An Investigation of Dairy Cattle Welfare in Commercial Iranian Farms: Results from Management Practices, Resource-Based Measures, and Farm Records †

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Population

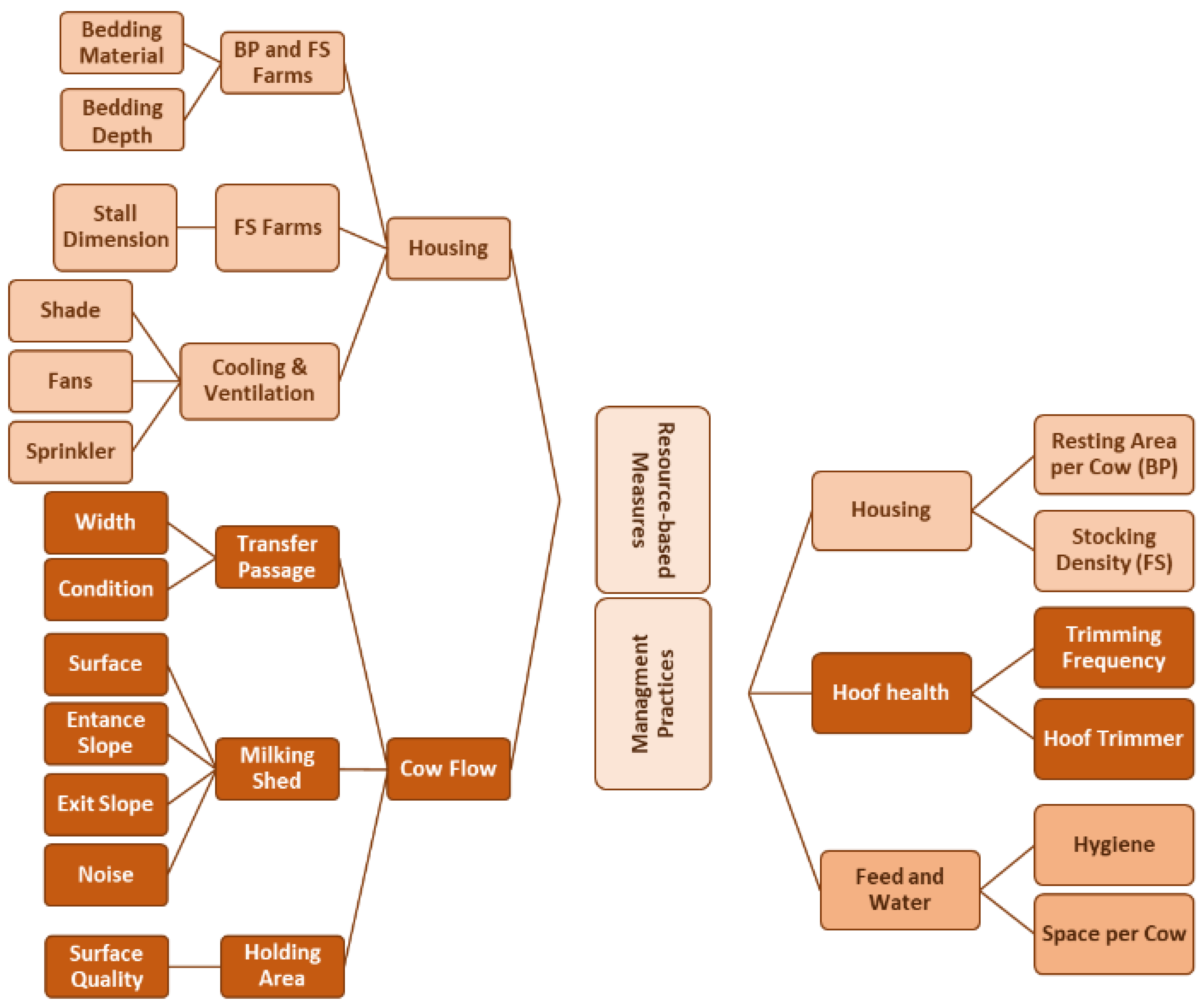

2.2. Protocol Development

2.3. Data Collection Process

2.3.1. Housing

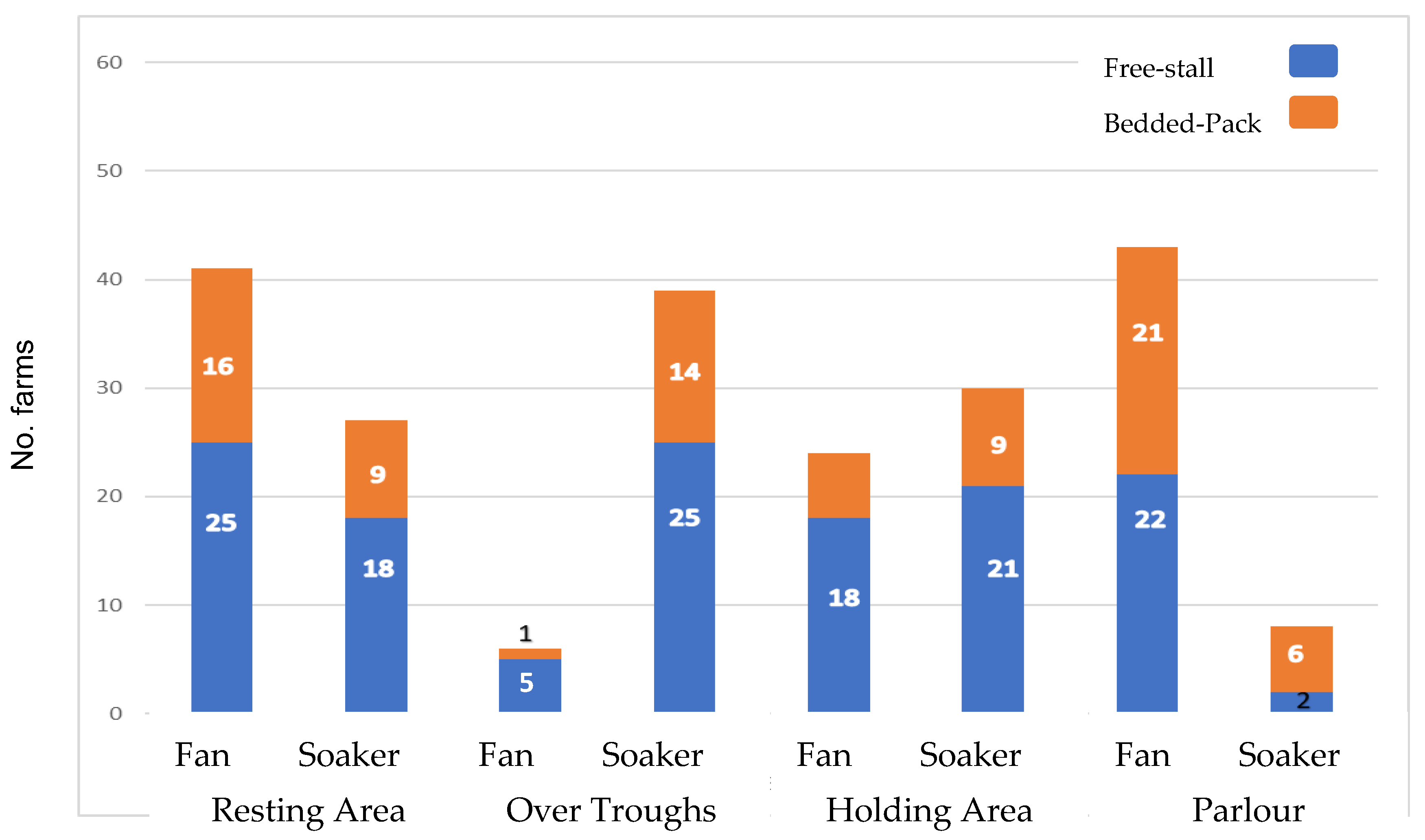

Cooling and Ventilation

Free-Stall Farms

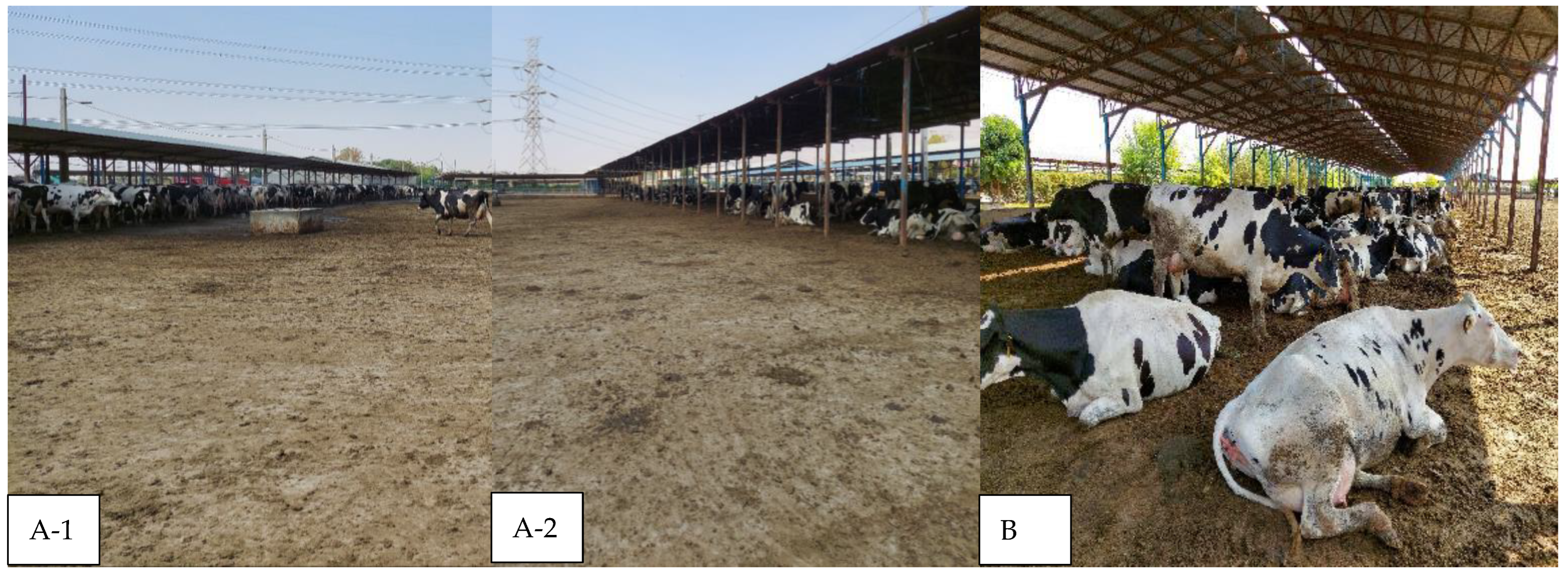

Bedded-Pack Farms

2.3.2. Water and Feed Availability

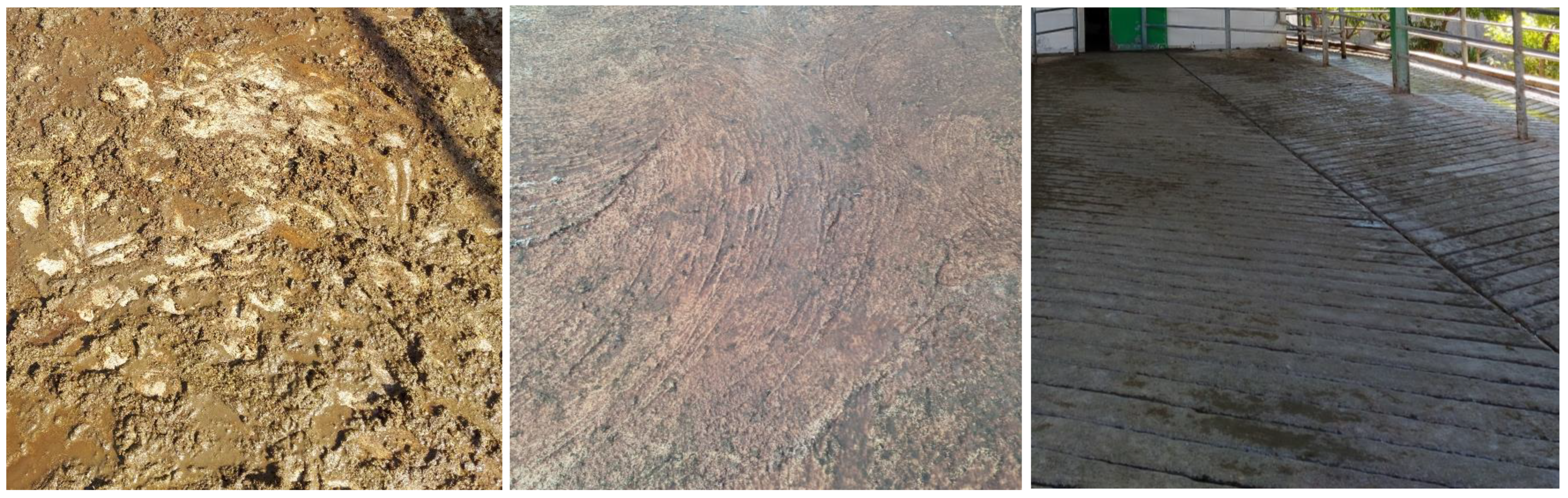

2.3.3. Cow Flow

Transfer Passage

Milking Parlour

2.3.4. Hoof Health Management

2.3.5. Farm Records

2.4. Statistical Analysis

3. Results

3.1. Housing

3.1.1. Cooling and Ventilation

3.1.2. Free-Stall Farms

3.1.3. Bedded-Pack Farms

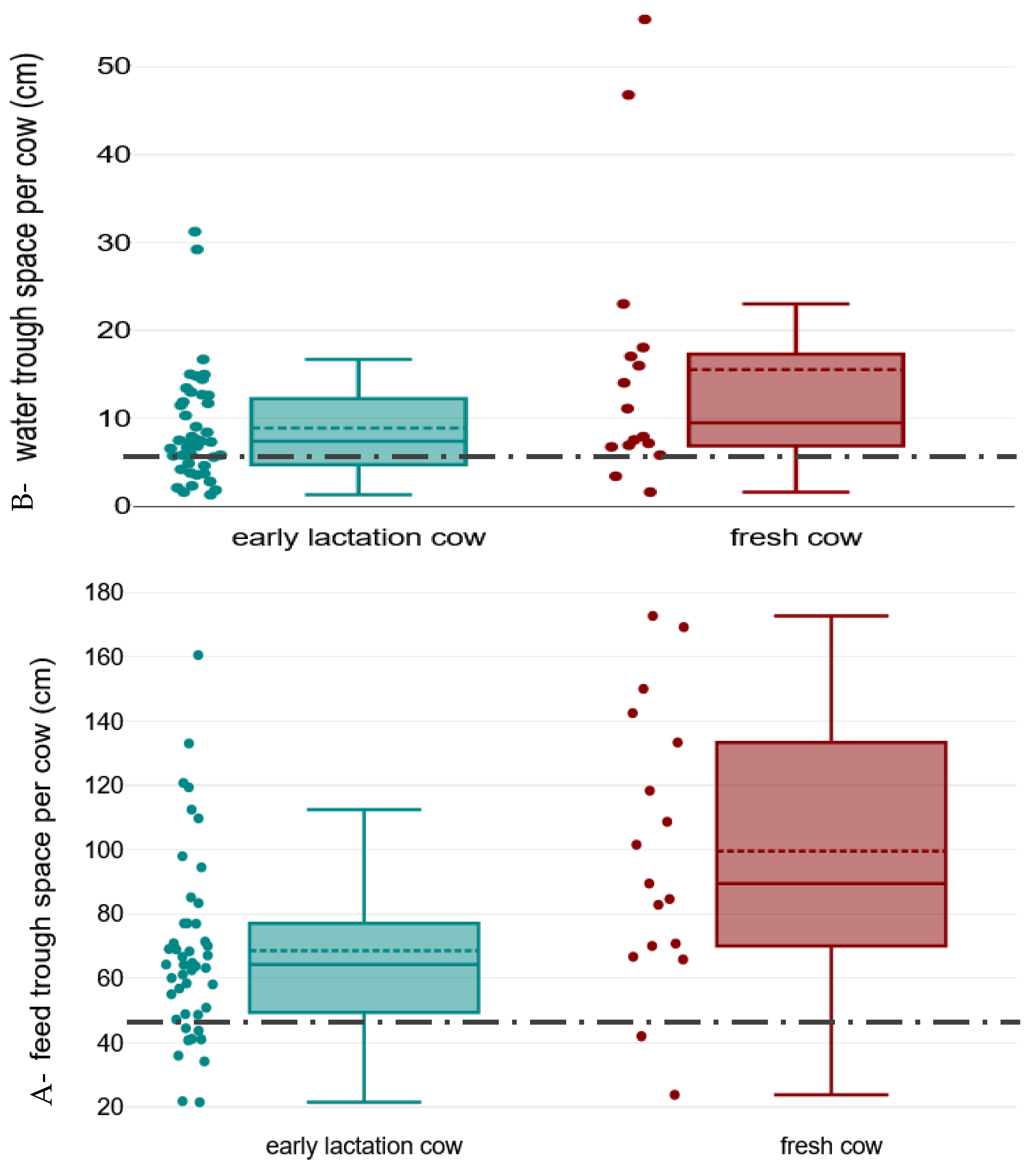

3.2. Water and Feed Availability

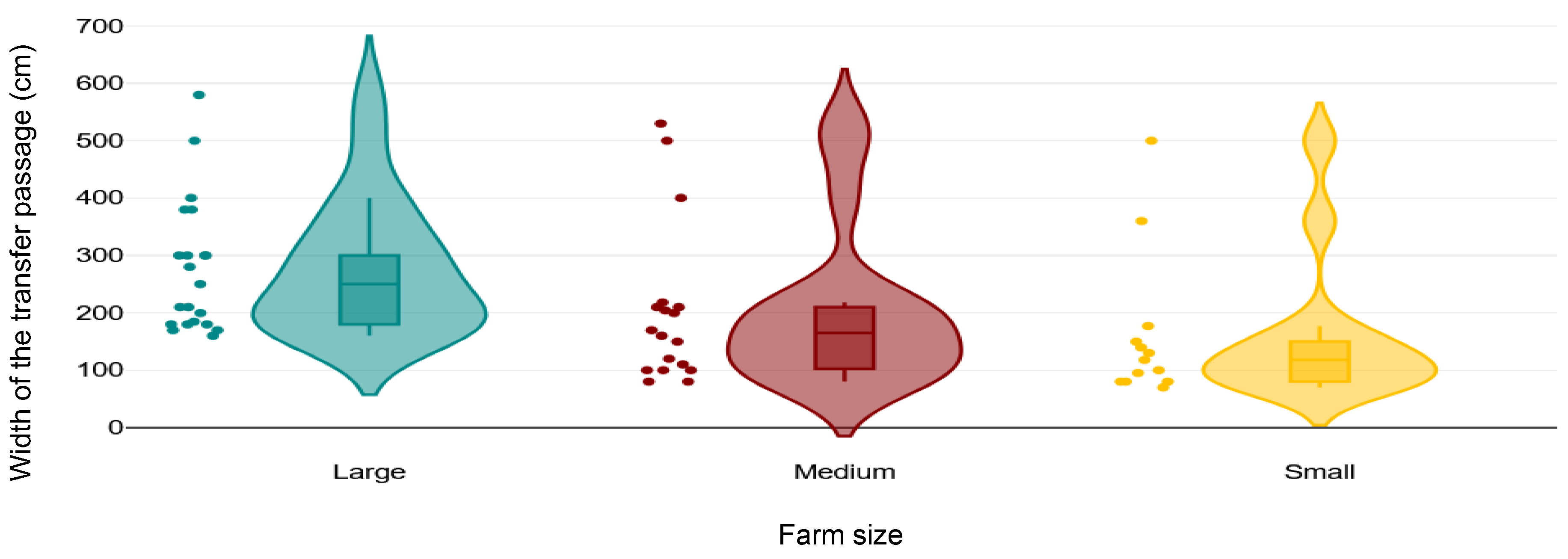

3.3. Cow Flow

3.3.1. Transfer Passage

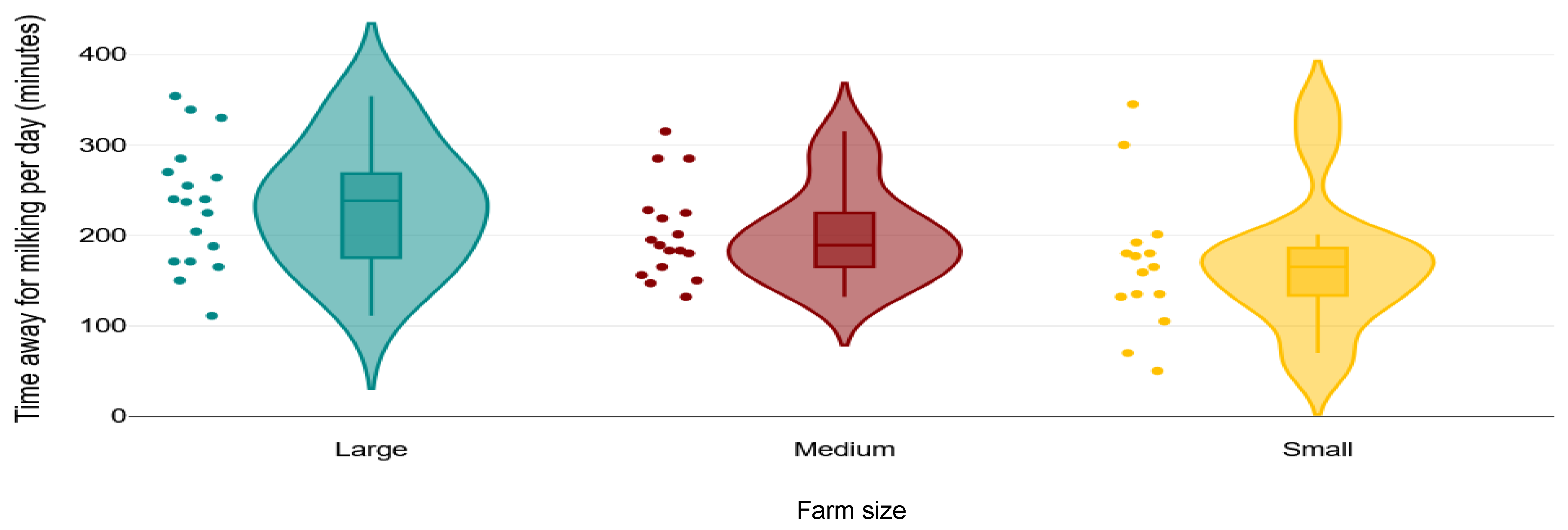

3.3.2. Milking Parlour

3.3.3. Hoof Health Management

3.4. Farm Records

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bewley, J.M.; Robertson, L.M.; Eckelkamp, E.A. A 100-Year Review: Lactating dairy cattle housing management. J. Dairy Sci. 2017, 100, 10418–10431. [Google Scholar] [CrossRef]

- Laven, R.; Holmes, C. A review of the potential impact of increased use of housing on the health and welfare of dairy cattle in New Zealand. N. Z. Vet. J. 2008, 56, 151–157. [Google Scholar] [CrossRef]

- Arnott, G.; Ferris, C.; O’Connell, N. Welfare of dairy cows in continuously housed and pasture-based production systems. Animal 2017, 11, 261–273. [Google Scholar] [CrossRef]

- Nielsen, S.S.; Alvarez, J.; Bicout, D.J.; Calistri, P.; Canali, E.; Drewe, J.A.; Garin-Bastuji, B.; Gonzales Rojas, J.L.; Gortázar Schmidt, C. Welfare of dairy cows. EFSA J. 2023, 21, e07993. [Google Scholar] [CrossRef]

- Fraser, D. Understanding animal welfare. Acta Vet. Scand. 2008, 50, S1. [Google Scholar] [CrossRef] [PubMed]

- Kaurivi, Y.B.; Laven, R.; Hickson, R.; Stafford, K.; Parkinson, T. Identification of suitable animal welfare assessment measures for extensive beef systems in New Zealand. Agriculture 2019, 9, 66. [Google Scholar] [CrossRef]

- Jafari-Gh., A.; Laven, R.; Khaloubagheri, F.; Mirrahimi, M.H.; Jafari-Gh., S.; Banadaky, M.D.; Mueller, K.R.; Vallee, E. An Investigation of Dairy Cattle Welfare in Commercial Iranian Farms: Results from Animal- and Stockperson-Based Measures. Animals 2025, 15, 359. [Google Scholar] [CrossRef] [PubMed]

- Webster, A.; Main, D.; Whay, H. Welfare assessment: Indices from clinical observation. Anim. Welf. 2004, 13, S93–S98. [Google Scholar] [CrossRef]

- Main, D.; Whay, H.; Leeb, C.; Webster, A. Formal animal-based welfare assessment in UK certification schemes. Anim. Welf. 2007, 16, 233–236. [Google Scholar] [CrossRef]

- Whay, H.; Main, D.; Green, L.; Webster, A. Assessment of the welfare of dairy caftle using animal-based measurements: Direct observations and investigation of farm records. Vet. Rec. 2003, 153, 197–202. [Google Scholar] [CrossRef]

- Goodman, L.A. Snowball sampling. Ann. Math. Stat. 1961, 32, 148–170. [Google Scholar] [CrossRef]

- National Research Council. Nutrient Requirements of Dairy Cattle: 2001; National Academies Press: Washington, DC, USA, 2001. [Google Scholar]

- von Keyserlingk, M.A.; Barrientos, A.; Ito, K.; Galo, E.; Weary, D.M. Benchmarking cow comfort on North American freestall dairies: Lameness, leg injuries, lying time, facility design, and management for high-producing Holstein dairy cows. J. Dairy Sci. 2012, 95, 7399–7408. [Google Scholar] [CrossRef] [PubMed]

- Chapinal, N.; Barrientos, A.; Von Keyserlingk, M.; Galo, E.; Weary, D. Herd-level risk factors for lameness in freestall farms in the northeastern United States and California. J. Dairy Sci. 2013, 96, 318–328. [Google Scholar] [CrossRef]

- Cook, N.; Hess, J.; Foy, M.; Bennett, T.; Brotzman, R. Management characteristics, lameness, and body injuries of dairy cattle housed in high-performance dairy herds in Wisconsin. J. Dairy Sci. 2016, 99, 5879–5891. [Google Scholar] [CrossRef]

- Welfare Quality. Welfare Quality® Assessment Protocol for Cattle. Available online: https://www.welfarequalitynetwork.net/media/1088/cattle_protocol_without_veal_calves.pdf (accessed on 13 October 2025).

- Sapkota, S.; Laven, R.; Müller, K.; Kells, N. Animal welfare assessment: Can we develop a practical, time-limited assessment protocol for pasture-based dairy cows in New Zealand? Animals 2020, 10, 1918. [Google Scholar] [CrossRef]

- Speed, J. Lameness Prevention in Dairy Cows. 2008. Available online: https://www.nuffieldscholar.org/sites/default/files/reports/2008_UK_Jo-Speed_Lameness-Prevention-In-Dairy-Cows.pdf (accessed on 13 October 2025).

- Chesterton, N. Cow Flow and Facilities. Available online: https://www.lamecow.co.nz/pdf/Cow%20flow%20and%20facilities.pdf (accessed on 16 February 2025).

- Anonymous. Freestall Dimensions. Available online: https://thedairylandinitiative.vetmed.wisc.edu/adult-cow-housing/freestall-design-and-dimensions/ (accessed on 13 October 2025).

- Chesterton, N. Dealing with Slopes. Available online: http://www.lamecow.co.nz/pdf/slopesandsteps.pdf (accessed on 16 February 2025).

- DATAtab-Team. DATAtab: Online Statistics Calculator. Available online: https://datatab.net (accessed on 13 October 2025).

- Keshavarzi, H.; Sadeghi-Sefidmazgi, A.; Stygar, A.H.; Kristensen, A.R. Effects of abortion and other risk factors on conception rate in Iranian dairy herds. Livest. Sci. 2017, 206, 51–58. [Google Scholar] [CrossRef]

- Mirzaie, B.; Sadeghi-Sefidmazgi, A.; Zhandi, M. A Survey Study on Management Practices Associated with Voluntary Waiting Period and Its Effects on Reproductive Performance of dairy cows in Iranian Dairy Farms. Vet. Med. Sci. 2024, 10, e70107. [Google Scholar] [CrossRef]

- Collier, R.J.; Dahl, G.E.; VanBaale, M.J. Major Advances Associated with Environmental Effects on Dairy Cattle. J. Dairy Sci. 2006, 89, 1244–1253. [Google Scholar] [CrossRef]

- Schutz, K.; Rogers, A.; Poulouin, Y.; Cox, N.; Tucker, C. The amount of shade influences the behavior and physiology of dairy cattle. J. Dairy Sci. 2010, 93, 125–133. [Google Scholar] [CrossRef]

- Carter, L.S.; Rutter, S.; Ball, D.; Gibbons, J.; Haskell, M. Dairy cow trade-off preference for 2 different lying qualities: Lying surface and lying space. J. Dairy Sci. 2021, 104, 862–873. [Google Scholar] [CrossRef] [PubMed]

- Ruud, L.; Stokke, T.; Bøe, K.; Hettasch, T.; Skjølberg, P. Hus for storfe-Norske anbefalinger (Cattle housing-Norwegian recommendations). Nor. Cattle Health Serv. 2003, 1, 1–146. [Google Scholar]

- Zappavigna, P.; Lensink, J.; Flaba, J.; Ventorp, M.; Greaves, R.; Heiko, G.; Ofner-Schrock, E.; Ryan, T.; Van Gaenegem, L. The Design of Dairy Cow and Replacement Heifer Housing Report of the CIGR Section II Working Group; CIGR: Liège, Belgium, 2014. [Google Scholar]

- Telezhenko, E.; von Keyserlingk, M.A.; Talebi, A.; Weary, D.M. Effect of pen size, group size, and stocking density on activity in freestall-housed dairy cows. J. Dairy Sci. 2012, 95, 3064–3069. [Google Scholar] [CrossRef]

- Krawczel, P.; Klaiber, L.; Butzler, R.; Klaiber, L.; Dann, H.; Mooney, C.; Grant, R. Short-term increases in stocking density affect the lying and social behavior, but not the productivity, of lactating Holstein dairy cows. J. Dairy Sci. 2012, 95, 4298–4308. [Google Scholar] [CrossRef]

- Wang, F.; Shao, D.; Li, S.; Wang, Y.; Azarfar, A.; Cao, Z. Effects of stocking density on behavior, productivity, and comfort indices of lactating dairy cows. J. Dairy Sci. 2016, 99, 3709–3717. [Google Scholar] [CrossRef]

- Burkhardt, F.K.; Hayer, J.J.; Heinemann, C.; Steinhoff-Wagner, J. Drinking behavior of dairy cows under commercial farm conditions differs depending on water trough design and cleanliness. Appl. Anim. Behav. Sci. 2022, 256, 105752. [Google Scholar] [CrossRef]

- Jensen, M.B.; Vestergaard, M. Invited review: Freedom from thirst—Do dairy cows and calves have sufficient access to drinking water? J. Dairy Sci. 2021, 104, 11368–11385. [Google Scholar] [CrossRef]

- Des Roches, A.D.B.; Veissier, I.; Coignard, M.; Bareille, N.; Guatteo, R.; Capdeville, J.; Gilot-Fromont, E.; Mounier, L. The major welfare problems of dairy cows in French commercial farms: An epidemiological approach. Anim. Welf. 2014, 23, 467–478. [Google Scholar] [CrossRef]

- Andreasen, S.; Sandøe, P.; Forkman, B. Can animal-based welfare assessment be simplified? A comparison of the Welfare Quality® protocol for dairy cattle and the simpler and less time-consuming protocol developed by the Danish Cattle Federation. Anim. Welf. 2014, 23, 81–94. [Google Scholar] [CrossRef]

- Ahangaran, H.; Ghorbani, G.; SADEGHI, S.A.; Khorvash, M.; Beyranvand, H. Heat stress effects during different seasons on milk production in dairy cattle of Isfahan. In Proceedings of the 2nd International Conference on Agriculture and Natural Resources, Razi University, Kermanshah, Iran, 25 December 2013. [Google Scholar]

- Dairy, N.Z. Farm Infrastructure. Available online: https://www.dairynz.co.nz/media/lfgiafti/facts_and_figures_chapter_11_updated_december_2021.pdf (accessed on 13 October 2025).

- Cook, N.B.; Nordlund, K.V. Behavioral needs of the transition cow and considerations for special needs facility design. Vet. Clin. Food Anim. Pract. 2004, 20, 495–520. [Google Scholar] [CrossRef]

- Jafari-Gh., A.L.R.; Khaloubagheri, F.; Mirrahimi, S.M.H.; Jafari-Gh., S.; Dehghan-Banadaki, M.; Muller, K.; Vallee, E. Prevalence of lameness and hock injuries on intensive Iranian dairy cattle farms. In Proceedings of the 14th International Conference on Lameness in Ruminants, Venice, Italy, 19 September 2024. [Google Scholar]

- Espejo, L.; Endres, M. Herd-level risk factors for lameness in high-producing Holstein cows housed in freestall barns. J. Dairy Sci. 2007, 90, 306–314. [Google Scholar] [CrossRef] [PubMed]

- Munksgaard, L.; Jensen, M.B.; Pedersen, L.J.; Hansen, S.W.; Matthews, L. Quantifying behavioural priorities—Effects of time constraints on behaviour of dairy cows, Bos taurus. Appl. Anim. Behav. Sci. 2005, 92, 3–14. [Google Scholar] [CrossRef]

- Rushen, J.; de Passillé, A.M. Effects of Roughness and Compressibility of Flooring on Cow Locomotion. J. Dairy Sci. 2006, 89, 2965–2972. [Google Scholar] [CrossRef]

- Shearer, J.; Van Amstel, S. Effect of flooring and/or flooring surfaces on lameness disorders in dairy cattle. In Proceedings of the Western Dairy Management Conference, Reno, NV, USA, 7–9 March 2007; pp. 1–12. [Google Scholar]

- Jewell, M.; Cameron, M.; Spears, J.; McKenna, S.; Cockram, M.; Sanchez, J.; Keefe, G. Prevalence of lameness and associated risk factors on dairy farms in the Maritime Provinces of Canada. J. Dairy Sci. 2019, 102, 3392–3405. [Google Scholar] [CrossRef]

- Faezi, M.; Mokhtari, A.; Mohamadnia, A. Detection of Treponema phylotypes from digital dermatitis lesions and effect of different phylotypes on lesion size. Vet. Res. Forum 2022, 13, 79. [Google Scholar]

- Pedersen, S.I.; Huxley, J.N.; Hudson, C.D.; Green, M.J.; Bell, N.J. Preventive hoof trimming in dairy cattle: Determining current practices and identifying future research areas. Vet. Rec. 2022, 190, e1267. [Google Scholar] [CrossRef]

- Nadi, P.; Azizzadeh, M.; Mohamadnia, A. Incidence of hoof lesions in dairy farms in Iran. In Proceedings of the First Regional Conference on Cow Comfort and Lameness, Tehran, Iran, 10–12 May 2016. [Google Scholar]

- Foroughi, P.; Golbabaei, F.; Sadeghi-Yarandi, M.; Yaseri, M.; Fooladi, M.; Kalantary, S. Occupational exposure, carcinogenic and non-carcinogenic risk assessment of formaldehyde in the pathology labs of hospitals in Iran. Sci. Rep. 2024, 14, 12006. [Google Scholar] [CrossRef] [PubMed]

- Mahnani, A.; Sadeghi-Sefidmazgi, A.; Cabrera, V. Consequences and economics of metritis in Iranian Holstein dairy farms. J. Dairy Sci. 2015, 98, 6048–6057. [Google Scholar] [CrossRef] [PubMed]

- Hashemi, M.; Kafi, M.; Safdarian, M. The prevalence of clinical and subclinical mastitis in dairy cows in the central region of Fars province, south of Iran. Iran. J. Vet. Res. 2011, 12, 236–241. [Google Scholar]

| Measure | Unit | Mean | 95% CI for Mean | First Quartile | Median | Third Quartile | Minimum | Maximum | n | |

|---|---|---|---|---|---|---|---|---|---|---|

| Lower | Upper | |||||||||

| Feed and water availability | ||||||||||

| Feed space/head early lactation cow 1 | cm | 68.5 | 60.1 | 77.0 | 48.8 | 64.2 | 77.1 | 21.5 | 160.5 | 46 |

| Feed space/head fresh cow 2 | cm | 99.6 | 77.4 | 121.7 | 70.0 | 89.5 | 133.3 | 23.8 | 172.7 | 17 |

| Water space/head early lactation cow | cm | 8.87 | 6.91 | 10.8 | 4.60 | 7.37 | 12.6 | 1.30 | 31.2 | 43 |

| Water space/head fresh cow | cm | 15.5 | 7.47 | 23.6 | 6.83 | 9.51 | 17.6 | 1.60 | 55.4 | 16 |

| Distance to water after parlour | m | 77.7 | 56.6 | 98.9 | 30.0 | 50.0 | 100 | 0 | 380 | 59 |

| Housing in bedded-pack farms | ||||||||||

| Bedding depth in bedded-pack farms | cm | 20.3 | 14.7 | 25.9 | 12.5 | 15.0 | 30.0 | 2.0 | 80.0 | 32 |

| Resting area/head early lactating cow | cm2 | 575 | 420 | 730 | 300 | 463 | 485 | 125 | 1558 | 25 |

| Resting area/head fresh cow | cm2 | 784 | 505 | 1063 | 571 | 808 | 1042 | 452 | 1586 | 9 |

| Housing in free-stall farms | ||||||||||

| Bedding depth in free-stall farms | cm | 12.6 | 8.52 | 16.6 | 5.0 | 10.0 | 17.5 | 2.0 | 50.0 | 28 |

| Stocking density in free-stall farms 3 | % | 98.7 | 86.6 | 110.7 | 85.3 | 95.2 | 121.0 | 33.3 | 139.5 | 21 |

| Length—single-row stalls | cm | 230 | 214 | 246 | 215 | 228 | 240 | 210 | 275 | 9 |

| Length—double-row stalls | cm | 247 | 238 | 256 | 230 | 255 | 260 | 205 | 273 | 21 |

| Width | cm | 116 | 114 | 118 | 115 | 116 | 120 | 105 | 125 | 24 |

| Brisket height | cm | 20.4 | 3.47 | 37.4 | 10.0 | 15.0 | 25.0 | 8.0 | 60.0 | 7 |

| Low loop height | cm | 33.3 | 29.2 | 37.3 | 28.0 | 32.0 | 40.0 | 18.0 | 60.0 | 23 |

| Loop diameter | cm | 77.0 | 74.4 | 79.6 | 74.0 | 77.0 | 80.0 | 64.0 | 92.0 | 23 |

| Neck rail height | cm | 124 | 121 | 127 | 116 | 125 | 130 | 115 | 135 | 23 |

| Curb to brisket | cm | 220 | 201 | 239 | 205 | 215 | 225 | 205 | 265 | 7 |

| Rear curb width | cm | 15.2 | 12.3 | 18.0 | 10.0 | 15.0 | 20.0 | 8.0 | 33.0 | 23 |

| Rear curb to neck rail | cm | 163 | 155 | 171 | 160 | 165 | 170 | 115 | 195 | 23 |

| Rear curb to stall divider | cm | 34.1 | 27.6 | 40.5 | 25.0 | 30.0 | 40.0 | 13.0 | 75.0 | 23 |

| Cow flow management | ||||||||||

| Returning time per milking 4 | min | 66.2 | 59.9 | 72.4 | 50.0 | 61.0 | 80.0 | 25.0 | 118 | 54 |

| Milking shed entrance slope | % | 6.0 | 4.7 | 7.3 | 3.0 | 5.0 | 8.0 | 0 | 21.0 | 59 |

| Milking shed exit slope | % | 6.8 | 5.3 | 8.3 | 3.0 | 5.0 | 10.0 | 0 | 25.0 | 59 |

| Transfer passage width | cm | 225 | 187 | 262 | 120 | 180 | 300 | 70 | 580 | 52 |

| Maximum walking distance | m | 193 | 153 | 232 | 120 | 160 | 230 | 50 | 560 | 38 |

| Farm Recorded Data 1 | Unit | Mean | 95% CI for Mean | First Quartile | Median | Third Quartile | Minimum | Maximum | N 2 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Lower | Upper | |||||||||

| Mastitis 3 | % | 18.2 | 10.9 | 25.6 | 5.4 | 14.6 | 23.6 | 1.40 | 77.0 | 25 |

| Lameness 3 | % | 12.8 | 9.11 | 16.4 | 6.05 | 8.25 | 18.0 | 1.70 | 38.7 | 32 |

| Culling | % | 27.5 | 21.4 | 33.5 | 18.0 | 25.0 | 33.1 | 5.20 | 65.3 | 28 |

| Calf Mortality | % | 7.31 | 5.21 | 9.40 | 3.47 | 6.10 | 9.57 | 0 | 28.3 | 31 |

| Days Open | days | 138.7 | 126.4 | 151.1 | 121.0 | 133.0 | 150.0 | 103.0 | 238.0 | 22 |

| Average Milk Yield | Litre/day/cow | 35.4 | 34.1 | 36.6 | 33.2 | 36.0 | 38.0 | 26.0 | 43.6 | 42 |

| Milk Fat | % | 3.51 | 3.42 | 3.61 | 3.40 | 3.50 | 3.70 | 2.70 | 4.00 | 35 |

| Milk Protein | % | 3.13 | 3.07 | 3.19 | 3.02 | 3.09 | 3.20 | 2.90 | 3.50 | 26 |

| Milk SCC × 1000 | cells/mL of milk | 244.8 | 184.5 | 305.0 | 185.0 | 214.5 | 259.0 | 63.0 | 800.0 | 24 |

| Days in Milk | days | 178 | 170 | 186 | 158 | 179 | 190 | 148 | 230 | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jafari-Gh., A.; Laven, R.; Khaloubagheri, F.; Jafari-Gh., S.; Mirrahimi, M.H.; Dehghan Banadaky, M.; Mueller, K.R.; Vallee, E. An Investigation of Dairy Cattle Welfare in Commercial Iranian Farms: Results from Management Practices, Resource-Based Measures, and Farm Records. Animals 2025, 15, 3001. https://doi.org/10.3390/ani15203001

Jafari-Gh. A, Laven R, Khaloubagheri F, Jafari-Gh. S, Mirrahimi MH, Dehghan Banadaky M, Mueller KR, Vallee E. An Investigation of Dairy Cattle Welfare in Commercial Iranian Farms: Results from Management Practices, Resource-Based Measures, and Farm Records. Animals. 2025; 15(20):3001. https://doi.org/10.3390/ani15203001

Chicago/Turabian StyleJafari-Gh., Ali, Richard Laven, Fatima Khaloubagheri, Saeid Jafari-Gh., Mohsen Haji Mirrahimi, Mehdi Dehghan Banadaky, Kristina Ruth Mueller, and Emilie Vallee. 2025. "An Investigation of Dairy Cattle Welfare in Commercial Iranian Farms: Results from Management Practices, Resource-Based Measures, and Farm Records" Animals 15, no. 20: 3001. https://doi.org/10.3390/ani15203001

APA StyleJafari-Gh., A., Laven, R., Khaloubagheri, F., Jafari-Gh., S., Mirrahimi, M. H., Dehghan Banadaky, M., Mueller, K. R., & Vallee, E. (2025). An Investigation of Dairy Cattle Welfare in Commercial Iranian Farms: Results from Management Practices, Resource-Based Measures, and Farm Records. Animals, 15(20), 3001. https://doi.org/10.3390/ani15203001