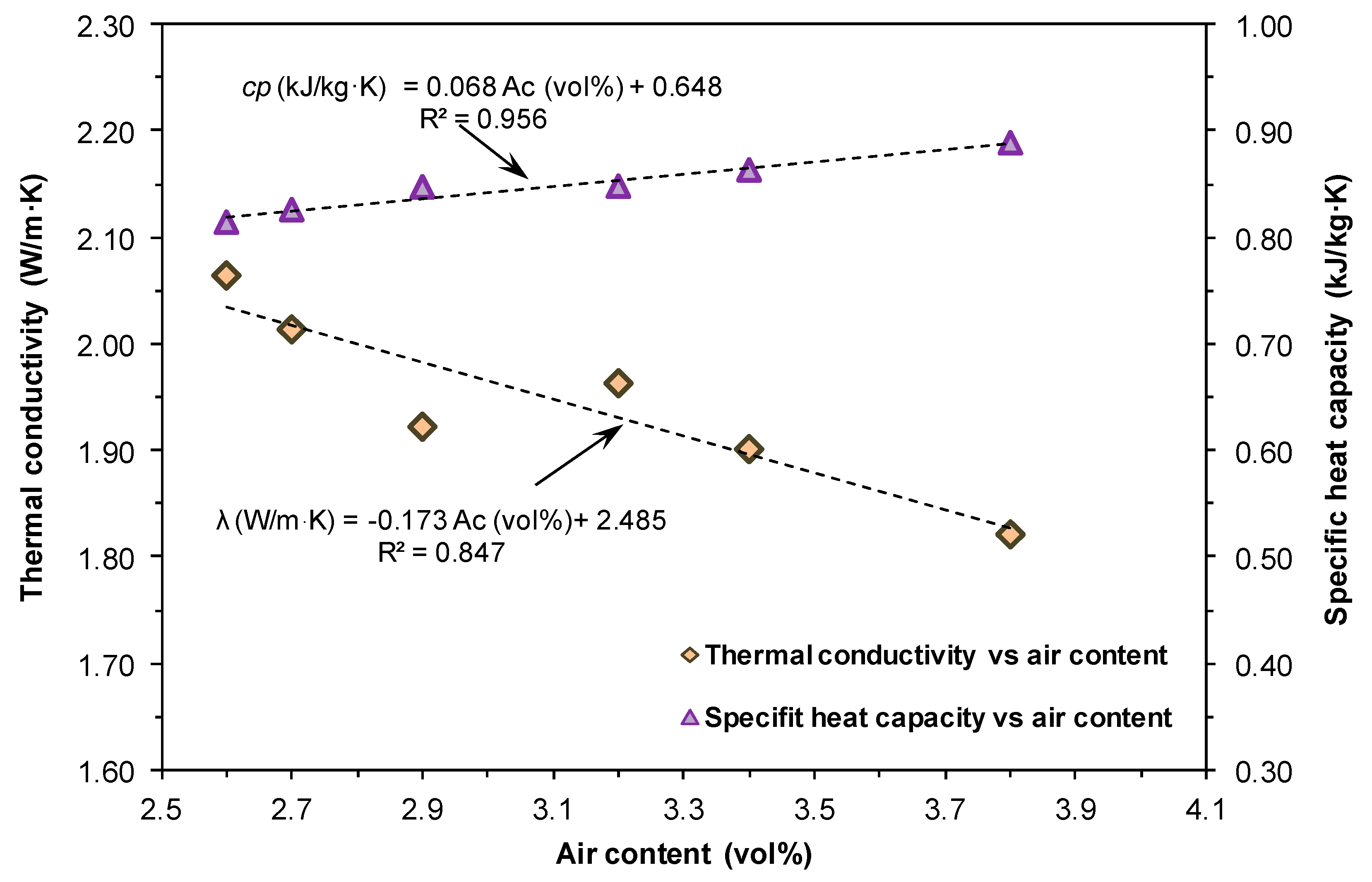

3.4.1. Thermal Conductivity

3.4.2. Specific Heat Capacity

3.5. Cross-Property Relationships

3.5.1. Thermal Properties and Air Content

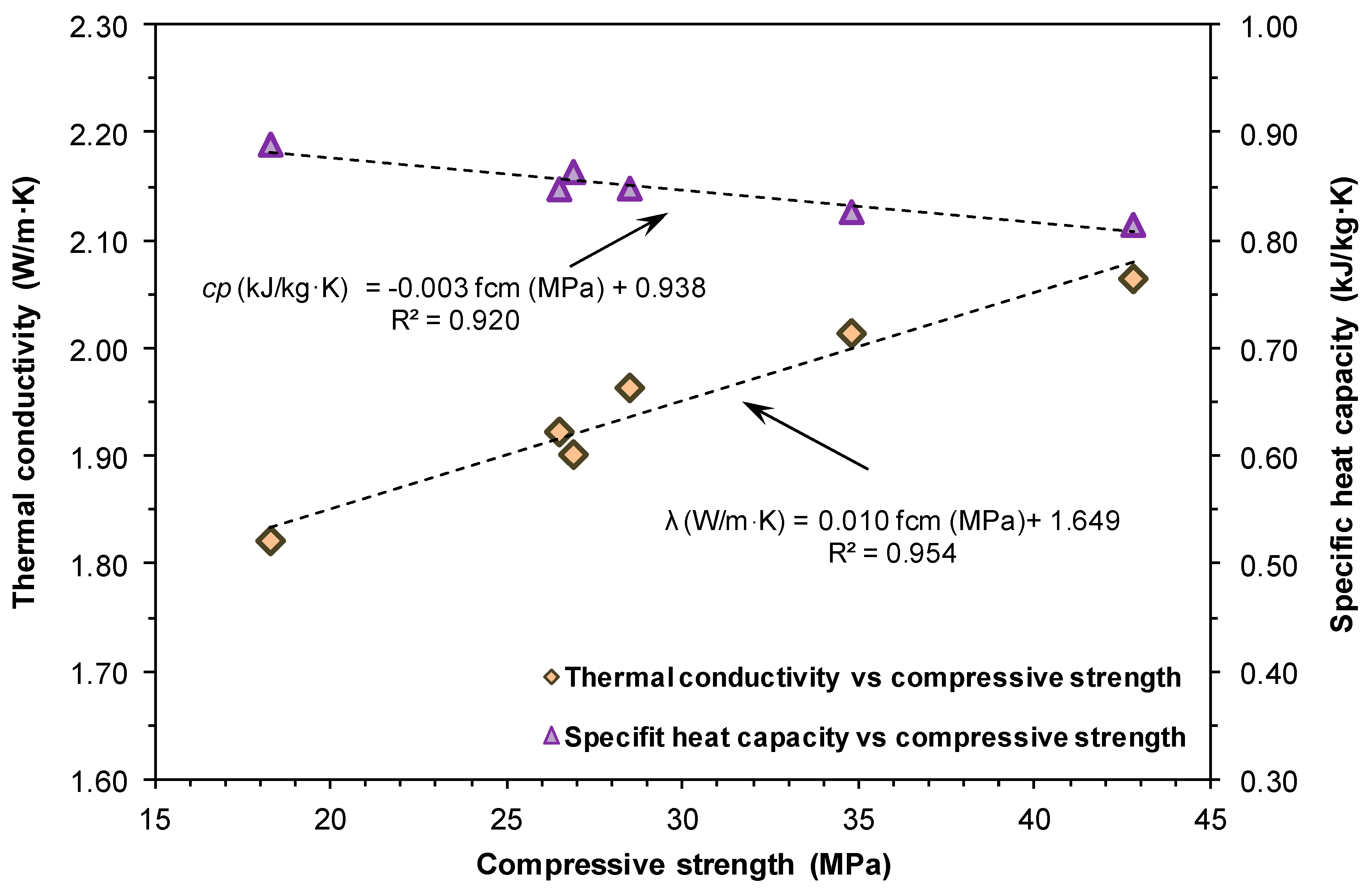

3.5.2. Thermal Properties and Compressive Strength

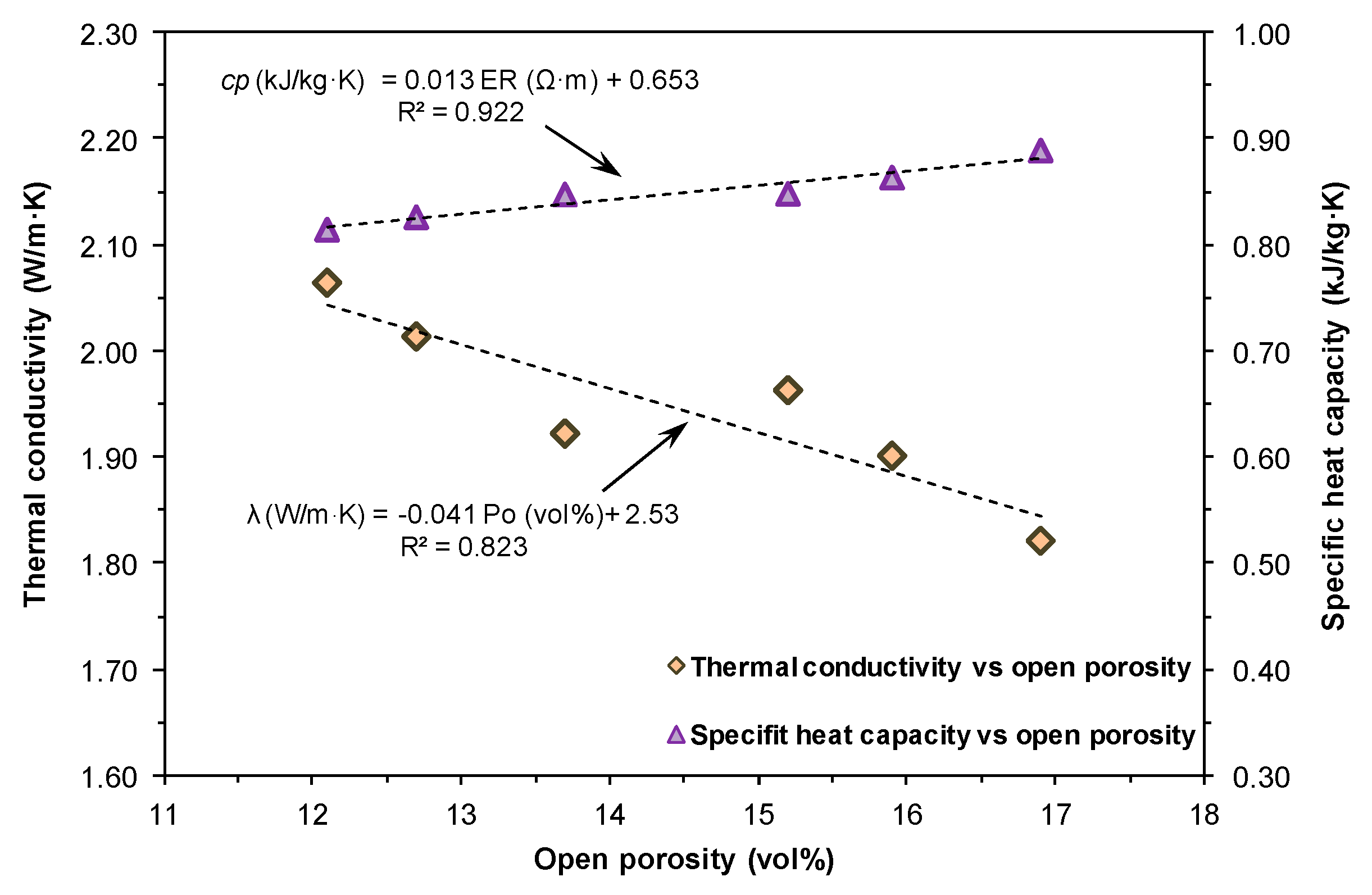

3.5.3. Thermal Properties and Open Porosity

3.5.4. Thermal Properties and Electrical Conductivity

4. Conclusions

- The use of GRC to replace 25% of OPC and MRA to replace 50% of NA lowered concrete fresh-state density by 6.2% and raised its air content by 30%. All the recycled material concrete mixes studied had an air content under 4.5%, the upper limit recommended by the ACI committee for structural concrete;

- Porosity rose by 39.7% in the mixes with 25% GRC and 50% MRA and by 13.2% in the mixes with 25% GRC and 100% NA relative to the reference mix made with 100% OPC and 100% NA;

- The decline in dry density and the rise in electrical conductivity were associated with the incorporation of GRC in mixes with 100% NA as well as those with 50% MRA due to the higher porosity in the recycled materials;

- The use of 25% GRC in conjunction with 50% MRA reduced thermal conductivity by 11.8% and raised specific heat capacity by 9.1%, whilst the values for 25% GRC with 100% NA were a 6.9% reduction in thermal conductivity and a 4.1% rise in specific heat capacity, both relative to concrete with 100% natural aggregate (NA);

- Due to their greater porosity, the new recycled materials concrete may provide better thermal insulation and greater thermal inertia than conventional concrete;

- Cross-referencing concrete properties showed that, whereas using GRC and MRA as replacement materials had an adverse effect on concrete’s compressive strength, it improved its thermal properties;

- Mixes with 25% GRC and 100% NA and those with 10% GRC and 50% MRA, with compressive strength values of >25 MPa, are not only apt for use in building construction, but afford greater energy efficiency than conventional concrete.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Paris, J.M.; Roessler, J.G.; Ferraro, C.C.; De Ford, H.D.; Townsend, T.G. A review of waste products utilized as supplements to Portland cement in concrete. J. Clean. Prod. 2016, 121, 1–18. [Google Scholar] [CrossRef]

- Mo, L.; Deng, M.; Tang, M. Effects of calcination condition on expansion property of MgO-type expansive agent used in cement-based materials. Cem. Concr. Res. 2010, 40, 437–446. [Google Scholar] [CrossRef]

- Mália, M.; de Brito, J.; Pinheiro, M.D.; Bravo, M. Construction and demolition waste indicators. Waste Manag. Res. 2013, 31, 241–255. [Google Scholar] [CrossRef]

- Kurad, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Effect of incorporation of high volume of recycled concrete aggregates and fly ash on the strength and global warming potential of concrete. J. Clean. Prod. 2017, 166, 485–502. [Google Scholar] [CrossRef]

- De Brito, J. Recycled Aggregate in Concrete—Use of Industrial, Construction and Demolition Waste; Springer: Berlin/Heidelberg, Germany, 2012; Available online: https://www.springer.com/gp/book/9781447145394 (accessed on 10 April 2020).

- Subaşı, S.; Öztürk, H.; Emiroğlu, M. Utilizing of waste ceramic powders as filler material in self-consolidating concrete. Constr. Build. Mater. 2017, 149, 567–574. [Google Scholar] [CrossRef]

- Ge, Z.; Wang, Y.; Sun, R.; Wu, X.; Guan, Y. Influence of ground waste clay brick on properties of fresh and hardened concrete. Constr. Build. Mater. 2015, 98, 128–136. [Google Scholar] [CrossRef]

- Kannan, D.M.; Aboubakr, S.H.; El-Dieb, A.S.; Reda Taha, M.M. High performance concrete incorporating ceramic waste powder as large partial replacement of Portland cement. Constr. Build. Mater. 2017, 144, 35–41. [Google Scholar] [CrossRef]

- Vejmelková, E.; Keppert, M.; Rovnaníková, P.; Ondráček, M.; Keršner, Z.; Černý, R. Properties of high performance concrete containing fine-ground ceramics as supplementary cementitious material. Cem. Concr. Compos. 2012, 34, 55–61. [Google Scholar] [CrossRef]

- Cantero, B.; Sáez del Bosque, I.F.; Matías, A.; Sánchez de Rojas, M.I.; Medina, C. Inclusion of construction and demolition waste as a coarse aggregate and a cement addition in structural concrete design. Arch. Civ. Mech. Eng. 2019, 19, 1338–1352. [Google Scholar] [CrossRef]

- Liu, Q.; Tong, T.; Liu, S.; Yang, D.; Yu, Q. Investigation of using hybrid recycled powder from demolished concrete solids and clay bricks as a pozzolanic supplement for cement. Constr. Build. Mater. 2014, 73, 754–763. [Google Scholar] [CrossRef]

- Bravo, M.; de Brito, J.; Evangelista, L. Thermal performance of concrete with recycled aggregates from CDW plants. Appl. Sci. 2017, 7, 740. [Google Scholar] [CrossRef]

- Zhu, L.; Dai, J.; Bai, G.; Zhang, F. Study on thermal properties of recycled aggregate concrete and recycled concrete blocks. Constr. Build. Mater. 2015, 94, 620–628. [Google Scholar] [CrossRef]

- Marie, I. Thermal conductivity of hybrid recycled aggregate—Rubberized concrete. Constr. Build. Mater. 2017, 133, 516–524. [Google Scholar] [CrossRef]

- Sargam, Y.; Wang, K.; Alleman, J.E. Effects of modern concrete materials on thermal conductivity. J. Mater. Civ. Eng. 2020, 32, 04020058. [Google Scholar] [CrossRef]

- Asadi, I.; Shafigh, P.; Abu Hassan, Z.F.B.; Mahyuddin, N.B. Thermal conductivity of concrete—A review. J. Build. Eng. 2018, 20, 81–93. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, A.; Shi, F.; Liu, J.; Cao, P.; Du, T.; Gu, H. Development of relationships between permeability coefficient and electrical and thermal conductivity of recycled aggregates permeable cement concrete. Constr. Build. Mater. 2020, 254, 119247. [Google Scholar] [CrossRef]

- Faury, J. Le Béton; Dunod: Paris, France, 1958. [Google Scholar]

- European Committee for Standardization. EN 206 Concrete. Part 1: Specification, Performance, Production and Conformity; European Committee for Standardization: Brussels, Belgium, 2013. [Google Scholar]

- Bogas, J.A.; Carriço, A.; Pereira, M.F.C. Mechanical characterization of thermal activated low-carbon recycled cement mortars. J. Clean. Prod. 2019, 218, 377–389. [Google Scholar] [CrossRef]

- Diliberto, C.; Lecomte, A.; Mechling, J.-M.; Izoret, L.; Smith, A. Valorisation of recycled concrete sands in cement raw meal for cement production. Mater. Struct. 2017, 50, 127. [Google Scholar] [CrossRef]

- Kim, Y.-J. Quality properties of self-consolidating concrete mixed with waste concrete powder. Constr. Build. Mater. 2017, 135, 177–185. [Google Scholar] [CrossRef]

- Kim, Y.J.; Choi, Y.W. Utilization of waste concrete powder as a substitution material for cement. Constr. Build. Mater. 2012, 30, 500–504. [Google Scholar] [CrossRef]

- Kwon, E.; Ahn, J.; Cho, B.; Park, D. A study on development of recycled cement made from waste cementitious powder. Constr. Build. Mater. 2015, 83, 174–180. [Google Scholar] [CrossRef]

- Xiao, J.; Ma, Z.; Sui, T.; Akbarnezhad, A.; Duan, Z. Mechanical properties of concrete mixed with recycled powder produced from construction and demolition waste. J. Clean. Prod. 2018, 188, 720–731. [Google Scholar] [CrossRef]

- Li, S.; Li, Q.; Zhao, X.; Luo, J.; Gao, S.; Yue, G.; Su, D. Experimental study on the preparation of recycled admixtures by using construction and demolition waste. Materials 2019, 12, 1678. [Google Scholar] [CrossRef] [PubMed]

- European Committee for Standardization. EN 933. Tests for Geometrical Properties of Aggregates—Part 11: Classification Test for the Constituents of Coarse Recycled Aggregate; European Committee for Standardization: Brussels, Belgium, 2010. [Google Scholar]

- Instrucción de Hormigón Estructural. EHE-08; Spanish Code on Structural Concrete: Madrid, Spain, 2008; Available online: https://www.mitma.gob.es/recursos_mfom/1820100.pdf (accessed on 5 April 2020).

- Agrela, F.; Sanchez de Juan, M.; Ayuso, J.; Geraldes, V.L.; Jimenez, J.R. Limiting properties in the characterisation of mixed recycled aggregates for use in the manufacture of concrete. Constr. Build. Mater. 2011, 25, 3950–3955. [Google Scholar] [CrossRef]

- European Committee for Standardization. EN 1097. Tests for Mechanical and Physical Properties of Aggregates. Part 6: Determination of Particle Density and Water Absorption; European Committee for Standardization: Brussels, Belgium, 2014. [Google Scholar]

- Rodrigues, F.; Evangelista, L.; de Brito, J. A new method to determine the density and water absorption of fine recycled aggregates. Mater. Res. 2013, 16, 1045–1051. [Google Scholar] [CrossRef]

- European Committee for Standardization. EN 1097. Tests for Mechanical and Physical Properties of Aggregates. Part 2: Methods for the Determination of Resistance to Fragmentation; European Committee for Standardization: Brussels, Belgium, 2010. [Google Scholar]

- European Committee for Standardization. EN 933. Tests for Geometrical Properties of Aggregates. Part 3: Determination of Particle Shape—Flakiness Index; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- European Committee for Standardization. EN 12390. Testing Hardened Concrete. Part 2: Making and Curing Specimens for Strength Tests; European Committee for Standardization: Brussels, Belgium, 2009. [Google Scholar]

- European Committee for Standardization. EN 12350. Testing Fresh Concrete. Part 2: Slump-Test; European Committee for Standardization: Brussels, Belgium, 2009. [Google Scholar]

- European Committee for Standardization. EN 12350. Testing Fresh Concrete. Part 6: Density; European Committee for Standardization: Brussels, Belgium, 2009. [Google Scholar]

- European Committee for Standardization. EN 12350. Testing Fresh Concrete. Part 7: Air Content—Pressure Methods; European Committee for Standardization: Brussels, Belgium, 2009. [Google Scholar]

- European Committee for Standardization. EN-12390. Testing Hardened Concrete. Part 3: Compressive Strength of Test Specimens; European Committee for Standardization: Brussels, Belgium, 2009. [Google Scholar]

- Spanish Committee for Standardization. UNE-83980. Concrete Durability. Test Methods. Determination of the Water Absorption, Density and Accessible Porosity for Water in Concrete; Spanish Committee for Standardization: Brussels, Belgium, 2014. [Google Scholar]

- Spanish Committee for Standardization. UNE 83988. Concrete Durability. Test Methods. Determination of the Electrical Resistivity. Part 2: Four Point or Wenner Method; Spanish Committee for Standardization: Madrid, Spain.

- ISOMET 2114. Applied Precision Ltd.: Bratislava, Slovakia, 2010. Available online: https://www.appliedp.com/download/catalog/isomet_pc_en.pdf (accessed on 7 April 2020).

- Ferreira, L.; de Brito, J.; Barra, M. Influence of the pre-saturation of recycled coarse concrete aggregates on concrete properties. Mag. Concr. Res. 2011, 63, 617–627. [Google Scholar] [CrossRef]

- ACI Committee 301. ACI 310-10. Specifications for Structural Concrete; ACI: Farmington Hills, MI, USA, 2010; 77p. [Google Scholar]

- Letelier, V.; Ortega, J.; Muñoz, P.; Tarela, E.; Moriconi, G. Influence of waste brick powder in the mechanical properties of recycled aggregate concrete. Sustainability 2018, 10, 1037. [Google Scholar] [CrossRef]

- Cantero, B.; Sáez del Bosque, I.F.; Matías, A.; Medina, C. Statistically significant effects of mixed recycled aggregate on the physical-mechanical properties of structural concretes. Constr. Build. Mater. 2018, 185, 93–101. [Google Scholar] [CrossRef]

- Bravo, M.; de Brito, J.; Pontes, J.; Evangelista, L. Mechanical performance of concrete made with aggregates from construction and demolition waste recycling plants. J. Clean. Prod. 2015, 99, 59–74. [Google Scholar] [CrossRef]

- Medina, C.; Zhu, W.; Howind, T.; Sánchez de Rojas, M.I.; Frías, M. Influence of mixed recycled aggregate on the physical—Mechanical properties of recycled concrete. J. Clean. Prod. 2014, 68, 216–225. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, J.; Chen, F.; Liu, C.; Chen, X. Utilization of waste clay bricks as coarse and fine aggregates for the preparation of lightweight aggregate concrete. J. Clean. Prod. 2018, 201, 706–715. [Google Scholar] [CrossRef]

- Medina, C.; Zhu, W.; Howind, T.; Frías, M.; Sánchez de Rojas, M.I. Effect of the constituents (asphalt, clay materials, floating particles and fines) of construction and demolition waste on the properties of recycled concretes. Constr. Build. Mater. 2015, 79, 22–33. [Google Scholar] [CrossRef]

- Cantero, B.; Sáez del Bosque, I.F.; Matías, A.; Sánchez de Rojas, M.I.; Medina, C. Water transport mechanisms in concretes bearing mixed recycled aggregates. Cem. Concr. Compos. 2020, 107, 103486. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.A.; de Brito, J.; Fiol, F. Micro- and macro-porosity of dry- and saturated-state recycled aggregate concrete. J. Clean. Prod. 2019, 211, 932–940. [Google Scholar] [CrossRef]

- Pedro, D.; de Brito, J.; Evangelista, L. Durability performance of high-performance concrete made with recycled aggregates, fly ash and densified silica fume. Cem. Concr. Compos. 2018, 93, 63–74. [Google Scholar] [CrossRef]

- Adamson, M.; Razmjoo, A.; Poursaee, A. Durability of concrete incorporating crushed brick as coarse aggregate. Constr. Build. Mater. 2015, 94, 426–432. [Google Scholar] [CrossRef]

- Levy, S.M.; Helene, P. Durability of recycled aggregates concrete: A safe way to sustainable development. Cem. Concr. Res. 2004, 34, 1975–1980. [Google Scholar] [CrossRef]

- Çakır, Ö. Experimental analysis of properties of recycled coarse aggregate (RCA) concrete with mineral additives. Constr. Build. Mater. 2014, 68, 17–25. [Google Scholar] [CrossRef]

- Chen, C.-T.; Chang, J.-J.; Yeih, W. The effects of specimen parameters on the resistivity of concrete. Constr. Build. Mater. 2014, 71, 35–43. [Google Scholar] [CrossRef]

- Fan, C.-C.; Huang, R.; Hwang, H.; Chao, S.-J. Properties of concrete incorporating fine recycled aggregates from crushed concrete wastes. Constr. Build. Mater. 2016, 112, 708–715. [Google Scholar] [CrossRef]

- Demirboǧa, R. Influence of mineral admixtures on thermal conductivity and compressive strength of mortar. Energy Build. 2003, 35, 189–192. [Google Scholar] [CrossRef]

- European Committee for Standardization. EN 1992. Eurocode 2: Design of Concrete Structures. Part 1–2: General Rules–Structural Fire Design; European Committee for Standardization: Brussels, Belgium, 2003. [Google Scholar]

- Real, S.; Gomes, M.G.; Moret Rodrigues, A.; Bogas, J.A. Contribution of structural lightweight aggregate concrete to the reduction of thermal bridging effect in buildings. Constr. Build. Mater. 2016, 121, 460–470. [Google Scholar] [CrossRef]

- Pavlu, T.; Fortova, K.; Divis, J.; Hajek, P. The utilization of recycled masonry aggregate and recycled EPS for concrete blocks for mortarless masonry. Materials 2019, 12, 1923. [Google Scholar] [CrossRef] [PubMed]

- Dodds, W.; Goodier, C.; Christodoulou, C.; Austin, S.; Dunne, D. Durability performance of sustainable structural concrete: Effect of coarse crushed concrete aggregate on microstructure and water ingress. Constr. Build. Mater. 2017, 145, 183–195. [Google Scholar] [CrossRef]

- Singh, N.; Singh, S.P. Evaluating the performance of self compacting concretes made with recycled coarse and fine aggregates using non destructive testing techniques. Constr. Build. Mater. 2018, 181, 73–84. [Google Scholar] [CrossRef]

| Property | OPC | RB10 | RB25 | EN 197-1 1 | |

|---|---|---|---|---|---|

| Setting time (min) | Initial | 84 | 90 | 91 | ≥60 |

| Final | 136 | 138 | 141 | - | |

| Water content (g) | 143 | 144 | 147 | - | |

| Normal consistency (mm) | 36 | 35 | 35 | 34 ± 2 | |

| 28 d compressive strength (MPa) | 67.5 ± 1.0 | 62.6 ± 1.0 | 51.39 ± 2.2 | ≥42.5 | |

| Parameter | Value | Property | Value |

|---|---|---|---|

| Cement type | CEM II/A-L 42.5 R | Slump class 2 | S3 |

| Cement content | 300 kg/m3 | Compressive strength 3 | 39.8 MPa |

| w/ceff 1 | 0.55 | Splitting tensile strength 3 | 2.75 MPa |

| Coarse aggregate | 1020 kg/m3 (crushed limestone) | Modulus of elasticity 3 | 38.9 GPa |

| Fine aggregate | 910 kg/m3 (natural river sand) |

| Constituent | Label | Content (wt%) |

|---|---|---|

| Concrete and mortar | Rc | 47.1 |

| Natural stone | Ru | 25.2 |

| Clay materials | Rb | 22.6 |

| Bituminous materials | Ra | 0.2 |

| Glass | Rg | 1.7 |

| Floating particles | FL | 1 |

| Gypsum | X1 | 1.8 |

| Metals | X2 | 0.4 |

| Property | NS-F | NS-C | NC-M | NC-G | MRA | EHE 08 |

|---|---|---|---|---|---|---|

| Dry density (kg/m3) [30] | 2581 | 2583 | 2600 | 2620 | 2069 | - |

| SSD 1 density (kg/m3) [30] | 2601 | 2609 | 2630 | 2670 | 2256 | - |

| 24 h water absorption (wt%) [30] | 0.4 | 0.5 | 1.3 | 1.3 | 9.1 | ≤5 |

| 10 min water absorption (wt%) [31] | 0.2 | 0.3 | 0.5 | 0.6 | 8.1 | - |

| Los Angeles coefficient (wt%) [32] | - | - | 28 | 26 | 46 | ≤40 |

| Flakiness index (wt%) [33]. | - | - | 13 | 16 | 20 | <35 |

| Parameter Tested | Standard | Specimen Dimensions |

|---|---|---|

| Fresh properties | ||

| Slump | EN 12350:2 [35] | - |

| Fresh density | EN 12350-6 [36] | |

| Air content | EN 12350-7 [37] | |

| Mechanical properties | ||

| Compressive strength | EN 12390-3 [38] | 150 mm Ø × 300 mm |

| Tensile strength | ||

| Physical properties | ||

| Open porosity Dry density | UNE 83,980 [39] | 100 × 100 × 100 mm |

| Electrical resistivity | UNE 83988-2 [40] | 100 mm Ø × 200 mm |

| Thermal properties | ||

| Thermal conductivity | ISOMET 2114 [41] | 100 × 100 × 500 mm |

| Volume heat capacity | ||

| Component | Amount (kg/m3) | |||||

|---|---|---|---|---|---|---|

| NAC | N10/0 | N25/0 | R0/50 | R10/50 | R25/50 | |

| Cement | 300.0 | 270.0 | 225.0 | 300.0 | 270.0 | 225.0 |

| GRC | - | 30.0 | 75.0 | - | 30.0 | 75.0 |

| Total water | 171.3 | 177.1 | 183.3 | 205.2 | 211.2 | 217.2 |

| NS-F | 154.0 | 150.0 | 154.0 | 154.0 | 154.0 | 154.0 |

| NS-C | 754.5 | 754.5 | 754.5 | 754.5 | 754.5 | 754.5 |

| NG-M | 367.0 | 367.0 | 367.0 | 183.6 | 183.6 | 183.6 |

| NG-G | 653.0 | 653.0 | 653.0 | 326.5 | 326.5 | 326.5 |

| MRA | - | - | - | 449.0 | 449.0 | 449.0 |

| Agg. Group | Mix | w/beff | Slump (mm) | Density (kg/m3) | Air Content (vol%) |

|---|---|---|---|---|---|

| NA | NAC | 0.56 | 65 ± 2.8 | 2367 ± 8 | 2.6 ± 0.2 |

| N10/0 | 0.58 | 74 ± 2.5 | 2340 ± 9 | 2.7 ± 0.2 | |

| N25/0 | 0.60 | 65 ± 3.7 | 2309 ± 10 | 2.9 ± 0.1 | |

| MRA | R0/50 | 0.59 | 75 ± 3.1 | 2251 ± 11 | 3.2 ± 0.1 |

| R10/50 | 0.61 | 61 ± 3.7 | 2244 ± 12 | 3.4 ± 0.2 | |

| R25/50 | 0.63 | 63 ± 4.2 | 2219 ± 10 | 3.8 ± 0.2 |

| NA mix | MRA mix | |||||

|---|---|---|---|---|---|---|

| Parameter/Differential | NAC | N10/0 | N25/0 | R0/50 | R10/50 | R25/50 |

| ρdry (kg/m3) | 2290 ± 35 | 2227 ± 20 | 2158 ± 25 | 2101 ± 40 | 2052 ± 38 | 1990 ± 42 |

| Δ with GRC (%) | - | −2.8 | −5.8 | - | −2.3 | −5.3 |

| Δ with MRA (%) | -8.3 | −7.9 | −7.8 | |||

| Δ with GRC (%) × MRA (%) | −10.4 | −13.1 | ||||

| Po (vol%) | 12.1 ± 0.2 | 12.7 ± 0.3 | 13.7 ± 0.3 | 15.2 ± 0.4 | 15.9 ± 0.5 | 16.9 ± 0.3 |

| Δ with GRC (%) | - | 5.0 | 13.2 | - | 4.6 | 11.2 |

| Δ with MRA (%) | 26.5 | 25.2 | 23.4 | |||

| Δ with GRC (%) × MRA (%) | 31.4 | 39.7 | ||||

| EC (10−3 Ω·m−1) | 8.8 ± 0.5 | 9.5 ± 0.3 | 10.6 ± 0.3 | 9.9 ± 0.3 | 10.2 ± 0.2 | 11.1 ± 0.4 |

| Δ with GRC (%) | - | −7.1 | −16.8 | − | −3.0 | −10.9 |

| Δ with MRA (%) | −10.6 | −6.7 | −4.3 | |||

| Δ with GRC (%) × MRA (%) | −13.3 | −20.4 | ||||

| NA mix | MRA mix | |||||

|---|---|---|---|---|---|---|

| Parameter/Differential | NAC | N10/0 | N25/0 | R0/50 | R10/50 | R25/50 |

| λ (W/m·K) 1 | 2.064 | 2.013 | 1.922 | 1.963 | 1.901 | 1.821 |

| Δ with GRC (%) | - | −2.5 | −6.9 | - | −3.1 | −7.2 |

| Δ with MRA (%) | −4.9 | −5.6 | −5.3 | |||

| Δ with GRC (%) × MRA (%) | −7.9 | −11.8 | ||||

| Volume heat capacity (MJ/m3·K) 1 | 1.864 | 1.839 | 1.828 | 1.781 | 1.771 | 1.768 |

| cρ (kJ/m3·K) | 0.814 | 0.826 | 0.847 | 0.848 | 0.863 | 0.888 |

| Δ with GRC (%) | - | 1.4 | 4.1 | - | 1.8 | 4.8 |

| Δ with MRA (%) | 4.1 | 4.5 | 4.9 | |||

| Δ with GRC (%) × MRA (%) | 6.0 | 9.1 | ||||

| NA mix | MRA mix | |||||

|---|---|---|---|---|---|---|

| Parameter/Differential | NAC | N10/0 | N25/0 | R0/50 | R10/50 | R25/50 |

| λs (W/m·K) 1 | 2.345 | 2.303 | 2.223 | 2.310 | 2.256 | 2.186 |

| Δ with GRC (%) | - | −1.8 | −5.2 | - | −2.4 | −5.4 |

| Δ with MRA (%) | −1.5 | −2.0 | −1.7 | |||

| Δ with GRC (%) × MRA (%) | −3.8 | −6.8 | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cantero, B.; Bravo, M.; de Brito, J.; Sáez del Bosque, I.F.; Medina, C. Thermal Performance of Concrete with Recycled Concrete Powder as Partial Cement Replacement and Recycled CDW Aggregate. Appl. Sci. 2020, 10, 4540. https://doi.org/10.3390/app10134540

Cantero B, Bravo M, de Brito J, Sáez del Bosque IF, Medina C. Thermal Performance of Concrete with Recycled Concrete Powder as Partial Cement Replacement and Recycled CDW Aggregate. Applied Sciences. 2020; 10(13):4540. https://doi.org/10.3390/app10134540

Chicago/Turabian StyleCantero, Blas, Miguel Bravo, Jorge de Brito, Isabel Fuencisla Sáez del Bosque, and César Medina. 2020. "Thermal Performance of Concrete with Recycled Concrete Powder as Partial Cement Replacement and Recycled CDW Aggregate" Applied Sciences 10, no. 13: 4540. https://doi.org/10.3390/app10134540

APA StyleCantero, B., Bravo, M., de Brito, J., Sáez del Bosque, I. F., & Medina, C. (2020). Thermal Performance of Concrete with Recycled Concrete Powder as Partial Cement Replacement and Recycled CDW Aggregate. Applied Sciences, 10(13), 4540. https://doi.org/10.3390/app10134540