1. Introduction

Filler is a necessary component to maximize the stability of asphalt mixture. It plays a role in increasing the bonding between asphalt and aggregate, which is typically chosen on the basis of the material’s properties [

1]. Many types of waste materials can be used in various purposes, such as the replacement of mineral fillers or additives to increase the asphalt mixture performance [

2]. The use of these materials can help not only to solve environmental problems, but also it can enhance the economic value to those materials [

3].

The use of natural fibers in asphalt mixtures to improve the moisture damage resistance and rutting resistance has been proposed in many researches, such as fibers from banana trees [

4], bamboo plants [

5], cellulose [

6], coconut [

7,

8], hemp [

9], jute [

10], kapok [

11], peat [

12,

13], and sisal [

14]. The capability of water absorption of each type of fiber is different. Recently, some researchers have conducted the replacement of mineral filler by bagasse ash fillers. They found that replacing bagasse ash filler in asphalt mixture can improve performances of the Marshall stability, flow, and resilient modulus of hot-mix asphalt (HMA) [

15,

16]. De Majer, P.K. studied the effects of adding peat powder and peat fibers into bituminous binders and asphalt mix. It was found that adding more peat powder resulted in higher stiffness [

17]. In addition, a study of coconut coir dust [

18] found that the content of coconut coir dust should be optimum to obtain the mechanical properties. If the content is exceeded, the properties will change, resulting in weakening asphalt mixtures.

In this study, researchers focused on the effect of using different natural fillers in asphalt mixture on moisture damage resistance. The coconut peat and bagasse were selected as fillers in this study since the quantity of these two natural waste materials in Thailand is relatively high. About 4,500,000 tons and 50,000 tons of the bagasse and coconut peat are produced a year, respectively, while about 2,000,000 tons/year of the aggregate fillers for asphalt road construction are used. As a result, the amount of natural waste materials was considered to minimize agricultural waste disposal through the substitution of aggregate fillers with bagasse and coconut peat.

Nowadays, moisture damage is of concern for pavement in Thailand. It is commonly found that most pavements are damaged by moisture from rainwater and undrained water. Moisture damage can be caused by either of two main mechanisms: An adhesive failure between the asphalt binder and the aggregate surface, or a cohesive failure of the asphalt mastic bond resulting from an interaction with moisture. Adhesive failure is the loss of the bond between the asphalt binder and aggregate, in which the asphalt binder acts as an adhesive and the aggregate acts as an adherend [

19]. However, this failure is considered the only asphalt binder phase in asphalt mixture, which cannot address the other mechanism. Cohesion loss of asphalt mastic bond is another mechanism affecting moisture damage in asphalt mixtures. It occurs when the asphalt mastic is weakened by the diffusion of water into the asphalt binder and the migration of water through the mastic to the mastic-aggregate interface [

20]. By reducing the strength of the mastic due to moisture accumulation and void swelling, water may affect the coherent loss the mastic-aggregate interface [

21]. To determine the adhesive and cohesive failures of asphalt binder and mastic, the Binder Bond Strength (BBS) test can be used as a robust test [

22,

23]. However, the most widely used moisture damage resistance standard test for asphalt mixture specimen is the indirect tensile strength (ITS) test specified in American Association of State Highway and Transportation Officials T 283 (AASHTO T 283) and Hamburg Wheel Tracking Test (HWT). There have been no robust other alternative tests that can determine the moisture damage resistance of asphalt mixture. One device that may be applied in measuring this failure in asphalt mixture is the pull-off tensile strength device, which is typically used for measuring the tensile strength of concrete surfaces and the bond strength or tensile strength of concrete repair.

In this study, coconut peat and baggage fillers were selected, as they were hypothesized to leverage the moisture damage resistance in asphalt mixture. With the increasing value of waste natural materials for agriculturists and the search for an alternative test to determine moisture damage resistance, the objectives in this study were to investigate the effects of waste natural fillers in asphalt mixture on adhesive bonding caused by moisture, and to determine whether the pull off tensile strength (POTS) test is a potential method in measuring moisture damage resistance in a laboratory.

2. Materials and Methods

Four types of fillers obtained from various Thailand quarries and fields were selected to use in the asphalt mix design, including limestone, granite, bagasse, and coconut peat. These four fillers exhibited significantly different moisture absorption when subjected to laboratory conditions as shown in

Table 1. However, it is unclear whether different fillers’ moisture absorptions can be correlated to the resistance to moisture damage, as filler exists in the asphalt mastics. In this study, fillers were added in the asphalt mixture at 20–30% by volume.

From

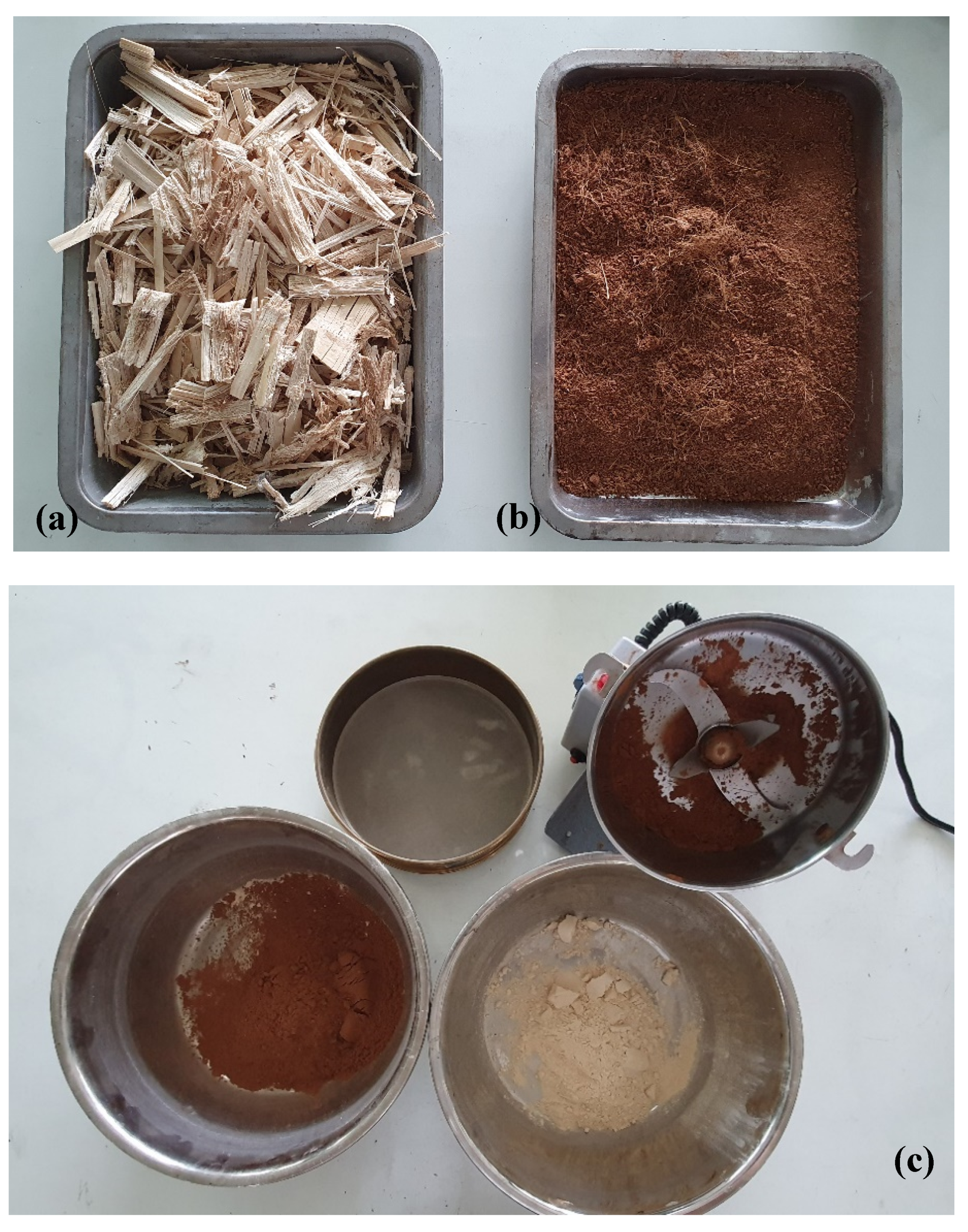

Table 1, it is shown that the water absorption of bagasse and coconut peat (69.3% and 52.5%, respectively) were much higher than those of limestone and granite (1.59% and 0.45%, respectively). Two different waste natural fillers, bagasse (

Figure 1a) and coconut peat (

Figure 1b), were grinded by grinding machine. Then, they were sieved with sieve number 200 (0.075 mm) to obtain fillers from passing through the sieve as shown in

Figure 1c. The asphalt binder AC 60–70 was obtained from the TIPCO Asphalt PCL (Bangkok, Thailand) used in this study. Two types of aggregate were used: Limestone and granite. Aggregate gradation was designed according to the high traffic volume of Superpave specification (

Figure 2).

To select the filler contents, the densities of each filler must be known. Bagasse and coconut peat fillers were estimated at densities of 0.379 g/cm3 and 0.289 g/cm3, respectively, while the limestone and granite fillers were equal to 2.62 g/cm3 and 2.58 g/cm3, respectively. Results show that the waste natural fillers gave less densities than mineral fillers about 7–10 times. Therefore, if the same volume of filler is used, there will be much less waste natural fillers than mineral ones in terms of weight. In the AASHTO specification, the mix design specification suggests that agencies consider changing the limit of dust-to-binder (D/B) ratio for coarse-graded mixes to 0.8 to 1.6 by weight. As a result, the added filler of 20% by volume was made to maintain the minimum dust-to-binder ratio for mineral fillers. By selecting another higher filler amount for waste natural fillers, the critical D/B ratio for mineral filler was set at 40% by volume. However, it was not appropriate for the asphalt mixture, as the workability was poor. Therefore, the use of 30% by volume was selected as the maximum threshold for adding waste natural filler.

2.1. Indirect Tensile Strength Test

The indirect tensile strength (ITS) test, as indicated in AASHTO T283, is prevalently used to determine moisture damage resistance in asphalt mixture. The static indirect tensile strength of a specimen is determined with a loading rate of 51 mm/min. The peak load is recorded and divided by geometrical factors to obtain the split tensile strength as presented in Equation (1).

where S

t = Indirect tensile strength (kPa),

P = maximum load (N),

t = specimen height immediately before test (mm), and

D = specimen diameter (mm).

Two test conditions (i.e., dry and wet) were conducted. In the dry condition, samples were kept for 24 h at room temperature before being subjected to a test. In the wet condition, samples were kept in a temperature-controlled water bath at 60 ± 1 °C for 24 h. The testing method was implemented in the Superpave system measured by the ITS testing machine to determine the susceptibility to moisture of the asphalt mixture. The samples subjected to two conditions were tested to obtain the results of each tensile strength. Then, the tensile strength ratio (TSR) to determine the suitable mixtures for resistance to moisture damage was calculated as shown in Equation (2).

2.2. Pull-Off Tensile Strength Test

In the 1970s, the POTS test was developed in England to assess in situ concrete strength due to concrete problems created with high aluminum cement [

24]. Also, this test can be used to verify the adherence quality of the concrete repair material [

25]. The POTS test is standardized in UK and USA (ASTM C 1583) and recognizes the approach as a way of estimating the compressive strength in field [

26]. This approach is appropriate for use on beams and slabs and in short-section structural elements. However, it has not been shown in any studies using this method for determining the tensile strength for moisture damage resistance in asphalt mixture. The POTS test is based on the basic assumption that an asphalt-mixed surface-layer of a metal disc (Dolly) has a direct traction force (tensile strength) of the material. The tensile force recorded that causes breakage can be used to determine the tensile strength. The POTS device and all setups are shown in

Figure 3.

Before testing, the sample preparation needed to be proceeded in order. Once cured at room temperature for 24 h, two sets of Marshall samples were attached to the dollies (

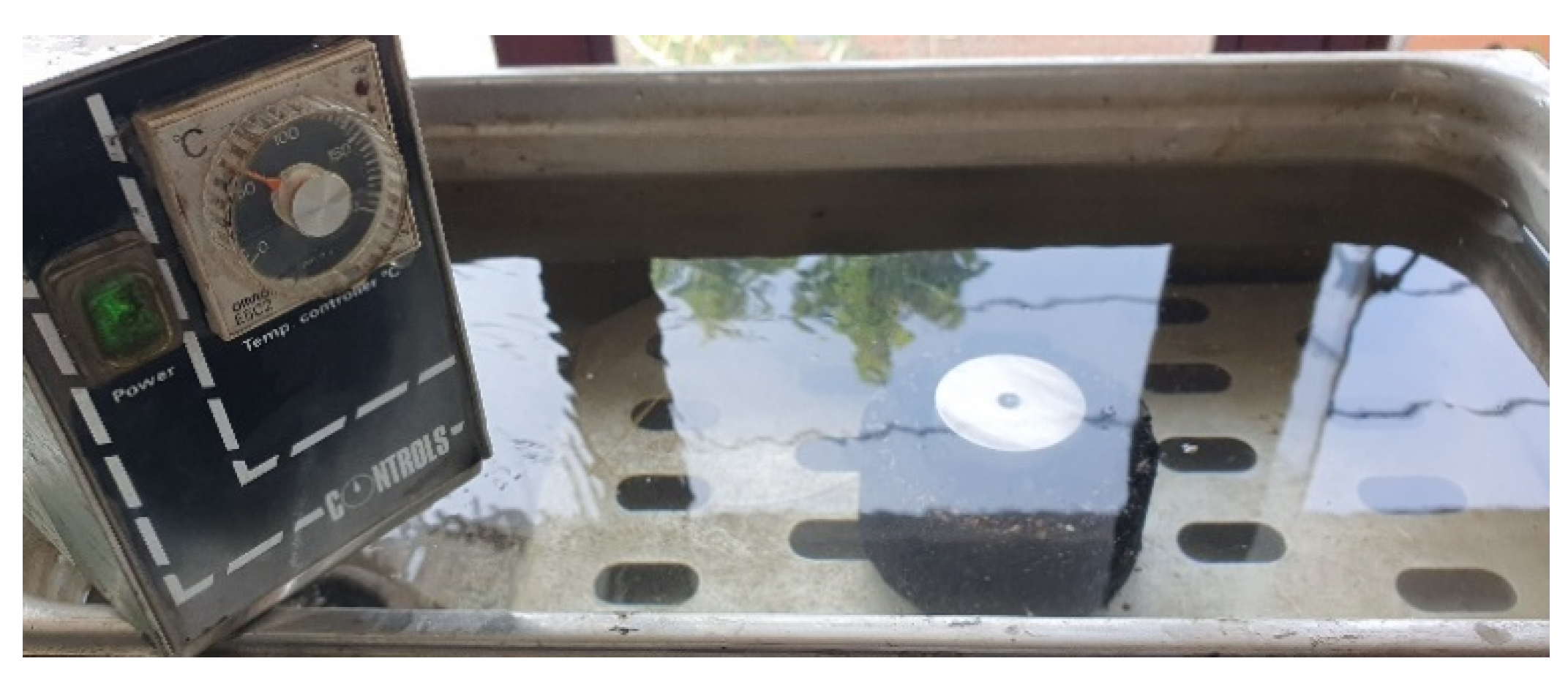

Figure 4). After the preparation of the asphalt mixture samples, the coring machine was used to drill 4-mm-thick holes into asphalt mixtures and perpendicular to the surface. It is necessary to maintain perpendicularity while drilling over the dolly, so that the dolly is not affected by any adhesive bonds. Two conditions for curing samples were conducted: Curing at maximum temperature of performance grade (PG) for 24 h in dry condition, and curing in a water bath for 2 h (

Figure 5) at maximum temperature of PG in wet condition. After curing, samples were removed from the water and maintained at room temperature for 1 h before testing. The use of the maximum temperature of PG as the wet condition temperature was from the preliminary result. Since this method was deemed to be the direct tensile strength method, a higher temperature was needed, otherwise the dolly would not be removed from the asphalt mixture. In this study, after testing the PG, the maximum temperature of AC60-70 was 64 °C, which is Performance Grade 64 (PG64). When a sample was ready, a dolly was attached to the pull-off tensile strength testing device using the coupling device. Then, the tensile load was applied to the test sample with the tensile load maintained at a constant rate during the test so that the force was parallel to and coincident with the axis of the sample. The parameter was calculated and recorded as the POTS calculated using Equation (3):

3. Results and Analysis

3.1. Effect of Filler Type and Volume on Moisture Damage Resistance

Mineral fillers are important factors in asphalt mixtures as they assist in increasing the stiffness of asphalt binder, thus providing more resistance to rutting at high temperatures. However, fillers can also impact asphalt bonding to aggregates, thus increasing the susceptibility to moisture of the asphalt mixtures. A previous study [

23] showed that the type of mineral fillers affected moisture damage resistance. However, there has not been studies on the effect of different asphalt mastic volume on moisture damage resistance. Four types of filler, including limestone, granite, bagasse, and coconut peat were added to the asphalt binder at 20% and 30% by volume of the asphalt mastic.

Table 2 shows the values of ITS test on asphalt mixtures with limestone aggregate and different filler contents (i.e., 20% and 30% by volume) for all four filler types in the dry and wet conditions. The results show show that in the dry condition, the values of ITS of 20% filler were in the range of 0.24–0.28 MPa, while the those of 30% filler showed higher strength in the range of 0.27–0.32 MPa for all filler types. Similarly, results show that after the wet conditioning, the ITS values of 20% filler were lower than those of 30% filler for all filler types.

Table 3 shows the values of ITS test on asphalt mixtures with granite aggregate and different filler contents (i.e., 20% and 30% by volume) for all four filler types in the dry and wet conditions. The results are different from the limestone aggregate, as the higher content of filler yielded lower values of ITS in the dry condition. Similarly, in the wet condition, the ITS values at higher content (i.e., 30% by volume) of filler were higher than those at lower content (i.e., 20% by volume).

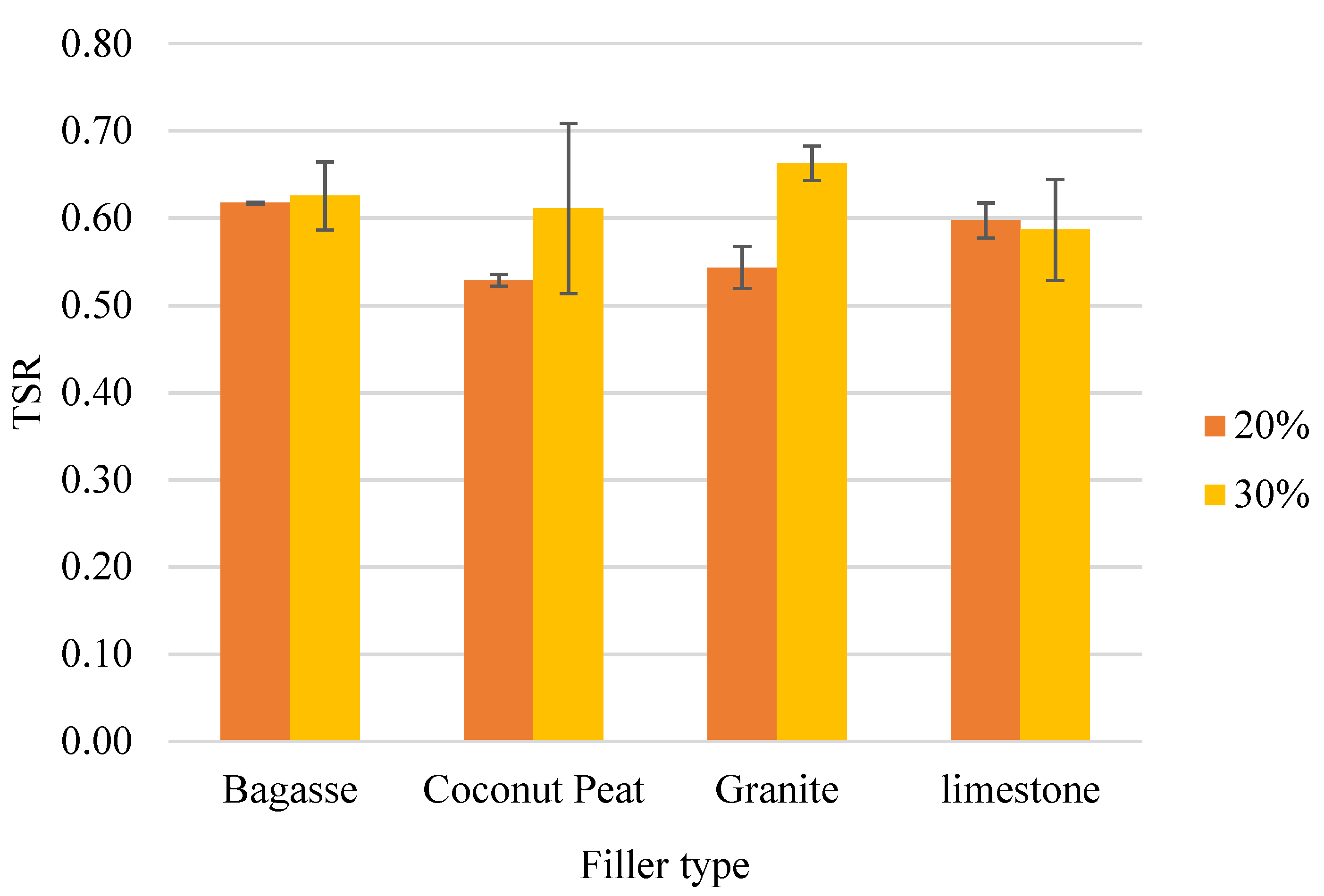

To identify the potential effect of filler types on moisture damage resistance, the TSR was calculated as the indicator from the ITS testing.

Figure 6 shows the ratio of tensile strength after the wet conditioning of asphalt mixtures with limestone aggregate for all filler types. The results show that the TSR values for both filler contents were above the 0.7, which is a typical specification threshold of minimum tensile strength ratio. The results show that both waste natural materials (i.e., bagasse and coconut peat) can be used as fillers at 20% and 30% by volume for limestone aggregate to resist the moisture damage in asphalt mixture since they showed the values of TSR in range of 0.73–0.89. The results also show that the TSR for the 20% filler gave higher values than those for the 30% filler. In contrast, TSR for granite aggregate present lower values than 0.7 for all fillers as shown in

Figure 7. However, using waste natural fillers (i.e., 0.61 and 0.63 for bagasse and coconut peat, respectively) could give higher TSR than that of limestone filler (i.e., 0.59) for 30% filler content. In addition, the results conversely show that the TSR for the 20% filler gave lower values than those for the 30% filler.

This indicates that the TSR is dependent on aggregate type and filler content. If the mixture contains limestone aggregate, the moisture damage resistance will pass 0.7 TSR for both filler contents at high traffic volume gradation. However, increasing filler content can give rise to lower TSR. Conversely, it appears that the mixture contains granite aggregate, the moisture damage resistance will not pass 0.7 TSR for both filler contents at high traffic volume gradation. In this study, results preliminarily confirm that bagasse and coconut peat can be used as a filler in a mixture with limestone aggregate at high traffic volume design to resist moisture damage. Further studies are needed to verify the optimum filler contents for all traffic volume designs and establish threshold of filler content for bagasse and coconut peat.

3.2. Evaluation of Using POTS Test for Determining Moisture Damage Resistance

In this section, the POTS test was conducted to apply a new method for measuring the moisture damage resistance in asphalt mixture. This method was adapted from the standard specified in ASTM C 1583 that is measured in concrete. The test was proceeded in the concept of direct tensile method, thus enhancing the reliability of moisture damage resistance. The advantage of this method is that the device is portable, inexpensive, and applicable to field testing. Two aggregates, granite and limestone with only granite filler, were tested in this study. Fillers were added to the asphalt binder at 20% and 30% by volume of asphalt mastic.

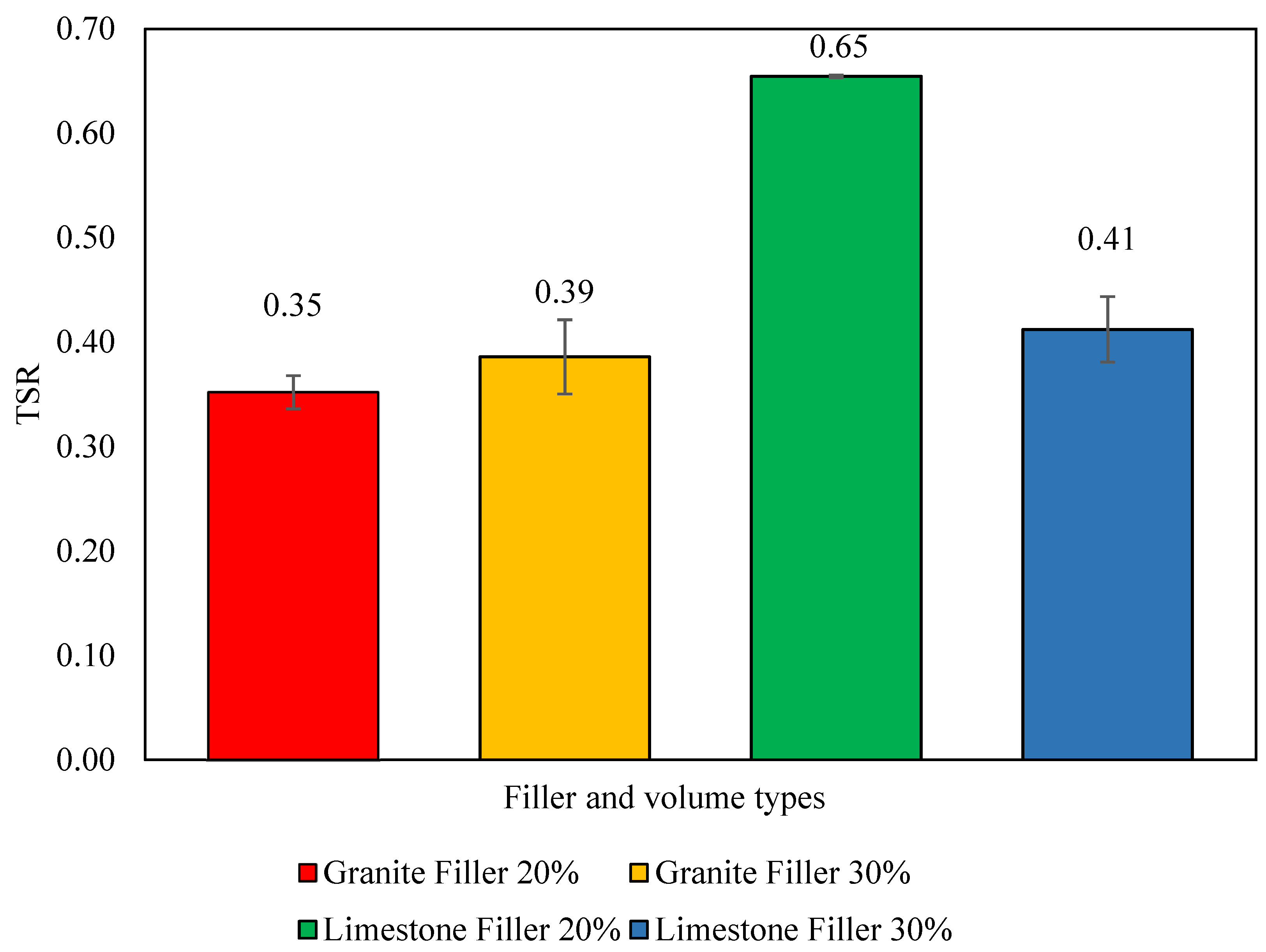

Table 4 shows the values of POTS test on asphalt mixtures and different filler contents (i.e., 20% and 30% by volume) for both aggregate types in the dry and wet conditions. Results show that in the dry condition, the value of POTS of 20% filler for limestone (i.e., 2.00 kPa) was about three-times lower than that for granite (i.e., 6.15 kPa), while that of POTS of 30% filler for limestone (i.e., 7.25 kPa) showed higher strength than that of granite (i.e., 4.52 kPa). Similarly, the results show the same trend in the wet condition. Results show that the POTS value of 20% filler after the wet conditioning was higher than that of 30% filler for limestone, while it shows converse results for granite.

Figure 8 displays the TSR of POTS after the wet conditioning of asphalt mixtures with granite aggregate for both filler types. Results show that the TSR were in range of 0.35–0.65, in which the 20% limestone filler gave the highest TSR value, while the 20% granite filler showed the lowest value. This indicates that the TSR is dependent on filler type and filler content. The results correspond to those measured by the ITS test. However, the specification of 0.7 TSR as a threshold for the ITS test cannot be standardized on the POTS test, as many factors for two tests are different. Therefore, to confirm that the results from POTS test are valid to determine moisture damage resistance, the TSR values for the two methods, the ITS and POTS tests, need to be correlated.

3.3. Correlation of ITS and POTS Ratio

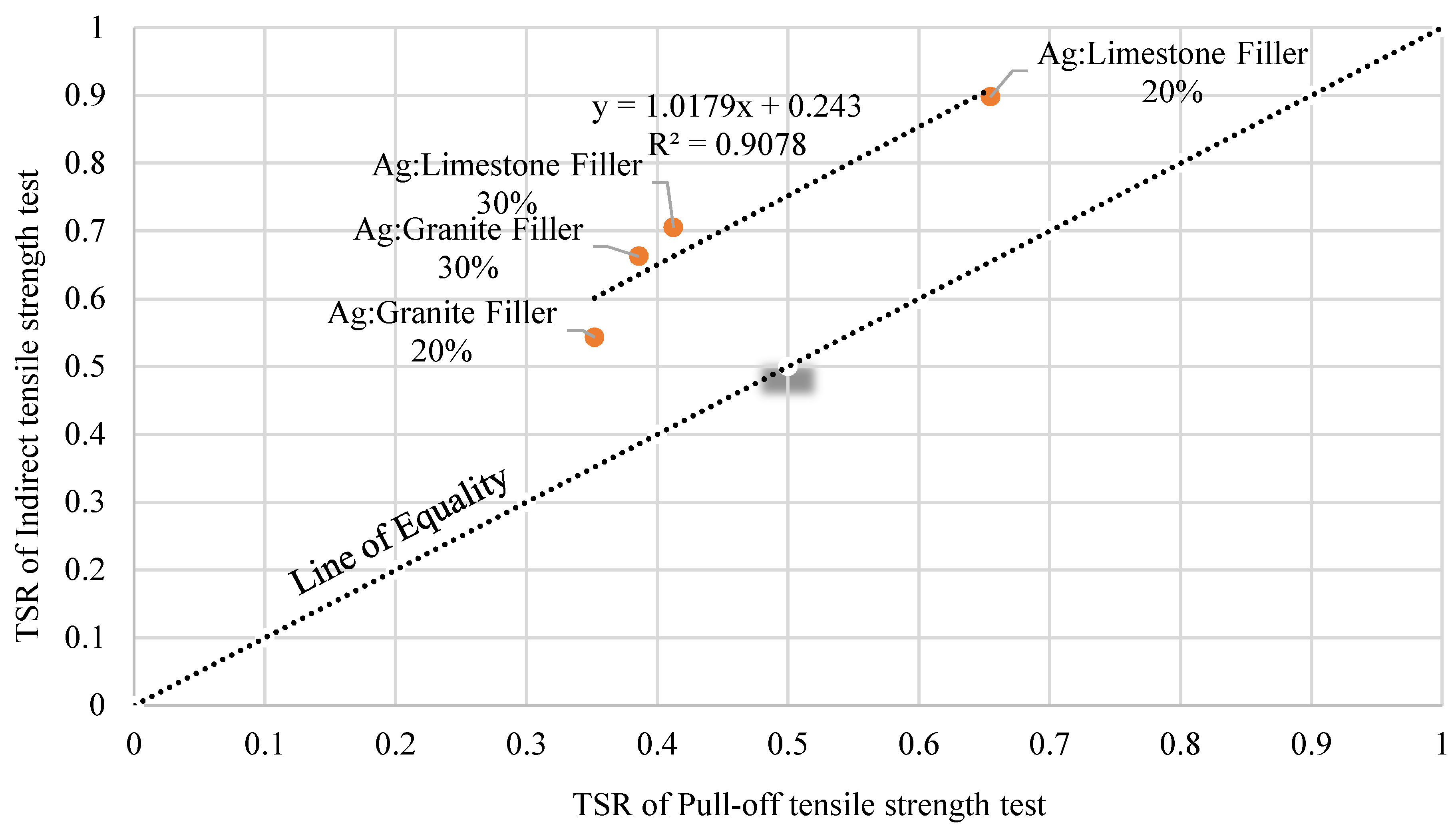

This section discusses the relationship between the TSRs from indirect tensile strength test and pull-off tensile strength test on sample groups using granite filler at both 20% and 30% by volume together with both granite and limestone aggregate. The tensile strength ratio for two methods can be correlated to verify the potential of using POTS as the alternative method for quantifying moisture damage in asphalt mixture.

The relationship of the TSR values of the ITS and POTS tests is shown in

Figure 9, which illustrates that there is no equality between the two tests, but there is a very strong linear relationship. This might be due to the different concepts for obtaining the strength of ITS and POTS tests. Also, the temperatures and curing time used for POTS test were just in primary stage of study, and further studies optimizing these factors are required. Additionally, results show that the TSR values of the ITS test showed positive and rational relationships with those of the POTS test. A good significant slope relationship can be established between ITS and POTS with R

2 of 0.91 as shown in

Figure 9. All samples on ITS test were above the equality line. These results are logical, as the ITS uses the concept of compressive strength, which can yield the lower values of strength than those of POTS, which uses the premise of tensile strength. For the TSR of indirect tensile strength, the prediction model is presented, as shown in Equation (4).

where Y = TSR of the indirect tensile strength test and X = TSR of the pull-off tensile strength test.

4. Summary of Findings

In this study, the researchers adopted bagasse and coconut peat, replacing mineral fillers to find the potential of adopting waste materials in the asphalt industry. Also, a comprehensive experiment was completed to investigate the effect of different fillers on moisture damage resistance. In addition, the POTS test was verified to be a potential method in measuring moisture damage resistance in a laboratory.

The experimental results indicate that the TSR is dependent on aggregate type and filler content. The following points summarize the main findings of the study.

The results show that TSR values for 20% and 30% filler contents are above 0.7 for the limestone aggregate. This indicates that both waste natural fillers (i.e., bagasse and coconut peat) can be used as fillers at 20% and 30% by volume to prevent the moisture damage in asphalt mixture at high traffic volume.

Using both bagasse and coconut peat fillers could give higher TSR than limestone filler for 30% filler content for granite aggregate at high traffic volume.

Results also showed that filler contents affect the moisture damage resistance at high traffic volume. Moisture damage resistance is dependent on type of aggregate used. When limestone was used as the aggregate, the TSR values presented higher at higher filler content, whereas the TSR values presented lower at lower filler content for the granite aggregate.

The POTS specified in ASTM C 1583 was adapted for measuring the direct tensile strength for the asphalt mixture. Results showed the POTS values were much higher (about 5–23 times) than the ITS values for the dry and wet conditions. This is logical, as the POTS uses the concept of direct tensile strength method, which can give higher values and even increase the temperature testing.

The preliminary results are promising in terms of creating a preparation process in which samples were cured at maximum temperature of PG for 24 h in the dry condition, while samples were cured in a water bath for 2 h in. the wet condition. Thus, the POTS test can successfully measure the effect of moisture on asphalt mixtures.

Results also showed that asphalt mixtures with bagasse and coconut peat fillers can effectively prevent the moisture damage resistance. In addition, with the preliminary result, it was found that the POTS test showed a very good R2 for a relation of TSR with the ITS test. The conclusion of the relationship was not therefore proven because the findings of this analysis are preliminary. Further scenarios of asphalt mixtures should be developed to confirm whether these two methods are connected to linear or other curve fittings.

The TSR values for the POTS test were approximately 0.65-times lower than those of the ITS test. The reason can be attributed to the different curing temperature, curing time, and concept of testing. Therefore, to establish the TSR specification of the POTS test, different scenarios of curing temperature, curing time, and asphalt mixtures should be used.

Results showed that the TSR presented in the POTS test for the asphalt mixture, which showed the mixtures with granite filler gave lower TSR than those with limestone filler. This result is comparable to the stripping point presented in Hamburg Wheel Tracking Test (HWT), which showed the same trend as TSR in the POTS test [

27].

5. Conclusions and Recommendation

It can be concluded that bagasse and coconut peat can used as a filler in a mixture with limestone aggregate at high traffic volume design to resist moisture damage. Also, the POTS is a promising tool of measuring the direct tensile strength of an asphalt mixture to determine moisture damage resistance with the advantages of better simulating the field behavior, lower cost of equipment, and light weight. For these reasons, the industry can benefit from adopting this test rather than using heavy and costly equipment. However, it is necessary to establish the specification by determining more POTS tests.

Further studies are needed to verify the optimum filler contents for all traffic volume designs and establish threshold of filler content for bagasse and coconut peat. Different types of asphalt, aggregate, filler, and volume of traffic should be considered for the future research with different performance tests. Additionally, the use of POTS device can be confirmed by verifying different scenarios of curing temperature, curing time, and asphalt mixture.

Author Contributions

Conceptualization, P.C.; methodology, K.R. and P.C.; experiment, K.R.; formal analysis, K.R. and P.C.; resources, K.R.; data curation, K.R.; writing—original draft preparation, K.R.; writing—review and editing, P.C. All authors have read and agreed to the published version of the manuscript.

Acknowledgments

The authors gratefully acknowledge the support from King Mongkut’s Institute of Technology Ladkrabang. We would like to thank to TIPCO Asphalt PCL for providing the asphalt binder for this research. We also appreciate all members in Civil Engineering Department for the support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Imam, U.S. Evaluation of the Effect of Bagasse Ash as Filler in Hot Mix Recycled Asphalt Pavement. Unpublished Thesis, Department of Civil Engineering Ahmadu Bello University, Zaira, Nigeria, 2010. [Google Scholar]

- Murana, A.A.; Ahmed, A.A.; Jegede, F.T. Suitability of Bagasse Ash as a Filler Material in Hot Mix Asphalt Concrete. In Proceedings of the 5th West Africa Built Environment Research (WABER), Accra, Ghana, 12–14 August 2013. [Google Scholar]

- Huwae, D.D.M.; Tanijaya, J. The Use of Plastic Mineral Water Bottles and Scrapped Tire Rubber for Improving the Performance of Mixed Asphalt Concrete. In Proceedings of the EASEC 13, Sapporo, Japan, 11–13 September 2013. Paper No. 62. [Google Scholar]

- Bindu, C.S.; Beena, K.S. Infiuence of additives on the drain down characteristics of stone matrix asphalt mixtures. Int. J. Res. Eng. Technol. 2014, 3, 83–88. [Google Scholar]

- Sheng, Y.; Zhang, B.; Yan, Y.; Li, H.; Chen, Z.; Chen, H. Laboratory investigation on the use of bamboo fiber in asphalt mixtures for enhanced performance. Arab. J. Sci. Eng. 2019, 44, 4629–4638. [Google Scholar] [CrossRef]

- Tamburini, C.; Ziyani, L.; Dony, A.; Rohart, C.; Toraldo, E. Promotion of bitumen-impregnated cellulose fibers from lightweight roofing tiles in stone mastic asphalt. In RILEM252-CMB: RILEM252-CMB-Symposium on Chemo-Mechanical Characterization of Bituminous Materials; Poulikakos, L.D., Falchetto, A.C., Wistuba, M.P., Hofko, B., Porot, L., di Benedetto, H., Eds.; Springer: Cham, Switzerland, 2019; Volume 20, pp. 306–3011. [Google Scholar]

- Awanti, S.S.; Habbal, A.; Hiremath, P.N.; Tadibidi, S.; Hallale, S.N. Characterization of stone matrix asphalt with cellulose and coconut fiber. In Advance in Civil Engineering and Building Materials; Chang, S., al Bahar, S.K., Zhao, J., Eds.; Taylor & Francis Group: London, UK, 2012; pp. 639–642. [Google Scholar]

- Ting, T.L.; Jaya, R.P.; Hassan, N.A.; Yaacob, H.; Jayanti, D.S. A review of utilization of coconut shell and coconut fiber. Road Constr. J. Sci. Eng. 2015, 76, 121–125. [Google Scholar]

- Delgado, H.; Arnaud, L. Investigation of the fatigue properties of asphalt mixtures reinforced with natural fibers. In Proceedings of the International Conference Bituminous Mixtures and Pavements, Thessaloniki, Greece, 1–3 June 2011. [Google Scholar]

- Kumar, P.; Sikdar, P.K.; Bose, S.; Chandra, S. Use of jute fiber in stone matrix asphalt. Road Mater 2004, 5, 239–249. [Google Scholar] [CrossRef]

- Dong, T.; Xu, G.; Wang, F. Adsorption and adhesiveness of kapok fiber to different oils. J. Hazard Mater 2015, 296, 101–111. [Google Scholar] [CrossRef] [PubMed]

- Kudrjashov, A.P.; Kudrjashov, I.V.; Kudrjashov, P.A.; Germashev, V.G.; Jadykina, V.V. Stabilising Additive for Peat-Based Asphalt-Concrete Mixture (Versions) and Method of Producing Structure-Forming Agent Thereof. Patent RU 2479524 C2, 2013. [Google Scholar]

- Soenen, H.; KaraDeMaeijer, P.; Blom, J.; Vandenbergh, W. Peat as an example of a natural fiber in bitumen. In RILEM 252-CMB: RILEM252-CMB-Symposium on Chemo-Mechanical Characterization of Bituminous Materials; Poulikakos, L.D., Falchetto, A.C., Wistuba, M.P., Hofko, B., Porot, L., di Benedetto, H., Eds.; Springer: Cham, Switzerland, 2019; Volume 20, pp. 300–305. [Google Scholar]

- Kumar, N.R.; Sunitha, V. Experimental investigation of stone mastic asphalt with sisal fiber. Int. J. Eng. Res. Technol. 2016, 5, 546–550. [Google Scholar]

- Zainudin, M.Z.; Khairuddin, F.H.; Ng, C.P.; Osmi, C.; Khadijah, S.; Misnon, N.; Murniati, S. Effect of Sugarcane Bagasse Ash as Filler in Hot Mix Asphalt. Mater. Sci. Forum 2016, 846, 683–689. [Google Scholar] [CrossRef]

- Huwae, D.D.M.; Parera, L.R.; Tanijaya, J. Bagasse-Ash as Filler in HRS (Hot Rolled Sheet) Mixture. In Proceedings of the 2016 World Congress on Advances in Civil, Environmental, and Materials Research 1, Jeju Island, Korea, 28 August–1 September 2016. [Google Scholar]

- Kara De Maeijer, P.; Soenen, H.; Van den bergh, W.; Blom, J.; Jacobs, G.; Stoop, J. Peat Fibers and Finely Ground Peat Powder for Application in Asphalt. Infrastructures 2019, 4, 3. [Google Scholar] [CrossRef]

- Loaiza, A.; Aristizábal, E.F.; Colorado, H.A. Evaluation of asphalt binder blended with coconut coir dust and residual coconut fibers for structural applications. Rev. de la Construcción 2018, 542–554. [Google Scholar] [CrossRef]

- Harvey, J.; Cebon, D. Failure mechanisms in viscoelastic films. J. Mater. Sci. 2003, 38, 1021–1032. [Google Scholar] [CrossRef]

- Cheng, D.; Little, D.N.; Lytton, R.L.; Holste, J.C. Surface energy measurement of asphalt and its application to predicting fatigue and healing in asphalt mixtures. Transp. Res. Rec. 2002, 1810, 44–53. [Google Scholar] [CrossRef]

- Terrel, R.L.; Al-Swailmi, S. Water sensitivity of asphalt-aggregate mixes. In Test Selection, Washington, DC, SHRP Report A-403, Strategic Highway Research Program; National Research Council: Washington, DC, USA, 1994. [Google Scholar]

- Moraes, R.; Velasquez, R.; Bahia, H. Measuring effect of moisture on asphalt aggregate bond with the Bitumen Bond Strength test. J.Transp. Res. Board 2011, 2209, 70–81. [Google Scholar] [CrossRef]

- Chaturabong, P.; Bahia, H.U. Effect of moisture on the cohesion of asphalt mastics and bonding with surface of aggregates. Road Mater. Pavement Des. 2016, 22, 741–753. [Google Scholar] [CrossRef]

- Long, A.E.; Murray, A. The Pull-off Partially Destructive Test for Concrete. In In-Situ Non-Destructive Testing of Concrete, SP-82, Detroit; American Concrete Institute: Farmington Hills, MI, USA, 1984. [Google Scholar]

- Gonçalves, A.F. Novos Ensaios Não Destrutivos Para a Determinação da Resistência do Betão Nas Estruturas; Laboratório Nacional de Engenharia Civil: Lisboa, Portugal, 1986. [Google Scholar]

- Testing concrete. In Recommendations for the Assessment of Concrete Strength by Near-to-Surface Tests, BS 1881, Part 207; British Standards Institution: London, UK, 1992.

- Chaturabong, P.; Bahia, H.U. Mechanisms of asphalt mixture rutting in the dry Hamburg Wheel Tracking test and the potential to be alternative test in measuring rutting resistance. Constr. Build. Mater. 2017, 146, 175–182. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).