Eco-innovative Practices for Sustainable Consumption and Production: What are the Possible Benefits for Companies?

Abstract

:1. Introduction

2. The Importance of Sustainable Consumption and Production and the Effects on Company Performances

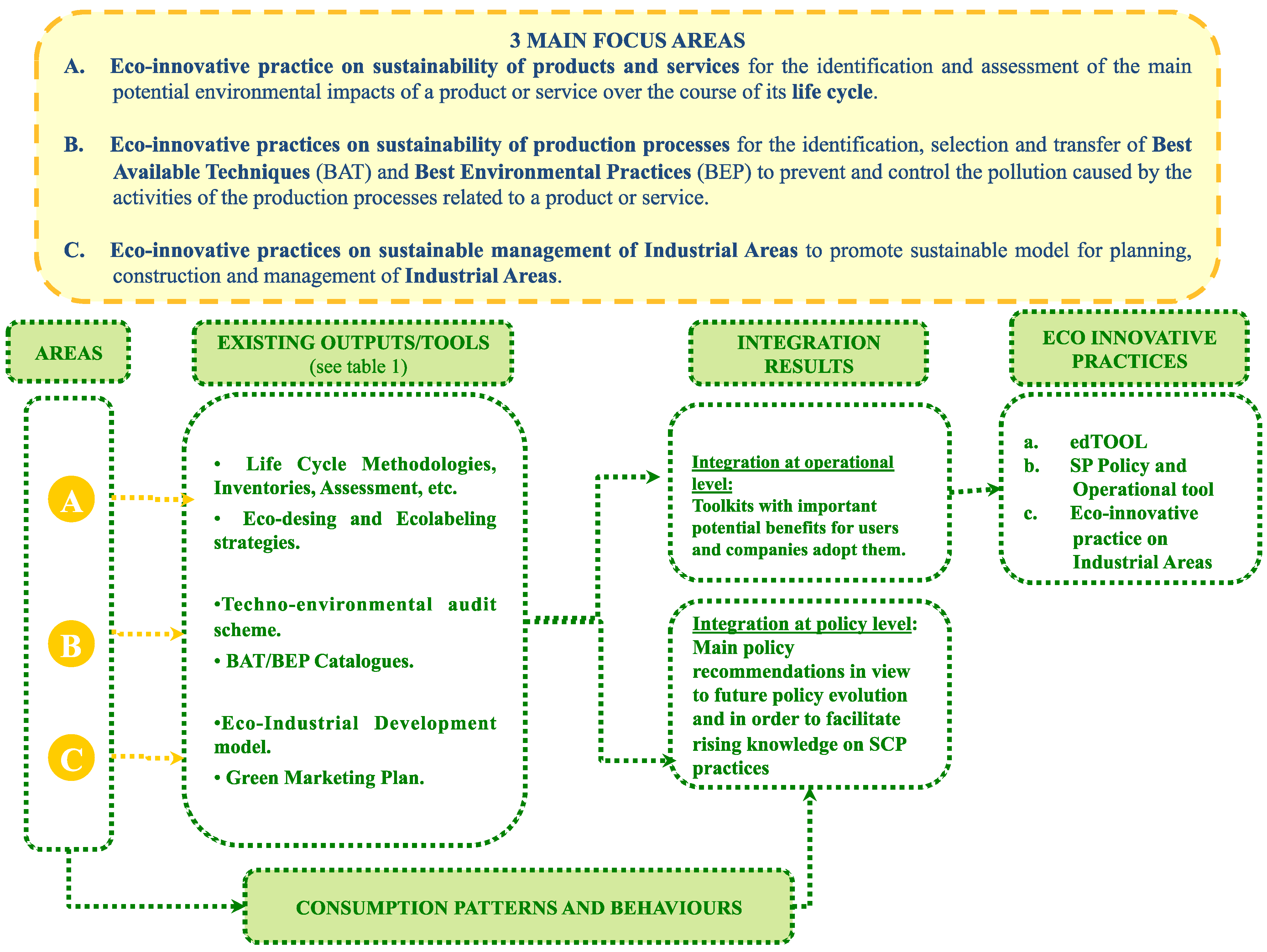

3. Brief Introduction on the ECO SCP MED Project and on Three Focus Areas: Sustainability of Products/Services, Sustainability of Production Processes, Sustainable Management of Industrial Areas.

4. Method

| No. | Outputs | Area: Products and Services | Area: Management of Industrial Areas | Area: Production Processes |

|---|---|---|---|---|

| 1 | International Benchmark in industrial areas | X | ||

| 2 | Establishment of the Regional IPPC Centers | X | ||

| 3 | Regional Network for CSR Competence | |||

| 4 | Database of Best Practices developed in Industrial MED Areas | X | ||

| 5 | Guide for the construction of eco-efficient industrial buildings | X | ||

| 6 | MEID procedural model | X | ||

| 7 | Catalogue of BAT (Best Available Technologies) and BEP (Best Environmental Practices) in Mediterranean Agro-food Sector | X | ||

| 8 | MED-IPPC-NET Guidelines on the Best Practices on IPPC Permitting and Following-up Procedure | X | ||

| 9 | Ecodesign Pilot Project | X | ||

| 10 | LCADB (Life Cycle Inventories—Regional Database for Southwest Europe) | X | ||

| 11 | CO2ZW ® | X | ||

| 12 | Innovative service guidelines | X | X | |

| 13 | Interregional Analysis for the implementation of the IPPC Directive | X | ||

| 14 | Process and Best Available Techniques Databases | X | ||

| 15 | Interregional Characterization Mediterranean Agrofood Subsectors | X | ||

| 16 | Methodology for techno environmental assessment for SMES | X | ||

| 17 | Demonstration of a Sustainable and Effective 2nd Generation Biofuels Application in an Urban Environment.doc | X | ||

| 18 | Establishing Public-Private Partnerships (PPPs) for WCO collection | X | ||

| 19 | Policy Measures for Promoting Waste Cooking Oil Collection | X | ||

| 20 | Mediterranean region and the development of renewable energy sources | X | X |

- (a)

- an open discussion section;

- (b)

- a validation of the practices.

- −

- assessment and validation;

- −

- further development;

- −

- application;

- −

- dissemination

| Judgment | Score |

|---|---|

| Strongly negative/Poor/Not important | 1 |

| Negative/Below average/ | 2 |

| Average/Average/average importance | 3 |

| Positive/Good/Important | 4 |

| Strongly Positive/Excellent/Very important | 5 |

5. Results

| Research Group (Acronyms) | Output/tools capitalised | Eco-innovative practices |

|---|---|---|

| (A) Eco-innovative practice on sustainability of products and services: | ||

| UAB | Ecodesign Pilot Project | edTOOL |

| LCADB (Life Cycle Inventories—Regional Database for Southwest Europe) | ||

| Province of Bologna | Innovative service guidelines | |

| B) Eco-innovative practices on sustainability of production processes: | ||

| SSSUP | Interregional Analysis for the implementation of the IPPC Directive. | SP Policy tool |

| IAT | MED-IPPC-NET Guidelines on the Best Practices on IPPC Permitting and Following-up Procedure. | |

| Province of Bologna | Establishment of the Regional IPPC Centers. | |

| ZRS Bistra PTUJ | Interregional Characterization Mediterranean Agro-food Subsectors. | SP Operational tool |

| Methodology for techno environmental assessment for SMES. | ||

| IAT | Catalogue of BAT (Best Available Technologies) and BEP (Best Environmental Practices) in Mediterranean Agro-food Sector. | |

| SSSUP | Process and Best Available Techniques Databases. | |

| C) Eco-innovative practices on sustainable management of Industrial Areas: | ||

| CCI - Nice Côte d'Azur | International Benchmark in industrial areas | |

| ENEA | Database of Best Practices developed in Industrial MED Areas | |

| Guide for the construction of eco-efficient industrial buildings | ||

| MEID procedural model | ||

| UAB | CO2ZW ® | |

| Province of Bologna | Innovative service guidelines | |

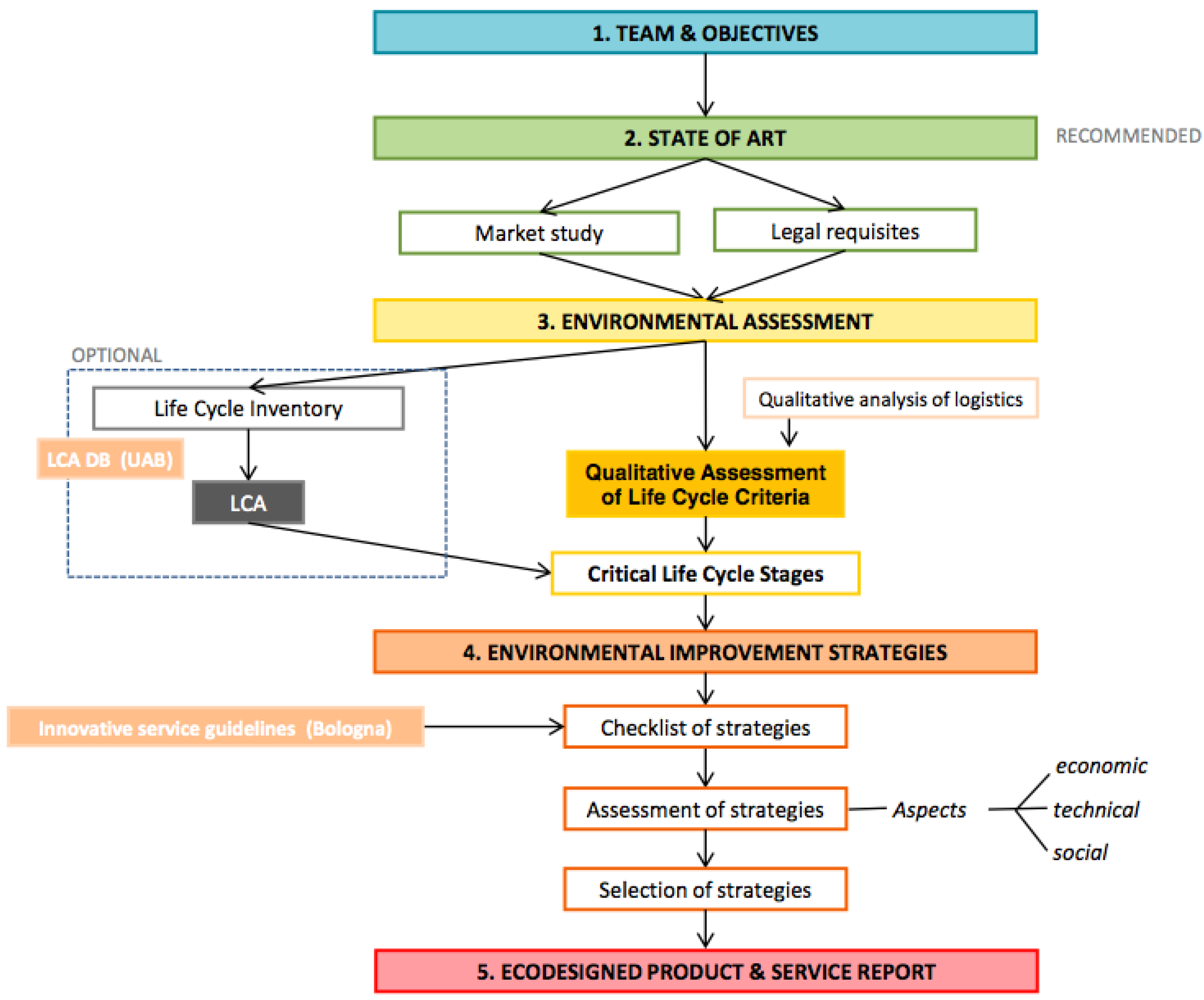

5.1. Eco-innovative Practice on Sustainability of Products and Services

- (a)

- The first step is the Initial Definition, which includes creating the team, describing the project, and setting objectives. It would be advisable to hold a kick-off meeting in order to present the ecodesign project (including description and objectives) and to introduce all the team members. In addition, this could be useful for the coordinator in order to find support for the development of the following step. This presentation session could be done in one hour. An alternative way would be to substitute this meeting by creating a mailing list and sharing the information by this means.

- (b)

- The second step (state of art in Figure 3) consists on describing legal requisites and market study (if necessary) and preparing the environmental assessment module.

- (c)

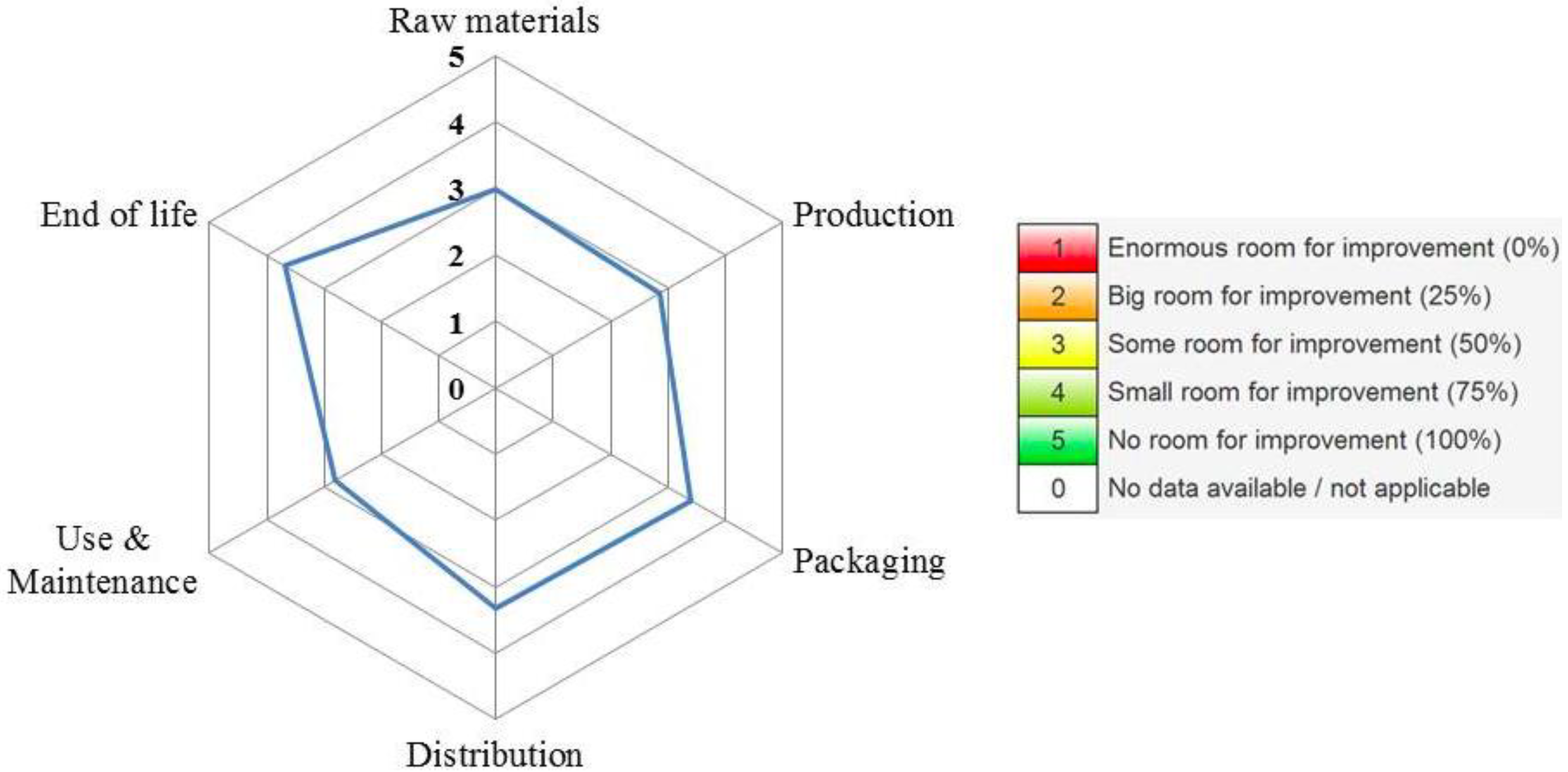

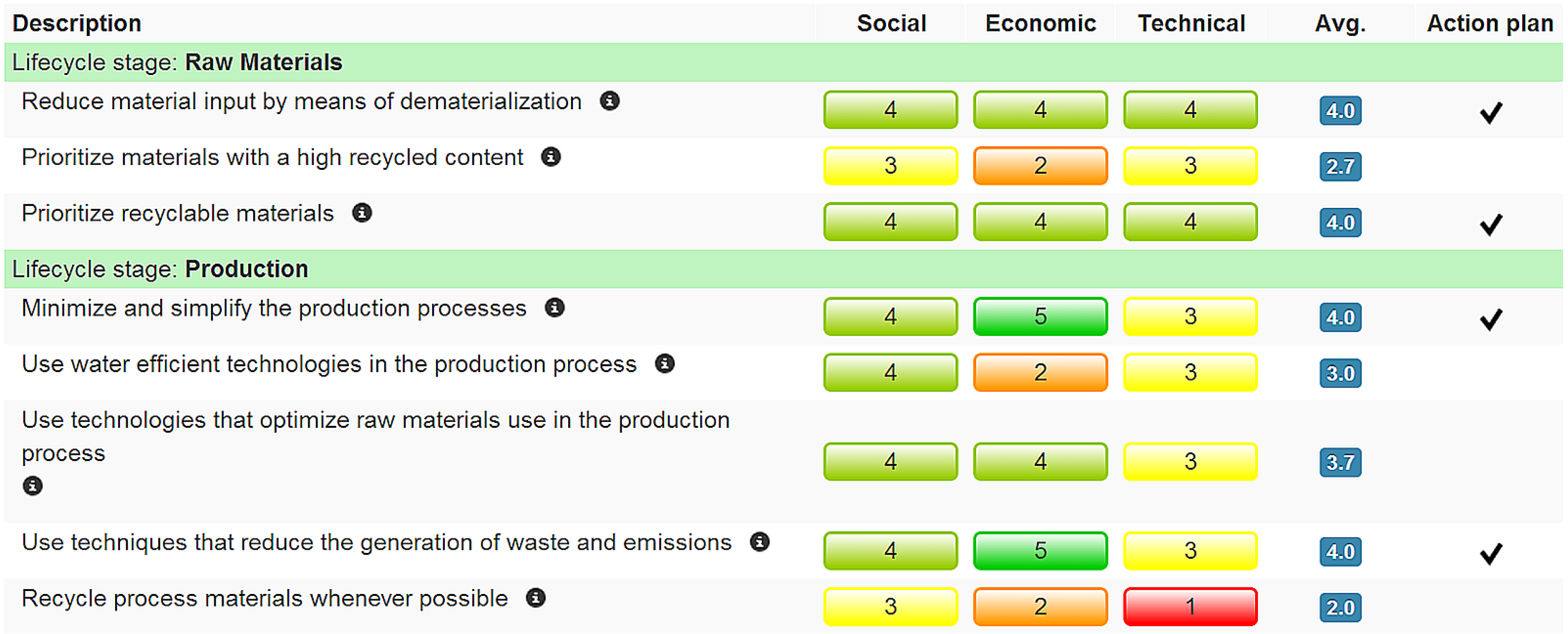

- The third step will consist of the Environmental Assessment (Figure 3), which will be carried out individually by every member of the ecodesign team and will provide information on the critical environmental hotspots. It includes a Qualitative Assessment of Life Cycle Criteria. This is a qualitative environmental assessment based on the study of life cycle stages. In brief, this practice places in a spider web diagram (Figure 4) the various life cycle stages and shows a score which is representative of the degree of environmental performance of each stage against several criteria that characterize them. The methodology gets inspiration from the Ecodesign Strategy Wheel. This environmental assessment starts with a definition of the life cycle stages of the analyzed product or service. The edTOOL presents a table which includes the most common life cycle stages for any product/service. Then, after the definition of life cycle stages, it is time to select relevant life cycle criteria that will be later assessed in environmental terms (in the following steps). For each life cycle stage, a selection of default life cycle criteria is presented, which will be used in order to perform an environmental assessment of the reference product/service. The criteria included in the table should be adapted to each project. The Coordinator will be in charge to customize the life cycle criteria on behalf of the whole ecodesign team. Additional life cycle criteria can be added from a predefined list with other criteria. The process of criteria customization should be done in a workshop session (about 2 hours) with the whole ecodesign team. The aim of the workshop will be to reach an agreement on what are the most relevant life cycle criteria for the product/service under study. This implicitly means that all team members will understand the meaning of each life cycle criteria (since it is expected that later each of the members will individually assess each criteria).

- (d)

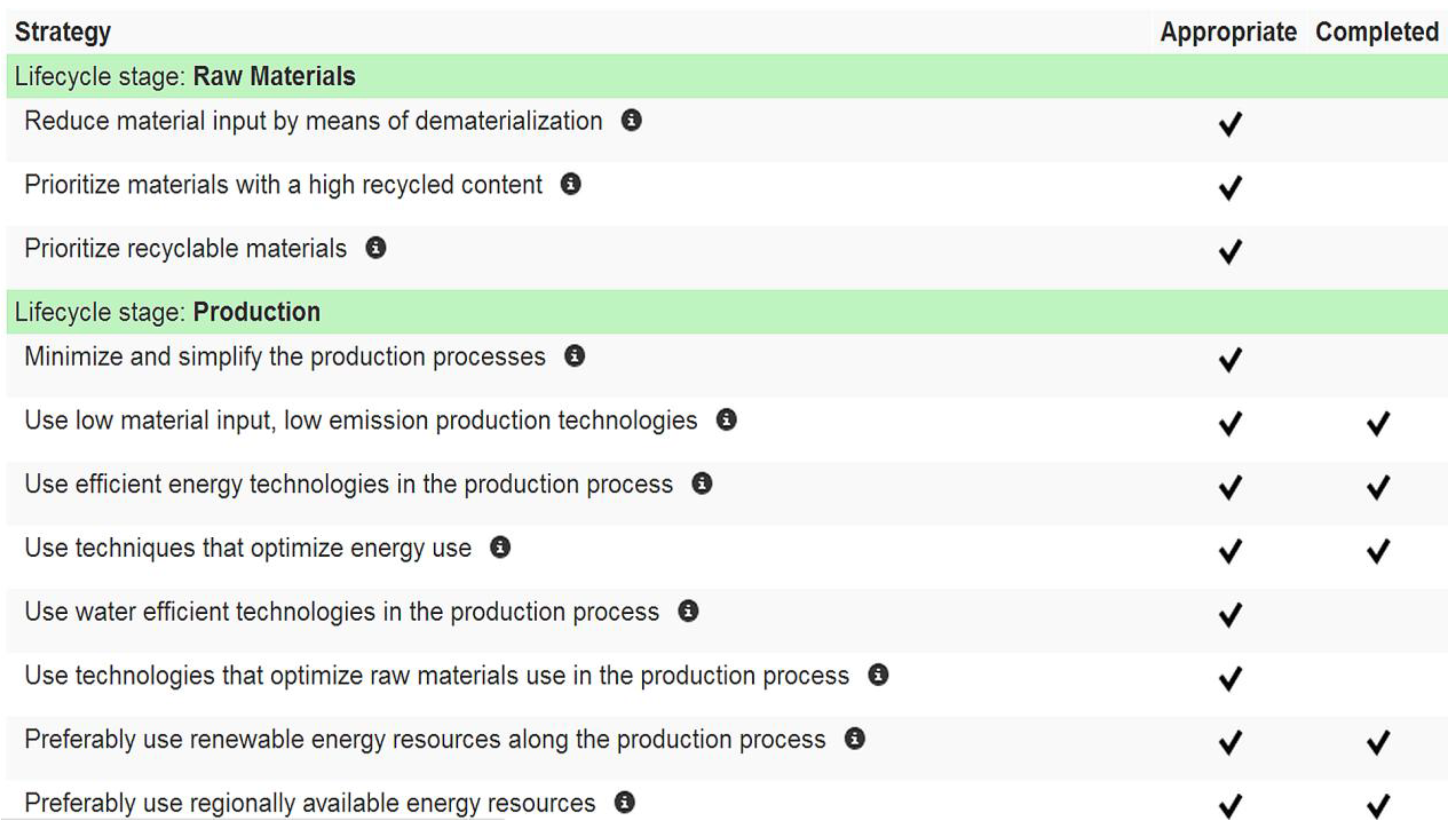

- The fourth step will be the Ecodesign Strategy Selection, along which the Coordinator will prioritize and refine ecostrategies in order to improve the environmental performance of the product/service.

- are appropriate for the assessed product/service, meaning that it does make sense to implement such strategy in the product/service under study.

- have already been completed for the product/service under study, meaning that such strategies have already been applied.

- (e)

- And finally the Summary report which will present the results for the whole process. At the end of use, a Summary report is automatically generated which includes all the information and results related to the ecodesign process. There are two types of Report, the so-called ‘Summary Report’ that is composed of a pre-determined set of parts of the methodology, and a Customized Report, whose content can be tailored to each project.

| Strategy | Action | Deadline | Responsible |

|---|---|---|---|

| Reduce material input by means of dematerialization | Reduce thickness of the blade (from 3 to 2.5 mm) | 2015-01-01 | Head of Technical Department |

| Prioritize recyclable materials | Handle with recycled PP content inside and virgin PP outside (by means of co-injection) | 2014-09-01 | Head of Technical Department |

| Minimize and simplify the production processes | Automatization of metal die-cast process to reduce process waste | 2016-01-01 | Head of Technical Department |

| Use technique that reduce the generation of waste and emissions | Automatization of metal die-cast process to reduce process waste | 2016-01-01 | Head of Technical Department |

- Ecodesign Team

- Description and Objectives

- Environmental Assessment

- Spider diagram

- Action Plan

5.2. Eco-innovative Practices on Sustainability of Production Processes

- Guidelines on best practices on IPPC permitting and following-up procedures which contains, per each one of the best practices identified, the legislative references and requirements, description of the best practice, deployment and results.

- Permit template which is divided into three different sections (with their correspondent subsections): General Information, environmental conditions and technical annexes.

- Applicant guidelines which provides guidance to the owner of the facility on the content of a permit issued according to the IPPC Directive. The list of the content is in concordance with the template permit and with the public officer guidelines.

- Public officer guidelines which provides guidance to the Competent Authority on the content of the permit issued according to the IPPC Directive. The list of the content is in concordance with the template of the permit and with the applicant guidelines.

- Software application which was delivered to help users to apply the SP Policy practice.

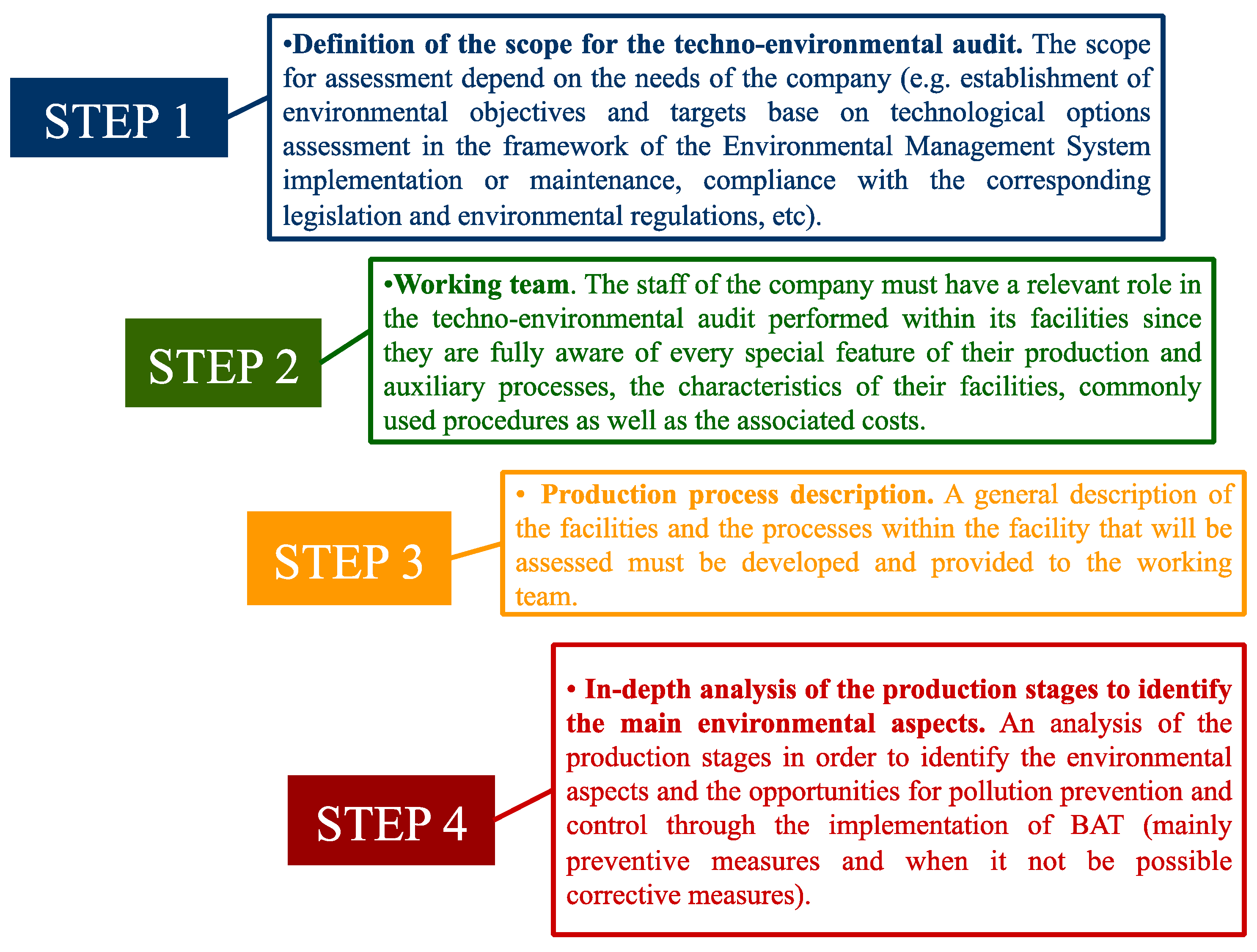

- Consumptions–side analysis:

- −

- Raw materials used: description of the kind of raw materials used;

- −

- Water use: description of the types of water (e.g. process water, cooling water, wash water, etc.), sources of water (e.g., tap water, ground water, recuperation/recycling streams, etc.) and amount used per type and source;

- −

- Energy use and related emissions: description of what kind of energy flows exist (e.g., fossil fuels, renewal energy, etc.), where are they used and how much is used (e.g., kWh, ton per kg product produced, etc.).

- Emissions-side analysis:

- −

- Waste generation: description of what kind of waste fractions are produced (and where), the amount of waste (per fraction);

- −

- Waste water emissions: description of where do waste water streams arise, and what type of pollutants can be found in the waste water;

- −

- Air emissions/dust/odor: description of the sources of air emissions, type of pollutants found in the air emissions and the amounts;

- −

- Soil and groundwater contamination: description of which process steps can contaminate the soil (e.g., spillages and leaks);

- −

- Achieved environmental benefits: emission reduction percentages, total amount of emissions prevented;

- −

- Environmental performance and operational data;

- −

- Cross-media effects;

- −

- Considerations relevant to applicability (e.g., why and when is the technique applicable/non applicable);

- −

- Economics: Information on the costs of techniques (e.g., capital/investment, operating and maintenance including details on how these costs have been calculated/estimated) and any possible savings following from their application (e.g., reduced raw material or energy consumption, waste charges, reduced payback time compared to other techniques), revenues or other benefits (including details on how these have been calculated/estimated);

- −

- Driving force for implementation.

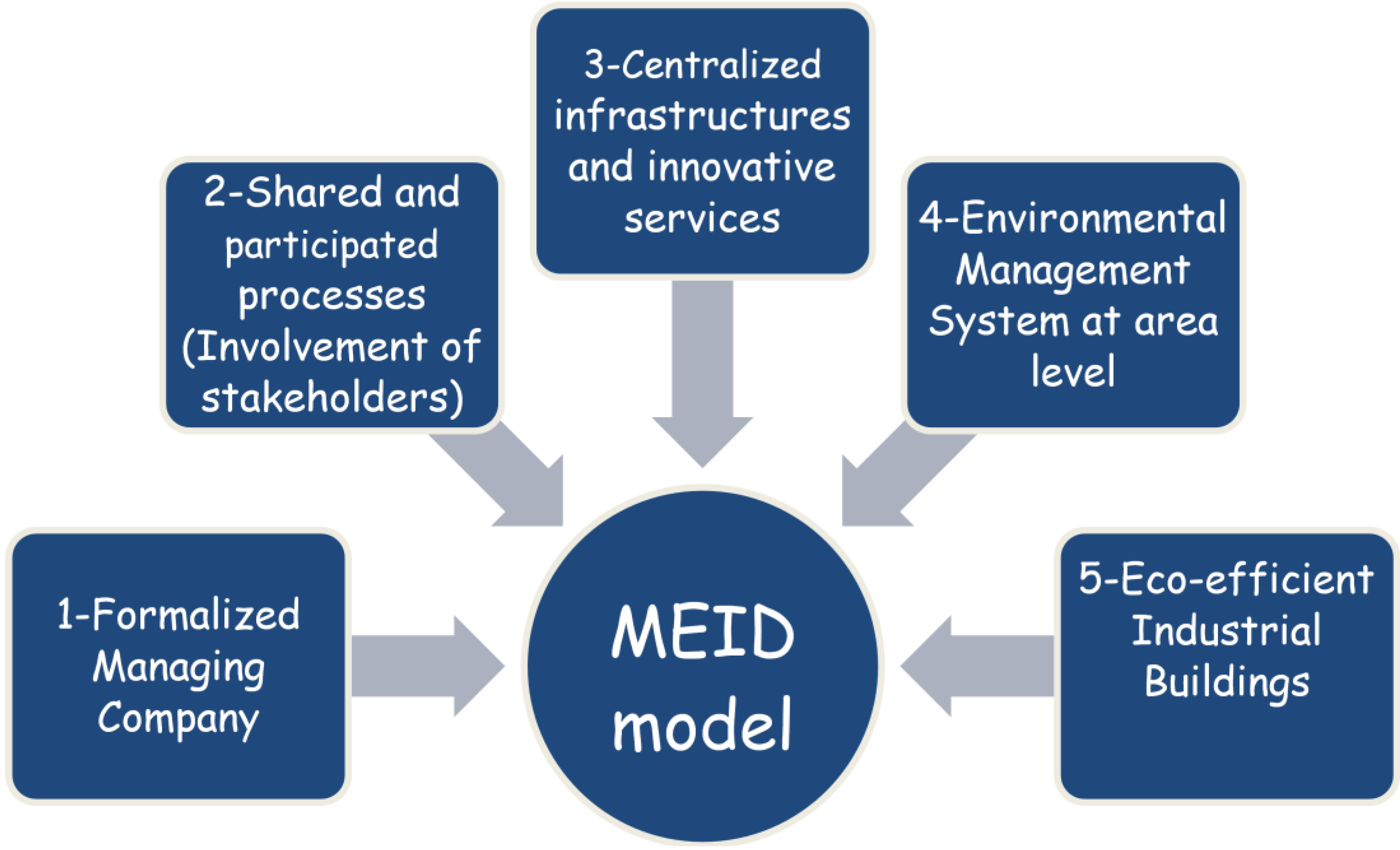

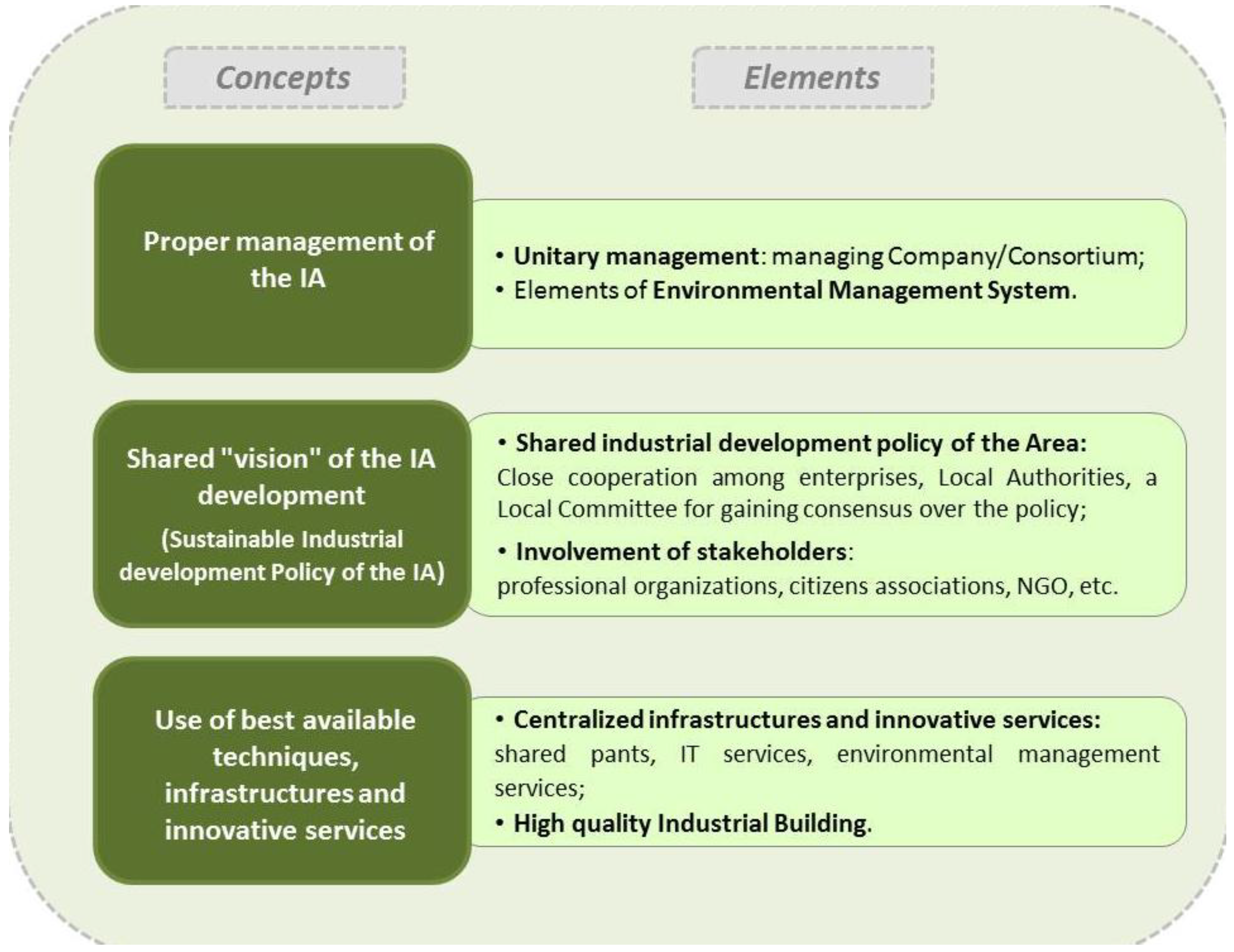

5.3.Eco-Innovative Practices on Sustainable Management of Industrial Areas

- −

- Mediterranean Eco Industrial Development (MEID) model, made-up of a series of necessary steps to be followed in order to implement a sustainable management of Mediterranean IAs. The Model procedure systematizes several project experiences which have been realized at a European and local level, taking into consideration the specificities of the MED area. Since IAs of the Mediterranean have different levels of management and, most of all, have heterogeneous management, three different paths have been detected and should be followed according to the starting point of each IA [57]:

- −

- Path 1—Planning and design of a new Industrial Area;

- −

- Path 2—Towards MEID Model in non-structured Industrial Areas;

- −

- Path 3—MEID Model in structured Industrial Area.

- −

- a check-list with a scoring system to (self) evaluate the status of an IA with regard to its most relevant aspects. The checklist is based on 13 yes/no questions divided in five main areas, considered the most relevant for IA management: management, infrastructures and centralized services, energy/environmental quality of industrial buildings, animation/participation, green marketing/external communication. According to the answer, at each question is given a score which depends by the relative importance of the related area. The scores are then summed up to have a unique score of the IA. The weighting system is based on a qualitative expert judgment and has been built on the experience gathered in several European projects as MEID, Ecomark and SIAM - Sustainable Industrial Area Model [59]. To increase its usability, the tool has been developed on excel program;

- −

- a web database of best practices which can be adopted in MED IAs for improving their environmental, social and economic profile. It includes environmental, social and economic solutions referred to centralized established infrastructures as well as innovative services in IAs of the Mediterranean Region. To develop this tool, the database of MEID project, almost 150 examples of best practices related to about 50 IAs of MEID partner countries, has been integrated with the content of Ecomark project, about 30 added IAs;

- −

- a guide to support the different agents involved in the process of design, construction and maintenance of Eco-efficient Sustainable Industrial Buildings to evaluate and improve their environmental and energy performances. It consists in 88 good practices related to the entire building lifecycle. Each measure is scored and weighted according to the relative importance of the area of action (e.g.: material, energy, waste, ecosystem, etc.) The weighting system allows to reach a unique score for the entire building;

- −

- software for calculating the carbon footprint of waste management in IAs. It is an adaptation of CO2ZW® software by Zero Waste project [60], an excel based software created for municipality waste, to IAs context. It allows to calculate the greenhouse gas emissions (in carbon dioxide equivalents) from the management of the waste fraction of IAs assimilated to urban waste. The output can be used as a guide for driving local government policy in the context of waste sector operations;

- −

- a check-list to present to IA managers, Local Authorities, general stakeholders (Development Agencies, businesses promoters) the steps and the phases for carrying out an innovative sustainable logistics service which includes the planning, organization, management, execution and control of freight transport operations also by integrating information, transport, inventory, warehousing, materials handling, packaging and even security activities. It is based on the Ecomark project activities, in particular on two operative tools: software for routes and one for loads optimization.

- −

- a system perspective in managing environmental issues;

- −

- a single source of information, examples of good practices, case studies on sustainable IAs;

- −

- an internationally accepted model in managing IAs to which to refer and to propose to Local Authorities;

- −

- tools for scoring IAs and measure the progress towards resource efficiency and sustainability.

6. Discussion

- −

- reducing the industrial settlements dispersion in the territory;

- −

- sustaining industrial development by means of optimized transport networks for goods and people and also for local resources handling;

- −

- reducing environmental impacts caused by the industries concentration;

- −

- aggregating the demand and transfer of technological innovation related to environmental, energy and water resources.

7. Conclusions

List of acronyms

| BAT | Best Available Techniques |

| BAT-AEL | Emission Level Associated with the Best Available Techniques |

| BREF | Best Available Technique Reference Document |

| CO2ZW | The Carbon Footprint Tool for Waste management in Europe |

| ECO-SCP-MED | Integrating Experiences and Recommendations in Eco-Innovation for Sustainable Production and Consumption in the Mediterranean Area |

| EdTOOL | Eco-design Tool |

| EIPPCB | European Integrated Pollution Prevention and Control Bureau. |

| ELV | Emission Limit Values |

| EMAS | Eco-Management and Audit Scheme |

| ENISA | Empresa Nacional de Innovación |

| ERDF | European Regional Development Fund |

| IA | Industrial Area |

| IED | Industrial Emissions Directive |

| IPPC | Integrated Pollution Prevention and Control |

| IPTS | Institute for Prospective Technological Studies |

| JPOI | Johannesburg Plan of Implementation |

| LCA | Life Cycle Analysis |

| MED IPPC NET | Network for strengthening and improving the implementation of the IPPC European Directives regarding the Integrated Pollution Prevention and Control in the Mediterranean |

| MEID | Mediterranean Eco Industrial Development |

| OECD | The Organization for Economic Co-operation and Development |

| SCP | Sustainable Consumption and Production |

| SCP/SIM | Sustainable Consumption and Production and Sustainable Industrial Policy |

| SIAM | Sustainable Industrial Area Model |

| SME | Small and Medium Enterprises |

| SP | sustainability of production processes |

Author Contributions

Conflicts of Interest

References and Notes

- Ministry of Environment Norway. Report of the Sustainable Consumption Symposium; Ministry of Environment Norway: Oslo, Norway, 1994.

- United Nations. Report of the World Commission on Environment and Development: Our Common Future; Oxford University Press: Oxford, UK, 1987. [Google Scholar]

- United Nations Environment Programme. Division of Technology, Industry, and Economics, 10 Yesr Framework of Programmes on Sustainable Consumption and Production (10YFP). Available online: http://www.unep.fr/scp/marrakech/10yfp.htm (accessed on 23 July 2014).

- McDonough, W.; Braungart, M. Cradle-to-Cradle: Remaking the Way We Make Things; North Point Press: New York, NY, USA, 2002. [Google Scholar]

- Jackson, T. Prosperity without Growth: Economics for a Finite Planet; Earthscan: London, UK, 2009. [Google Scholar]

- United Nations Sustainable Development. United Nations Conference on n Environment & Development Rio de Janerio, Brazil, 3 to 14 June 1992. Agenda 21. Available online: http://sustainabledevelopment.un.org/content/documents/Agenda21.pdf (accessed on 23 July 2014).

- Barber, J. Mapping the movement to achieve sustainable production and consumption in North America. J. Cleaner Prod. 2007, 15, 499–512. [Google Scholar] [CrossRef]

- The Organization for Economic Co-operation and Development (OECD). Towards Sustainable Household Consumption? Trends and Policies in OECD Countries; OECD: Paris, France, 2002. [Google Scholar]

- Lowell Center for Sustainable Production. Sustainable Production: A Working Definition; University of Massachusetts Lowell: Lowell, MA, USA, 1998. [Google Scholar]

- Veleva, V.; Ellenbecker, M. Indicators of sustainable production: Framework and methodology. J. Cleaner Prod. 2001, 9, 519–549. [Google Scholar] [CrossRef]

- US EPA. United States Environmental Protection Agency. In Pollution Prevention Act; EPA: Washington, USA, 1990. [Google Scholar]

- Lehtoranta, S.; Nissinen, A.; Mattila, T.; Melanen, M. Industrial symbiosis and the policy instruments of sustainable consumption and production. J. Cleaner Prod. 2011, 19, 1865–1875. [Google Scholar]

- Lemming, G.; Hauschild, M.Z.; Bjerg, P.L. Life cycle assessment of soil and groundwater remediation technologies: Literature review. Int. J. Life Cycle Assess. 2010, 15, 115–127. [Google Scholar] [CrossRef]

- Obradovikj Grncarovska, T.; Dukovski, V.; Sharma, M. An integrated product policy decision framework. Manag. Environ. Q. Int. J. 2014, 25, 63–74. [Google Scholar]

- Fishbein, B. Extended producer responsibility: A new concept spreads around the world. Rutgers University Demanufacturing Partnership Program Newsletter, Vol. 1, No. 2 Winter 1996. Available online: http://archive.grrn.org/resources/Fishbein.html (accessed on 30 July 2014).

- Lindhqvist, T.; Lidgren, K. Models for Extended Producer Responsibility in Ministry of the Environment, From the Cradle to the Grave—six studies of the environmental impact of products, Ministry of the Environment: Stockholm, Sweden, 1990.

- European Commission. In Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions on the Sustainable Consumption and Production and Sustainable Industrial Policy Action Plan; Ministry of the Environment: European Commission; Brussels, Belgium. 2008; p. n. 397. [Google Scholar]

- ECO SCP MED Project. Deliverable 11: “Integrated SCP-MED Model”. In Integrating Experiences and Recommendations in Eco-Innovation for Sustainable Production and Consumption in the Mediterranean Area; Scuola Superiore Sant’Anna with the contribution of all partners of the project ECO SCP MED; 2014; unpublished report (internal use only). [Google Scholar]

- European Environment Agency. Progress in Sustainable Consumption and Production in Europe: Indicator-Based Report; ETC/SCP Working Paper; European Topic Centre on Sustainable Consumption and Porduction: Copenhagen, Denmark, 2011. [Google Scholar]

- Danish Technological Institute and PLANET S.A. SMEs and the Environment in the European Union; Main Report, 2010. Europäische Kommission / Generaldirektion Unternehmen und Industrie. Available online: http://edz.bib.uni-mannheim.de/daten/edz-h/gdb/10/main_report_en.pdf (accessed on 8 May 2014).

- AEA; CE Delft; Scuola Superiore Sant’Anna. Support for the Impact Assessment of the Review of the 2008 Sustainable Production and Consumption Action Plan; Final Report.; AEA Technology plc, 2012; unpublished report (internal use only). [Google Scholar]

- Sarkis, J. A strategic decision framework for green supply chain management. J. Clean. Prod. 2003, 11, 397–409. [Google Scholar] [CrossRef]

- Kong, N.; Salzmann, O.; Steger, U.; Ionescu-Somers, A. Moving business/industry towards sustainable consumption: The role of NGOs. Eur. Manage. J. 2002, 20, 109–127. [Google Scholar] [CrossRef]

- Bocken, N.; Allwood, J. Strategies to reduce the carbon footprint of consumer goods by influencing stakeholders. J. Clean. Prod. 2012, 35, 118–129. [Google Scholar] [CrossRef]

- Porter, M.; van der Linde, C. Toward a new conception of the environment competitiveness relationship. J. Econ. Perspect. 1995, 9, 97–118. [Google Scholar] [CrossRef]

- Testa, F.; Daddi, T.; De Giacomo, M.R.; Iraldo, F.; Frey, M. The effect of Integrated Pollution Prevention and Control regulation on facility performance. J. Cleaner Prod. 2014, 64, 91–97. [Google Scholar] [CrossRef]

- IEFE. Bocconi University (partners: Adelphi Consult, IOEW—Office Heidelberg, SPRU, Sussex University, Valør & Tinge A/S). EVER: Evaluation of EMAS and Eco-label for their Revision, DG Environment European Community, Brussels. 2005. Available online: ec.europa.eu/environment/ecolabel/documents/EU-Ecolabel-revision.pdf (accessed on 8 May 2014).

- Rennings, K. Redefining Innovation—Eco-Innovation Research and the Contribution from Ecological Economics. Ecol. Econ. 2000, 32, 319–332. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; Allwood, J.M.; Willey, A.R.; King, J.M.H. Development of an eco-ideation tool to identify stepwise greenhouse gas emissions reduction options for consumer goods. J. Cleaner Prod. 2011, 19, 1279–1287. [Google Scholar] [CrossRef]

- ENISA. Ecodesing Pilot Projects (Proyecto Piloto de Ecodiseño). 2012. Available online: http://www.enisa.es/es/i-d-e/doc/recursos (accessed on 25 July 2014).

- Province of Bologna. Ecomark Project. 2013. Available online: http://www.ecomarkproject.eu/en/documents (accessed on 10 March 2014).

- Sostenipra. edTool. 2012. Available online: http://edtool.sostenipra.cat/ (accessed on 16 July 2014).

- Farreny, R.; Gasol, C.M.; García-Lozano, R.; Rieradevall, J.; Llorach, P.; Gabarrell, X. Ecodesign Tool. Inèdit Innovació S.L. Sostenipra. 2014. Available online: http://edtool.sostenipra.cat/edTOOL/static/USER_GUIDE_edTOOL.pdf (accessed on 25 July 2014).

- González-García, S.; Salinas-Mañas, L.; García-Lozano, R.; Gabarrell, X.; Rieradevall, J.; Feijoo, G.; Moreira, M.T. The application of ecodesign methodology in SMEs run according to lean management: The case of a furniture publishing company. Environ. Eng. Manag. J. Accepted for publication in July 2012.

- González-García, S.; García Lozano, R.; Buyo, P.; Pascual, R.C.; Gabarrell, X.; Rieradevall i Pons, J.; Moreira, M.T.; Feijoo, G. Eco-innovation of a wooden based modular social playground: Application of LCA and DfE methodologies. J. Cleaner Prod. 2012, 27, 21–31. [Google Scholar] [CrossRef]

- González-García, S.; García Lozano, R.; Moreira, M.T.; Gabarrell, X.; Rieradevall i Pons, J.; Feijoo, G.; Murphy, R.J. Eco-innovation of a wooden childhood furniture set: An example of environmental solutions in the wood sector. Sci. Total Environ. 2012, 426, 318–326. [Google Scholar] [CrossRef] [PubMed]

- González-García, S.; Gasol, C.M.; Lozano, R.G.; Moreira, M.T.; Gabarrell, X.; Rieradevall i Pons, J.; Feijoo, G. Assessing the global warming potential of wooden products from the furniture sector to improve their ecodesign. In Sci. Total Environ.; 2011; Volume 410–411, pp. 16–25. [Google Scholar]

- González-García, S.; Lozano, R.G.; Estévez, J.C.; Pascual, R.C.; Moreira, M.T.; Gabarrell, X.; Rieradevall i Pons, J.; Feijoo, G. Environmental assessment and improvement alternatives of a ventilated wooden wall from LCA and DfE perspective. Int. J. Life Cycle Assess. 2012, 17, 432–443. [Google Scholar] [CrossRef]

- González-García, S.; Silva, F.J.; Moreira, M.T.; Pascual, R.C.; Lozano, R.G.; Gabarrell, X.; Rieradevall i Pons, J.; Feijoo, G. Combined application of LCA and eco-design for the sustainable production of wood boxes for wine bottles storage. Int. J. Life Cycle Assess. 2011, 16, 224–237. [Google Scholar] [CrossRef]

- Rives, J.; Fernandez-Rodriguez, I.; Rieradevall, J.; Gabarrell, X. Integrated environmental analysis of the main cork products in southern Europe (Catalonia—Spain). J. Cleaner Prod. 2013, 51, 289–298. [Google Scholar] [CrossRef]

- FINSA. Finsa Ecodiseño Project 2011. Available online: http://www.finsa.es/publicaciones/finsablog-nl.nsf/dx/ecodise%C3%B1o-project (accessed on 25 July 2014).

- ENISA; Sostenipra; ICTA; USC; Inèdit, & Finsa. Breve Resumen del informe técnico ecodiseño deunacaja para tresbotellas. Proyecto Piloto de Ecodiseño de Enisa. 2011. Available online: http://www.enisa.es/es/i-d-e/doc/recursos (accessed on 25 July 2014).

- ENISA. ARCOS knives. 2014. Available online: http://en.arcos.com/?icache=1 (accessed on 10 April 2014).

- ENISA; Sostenipra; ICTA; USC; Inèdit, & Arcos. Resumen del informe técnico ecodiseño de un cuchillo Proyecto Piloto de Ecodiseño. 2012. Available online: http://www.enisa.es/documentos_web/documentos/ARCOS_resumen.pdf (accessed on 8 May 2014).

- Council of European Union. Council Directive 96/61/EC of 24 September 1996 concerning integrated pollution prevention and control. In OJEC; 1996; Volume L 257, pp. 26–40. [Google Scholar]

- European Parliament and Council of European Union. Directive 2010/75/EU of the European Parliament and of the Council of 24 November 2010 on industrial emissions (integrated pollution prevention and control). In Official Journal of the European Union; L334; pp. 17–119. 17 December 2010; European Commission, Brussels. [Google Scholar]

- Schoenberger, H. Integrated pollution prevention and control in large industrial installations on the basis of best available techniques—The Sevilla Process. J. Cleaner Prod. 2009, 17, 1526–1529. [Google Scholar] [CrossRef]

- European Parliament and Council of European Union. Directive 2010/75/EU of the European Parliament and of the Council of 24 November 2010 on industrial emissions (integrated pollution prevention and control). In OJEC; 2010; Volume L 334, pp. 17–119. [Google Scholar]

- Daddi, T.; De Giacomo, M.R.; Testa, F.; Frey, M.; Iraldo, F. The effects of Integrated Pollution Prevention and Control regulation on companies management and competitiveness. In Bus. Strat. Env.; Article first published online: 22 August 2013. [CrossRef]

- European Commission. Directorate General Environment. Directorate G: Sustainable Development and Integration. Unit G.2 Industry and Environment. Analysis of Member States’ first implementation reports on the IPPC Directive (EU-15). Final report; June 2004; LDK-ECO Environmental Consultants S.A., Athens, Greece. [Google Scholar]

- European Commission; DG Environment; Industrial Emissions Unit. Analysis of the Reports submitted by Member States on the Implementation of Directive 96/61/EC for the period 2003–2005. Final report. April 2009. LDK-ECO S.A. Environmental Consultants. Available online: http://forum.eionet.europa.eu/x_reporting-guidelines/library/ippc/reporting-period-2003-05/analysis_2003-2005 (accessed on 24 July 2014).

- Van den Abeele, L.; Dils, E.; Polders, C.; Nelen, D.; Goovaerts, L.; Vanderreydt, I. Analysis of the reports submitted by Member States on the implementation of Directive 2008/1/EC, Directive 2000/76/EC, Directive 1999/13/EC and further development of the web platform to publish the information. Report on subtask 3.2: Analysisi report of Member States implementation of IPPC and WI Directives. March 2011. Available online: http://iris.eionet.europa.eu/assets/downloads/Final-report-IPPC-24032011.pdf (accessed on 25 July 2014).

- Raya, I.; Vázquez, V.L. Sharing experiences to improve pollution prevention and control in the Mediterranean area. International Innovation. Disseminating science, research and technology. 2009, 56–58. [Google Scholar]

- Gibbs, D.; Deutz, P. Implementing industrial ecology? Planning for eco-industrial parks in the USA. Geoforum 2005, 36, 452–464. [Google Scholar] [CrossRef]

- Gibbs, D.; Deutz, P.; Proctor, A. Industrial Ecology and Eco-industrial Development: A potential paradigm for Local and Regional development? Reg. Stud. 2005, 39, 171–183. [Google Scholar]

- Gibbs, D. Industrial Symbiosis and Eco-Industrial Development: An Introduction. Geography Compass 2008, 2, 1138–1154. [Google Scholar] [CrossRef]

- Tarantini, M.; Preka, R.; Dominici Loprieno, A.; Litido, M.; Segreto, M.A.; Di Paolo, A. Sustainable Industrial Areas in Mediterranean Countries; Toolkit for SMEs and Local Authorities—MEID project; ENEA: Rome, Italy, 2013. [Google Scholar]

- Tarantini, M.; Dominici Loprieno, A.; Preka, R.; Segreto, M.A. The management model of the MEID project: Tools for Sustainable Industrial Areas and opportunities for SMEs. In Proceedings of International Forum “Increasing the competitiveness of industrial areas. New tools and challenges: Perspectives and incentives of the European policies, Bruxelles, Belgium,, 7 June 2012; ENEA: Rome, Italy, 2012. [Google Scholar]

- SIAM project. ENEA: Bologna, Italy. Available online: http://www.life-siam.bologna.enea.it/ (accessed on 17 July 2014).

- EFXINI POLI; et al. Low Cost - Zero Waste Municipality Project (Zero waste project). Available online: http://co2zw.eu.sostenipra.cat/ (accessed on 17 July 2014).

- Buttol, P.; Buonamici, R.; Naldesi, L.; Rinaldi, C.; Zamagni, A.; Masoni, P. Integrating services and tools in an ICT platform to support eco-innovation in SMEs. Clean Technol. Environ. Policy 2012, 14, 211–221. [Google Scholar] [CrossRef]

- Baumann, H.; Boons, F.; Bragd, A. Mapping the green product development field: Engineering, policy and business perspectives. J. Clean. Prod. 2002, 10, 409–425. [Google Scholar] [CrossRef]

- Van Hemel, C.; Cramer, J. Barriers and stimuli for ecodesign in SMEs. J. Clean. Prod. 2002, 10, 439–445. [Google Scholar] [CrossRef]

- Luttropp, C.; Lagerstedt, J. EcoDesign and the Ten Golden Rules: Generic advice for merging environmental aspects into product development. J. Clean. Prod. 2006, 14, 1396–1408. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

De Giacomo, M.R.; Loprieno, A.D.; Tarantini, M.; Preka, R.; Litido, M.; Furphy, A.D.; Calvo, V.V.; Llorach-Massana, P.; Gasol, C.M.; Rieradevall, J.; et al. Eco-innovative Practices for Sustainable Consumption and Production: What are the Possible Benefits for Companies? Adm. Sci. 2014, 4, 242-275. https://doi.org/10.3390/admsci4030242

De Giacomo MR, Loprieno AD, Tarantini M, Preka R, Litido M, Furphy AD, Calvo VV, Llorach-Massana P, Gasol CM, Rieradevall J, et al. Eco-innovative Practices for Sustainable Consumption and Production: What are the Possible Benefits for Companies? Administrative Sciences. 2014; 4(3):242-275. https://doi.org/10.3390/admsci4030242

Chicago/Turabian StyleDe Giacomo, Maria Rosa, Arianna Dominici Loprieno, Mario Tarantini, Rovena Preka, Maria Litido, Anne Dominique Furphy, Víctor Vázquez Calvo, Pere Llorach-Massana, Carles M. Gasol, Joan Rieradevall, and et al. 2014. "Eco-innovative Practices for Sustainable Consumption and Production: What are the Possible Benefits for Companies?" Administrative Sciences 4, no. 3: 242-275. https://doi.org/10.3390/admsci4030242

APA StyleDe Giacomo, M. R., Loprieno, A. D., Tarantini, M., Preka, R., Litido, M., Furphy, A. D., Calvo, V. V., Llorach-Massana, P., Gasol, C. M., Rieradevall, J., Farreny, R., & Gabarrell, X. (2014). Eco-innovative Practices for Sustainable Consumption and Production: What are the Possible Benefits for Companies? Administrative Sciences, 4(3), 242-275. https://doi.org/10.3390/admsci4030242