Bird Health, Housing and Management Routines on Swedish Organic Broiler Chicken Farms

Abstract

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Farm Visits

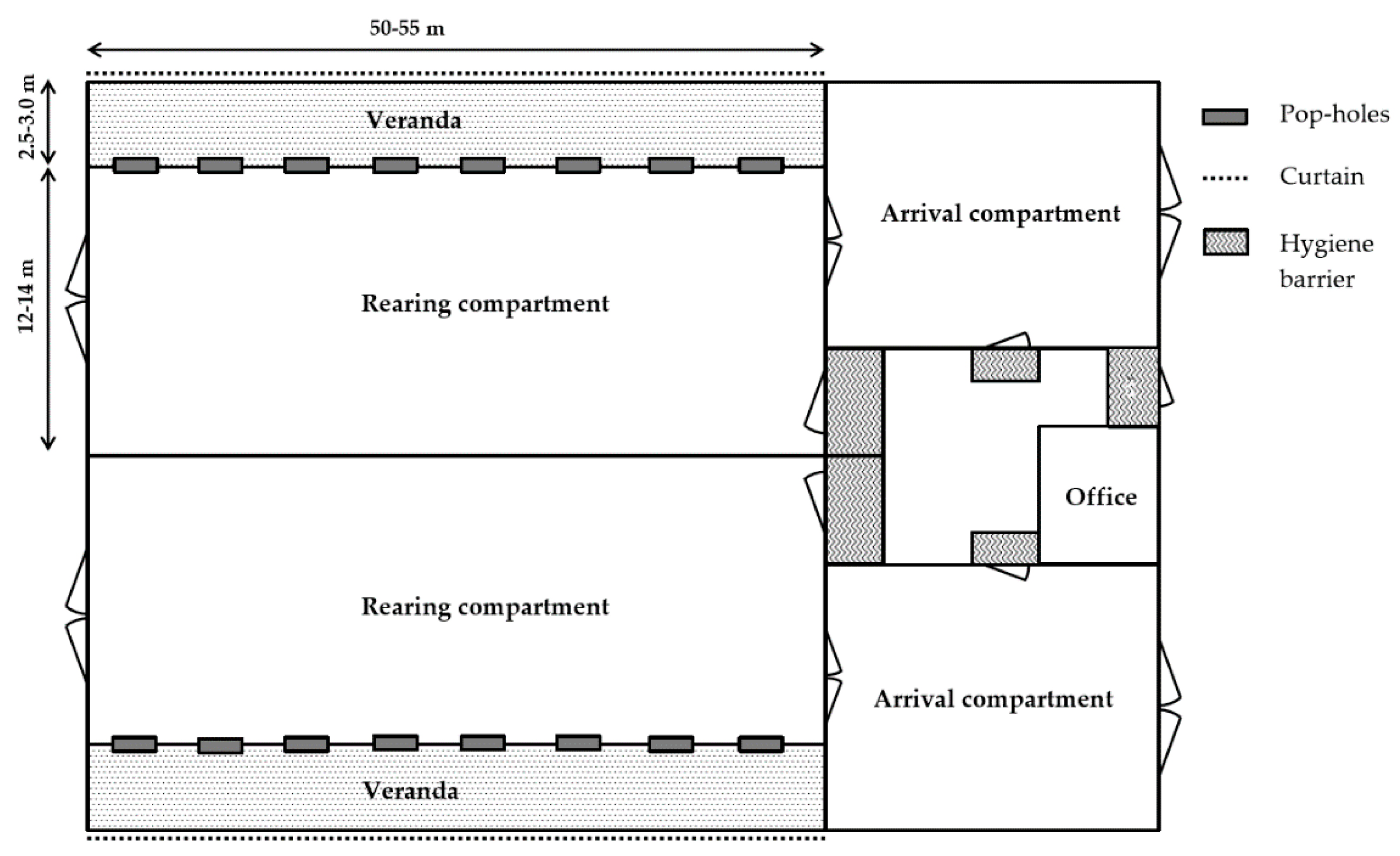

2.1.1. Housing and Indoor Environment

2.1.2. Gait Scoring and Clinical Examination

2.2. Statistical Analyses

3. Results

3.1. Animals and Farm Management

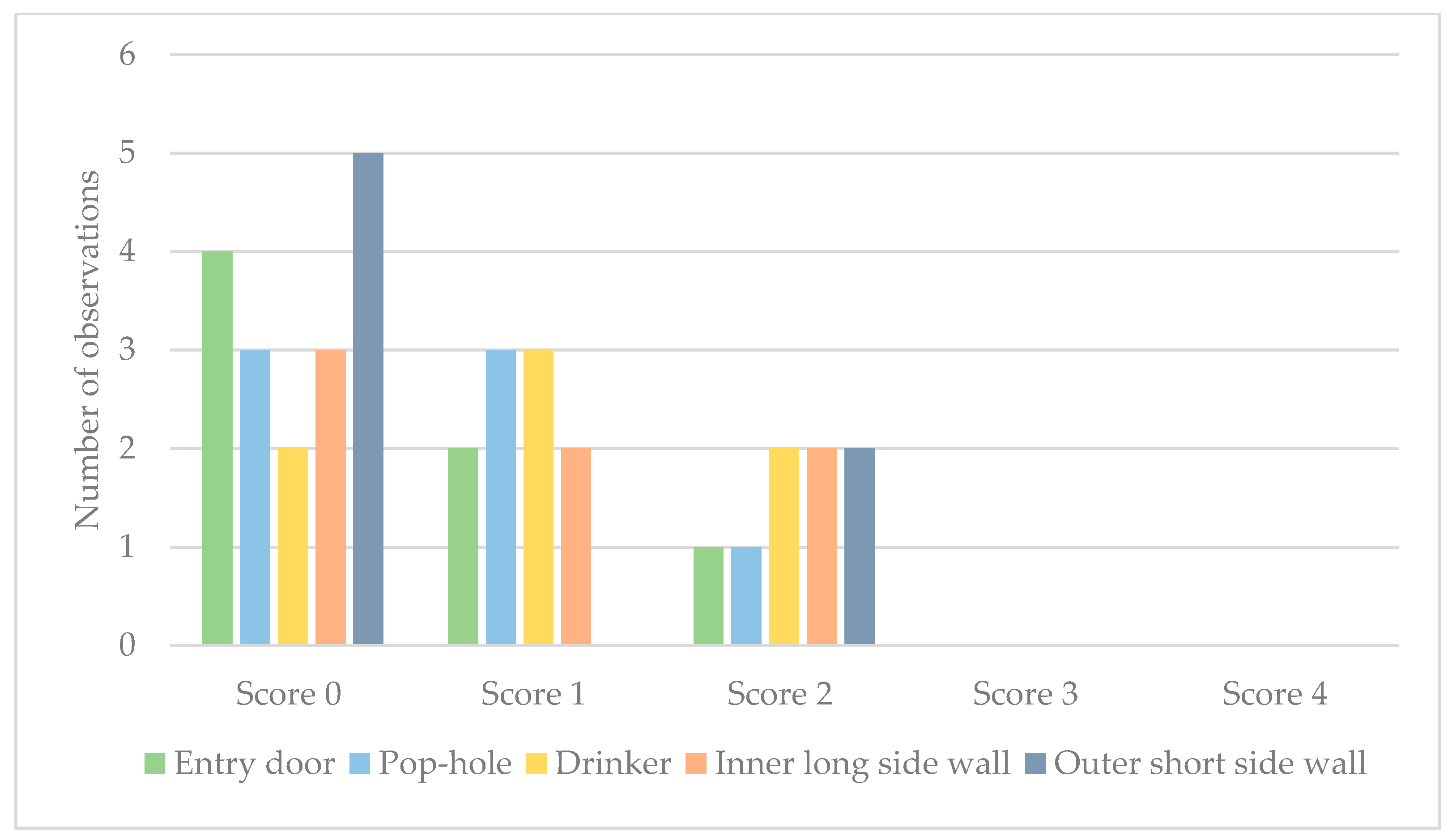

3.2. Housing

Indoor Environment

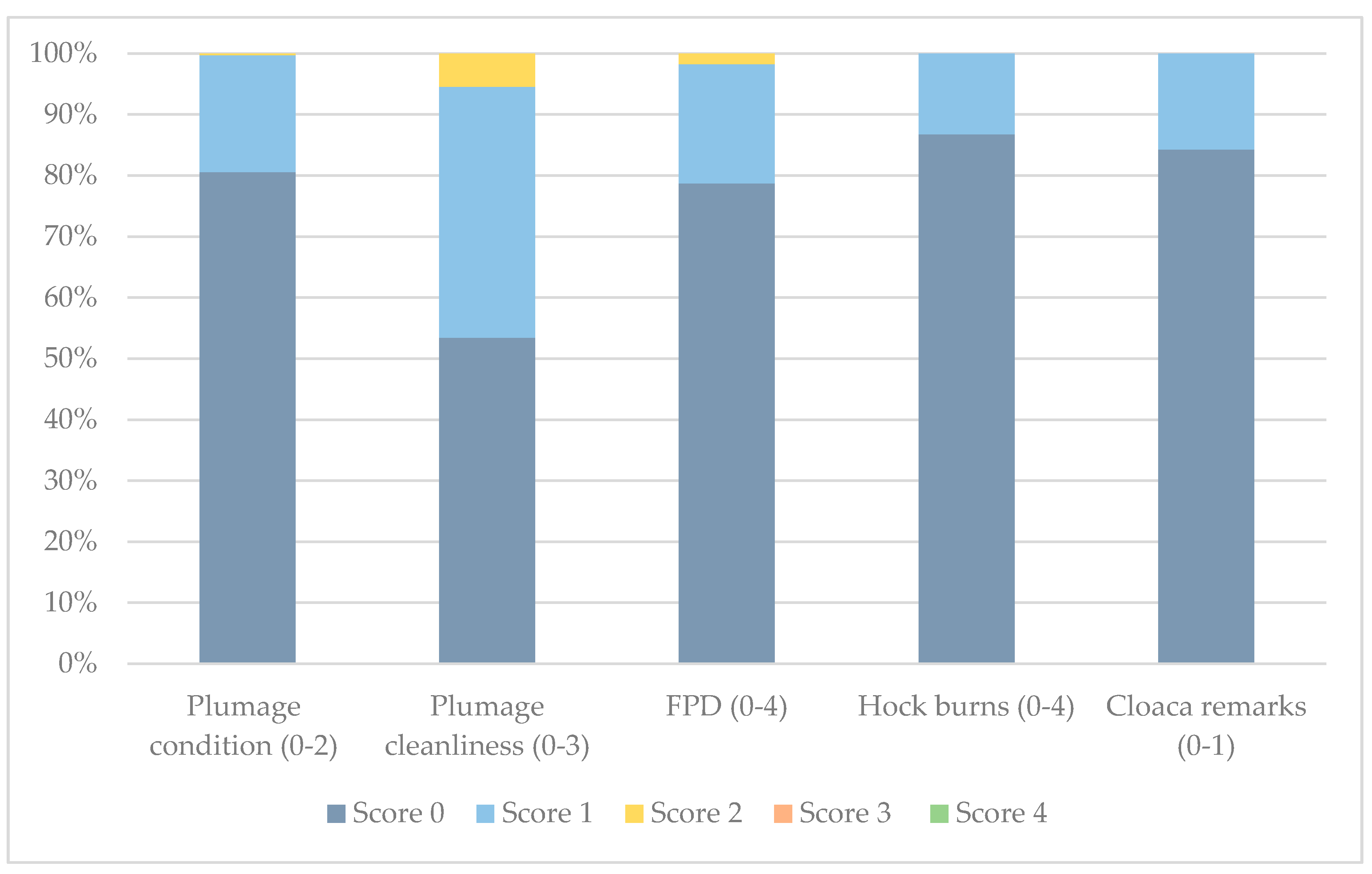

3.3. Health

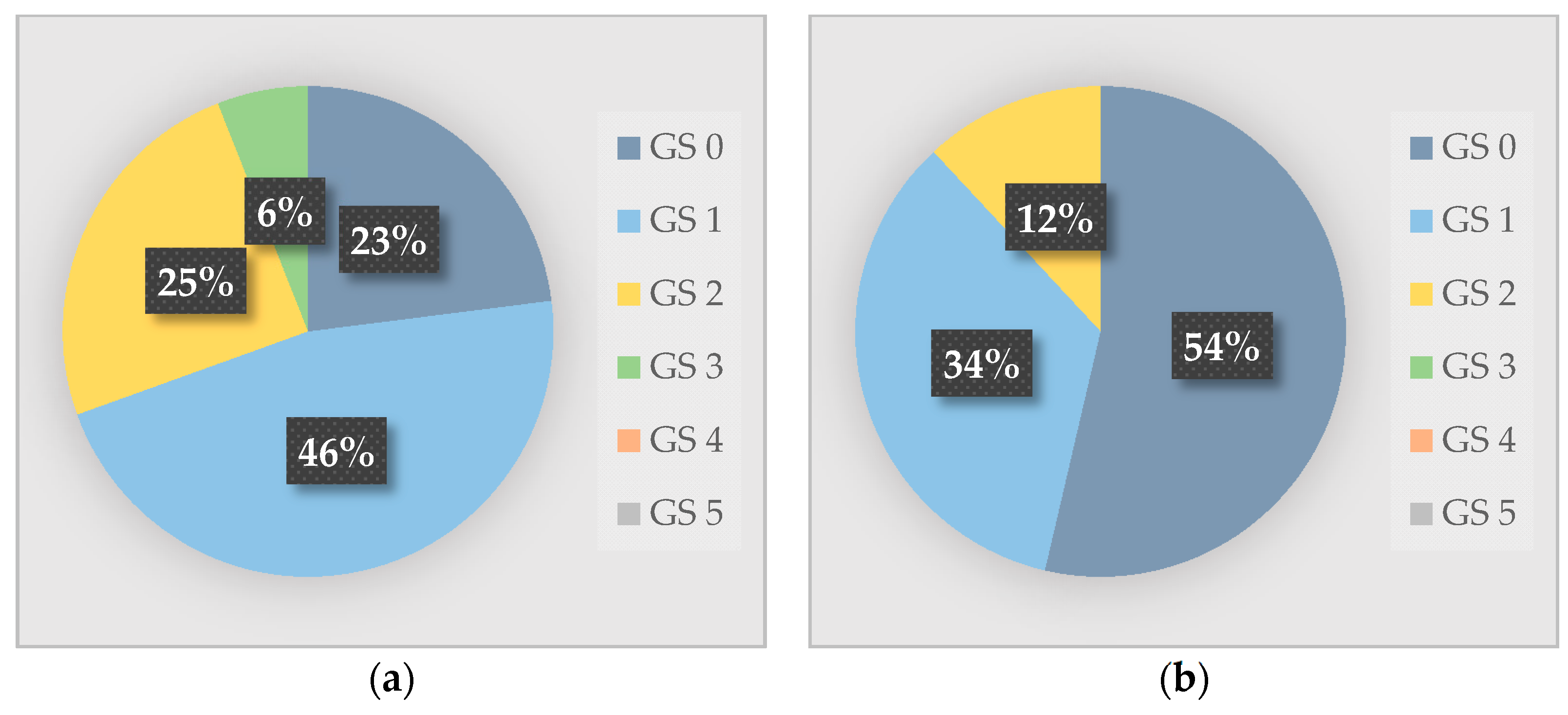

3.3.1. Foot and Leg Health

3.3.2. Integument

3.3.3. Gut Health

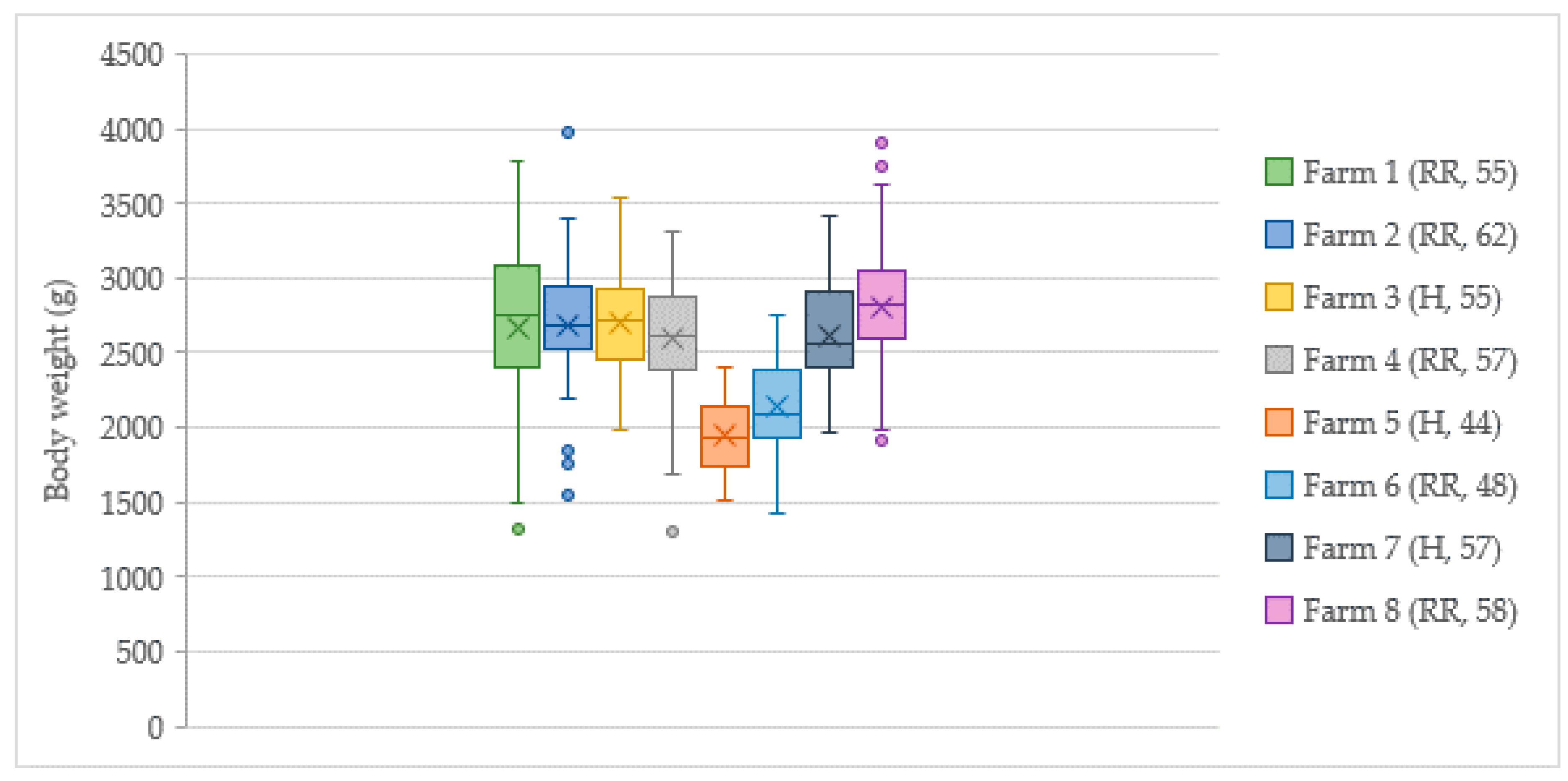

3.3.4. Body Weight

3.4. Production

4. Discussion

4.1. Housing and Indoor Environment

4.2. Farm Management

4.3. Health

4.3.1. Foot Pad Dermatitis and Hock Burns

4.3.2. Gait

4.3.3. Plumage

4.4. Production

4.4.1. Average Daily Weight Gain

4.4.2. Flock Body Weight Uniformity

4.4.3. Mortality

4.5. Limitations of the Study

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Questions | ||

|---|---|---|

| General information | Hybrid | Rowan Ranger □ |

| Hubbard □ | ||

| Other: | ||

| Organic production | Since year: | |

| Conventional before: □ Yes □ No | ||

| If yes, since year: | ||

| Buildings | New □ Rebuilt □ | |

| Maximum capacity (number of birds): | ||

| Same number of birds winter-/summertime: □ Yes □ No | ||

| Observed flock | Current age: | |

| Original number of birds: | ||

| Current number of birds: | ||

| Current average body weight: | ||

| Hatching and young chicks | Hatching | On-farm □ or day-old chicks □ |

| If on-farm hatching, brooding days: | ||

| Name of hatchery: | ||

| Distance transported: | ||

| Arrival rooms | □ Yes □ No | |

| If yes, age when moved to rearing room: | ||

| If yes, method for moving to rearing room: | ||

| Indoor environment | Temperature scheme (C°): | |

| Natural light: □ Yes □ No | ||

| Artificial light scheme (hours): | ||

| Medical treatments | Vaccinations: □ Yes □ No | |

| If yes, what: | ||

| Other medical treatments: □ Yes □ No | ||

| If yes, what: | ||

| Critical points | □ Yes □ No | |

| If yes, age(s) or phase(s): | ||

| Measures of prevention: | ||

| Housing (rearing compartment) | Indoor environment | Temperature (C°): |

| Natural (N) light: □ Yes □ No | ||

| Artificial (A) light type: | ||

| Night time (A) (hours): | ||

| Dusk and dawn simulated (A): □ Yes □ No | ||

| If yes, time/duration: | ||

| Litter type: | ||

| Underfloor heating: □ Yes □ No | ||

| Air quality | Ventilation type: | |

| Ammonia monitoring: | ||

| Ammonia regulation: | ||

| Environmental enrichment | Object(s): | |

| Amount/number: | ||

| Distribution: | ||

| Time of year provided: | ||

| Age of installation: | ||

| Roughage | Type(s): | |

| Supplier: | ||

| Amount: | ||

| Distribution: | ||

| Time of year provided: | ||

| Production | Mortality | This flock (%): |

| Average (%): | ||

| Main reasons: | ||

| Culling | Average number of birds: | |

| Main reasons: | ||

| Hatching | % of eggs discarded/not hatched: | |

| Slaughter | Thinning: □ Yes □ No | |

| Age(s): | ||

| Abattoir: | ||

| Distance transported: | ||

| Harvesting: Trained team □ Selves □ | ||

| Comments on harvesting: | ||

| Growth | Expected average slaughter weight: | |

| Average daily weight gain: | ||

| Feed conversion rate: | ||

| Feed specifics | Supplier: | |

| Starter (type and age period): | ||

| Rearing (type and age period): | ||

| Finisher: (type and age period): | ||

| Outdoor area | Free-range access (pop-holes/curtain open) | From age: |

| Hours per day: | ||

| Months per year: | ||

| Weather conditions: | ||

| Birds’ free-ranging behaviour | Age when first ranging: | |

| Weather conditions preferred by chickens: | ||

| Weather conditions disliked by chickens: | ||

| Average distance from house (m): | ||

| Maximum distance from house (m): | ||

| Predators | Problem: □ Yes □ No | |

| If yes, what species: | ||

| Measures of prevention: | ||

| Free-range characteristics | Area: | |

| Vegetation: Natural □ Planted □ |

References

- Fraser, D.; Weary, D.M.; Pajor, E.A.; Milligan, B.N. A Scientific Conception of Animal Welfare that Reflects Ethical Concerns. Anim. Welfare 1997, 6, 187–205. [Google Scholar]

- Tallentire, C.W.; Edwards, S.A.; Van Limbergen, T.; Kyriazakis, I. The challenge of incorporating animal welfare in a social life cycle assessment model of European chicken production. Int. J. Life Cycle Assess. 2019, 24, 1093–1104. [Google Scholar] [CrossRef]

- International Federation of Organic Movement (IFOAM)—Organics International. Available online: https://www.ifoam.bio/why-organic/principles-organic-agriculture/principle-fairness (accessed on 28 August 2020).

- Council Regulation (EC) No 834/2007 of 28 June 2007 on Organic Production and Labelling of Organic Products and Repealing Regulation (EEC) No 2092/91. OJ L 189, 20.7.2007. pp. 1–23. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32007R0834 (accessed on 11 November 2020).

- Commission Regulation (EC) No 889/2008 of 5 September 2008 Laying down Detailed Rules for the Implementation of Council Regulation (EC) No 834/2007 on Organic Production and Labelling of Organic Products with Regard to Organic Production, Labelling and Control. OJ L 250, 18.9.2008. pp. 1–84. Available online: https://eur-lex.europa.eu/eli/reg/2008/889/oj (accessed on 11 November 2020).

- Castellini, C.; Mugnai, C.; Moscati, L.; Mattioli, S.; Amato, M.G.; Mancinelli, A.C.; Dal Bosco, A. Adaptation to organic rearing system of eight different chicken genotypes: Behaviour, welfare and performance. Ital. J. Anim. Sci. 2016, 15, 37–46. [Google Scholar] [CrossRef]

- Wallenbeck, A.; Wilhelmsson, S.; Jönsson, L.; Gunnarsson, S.; Yngvesson, J. Behaviour in one fast-growing and one slower-growing broiler (Gallus gallus domesticus) hybrid fed a high- or low-protein diet during a 10-week rearing period. Acta Agric. Scand Sect. A Anim. Sci. 2016, 66, 168–176. [Google Scholar] [CrossRef]

- Yngvesson, J.; Wedin, M.; Gunnarsson, S.; Jönsson, L.; Blokhuis, H.; Wallenbeck, A. Let me sleep! Welfare of broilers (Gallus gallus domesticus) with disrupted resting behaviour. Acta Agric. Scand. Section A Anim. Sci. 2017, 67, 123–133. [Google Scholar] [CrossRef]

- Rowan Ranger, Aviagen SweChick AB, Åstorp, Sweden. Available online: http://eu.aviagen.com/brands/rowan-range/products/rowan-ranger (accessed on 11 November 2020).

- Hubbard, Hubbard SAS, Quintin, France. Available online: https://www.hubbardbreeders.com/ (accessed on 11 November 2020).

- The Swedish Board of Agriculture. Statistiska Meddelanden: Ekologisk Animalieproduktion 2018 [Statistical Report: Organic Animal Production 2018]; The Swedish Board of Agriculture: Jönköping, Sweden, 2019; Volume JO 27 SM 1901. [Google Scholar]

- Holstensson, K. Individual Variation in Live Weight of Slow-Growing Broiler Chickens—Effects on the Classification. BSc Thesis, Swedish University of Agricultural Sciences, Alnarp, Sweden, 2016. [Google Scholar]

- Bestman, M.; Bikker-Ouwejan, J. Predation in organic and free-range egg production. Animals 2020, 10, 177. [Google Scholar] [CrossRef]

- Sossidou, E.N.; Dal Bosco, A.; Castellini, C.; Grashorn, M.A. Effects of pasture management on poultry welfare and meat quality in organic poultry production systems. Worlds Poult. Sci. J. 2015, 71, 375–384. [Google Scholar] [CrossRef]

- Stadig, L.M.; Rodenburg, T.B.; Ampe, B.; Reubens, B.; Tuyttens, F.A.M. Effect of free-range access, shelter type and weather conditions on free-range use and welfare of slow-growing broiler chickens. Appl. Anim. Behav. Sci. 2017, 192, 15–23. [Google Scholar] [CrossRef]

- Dawkins, M.S.; Cook, P.A.; Whittingham, M.J.; Mansell, K.A.; Harper, A.E. What makes flee-range broiler chickens range? In situ measurement of habitat preference. Anim. Behav. 2003, 66, 151–160. [Google Scholar] [CrossRef]

- Rodriguez-Aurrekoetxea, A.; Leone, E.H.; Estevez, I. Effects of panels and perches on the behaviour of commercial slow-growing free-range meat chickens. Appl. Anim. Behav. Sci. 2015, 165, 103–111. [Google Scholar] [CrossRef]

- Fanatico, A.C.; Mench, J.A.; Archer, G.S.; Liang, Y.; Gunsaulis, V.B.B.; Owens, C.M.; Donoghue, A.M. Effect of outdoor structural enrichments on the performance, use of range area, and behavior of organic meat chickens. Poult. Sci. 2016, 95, 1980–1988. [Google Scholar] [CrossRef] [PubMed]

- Dal Bosco, A.; Mugnai, C.; Rosati, A.; Paoletti, A.; Caporali, S.; Castellini, C. Effect of range enrichment on performance, behavior, and forage intake of free-range chickens. J. Appl. Poultry Res. 2014, 23, 137–145. [Google Scholar] [CrossRef]

- SJVFS 2019:9. Case no L 150. Statens Jordbruksverks Föreskrifter och Allmänna råd om Försöksdjur [The Swedish Board of Agriculture’s Regulations on Research Animals]; The Swedish Board of Agriculture: Jönköping, Sweden, 2019.

- Welfare Quality®. Welfare Quality® Assessment Protocol For Poultry (Broilers, Laying Hens); Welfare Quality® Consortium: Lelystad, The Netherlands, 2009. [Google Scholar]

- Kjaer, J.; Maria Levrino, G.; Cepero, R. Applied Scoring of Integument and Health in Laying Hens. Anim. Sci. Pap. Rep. 2006, 23, 153–159. [Google Scholar]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2020. [Google Scholar]

- Toudic, C. Evaluating Uniformity in Broilers-Factors Affecting Variation, 2007. Available online: https://thepoultrysite.com/articles/evaluating-uniformity-in-broilers-factors-affecting-variation (accessed on 28 August 2020).

- KRAV. Swedish Private Organic Incorporated Association (Registered Trademark), Uppsala, Sweden. Available online: https://www.krav.se/en/ (accessed on 11 November 2020).

- KRAV. Regler för KRAV-Certifierad Produktion Utgåva 2019-20, Version 2 [Standards for KRAV-Certified Production 2019-20 Edition, 2nd Version]. Available online: https://www.krav.se/en/standards/download-krav-standards/ (accessed on 28 August 2020).

- Quintana, P.F.; Swedish Private Organic Incorporated Association (KRAV), Uppsala, Sweden. Personal communication, 9 November 2020.

- Big Dutchman AG, Vechta, Germany. Available online: https://www.bigdutchman.com/en/poultry-growing/products/broiler-production/ (accessed on 11 November 2020).

- McIlroy, S.G.; Goodall, E.A.; McMurray, C.H. A contact dermatitis of broilers -epidemiological findings. Avian Pathol. 1987, 16, 93–105. [Google Scholar] [CrossRef] [PubMed]

- Meluzzi, A.; Claudio, F.; Folegatti, E.; Sirri, F. Survey of chicken rearing conditions in Italy: Effects of litter quality and stocking density on productivity, foot dermatitis and carcase injuries. Br. Poult. Sci. 2008, 49, 257–264. [Google Scholar] [CrossRef]

- Haslam, S.M.; Knowles, T.G.; Brown, S.N.; Wilkins, L.J.; Kestin, S.C.; Warriss, P.D.; Nicol, C.J. Factors affecting the prevalence of foot pad dermatitis, hock burn and breast burn in broiler chicken. Br. Poult. Sci. 2007, 48, 264–275. [Google Scholar] [CrossRef]

- Weaver, W.D.; Meijerhof, R. The Effect of Different Levels of Relative Humidity and Air Movement on Litter Conditions, Ammonia Levels, Growth, and Carcass Quality for Broiler Chickens. Poult. Sci. 1991, 70, 746–755. [Google Scholar] [CrossRef]

- Martland, M.F. Wet litter as a cause of plantar pododermatitis, leading to foot ulceration and lameness in fattening turkeys. Avian Pathol. 1984, 13, 241–252. [Google Scholar] [CrossRef]

- Jong, I.; Gunnink, H.; Harn, J. Wet litter not only induces footpad dermatitis but also reduces overall welfare, technical performance, and carcass yield in broiler chickens. J. Appl. Poult. Res. 2014, 23, 51–58. [Google Scholar] [CrossRef]

- Hubbard Conventional Broiler Management Manual-Fast Growth. 2016. Available online: https://www.hubbardbreeders.com/documentation/recherchedocumentheque.html (accessed on 28 August 2020).

- ROSS Broiler Management Handbook. 2018. Available online: http://eu.aviagen.com/tech-center/ (accessed on 28 August 2020).

- EFSA Panel on Animal Health and Welfare (AHAW). Scientific Opinion on the use of animal-based measures to assess welfare of broilers. Efsa J. 2012, 10. [Google Scholar] [CrossRef]

- Butterworth, A.; De Jong, I.C.; Keppler, C.; Knierim, U.; Stadig, L.; Lambton, S. What is being measured, and by whom? Facilitation of communication on technical measures amongst competent authorities in the implementation of the European Union Broiler Directive (2007/43/EC). Anim. Int. J. Anim. Biosci. 2015, 10, 302–308. [Google Scholar] [CrossRef] [PubMed]

- Lund, V.P.; Nielsen, L.R.; Oliveira, A.R.S.; Christensen, J.P. Evaluation of the Danish footpad lesion surveillance in conventional and organic broilers: Misclassification of scoring. Poult. Sci. 2017, 96, 2018–2028. [Google Scholar] [CrossRef] [PubMed]

- Gouveia, K.G.; Vaz-Pires, P.; Martins da Costa, P. Welfare assessment of broilers through examination of haematomas, foot-pad dermatitis, scratches and breast blisters at processing. Anim. Welfare 2009, 18, 43–48. [Google Scholar]

- Pagazaurtundua, A.; Warriss, P.D. Levels of foot pad dermatitis in broiler chickens reared in 5 different systems. Br. Poult. Sci. 2006, 47, 529–532. [Google Scholar] [CrossRef] [PubMed]

- Louton, H.; Keppler, C.; Erhard, M.; van Tuijl, O.; Bachmeier, J.; Damme, K.; Reese, S.; Rauch, E. Animal-based welfare indicators of 4 slow-growing broiler genotypes for the approval in an animal welfare label program. Poult. Sci. 2019, 98, 2326–2337. [Google Scholar] [CrossRef] [PubMed]

- Rauch, E.; Keppler, C.; Damme, K.; Hausleitner, M.; Bachmeier, J.; Hartmann, J.; Louton, H. Test of different premium broiler genotypes under animal welfare label conditions. part II: Animal health. Eur. Poult. Sci. 2017, 81. [Google Scholar] [CrossRef]

- Wilhelmsson, S.; Yngvesson, J.; Jönsson, L.; Gunnarsson, S.; Wallenbeck, A. Welfare Quality® assessment of a fast-growing and a slower-growing broiler hybrid, reared until 10 weeks and fed a low-protein, high-protein or mussel-meal diet. Livest. Sci. 2019, 219, 71–79. [Google Scholar] [CrossRef]

- Mayne, R.K. A review of the aetiology and possible causative factors of foot pad dermatitis in growing turkeys and broilers. Worlds Poult. Sci. J. 2005, 61, 256–267. [Google Scholar] [CrossRef]

- Taira, K.; Nagai, T.; Obi, T.; Takase, K. Effect of litter moisture on the development of footpad dermatitis in broiler chickens. J. Vet. Med. Sci. 2014, 76, 583–586. [Google Scholar] [CrossRef]

- Sarica, M.; Yamak, U.; Boz, M. Effect of production systems on foot pad dermatitis (FPD) levels among slow-, medium- and fast-growing broilers. Arch. Geflugelkd. 2014, 78. [Google Scholar] [CrossRef]

- Taylor, P.S.; Hemsworth, P.H.; Groves, P.J.; Gebhardt-Henrich, S.G.; Rault, J.L. Frequent range visits further from the shed relate positively to free-range broiler chicken welfare. Anim. Int. J. Anim. Biosci. 2020, 14, 138–149. [Google Scholar] [CrossRef] [PubMed]

- Kjaer, J.B.; Su, G.; Nielsen, B.L.; Sørensen, P. Foot pad dermatitis and hock burn in broiler chickens and degree of inheritance. Poult. Sci. 2006, 85, 1342–1348. [Google Scholar] [CrossRef] [PubMed]

- Keppler, C.; Hoerning, B.; Knierim, U. Influence of daily weight gain and body weight on animal welfare of slow growing broiler strains under organic conditions. In Proceedings of the XIII European Poultry Conference, Tours, France, 23–27 October 2010. [Google Scholar]

- Ask, B. Genetic variation of contact dermatitis in broilers. Poult. Sci. 2010, 89, 866–875. [Google Scholar] [CrossRef] [PubMed]

- Kapell, D.N.R.G.; Hill, W.G.; Neeteson, A.M.; McAdam, J.; Koerhuis, A.N.M.; Avendaño, S. Genetic parameters of foot-pad dermatitis and body weight in purebred broiler lines in 2 contrasting environments. Poult. Sci. 2012, 91, 565–574. [Google Scholar] [CrossRef] [PubMed]

- Ferrante, V.; Mugnai, C.; Ferrari, L.; Marelli, S.P.; Spagnoli, E.; Lolli, S. Stress and reactivity in three Italian chicken breeds. Ital. J. Anim. Sci. 2016, 15, 303–309. [Google Scholar] [CrossRef]

- Fanatico, A.C.; Pillai, P.B.; Hester, P.Y.; Falcone, C.; Mench, J.A.; Owens, C.M.; Emmert, J.L. Performance, livability, and carcass yield of slow- and fast-growing chicken genotypes fed low-nutrient or standard diets and raised indoors or with outdoor access. Poult. Sci. 2008, 87, 1012–1021. [Google Scholar] [CrossRef]

- Taylor, P.S.; Hemsworth, P.H.; Groves, P.J.; Gebhardt-Henrich, S.G.; Rault, J.L. Ranging behavior relates to welfare indicators pre- and post-range access in commercial free-range broilers. Poult. Sci. 2018, 97, 1861–1871. [Google Scholar] [CrossRef]

- Kestin, S.C.; Gordon, S.; Su, G.; Sørensen, P. Relationships in broiler chickens between lameness, liveweight, growth rate and age. Vet. Rec. 2001, 148, 195. [Google Scholar] [CrossRef]

- Dixon, L.M. Slow and steady wins the race: The behaviour and welfare of commercial faster growing broiler breeds compared to a commercial slower growing breed. PLoS ONE 2020, 15, e0231006. [Google Scholar] [CrossRef]

- Tahamtani, F.M.; Hinrichsen, L.K.; Riber, A.B. Welfare assessment of conventional and organic broilers in Denmark, with emphasis on leg health. Vet. Rec. 2018, 183, 192. [Google Scholar] [CrossRef]

- Caplen, G.; Colborne, G.R.; Hothersall, B.; Nicol, C.J.; Waterman-Pearson, A.E.; Weeks, C.A.; Murrell, J.C. Lame broiler chickens respond to non-steroidal anti-inflammatory drugs with objective changes in gait function: A controlled clinical trial. Veter. J. 2013, 196, 477–482. [Google Scholar] [CrossRef] [PubMed]

- Danbury, T.C.; Weeks, C.A.; Chambers, J.P.; Waterman-Pearson, A.E.; Kestin, S.C. Self-selection of the analgesic drug carprofen by lame broiler chickens. Vet. Rec. 2000, 146, 307–311. [Google Scholar] [CrossRef] [PubMed]

- McMullin, P.F. The poultry integument in health and disease. In Poultry Feathers and Skin: The Poultry Integument in Health and Welfare, 1st ed.; Olukosi, O.A., Olori, V.E., Helmbrecht, A., Lambton, S., French, N.A., Eds.; CABI: Wallingford, UK, 2019; Volume 32, pp. 84–92. [Google Scholar]

- Ward, J.M.; Houston, D.C.; Ruxton, G.D.; McCafferty, D.J.; Cook, P. Thermal resistance of chicken (Gallus domesticus) plumage: A comparison between broiler and free-range birds. Br. Poult. Sci. 2001, 42, 558–563. [Google Scholar] [CrossRef] [PubMed]

- Butterworth, A. Effects of high stocking density on broiler chicken and turkeys. CAB Rev. Perspect. Agric. Veter. Sci. Nutr. Nat. Res. 2019, 14. [Google Scholar] [CrossRef]

- Heerkens, J.L.T.; Delezie, E.; Kempen, I.; Zoons, J.; Ampe, B.; Rodenburg, T.B.; Tuyttens, F.A.M. Specific characteristics of the aviary housing system affect plumage condition, mortality and production in laying hens. Poult. Sci. 2015, 94, 2008–2017. [Google Scholar] [CrossRef]

- Nicol, C.J.; Pötzsch, C.; Lewis, K.; Green, L.E. Matched concurrent case-control study of risk factors for feather pecking in hens on free-range commercial farms in the UK. Br. Poult. Sci. 2003, 44, 515–523. [Google Scholar] [CrossRef]

- Lambton, S.L.; Knowles, T.G.; Yorke, C.; Nicol, C.J. The risk factors affecting the development of gentle and severe feather pecking in loose housed laying hens. Appl. Anim. Behav. Sci. 2010, 123, 32–42. [Google Scholar] [CrossRef]

- SJVFS 2020:1. Föreskrifter om ändring i Statens jordbruksverksföreskrifter (SJVFS 2015:29) om ekologisk produktion och kontroll av ekologisk produktion . In [The Swedish Board of Agriculture’s Regulations on Organic Production and Control of Organic Production]; The Swedish Board of Agriculture: Jönköping, Sweden, 2020.

- Vasdal, G.; Granquist, E.G.; Skjerve, E.; De Jong, I.C.; Berg, C.; Michel, V.; Moe, R.O. Associations between carcass weight uniformity and production measures on farm and at slaughter in commercial broiler flocks. Poult. Sci. 2019, 98, 4261–4268. [Google Scholar] [CrossRef]

- Feddes, J.J.; Emmanuel, E.J.; Zuidhoft, M.J. Broiler performance, body weight variance, feed and water intake, and carcass quality at different stocking densities. Poult. Sci. 2002, 81, 774–779. [Google Scholar] [CrossRef]

- Gous, R.M. Nutritional and environmental effects on broiler uniformity. Worlds Poult. Sci. J. 2018, 74, 21–34. [Google Scholar] [CrossRef]

- Hughes, R.J.; Heberle, N.; Barekatain, R.; Edwards, N.; Hynd, P. Flock uniformity—Is it important and how is it assessed? In Proceedings of the Australian Poultry Science Symposium, Sydney, Australia, 16 February 2017.

- Lordelo, M.M.; Davis, A.J.; Wilson, J.L.; Dale, N.M. Cottonseed meal diets improve body weight uniformity in broiler breeder pullets. J. Appl. Poult. Res. 2004, 13, 191–199. [Google Scholar] [CrossRef]

- Xu, Y.; Stark, C.R.; Ferket, P.R.; Williams, C.M.; Brake, J. Effects of feed form and dietary coarse ground corn on broiler live performance, body weight uniformity, relative gizzard weight, excreta nitrogen, and particle size preference behaviors. Poult. Sci. 2015, 94, 1549–1556. [Google Scholar] [CrossRef] [PubMed]

- Hudson, B.P.; Lien, R.J.; Hess, J.B. Effects of Body Weight Uniformity and Pre-Peak Feeding Programs on Broiler Breeder Hen Performance. J. Appl. Poult. Res. 2001, 10, 24–32. [Google Scholar] [CrossRef]

- Zuidhof, M.J.; Holm, D.E.; Renema, R.A.; Jalal, M.A.; Robinson, F.E. Effects of broiler breeder management on pullet body weight and carcass uniformity. Poult. Sci. 2015, 94, 1389–1397. [Google Scholar] [CrossRef] [PubMed]

- Griffin, A.M.; Renema, R.A.; Robinson, F.E.; Zuidhof, M.J. The Influence of Rearing Light Period and the Use of Broiler or Broiler Breeder Diets on Forty-Two-Day Body Weight, Fleshing, and Flock Uniformity in Broiler Stocks. J. Appl. Poult. Res. 2005, 14, 204–216. [Google Scholar] [CrossRef]

- Souillard, R.; Répérant, J.M.; Experton, C.; Huneau-Salaun, A.; Coton, J.; Balaine, L.; Le Bouquin, S. Husbandry practices, health, and welfare status of organic broilers in France. Animals 2019, 9, 97. [Google Scholar] [CrossRef]

- Baxter, M.; Bailie, C.L.; O’Connell, N.E. Evaluation of a dustbathing substrate and straw bales as environmental enrichments in commercial broiler housing. Appl. Anim. Behav. Sci. 2018, 200, 78–85. [Google Scholar] [CrossRef]

| Measure | Scoring |

|---|---|

| Hock burns 1,2 | 0 (intact skin, no redness)–4 (severe lesions) |

| Food pad dermatitis 1,2 | 0 (intact skin)–4 (severe lesions) |

| Toe damage | 0 (no damage); 1 (damage ≤ one toe); 2 (damage > one toe) |

| Plumage cleanliness 1 | 0 (clean)–3 (very dirty) |

| Plumage condition 3 (body and flight feathers combined) | 0 (good plumage condition, no or very few feathers damaged); |

| 1 (completely or almost completely feathered with few feathers damaged, featherless area(s) <5 cm2); | |

| 2 (highly damaged feathers, with featherless area(s) ≥5 cm2); | |

| 3 (very high degree of damage to feathers, with no or only a few feather-covered areas) | |

| Skin lesions 4 | 0 (no lesions, or <3 pecks or scratches); 1 (≥ one lesion <2 cm or ≥3 pecks or scratches); 2 (≥ one lesion ≥2 cm) |

| Comb wounds 4 | 0 (no evidence of pecking wounds); 1 (wounds <3); 2 (wounds ≥3) |

| Comb colour | Normal; red; pale |

| Comb dehydration | Yes; no |

| Enlarged crop 4 | Yes; no |

| Signs of enteritis/diarrhoea 4 | Yes; no |

| Gait (lameness) 1 | 0 (normal, dextrous and agile); |

| 1 (slight abnormality, but difficult to define); | |

| 2 (definite and identifiable abnormality); | |

| 3 (obvious abnormality, affects ability to move); | |

| 4 (severe abnormality, only takes a few steps); | |

| 5 (incapable of walking) |

| Farm | Hybrid | Age (Days) | Plumage Condition 1 | Plumage Cleanliness 1 | FPD 2 | HB 3 | Cloaca Remarks | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 0 | 1 | 2 | 0 | 1 | 2 | 0 | 1 | No | Yes | |||

| 1 4 | RR | 55 | - | - | - | 62 | 34 | 4 | 84 | 16 | 0 | 88 | 12 | 98 | 2 |

| 2 | RR | 62 | 100 | 0 | 0 | 4 | 76 | 20 | 52 | 48 | 0 | 74 | 26 | 100 | 0 |

| 3 | H | 55 | 84 | 14 | 2 | 78 | 22 | 0 | 82 | 18 | 0 | 96 | 4 | 92 | 8 |

| 4 | RR | 57 | 32 | 68 | 0 | 52 | 44 | 4 | 98 | 2 | 0 | 100 | 0 | 56 | 44 |

| 5 | H | 44 | 100 | 0 | 0 | 86 | 14 | 0 | 86 | 14 | 0 | 94 | 6 | 80 | 20 |

| 6 | RR | 48 | 100 | 0 | 0 | 58 | 40 | 2 | 100 | 0 | 0 | 86 | 14 | 88 | 12 |

| 7 | H | 57 | 48 | 52 | 0 | 34 | 58 | 8 | 42 | 44 | 14 | 80 | 20 | 100 | 0 |

| 8 5 | RR | 58 | 100 | 0 | 0 | - | - | - | 86 | 14 | 0 | 76 | 24 | 60 | 40 |

| Farmer Estimates (%) | Calculated (%) | |||||

|---|---|---|---|---|---|---|

| Age (Days) | Eggs not Hatched/Discarded | Average Mortality Over Time (All Flocks) 1 | Observed Flock Mortality 1 (at Visit) | Observed Flock Mortality (at Visit) | Observed Flock Mortality (Post-Slaughter) | |

| On-farm hatching | ||||||

| Farm 1 | 55 | 8–10 | 4 | 6 | 6.7 3 | n/a 5 |

| Farm 2 | 62 | 4 | 4–4.5 | 6 | 6.7 3 | 8.9 3 |

| Farm 4 | 57 | 8–10 | 4–5 | 5–6 | 7.7 3 | 9.5 3 |

| Farm 6 | 48 | 5–6 | 2–3 | 2.2 2 | 10.2 3 | n/a 5 |

| Farm 8 | 58 | 5–10 | 3.5–4 | 3.5–4 | n/a 4 | n/a 5 |

| Day-old chicks | ||||||

| Farm 3 | 55 | n/a | 2–3 | 5–6 | 6.5 | n/a 5 |

| Farm 5 | 44 | n/a | 2 | 3–4 | 4.9 | 7.4 |

| Farm 7 | 57 | n/a | 3–4 | 3.5 2 | 3.5 | 7.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Göransson, L.; Yngvesson, J.; Gunnarsson, S. Bird Health, Housing and Management Routines on Swedish Organic Broiler Chicken Farms. Animals 2020, 10, 2098. https://doi.org/10.3390/ani10112098

Göransson L, Yngvesson J, Gunnarsson S. Bird Health, Housing and Management Routines on Swedish Organic Broiler Chicken Farms. Animals. 2020; 10(11):2098. https://doi.org/10.3390/ani10112098

Chicago/Turabian StyleGöransson, Lina, Jenny Yngvesson, and Stefan Gunnarsson. 2020. "Bird Health, Housing and Management Routines on Swedish Organic Broiler Chicken Farms" Animals 10, no. 11: 2098. https://doi.org/10.3390/ani10112098

APA StyleGöransson, L., Yngvesson, J., & Gunnarsson, S. (2020). Bird Health, Housing and Management Routines on Swedish Organic Broiler Chicken Farms. Animals, 10(11), 2098. https://doi.org/10.3390/ani10112098