Author Contributions

M.R.P.: Formal Analysis, Investigation, Data Curation, Writing—Original Draft, Writing—Review and Editing, Visualization; E.C.D.: Formal Analysis, Investigation, Writing—Review and Editing; E.M.d.P.: Formal Analysis, Investigation, Writing—Review and Editing, Project Administration; J.R.R.D.: Formal Analysis, Investigation, Writing—Review and Editing; L.G.G.: Formal Analysis, Investigation, Writing—Review and Editing; L.F.F.: Conceptualization, Writing—Review and Editing, Visualization, Supervision, Project Administration, Funding Acquisition. All authors have read and agreed to the published version of the manuscript.

Figure 1.

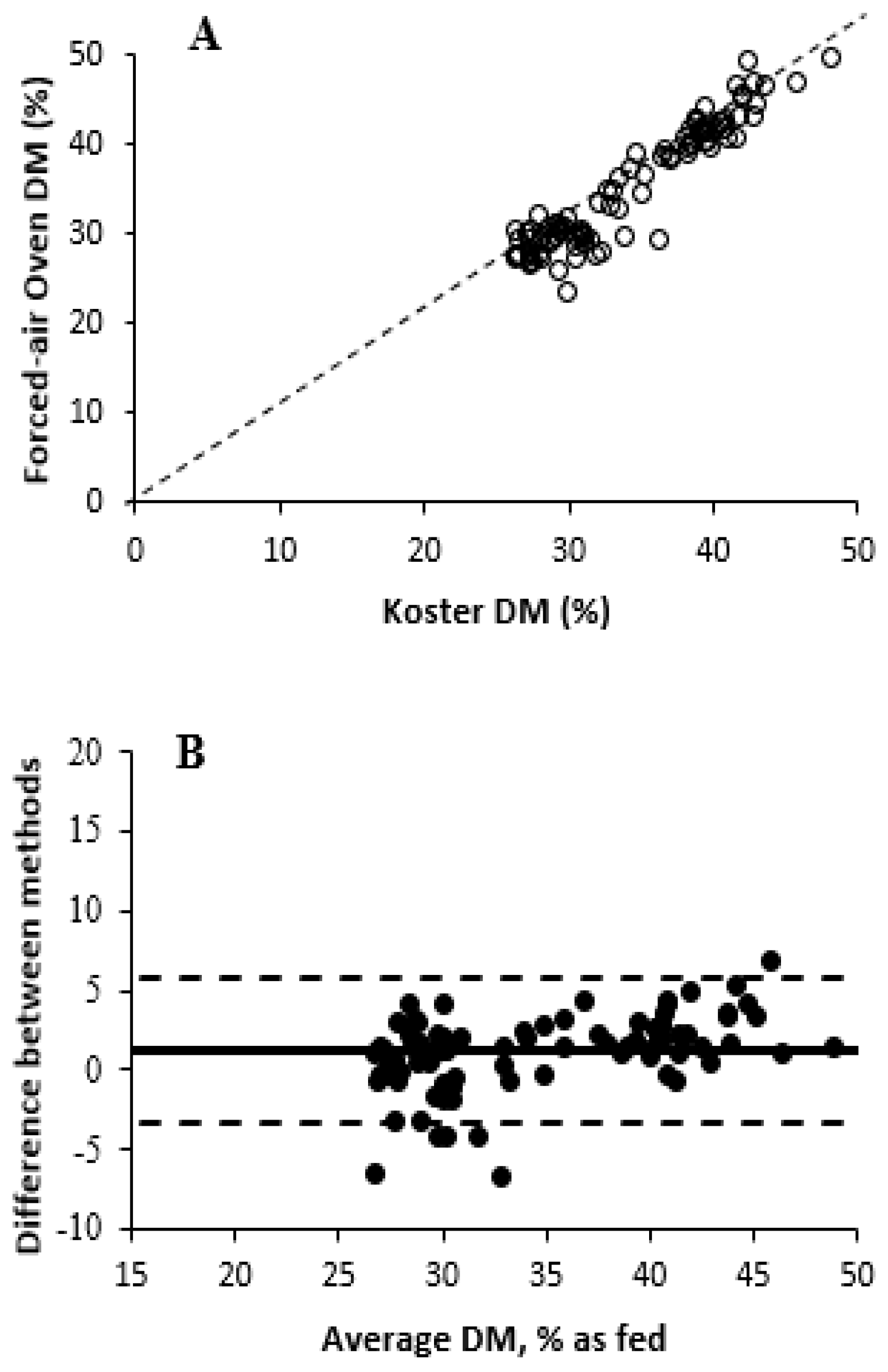

Comparison of dry matter measurement methods in whole-plant corn forage with forced-air oven drying as the reference method (Experiment 1). (A) Relationship between forced-air oven dry matter (%) values and Koster tester. Dashed line represents Y = X, if Koster tester was equivalent to forced-air oven values. (B) Bland–Altman plot illustrating agreement between forced-air oven and Koster tester prediction. The X-axis presents the average DM concentration between forced-air oven and Koster tester, and the Y-axis presents the difference in DM concentration between forced-air oven and Koster tester (forced-air oven/Koster tester). Central, upper, and lower horizontal lines correspond to the mean (1.14) and higher (5.70) and lower (−3.41) 95% limits of agreement (mean ± 1.96 SD), respectively (SD = 2.31).

Figure 1.

Comparison of dry matter measurement methods in whole-plant corn forage with forced-air oven drying as the reference method (Experiment 1). (A) Relationship between forced-air oven dry matter (%) values and Koster tester. Dashed line represents Y = X, if Koster tester was equivalent to forced-air oven values. (B) Bland–Altman plot illustrating agreement between forced-air oven and Koster tester prediction. The X-axis presents the average DM concentration between forced-air oven and Koster tester, and the Y-axis presents the difference in DM concentration between forced-air oven and Koster tester (forced-air oven/Koster tester). Central, upper, and lower horizontal lines correspond to the mean (1.14) and higher (5.70) and lower (−3.41) 95% limits of agreement (mean ± 1.96 SD), respectively (SD = 2.31).

Figure 2.

Comparison of dry matter measurement methods in whole-plant corn forage with forced-air oven drying as the reference method (Experiment 1). (A–C) Relationships between forced-air oven dry matter (%) values and all other pNIRS. Dashed line represents Y = X, if pNIRS were equivalent to forced-air oven values. Bland–Altman plot (Panel (D)). The X-axis presents the average DM concentration between forced-air oven and pNIRS 1, and the Y-axis presents the difference in DM concentration between forced-air oven and pNIRS 1 (forced-air oven/pNIRS 1). Central, upper, and lower horizontal lines correspond to the mean (3.75) and higher (9.74) and lower (−2.23) 95% limits of agreement (mean ±1.96 SD), respectively (SD = 3.05). Bland–Altman plot (Panel (E)). The X-axis presents the average DM concentration between forced-air oven and pNIRS 2, and the Y-axis presents the difference in DM concentration between forced-air oven and pNIRS 2 (forced-air oven/pNIRS 2). Central, upper, and lower horizontal lines correspond to the mean (4.45) and higher (10.87) and lower (−1.97) 95% limits of agreement (mean ±1.96 SD), respectively (SD = 3.27). Bland–Altman plot (Panel (F)). The X-axis presents the average DM concentration between forced-air oven and pNIRS 3, and the Y-axis presents the difference in DM concentration between forced-air oven and pNIRS 3 (forced-air oven/pNIRS 3). Central, upper, and lower horizontal lines correspond to the mean (4.98) and higher (12.35) and lower (−2.39) 95% limits of agreement (mean ± 1.96 SD), respectively (SD = 3.76).

Figure 2.

Comparison of dry matter measurement methods in whole-plant corn forage with forced-air oven drying as the reference method (Experiment 1). (A–C) Relationships between forced-air oven dry matter (%) values and all other pNIRS. Dashed line represents Y = X, if pNIRS were equivalent to forced-air oven values. Bland–Altman plot (Panel (D)). The X-axis presents the average DM concentration between forced-air oven and pNIRS 1, and the Y-axis presents the difference in DM concentration between forced-air oven and pNIRS 1 (forced-air oven/pNIRS 1). Central, upper, and lower horizontal lines correspond to the mean (3.75) and higher (9.74) and lower (−2.23) 95% limits of agreement (mean ±1.96 SD), respectively (SD = 3.05). Bland–Altman plot (Panel (E)). The X-axis presents the average DM concentration between forced-air oven and pNIRS 2, and the Y-axis presents the difference in DM concentration between forced-air oven and pNIRS 2 (forced-air oven/pNIRS 2). Central, upper, and lower horizontal lines correspond to the mean (4.45) and higher (10.87) and lower (−1.97) 95% limits of agreement (mean ±1.96 SD), respectively (SD = 3.27). Bland–Altman plot (Panel (F)). The X-axis presents the average DM concentration between forced-air oven and pNIRS 3, and the Y-axis presents the difference in DM concentration between forced-air oven and pNIRS 3 (forced-air oven/pNIRS 3). Central, upper, and lower horizontal lines correspond to the mean (4.98) and higher (12.35) and lower (−2.39) 95% limits of agreement (mean ± 1.96 SD), respectively (SD = 3.76).

![Animals 15 02349 g002 Animals 15 02349 g002]()

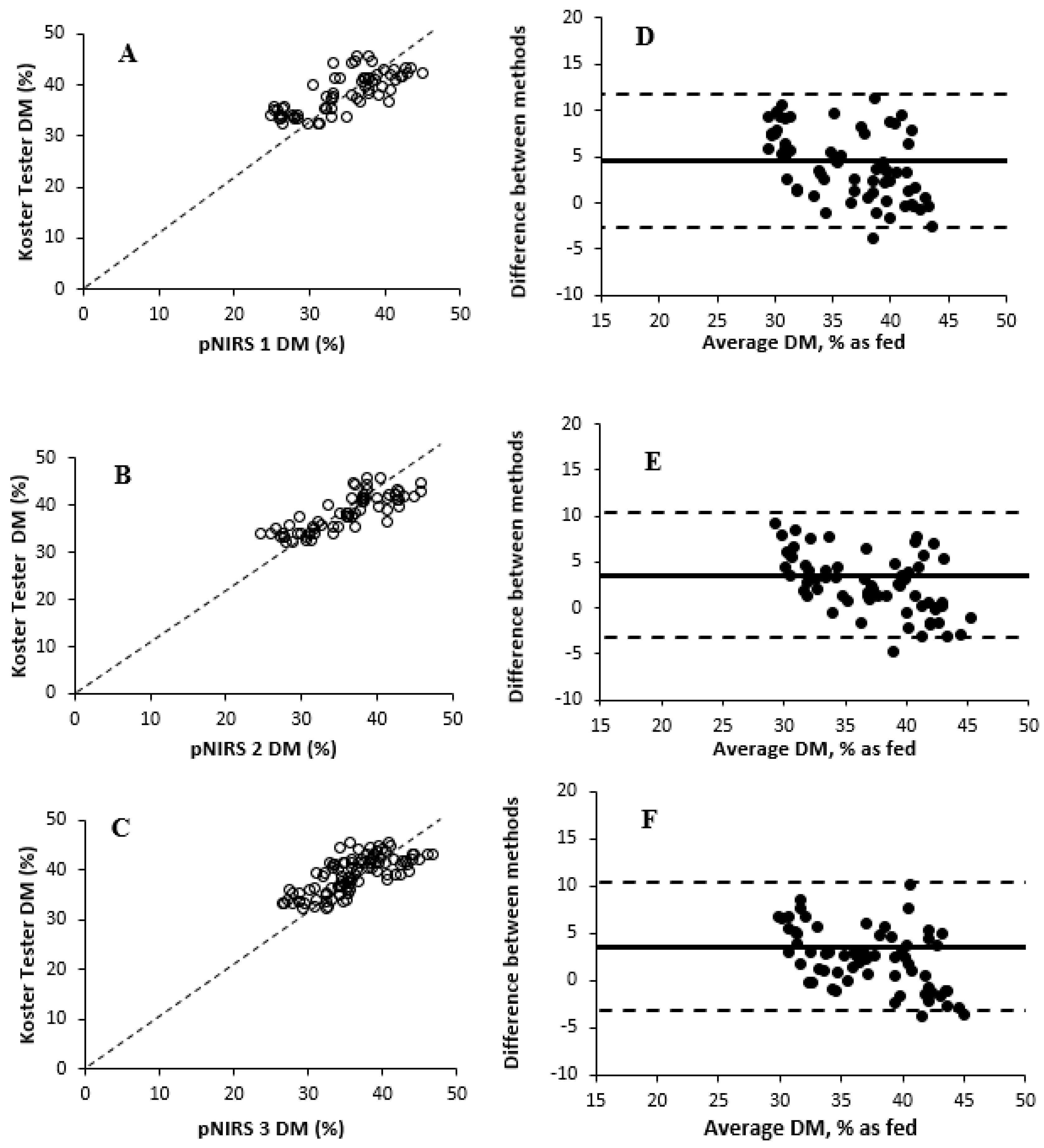

Figure 3.

Comparison of dry matter measurement methods in whole-plant corn forage with Koster tester as the reference method (Experiment 2). (A–C) Relationships between Koster tester dry matter (%) values and all other treatments in Experiment 2. Dashed line represents Y = X, if other treatments were equivalent to Koster tester values. Bland–Altman plot (Panel (D)). The X-axis presents the average DM concentration between Koster tester and pNIRS 1, and the Y-axis presents the difference in DM concentration between Koster tester and pNIRS 1 (Koster tester/pNIRS 1). Central, upper, and lower horizontal lines correspond to the mean (4.54) and higher (11.80) and lower (−2.72) 95% limits of agreement (mean ±1.96 SD), respectively (SD = 3.69). Bland–Altman plot (Panel (E)). The X-axis presents the average DM concentration between Koster tester and pNIRS 2, and the Y-axis presents the difference in DM concentration between Koster tester and pNIRS 2 (Koster tester/pNIRS 2). Central, upper, and lower horizontal lines correspond to the mean (3.60) and higher (10.44) and lower (−3.23) 95% limits of agreement (mean ±1.96 SD), respectively (SD = 3.49). Bland–Altman plot (Panel (F)). The X-axis presents the average DM concentration between Koster tester and pNIRS 3, and the Y-axis presents the difference in DM concentration between Koster tester and pNIRS 3 (Koster tester/pNIRS 3). Central, upper, and lower horizontal lines correspond to the mean (3.56) and higher (10.36) and lower (−3.23) 95% limits of agreement (mean ± 1.96 SD), respectively (SD = 3.47).

Figure 3.

Comparison of dry matter measurement methods in whole-plant corn forage with Koster tester as the reference method (Experiment 2). (A–C) Relationships between Koster tester dry matter (%) values and all other treatments in Experiment 2. Dashed line represents Y = X, if other treatments were equivalent to Koster tester values. Bland–Altman plot (Panel (D)). The X-axis presents the average DM concentration between Koster tester and pNIRS 1, and the Y-axis presents the difference in DM concentration between Koster tester and pNIRS 1 (Koster tester/pNIRS 1). Central, upper, and lower horizontal lines correspond to the mean (4.54) and higher (11.80) and lower (−2.72) 95% limits of agreement (mean ±1.96 SD), respectively (SD = 3.69). Bland–Altman plot (Panel (E)). The X-axis presents the average DM concentration between Koster tester and pNIRS 2, and the Y-axis presents the difference in DM concentration between Koster tester and pNIRS 2 (Koster tester/pNIRS 2). Central, upper, and lower horizontal lines correspond to the mean (3.60) and higher (10.44) and lower (−3.23) 95% limits of agreement (mean ±1.96 SD), respectively (SD = 3.49). Bland–Altman plot (Panel (F)). The X-axis presents the average DM concentration between Koster tester and pNIRS 3, and the Y-axis presents the difference in DM concentration between Koster tester and pNIRS 3 (Koster tester/pNIRS 3). Central, upper, and lower horizontal lines correspond to the mean (3.56) and higher (10.36) and lower (−3.23) 95% limits of agreement (mean ± 1.96 SD), respectively (SD = 3.47).

![Animals 15 02349 g003 Animals 15 02349 g003]()

Figure 4.

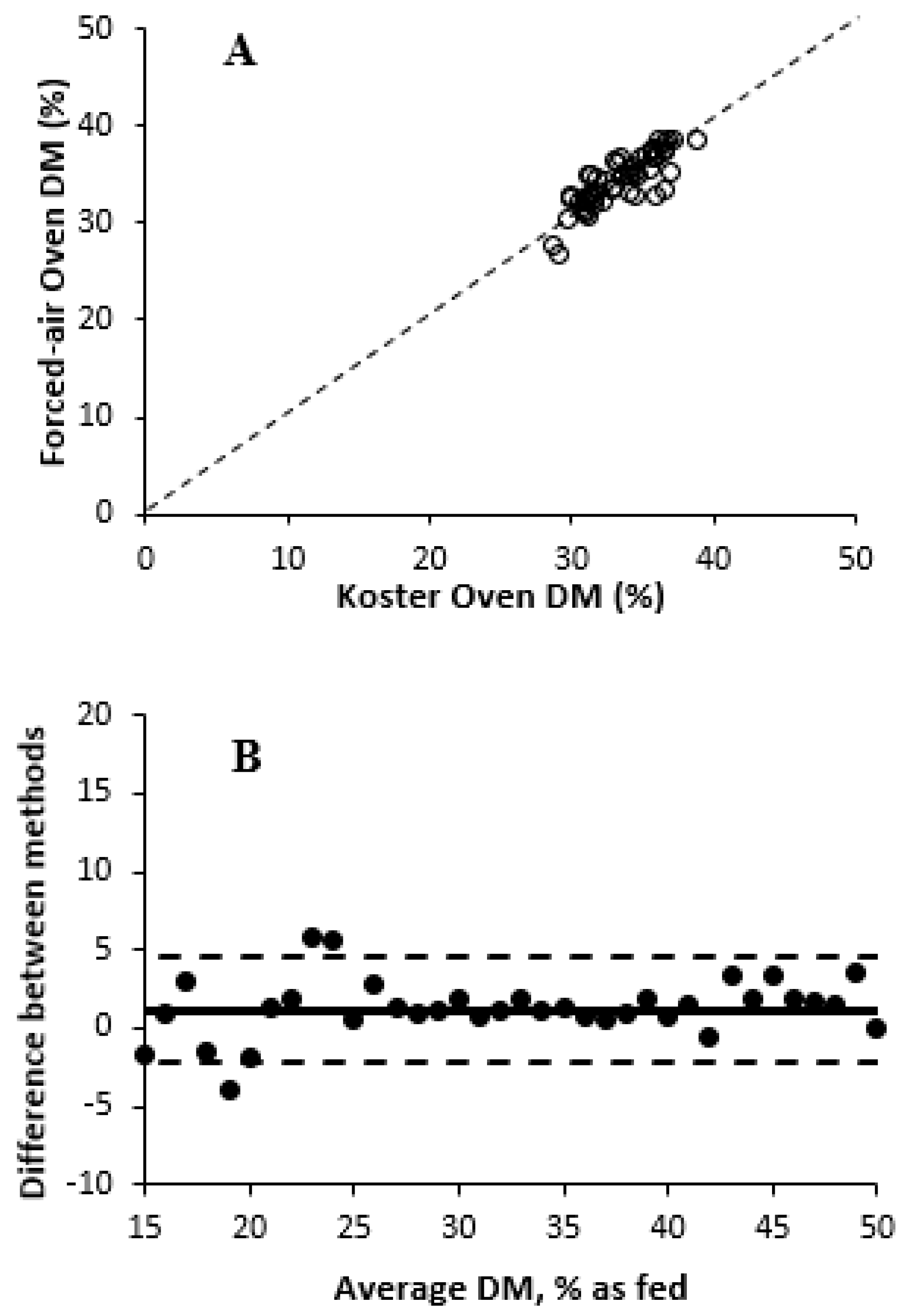

Comparison of dry matter measurement methods in whole-plant corn silage with forced-air oven drying as the reference method (Experiment 3). (A) Relationship between forced-air oven dry matter (%) values and Koster tester in Experiment 3. Dashed line represents Y = X, if Koster tester was equivalent to forced-air oven values. (B) Bland–Altman plot illustrating agreement between forced-air oven and Koster tester prediction. The X-axis presents the average DM concentration between forced-air oven and Koster tester, and the Y-axis presents the difference in DM concentration between forced-air oven and Koster tester (forced-air oven/Koster tester). Central, upper, and lower horizontal lines correspond to the mean (1.19) and higher (4.53) and lower (−2.15) 95% limits of agreement (mean ± 1.96 SD), respectively (SD = 1.70).

Figure 4.

Comparison of dry matter measurement methods in whole-plant corn silage with forced-air oven drying as the reference method (Experiment 3). (A) Relationship between forced-air oven dry matter (%) values and Koster tester in Experiment 3. Dashed line represents Y = X, if Koster tester was equivalent to forced-air oven values. (B) Bland–Altman plot illustrating agreement between forced-air oven and Koster tester prediction. The X-axis presents the average DM concentration between forced-air oven and Koster tester, and the Y-axis presents the difference in DM concentration between forced-air oven and Koster tester (forced-air oven/Koster tester). Central, upper, and lower horizontal lines correspond to the mean (1.19) and higher (4.53) and lower (−2.15) 95% limits of agreement (mean ± 1.96 SD), respectively (SD = 1.70).

Figure 5.

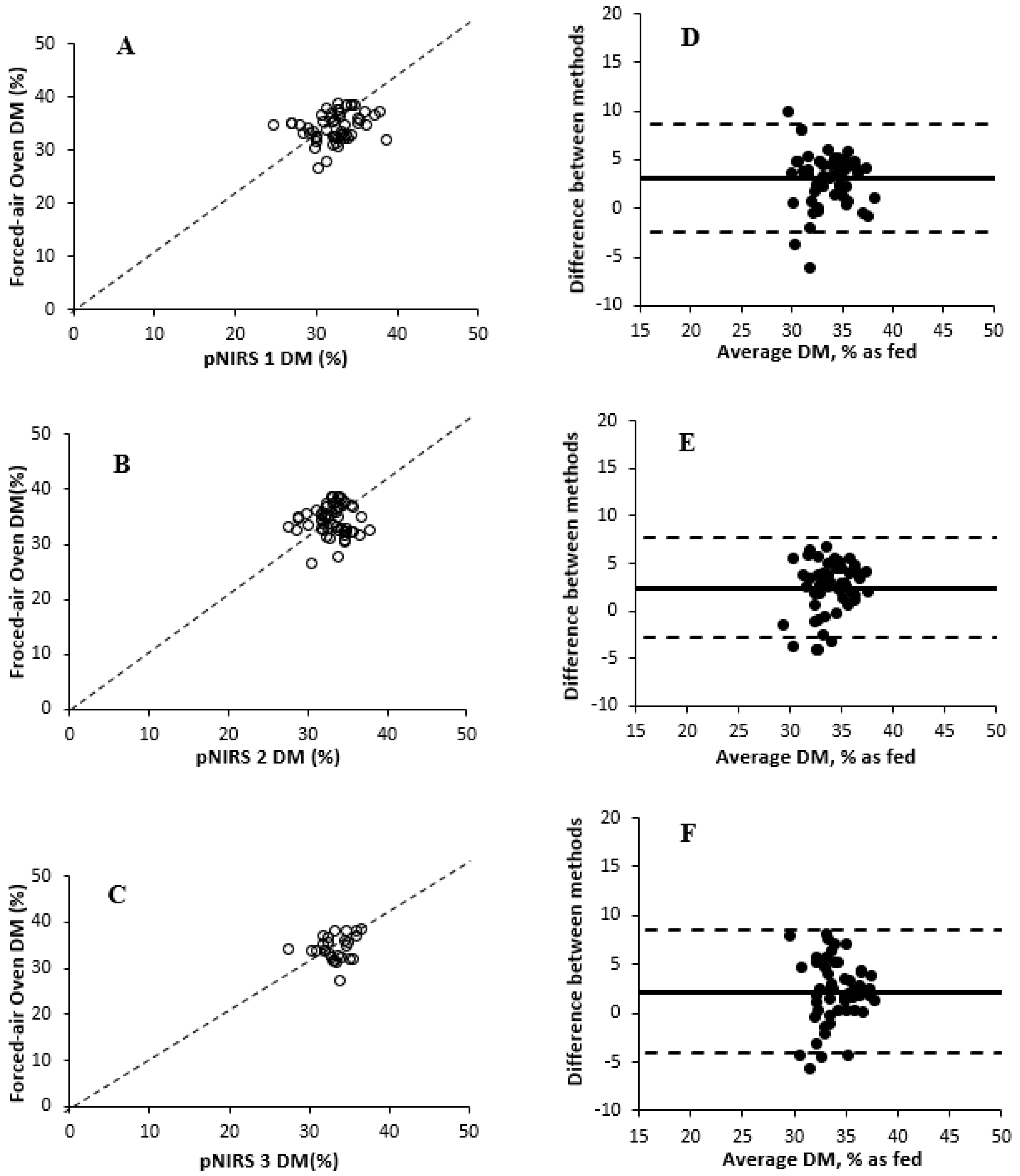

Comparison of dry matter measurement methods in whole-plant corn silage with forced-air oven drying as the reference method (Experiment 3). (A–C) Relationships between forced-air oven dry matter (%) values and all other pNIRS in Experiment 3. Dashed line represents Y = X, if pNIRS were equivalent to forced-air oven values. Bland–Altman plot (Panel (D)). The X-axis presents the average DM concentration between forced-air oven and pNIRS 1, and the Y-axis presents the difference in DM concentration between forced-air oven and pNIRS 1 (forced-air oven/pNIRS 1). Central, upper, and lower horizontal lines correspond to the mean (3.05) and higher (8.61) and lower (−2.51) 95% limits of agreement (mean ±1.96 SD), respectively (SD = 2.84). Bland–Altman plot (Panel (E)). The X-axis presents the average DM concentration between forced-air oven and pNIRS 2, and the Y-axis presents the difference in DM concentration between forced-air oven and pNIRS 2 (forced-air oven/pNIRS 2). Central, upper, and lower horizontal lines correspond to the mean (2.44) and higher (7.72) and lower (−2.83) 95% limits of agreement (mean ± 1.96 SD), respectively (SD = 2.69). Bland–Altman plot (Panel (F)). The X-axis presents the average DM concentration between forced-air oven and pNIRS 3, and the Y-axis presents the difference in DM concentration between forced-air oven and pNIRS 3 (forced-air oven/pNIRS 3). Central, upper, and lower horizontal lines correspond to the mean (2.20) and higher (8.49) and lower (−4.08) 95% limits of agreement (mean ± 1.96 SD), respectively (SD = 3.20).

Figure 5.

Comparison of dry matter measurement methods in whole-plant corn silage with forced-air oven drying as the reference method (Experiment 3). (A–C) Relationships between forced-air oven dry matter (%) values and all other pNIRS in Experiment 3. Dashed line represents Y = X, if pNIRS were equivalent to forced-air oven values. Bland–Altman plot (Panel (D)). The X-axis presents the average DM concentration between forced-air oven and pNIRS 1, and the Y-axis presents the difference in DM concentration between forced-air oven and pNIRS 1 (forced-air oven/pNIRS 1). Central, upper, and lower horizontal lines correspond to the mean (3.05) and higher (8.61) and lower (−2.51) 95% limits of agreement (mean ±1.96 SD), respectively (SD = 2.84). Bland–Altman plot (Panel (E)). The X-axis presents the average DM concentration between forced-air oven and pNIRS 2, and the Y-axis presents the difference in DM concentration between forced-air oven and pNIRS 2 (forced-air oven/pNIRS 2). Central, upper, and lower horizontal lines correspond to the mean (2.44) and higher (7.72) and lower (−2.83) 95% limits of agreement (mean ± 1.96 SD), respectively (SD = 2.69). Bland–Altman plot (Panel (F)). The X-axis presents the average DM concentration between forced-air oven and pNIRS 3, and the Y-axis presents the difference in DM concentration between forced-air oven and pNIRS 3 (forced-air oven/pNIRS 3). Central, upper, and lower horizontal lines correspond to the mean (2.20) and higher (8.49) and lower (−4.08) 95% limits of agreement (mean ± 1.96 SD), respectively (SD = 3.20).

![Animals 15 02349 g005 Animals 15 02349 g005]()

Table 1.

Effects of dry matter measurement methods in whole-plant corn forage with forced-air oven drying as the reference method (Experiment 1).

Table 1.

Effects of dry matter measurement methods in whole-plant corn forage with forced-air oven drying as the reference method (Experiment 1).

| Measurement Method | Mean | Standard Deviation | Minimum | Maximum |

|---|

| Forced-air oven 1 | 35.4 a | 6.74 | 23.4 | 49.6 |

| Koster testers 2 | 34.3 b | 5.68 | 26.3 | 48.1 |

| pNIRS 1 3 | 30.6 c | 6.41 | 18.4 | 42.0 |

| pNIRS 2 | 31.0 c | 6.92 | 18.8 | 43.0 |

| pNIRS 3 | 30.5 c | 7.22 | 17.2 | 42.2 |

Table 2.

Correlation 1 of dry matter measurement methods in whole-plant corn forage with forced-air oven drying as the reference method (Experiment 1).

Table 2.

Correlation 1 of dry matter measurement methods in whole-plant corn forage with forced-air oven drying as the reference method (Experiment 1).

| | Forced-Air Oven | Koster Testers | pNIRS 1 | pNIRS 2 | pNIRS 3 |

|---|

| Forced-air oven | 1.00 | 0.94 | 0.91 | 0.89 | 0.86 |

| | | <0.001 | <0.001 | <0.001 | <0.001 |

| Koster testers | | 1.00 | 0.88 | 0.88 | 0.85 |

| | | | <0.001 | <0.001 | <0.001 |

| pNIRS 1 2 | | | 1.00 | 0.85 | 0.85 |

| | | | | <0.001 | <0.001 |

| pNIRS 2 | | | | 1.00 | 0.86 |

| | | | | | <0.001 |

| pNIRS 3 | | | | | 1.00 |

Table 3.

Effects of dry matter measurement methods in whole-plant corn forage with forced-air oven drying as the reference method (Experiment 1) on residual moisture concentration (%).

Table 3.

Effects of dry matter measurement methods in whole-plant corn forage with forced-air oven drying as the reference method (Experiment 1) on residual moisture concentration (%).

| Drying Method | Residual Moisture 1 | Standard Error | Minimum | Maximum |

|---|

| Forced-air oven | 3.4% | 0.79 | 2.70 | 4.16 |

| Koster testers | 2.9% | 0.79 | 0.99 | 6.15 |

Table 4.

Evaluation of predicted dry matter concentration of whole-plant corn forage by Koster tester and pNIRS compared to observed values from forced-air oven drying as the reference method (Experiment 1; n = 48).

Table 4.

Evaluation of predicted dry matter concentration of whole-plant corn forage by Koster tester and pNIRS compared to observed values from forced-air oven drying as the reference method (Experiment 1; n = 48).

| Item | R2 | Mean Bias (% DM) | CCC 1 | RMSEP (% DM) 2 | SEP (% DM) 3 | MSEP Decomposition (%) 4 |

|---|

| Mean Bias | Slope | Random Errors |

|---|

| Koster testers 5 | 0.89 | −1.14 | 0.92 | 2.57 | 2.26 | 19.6 | 7.20 | 73.2 |

| pNIRS 1 6 | 0.84 | −4.90 | 0.72 | 5.59 | 2.70 | 76.3 | 0.20 | 23.5 |

| pNIRS 2 | 0.79 | −4.44 | 0.73 | 5.52 | 3.28 | 65.1 | 3.00 | 31.9 |

| pNIRS 3 | 0.74 | −4.97 | 0.68 | 6.23 | 3.61 | 63.9 | 5.40 | 30.7 |

Table 5.

Effects of dry matter measurement methods in whole-plant corn forage with Koster tester as the reference method (Experiment 2).

Table 5.

Effects of dry matter measurement methods in whole-plant corn forage with Koster tester as the reference method (Experiment 2).

| Measurement Method | Mean | Standard Deviation | Minimum | Maximum |

|---|

| Koster testers 1 | 37.2 a | 4.84 | 27.2 | 45.7 |

| pNIRS 1 2 | 32.7 c | 6.19 | 17.2 | 44.9 |

| pNIRS 2 | 33.7 b | 6.23 | 14.6 | 45.9 |

| pNIRS 3 | 33.6 b | 6.30 | 15.7 | 46.8 |

Table 6.

Correlation 1 of dry matter measurement methods in whole-plant corn forage with Koster tester as the reference method (Experiment 2).

Table 6.

Correlation 1 of dry matter measurement methods in whole-plant corn forage with Koster tester as the reference method (Experiment 2).

| | Koster Testers | pNIRS 1 | pNIRS 2 | pNIRS 3 |

|---|

| Koster testers | 1.00 | 0.80 | 0.83 | 0.84 |

| | | <0.001 | <0.001 | <0.001 |

| pNIRS 1 2 | | 1.00 | 0.89 | 0.89 |

| | | | <0.001 | <0.001 |

| pNIRS 2 | | | 1.00 | 0.89 |

| | | | | <0.001 |

| pNIRS 3 | | | | 1.00 |

Table 7.

Effects of dry matter measurement methods in whole-plant corn forage with Koster tester as the reference method (Experiment 2) on residual moisture concentration (%).

Table 7.

Effects of dry matter measurement methods in whole-plant corn forage with Koster tester as the reference method (Experiment 2) on residual moisture concentration (%).

| Drying Method | Residual Moisture 1 | Standard Error | Minimum | Maximum |

|---|

| Forced-air oven | 1.7% | 0.28 | 0.95 | 2.89 |

Table 8.

Evaluation of predicted dry matter concentration of whole-plant corn forage by pNIRS compared to observed values from Koster tester as the reference method (Experiment 2; n = 65).

Table 8.

Evaluation of predicted dry matter concentration of whole-plant corn forage by pNIRS compared to observed values from Koster tester as the reference method (Experiment 2; n = 65).

| Item | R2 | Mean Bias (% DM) | CCC 1 | RMSEP (% DM) 2 | SEP (% DM) 3 | MSEP Decomposition (%) 4 |

|---|

| Mean Bias | Slope | Random Errors |

|---|

| pNIRS 1 5 | 0.64 | −4.54 | 0.59 | 5.84 | 3.67 | 60.2 | 15.6 | 24.2 |

| pNIRS 2 | 0.69 | −3.60 | 0.67 | 4.99 | 3.46 | 51.8 | 19.5 | 28.7 |

| pNIRS 3 | 0.70 | −3.56 | 0.68 | 4.95 | 3.44 | 51.6 | 20.5 | 27.9 |

Table 9.

Evaluation of predicted dry matter concentration of whole-plant corn silage by Koster tester and pNIRS compared to observed values from forced-air oven drying as the reference method (Experiment 3).

Table 9.

Evaluation of predicted dry matter concentration of whole-plant corn silage by Koster tester and pNIRS compared to observed values from forced-air oven drying as the reference method (Experiment 3).

| Measurement Method | Mean | Standard Deviation | Minimum | Maximum |

|---|

| Forced-air oven 1 | 35.3 a | 2.11 | 30.4 | 38.6 |

| Koster testers 2 | 34.0 b | 2.06 | 29.8 | 37.2 |

| pNIRS 1 3 | 31.9 c | 2.91 | 24.6 | 37.9 |

| pNIRS 2 | 32.5 c | 2.02 | 27.6 | 35.7 |

| pNIRS 3 | 32.7 b,c | 2.53 | 25.7 | 37.1 |

Table 10.

Correlation 1 of dry matter measurement methods in whole-plant corn silage with forced-air oven drying as the reference method (Experiment 3).

Table 10.

Correlation 1 of dry matter measurement methods in whole-plant corn silage with forced-air oven drying as the reference method (Experiment 3).

| | Forced-Air Oven | Koster Testers | pNIRS 1 | pNIRS 2 | pNIRS 3 |

|---|

| Forced-air oven | 1.00 | 0.85 | 0.43 | 0.14 | 0.34 |

| | | <0.001 | 0.02 | 0.45 | 0.06 |

| Koster testers | | 1.00 | 0.30 | 0.16 | 0.19 |

| | | | 0.11 | 0.39 | 0.31 |

| pNIRS 1 2 | | | 1.00 | 0.59 | 0.56 |

| | | | | 0.001 | 0.001 |

| pNIRS 2 | | | | 1.00 | 0.56 |

| | | | | | 0.001 |

| pNIRS 3 | | | | | 1.00 |

Table 11.

Effects of dry matter measurement methods in whole-plant corn silage with forced-air oven drying as the reference method (Experiment 3) on residual moisture concentration (%).

Table 11.

Effects of dry matter measurement methods in whole-plant corn silage with forced-air oven drying as the reference method (Experiment 3) on residual moisture concentration (%).

| Drying Method | Residual Moisture 1 | Standard Error | Minimum | Maximum |

|---|

| Forced-air oven | 3.1% | 0.72 | 2.20 | 4.28 |

| Koster testers | 3.0% | 0.72 | 1.05 | 6.53 |

Table 12.

Evaluation of predicted dry matter concentration of whole-plant corn silage by Koster tester and pNIRS compared to observed values from forced-air oven drying as the reference method (Experiment 3; n = 27).

Table 12.

Evaluation of predicted dry matter concentration of whole-plant corn silage by Koster tester and pNIRS compared to observed values from forced-air oven drying as the reference method (Experiment 3; n = 27).

| Item | R2 | Mean Bias | CCC 1 | RMSEP (% DM) 2 | SEP (% DM) 3 | MSEP Decomposition (%) 4 |

|---|

| Mean Bias | Slope | Random Errors |

|---|

| Koster testers 5 | 0.72 | −1.30 | 0.71 | 1.73 | 1.14 | 56.0 | 2.50 | 41.5 |

| pNIRS 1 6 | 0.19 | −3.41 | 0.22 | 4.38 | 2.75 | 60.5 | 21.5 | 18.0 |

| pNIRS 2 | 0.02 | −2.76 | 0.08 | 3.85 | 2.68 | 51.0 | 20.4 | 28.6 |

| pNIRS 3 | 0.12 | −2.55 | 0.21 | 3.71 | 2.69 | 47.4 | 24.7 | 27.9 |