1. Introduction

In mammals, estrus is a behavioral sign that ensures that the female is ready to be mated close to the time of ovulation [

1,

2]. Standing estrus is often defined as true estrus, when the cow makes no effort to escape when mounted by other cows. Other signs of estrus include mounting of other cows, increased activity, and mucous discharge from the vulva. While standing to be mounted is recognized as the primary behavioral sign of estrus, other behaviors, such as anogenital sniffing, restlessness, bellowing, chin resting, head mounting, and an attempt to mount are considered secondary symptoms [

3]. Progesterone measurement in plasma or milk can aid detection of estrus by determining error in other detection methods, such as false positives when using activity [

4]. Although the online monitoring device of progesterone concentration is available, it does not fit for these commercial farms highly concerned about profit rates due to the equipment cost and expense of chemicals used per measurement.

The assessment and classification of estrus in dairy cows is directly related to the breeding efficiency, milk production, and economic benefits of dairy farms [

5]. A high estrus-detection level can stabilize total pregnancy rate, minimize the interval between calvings, and improve fertilization results. Undetected and falsely detected estrus activity will lead to increased input costs (e.g., artificial insemination, feed) [

6]. Therefore, accurate estrus detection is essential to maintain the productivity and reproductive performance of dairy herds.

Commonly, a low-cost approach to estrus detection is implemented on commercial farms by the visual observation of physiological and social behavior patterns [

7]. Nevertheless, the development of large dairy herds and all-year-round calving patterns in the dairy-farming industry undoubtedly hinders visual observation [

8]. In addition, the extreme decline in estrus duration over the last 50 years, increasing age, milk production, and environmental factors (e.g., higher ambient temperature, uncomfortable housing) can negatively affect length and intensity of estrus expression, leading to the low estrus-detection rate [

9]. Hence, a number of automated systems utilizing activity sensors (e.g., pedometers, activity-meters, 3D-accelerometers) have been developed, instead of manual inspection, to monitor the specific changes in a certain kind of estrus-accompanied behavior for promoting the discrimination performance [

10]. However, despite the use of estrus detection assisted by activity monitoring technologies, the randomness in the occurrence rate and intensity of a single behavior still makes correct identification difficult [

11]. To avoid the false identification of estrus caused by the limited value of using a single behavior, several studies proposed multivariate analysis methods to combine the features of different estrus behaviors. Jónsson et al. investigated a novel detection scheme based on observed distributions of the step count data and the lying balance [

12]. Reith et al. stated that the activity and rumination time measured by collar-mounted sensors can significantly increase the sensitivity of estrus recognition [

13]. The above-mentioned studies suggest that multi-behavior systems have the potential to improve estrus detection. Accordingly, in the use of multivariate discriminant analysis, the selected combination of behavioral metrics should contain as much effective estrus-related behaviors as possible, and adequately consider the impact of identification algorithms. Additionally, the time-window length is also intimately associated with the detection rate of estrus [

14,

15]. Consequently, we can improve the estrus detection effect through introducing practical discrimination algorithms based on the combination of multiple behavior parameters and optimizing the time-window length.

The cow’s location in the barn is one of the most direct reflections of the temporal and spatial variation for estrus behaviors. The ultra-wideband (UWB) radio technique has been proven to be accurate in harsh environments, such as those subject to high multipath error and many obstructions, with the possibility for monitoring specific interactions and movements that occur at estrus [

16]. Continuous location information achieved by UWB technology can not only advance the accuracy of behavior recognition, but can also provide a basis to analyze the spatial variability of behaviors with centimeter accuracy for estrus detection [

17]. The current study tested the hypothesis that activity, location and machine learning technologies can provide higher accuracy for the detection of estrus in dairy cows than is currently available.

The objective of this study is to assess combining location, acceleration, and machine learning technologies to detect estrus in dairy cows. Four machine learning algorithms (K-nearest neighbor (KNN), back-propagation neural network (BPNN), linear discriminant analysis (LDA), and classification and regression tree (CART)) were used to distinguish estrus cows. Moreover, the impact of algorithms and time-window lengths on detection rate was evaluated by sensitivity, specificity, precision, negative predictive value (NPV), accuracy, and F1 score.

2. Data Acquisition System

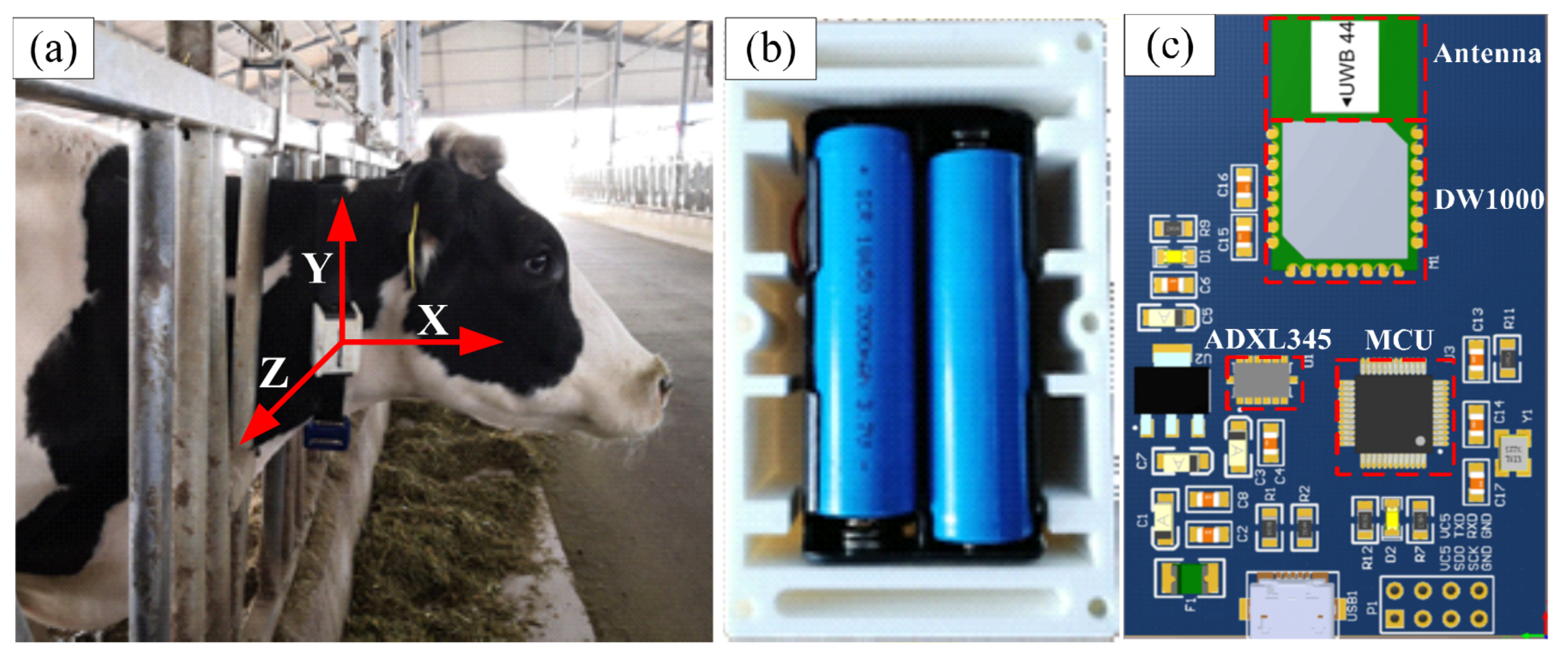

Our system contained a neck tag, eight anchor nodes, a receiver, and a laptop. The neck tag enabled the automated measurement of both location and acceleration of cow behaviors every second. The neck tag was mainly composed of a low-power microprocessor (STM32F103C8T6, STMicroelectronics Ltd., Geneva, Switzerland), a wireless transceiver (DW1000, Decawave Ltd., Dublin, Ireland) based on UWB, and a high-resolution accelerometer (ADXL345, Analog Devices Inc., Norwood, MA, USA). The neck tag was placed in a water-resistant plastic bag. The power supply consisted of two 3.7 V lithium ion batteries (ARB-L18-3500, FENIX Ltd., Shenzhen, China). The protected tag was inserted into a plastic case (102 × 63 × 53 mm) equipped with adjustable straps, and the total weight was approximately 200 g. The adjustable straps facilitated a proper fit of the neck tag to the dimension of cow’s neck in order to have the

y-axis of the coordinate system of the neck tag aligned with the upward direction perpendicular to the ground (

Figure 1). Furthermore, the 0.25 kg iron counterweight was worn below the neck for maintaining neck tag stable. The anchor node was identical to the neck tag, except that it was not equipped with an accelerometer and batteries. Each anchor node was powered by an AC/DC adapter and attached to a pole at a height of 1.8 m using cable ties. The position of Anchor 1 was defined as the origin of the plane coordinate system in the barn.

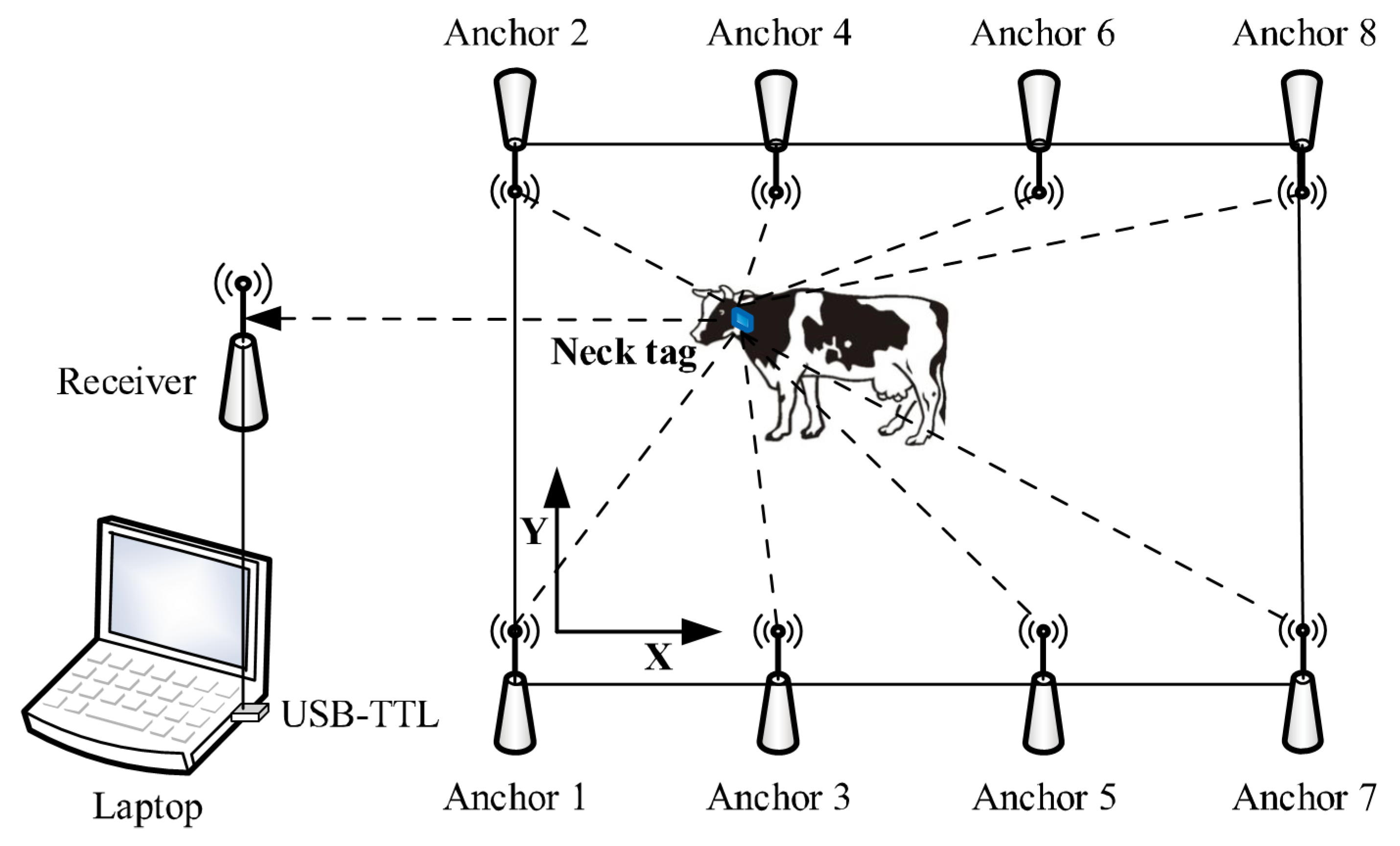

The distances between neck tag and anchor nodes installed at the boundary of studied area (

Figure 2) were calculated by double side two way ranging (DS-TWR) method [

18], and the two-dimensional location data of the neck tag can be solved by adopting trilateration localization algorithm. Acceleration data were synchronously recorded in three dimensions (

x-,

y- and

z- axis) of cow movements (range from −2 to +2 gravity). Both location and acceleration data were wirelessly transmitted with a frequency of 1 Hz to a receiver placed at a distance of about 10 m outside the monitoring area, and connected to a laptop with a USB to TTL module (PL-2303HX, Prolific Technology Inc., Taiwan). A laptop was used to gather incoming data, which were processed, analyzed to generate an estrus alert for individual cows using software on the laptop, or sent to a mobile device.

3. Experimental Setup and Data Collection

During our research, all animals were kept in a pathogen-free environment and fed naturally. The procedures for care and use of animals were approved by the Ethics Committee of the Henan University of Science and Technology, Luoyang, China. All of the experimental procedures were conducted in conformity with institutional guidelines for the care and use of laboratory animals at Henan University of Science and Technology and with the National Institutes of Health Guide for Care and Use of Laboratory Animals (NIH Pub. No. 85-23, revised 1996).

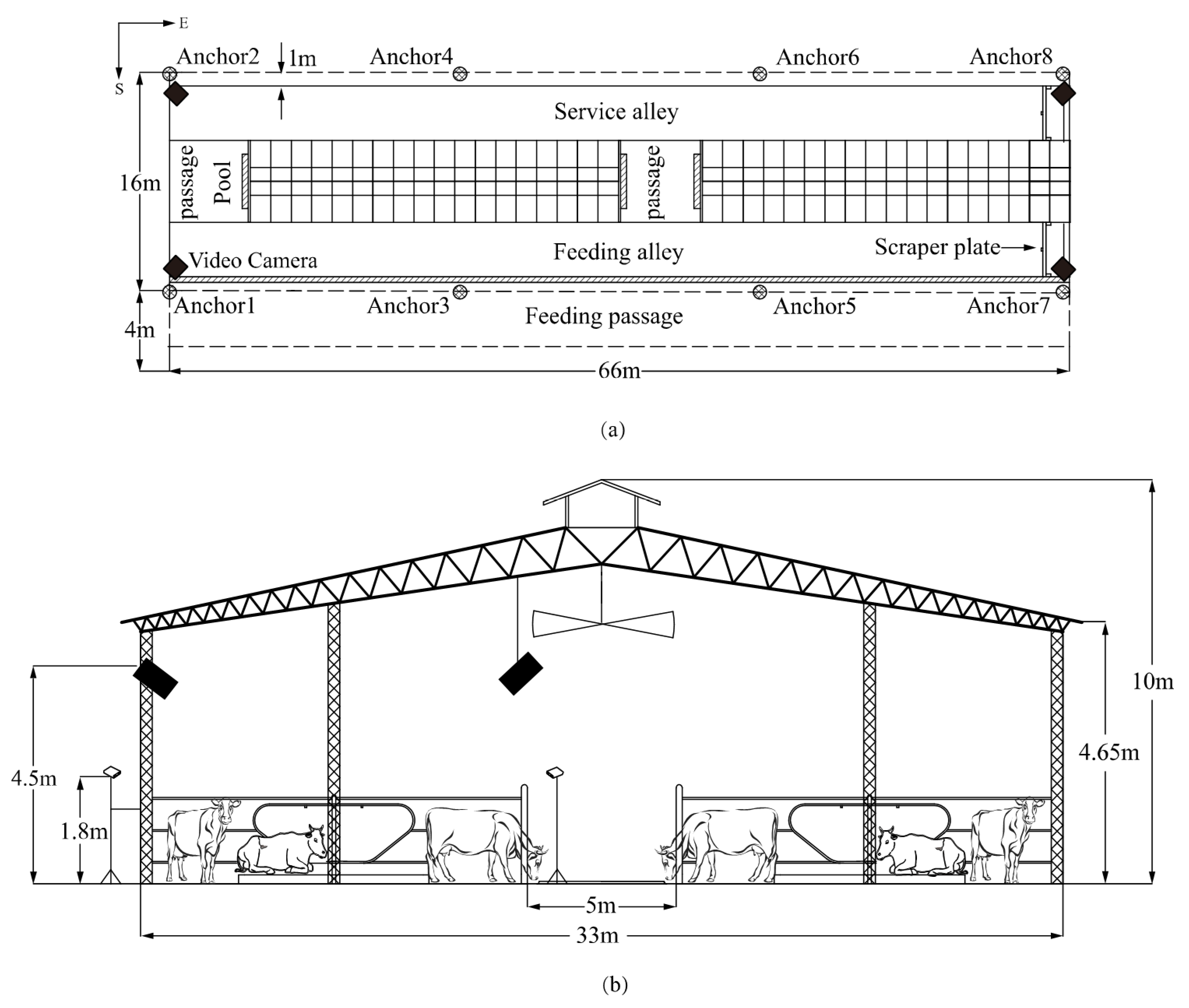

The experiment was undertaken in August 2019 for 12 days at the dairy unit of Sansege Dairy Co., Ltd. (33°05′50.64″ N, 112°32′25.32″ E), Nanyang, Henan Province, China. The study pens had a rectangular layout of 66 × 14 m in an east-west direction and included a drinking area, a row of self-locking headlock, and a row of head to head stall arranged with sand beds. The roof adopted symmetrical structure covered with steel trusses and fiber-board supported by purlins. The height of the barn and the eaves were 10 m and 4.65 m, respectively. Cows were milked twice a day at 5 a.m. and 5 p.m., and concrete floors were cleaned every 4 h with scraper plates. With the assistance of an experienced veterinarian, an unpregnant cow was randomly selected from 353 open lactating Holstein cows in the herd at 7 a.m. each day, and placed in the studied area for 6 h of monitoring without external interference from 8:00–11:00 a.m., and also 1:30–4:30 p.m. (

Figure 3).

A total of 12 cows were chosen during the study period (

Table 1). The statistical power of the experimental samples with a significance level of 0.05 was 0.676, which indicated there was a 67.6% or greater probability that the differences between samples can be correctly identified. Meanwhile, whether the cow was in estrus is determined by the standard criterion detailed in

Section 3.1. Due to data packet loss and accidental network delays, a total of 25,684 sets of original data were obtained, of which 23,456 sets of data with the duration of movement behavior exceeding 2 s were used for the analysis of estrus recognition algorithms.

3.1. Estrus Observations

To determine which cows are in estrus, the cows were observed to detect spontaneous behavioral estrus by applying four video cameras (SNC-VB640, Sony Corporation, Tokyo, Japan) for approximately 18.32 ± 1.5 h/d. These cameras were fixed at pillars about 4.5 m above the trial area in which the cows were housed, to prevent disturbing the animals. The cameras were connected to an external hard-drive video recorder (K-NL408K/CH, Panasonic Corporation, Osaka, Japan). Among all of the possible views available from the video system, plan views were the most appropriate here. A top view of the system provided a panoramic rectified image of the area of interest at a resolution of 1920 × 1080 pixels. Cows were plainly verified by an individual combination of colored tape on each cow. Two experienced observers differentiated estrus cows according to Van Eerdenburg et al. (1996) through retrospectively reviewing video recordings and recording their behaviors [

19]. The Intra-class correlation coefficient (ICC) of inter observer reliability was 0.997. Each behavior associated with estrus was allocated a certain number of points (

Table 2). If the sum of points during observation period exceeded 100, the animal was regarded to be in estrus.

According to the time-window length of 0.5 h, 1 h, and 1.5 h, we divided the acquired valid data into 144 groups, 72 groups, and 48 groups in accordance with the sampling sequence. Each group of data for each dairy cow corresponded to a judgment result as estrus status label by the standard criterion of estrus (

Table 2). Afterwards, we utilized the cow behavior analysis method for location and acceleration data proposed by Wang et al. (2018) to process the grouped data [

20]. Through the classification of behavior patterns, each group of data was transformed into twelve behavioral metrics associated with estrus (Kerbrat et al. (2004) and Aungier et al. (2015)): duration of standing, duration of lying, duration of walking, duration of feeding, duration of drinking, switching times between activity and lying, steps, displacement, average velocity, walking times, feeding times, drinking times [

21,

22]. The acquisition processes of behavioral metrics were classified into two categories. The steps, displacement, and average velocity were calculated by the continuous positioning data of monitored cows in every time window. For the other behavioral metrics, the acceleration data were firstly used to distinguish the behavior patterns of standing, lying, walking, feeding, drinking, lying down, and standing up by the BP-AdaBoost algorithm. Furthermore, applying the D-S evidence theory to fuse the belief assignment functions of behavior categories and location data, to improve the accuracy of behavior discrimination, and then the behavioral metrics were acquired by counting the duration or number of behaviors in an individual time window.

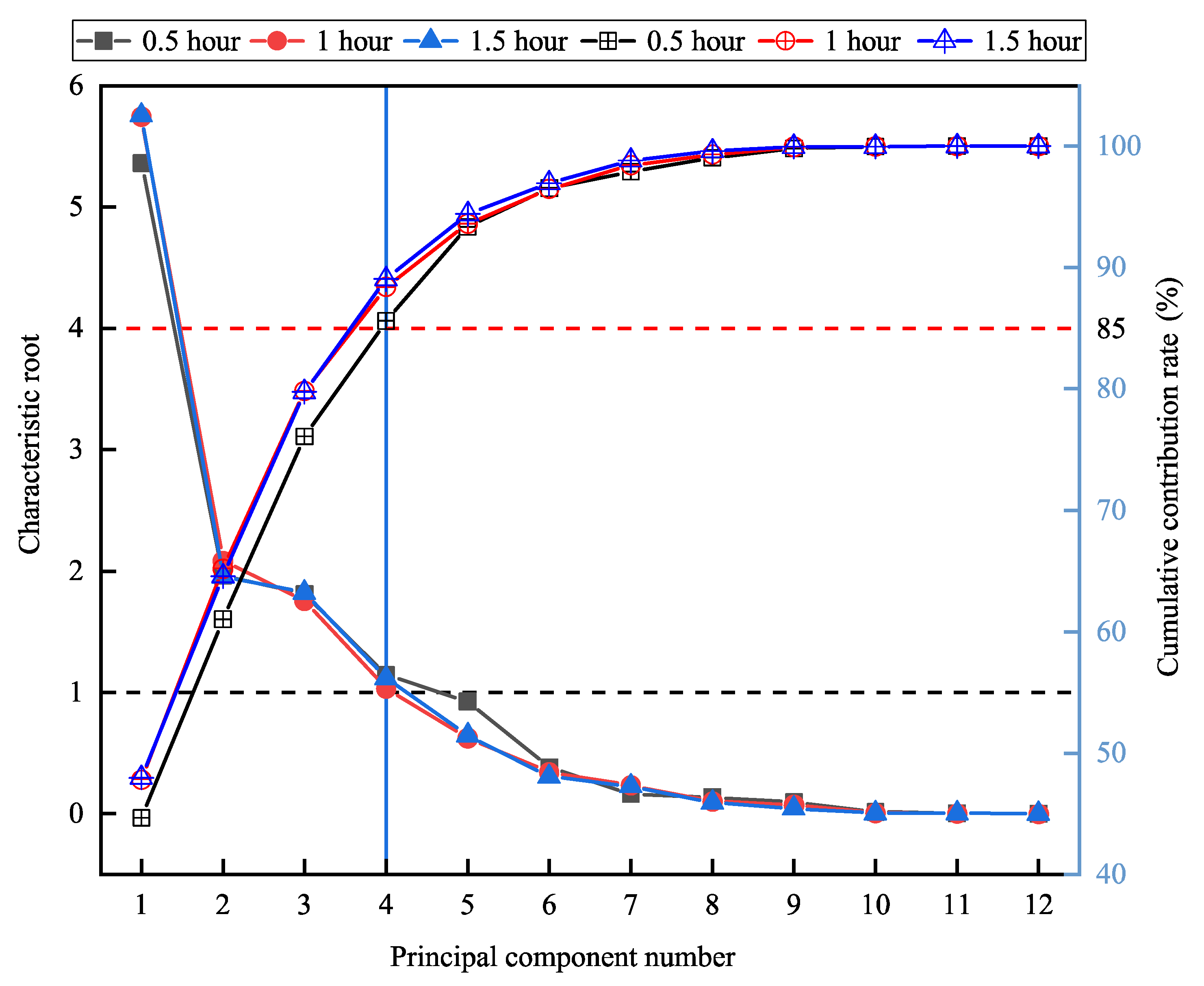

To withdraw dimension problems and difficulties in using data sets originated by over-comprehensive variables and overlapping description information, we adapted SPSS statistical program (SPSS 25.0 for Windows) to conduct principal component analysis (PCA) on all the reconstructed data groups for different time-window lengths. The Kaiser-Meyer-Olkin statistics (KMO > 0.7) and Bartlett’s Test of Sphericity (BTS < 0.05) were applied to carry out PCA adaptability inspection on the data [

23]. Moreover, in terms of the principle that the characteristic root was greater than 1, and the cumulative contribution rate was higher than 85%, appropriate principal components were selected as the estrus indicators. We then split the obtained data groups of each time-window length, after PCA dimensionality reduction processing, into training and testing sets for estrus recognition algorithms. Seventy percent of the data was selected as the training set, and the remaining 30% was used for the testing set.

3.2. Estrus Recognition Algorithms

In this study, four machine learning algorithms from SPSS, KNN, BPNN, LDA, and CART, were used to identify the estrus of dairy cows to select the optimal recognition method.

3.2.1. KNN

The KNN method is an instance-based learning method that stores all available data points and classifies new data points based on similarity measures [

24]. The idea underlying the KNN method is to assign new unclassified examples to the class to which the majority of its

K nearest neighbors belongs. As a result of the advantage of decreasing the misclassification error, the KNN algorithm has been used in applications such as data mining, statistical pattern recognition, image processing, and so on. We used the KNN method to classify the estrus states of cows, set Euclidean distance as the distance measure function, and realize the autonomous optimization of

k value within the range of 1–9, according to the 10-fold cross-validation of the training set and testing set.

3.2.2. BPNN

The BPNN model is made up of various layers of nodes, and is designated by the node characteristics, network interconnection geometry, and the learning rules (transfer functions). Learning is fed back into the model continuously to modify the weights of the nodes between layers to diminish the errors between the predicted and measured data [

25]. After determining the weights of the node through the training process, the BPNN model can be practiced for pattern identification with new data. We utilized the BPNN model to distinguish the cows in estrus, adopting the estrus indicators as the input layer and the estrus status label as the output layer. In the meantime, a hidden layer was built by the use of the automatic architecture in SPSS, and the adjustment mode of the number of hidden layer nodes was set to the best estimation accuracy. The activation functions of the hidden layer and the output layer were set as hyperbolic tangent and identity, and a cross-entropy function was selected as the error function. The maximum iteration times, training objectives, and learning efficiency were chosen as 1000, 0.00001, and 0.01, respectively. Additionally, the optimization algorithm applied the conjugate gradient method.

3.2.3. LDA

The LDA algorithm is a well-known method for dimensionality reduction and classification that projects high-dimensional data onto a low-dimensional space, where the data accomplishes maximum class separability [

26]. The derived features in LDA are linear combinations of the original features, in which the coefficients are from the transformation matrix. The optimal projection or transformation in classical LDA is obtained by minimizing the within-class distance and maximizing the between-class distance simultaneously, thus, to achieve the maximum class discrimination. It has been implemented successfully in many applications, including pattern recognition and data analysis. For detecting estrus cows by the utility of LDA, we selected Fisher’s discrimination criterion in multivariate analysis, and arranged the prior probability according to the sample size of estrus and non-estrus cows in the training set. Moreover, the Wilks Lambda statistic and leave-one-out cross-validation were employed, to assess discriminant value and discernment performance.

3.2.4. CART

With the use of tree-building algorithm, CART operates by recursively splitting the data until ending points, or terminal nodes, are obtained using preset rules [

27]. The CART technique essentially consists of an analytical process that the relative significance of each factor is evaluated and an integral process involving the identification of the optimal combination of independent variables over the dependent variable is utilized. CART has been widely conducted with a high level of accuracy and performance for classifying and forecasting problems. We established a CART model to monitor the estrus situations of cows through SPSS, set the maximum tree depth as 5, the minimum cases in parent node as 7, and the number of child nodes as 3. By applying the Gini index as an attribute selection measure, the nodes were split, and the decision tree was pruned. Meanwhile, the maximum difference in risk generated during pruning was set as 0.

6. Discussion

As one of the main reasons for the degradation of cow reproductive performance, the importance of estrus detection is self-evident. A large number of studies have revealed that abnormal behavior and time allocations of cows in estrus can be employed as an indicator of estrus detection. On this basis, various estrus automated detection systems have been developed. Rorie et al. used a rump-attached detector and obtained an accuracy of 87.5% by monitoring mounting activity [

29]. Brehme et al. applied a combination of sensors to determine activity, lying time, and temperature, and detected estrus with 90% accuracy [

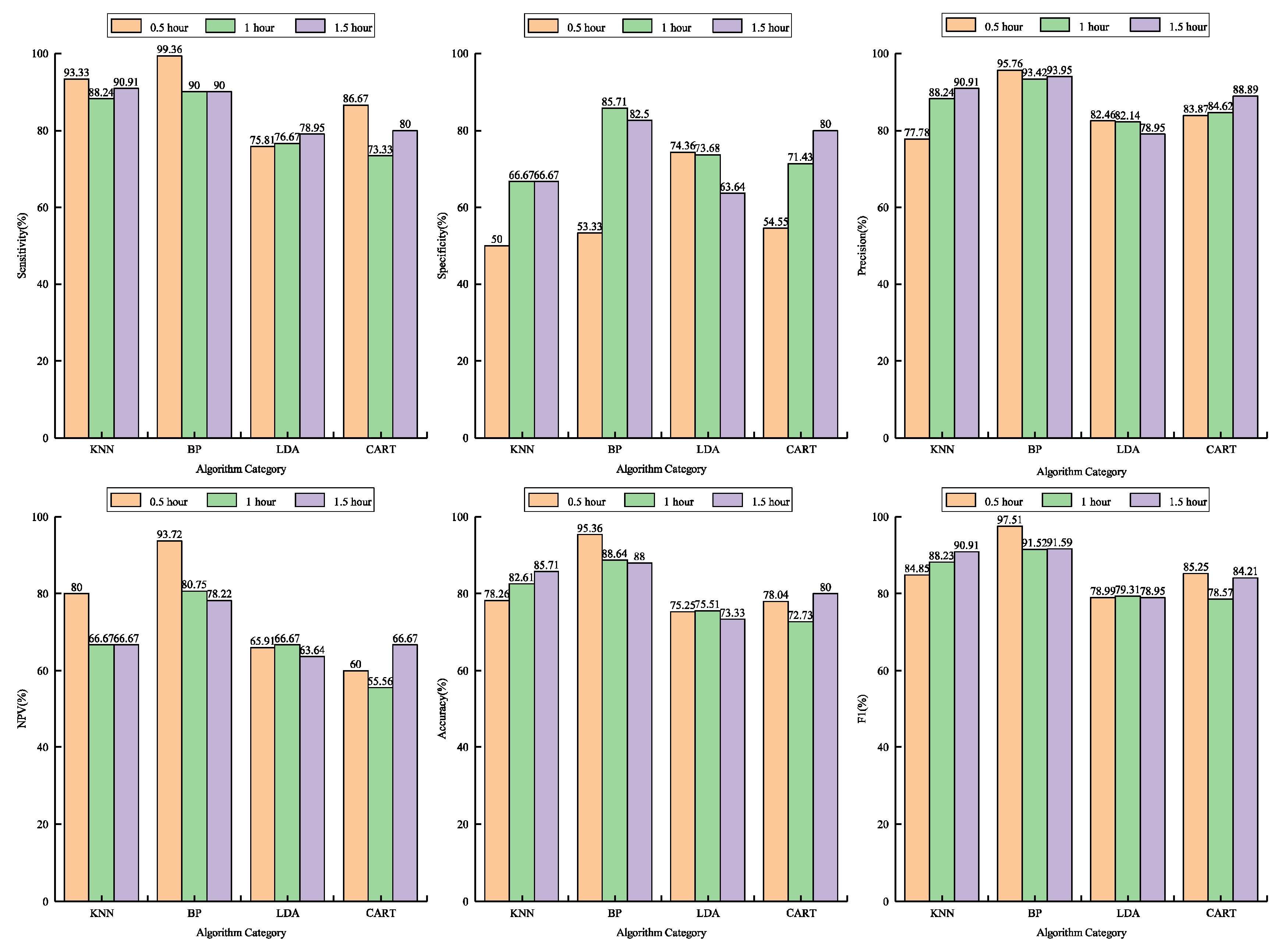

30]. The current study also validated the indicative effect of using behavioral changes to detect estrus. According to the estrus indicators established by twelve behavioral metrics, the average sensitivity, average specificity, average precision, average NPV, average accuracy, and average F1 score identified by the four machine learning algorithms were 85.27%, 68.54%, 86.75%, 70.38%, 81.12%, and 85.83%, respectively. The average sensitivity, average precision, and average F1 score (all above 85%) performed well, which was because the selected combination of behavior categories can contain more extra estrus information and provide a more accurate discrimination basis. Nevertheless, the average specificity and average NPV (both less than 80%) were much lower. The two parameters should be further improved in terms of false-positive alerts and false-negative alerts caused by unclear differentiation of estrus or non-estrus behaviors, which can be produced through time-window length, the original information missed by PCA, and estrus intensity. In addition, the specificity and NPV of BPNN in the 1-h time window were 85.17% and 80.75%, respectively. It can be noticed that the difference in algorithm selection and monitoring interval is additionally an essential factor affecting the performance of these two parameters. Moreover, accuracy is influenced by sensitivity, specificity, precision, and NPV. The average accuracy of the four algorithms reached 81.12%, and the detection accuracy of BPNN with the best performance was more than 88% under different time windows.

Cow location information has a definite value for individual identification, behavior classification, and feeding management. Numerous studies have been conducted on cow positioning. Porto et al. proved that the real-time location system with UWB technology could acquire an average position error of 0.11 m in the semi-open barn [

31]. By utilizing the indoor positioning system based on ultra-high frequency (UHF) technique, Ipema et al. achieved a static position error of 0.3 ± 0.25 m in the barn [

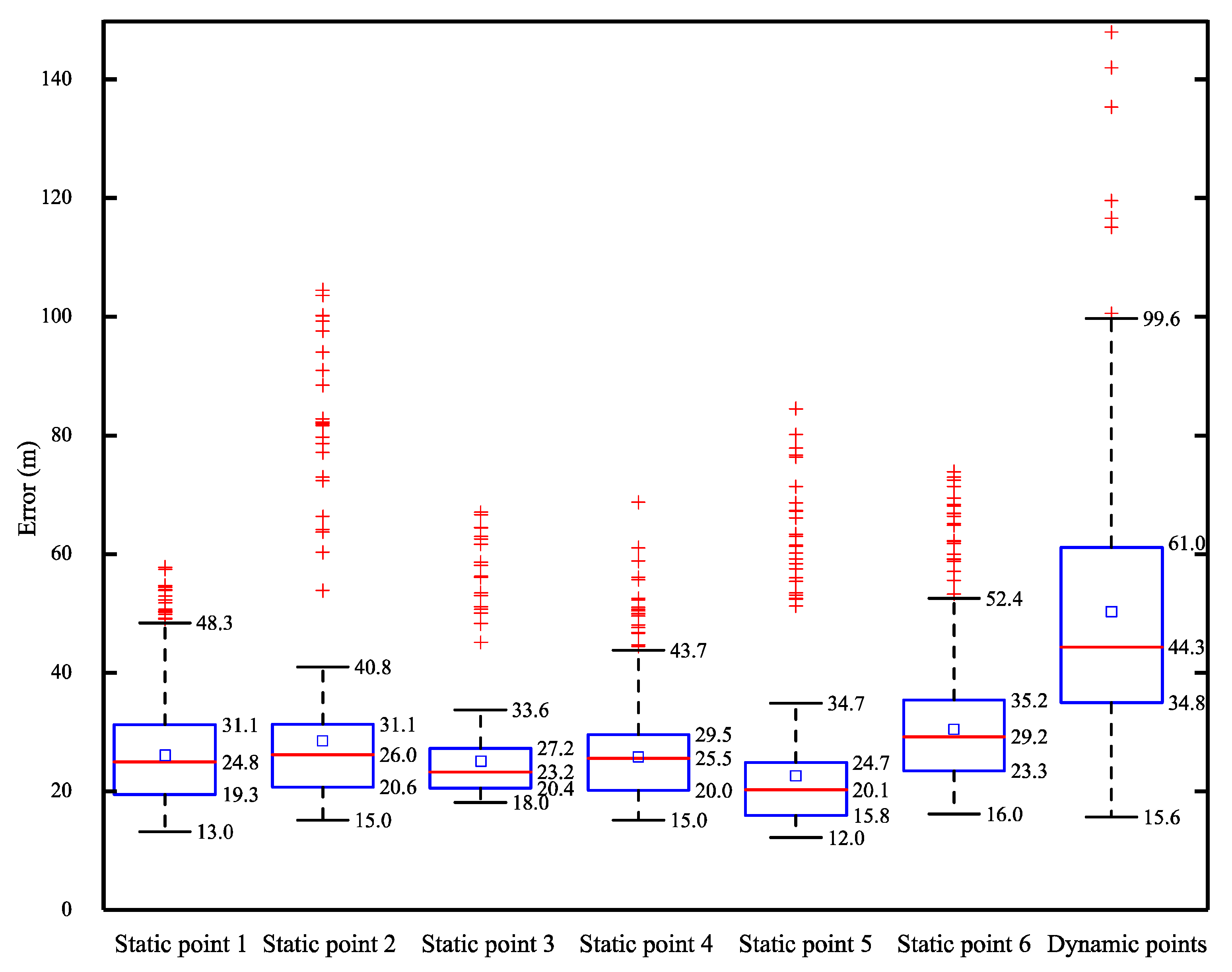

32]. In this study, UWB technology was used to obtain the planimetric coordinates of the cow, and the eight anchor nodes were deployed based on the rectangular partition to accomplish the reliable coverage of radio frequency signals in the studied area. At the same time, we also performed some improvements in the positioning mechanism. Firstly, the neck tag was set to communicate with the nearest four adjacent anchor nodes in turn for avoiding the possible ranging failure affected by channel congestion. Secondly, the ranging correction based on signal power and antenna delay correction were adopted to diminish the range measurement error caused by the obstruction of the housing facilities. Additionally, compared with the radio frequency identification (RFID) system integrated with UHF, UWB technology can enhance positioning accuracy through short pulse signal propagation. The final results showed that the static error and dynamic error of the positioning method practiced in this work were 0.25 ± 0.06 m and 0.45 ± 0.15 m. The smaller positioning error can adequately record the behaviors of each cow in real time.

Multiple studies on cow estrus detection using behavioral metrics mostly used statistical analysis methods. Moore et al. identified 55% of visually observed estrus by comparing the variation of mean daily activity [

33]. Jónsson et al. achieved a sensitivity of 88.9% using the means from statistical change detection [

34]. Machine learning methods can describe multiple complex interaction relationships or nonlinear relationships, and, thus, bring about remarkable predictive accuracy. Therefore, machine learning methods are suitable alternatives to statistical approaches for automated detection systems of cow estrus, as they focus on the prediction and ability to discriminate behavioral signs. In this study, each set of estrus indicators extracted from the acquisition data sets grouped by monitoring intervals was utilized as the input of a training set, and the estrus status of the corresponding cow determined by the visual observation was adopted as the output of the training set. Afterwards, through the learning of constructed training sets, KNN, BPNN, LDA, and CART algorithms were modeled to identify cows in estrus, and the accuracy of these machine learning methods would be improved with the increase in the number of training sets. Moreover, the prospect of machine learning technology is to perceive the characteristics of estrus activities of dairy herds for enhancing the accuracy in large scale application, and the training process does not rely on the estrus data of an individual cow. This study verified the estrus detection performance of KNN, BPNN, LDA, and CART algorithms, with the accuracy range of 72.73% to 95.36%, and the average sensitivity of 90.83%, 93.12%, 77.14%, and 80%, respectively. We preliminarily presumed that BPNN had the most reliable estrus detection effect, followed by KNN, CART, and LDA. Furthermore, the performance of the four algorithms in terms of accuracy and F1 score proved our judgment on the ranking of the estrus detection capability of these algorithms. For NPV, BPNN was incomparably ahead of the four kinds of algorithms in each time length. Therefore, we determined that the BPNN algorithm with the 0.5-h time window was the optimal detection method.

The difference of implementation principle may chiefly offer the disparity in estrus detection rate of these algorithms. For example, BPNN and CART achieved the accuracy of 95.36% and 72.73% in the time window of 0.5 h and 1 h, respectively, which was because of the result that the BPNN algorithm obtained the optimal weight of each layer through the forward propagation of signal and the backpropagation of error. Although CART is easy to understand and analyze visually, the risk of underfitting of the pruned decision tree is one of the possible reasons for the low accuracy due to the measures of pruning and limiting the depth of the decision tree, to prevent overfitting. In general, compared with statistical methods, these four machine learning methods have a more robust ability to mine and interpret estrus behaviors, and can dependably predict emerging data under the estrus discrimination rules summarized in the learning phase. However, the online identification and detection accuracy of these four algorithms still need to be confirmed by a large number of animals in the future.

Various behaviors have different levels of indicating function on cow estrus. Accordingly, in the studies of estrus detection based on behavioral signs [

35], the choice of behavioral metrics is crucial to enhance the detection level. For instance, Valenza et al. recognized 66% estrus events by the pressure-activated Heatmount detectors affixed midline to the rump between the tail head and the tuber coxae for all cows in the experiment [

36]. In this study, twelve behavioral metrics were reduced to estrus indicators by PCA, which not only guaranteed the comprehensiveness of temporal and spatial information of estrus behaviors, but also effectively restricted the data scale of algorithm training. Compared with the estrus detection methods using single behavior or several behaviors, this study had more advantages in reducing the misjudgments generated by the short-term abnormal behavioral changes during estrus, under the premise of considering the influence of the time window.

The interval for monitoring is intimately associated with the detection rate of estrus, which is critical to monitoring short-term abnormal behavioral variations and the stability of long-term detection. By utilizing sensitivity, specificity, precision, NPV, accuracy, and F1 score, this study assessed the detection performance of KNN, BPNN, LDA, and CART algorithms in 0.5-h, 1-h, and 1.5-h time windows, respectively. Through the two-factor analysis of variance, it can be discovered that the time window and its combination with algorithms had significant effects on specificity and precision. Meanwhile, the algorithm type also had a considerable impact on precision. In addition, the time window had no vital influence on other parameters (p > 0.07), but these parameters were significantly affected by algorithm types. The impact of these factors on enhancing the detection rate should be regarded while establishing the estrus detection model.

Although we evaluated the estrus detection capability of the developed neck tag for 12 Holstein cows, further trials should be carried out by increasing the number of enrolled cows and deployment scale. The optimal combination of algorithm and time window proposed in this work still needs to take into account the influence of factors such as milk yield and parity on the detection applicability. The next step in the development of this system is to advance real-time analysis functions. Once the functionality and reliability have been confirmed on a larger scale, commercialization is possible.