Ensiling Process in Commercial Bales of Horticultural By-Products from Artichoke and Broccoli

Simple Summary

Abstract

1. Introduction

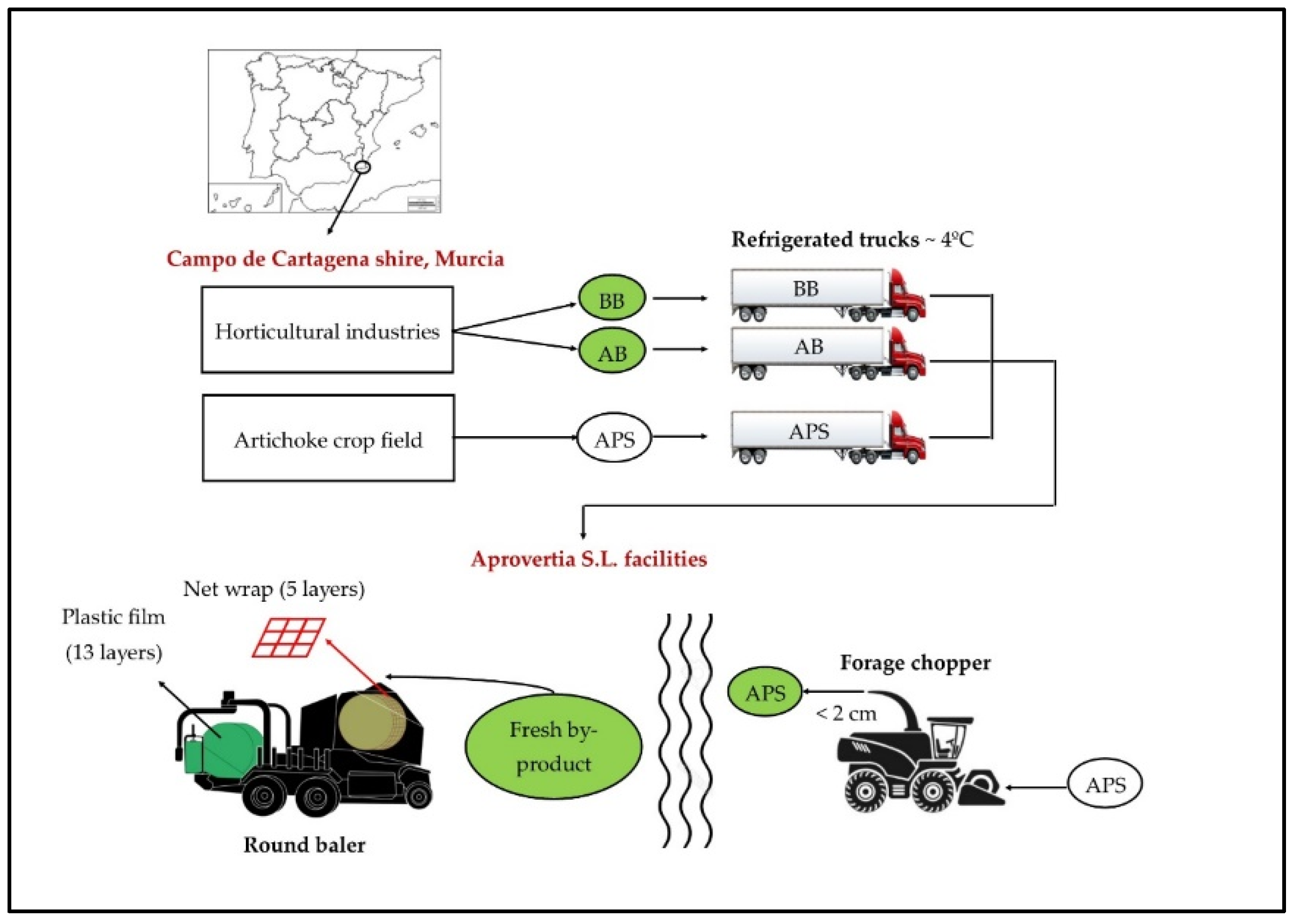

2. Materials and Methods

3. Results

3.1. Microbiology

3.2. Physico-Chemical Parameters and Nutritional Composition

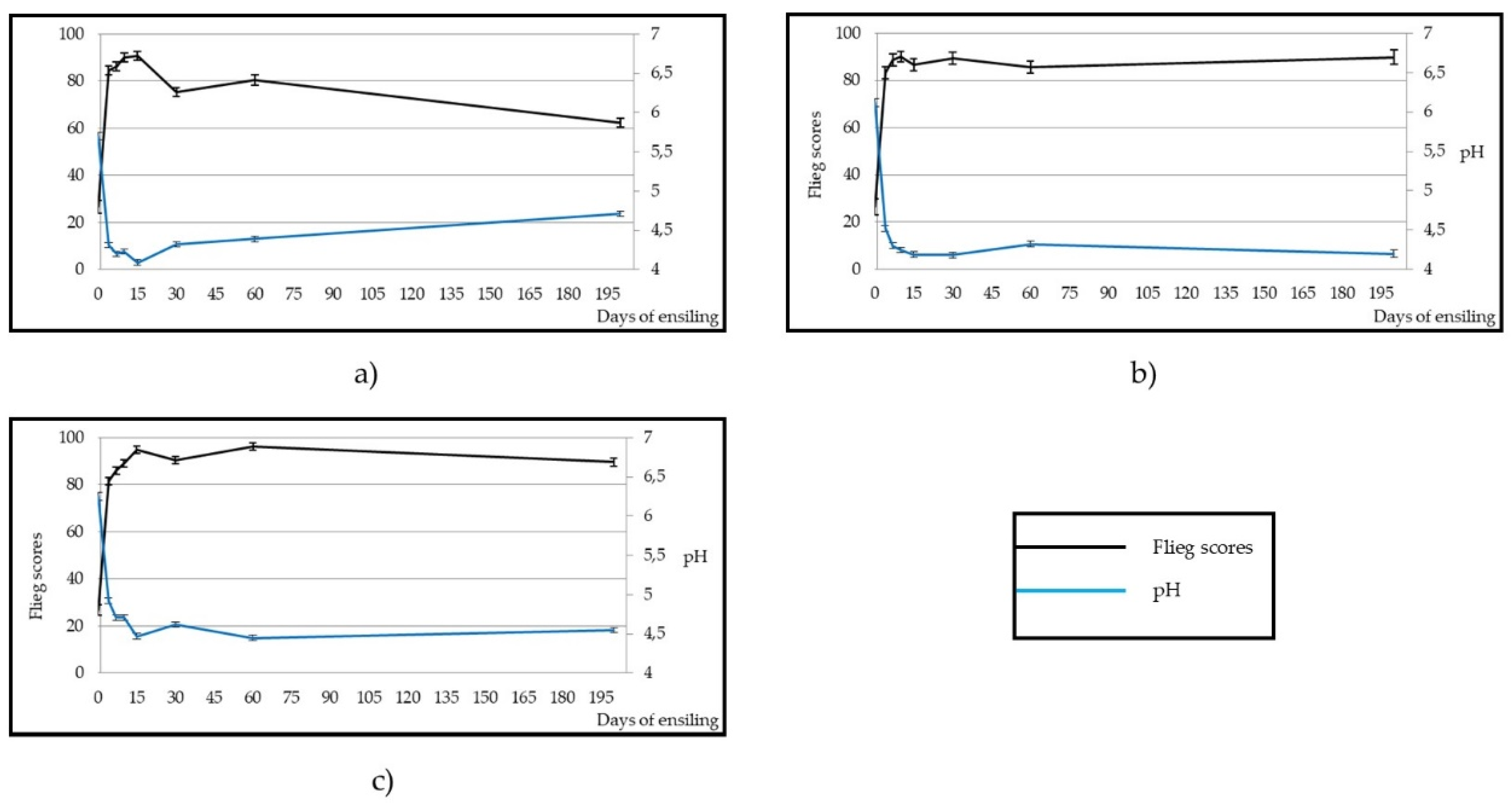

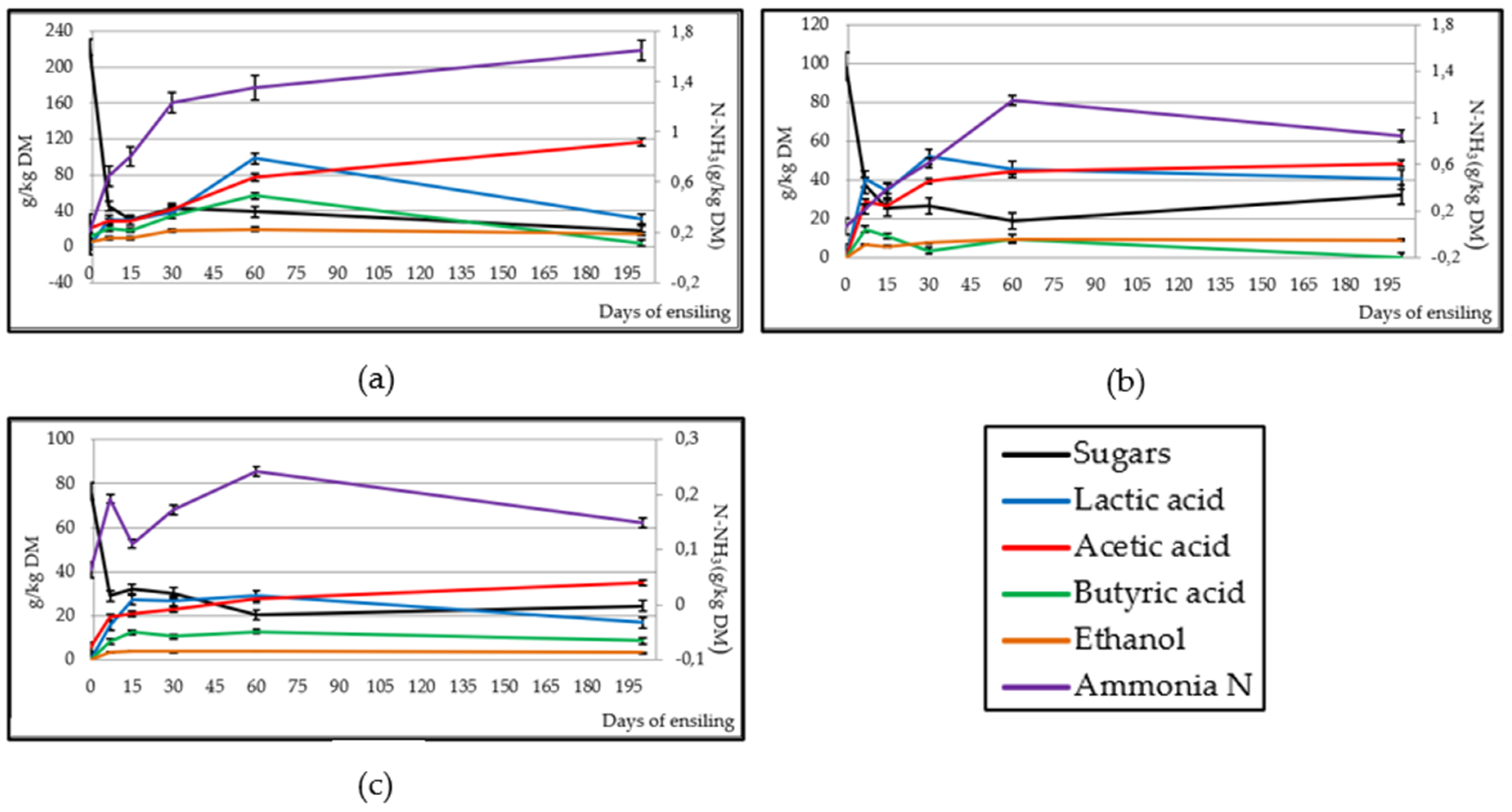

3.3. Fermentation

3.4. Phytosanitary Residues Evaluation

3.5. Manufacturing Costs

4. Discussion

4.1. Microbiology

4.2. Physico-Chemical Parameters and Nutritional Composition

4.3. Fermentation

4.4. Phytosanitary Residues Evaluation

4.5. Manufacturing Costs

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Food and Agriculture Organization of the United Nations. Available online: http://www.fao.org/faostat/en/#home (accessed on 17 June 2019).

- Christaki, E.; Bonos, E.; Florou-Paneri, P. Nutritional and functional properties of Cynara crops (globe artichoke and cardoon) and their potential applications: A review. Int. J. Appl. Sci. Technol. 2012, 2, 64–70. [Google Scholar]

- Mongabay. Available online: http://data.mongabay.com/commodities/ (accessed on 17 June 2019).

- Lattanzio, V.; Kroon, P.A.; Linsalata, V.; Cardinali, A. Globe artichoke: A functional food and source of nutraceutical ingredients. J. Funct. Foods 2009, 1, 131–144. [Google Scholar] [CrossRef]

- Hernández, F.; Pulgar, M.A.; Cid, J.M.; Moreno, R.; Ocio, E. Nutritive assessment of artichoke crop residues (Cynara scolymus L.): Sun dried leaves and whole plant silage. Arch. Zootec. 1992, 41, 257–264. [Google Scholar]

- Wernli, C.; Thames, I. Utilization of fodder residue of artichoke (Cynara scolymus L.) as silage. I. Factors affecting its conservation. Avances Prod. Anim. 1989, 14, 79–89. [Google Scholar]

- Ros, M.; Pascual, J.A.; Ayuso, M.; Morales, A.B.; Miralles, J.R.; Solera, C. Estrategias Sostenibles para un Manejo Integral de los Residuos y Subproductos Orgánicos de la Industria Agroalimentaria. Proyecto Life+ Agrowaste; CEBAS-CSIC; CTC; AGRUPAL: Murcia, Spain, 2012. [Google Scholar]

- Vasta, V.; Nudda, A.; Cannas, A.; Lanza, M.; Priolo, A. Alternative feed resources and their effects on the quality of meat and milk from small ruminants. Anim. Feed Sci. Technol. 2008, 146, 223–246. [Google Scholar] [CrossRef]

- Bryszak, M.; Szumacher-Strabel, M.; El-Sherbiny, M.; Stochmal, A.; Oleszek, W.; Roj, E.; Patra, A.K.; Cieslak, A. Effects of berry seed residues on ruminal fermentation, methane concentration, milk production, and fatty acid proportions in the rumen and milk of dairy cows. J. Dairy Sci. 2019, 102, 1257–1273. [Google Scholar] [CrossRef]

- Mogodiniyai, K.; Rustas, B.O.; Spörndly, R.; Udén, P. Prediction models of silage fermentation products on crop composition under strict anaerobic conditions: A meta-analysis. J. Dairy Sci. 2013, 96, 6644–6649. [Google Scholar] [CrossRef]

- Choong, C.; Teow, C.C.; Truong, V.; McFeeters, R.F.; Thompson, R.L.; Pecota, K.V.; Yencho, G.C. Antioxidant activities, phenolic and -carotene contents of sweet potato genotypes with varying flesh colours. Food Chem. 2007, 103, 829–838. [Google Scholar]

- Łozicki, A.; Koziorzebska, A.; Halika, G.; Dymnicka, M.; Arkuszewska, E.; Niemiec, T.; Bogdan, J. Effect of ensiling pumpkin (Cucurbita maxima D.) with dried sugar beet pulp on the content of bioactive compounds in silage and its antioxidant potential. Anim. Feed Sci. Technol. 2015, 206, 108–113. [Google Scholar] [CrossRef]

- Meneses, M.; Megías, M.D.; Madrid, J.; Martínez-Teruel, A.; Hernández, F.; Oliva, J. Evaluation of the phytosanitary, fermentative and nutritive characteristics of the silage made from crude artichoke (Cynara scolymus L.) by-product feeding for ruminants. Small Rumin. Res. 2007, 70, 292–296. [Google Scholar] [CrossRef]

- Megías, M.D.; Meneses, M.; Madrid, J.; Hernández, F.; Martínez-Teruel, A.; Cano, J.A. Nutritive, fermentative and environmental characteristics of silage of two industrial broccoli (Brassica oleracea, var. Itálica) by-products for ruminant feed. Int. J. Agric. Biol. 2014, 16, 307–313. [Google Scholar]

- Meneses, M.; Martínez-Marín, A.L.; Madrid, J.; Martínez-Teruel, A.; Hernández, F.; Megías, M.D. Ensilability, in vitro and in vivo values of the agro-industrial by-products of artichoke and broccoli. Environ. Sci. Pollut. Res. Int. 2020, 27, 2919–2925. [Google Scholar] [CrossRef] [PubMed]

- Marsico, G.; Ragni, M.; Vicenti, A.; Caputi Jambrenghi, A.; Tateo, A.; Giannico, F.; Vonghia, G. The quality of meat from lambs and kids reared on feeds based on artichoke (Cynara scolymus L.) bracts. Acta Hortic. 2005, 681, 489–494. [Google Scholar] [CrossRef]

- Jaramillo, D.P.; Buffa, M.N.; Rodríguez, M.; Pérez-Baena, I.; Guamis, B.; Trujillo, A.J. Effect of the inclusion of artichoke silage in the ration of lactating ewes on the properties of milk and cheese characteristics during ripening. J. Dairy Sci. 2010, 3, 1412–1419. [Google Scholar] [CrossRef] [PubMed]

- Cajarville, C.; Gonzalez, J.; Repetto, J.L.; Rodriguez, C.A.; Martinez, A. Nutritive value of green forage and crop by-products of Cynara cardunculus. Ann. Zootech. 1999, 48, 353–365. [Google Scholar] [CrossRef]

- De Ruiter, J.; Wilson, D.; Maley, S.; Fletcher, A.; Fraser, T.; Scott, W.; Berryman, S.; Dumbleton, A.; Nichol, W. Management Practices for Forage Brassicas; Dairy, N.Z., Ed.; Forage Brassica Development Group: Hamilton, New Zealand, 2009; p. 64. [Google Scholar]

- Yi, X.W.; Yang, F.; Liu, J.X.; Wang, J.K. Effects of replacement of concentrate mixture by broccoli byproducts on lactating performance in dairy cows. Asian Aust. J. Anim. Sci. 2015, 28, 1449–1453. [Google Scholar] [CrossRef]

- Panwar, V.S.; Sheoran, N.; Vinus; Tewatia, B.S. Chemical composition and nutritive value of broccoli crop residue in goats. Forage Res. 2017, 43, 50–53. [Google Scholar]

- Meneses, M. Evaluación Nutritiva y Fermentativa del Ensilado de Dos Subproductos Agroindustriales, Brócoli (Brassica oleracea, var. Itálica) y Alcachofa (Cynara scolymus L.) para su Empleo en la Alimentación Animal. Ph.D. Thesis, University of Murcia, Murcia, Spain, 2002. [Google Scholar]

- Muelas, R.; Monllor, P.; Romero, G.; Sayas-Barberá, E.; Navarro, C.; Díaz, J.R.; Sendra, E. Milk technological properties as affected by including artichoke by-products silages in the diet of dairy goats. Foods 2017, 6, 112. [Google Scholar] [CrossRef]

- Monllor, P.; Romero, G.; Sendra, E.; Atzori, A.S.; Díaz, J.R. Short-term effect of the inclusion of silage artichoke by-products in diets of dairy goats on milk quality. Animals 2020, 10, 339. [Google Scholar] [CrossRef]

- Díaz, J.R.; Fenoll, J.; Fenoll, A.; Romero, G.; Sendra, E. Procedimiento de Fabricación de Microsilos a Partir de Alcachofas (Cynara scolymus L.) para la Alimentación Animal. U.S. Patent ES2607220B1, 10 January 2018. [Google Scholar]

- McDonald, P.; Henderson, A.R. Buffering capacity of herbage samples as a factor in ensilage. J. Sci. Food Agric. 1962, 13, 395–400. [Google Scholar] [CrossRef]

- Kilic, A. Silo Feed; Instruction, Education and Application Proposals; Bilgehan Press: Izmir, Turkey, 1986. [Google Scholar]

- Asociación Española de Normalización y Certificación. Microbiology of Food, Animal Feed and Water—Preparation, Production, Storage and Performance Testing of Culture Media; AENOR: Madrid, Spain, 2015. [Google Scholar]

- Arias, C.; Oliete, B.; Seseña, S.; Jiménez, L.; Palop, L.; Pérez-Guzmán, M.D.; Arias, R. Importance of on-farm management practices on lactate-fermenting Clostridium spp. spore contamination of total mixed ration of Manchega ewe feeding. Determination of risk factors and characterization of Clostridium population. Small Rumin. Res. 2016, 139, 39–45. [Google Scholar] [CrossRef]

- Association of Official Analytical Chemists. Official Methods of Analysis, 16th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 1999. [Google Scholar]

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for dietary neutral detergent fibre and nonstarch polysacacharides in relation to animal nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef]

- Menke, K.H.; Steingass, H. Estimation of the energetic feed value obtained from chemical analysis and in vitro gas production using rumen fluid. Anim. Res. 1988, 23, 103–116. [Google Scholar]

- Kim, D.O.; Seung, W.J.; Lee, C.Y. Antioxidant capacity of phenolic phytochemicals from various cultivars of plums. Food Chem. 2003, 81, 321–326. [Google Scholar] [CrossRef]

- Feng-Xia, L.; Shu-Fang, F.; Xiu-Fang, B.; Fang, C.; Xiao-Jun, L.; Xiao-Song, H.; Ji-Hong, W. Physico-chemical and antioxidant properties of four mango (Mangifera indica L.) cultivars in China. Food Chem. 2013, 138, 396–405. [Google Scholar]

- Cai, Y.; Benno, Y.; Ogawa, M.; Ohmomo, S.; Kumai, S.; Nakase, T. Influence of lactobacillus spp. from an inoculant and of weissella and leuconostoc spp. from forage crops on silage fermentation. Appl. Environ. Microbiol. 1998, 64, 2982–2987. [Google Scholar] [CrossRef]

- Khota, W.; Pholsen, S.; Higgs, D.; Cai, Y. Natural lactic acid bacteria population of tropical grasses and their fermentation factor analysis of silage prepared with cellulase and inoculant. J. Dairy Sci. 2016, 99, 9768–9781. [Google Scholar] [CrossRef]

- Wen, A.; Yuan, X.; Wang, J.; Desta, S.T.; Shao, T. Effects of four short-chain fatty acids or salts on dynamics of fermentation and microbial characteristics of alfalfa silage. Anim. Feed Sci. Technol. 2017, 223, 141–148. [Google Scholar] [CrossRef]

- Muller, T.; Behrendt, U.; Muller, M. Antagonistic activity in plant-associated lactic acid bacteria. Microbiol. Res. 1996, 151, 63–70. [Google Scholar] [CrossRef]

- Woolford, M.K. The Silage Fermentation; Microbiological Series; Marcel Dekker Inc: New York, NY, USA; Basel, Switzerland, 1984; Volume 14. [Google Scholar]

- Santos, E.M.; Pereira, O.G.; Garcia, R.; Ferreira, C.D.L.; Oliveira, J.S.; Silva, T.C.; Rosa, L.O. Microbial populations, fermentative profile and chemical composition of signalgrass silages at different regrowth ages. Rev. Bras. Zootecn. 2011, 40, 747–755. [Google Scholar] [CrossRef]

- Ni, K.; Wang, F.; Zhu, B.; Yang, J.; Zhou, G.; Pan, Y.; Tao, Y.; Zhong, J. Effects of lactic acid bacteria and molasses additives on the microbial community and fermentation quality of soybean silage. Bioresour. Technol. 2017, 238, 706–715. [Google Scholar] [CrossRef]

- Kung, L.; Shaver, R.D.; Grant, R.J.; Schmidt, R.J. Silage review: Interpretation of chemical, microbial, and organoleptic components of silages. J. Dairy Sci. 2018, 101, 4020–4033. [Google Scholar] [CrossRef]

- Kung, L.; Sheperd, A.C.; Smagala, A.M.; Endres, K.M.; Bessett, C.A.; Ranjit, N.K.; Glancey, J.L. The effect of preservatives based on propionic acid on the fermentation and aerobic stability of corn silage and a total mixed ration. J. Dairy Sci. 1998, 81, 1322–1330. [Google Scholar] [CrossRef]

- Windle, M.C.; Kung, L. The effect of a feed additive on the feeding value of a silage-based TMR exposed to air. J. Dairy Sci. 2013, 96, 16. [Google Scholar]

- Junges, D.; Morais, G.; Spoto, M.H.F.; Santos, P.S.; Adesogan, A.T.; Nussio, L.G.; Daniel, J.L.P. Short communication: Influence of various proteolytic sources during fermentation of reconstituted corn grain silages. J. Dairy Sci. 2017, 100, 9048–9051. [Google Scholar] [CrossRef]

- Robinson, P.H.; Swanepoel, N.; Heguy, J.M.; Price, T.; Meyer, D.M. ‘Shrink’ losses in commercially sized corn silage piles: Quantifying total losses and where they occur. Sci. Total Environ. 2016, 542, 530–539. [Google Scholar] [CrossRef]

- McDonald, P.; Henderson, A.R.; Heron, S.J.E. The Biochemistry of Silage; Chalcombe Publications: Marlow Bottom, UK, 1991. [Google Scholar]

- Cai, Y.; Benno, Y.; Ogawa, M.; Kumai, S. Effect of applying lactic acid bacteria isolated from forage crops on fermentation characteristics and aerobic deterioration of silage. J. Dairy Sci. 1999, 82, 520–526. [Google Scholar] [CrossRef]

- Shinners, K.J.; Wepner, A.D.; Muck, R.E.; Weimer, P.J. Aerobic and anaerobic storage of single-pass, chopped corn stover. Bioenerg. Res. 2011, 4, 61–75. [Google Scholar] [CrossRef]

- Makoni, N.F.; Broderick, G.A.; Muck, R.E. Effect of modified atmospheres on proteolysis and fermentation of ensiled alfalfa. J. Dairy Sci. 1997, 80, 912–920. [Google Scholar] [CrossRef]

- Kennedy, S.J. An evaluation of three bacterial inoculants and formic acid as additive for harvest grass. Grass Forage Sci. 1994, 47, 75–87. [Google Scholar] [CrossRef]

- Zhao, Y.; Yu, J.; Liu, J.; Yang, H.; Gao, L.; Yuan, X.; Cui, Z.; Wanga, X. Material and microbial changes during corn stalk silage and their effects on methane fermentation. Bioresour. Technol. 2016, 222, 89–99. [Google Scholar] [CrossRef]

- Wang, J.; Chen, L.; Yuan, X.; Guo, G.; Li, J.; Bai, Y.; Shao, T. Effects of molasses on the fermentation characteristics of mixed silage prepared with rice straw, local vegetable by-products and alfalfa in Southeast China. J. Int. Agric. 2017, 16, 664–670. [Google Scholar] [CrossRef]

- Megías, M.D.; Cherney, J.H.; Cherney, D.J.R. Effects of phenolic compounds in cell walls of orange and artichoke by-product silages on in vitro digestibility. J. Appl. Anim. Res. 1997, 12, 127–136. [Google Scholar] [CrossRef]

- Gasa, J.; Castrillo, C. Criterios de Utilización de Subproductos Agroindustriales en la Alimentación de Ruminates. Hojas Divulgadoras n° 13/91; Instituto Nacional de Reforma y Desarrollo Agrario: Madrid, Spain, 1992. [Google Scholar]

- Sun, Y.-P.; Chou; Yu, C.-C. Antioxidant activity of lactic-fermented Chinese cabbage. Food Chem. 2009, 115, 912–917. [Google Scholar]

- Jung, H.G. Inhibition of structural carbohydrate fermentation by forages phenolics. J. Sci. Food Agric. 1985, 36, 74–80. [Google Scholar] [CrossRef]

- Ashbell, G.; Donahaye, E. Losses in orange peel silage. Agric. Wastes 1984, 14, 73–77. [Google Scholar] [CrossRef]

- Umana, R.; Staples, C.R.; Bates, D.B.; Wilcox, C.J.; Mahana, W.C. Effects of a microbial inoculant and (or) sugarcane molasses on the fermentation, aerobic stability and digestibility of bermudagrass ensiled at two moisture contents. J. Anim. Sci. 1991, 69, 4588–4601. [Google Scholar] [CrossRef]

- Aksu, T.; Baytok, E.; Bolat, D. Effects of a bacterial silage inoculant on corn silage fermentation and nutrient digestibility. Small Rumin. Res. 2004, 55, 249–252. [Google Scholar] [CrossRef]

- Zhong, R.; Zhao, C.; Feng, P.; Wang, Y.; Zhao, X.; Luo, D.; Cheng, L.; Liu, D.; Fang, Y. Effects of feeding ground versus pelleted total mixed ration on digestion, rumen function and milk production performance of dairy cows. Int. J. Dairy Technol. 2019, 73, 22–30. [Google Scholar] [CrossRef]

- Driheuis, F.; van Wikselaar, P.G. The occurrence and prevention of ethanol fermentation in high-dry-matter grass silage. J. Sci. Food Agric. 2000, 80, 711–718. [Google Scholar] [CrossRef]

- Lonja de Cereales de Albacete. Cotizaciones de Cereal de la Semana 17. 2020. Available online: https://www.oviespana.com/informacion-de-ovino/cotizaciones-de-mercado/precios-nacionales-de-materias-primas-alimentarias-de-ovino/lonja-de-cereales-de-albacete/lonja-agropecuaria-de-albacete-cotizaciones-de-cereal-semana-17-23-04-2020 (accessed on 29 April 2020).

- Fundación Española para el Desarrollo de la Nutrición Animal. Tablas de Composición de Alimentos y Valor Nutritivo; FEDNA: Madrid, Spain, 2019. [Google Scholar]

| Silage | Days of Ensiling | SEM | p-Value | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 4 | 7 | 10 | 15 | 30 | 60 | 200 | |||

| Dry matter (g/kg) | ||||||||||

| BB | 174bc | 184ab | 172bc | 197ab | 173bc | 142d | 181ab | 154cd | 6.79 | *** |

| AB | 256a | 220b | 203bcd | 201bcd | 207bc | 183d | 192cd | 190cd | 8.66 | *** |

| APS | 283abc | 291abc | 273cd | 286abc | 268d | 277bcd | 271cd | 258e | 4.21 | *** |

| Organic matter (g/kg DM) | ||||||||||

| BB | 849a | 840a | 826b | 828b | 821b | 3.5 | *** | |||

| AB | 912 | 927 | 912 | 912 | 916 | 9.4 | n.s. | |||

| APS | 839b | 849a | 837b | 833bc | 828c | 2.3 | *** | |||

| Ether extract (g/kg DM) | ||||||||||

| BB | 20.2b | 23.4b | 29.1a | 23.2b | 32.1a | 1.97 | ** | |||

| AB | 19.6 | 29.3 | 25.8 | 28,0 | 29.6 | 3.41 | n.s. | |||

| APS | 26.3b | 31.4ab | 35.7a | 34.7a | 34.6a | 2.22 | * | |||

| Crude protein (g/kg DM) | ||||||||||

| BB | 195a | 199a | 204a | 153c | 174b | 4.6 | *** | |||

| AB | 117b | 126b | 125b | 122b | 145a | 3.7 | *** | |||

| APS | 78.7a | 78.3a | 67.1b | 76.9a | 78.1a | 1.2 | *** | |||

| Neutral detergent fibre (g/kg DM) | ||||||||||

| BB | 395ab | 356bc | 311d | 342cd | 430a | 11.7 | *** | |||

| AB | 589a | 530ab | 510b | 541ab | 528ab | 17.1 | * | |||

| APS | 547ab | 555ab | 540b | 532b | 571a | 9.9 | ** | |||

| Acid detergent fibre (g/kg DM) | ||||||||||

| BB | 272b | 266b | 233c | 259b | 326a | 8.2 | *** | |||

| AB | 398 | 359 | 353 | 379 | 354 | 13.3 | n.s. | |||

| APS | 358ab | 365a | 361a | 336b | 374a | 7.3 | *** | |||

| Acid detergent lignin (g/kg DM) | ||||||||||

| BB | 77.9a | 65.0b | 35.1c | 35.1c | 63.4b | 3.63 | *** | |||

| AB | 131a | 81b | 80b | 84b | 89b | 6.8 | *** | |||

| APS | 84.5bc | 87.1b | 91.9b | 77.1c | 107.9a | 2.67 | *** | |||

| In vitro dry matter digestibility (g/kg DM) | ||||||||||

| BB | 888a | 829b | 857ab | 800b | 822b | 14.7 | ** | |||

| AB | 670b | 724ab | 723ab | 737ab | 769a | 23.2 | * | |||

| APS | 606b | 579c | 632a | 629ab | 615ab | 7.1 | *** | |||

| Total polyphenols (g/kg DM) | ||||||||||

| BB | 5.86c | 8.85a | 9.59a | 7.48b | 6.73ab | 0.308 | *** | |||

| AB | 1.96d | 7.60c | 10.08b | 15.29a | 7.56c | 0.734 | *** | |||

| APS | 5.02b | 5.47ab | 5.95a | 5.55ab | 4.96b | 0.240 | ** | |||

| Phytosanitary | Type | BB | AB | APS | MRL | Legislation |

|---|---|---|---|---|---|---|

| Cypermethrin | Insecticide | n.d. | n.d. | 0.240 | 2.00 | UE 520/2011 |

| Chlorpyrifos | Insecticide | n.d. | n.d. | 0.085 | 1.00 | CE 839/2008 |

| Imidacloprid | Insecticide | 0.023 | n.d. | 0.034 | 0.50 | UE 491/2014 |

| Miclobutanil | Fungicide | n.d. | 0.044 | 0.220 | 0.50 | UE 2016/567 |

| Spirotetramat | Insecticide | 0.053 | n.d. | n.d. | 1.00 | UE 2015/845 |

| Triadimefon | Fungicide | n.d. | n.d. | 0.700 | 1.00 | CE 459/2010 |

| Costs | BB | AB | APS |

|---|---|---|---|

| Raw material | 4 | 10 | 5 |

| Inner netwrap and plastic film | 7.9 | 7.6 | 8.1 |

| Workforce, other production and marketing costs | 7.3 | 7.3 | 7.3 |

| Total (fresh matter) | 19.2 | 24.9 | 20.4 |

| Total (dry matter) | 125 | 131 | 79 |

| Total (€/kg CP) | 0.718 | 0.903 | 1.01 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Monllor, P.; Romero, G.; Muelas, R.; Sandoval-Castro, C.A.; Sendra, E.; Díaz, J.R. Ensiling Process in Commercial Bales of Horticultural By-Products from Artichoke and Broccoli. Animals 2020, 10, 831. https://doi.org/10.3390/ani10050831

Monllor P, Romero G, Muelas R, Sandoval-Castro CA, Sendra E, Díaz JR. Ensiling Process in Commercial Bales of Horticultural By-Products from Artichoke and Broccoli. Animals. 2020; 10(5):831. https://doi.org/10.3390/ani10050831

Chicago/Turabian StyleMonllor, Paula, Gema Romero, Raquel Muelas, Carlos A. Sandoval-Castro, Esther Sendra, and José Ramón Díaz. 2020. "Ensiling Process in Commercial Bales of Horticultural By-Products from Artichoke and Broccoli" Animals 10, no. 5: 831. https://doi.org/10.3390/ani10050831

APA StyleMonllor, P., Romero, G., Muelas, R., Sandoval-Castro, C. A., Sendra, E., & Díaz, J. R. (2020). Ensiling Process in Commercial Bales of Horticultural By-Products from Artichoke and Broccoli. Animals, 10(5), 831. https://doi.org/10.3390/ani10050831