Effect of Different Percentage of Camelina sativa Cake in Laying Hens Diet: Performance, Welfare, and Eggshell Quality

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Birds Housing and Feeding

2.2. Characterization of Camelina Cake and Diets

2.2.1. Analysis of Antioxidants

2.2.2. Fatty Acid Composition

2.2.3. Antinutritional Compounds

2.2.4. Volatile Organic Compounds (VOCs)

2.3. Data Collection

2.3.1. Birds Performance and Welfare

2.3.2. Eggshell Quality

2.3.3. Statistical Analysis

2.4. Ethical Statement

3. Results and Discussion

3.1. Characterization of Camelina Cake and Diets

3.1.1. Antioxidants

3.1.2. Fatty Acid Composition

3.1.3. Antinutritional Compounds

3.1.4. Volatile Organic Compounds

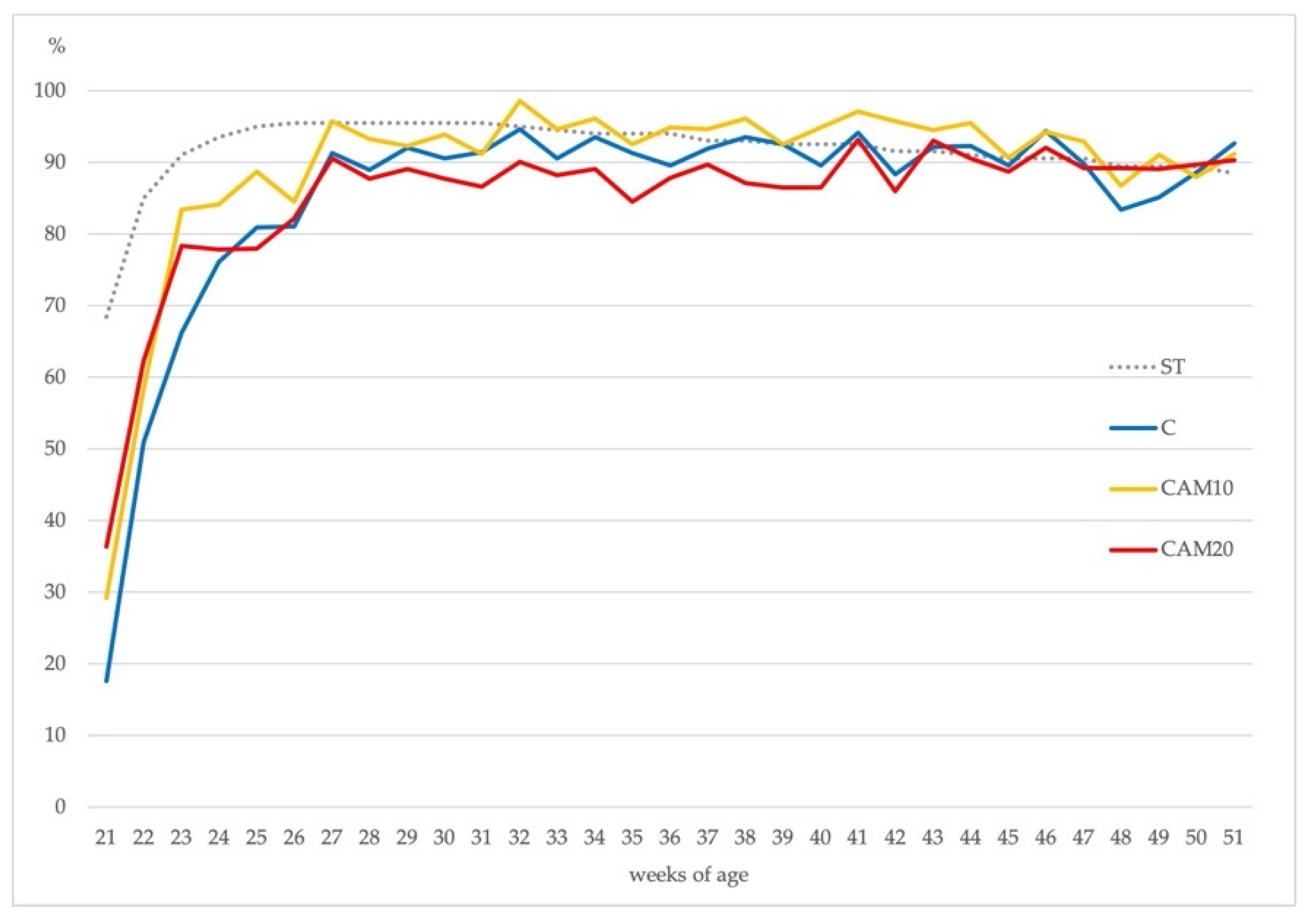

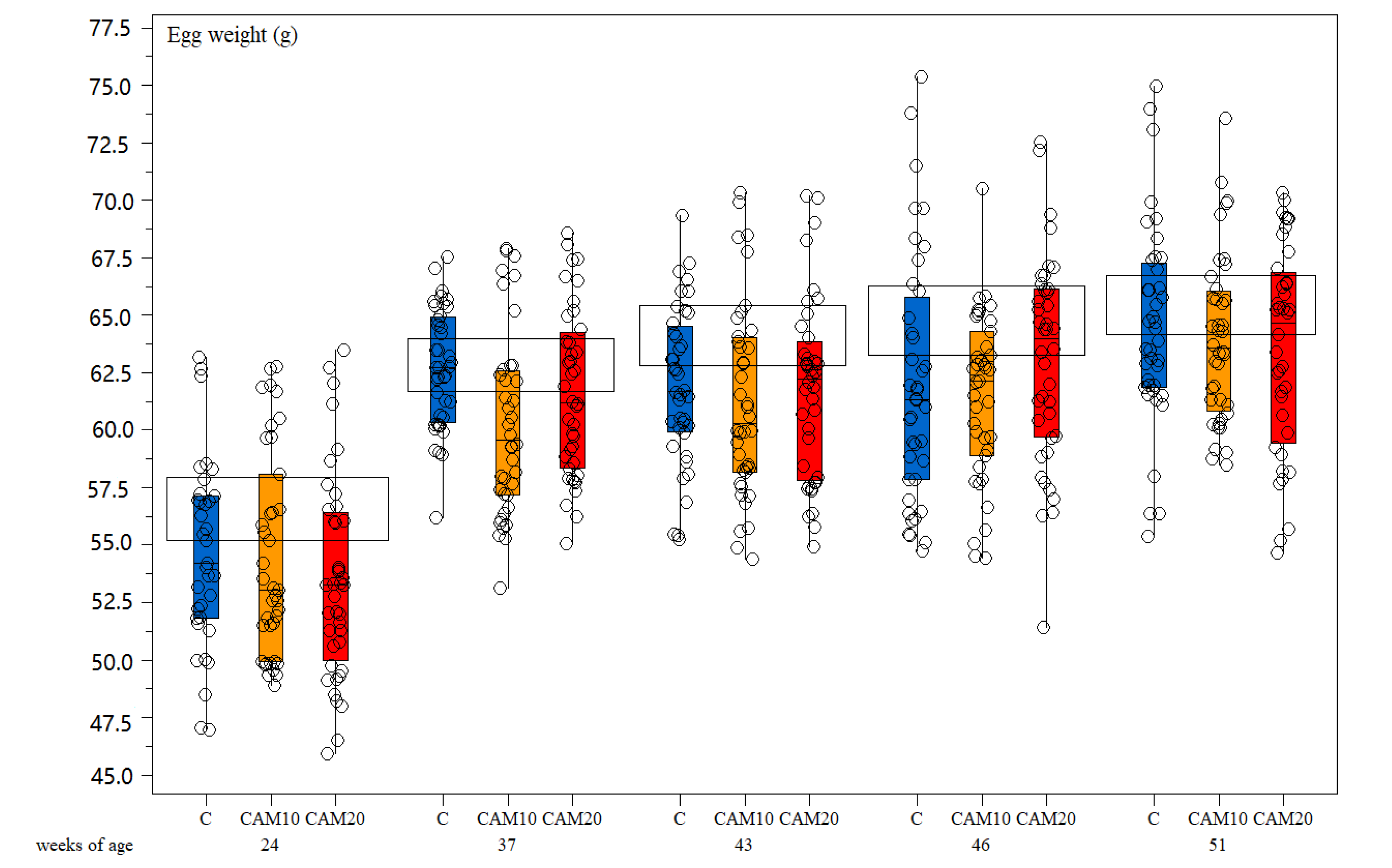

3.2. Birds Performance and Welfare

3.3. Eggshell Mechanical and Quality Traits

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Parliament, T.E.; Parliament, E.; Community, E.E. European Parliament 2014–2019; European Parliament: Strasbourg, France, 2018. [Google Scholar]

- Smith, N.O. Crops for Industry and Energy in Europe; Office for Official Publications of the European Communities: Brussels, Belgium, 1997; ISBN 9282794156. [Google Scholar]

- Gugel, R.K.; Falk, K.C. Agronomic and seed quality evaluation of Camelina sativa in western Canada. Can. J. Plant Sci. 2006, 86, 1047–1058. [Google Scholar] [CrossRef]

- Berti, M.; Gesch, R.; Eynck, C.; Anderson, J.; Cermak, S. Camelina uses, genetics, genomics, production, and management. Ind. Crops Prod. 2016, 94, 690–710. [Google Scholar] [CrossRef]

- Zohary, D.; Hopf, M. Domestication of Plants in the Old World: The Origin and Spread of cultivated Plants in West Asia, Europe and the Nile Valley; Oxford University Press: Oxford, UK, 2000; ISBN 0198503563. [Google Scholar]

- Vollmann, J.; Moritz, T.; Kargl, C.; Baumgartner, S.; Wagentristl, H. Agronomic evaluation of camelina genotypes selected for seed quality characteristics. Ind. Crops Prod. 2007, 26, 270–277. [Google Scholar] [CrossRef]

- Masella, P.; Martinelli, T.; Galasso, I. Agronomic evaluation and phenotypic plasticity of Camelina sativa growing in Lombardia, Italy. Crop Pasture Sci. 2014, 65, 453–460. [Google Scholar] [CrossRef]

- Zanetti, F.; Eynck, C.; Christou, M.; Krzyżaniak, M.; Righini, D.; Alexopoulou, E.; Stolarski, M.J.; Van Loo, E.N.; Puttick, D.; Monti, A. Agronomic performance and seed quality attributes of Camelina (Camelina sativa L. crantz) in multi-environment trials across Europe and Canada. Ind. Crops Prod. 2017, 107, 602–608. [Google Scholar] [CrossRef]

- Fröhlich, A.; Rice, B. Evaluation of Camelina sativa oil as a feedstock for biodiesel production. Ind. Crops Prod. 2005, 21, 25–31. [Google Scholar] [CrossRef]

- Zaleckas, E.; Makarevičienė, V.; Sendžikienė, E. Possibilities of using Camelina sativa oil for producing biodiesel fuel. Transport 2012, 27, 60–66. [Google Scholar] [CrossRef]

- Agusdinata, D.B.; Zhao, F.; Ileleji, K.; DeLaurentis, D. Life cycle assessment of potential biojet fuel production in the United States. Environ. Sci. Technol. 2011, 45, 9133–9143. [Google Scholar] [CrossRef]

- Matthäus, B.; Zubr, J. Variability of specific components in Camelina sativa oilseed cakes. Ind. Crops Prod. 2000, 12, 9–18. [Google Scholar] [CrossRef]

- Ibrahim, F.M.; El Habbasha, S.F. Chemical composition, medicinal impacts and cultivation of camelina (Camelina sativa). Int. J. PharmTech. Res. 2015, 8, 114–122. [Google Scholar]

- Cherian, G. Camelina sativa in poultry diets: Opportunities and challenges. In Biofuel co-Products as Livest. Feed Oppor. Challenges; FAO: Rome, Italy, 2012; pp. 303–310. [Google Scholar]

- Colombini, S.; Broderick, G.A.; Galasso, I.; Martinelli, T.; Rapetti, L.; Russo, R.; Reggiani, R. Evaluation of Camelina sativa (L.) Crantz meal as an alternative protein source in ruminant rations. J. Sci. Food Agric. 2014, 94, 736–743. [Google Scholar] [CrossRef] [PubMed]

- Zubr, J.; Matthäus, B. Effects of growth conditions on fatty acids and tocopherols in Camelina sativa oil. Ind. Crops Prod. 2002, 15, 155–162. [Google Scholar] [CrossRef]

- Abramovič, H.; Butinar, B.; Nikolič, V. Changes occurring in phenolic content, tocopherol composition and oxidative stability of Camelina sativa oil during storage. Food Chem. 2007, 104, 903–909. [Google Scholar] [CrossRef]

- Aziza, A.E.; Quezada, N.; Cherian, G. Feeding Camelina sativa meal to meat-type chickens: Effect on production performance and tissue fatty acid composition. J. Appl. Poult. Res. 2010, 19, 157–168. [Google Scholar] [CrossRef]

- Ryhänen, E.; Perttilä, S.; Tupasela, T.; Valaja, J.; Eriksson, C.; Larkka, K. Effect of Camelina sativa expeller cake on performance and meat quality of broilers. J. Sci. Food Agric. 2007, 87, 1489–1494. [Google Scholar] [CrossRef]

- Pekel, A.Y.; Patterson, P.H.; Hulet, R.M.; Acar, N.; Cravener, T.L.; Dowler, D.B.; Hunter, J.M. Dietary camelina meal versus flaxseed with and without supplemental copper for broiler chickens: Live performance and processing yield. Poult. Sci. 2009, 88, 2392–2398. [Google Scholar] [CrossRef]

- Cherian, G.; Campbell, A.; Parker, T. Egg quality and lipid composition of eggs from hens fed Camelina sativa. J. Appl. Poult. Res. 2009, 18, 143–150. [Google Scholar] [CrossRef]

- Quentin, M.; Bouvarel, I.; Picard, M. Effects of crude protein and lysine contents of the diet on growth and body composition of slow-growing commercial broilers from 42 to 77 days of age. Anim. Res. 2005, 54, 113–122. [Google Scholar] [CrossRef]

- Hetland, H.; Choct, M.; Svihus, B. Role of insoluble non-starch polysaccharides in poultry nutrition. Worlds Poult. Sci. J. 2004, 60, 415–422. [Google Scholar] [CrossRef]

- Tarlton, J.F.; Wilkins, L.J.; Toscano, M.J.; Avery, N.C.; Knott, L. Reduced bone breakage and increased bone strength in free range laying hens fed omega-3 polyunsaturated fatty acid supplemented diets. Bone 2013, 52, 578–586. [Google Scholar] [CrossRef]

- Roberts, J.R. Factors affecting egg internal quality and egg shell quality in laying hens. J. Poult. Sci. 2004, 41, 161–177. [Google Scholar] [CrossRef]

- Ketta, M.; Tůmová, E. Eggshell structure, measurements, and quality-affecting factors in laying hens: A review. Czech J. Anim. Sci. 2016, 61, 299–309. [Google Scholar] [CrossRef]

- Mabe, I.; Rapp, C.; Bain, M.M.; Nys, Y. Supplementation of a corn-soybean meal diet with manganese, copper, and zinc from organic or inorganic sources improves eggshell quality in aged laying hens. Poult. Sci. 2003, 82, 1903–1913. [Google Scholar] [CrossRef] [PubMed]

- Herkeľ, R.; Gálik, B.; Bíro, D.; Rolinec, M.; Šimko, M.; Juráček, M.; Arpášová, H.; Hanušovský, O. The effect of essential oils on quality and mineral composition of eggshell. Acta Fytotech. Zootech. 2017, 20, 36–40. [Google Scholar] [CrossRef]

- Pavlović, Z.; Miletić, I.; Jokić, Ž.; Pavlovski, Z.; Škrbić, Z.; Šobajić, S. The effect of level and source of dietary selenium supplementation on eggshell quality. Biol. Trace Elem. Res. 2010, 133, 197–202. [Google Scholar] [CrossRef] [PubMed]

- Świątkiewicz, S.; Arczewska-Włosek, A.; Krawczyk, J.; Puchała, M.; Jozefiak, D. Dietary factors improving eggshell quality: An updated review with special emphasis on microelements and feed additives. Worlds Poult. Sci. J. 2015, 71, 83–94. [Google Scholar] [CrossRef]

- Rayan, G.N.; Galal, A.; Fathi, M.M.; El-Attar, A.H. Impact of layer breeder flock age and strain on mechanical and ultrastructural properties of eggshell in chicken. Int. J. Poult. Sci. 2010, 9, 139–147. [Google Scholar] [CrossRef]

- Brand-Williams, W.; Cuvelier, M.-E.; Berset, C. Use of a free radical method to evaluate antioxidant activity. LWT-Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Russo, R.; Reggiani, R. Antioxidants in flour of the oilseed crop Camelina sativa (L.) Crantz. Int. J. Plant Biol. 2018, 9. [Google Scholar] [CrossRef]

- Gimeno, E.; Calero, E.; Castellote, A.I.; Lamuela-Raventos, R.M.; De la Torre, M.C.; Lopez-Sabater, M.C. Simultaneous determination of α-tocopherol and β-carotene in olive oil by reversed-phase high-performance liquid chromatography. J. Chromatogr. A 2000, 881, 255–259. [Google Scholar] [CrossRef]

- O’fallon, J.V.; Busboom, J.R.; Nelson, M.L.; Gaskins, C.T. A direct method for fatty acid methyl ester synthesis: Application to wet meat tissues, oils, and feedstuffs. J. Anim. Sci. 2007, 85, 1511–1521. [Google Scholar] [CrossRef] [PubMed]

- Placha, I.; Ocelova, V.; Chizzola, R.; Battelli, G.; Gai, F.; Bacova, K.; Faix, S. Effect of thymol on the broiler chicken antioxidative defence system after sustained dietary thyme oil application. Br. Poult. Sci. 2019, 60, 589–596. [Google Scholar] [CrossRef]

- Russo, R.; Reggiani, R. Glucosinolates and Sinapine in camelina meal. Proc. Food Nutr. Sci. 2017, 8, 1063–1073. [Google Scholar] [CrossRef]

- Bjerg, B.; Olsen, O.; Rasmussen, K.W.; Srensen, H. New principles of ion-exchange techniques suitable to sample preparation and group separation of natural products prior to liquid chromatography. J. Liq. Chromatogr. 1984, 7, 691–707. [Google Scholar] [CrossRef]

- Clausen, S.; Larsen, L.M.; Plöger, A.; Soerensen, H. Aromatic choline esters in rapeseed. World Crop. Prod. Util. Descr. 1985, 11, 61–72. [Google Scholar]

- Battelli, G.; Scano, P.; Albano, C.; Cagliani, L.R.; Brasca, M.; Consonni, R. Modifications of the volatile and nonvolatile metabolome of goat cheese due to adjunct of non-starter lactic acid bacteria. LWT 2019, 116, 108576. [Google Scholar] [CrossRef]

- Quality, W. Welfare Quality® Assessment Protocol for Cattle; Welfare Quality: Lelystad, The Netherlands, 2009; Volume 180. [Google Scholar]

- Nedomova, S.; Severa, L.; Buchar, J. Influence of hen egg shape on eggshell compressive strength. Int. Agrophys. 2009, 23, 249–256. [Google Scholar]

- Narushin, V.G. Egg geometry calculation using the measurements of length and breadth. Poult. Sci. 2005, 84, 482–484. [Google Scholar] [CrossRef]

- Corportation, I.B.M. IBM SPSS Statistics for Windows (Version 25.0 Armonk); IBM Corp.: Armonk, NY, USA, 2017. [Google Scholar]

- Acamovic, T.; Gilbert, C.; Lamb, K.; Walker, K.C. NUTRITION Nutritive value of Camelina sativa meal for poultry. Br. Poult. Sci. 1999, 40, 27. [Google Scholar] [CrossRef]

- Tripathi, M.K.; Mishra, A.S. Glucosinolates in animal nutrition: A review. Anim. Feed Sci. Technol. 2007, 132, 1–27. [Google Scholar] [CrossRef]

- Matthäs, B. Antinutritive compounds in different oilseeds. Lipid/Fett 1997, 99, 170–174. [Google Scholar] [CrossRef]

- Chin, H.-W.; Lindsay, R.C. Mechanisms of formation of volatile sulfur compounds following the action of cysteine sulfoxide lyases. J. Agric. Food Chem. 1994, 42, 1529–1536. [Google Scholar] [CrossRef]

- Kakani, R.; Fowler, J.; Haq, A.-U.; Murphy, E.J.; Rosenberger, T.A.; Berhow, M.; Bailey, C.A. Camelina meal increases egg n-3 fatty acid content without altering quality or production in laying hens. Lipids 2012, 47, 519–526. [Google Scholar] [CrossRef] [PubMed]

- Geng, A.L.; Liu, H.G.; Zhang, Y.; Zhang, J.; Wang, H.H.; Chu, Q.; Yan, Z.X. Effects of indoor stocking density on performance, egg quality, and welfare status of a native chicken during 22 to 38 weeks. Poult. Sci. 2020, 99, 163–171. [Google Scholar] [CrossRef] [PubMed]

- Frame, D.D.; Palmer, M.; Peterson, B. Use of Camelina sativa in the diets of young turkeys. J. Appl. Poult. Res. 2007, 16, 381–386. [Google Scholar] [CrossRef]

- Pescatore, T.; Jacob, J. Kentucky 4-H Poultry: Evaluating Egg-Laying Hens. 2012. Available online: http://www2.ca.uky.edu/agcomm/pubs/4aj/4aj07po/4aj07po.PDF (accessed on 11 August 2020).

- Iqbal, Z.; Drake, K.; Swick, R.A.; Taylor, P.S.; Perez-Maldonado, R.A.; Ruhnke, I. Effect of pecking stones and age on feather cover, hen mortality, and performance in free-range laying hens. Poult. Sci. 2020, 99, 2307–2314. [Google Scholar] [CrossRef]

- Altuntaş, E.; Şekeroğlu, A. Effect of egg shape index on mechanical properties of chicken eggs. J. Food Eng. 2008, 85, 606–612. [Google Scholar] [CrossRef]

- Anderson, K.E.; Tharrington, J.B.; Curtis, P.A.; Jones, F.T. Shell characteristics of eggs from historic strains of single comb white leghorn chickens and the relationship of egg shape to shell strength. Int. J. Poult. Sci. 2004, 3, 17–19. [Google Scholar] [CrossRef]

- Sirri, F.; Zampiga, M.; Berardinelli, A.; Meluzzi, A. Variability and interaction of some egg physical and eggshell quality attributes during the entire laying hen cycle. Poult. Sci. 2018, 97, 1818–1823. [Google Scholar] [CrossRef]

- Vasilachi, A.; Criste, R.D.; Cornescu, M.G.; Olteanu, M.; Panaite, T.D.; Sredanović, S.A.; Spasevski, N. Effect of the dietary camelina meal on layer performance. In Proceedings of the 6th Central European Congress on Food-CEFood Congress; Institute of Food Technology, Novi Sad, Serbia, 23–26 May 2012. [Google Scholar]

- Aziza, A.E.; Panda, A.K.; Quezada, N.; Cherian, G. Nutrient digestibility, egg quality, and fatty acid composition of brown laying hens fed camelina or flaxseed meal. J. Appl. Poult. Res. 2013, 22, 832–841. [Google Scholar] [CrossRef]

- Cherian, G.; Quezada, N. Egg quality, fatty acid composition and immunoglobulin Y content in eggs from laying hens fed full fat camelina or flax seed. J. Anim. Sci. Biotechnol. 2016, 7, 15. [Google Scholar] [CrossRef] [PubMed]

- Quezada, N.; Cherian, G. Lipid characterization and antioxidant status of the seeds and meals of Camelina sativa and flax. Eur. J. lipid Sci. Technol. 2012, 114, 974–982. [Google Scholar] [CrossRef]

- Al-Harthi, M.A. The effect of natural and synthetic antioxidants on performance, egg quality and blood constituents of laying hens grown under high ambient temperature. Ital. J. Anim. Sci. 2014, 13, 3239. [Google Scholar] [CrossRef]

- Ni, Y.; Zhu, Q.; Zhou, Z.; Grossmann, R.; Chen, J.; Zhao, R. Effect of dietary daidzein on egg production, shell quality, and gene expression of ER-α, GH-R, and IGF-IR in shell glands of laying hens. J. Agric. Food Chem. 2007, 55, 6997–7001. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Li, Y.; Liu, H.-N.; Suo, Y.-L.; Hu, L.-L.; Feng, X.-A.; Zhang, L.; Jin, F. Effect of quercetin on performance and egg quality during the late laying period of hens. Br. Poult. Sci. 2013, 54, 510–514. [Google Scholar] [CrossRef]

| Parameter | Amount | Parameter | Amount |

|---|---|---|---|

| Gross Energy, MJ/kg | 17.88 | Antioxidant activity and compounds | |

| Proximate analysis * | DPPH radical scavenging activity, % | 76.5 | |

| Crude protein, % | 37.17 | Total phenolic content (TPC), mgCAE **/g | 22.7 |

| Crude fat, % | 19.17 | Flavonoids, g/kg | 4.83 |

| Crude fiber, % | 10.72 | Tannins, g/kg | 6.40 |

| Ash, % | 6.80 | Tocopherols, mg/kg | 687 |

| Neutral-detergent fiber (NDF), % | 35.63 | Antinutritional compounds | |

| Fatty acid composition | Glucosinolates, mmol/kg | 15.5 | |

| saturated fatty acids (SFA), g/kg | 16.1 | Sinapine, g/kg | 2.26 |

| monounsaturated fatty acids (MUFA), g/kg | 44.4 | ||

| n-6 polyunsaturated fatty acids (PUFA), g/kg | 34.1 | ||

| n-3 PUFA, g/kg | 63.6 | ||

| n-6/n-3 | 0.54 |

| Control (C) | Camelina 10% (CAM10) | Camelina 20% (CAM20) | |

|---|---|---|---|

| Ingredients, g/kg | |||

| Corn | 537.5 | 524.0 | 508.5 |

| Soybean meal | 320 | 247 | 174 |

| Calcium carbonate | 95 | 95 | 95 |

| Camelina cake | 0 | 100 | 200 |

| Soybean oil | 25 | 11.5 | 0 |

| Dicalcium phosphate | 12 | 12 | 12 |

| Vitamin premix * | 5 | 5 | 5 |

| Salt | 4 | 4 | 4 |

| Methionine | 1.5 | 1.5 | 1.5 |

| Metabolizable Energy, MJ/kg | |||

| 11.05 | 10.88 | 10.77 | |

| Analytic Composition % | |||

| Crude Protein | 18.08 | 18.32 | 18.54 |

| Crude Fat | 5.30 | 5.51 | 5.90 |

| Crude Fiber | 3.17 | 3.69 | 4.20 |

| Ash | 14.12 | 14.26 | 14.40 |

| L-Lysine | 0.90 | 0.96 | 1.02 |

| Methionine | 0.43 | 0.45 | 0.46 |

| Methionine + Cysteine | 0.75 | 0.66 | 0.56 |

| L-Threonine | 0.71 | 0.75 | 0.79 |

| Ca | 4.15 | 4.15 | 4.16 |

| P | 0.56 | 0.57 | 0.58 |

| Available P | 0.35 | 0.33 | 0.32 |

| Na | 0.17 | 0.16 | 0.16 |

| Cl | 0.22 | 0.22 | 0.22 |

| Experimental Diets | |||

|---|---|---|---|

| Parameter | Control (C) | CAM10 | CAM20 |

| DPPH, % | 28.2 ± 0.30 | 70.2 ± 0.20 | 74.6 ± 0.10 |

| TPC, mgCAE/g | 8.5 ± 0.10 | 10.9 ± 0.10 | 12.3 ± 0.20 |

| Flavonoids, g/kg | 2.24 ± 0.03 | 4.44 ± 0.06 | 7.92 ± 0.10 |

| Tannins, g/kg | 3.38 ± 0.05 | 4.18 ± 0.04 | 4.52 ± 0.05 |

| Tocopherols, mg/kg | 321 ± 20 | 464 ± 12 | 537 ± 10 |

| SFA, g/kg | 5.6 ± 0.20 | 7.3 ± 0.05 | 8.0 ± 0.08 |

| MUFA, g/kg | 7.5 ± 0.26 | 11.6 ± 0.00 | 12.0 ± 0.04 |

| n-6 PUFA, g/kg | 15.2 ± 0.62 | 21.9 ± 0.27 | 22.5 ± 0.05 |

| n-3 PUFA, g/kg | 1.0 ± 0.04 | 8.7 ± 0.22 | 14.3 ± 0.02 |

| n-6/n-3 | 15.83 | 2.53 | 1.57 |

| Glucosinolates, mmol/kg | 0 | 1.66 ± 0.08 | 3.37 ± 0.02 |

| Sinapine, g/kg | 0 | 0.12 ± 0.01 | 0.46 ± 0.01 |

| Performance | C | CAM10 | CAM20 |

|---|---|---|---|

| Average Daily Intake (g/day/hen) | 128.57 ± 4.94 | 122.35 ± 5.03 | 114.04 ± 6.12 |

| Egg production/week | 464.16 ± 14.70 | 499.00 ± 13.40 | 473.94 ± 11.00 |

| Egg weight (g) | 62.64 ± 4.26 | 62.16 ± 3.77 | 61.79 ± 3.72 |

| FCR | 2.44 ± 0.10 | 2.19 ± 0.12 | 2.22 ± 0.11 |

| Initial hen’s weight (g) | 1872.5 ± 30.9 | 1765.0 ± 34.6 | 1782.5 ± 35.4 |

| Final hen’s weight (g) | 2060.0 ± 40.5 | 2065.0 ± 35.2 | 2000.0±46.7 |

| Body Part | Week | C | CAM10 | CAM20 |

|---|---|---|---|---|

| Head-Neck | 23 | 4.0 | 4.0 | 4.0 |

| 39 | 4.0 | 4.0 | 3.6 | |

| 51 | 3.7 | 3.6 | 3.9 | |

| Back | 23 | 4.0 | 4.0 | 4.0 |

| 39 | 4.0 | 4.0 | 3.6 | |

| 51 | 3.7 | 3.6 | 3.9 | |

| Tail | 23 | 4.0 | 4.0 | 4.0 |

| 39 | 4.0 | 4.0 | 4.0 | |

| 51 | 4.0 | 3.9 | 4.0 | |

| Wings | 23 | 4.0 | 4.0 | 4.0 |

| 39 | 4.0 | 4.0 | 4.0 | |

| 51 | 4.0 | 3.6 | 4.0 | |

| Vent-cloaca | 23 | 4.0 | 4.0 | 4.0 |

| 39 | 4.0 | 4.0 | 4.0 | |

| 51 | 4.0 | 4.0 | 4.0 |

| Factors | Response Variables | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| D 1 | H 2 (w) | Fmax 3 (N) | % Def 4 | Ea 5 (N × mm) | % Shell 6 | T 7 (mm) | |||||

| C | 47.6 | 0.65 | 9 | 10.1 | 0.37 | a,b | |||||

| CAM10 | 48.4 | 0.68 | 9 | 10.2 | 0.38 | a | |||||

| CAM20 | 47.6 | 0.68 | 9 | 9.9 | 0.36 | b | |||||

| 24 | 50.5 | 0.74 | 10 | 10.3 | a | 0.37 | |||||

| 43 | 45.2 | 0.60 | 8 | 9.8 | b | 0.37 | |||||

| C | 24 | 53.2 | a | 0.75 | a | 11 | a | 10.5 | 0.38 | ||

| 43 | 42.3 | b | 0.55 | c | 7 | c | 9.7 | 0.36 | |||

| CAM10 | 24 | 50.6 | a | 0.73 | a,b | 10 | a,b | 10.4 | 0.37 | ||

| 43 | 46.3 | a,b | 0.62 | b,c | 8 | b,c | 10.0 | 0.38 | |||

| CAM20 | 24 | 48.2 | a,b | 0.73 | a,b | 9 | a,b | 10.1 | 0.36 | ||

| 43 | 46.9 | a,b | 0.62 | b,c | 8 | b,c | 9.7 | 0.37 | |||

| Pooled SEM | 2.235 | 0.006 | 0.252 | 0.222 | 0.0003 | ||||||

| ANOVA | p | ||||||||||

| H | <0.001 | <0.001 | <0.001 | <0.001 | 0.931 | ||||||

| D | 0.875 | 0.408 | 0.845 | 0.118 | 0.043 | ||||||

| H × D | 0.033 | 0.048 | 0.026 | 0.320 | 0.093 | ||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lolli, S.; Grilli, G.; Ferrari, L.; Battelli, G.; Pozzo, S.; Galasso, I.; Russo, R.; Brasca, M.; Reggiani, R.; Ferrante, V. Effect of Different Percentage of Camelina sativa Cake in Laying Hens Diet: Performance, Welfare, and Eggshell Quality. Animals 2020, 10, 1396. https://doi.org/10.3390/ani10081396

Lolli S, Grilli G, Ferrari L, Battelli G, Pozzo S, Galasso I, Russo R, Brasca M, Reggiani R, Ferrante V. Effect of Different Percentage of Camelina sativa Cake in Laying Hens Diet: Performance, Welfare, and Eggshell Quality. Animals. 2020; 10(8):1396. https://doi.org/10.3390/ani10081396

Chicago/Turabian StyleLolli, Susanna, Guido Grilli, Lorenzo Ferrari, Giovanna Battelli, Sara Pozzo, Incoronata Galasso, Roberto Russo, Milena Brasca, Remo Reggiani, and Valentina Ferrante. 2020. "Effect of Different Percentage of Camelina sativa Cake in Laying Hens Diet: Performance, Welfare, and Eggshell Quality" Animals 10, no. 8: 1396. https://doi.org/10.3390/ani10081396

APA StyleLolli, S., Grilli, G., Ferrari, L., Battelli, G., Pozzo, S., Galasso, I., Russo, R., Brasca, M., Reggiani, R., & Ferrante, V. (2020). Effect of Different Percentage of Camelina sativa Cake in Laying Hens Diet: Performance, Welfare, and Eggshell Quality. Animals, 10(8), 1396. https://doi.org/10.3390/ani10081396