1. Introduction

Plastic is seen as one of the most efficient materials and is used in all walks of life today, as it was designed to be strong, light, highly moldable, and resistant to degradation [

1]. Since 1975, global plastic resin production has increased significantly and is continuing to increase [

2]. However, conventional waste management practices recycle only a small fraction of plastic waste (typically less than 10% in the U.S., compared to more than 50% in some European countries), while the remainder is landfilled or incinerated, creating significant environmental burdens [

3,

4]. Circular economies can help overcome many environmental and financial challenges compared to other economical approaches through their use of waste as a resource [

5]. Circular economies apply resource constraints to minimize waste, facilitate trade between users, use technological development to stay viable, and decouple constrained resources, influencing customers to get the most out of their products [

6]. There are challenges in designing a circular economy of plastics [

7]. First, there is a lack of information about the specific composition of the plastic waste that is arriving at recycling centers [

8]. This affects the ability of recyclers to comply with regulations or sort the materials efficiently and creates uncertainty about the recycled materials market outlet [

9]. Second, the reprocessed polymers face quality degradation challenges compared to virgin materials [

10]. These reprocessed plastics are often made into low-value products, resulting in a low profit margin in the supply chain [

11]. Third, most material recovery facilities (MRFs) are located outside the US, where less strict environmental policies are imposed on polymer reprocessing [

12]. Therefore, because of these challenges and complexities, an environmentally sound circular economy has not been developed in the U.S. and needs to be designed creatively to generate high value for waste polymers [

13].

1.1. Selection Challenges

Challenges of recycling originate at the source of street-side pickups, where many types of recyclable materials, such as plastics, cardboard, glass, and aluminum, are generally picked up and commingled [

14]. If these recyclables haven’t been cleaned, they can potentially bring in harmful substances that hinder the recycling process [

15]. Contaminated plastics in recycling bins become waste because it’s cheaper and easier to throw them away than to clean them [

14]. Lack of public knowledge of resin codes also creates a barrier between collecting and sorting plastics because most people think that all plastic is recyclable, but only certain types are [

16]. For example, polyethylene terephthalate (PET, #1) and high-density polyethylene (HDPE, #2) are widely reprocessed, while others such as polyvinyl chloride (PVC, #3), low-density polyethylene (LDPE, #4), and polystyrene (PS, #6) present significant challenges due to contamination, additives, or unfavorable economics [

15]. Biodegradable and bio-based plastics such as polylactic acid (PLA) are increasingly used, yet their recycling infrastructure is still limited. Recognizing these material-specific barriers is essential for designing effective localized solutions. Various methods have been developed to improve sorting efficiency. Spectroscopy is one method, measuring wavelengths shot into the plastics and reflected to identify chemical composition [

17]. This allows for quicker sorting, and multiple tests can be run to ensure that the plastic is fully and properly separated [

18]. Microsorting is another way to sort little bits of plastic [

19]. An example of microsorting is using the float tank method, which suspends different types of plastic chunks and scraps at different levels to aid in sorting the plastics. This method can also clean the plastic to an extent [

20]. After collecting and sorting polymers, we begin to look at the issues that are involved in reprocessing polymers to make tangible goods [

21].

1.2. Reprocessing Challenges

Plastic can only be recycled a few times because the long molecules that make up plastic stretch can degrade, causing the newly reprocessed plastics to be weaker [

22]. Also, as plastics get melted, contamination can occur, which can also degrade the plastic molecules [

23]. There are many types of reprocessing methods available; the most popular are injection molding, plastic extrusion, blow molding, and compression molding [

24]. One large topic of research is the mixing of polymers to engineer a plastic that can be tough and chemically resistant [

25]. Most often, it is pure polymers that are the strongest and most sought after because they do not run the risk of contamination and degradation [

26]. A study engineered a plastic that can be broken down to a molecular level and completely changed without losing its strength and quality. This plastic is called polydiketoenamine, or PDK [

27]. Another study on cross-linked polymers is looking at how chemical, thermal, photo-, or biodegradation may recast new products based on the needs of a supplier [

28]. Thermosets are known for not being able to be melted with heat, but studies are now showing that if you add biorenewable components to thermosets, it can create a new end-of-life scenario for the once unrecyclable polymer [

29]. This will allow more plastics that could not previously be recycled to be recycled and will open up more space in landfills. Although this study does not present new experimental data on the mechanical or chemical properties of recycled plastics, prior research demonstrates that recycled polymers can perform adequately in additive manufacturing. For example, studies on recycled PLA and PET have reported tensile strengths and stiffness values comparable to those of virgin materials when processing conditions are optimized [

30]. Other work has shown that repeated recycling cycles gradually reduce mechanical performance, but materials remain suitable for non-structural applications such as prototyping, educational models, and small consumer goods [

31]. These findings confirm the technical feasibility of reprocessing PLA, ABS, PET, and PETG through 3D printing and support the practical approach adopted in this project. In addition to mechanical recycling, emerging technologies such as chemical recycling are being explored to overcome quality degradation challenges. Approaches such as depolymerization, pyrolysis, and solvent-based recovery allow plastics to be broken down into their chemical constituents and remanufactured into high-quality polymers [

32]. These methods show promise for producing materials with properties comparable to virgin plastics, but they often require significant capital investment, advanced infrastructure, and strict process controls. As a result, they are not yet widely implemented at community or educational scales.

1.3. Demand for a Circular Economy Model for Plastic Reprocessing

There are a lot of different factors that go into the life cycle of polymers and whole products [

33]. Some bio-based polymers (e.g., PLA) become nonbiodegradable due to the chemicals and compounds added to the plastics while they are being created, such as slip additives, light stabilizers, monomers, and oligomers. While the use of additives allows plastic to be stronger, cleaner, safer, and more colorful, these additives are also the reason most such plastics are not biodegradable [

34]. In a study on packaging efficiency, they found that packages for single items have a larger environmental impact than items that are purchased in bulk [

35]. Other research has also concluded that it is essential to procure material value and expand resource productivity so that a direct economic incentive can be provided in order to circumvent leakage into the natural environment. This also permits the transition to a viably sourced starting material by minimizing its scale [

36]. A study of bike manufacturers who use recycled materials to make their products found that by working this business model into a circular economy, the supply chain became more important [

37]. In another study, a large global supplier turned to purchasing recycled materials because of the increase in price and demand for virgin material [

38]. Based on evidence presented by a food waste biorefinery case study, a successful approach for a circular economy in plastics would be a model that contained a network of products, procedures, and businesses that collaborate to sustainably address challenges to plastic recycling from collection to remanufacturing [

39].

There have been many models made and studied to limit the amount of plastic waste that is entering landfills and increase recycling to extend the life cycle of those polymers [

40,

41,

42]. While most studies emphasize national or industrial-scale recycling systems, much less attention has been given to community-level initiatives that combine environmental benefits with social and educational value. Community-focused initiatives such as the Precious Plastic movement, makerspaces, and university recycling labs have shown that small-scale reprocessing is technically feasible and can raise awareness about sustainability. However, these projects often concentrate on technical demonstration without fully integrating educational outreach or structured community engagement. The central hypothesis of this study is that a localized plastics reprocessing workspace can create environmental and social value by demonstrating practical recycling methods and engaging students and community members in hands-on learning. The novelty of this work lies in integrating technical reprocessing steps (shredding, extrusion, injection molding, and 3D printing) with educational outreach in a university setting. Unlike most circular economy models, which emphasize large-scale industrial systems, this project highlights the potential of community-level initiatives that not only divert waste from landfills but also serve as platforms for education, creativity, and sustainable behavior change [

43].

The objective of this study is to design a circular economy life cycle model for plastics and recreate value from waste polymers with community engagement. Specifically, it includes the following objectives:

Design the circular economy model for waste plastics from waste treatment to product manufacturing.

Create a case study to demonstrate the proposed circular economy life cycle in a college town community.

Conduct a life cycle sustainability assessment to evaluate the economic, environmental, and social impact of the design.

2. Materials and Methods

2.1. The Circular Economy Model

In a circular economy model (

Figure 1), the goal is to design out waste, remanufacture products, and generate economic value. The workspace is optimized for commonly reprocessable plastics such as PLA, ABS, PET, and PETG, which are widely available in the university setting. Other plastics, such as PVC and PS, were excluded due to contamination risks or lack of processing compatibility with available equipment. Labor was not included as a cost in the recycling flow model, since undergraduate assistants operated the lab as part of their academic responsibilities. There are 5 basic steps that coincide with the circular economy model. After the product sale, plastic products are put into use. As the products get used, they are either thrown out or reprocessed. When plastics are recycled, they are sorted and cleaned. Also, in the recycling stage, items recycled are checked to ensure that the material can still be used after remanufacturing. As the recycling stage happens, the design for new products is occurring. The products that are being designed are often less detailed or strong than virgin plastic products, so the items tend to be more basic. Once the designs are set and all the material is recycled correctly, the recycled products go into the reprocessing stage of the cycle. This is where the recycled material is remanufactured and turned into tangible goods. Finally, as the products come out of the reprocessing, they are sold, and the cycle continues.

2.2. Collection

The collection of waste plastics can be in different formats depending on the scale of the operation and the workspace capacity. At the initial stage or small capacity, recycled plastics can be collected through drop-off and pick-up bins, wherein a person donating would either schedule a time to drop off their recyclable materials or have them picked up. Ideally, the plastics should be clean and without contaminants or liquid. Staff members who directly handle waste plastics should be protected from germs and bacteria on the waste materials. Collected plastics primarily consisted of post-consumer PET bottles, PLA from discarded 3D prints, and ABS containers. Items were pre-sorted by type and washed to remove contaminants before processing. While precise quantities varied across semesters, a typical weekly collection yielded several kilograms of material suitable for shredding and reprocessing. Collected plastics also need to be sorted based on the polymer type and color. Therefore, water supply, bins, and PPEs are basic equipment that need to be prepared for the collection stage. For a larger capacity, the workspace can collaborate with the university’s waste management facility to acquire a constant supply of plastic waste.

2.3. Product Design

Product design is a critical step to the circular economy model because it determines the regenerated value from the plastic waste. The goal of the product design is to create product models that add enough value to not only cover the costs of reprocessing but also generate profit to sustain the operation of the workspace. Products designed to be used in the remanufacturing of waste need to be examined for their uses, design complexity, strength, and durability. In the remanufacturing of products, the uses are a major factor in determining which products are to be designed. Because reprocessed polymers have lower quality compared to virgin materials, the design of products will first need to meet the functional requirements and be aesthetically appealing to customers. While various products can be made through typical processes such as injection molding, extrusion, and 3D printing, the selection of products should consider market need, product price, processing time, workspace ability, and complexity of manufacturing. As the workspace is established within the university and the community, the targeted customers are university students, local residents, and alumni. Therefore, product ideas can be brainstormed to reach them as a priority. A long-term plan would be to establish a cloud-based product design platform for 3D printing. Customers can create their own designs and upload the models on the platform, and then the products will be made within the workspace for pickup. This cyber-manufacturing approach will be especially attractive to college students and customers with an engineering background and can incorporate 3D drawing tools such as Fusion 360, SolidWorks, and AutoCAD.

2.4. Processes

The processes needed in remanufacturing include sorting, cleaning, shredding, making the material into a new product, and quality testing. The purpose of sorting is to group the same plastic together to accumulate that plastic as raw material for production. Typical plastics are PET, HDPE, PP, PV, LDPE, PS, PLA, and ABS. They are usually collected in their product form, such as bottles and containers. Cleaning of the product will limit contamination between other materials, chemicals, or other things that could be found within the material. Shredding the plastics will transform large pieces of products into small pieces that can be easily melted in the processing equipment. Plastic products are usually made using four processes: injection molding, extrusion, compression, and 3D printing. Because of the equipment capacity in such workspaces, waste plastics processed with injection molding are typically made into repeatable, small-sized products such as key tags. Molds need to be designed and premade. In universities, molds can be made in machining shops, while if the workspace is held in the community, molds can be made in local workshops. During the injection molding process, quality is affected by the flow of the melted polymer and the solidification of the polymer in the mold. For injectors with low capacity, the melting of the polymer can be the bottleneck that increases the cycle time. However, it can be overcome by pre-heating the polymer and storing it in a controlled environment. Like injection molding, the extrusion process melts the shredded polymer and extrudes it through a die. Material is pushed out to make long, uniform products such as straws, pipes, and screws. Extrusion machines are best utilized as a production process that can make products that are long and then can be broken up into smaller pieces as the manufacturer sees fit. Also, with extrusion machines, different ends can be applied to produce different shapes and materials. The material, with the utilization of these nozzles, can be rounded, squared, or have a non-uniform shape. The melted waste plastics can also be compressed into blocks or shapes with a compression machine. Based on the design of the mold, products can be made for multiple purposes, such as plates and sheets. The raw material (usually not melted plastics) can also be mixed with sand or cement to create pavement or building blocks. Waste plastics can also be made into 3D filament through a filament extruder. To control the quality of the filament, waste plastics need to be carefully sorted based on the polymer type and color because their melting temperature varies. Compared to traditional processes, 3D printing provides flexibility in product shapes, geometries, and designs. The workspace can engage the university students and the local community residents to creatively design products that can be made in the workspace using recycled plastics. A drawback of this process is the long processing time, which could take many hours, or even days, depending on the size, design, and degree of detailing while printing. However, 3D printers can process overnight, and it does not require attention over the whole process. Material losses occurred primarily as fines during shredding and as failed prints or support structures during 3D printing. These residues were re-collected and, where feasible, re-shredded for reuse. Such iterative processing illustrates both the opportunities and challenges of achieving a truly closed-loop recycling system.

3. Case Study

3.1. Background of the Case Study

The case study was conducted in a university that is located on the East Coast of the United States. The area with a population of 120,000 began recycling efforts in the late 1990s, which created a commingled curbside recycling program and drop-off center for recyclable materials, including plastic, PET, and HDPE (#1 and #2, respectively). The original system for collecting these recyclables was very similar to the current curbside garbage collection, which consists of the town being divided into sectors, which are allocated a date and time for when the waste bins will be collected. However, plastic recycling was seriously hit by overseas policy changes, and plastic waste began to pile up in many towns. Therefore, in late 2018, the city began to stop providing curbside recycling pickup. Now, for people wishing to recycle, they must take their pre-sorted recyclables to the Recycling Convenience Center to separate the sorted #1 and #2 plastics and other materials into their desired bins for them to be sold as commodities. The university began recycling in 1995, and it took off drastically after that, even achieving a recycling rate of 43% of all waste, surpassing the state’s recommended rate of 25%. The university began collaborating with a manufacturing company in 2008 in an initiative to assist the university in recycling plastic bags, which then would be used by the manufacturer as an alternative in the production of some of their products. Following that initiative, the university began placing plastic bins around its campus to promote recycling among its students and faculty. In response, the university implemented roughly 350 waste bins across campus for the purpose of collecting recyclables. On each one of these bins, there are pictures and descriptions of what types of plastic, paper, cans, and glass can be accepted by the recycling center. Once the bins are ready for pick up, the recyclables are taken to a Recycling Facility to be sorted and grouped by material. It is then prepared for transport and collection by a packaging company. Currently, the university’s recycling bins no longer collect the same range of recyclables, and plastic collection was halted due to a lack of local markets. Therefore, a plastics reprocessing project was initiated to engage both the university and the community in seeking solutions.

3.2. The Workspace

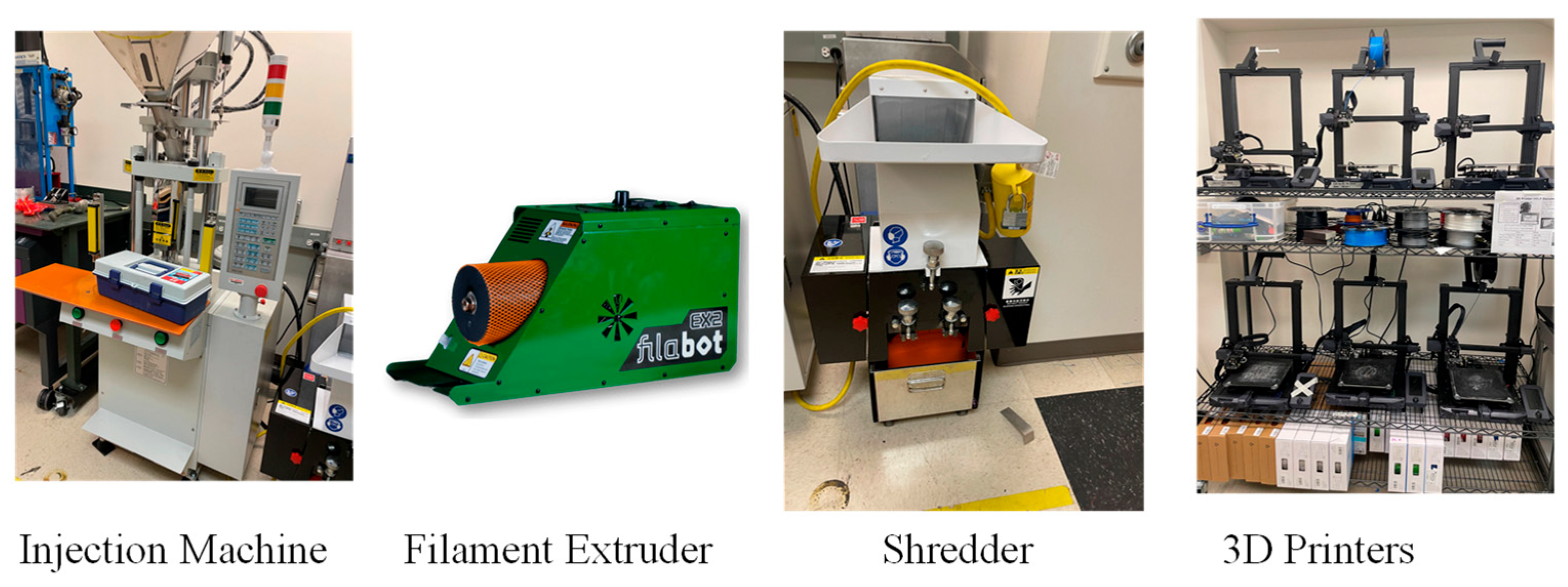

The workspace is located in an academic building housing STEM majors. The space is designed to have two staff members (undergraduate assistants) in the lab every week. Each staff member works a total of 6 h a week. The workspace is where all products and machines will be built and kept. The materials in the workspace include tools, including a socket set, screwdriver set, and hex key set; sorted and cleaned recyclable plastic items; and dye. The tool sets are used to initially build the machines and for routine upkeep to ensure they are always working properly and maximizing efficiency. The dye will be used to dye the plastic flakes if a certain color is desired. The collected plastic items will be used in the various machines in the workspace. The workspace is composed of four different machines (

Figure 2) that allow the staff to conduct the different processes required to break down and reprocess the recycled plastics. The four machines are a plastic shredder, an injection molding machine, a filament extruder, and the 3D printers. They are commercially available desktop 3D printers (e.g., Creality Ender-3) and a filament extruder (Filabot EX2). The injection molding machine was a WirePro PI-F16, with a capacity suitable for small items such as coasters and keychains. The majority of plastics collected through campus bins were managed by an external company, which transported them to landfills. The workspace itself was used solely for educational and demonstration purposes; therefore, only a minimal amount of plastic waste was handled within the workspace. While a full quantitative mass balance was not conducted, visual sorting and material checks indicated that over 80–90% of collected PLA, PET, ABS, and PETG could be processed, with the remainder excluded due to contamination or incompatibility.

The plastic recycling shredder machine cuts the plastic items into small flakes that can then be used in other machines to create new products. The material needed to use this machine is the washed and sorted plastic items that have been dropped off or collected throughout the campus or community. Once the plastic is shredded, it will be stored in bins in the lab so that there is easy access and it allows for quick product making. The plastic recycling injection machine allows for the shredded plastic flakes to be heated and injected into preexisting molds. The molds can be made in the industrial and manufacturing systems lab on campus. The only material needed to use this machine is the plastic flakes that have been previously shredded. The 3D printing filaments can be made through a commercially available filament extruder that melts recycled plastics. Process settings will be explored and optimized to ensure the quality of filaments. All machines in the workspace can create a variety of new products.

Figure 3 below shows the process the plastic will go through from the beginning steps of plastic preparation to the end step of producing a new product using the machines in the lab.

The workspace is operated by two lab TAs who will work 1.5-h days, 4 days a week. The TAs manage the lab during open lab hours and will simultaneously support the workspace. They oversee collecting the plastic waste, sorting and cleaning the plastic, and operating the machines. One TA will collect the waste plastics. The waste will then be brought back to the workspace, where both staff members will sort and clean the plastic. Once the plastic is sorted, it can be put through the shredder. Once it is cleaned and sorted, it can be put into storage, ready to be used as the feedstock in other machines. This allows the staff members to make products on demand and not wait for the initial shredding of the waste; each day, new material is brought in. The different machine processes can be run simultaneously, depending on what products are being made that day. Plastic can be shredded while the 3D printer, extruder, and injection machine are being utilized to produce different products. This will allow the workspace to be efficient and optimize the time that the staff members are there to oversee the processes. The 3D printer will also be optimized by beginning the printing of larger products right before leaving the workspace, so they can print overnight and be finished by the next morning. This will allow the smaller items with a shorter print time to be printed during the open hours of the workspace and allow for production during off-hours.

3.3. Designs

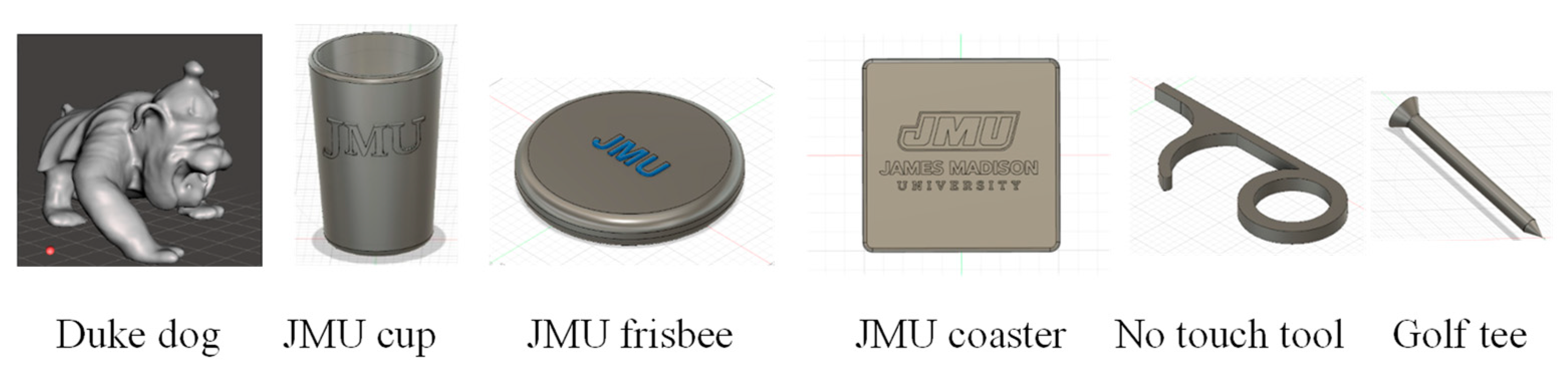

As part of the case study, the project team conducted an exploratory study to understand product preferences across different age groups within the local community. This approach generated valuable insights into consumer preferences, enabling the team to align design decisions with the expectations and interests of the target market. Once the most promising products were identified, the team proceeded to develop base models using computer-aided design (CAD) tools. SolidWorks and Autodesk Fusion 360 were used to create virtual prototypes, allowing for easy iteration and refinement of designs without the need for physical re-prototyping. After the designs were finalized, the files were uploaded to the 3D printers for fabrication using recycled materials.

The selection of manufacturing methods was guided by the complexity and functionality of each design. For intricate shapes with fine details, 3D printing was chosen as the preferred method due to its ability to produce precise, repeatable models with minimal risk of damaging the final product. Molds would have been impractical for these designs, as repeated removal of detailed parts could lead to deformation or breakage. The products manufactured via 3D printing included the Duke Dog statue, JMU glass, and JMU Frisbee, as shown in

Figure 4.

For products requiring less detail but still more complexity than basic shapes, injection molding was selected. This process, which involves injecting molten plastic into a mold, is highly efficient for mass-producing uniform items (Rosato, 2000). The Golf Tee, Coaster, and No Touch Tool can also be made using this method. While demonstration products included items such as cups, it is recognized that plastics sourced from post-consumer waste are not approved for food-contact use. These prototypes were produced solely for educational and illustrative purposes, not for distribution as food-grade products.

While the initial designs can effectively meet current consumer demands, there is also a need for ongoing design updates to stay aligned with market trends. Regular client outreach initiatives—such as periodic surveys—can be used to identify shifting preferences and ensure continued relevance. Incorporating customer feedback directly into the design cycle enables the project to remain responsive, competitive, and innovative. In addition, to increase accessibility and community impact, the project envisions developing an open-source database of CAD files for 3D printing. This would allow students and community members to share designs, replicate useful products, and further extend the educational value of the workspace. In this way, proactive engagement with consumers not only drives product development but also strengthens the overall impact and adaptability of the circular economy model.

3.4. Cost-Benefit Analysis

A cost-benefit analysis was conducted to evaluate the financial feasibility of the plastic reprocessing circular economy model. The analysis considered both fixed and variable costs, including labor, energy, space, materials, and the initial investment in equipment and tools.

A breakdown of the initial investment is provided in

Table 1. The equipment costs were recorded at the time of purchase. For labor, the standard student employee wage at the university is

$12 per hour. The workspace is staffed by two undergraduate TAs, each working approximately 6 h per week. Labor costs were excluded from the variable cost analysis because undergraduate assistants staffed the workspace as part of their academic duties and were paid through existing departmental budgets. In other community contexts, labor would be a significant factor and would need to be incorporated. Therefore, the cost of supporting the workspace can be neglected. Energy costs in

Table 2 were calculated using the local electricity rate (

$0.122/kWh), multiplied by the average power demand of each machine and its operation time per unit. For example, a 3D printer operating at 0.5 kW for 10 h results in 5 kWh of consumption, corresponding to

$0.61 at local rates. As an academic institution, the university is exempt from sales tax. However, to ensure a complete cost overview, taxes and shipping were included where applicable.

To determine the breakeven point, the following formula was applied:

Variable cost was calculated based on the energy expenses per product (

Table 2). For analysis purposes, manufacturing methods were grouped into two categories: 3D printing and extrusion/injection molding.

Assumptions were made based on empirical data and equipment performance:

3D printing takes approximately 10 h per product, with only 30 min of active labor.

Injection and extrusion processes were estimated to produce one unit every 30 min, as only a small amount of products need to be made.

Using Equation (1):

For 3D printing, the initial investment was $300, the average unit price was $5, and the variable cost was $0.61, resulting in a breakeven point of approximately 70 units. The $5 unit price was used as an illustrative estimate based on similar small 3D printed or molded items sold through campus stores and online craft marketplaces. This figure is intended for breakeven analysis rather than as a formal market valuation.

For the injection molding group, the combined equipment investment was $6000, the average unit price was $5, and the variable cost was $0.04, resulting in a breakeven point of approximately 1210 units.

After the initial investment, the workspace can reach breakeven in around 2 years by selling 10 products per week. These findings demonstrate the project’s financial viability. Rather than focusing on commercial sale, the workspace is best understood as an educational and open-lab environment, where students and community members can produce items for personal use, prototyping, or design projects. While limited sales (e.g., branded university items) are possible, the primary value lies in experiential learning, creativity, and skill-building rather than large-scale product commercialization.

3.5. Environmental Impact

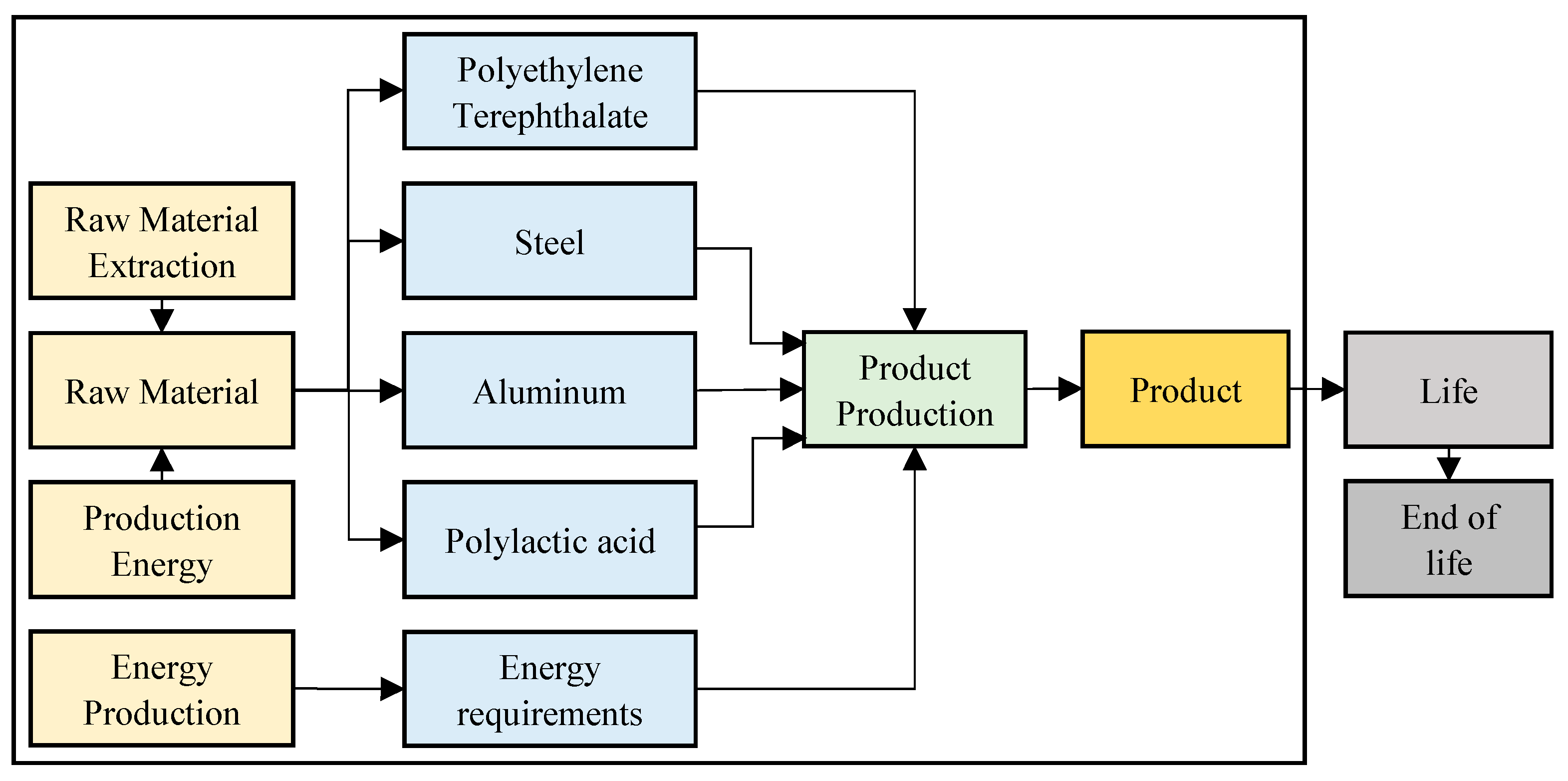

The Life Cycle Assessment (LCA) for the workspace focused on analyzing the environmental impacts associated with both product manufacturing and the production of input materials. The functional unit was defined separately for each product type as “one unit of the given product,” allowing item-level comparison. We acknowledge that this approach does not account for differences in product lifespan or functional utility. Future studies should therefore consider functional units that reflect service life or use-phase performance in order to provide more comprehensive comparisons across diverse product categories. The system boundary for this analysis is illustrated in

Figure 5 below.

The boundaries of this assessment excluded the transportation of raw materials to the Plastics Reprocessing workspace and the construction of machinery used within the workspace. Water consumption was not modeled because the pre-cleaning of plastics relied on existing campus facilities, and the amount used is minimal since it occurs only across different batches of recycled plastics. Additionally, since the products are manufactured from recycled plastics, the assessment does not include the initial life or end-of-life treatment of these materials. It is assumed that the products could themselves be recycled again through the same system at the end of their useful life.

To calculate the energy and material requirements for each product, individual components were analyzed for volume and mass using Autodesk Fusion 360. The specific machines used to produce each product were identified to determine their associated material use. Notably, all products underwent shredding, and for those made with 3D printing, filament extrusion was also included. The breakdown of product mass, volume, and corresponding manufacturing process is presented in

Table 3.

Each machine’s physical composition was recorded and used to estimate the material use per product, assuming simplified material types: steel, aluminum, or PLA (for 3D printed parts). Operational characteristics such as energy consumption, extrusion rates, and shredding capacities were integrated into the assessment. It was assumed that the machines would have a lifespan of 10 years. The resulting material and energy requirements per product are summarized in

Table 4.

The use of machine materials was derived from an approximation of the machine’s construction materials, considering that each piece of equipment was primarily made from steel, aluminum, or PLA. The PET used in all products originated from post-consumer recycled plastics. This input was recorded as a negative value in the life cycle inventory, consistent with standard LCA practice for recycled inputs.

The complete inventory was modeled and analyzed using the openLCA software, applying the CML (baseline) method, version 4.4. The results of the environmental impact categories for one unit of each product are presented in

Table 5.

The LCA results demonstrate that the Plastics Reprocessing workshop has a net-positive environmental impact across all categories except for ozone depletion, where a marginal increase in CFC-11 equivalent was observed. This trade-off is significantly outweighed by reductions in climate change potential, marine ecotoxicity, and resource depletion due to the use of recycled PET as the primary material input.

For comparison, prior life cycle studies show that the environmental burdens of landfilling or incinerating the same mass of plastic waste are significantly higher than those of localized recycling. Landfilling one kilogram of mixed plastics typically results in 1.2–1.6 kg CO

2-eq emissions, primarily from landfill gas generation and leachate treatment, with minimal material recovery [

44]. Incineration of one kilogram of plastics can emit 2.5–3.0 kg CO

2-eq, depending on the energy recovery efficiency, while also releasing pollutants such as NOx and particulate matter [

45]. By contrast, recycling one kilogram of PET or PLA into new products has been reported to avoid 1.1–2.4 kg CO

2-eq compared to virgin production, depending on process efficiency [

46,

47]. These findings indicate that even a small-scale recycling workspace provides net environmental benefits over landfilling or incineration, despite its limitations in scale and product range.

It is important to note that these results are based on the production of a single unit of each product. Given the scalable nature of the workspace, the cumulative benefits of producing hundreds or thousands of such items would further amplify the environmental advantages, making a compelling case for the widespread adoption of community-based recycling and remanufacturing systems.

3.6. Social and Education Impact

To enhance the Plastics Reprocessing workspace, a comprehensive outreach and social impact strategy could be established, utilizing a community-focused approach. It includes engaging students, local residents, faculty, alumni, and local schools through targeted educational initiatives and participatory programs.

Identifying potential target audiences would be the first step, including students and their families, university faculty, local residents, and online communities. Products could be priced strategically, reflecting actual production costs, while remaining accessible and attractive to potential consumers. This approach ensures the economic sustainability of the initiative and facilitates ongoing reinvestment into project operations and outreach. To enhance convenience and accessibility, two purchasing channels could be used: an online storefront and direct sales within the recycling workspace. Both options would allow consumers to easily explore and obtain products, promoting a straightforward and efficient purchasing experience. Communication would play a vital role in outreach efforts. Establishing active social media accounts on platforms could provide continuous updates on new products, recycling tips, and environmental awareness campaigns. These channels would not only highlight the transformation of recycled plastics into innovative products but also educate the public about broader sustainability issues. A dedicated website could further amplify these efforts by sharing project goals, mission, and potential impact, serving as an additional resource for consumer engagement. Conducting preliminary market surveys could be another essential component, allowing the project team to better understand the preferences, expectations, and willingness-to-pay among potential consumers. Survey results would guide product selection and outreach strategies, ensuring alignment with community interests and market demands.

This work uses a model for implementing circular economy principles at a community level. Such an initiative could demonstrate how locally managed recycling and remanufacturing activities may deliver both environmental and economic benefits, while simultaneously fostering public engagement and education. On a broader scale, this model could provide a replicable blueprint for similar institutions and communities interested in developing decentralized recycling systems. By reducing dependency on landfill disposal and revitalizing local recycling practices, the project could potentially spark a shift toward greater consumer interest in sustainable products made from recycled materials. At an international level, demonstrating the technical feasibility and community benefits of this localized circular economy model could position communities adopting it as leaders in sustainable practices. Such projects may inspire broader global adoption of similar systems, contributing significantly to international environmental preservation efforts.

An important contribution of this work lies in its educational role. The plastics reprocessing workspace was designed not only as a recycling facility but also as a teaching and outreach platform. University students were actively engaged in all stages of the process, from collection and sorting to shredding, extrusion, 3D printing, and injection molding. By participating in these activities, students gained practical skills in materials handling, computer-aided design, and manufacturing workflows, while also developing awareness of sustainability and circular economy principles.

The workspace also functions as an “open lab” accessible to a broader community of users. Students and faculty from engineering, architecture, and design programs used recycled plastics in their projects, demonstrating cross-disciplinary applications. The facility was further leveraged for demonstrations to K–12 school groups and visitors, extending its educational value beyond the university. In future iterations, the development of an open-source CAD file database for 3D-printed items could further enhance learning opportunities by allowing students and community members to access and share designs.

By linking technical recycling practices with experiential learning, the workspace exemplifies how a localized circular economy model can achieve impact not only in material recovery but also in education, skill-building, and community engagement. This dual role strengthens the relevance of the project and supports the framing of the study as an “educational” case of circular economy practice.

4. Discussion

The results of this study indicate that an educational plastics reprocessing workspace is technically feasible and provides strong educational and social benefits, even though its economic feasibility remains limited. Energy costs were modest, and products could be fabricated reliably, but scaling this model beyond an academic context would require addressing labor costs and broader infrastructure needs.

When compared with other circular economy initiatives, important distinctions emerge. Community-based projects such as the Precious Plastic movement have demonstrated that small-scale recycling can successfully reprocess plastics into useful goods and raise public awareness. Similarly, makerspaces and community fabrication labs have incorporated recycling equipment to encourage sustainable prototyping and design. However, these initiatives often operate informally or focus primarily on technical demonstration. By contrast, the present case study explicitly embeds plastics reprocessing into a university setting, where it functions not only as a technical workspace but also as a structured educational platform linked to curricula, outreach activities, and research. This integration of recycling and education differentiates the model and broadens its social impact.

The life cycle assessment suggests that workspace products have lower environmental impacts than those made from virgin plastics. Nevertheless, the analysis did not compare directly to landfill, incineration, or municipal mechanical recycling, which limits generalizability. Likewise, mechanical and chemical testing were not conducted in this study, though previous research shows that recycled PLA, ABS, and PET can maintain adequate performance for non-structural applications [

48]. These limitations highlight that the present findings should be interpreted as a demonstration of feasibility rather than as a comprehensive validation of recycling performance.

5. Conclusions

This study concludes that the Plastics Reprocessing Workspace provides a replicable, community-scale model of circular economy practice that is both technically viable and socially impactful. By integrating shredding, extrusion, injection molding, and 3D printing into a localized workflow, the project demonstrates how common polymers such as PLA, ABS, PET, and PETG can be reprocessed into useful items while engaging students and the broader community.

The novelty of this approach lies in its dual role: it is at once a technical demonstration of small-scale recycling processes and an educational platform embedded within a university setting. This combination distinguishes it from other community recycling initiatives, which often emphasize awareness or production but do not integrate recycling directly into curricula, research, and outreach.

At the same time, several limitations must be acknowledged. The study did not include direct testing of the mechanical or chemical properties of recycled plastics, which constrains conclusions about product quality. The life cycle assessment compared recycled plastics only to virgin materials, without benchmarking against landfilling, incineration, or municipal recycling. Assumptions about labor costs, market demand, and product pricing also restrict the economic generalizability of the findings. These limitations suggest that the model is best understood as an educational and demonstration platform rather than a substitute for industrial recycling systems.

Despite these constraints, the results highlight important opportunities. Universities and small towns can adopt similar models to reduce landfill waste, promote sustainable behavior, and provide students with hands-on training in circular economy practices. Future work may include developing open-source CAD libraries, scaling the model to larger product categories, and integrating recycled plastics into mainstream supply chains.

In sum, the Plastics Reprocessing Workspace illustrates how localized recycling initiatives, when embedded in education and community engagement, can advance sustainability, foster innovation, and contribute to resilience at the local level.