The Effect of Curing Conditions on Selected Properties of Recycled Aggregate Concrete

Abstract

1. Introduction

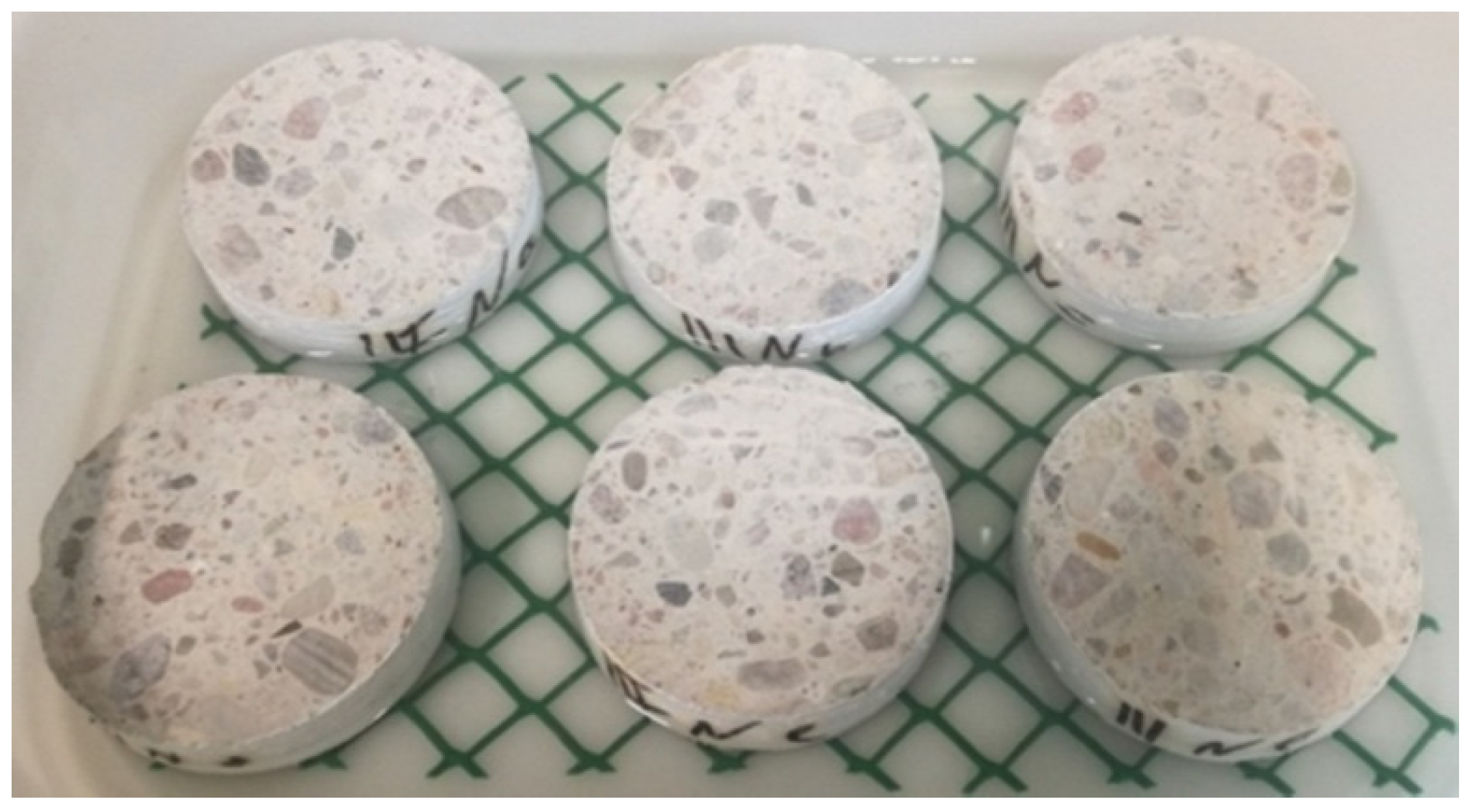

2. Materials and Methods

2.1. Materials

2.2. Methods

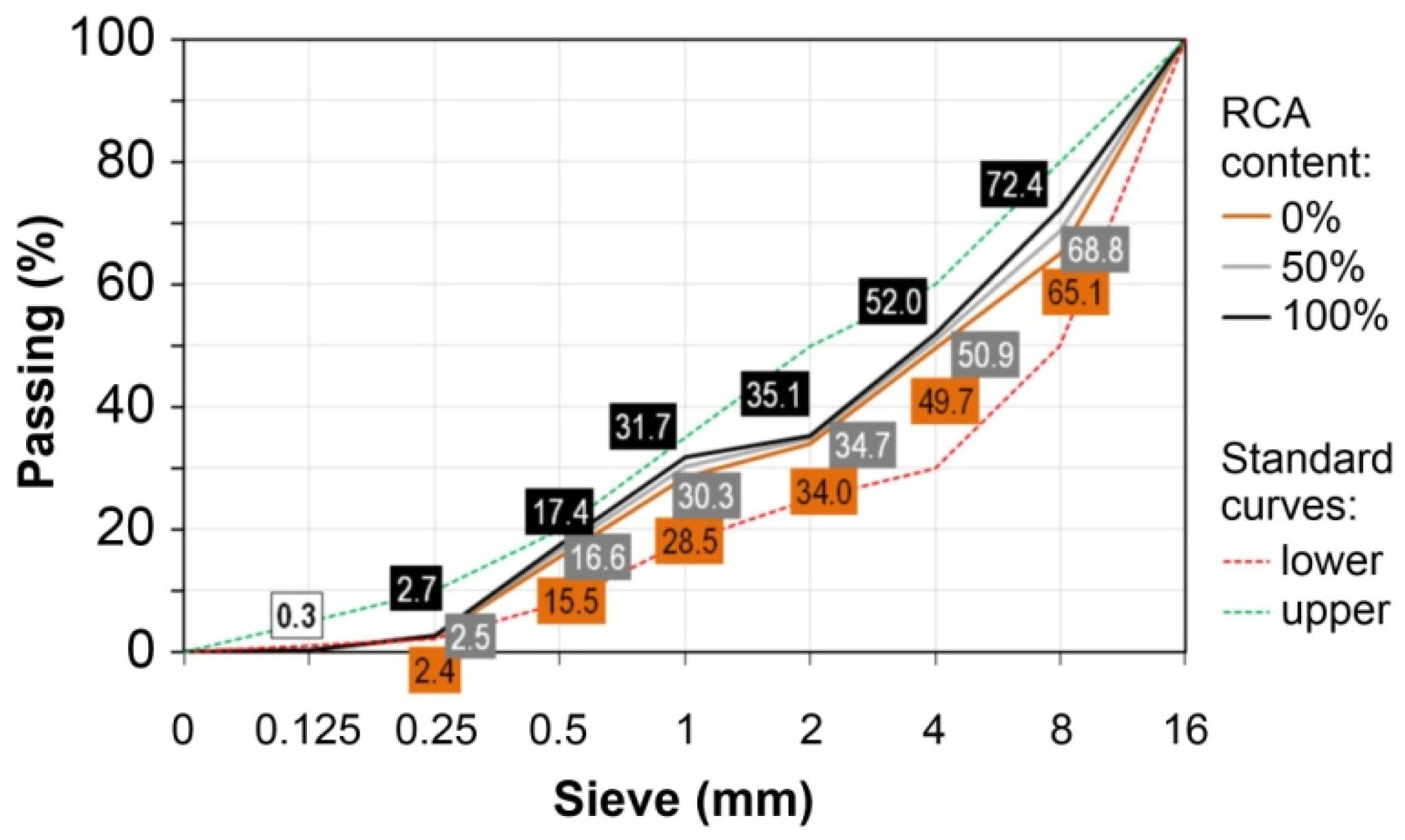

2.2.1. Granulometric Analysis of Aggregate

2.2.2. Water Absorption of Recycled Concrete Aggregate

- preparing aggregate samples (for each fraction: 4/6, 6/8, 8/12, and 12/16 mm) and weighing them using scales,

- putting the aggregate into small buckets,

- adding water to each bucket with an aggregate sample,

- waiting for 2 h in order to pre-soak the aggregate samples in water,

- removing aggregate samples from the bucket (using a sieve) and placing them on a towel for drying,

- waiting until the surface of aggregate was still in a wet state but without a visible layer of water on the grains’ surface,

- rotating the grains of aggregate in order to ease the evaporation of the surface layer of water,

- weighing the aggregate in wet state.

2.2.3. Concrete Recipes

2.2.4. Manufacturing Concrete Mixes

2.2.5. Properties of Concrete Mixes

2.2.6. Properties of Hardened Concretes

2.2.7. Eco-Efficiency and Eco-Durability Indexes

2.2.8. ANOVA and Tukey’s Test

3. Results and Discussion

3.1. Fresh Mix Properties

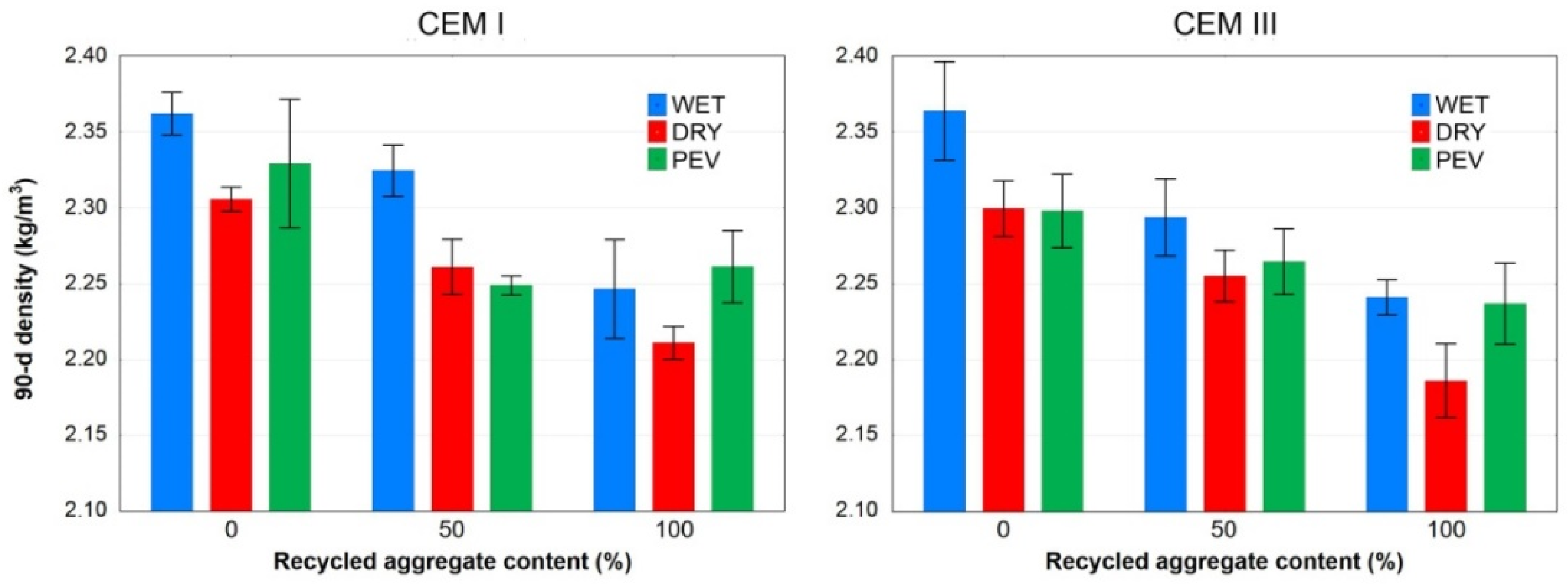

3.2. Density

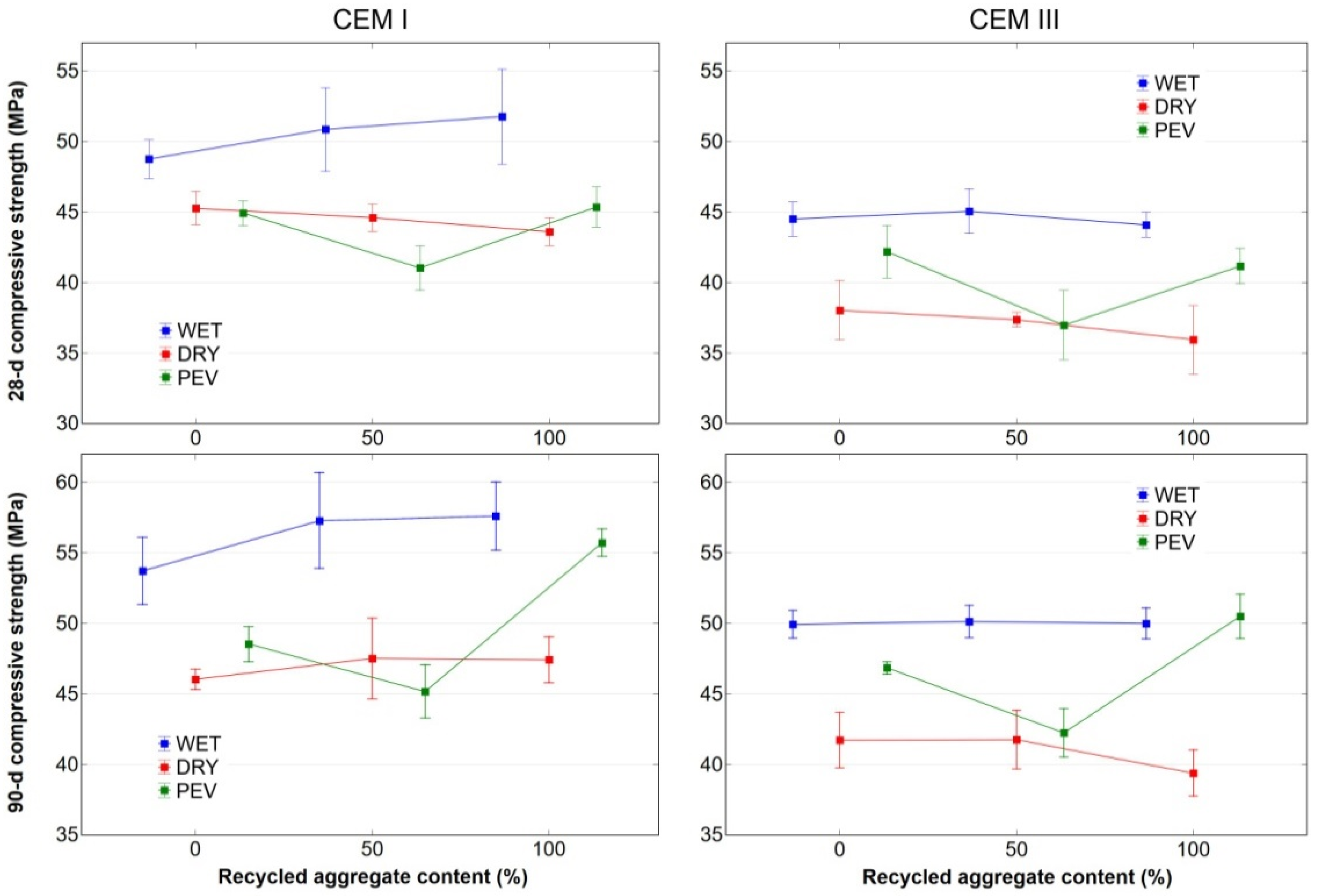

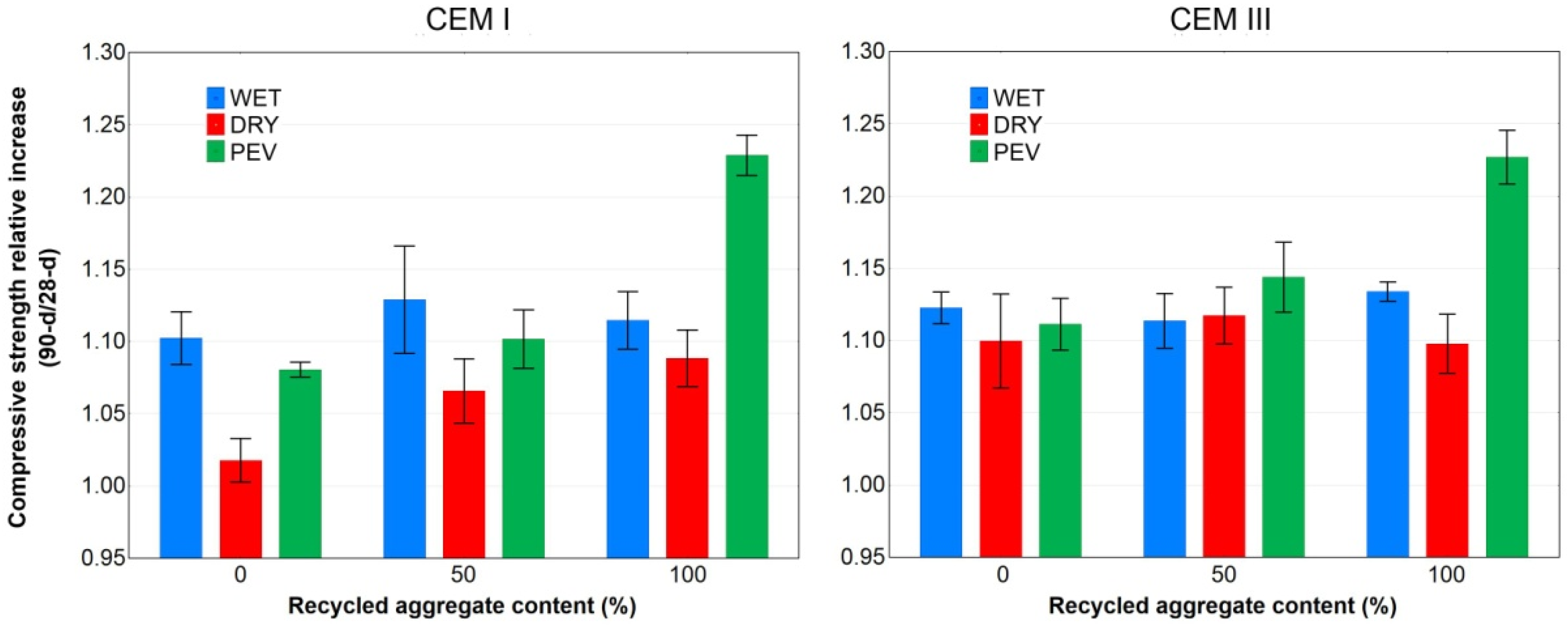

3.3. Compressive Strength

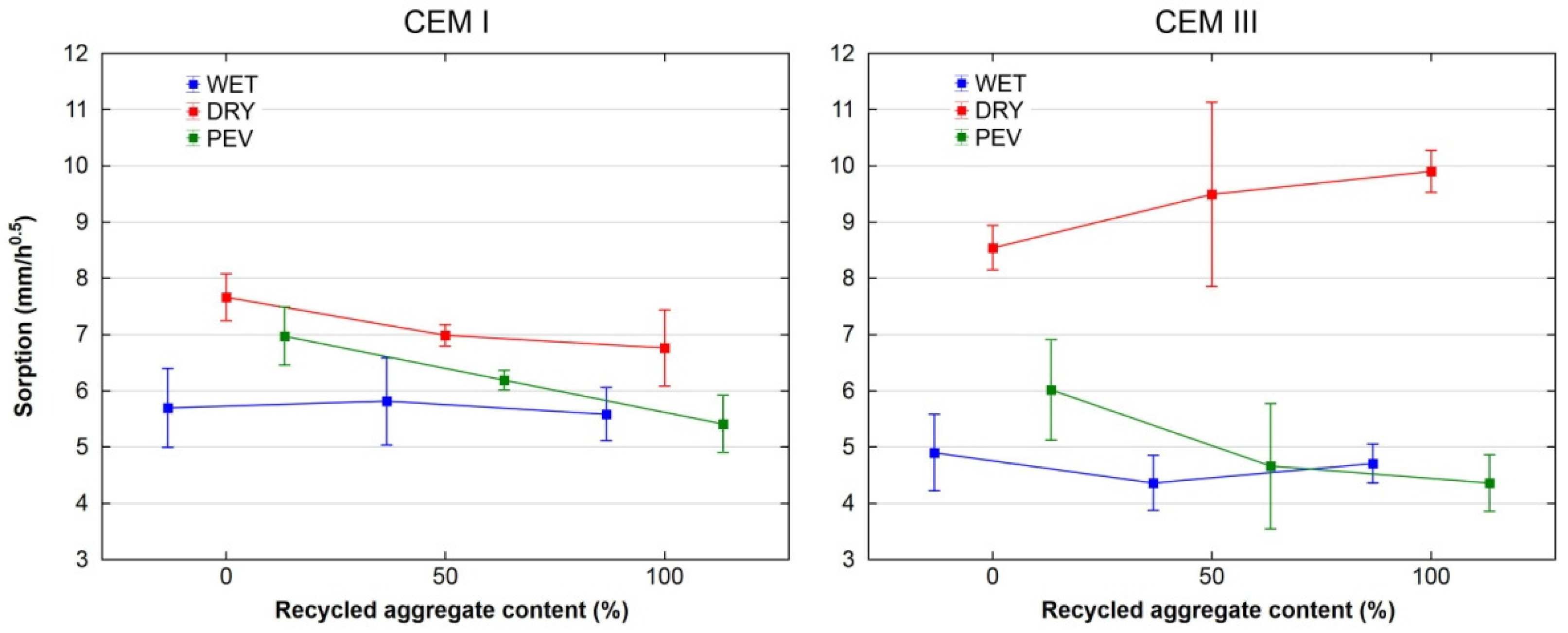

3.4. Sorption

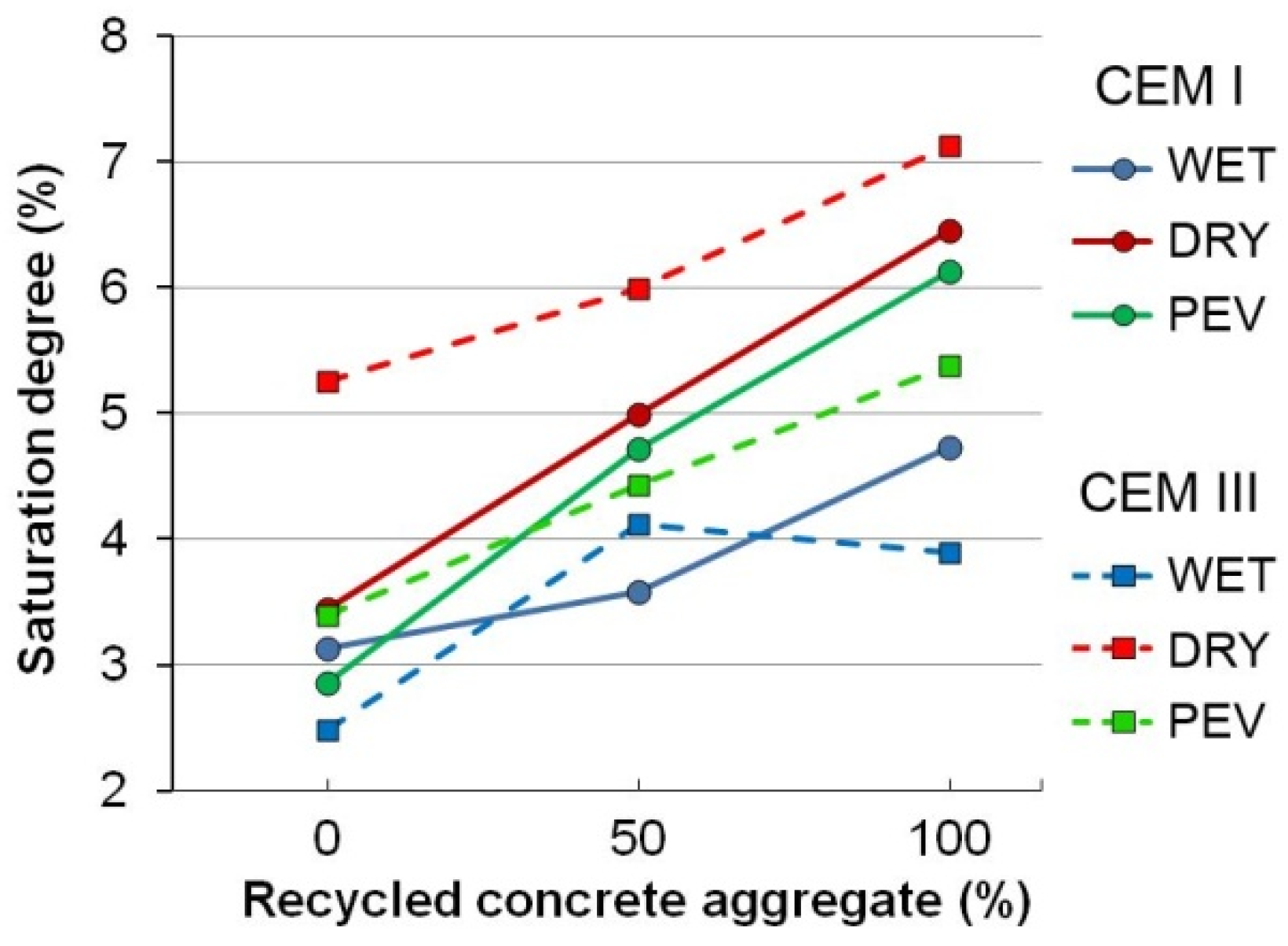

3.5. Saturation Degree

3.6. Eco-Efficiency and Eco-Durability Indexes

4. Conclusions

- Concrete mix made of CEM I turned out to be more sensitive to slump loss at the maximal content of RCA in comparison to concrete mix with blast-furnace slag cement as a binder. However, the worst influence of RCA presence on air content in concrete mix occurred when blast-furnace slag cement was used.

- Dry conditions of hardening were perceived as more hazardous for compressive strength in the case of concretes made of both CEM I and CEM III cement.

- Protection against drying (water evaporation) can be more sufficient for concrete with high amounts of RCA than for ordinary concrete, taking into account compressive strength and in comparison to wet conditions of curing.

- Statistical analysis showed that the influence of RCA participation on compressive strength was less meaningful than the way of curing for two opposite conditions (wet and dry).

- The conditions of hardening influenced the sorption of concrete, being definitely better for wet curing and with protection against drying (water evaporation) and in both cases better for CEM III than CEM I as a binder.

- The binder intensity index bi was slightly higher for CEM III than CEM I. However, the carbon dioxide emission index ci was better in cases where blast-furnace slag cement was used as a binder.

- In terms of durability, the authors of this paper propose the eco-durability index S-CO2, especially for composites with recycled aggregate. In the conducted research, more favorable values of this index were obtained for concrete with blast-furnace slag cement, but under the condition of proper curing.

Author Contributions

Funding

Conflicts of Interest

References

- Andrew, R.M. Global CO2 emissions from cement production. Earth Syst. Sci. Data. 2018, 10, 2213–2239. [Google Scholar] [CrossRef]

- Flower, D.J.; Sanjayan, J.G. Greenhouse Gas Emissions Due to Concrete Manufacture. In Handbook of Low Carbon Concrete; Nazari, A., Sanjayan, J.G., Eds.; Elsevier: Oxford, UK, 2017; Chapter 1; pp. 1–16. [Google Scholar] [CrossRef]

- Pawluczuk, E.; Kalinowska-Wichrowska, K. Ocena zastosowania spoiwa z recyklingu do betonów drobnoziarnistych. Civ. Environ. 2015, 6, 193–200. [Google Scholar]

- Pawluczuk, E.; Kozak, K. Wpływ stosowania drobnego kruszywa z recyklingu na wybrane właściwości kompozytów cementowych. Civ. Environ. 2016, 7, 39–45. [Google Scholar]

- Zhao, Z.; Remond, S.; Damidot, D.; Xu, W. Influence of fine recycled concrete aggregates on the properties of mortars. Constr. Build. Mater. 2015, 8, 179–186. [Google Scholar] [CrossRef]

- Yacoub, A.; Djerbi, A.; Fen-Chong, T. Water absorption in recycled sand: New experimental methods to estimate the water saturation degree and kinetic filling during mortar mixing. Constr. Build. Mater. 2018, 158, 464–471. [Google Scholar] [CrossRef]

- Shima, H.; Tateyashiki, H.; Matsuhashi, R.; Yoshida, Y. An advanced concrete recycling technology and its applicability assessment through input-output analysis. J. Adv. Concr. Technol. 2005, 6, 53–67. [Google Scholar] [CrossRef]

- Pawluczuk, E.; Kalinowska-Wichrowska, K.; Bołtryk, M.; Jiménez, J.R.; Fernández, J.M. The influence of heat and mechanical treatment of concrete rubble on the properties of recycled aggregate concrete. Materials 2019, 12, 367. [Google Scholar] [CrossRef]

- Katz, A. Treatments for the improvement of recycled aggregate. J. Mater. Civ. Eng. 2004, 16, 597–603. [Google Scholar] [CrossRef]

- Kim, H.S.; Kim, B.; Kim, K.S.; Kim, J.M. Quality improvement of recycled aggregates using the acid treatment method and the strength characteristics of the resulting mortar. J. Mater. Cycles Waste Manag. 2017, 19, 968–976. [Google Scholar] [CrossRef]

- Grabiec, A.M.; Klama, J.; Zawal, D.; Krupa, D. Modification of recycled concreteaggregate by calcium carbonate biodeposition. Constr. Build. Mater. 2012, 34, 145–150. [Google Scholar] [CrossRef]

- Qiu, J.; Tng, D.Q.S.; Yang, E.H. Surface treatment of recycled concrete aggregatesthrough microbial carbonate precipitation. Constr. Buid. Mater. 2014, 57, 144–150. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Butera, A.; Le, K.N. Carbon-conditioned recycled aggregate in concreteproduction. J. Clean. Prod. 2016, 13, 672–680. [Google Scholar] [CrossRef]

- Li, L.; Poon, C.S.; Xiao, J.; Xuan, D. Effect of carbonated recycled coarse aggregate onthe dynamic compressive behavior of recycled aggregate concrete. Constr. Build. Mater. 2017, 151, 52–62. [Google Scholar] [CrossRef]

- Xiao, J. Modification of Modeled Recycled Aggregate Concrete by Carbonation. In Recycled Aggregate Concrete Structures; Springer: Berlin, Germany, 2017; pp. 115–124. ISBN 978-3-662-53985-9. [Google Scholar]

- Thomas, B.S.; Gupta, R.C.; Panicker, V.J. Recycling of waste tire rubber as aggregate in concrete: Durability-related performance. J. Clean. Prod. 2016, 112, 504–513. [Google Scholar] [CrossRef]

- Montero, J.; Laserna, S. Influence of effective mixing water in recycled concrete. Constr. Build. Mater. 2017, 132, 343–352. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Gao, X.F.; Tam, C.M.; Chan, C.H. New approach in measuring water absorption of recycled aggregates. Constr. Build. Mater. 2008, 22, 364–369. [Google Scholar] [CrossRef]

- Ferreira, L.; de Brito, J.; Barra, M. Influence of the pre-saturation of recycled coarse concrete aggregates on concrete properties. Mag. Concr. Res. 2013, 63, 617–627. [Google Scholar] [CrossRef]

- Maultzsch, M. Wykorzystanie Przetworzonego Gruzu Budowlanego-Przyczynek Do Zrównoważonego Rozwoju Technologii Betonu; Dni Betonu: Szczyrk, Poland, 2002. [Google Scholar]

- Dworzańczyk-Krzywiec, D. Wpływ zawartości kruszywa z recyklingu na wybrane właściwości betonów. Civ. Environ. Eng. 2011, 2, 229–233. [Google Scholar]

- Gołda, A.; Giergiczny, Z. Popiół lotny składnikiem betonu zawierającego kruszywa z odzysku gruzu betonowego. Cem. Wapno Beton 2007, 12, 201–206. [Google Scholar]

- De Oliveira, M.B.; Vazquez, E. The influence of retained moisture in aggregates from recycling on the properties of new hardened concrete. Waste Manag. 1996, 16, 113–117. [Google Scholar] [CrossRef]

- Pawluczuk, E. Kształtowanie strefy kontaktowej kruszywo-zaczyn w betonach recyklingowych. Bud. Inżynieria Środowiska 2011, 2, 369–376. [Google Scholar]

- Tam, V.W.Y.; Gao, X.F.; Tam, C.M. Microstructural analysis of recycled aggregate concrete produced from two-stage mixing approach. Cem. Concr. Res. 2005, 35, 1195–1203. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Sun, Z.; Lange, D.A.; Shah, S.P. Properties of interfacial transition zones in recycled aggregate concrete tested by nanoindentation. Cem. Concr. Compos. 2013, 32, 276–292. [Google Scholar] [CrossRef]

- Sáez del Bosque, I.F.; Zhu, W.; Howind, T.; Matías, A.; Sánchez de Rojas, M.I.; Medina, C. Properties of interfacial transition zones (ITZs) in concrete containing recycled mixed aggregate. Cem. Concr. Compos. 2017, 81, 25–34. [Google Scholar] [CrossRef]

- Djerbi, A. Effect of recycled coarse aggregate on the new interfacial transition zone concrete. Constr. Build. Mater. 2018, 190, 1023–1033. [Google Scholar] [CrossRef]

- Hojati, M.; Rajabipour, F.; Radlińska, A. Drying shrinkage of alkali-activated cements effect of humidity and curing temperature. Mater. Struct. 2019, 52, 118–132. [Google Scholar] [CrossRef]

- Humad, A.M.; Provis, J.L.; Ćwirzeń, A. Effects of curing conditions on shrinkagealkali-activated high-mgo swedish slag concrete. Front. Mater. 2019, 6, 287–306. [Google Scholar] [CrossRef]

- Fonseca, N.; De Brito, J.; Evangelista, L. The influence of curing conditions on the mechanical performance of concrete made with recycled concrete waste. Cem. Concr. Compos. 2011, 33, 637–643. [Google Scholar] [CrossRef]

- Gonzalez-Corominas, A.; Etxeberria, M.; Poon, C.S. Influence of steam curing on the pore structures and mechanical properties of fly-ash high performance concrete prepared with recycled aggregates. Cem. Concr. Compos. 2016, 71, 77–84. [Google Scholar] [CrossRef]

- Hanif, A.; Kim, Y.; Usman, M.; Park, C. Optimization of steam-curing regime for recycled aggregate concrete incorporating high early strength cement—A parametric study. Materials 2018, 11, 2487. [Google Scholar] [CrossRef]

- Damineli, B.L.; Kemeid, F.M.; Aguiar, P.S.; John, V.M. Measuring the eco-efficiency of cement use. Cem. Concr. Compos. 2010, 32, 555–562. [Google Scholar] [CrossRef]

- Kjellsen, K.O.; Guimaraes, M.; Nilsson, Å. The CO2 Balance of Concrete in a Life Cycle Perspective; Danish Technological Institute: Taastrup, Denmark, 2005; pp. 23–30. [Google Scholar]

- Kikuchi, T.; Kuroda, Y. Carbon dioxide uptake in demolished and crushed concrete. J. Adv. Concr. Technol. 2011, 9, 115–124. [Google Scholar] [CrossRef]

- Ortega, J.M.; Treminó, R.M.; Sánchez, I.; Climent, M.A. Effect of environment on the microstructure and properties of sustainable mortars with fly ash and slag after a 5-year exposure period. Sustainability 2018, 10, 663. [Google Scholar] [CrossRef]

- EN-1008:2002. Mixing Water for Concrete. Specification for Sampling, Testing and Assessing the Suitability of Water, Including Water Recovered from Processes in the Concrete Industry, as Mixing Water for Concrete. Available online: https://shop.bsigroup.com/ProductDetail/?pid=000000000019990036 (accessed on 20 May 2020).

- EN-933-2:1999. Test for Geometrical Properties of Aggregate—Part 2: Determination of Particle Size. Available online: https://infostore.saiglobal.com/en-au/Standards/EN-933-2-1995-330015_SAIG_CEN_CEN_759342/ (accessed on 20 May 2020).

- EN 12350-2:2009. Testing Fresh Concrete—Part 2. Slump flow. Available online: https://infostore.saiglobal.com/preview/98695517465.pdf?sku=870304_saig_nsai_nsai_2069434 (accessed on 20 May 2020).

- EN 12350-7:2009. Testing Fresh Concrete—Part 7. Air Content. Pressure Methods. Available online: https://infostore.saiglobal.com/preview/98695940447.pdf?sku=870311_SAIG_NSAI_NSAI_2069453 (accessed on 20 May 2020).

- EN 12350-3:2009. Testing Hardened Concrete—Part 3. Compressive strength of Test Specimens. Available online: https://infostore.saiglobal.com/preview/is/en/2009/i.s.en12390-3-2009%2Bac-2011.pdf?sku=1117182 (accessed on 20 May 2020).

- Olorunsogo, F.T.; Padayachee, N. Performance of recycled aggregate concrete monitored by durability indexes. Cem. Conc. Res. 2002, 6, 179–185. [Google Scholar] [CrossRef]

- EN 13057:2002. Products and Systems for the Protection and Repair of Concrete Structures. Test Methods. Determination of Resistance of Capillary Absorption. Available online: https://shop.bsigroup.com/ProductDetail?pid=000000000030058207 (accessed on 20 May 2020).

| Characteristic | Cement Type * | |

|---|---|---|

| CEM I | CEM III | |

| Compressive strength [MPa] after: | ||

| 2 days | 29.6 | 14.4 |

| 28 days | 56.8 | 52.7 |

| Blaine specific surface [m2/kg] | 387 | 467 |

| Ignition loss [%] | 3.2 | 0.7 |

| Insoluble parts [%] | 0.9 | 0.3 |

| SO3 [%] | 2.7 | 2.2 |

| Cl− [%] | 0.07 | 0.07 |

| Al2O3 [%] | 5.2 | 7.65 |

| Na2O eq [%] | 0.61 | 0.7 |

| MgO [%] | 1.2 | 1.4 |

| C3S [%] | 54.4 | 28.3 |

| C3A [%] | 8.9 | 3.7 |

| Constituent | Unit | PC_1 | PC_2 | PC_3 |

|---|---|---|---|---|

| CEM I 42,5 N-HSR/NA | [kg/m3] | 329 | 284 | 240 |

| Water | [kg/m3] | 148 | 156 | 156 |

| w/c ratio | [-] | 0.45 | 0.55 | 0.65 |

| Sand 0/2 mm | [kg/m3] | 646 | 645 | 649 |

| Gravel 2/8 mm | [kg/m3] | 804 | 814 | 834 |

| Gravel 8/16 mm | [kg/m3] | 536 | 543 | 556 |

| 60-d compressive strength * | [MPa] | 61.8 | 45.2 | 36.8 |

| Fraction (mm) | Mass of Aggregate (g) | Water Absorption | |

|---|---|---|---|

| Dry State | Wet State | (%) | |

| 4/6 | 400 | 411.3 | 2.8 |

| 6/8 | 600 | 614.2 | 2.4 |

| 8/12 | 800 | 823.6 | 3.0 |

| 12/16 | 1200 | 1228 | 2.3 |

| Constituent | Unit | 0% RCA | 50% RCA | 100% RCA |

|---|---|---|---|---|

| Cement (CEM I or CEM III) | (kg/m3) | 386 | 386 | 386 |

| Superplasticiser | (% of CEM) | 0.2 | 0.2 | 0.2 |

| w/c | (-) | 0.45 | 0.45 | 0.45 |

| Water | (kg/m3) | 175 | 175 | 175 |

| Wabs * | 0 | 11.5 | 23.0 | |

| W (total) | 175 | 186.5 | 198 | |

| Sand 0/2 mm | (kg/m3) | 577 | 616 | 648 |

| Natural 2/4 mm | 0 | 137 | 278 | |

| Gravel 2/8 mm | 636 | 316 | 0 | |

| Gravel 8/16 mm | 636 | 316 | 0 | |

| RCA 4/6 mm | (kg/m3) | 0 | 93 | 184 |

| RCA 6/8 mm | 0 | 79 | 157 | |

| RCA 8/12 mm | 0 | 139 | 278 | |

| RCA 12/16 mm | 0 | 101 | 202 |

| Cement Type | RCA Content (%) | Slump (mm) | Air Content (%) |

|---|---|---|---|

| CEM I | 0 | 135 | 3.6 |

| 50 | 150 | 4.4 | |

| 100 | 58 | 3.8 | |

| CEM III | 0 | 165 | 2.8 |

| 50 | 130 | 4.3 | |

| 100 | 120 | 4.9 |

| Cement Type | RCA (%) | Curing Conditions | fc 90-d (MPa) | Homogenous Groups | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | ||||

| III | 100 | Dry | 39.4 | *** | |||||||

| III | 0 | Dry | 41.8 | *** | *** | ||||||

| III | 50 | Dry | 41.8 | *** | *** | ||||||

| III | 50 | PEV | 42.3 | *** | *** | ||||||

| I | 50 | PEV | 45.2 | *** | *** | ||||||

| I | 0 | Dry | 46.1 | *** | |||||||

| III | 0 | PEV | 46.9 | *** | *** | ||||||

| I | 100 | Dry | 47.5 | *** | *** | *** | |||||

| I | 50 | Dry | 47.6 | *** | *** | *** | |||||

| I | 0 | PEV | 48.5 | *** | *** | *** | |||||

| III | 0 | Wet | 50.0 | *** | *** | ||||||

| III | 100 | Wet | 50.0 | *** | *** | ||||||

| III | 50 | Wet | 50.2 | *** | *** | ||||||

| III | 100 | PEV | 50.5 | *** | *** | ||||||

| I | 0 | Wet | 53.7 | *** | *** | ||||||

| I | 100 | PEV | 55.7 | *** | *** | ||||||

| I | 50 | Wet | 57.3 | *** | |||||||

| I | 100 | Wet | 57.6 | *** | |||||||

| Cement Type | RCA Content (%) | Curing Conditions | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Wet | Dry | PEV | ||||||||

| bi | ci | S-CO2 | bi | ci | S-CO2 | bi | ci | S-CO2 | ||

| CEM I | 0 | 7.2 | 5.5 | 0.231 | 8.4 | 6.4 | 0.172 | 8.0 | 6.0 | 0.189 |

| 50 | 6.7 | 5.1 | 0.226 | 8.1 | 6.4 | 0.188 | 8.5 | 6.5 | 0.212 | |

| 100 | 6.7 | 5.1 | 0.201 | 8.1 | 6.2 | 0.204 | 6.9 | 5.3 | 0.249 | |

| CEM III * | 0 | 7.7 | 2.8 | 0.567 | 9.3 | 3.3 | 0.325 | 8.2 | 3.0 | 0.462 |

| 50 | 7.7 | 2.8 | 0.636 | 9.3 | 3.3 | 0.293 | 9.1 | 3.3 | 0.596 | |

| 100 | 7.7 | 2.8 | 0.590 | 9.8 | 3.5 | 0.280 | 7.6 | 2.8 | 0.637 | |

| CEM III ** | 0 | 3.0 | 0.526 | 3.6 | 0.302 | 3.2 | 0.428 | |||

| 50 | 3.0 | 0.590 | 3.6 | 0.270 | 3.5 | 0.553 | ||||

| 100 | 3.0 | 0.547 | 3.8 | 0.260 | 3.0 | 0.591 | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grabiec, A.M.; Zawal, D.; Rasaq, W.A. The Effect of Curing Conditions on Selected Properties of Recycled Aggregate Concrete. Appl. Sci. 2020, 10, 4441. https://doi.org/10.3390/app10134441

Grabiec AM, Zawal D, Rasaq WA. The Effect of Curing Conditions on Selected Properties of Recycled Aggregate Concrete. Applied Sciences. 2020; 10(13):4441. https://doi.org/10.3390/app10134441

Chicago/Turabian StyleGrabiec, Anna M., Daniel Zawal, and Waheed Adewale Rasaq. 2020. "The Effect of Curing Conditions on Selected Properties of Recycled Aggregate Concrete" Applied Sciences 10, no. 13: 4441. https://doi.org/10.3390/app10134441

APA StyleGrabiec, A. M., Zawal, D., & Rasaq, W. A. (2020). The Effect of Curing Conditions on Selected Properties of Recycled Aggregate Concrete. Applied Sciences, 10(13), 4441. https://doi.org/10.3390/app10134441