Repeatability of the European Standardized Method for Measuring Sound Reflection and Sound Insulation of Noise Barriers

Abstract

1. Introduction

2. Materials and Methods

- the repeatability of the measurement system in the laboratory, applied to a full-scale barrier, obtained by comparing repeated measurements on the same acoustic barrier under the same boundary conditions, leaving the sound source and microphone grid in place;

- the repeatability of the measurement method in the laboratory, comparing repeated measurements on the same noise barriers and repositioning the movable components (i.e., loudspeaker and microphone grid) for each measurement;

- the repeatability of the measurement method applied on a barrier mounted along a highway under real-world conditions, repositioning the movable components for each measurement.

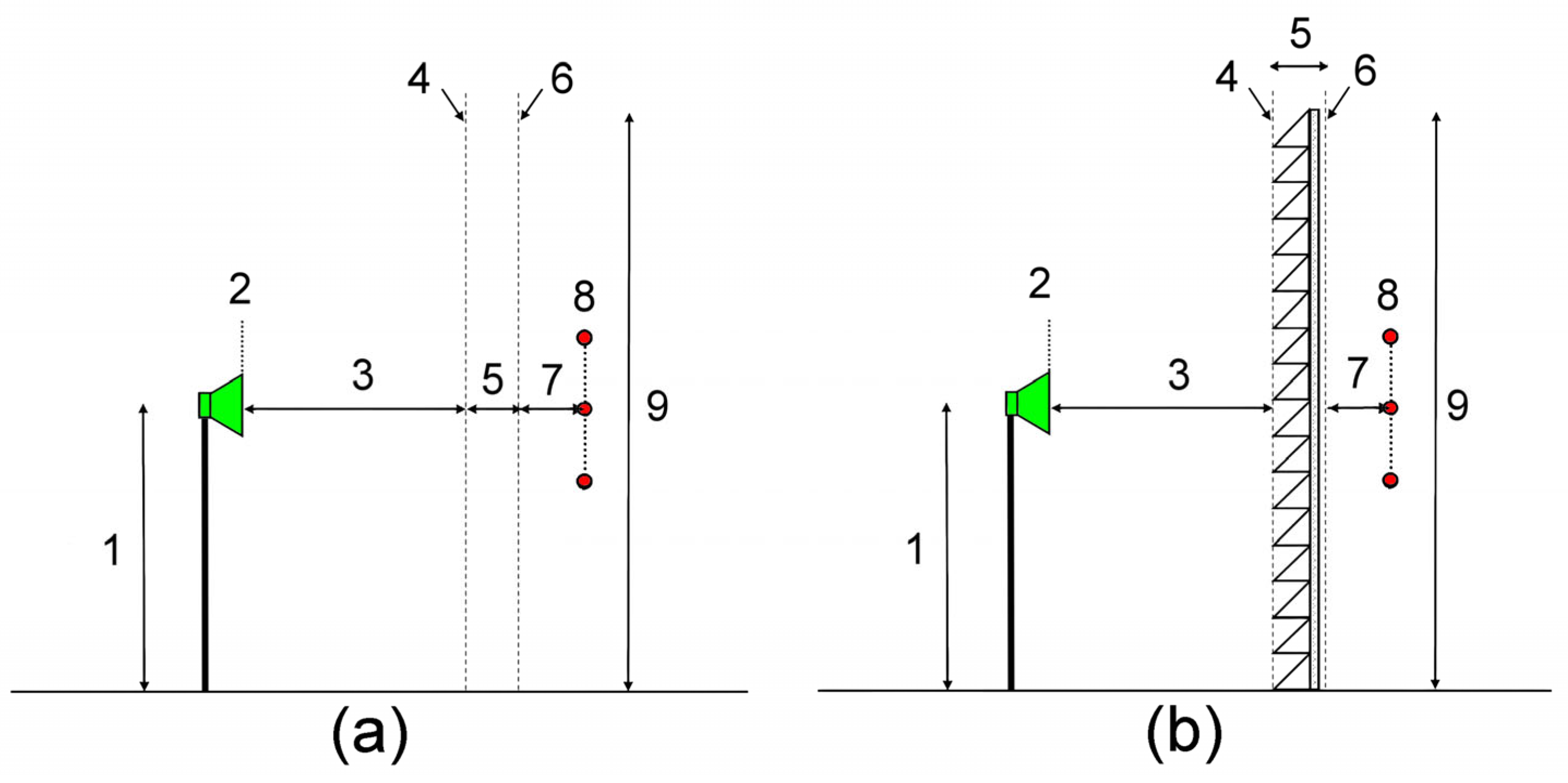

2.1. Sound Absorption Measurement

- hi,k(t) is the incoming free-field reference impulse response component from the k-th microphone;

- hr,k(t) is the reflected impulse response component, at the k-th microphone;

- wi,k(t) is the Adrienne time window [3] for the incident reference component of the free-field impulse response, at the k-th microphone;

- wr,k(t) is the Adrienne time window for the reflected component, at the k-th microphone;

- F is the symbol for the FFT operator;

- j is the index of the 1/3 octave frequency bands, from 100 Hz to 5 kHz;

- Δfj is the width of the j-th 1/3 octave frequency band;

- k is the number of the microphone, from 1 to 9;

- nj is the number of microphone positions on which to average;

- Cgeo,k is a geometrical divergence correction factor, to compensate the direct and reflected waves path difference, at the k-th microphone;

- Cdir,k (Δfj) is a loudspeaker directivity correction factor, at the k-th microphone;

- Cgain,k (Δfj) is a gain mismatch correction factor, used to correct errors in amplification settings between the free-field and barrier measurements, if required, at the k-th microphone.

2.2. Sound Insulation Measurement

- ht,k(t) is the transmitted impulse response component, at the k-th microphone;

- wt,k(t) is the Adrienne time window for the transmitted component, at the k-th microphone;

- n = the number of microphones on the grid.

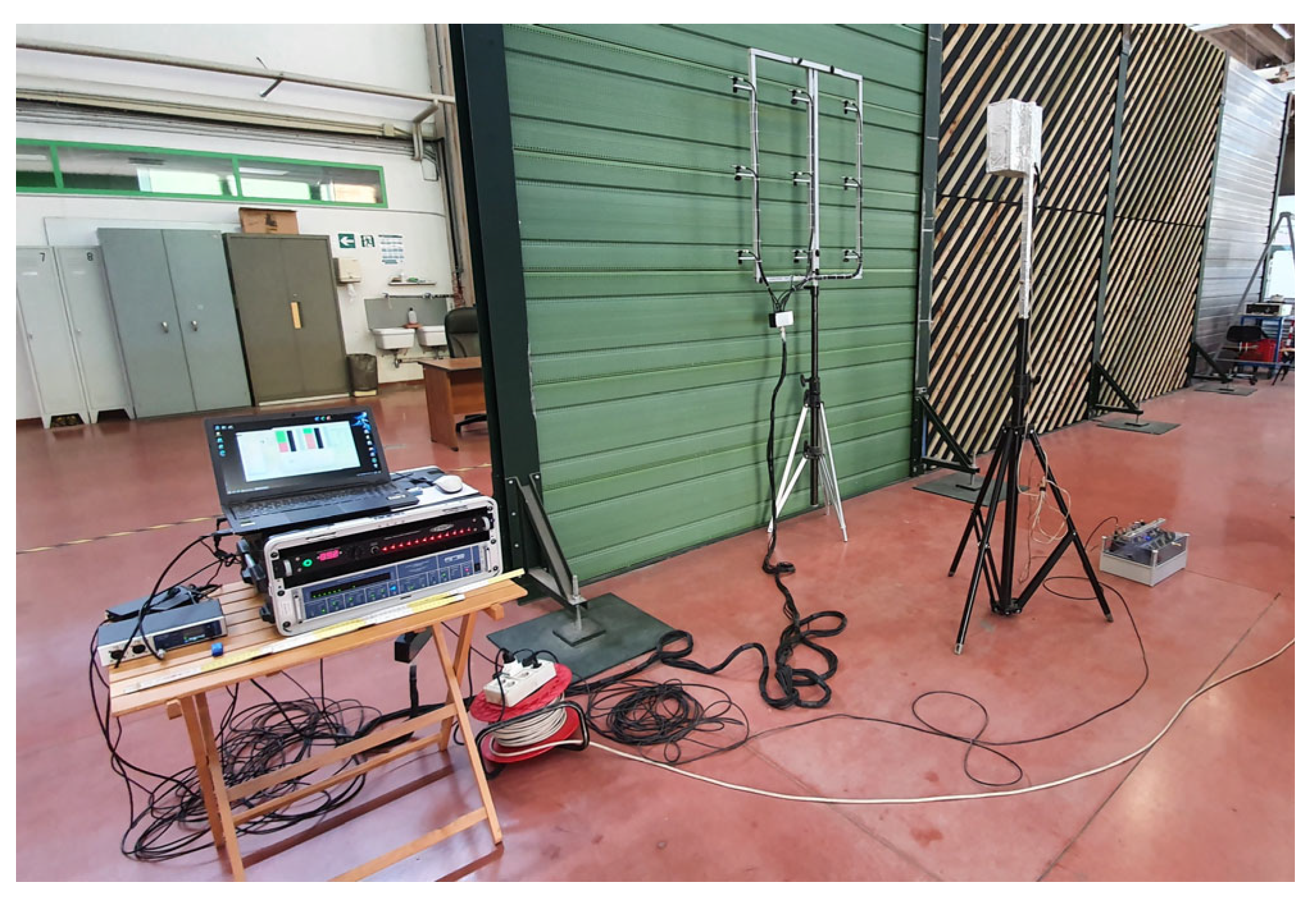

2.3. Measuring System

- sound source based on Sica Z002601 loudspeaker (120 W, 8 Ω), amplified by an ST CCA044V1 class-D amplifier, as described in detail in [8], connected to the output of the sound card by an Andoer MX5 2.4G wireless system (uncompressed digital audio data transmission, sampled at 48 kHz), to make it easier to measure the sound insulation behind the barrier without cable problems;

- microphones model PCB 130F20 and IEPE/ICP preamplifier TMP PS12A;

- RME M-16 AD multichannel ADC converter, connected by MADI protocol (over a single coaxial cable) to a MADI digital audio interface RME MADIface XT;

- Projectlead Traveller Pro 2.0 computer;

- MCIRMS measurement software, designed and programmed specifically for this type of measurement.

3. Repeatability Tests

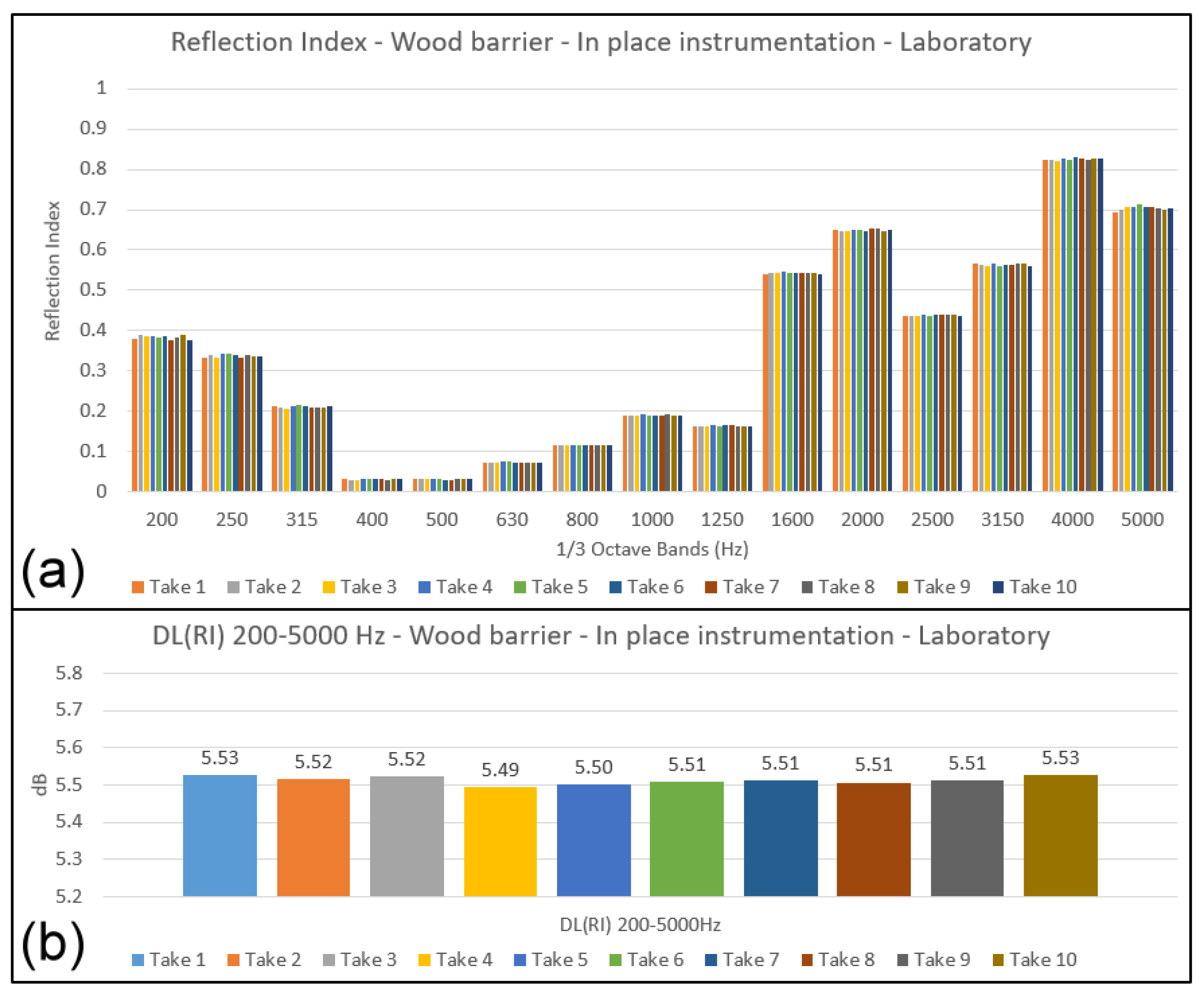

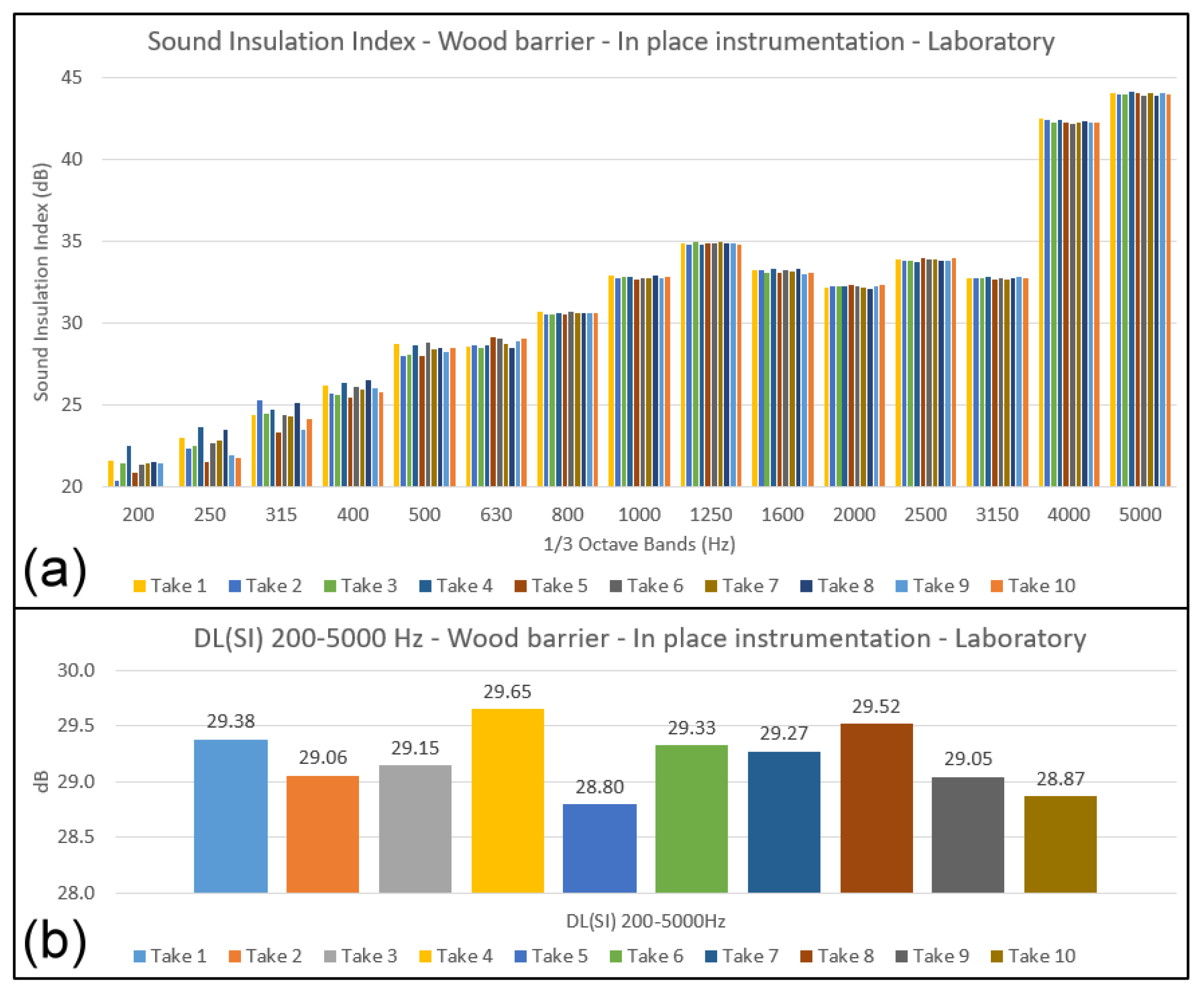

- sound reflection index and sound insulation index measurements in the laboratory on a non-flat wooden barrier, visible in Figure 1, leaving sound source and microphone grid in place (i.e., without moving them from one measurement to the other; test of measurement system repeatability), with a single free-field measurement being used for all measurements on the barrier;

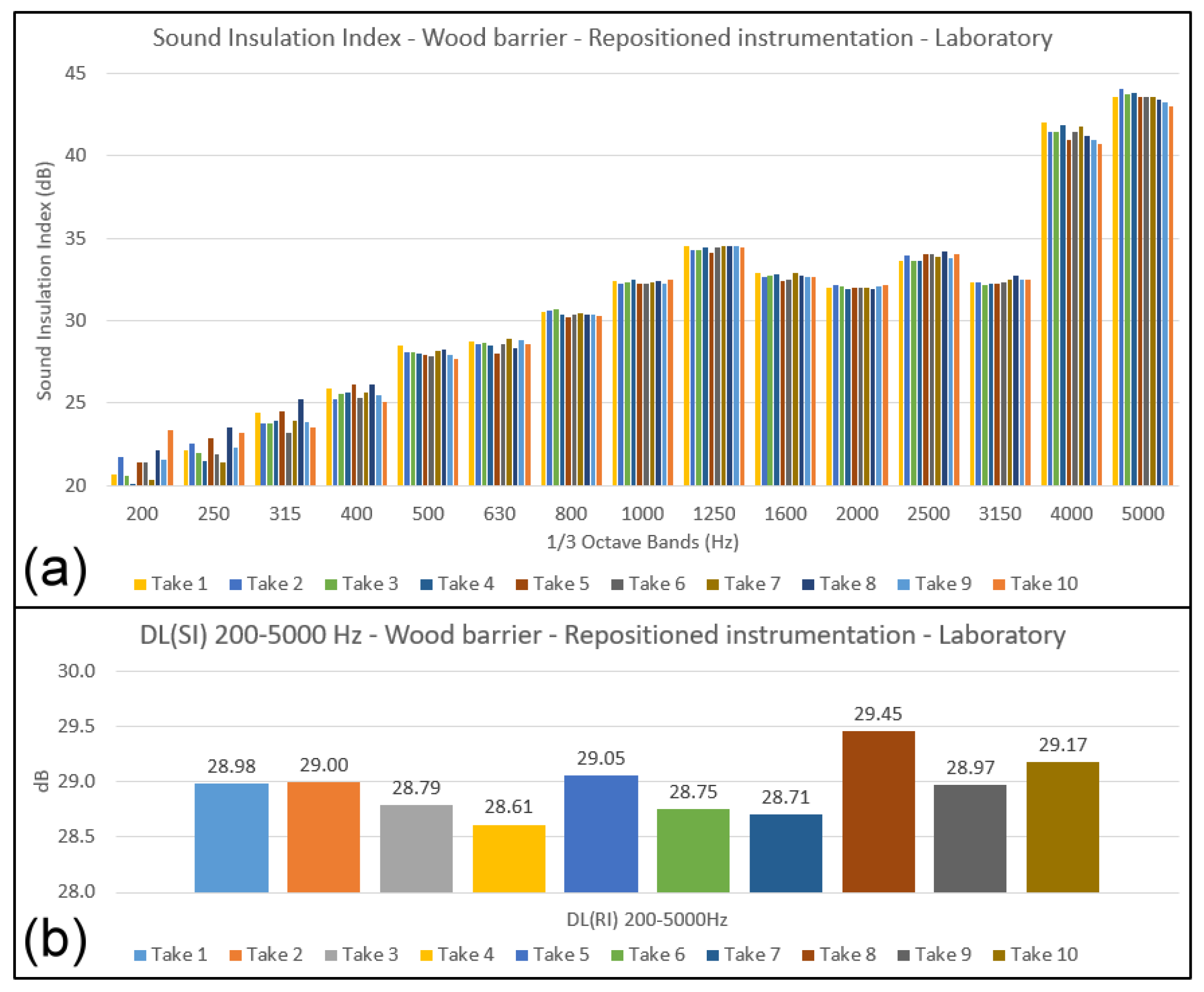

- measurements of sound reflection index and sound insulation index in the laboratory on the same non-flat wooden barrier as in the previous case, visible in Figure 1, repositioning the movable components (i.e., sound source and microphone grid) randomly within ±50 mm from the nominal position (marked on the floor) for each measurement (test of repeatability of measurement method on non-flat barrier);

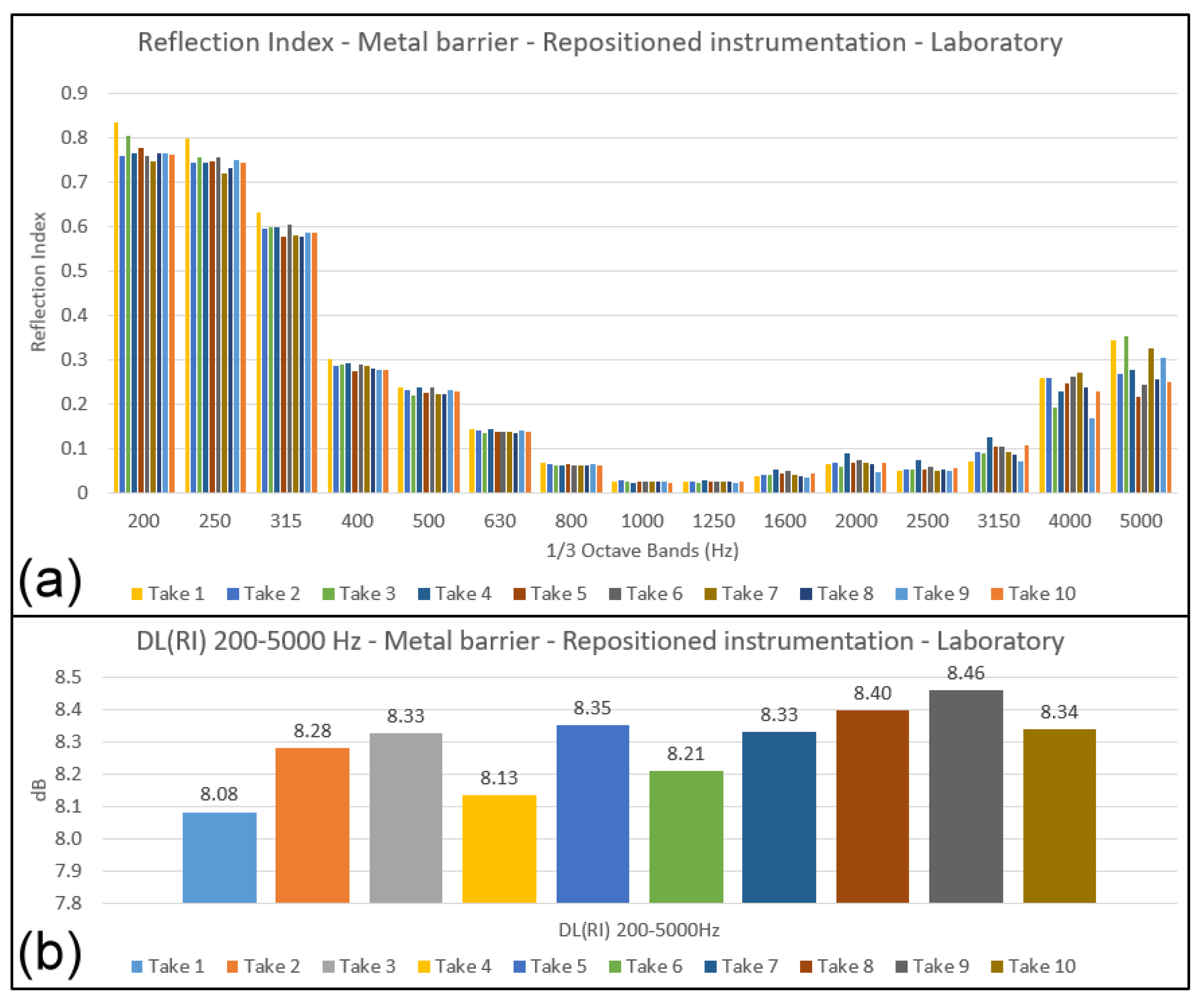

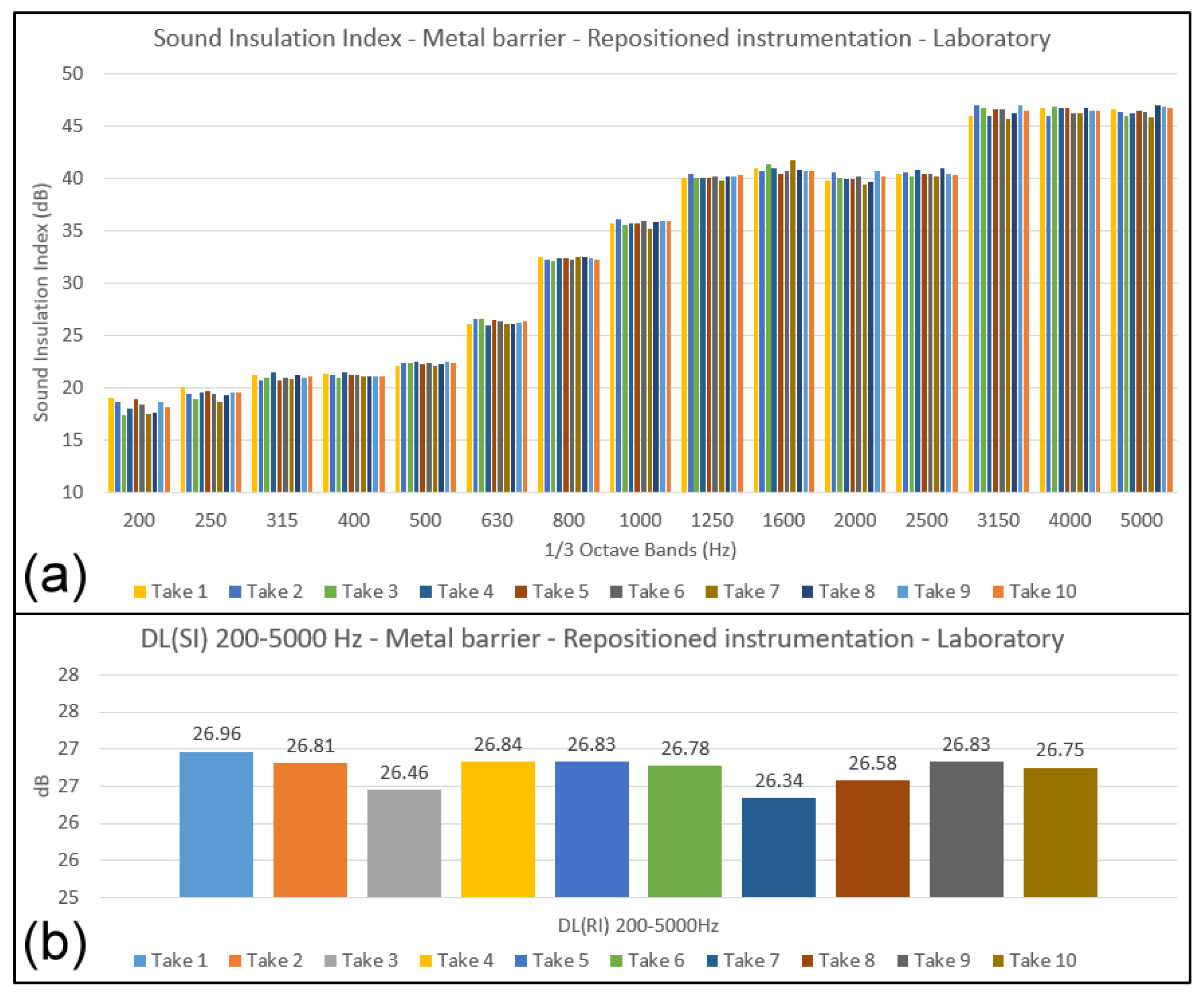

- measurements of sound reflection index and sound insulation index in laboratory on a perforated flat-surface metal barrier, visible in Figure 1 (colored green), repositioning the movable components (i.e., sound source and microphone grid) randomly within ±50 mm from the nominal position (marked on the floor) for each measurement (test of repeatability of measurement method on flat barrier);

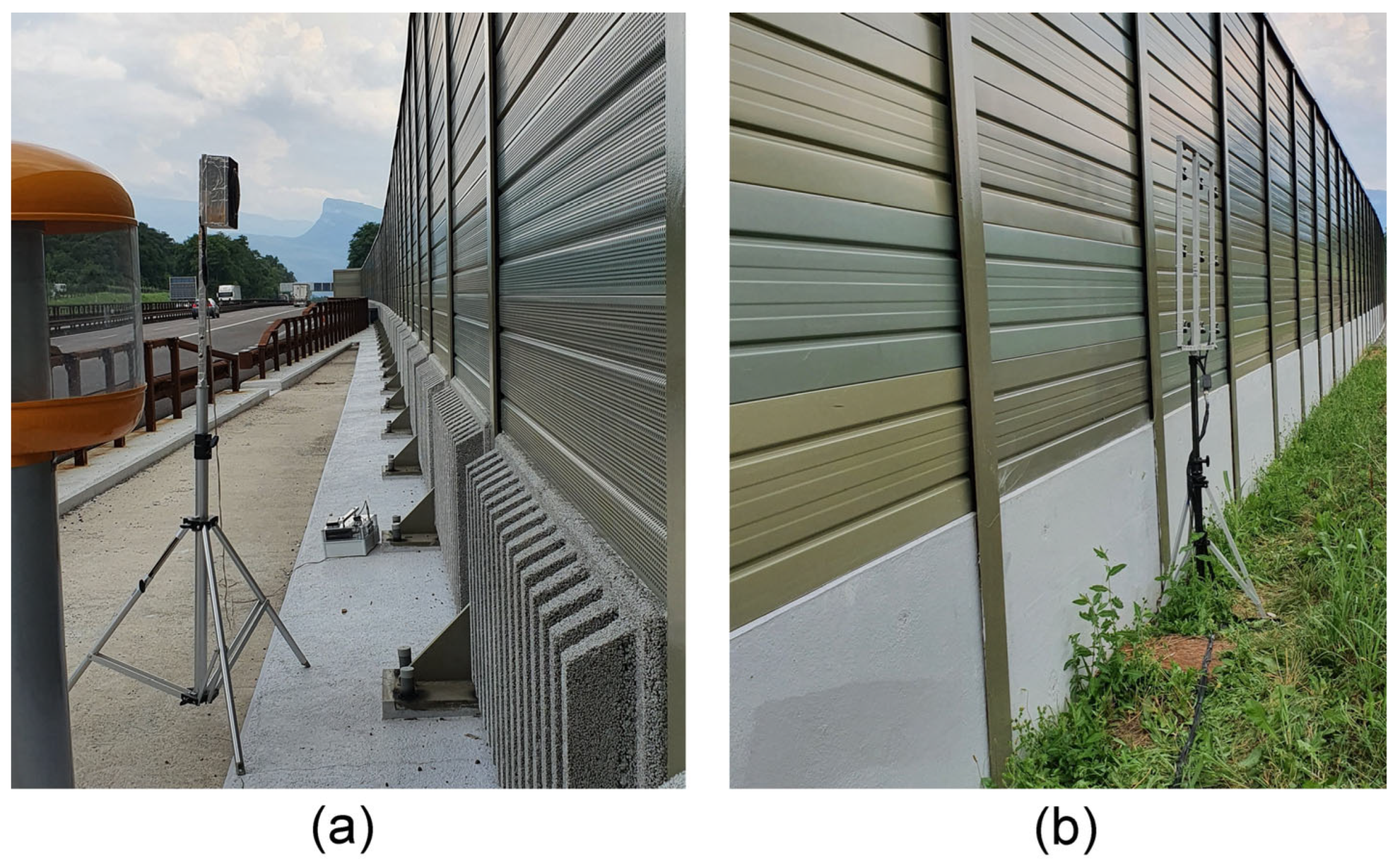

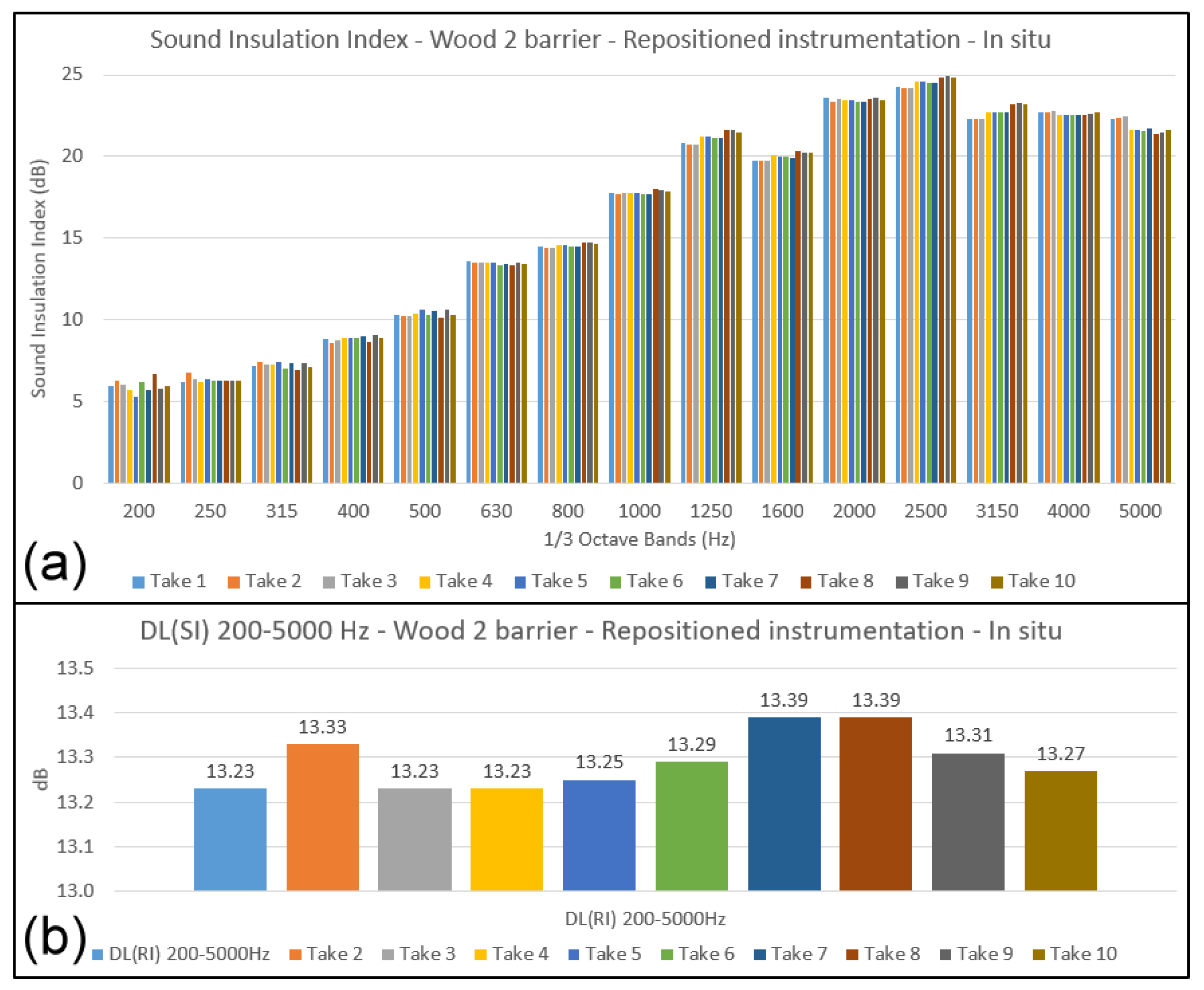

- measurements of sound reflection index and sound insulation index in situ, along the A22 Brennero highway near Verona (Italy), on a wooden barrier with a non-flat surface and concrete base, visible in Figure 2, repositioning the movable components (i.e., sound source and microphone grid) for each measurement (test of repeatability of the measurement method on a non-flat barrier and in real conditions). The main reasons for the in situ positioning problems are uneven ground, presence of obstacles on the ground, guardrails, uneven asphalt, ground with plants, and ground that is not flat. Note that this barrier has different acoustic characteristics from the wooden one tested in laboratory.

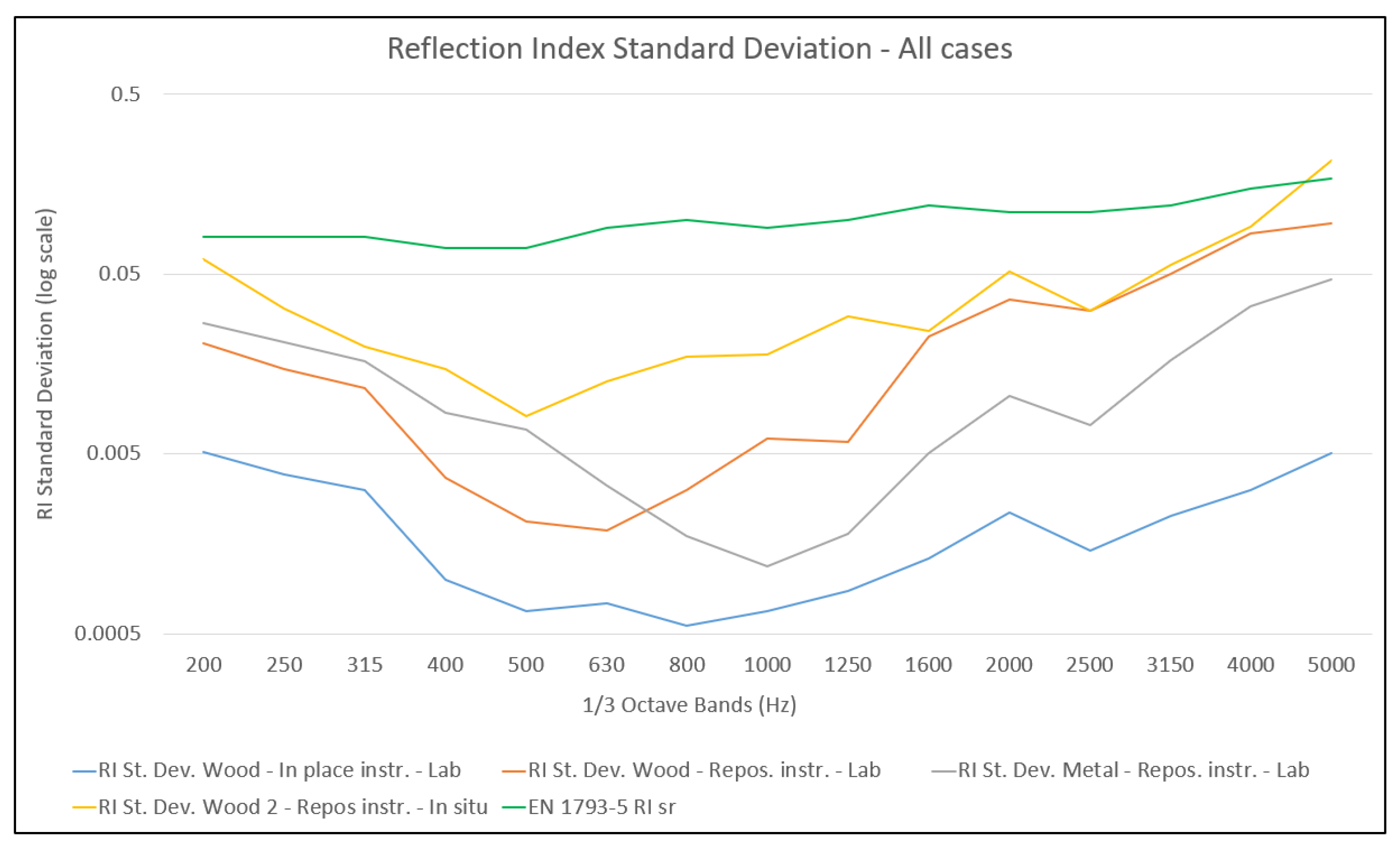

3.1. Sound Reflection Measurements

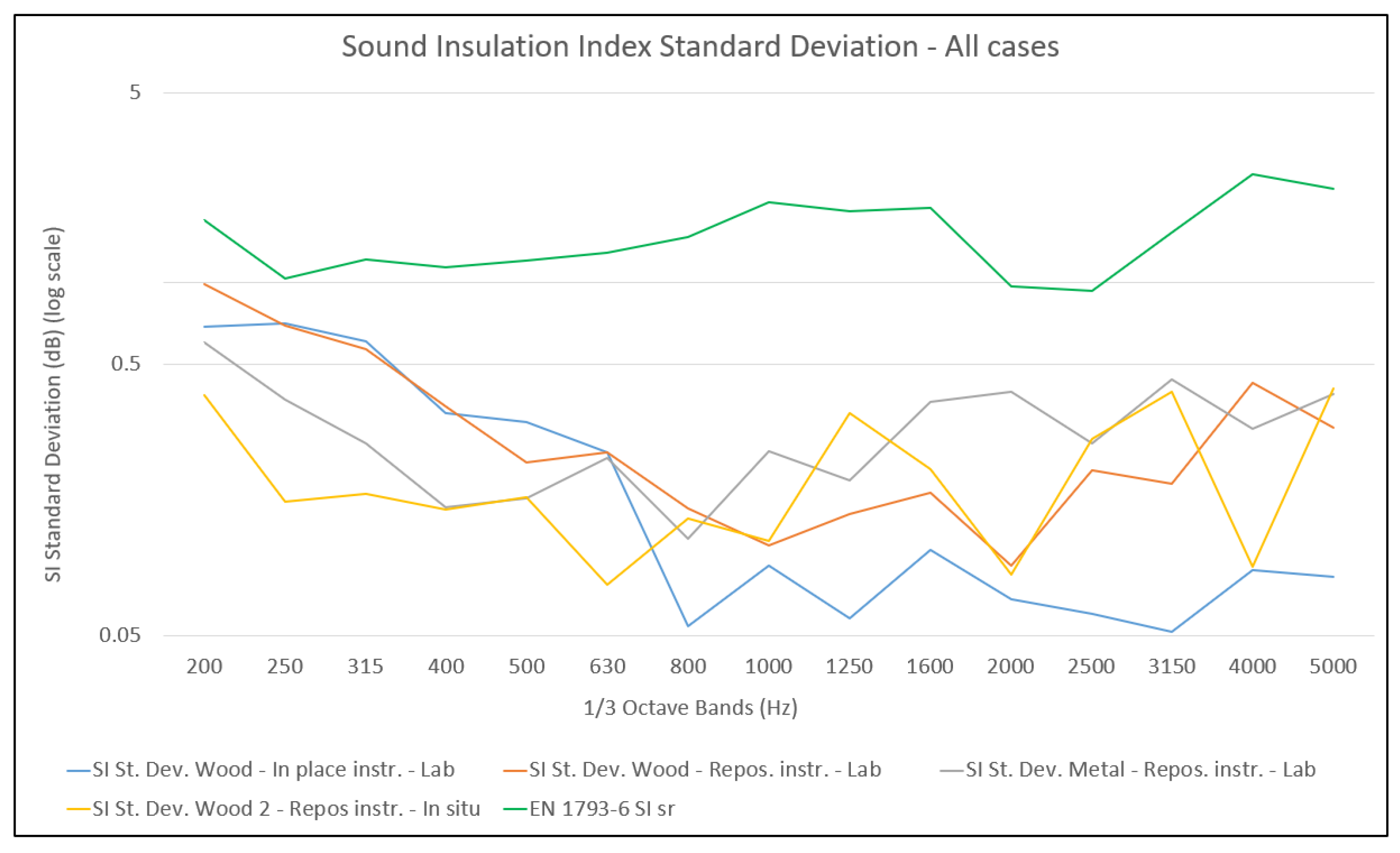

3.2. Sound Insulation Measurements

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Khosravipour, M.; Khanlari, P. The association between road traffic noise and myocardial infarction: A systematic review and meta-analysis. Sci. Total Environ. 2014, 731, 139226. [Google Scholar] [CrossRef]

- Stansfeld, S.; Clark, C.; Smuk, M.; Gallacher, J.; Babisch, W. Road traffic noise, noise sensitivity, noise annoyance, psychological and physical health and mortality. Environ. Health 2021, 20, 1–15. [Google Scholar] [CrossRef]

- EN 1793-5:2016/AC:2018; Road Traffic Noise Reducing Devices—Test Method for Determining the Acoustic Performance—Part 5: Intrinsic Characteristics—In Situ Values of Sound Reflection under Direct Sound Field Conditions. European Committee for Standardization: Brussels, Belgium, 2018.

- EN 1793-6:2018/A1:2021; Road Traffic Noise Reducing Devices—Test Method for Determining the Acoustic Performance—Part 6: Intrinsic Characteristics—In Situ Values of Airborne Sound Insulation under Direct Sound Field Conditions. European Committee for Standardization: Brussels, Belgium, 2021.

- Radosz, J. Acoustic performance of noise barrier based on sonic crystals with resonant elements. Appl. Acoust. 2019, 155, 492–499. [Google Scholar] [CrossRef]

- Morandi, F.; Miniaci, M.; Marzani, A.; Barbaresi, L.; Garai, M. Standardised acoustic characterisation of sonic crystals noise barriers: Sound insulation and reflection properties. Appl. Acoust. 2016, 114, 294–306. [Google Scholar] [CrossRef]

- Garai, M.; Schoen, E.; Behler, G.; Bragado, B.; Chudalla, M.; Conter, M.; Defrance, J.; Demizieux, P.; Glorieux, C.; Guidorzi, P. Repeatability and reproducibility of in situ measurements of sound reflection and airborne sound insulation index of noise barriers. Acta Acust. United Acust. 2014, 100, 1186–1201. [Google Scholar] [CrossRef]

- Robinson, P.; Xiang, N. On the subtraction method for in situ reflection and diffusion coefficient measurements. J. Acoust. Soc. Am. 2010, 127, EL99-104. [Google Scholar] [CrossRef] [PubMed]

- Garai, M.; Guidorzi, P. Sound reflection measurements on noise barriers in critical conditions. Build. Environ. 2015, 94, 752–763. [Google Scholar] [CrossRef]

- Garai, M.; Guidorzi, P.; Osele, A.; Costa, C. On-site check of the intrinsic acoustic characteristics of noise barriers: Preliminary results on the Italian A22 highway. In Proceedings of the Forum Acusticum, Lyon, France, 20–24 April 2020; pp. 431–437. [Google Scholar] [CrossRef]

- Morandi, F.; Miniaci, M.; Guidorzi, P.; Marzani, A.; Garai, M. Acoustic Measurements on a Sonic Crystals Barrier. Energy Procedia 2015, 78, 134–139. [Google Scholar] [CrossRef]

- Guidorzi, P.; Garai, M. A Low-Cost System for Quick Measurements on Noise Barriers in Situ. IEEE Trans. Instrum. Meas. 2022, 71, 6503714. [Google Scholar] [CrossRef]

- Borish, J.; Angell, J.B. An Efficient Algorithm for Measuring the Impulse Response Using Pseudorandom Noise. J. Audio Eng. Soc. 1983, 31, 478–488. [Google Scholar]

- Rife, D.D.; Vanderkooy, J. Transfer-function measurement with maximum-length sequences. J. Audio Eng. Soc. 1989, 37, 419–444. [Google Scholar]

- Rife, D.D. Modulation Transfer Function Measurement with Maximum Length Sequences. J. Audio Eng. Soc. 1992, 40, 779–790. [Google Scholar]

- Vanderkooy, J. Aspects of MLS measuring systems. J. Audio Eng. Soc. 1994, 42, 219–231. [Google Scholar]

- Mommertz, E. Angle-dependent in situ measurements of reflection coefficients using a subtraction technique. Applied Acoustics 1995, 46, 251–263. [Google Scholar] [CrossRef]

- Vorländer, M.; Kob, M. Practical aspects of MLS measurements in building acoustics. Applied Acoustics 1997, 52, 239–258. [Google Scholar] [CrossRef]

- Nielsen, J.L. Improvement of Signal-to-Noise Ratio in Long-Term MLS Measurements with High-Level Nonstationary Disturbances. J. Audio Eng. Soc. 1997, 45, 1063–1066. [Google Scholar]

- Vorländer, M.; Mommertz, E. Guidelines for the application of the MLS technique in building acoustics and in outdoor measurements. In Proceedings of the 1997 International Congress on Noise Control Engineering, Budapest, Hungary, 25–27 August 1997; pp. 1457–1462. [Google Scholar]

- Stan, G.; Embrechts, J.J.; Archambeau, D. Comparison of Different Impulse Response Measurement Techniques. J. Audio Eng. Soc. 2002, 50, 249–262. [Google Scholar]

- Ćirić, D. Comparison of influence of distortion in MLS and Sine Sweep technique. In Proceedings of the 19th International Congress on Acoustics, Madrid, Spain, 2–7 September 2007. paper RBA-07-020. [Google Scholar]

- Papadakis, N.M.; Antoniadou, S.; Stavroulakis, G.E. Effects of Varying Levels of Background Noise on Room Acoustic Parameters, Measured with ESS and MLS Methods. Acoustics 2023, 5, 563–574. [Google Scholar] [CrossRef]

| 1/3 Oct Band (Hz) | RI St. Dev. Wood In Place Instr. Lab | RI St. Dev. Wood Repos. Instr. Lab | RI St. Dev. Metal Repos. Instr. Lab | RI St. Dev. Wood 2 Repos Instr. In situ | EN 1793-5 RI sr |

|---|---|---|---|---|---|

| 200 | 0.0051 | 0.0207 | 0.0266 | 0.0603 | 0.0800 |

| 250 | 0.0038 | 0.0149 | 0.0210 | 0.0320 | 0.0800 |

| 315 | 0.0032 | 0.0116 | 0.0163 | 0.0198 | 0.0800 |

| 400 | 0.0010 | 0.0037 | 0.0085 | 0.0147 | 0.0700 |

| 500 | 0.0007 | 0.0021 | 0.0068 | 0.0081 | 0.0700 |

| 630 | 0.0007 | 0.0019 | 0.0033 | 0.0127 | 0.0900 |

| 800 | 0.0006 | 0.0031 | 0.0018 | 0.0174 | 0.1000 |

| 1000 | 0.0007 | 0.0061 | 0.0012 | 0.0179 | 0.0900 |

| 1250 | 0.0009 | 0.0058 | 0.0018 | 0.0291 | 0.1000 |

| 1600 | 0.0013 | 0.0224 | 0.0051 | 0.0240 | 0.1200 |

| 2000 | 0.0024 | 0.0361 | 0.0104 | 0.0517 | 0.1100 |

| 2500 | 0.0015 | 0.0314 | 0.0072 | 0.0311 | 0.1100 |

| 3150 | 0.0022 | 0.0505 | 0.0166 | 0.0562 | 0.1200 |

| 4000 | 0.0031 | 0.0841 | 0.0333 | 0.0921 | 0.1500 |

| 5000 | 0.0051 | 0.0963 | 0.0465 | 0.2129 | 0.1700 |

| 1/3 Oct Band (Hz) | SI St. Dev. Wood In Place Instr. Lab | SI St. Dev. Wood Repos. Instr. Lab | SI St. Dev. Metal Repos. Instr. Lab | SI St. Dev. Wood 2 Repos Instr. In situ | EN 1793-6 SI sr |

|---|---|---|---|---|---|

| 200 | 0.6863 | 0.9879 | 0.6023 | 0.3838 | 1.7000 |

| 250 | 0.7032 | 0.6953 | 0.3686 | 0.1561 | 1.3000 |

| 315 | 0.6050 | 0.5656 | 0.2547 | 0.1671 | 1.2100 |

| 400 | 0.3314 | 0.3495 | 0.1484 | 0.1459 | 1.1400 |

| 500 | 0.3071 | 0.2175 | 0.1604 | 0.1624 | 1.2000 |

| 630 | 0.2373 | 0.2356 | 0.2255 | 0.0769 | 1.2800 |

| 800 | 0.0544 | 0.1466 | 0.1133 | 0.1353 | 1.4700 |

| 1000 | 0.0906 | 0.1074 | 0.2392 | 0.1118 | 1.9700 |

| 1250 | 0.0578 | 0.1406 | 0.1862 | 0.3303 | 1.8300 |

| 1600 | 0.1040 | 0.1679 | 0.3646 | 0.2056 | 1.8800 |

| 2000 | 0.0680 | 0.0908 | 0.3972 | 0.0838 | 0.9700 |

| 2500 | 0.0602 | 0.2028 | 0.2557 | 0.2654 | 0.9300 |

| 3150 | 0.0518 | 0.1811 | 0.4374 | 0.3943 | 1.5300 |

| 4000 | 0.0874 | 0.4277 | 0.2892 | 0.0895 | 2.5000 |

| 5000 | 0.0823 | 0.2904 | 0.3881 | 0.4075 | 2.2200 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guidorzi, P.; Garai, M. Repeatability of the European Standardized Method for Measuring Sound Reflection and Sound Insulation of Noise Barriers. Environments 2023, 10, 139. https://doi.org/10.3390/environments10080139

Guidorzi P, Garai M. Repeatability of the European Standardized Method for Measuring Sound Reflection and Sound Insulation of Noise Barriers. Environments. 2023; 10(8):139. https://doi.org/10.3390/environments10080139

Chicago/Turabian StyleGuidorzi, Paolo, and Massimo Garai. 2023. "Repeatability of the European Standardized Method for Measuring Sound Reflection and Sound Insulation of Noise Barriers" Environments 10, no. 8: 139. https://doi.org/10.3390/environments10080139

APA StyleGuidorzi, P., & Garai, M. (2023). Repeatability of the European Standardized Method for Measuring Sound Reflection and Sound Insulation of Noise Barriers. Environments, 10(8), 139. https://doi.org/10.3390/environments10080139