Antibacterial Effect of Stainless Steel Surfaces Treated with a Nanotechnological Coating Approved for Food Contact

Abstract

1. Introduction

2. Materials and Methods

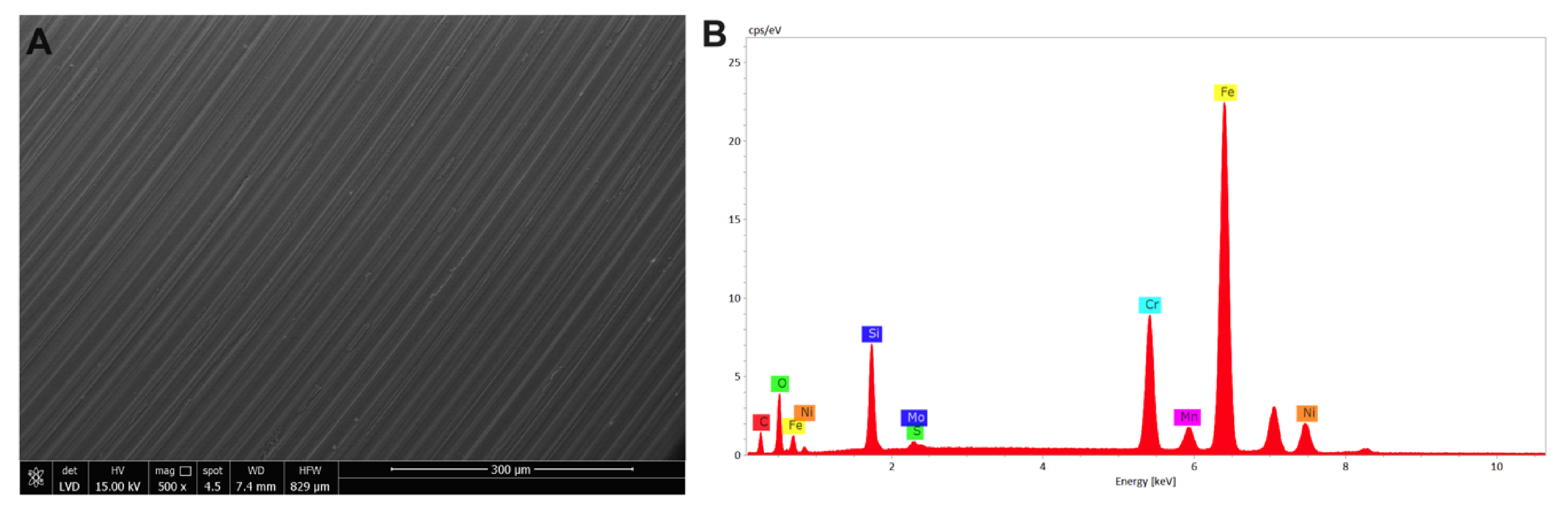

2.1. The Samples

2.2. NanoXHAM Coating

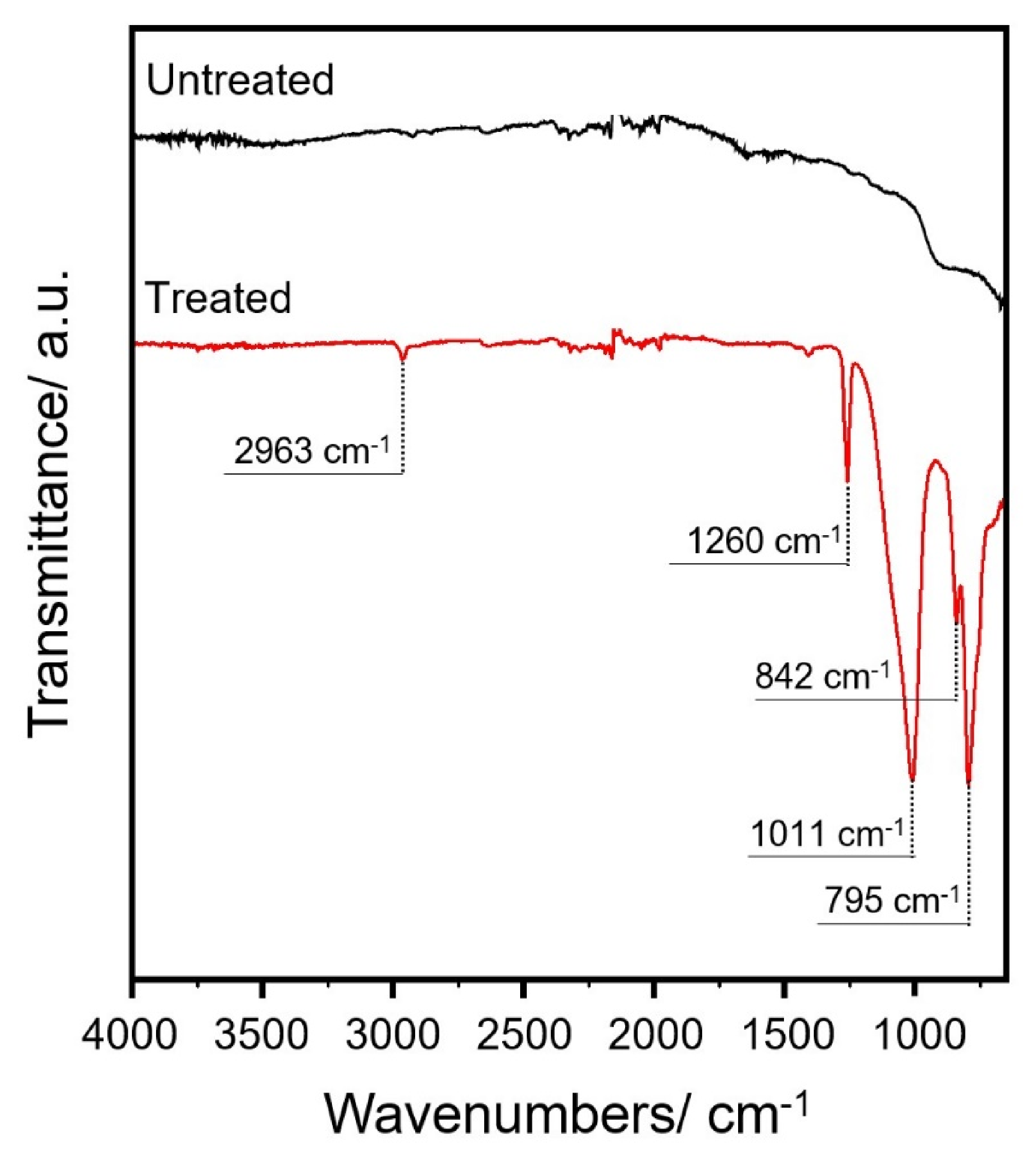

2.3. FT-IR Spectra

2.4. Bacterial Strains Used in This Study

2.5. Microbiological Analysis

2.6. Atomic Force Microscopy Analysis

2.7. Environmental Scanning Microscopy Analysis

2.8. Statistical Analysis

3. Results

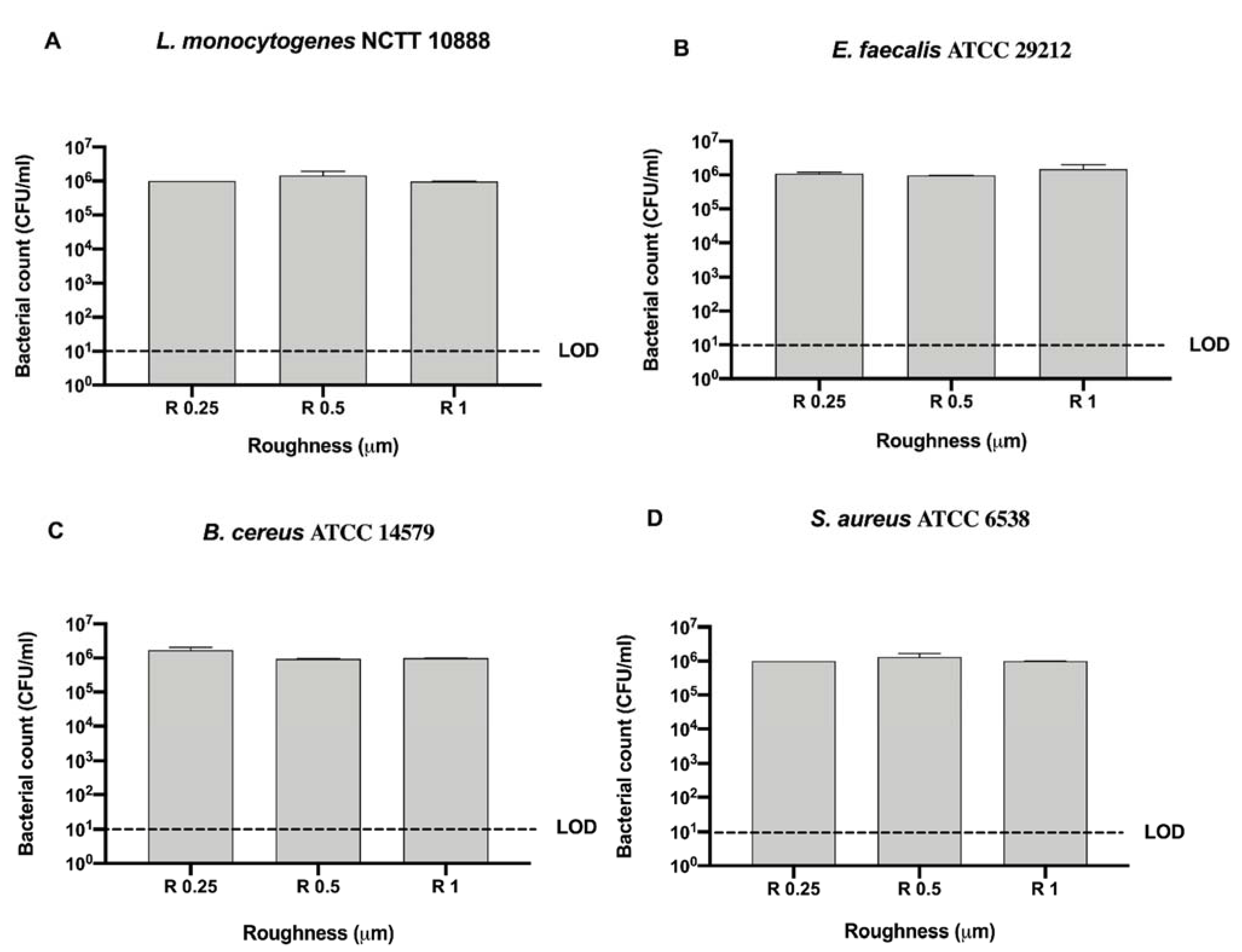

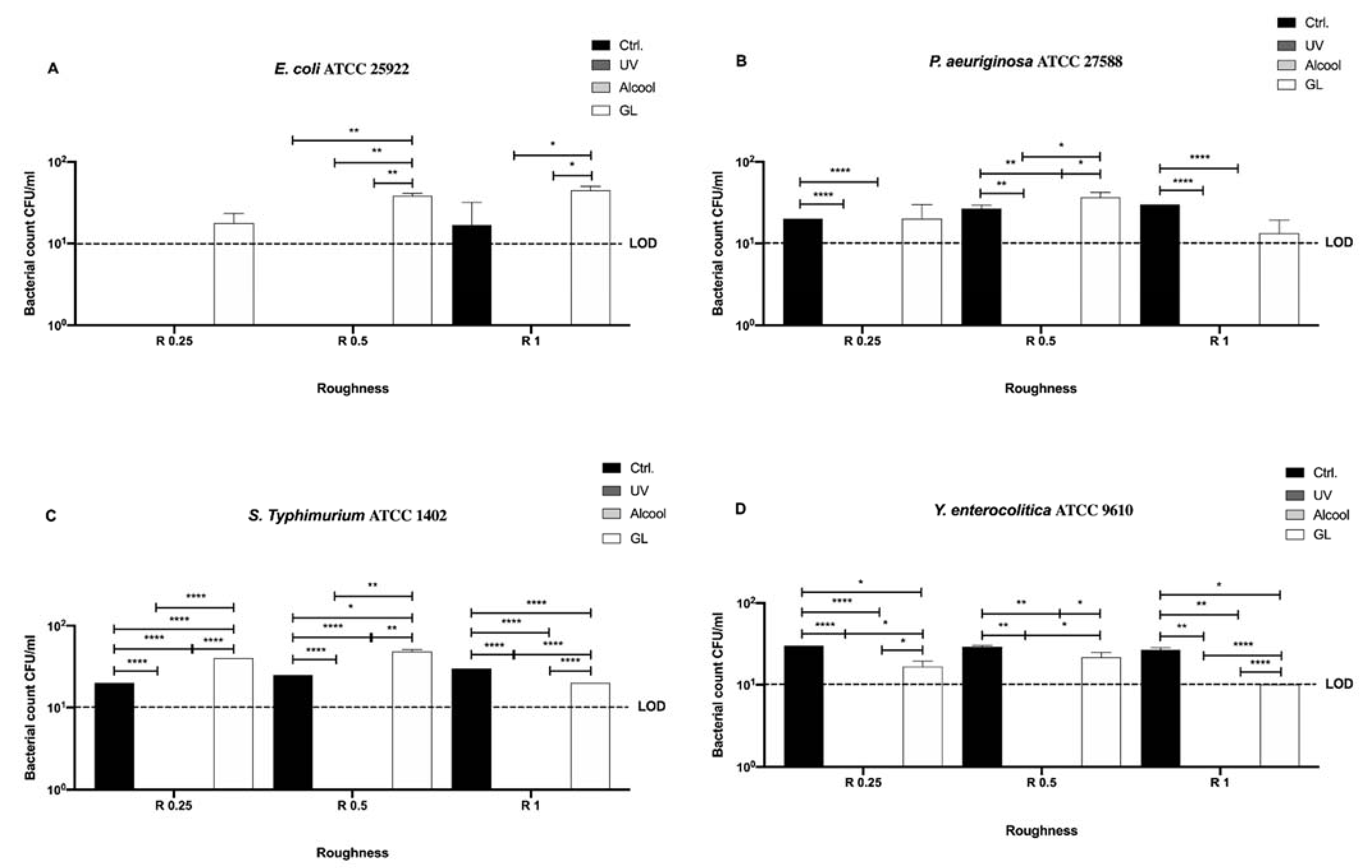

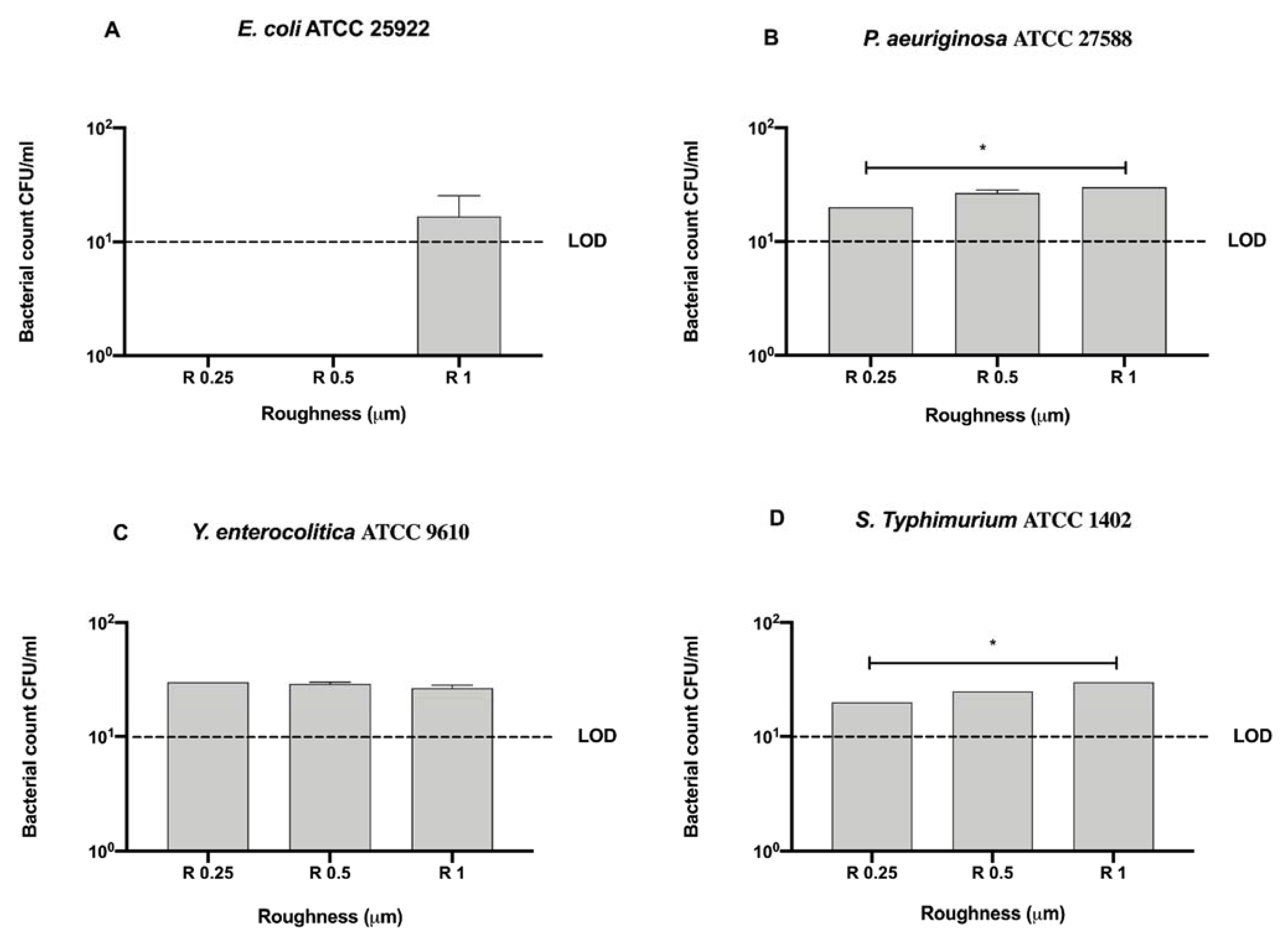

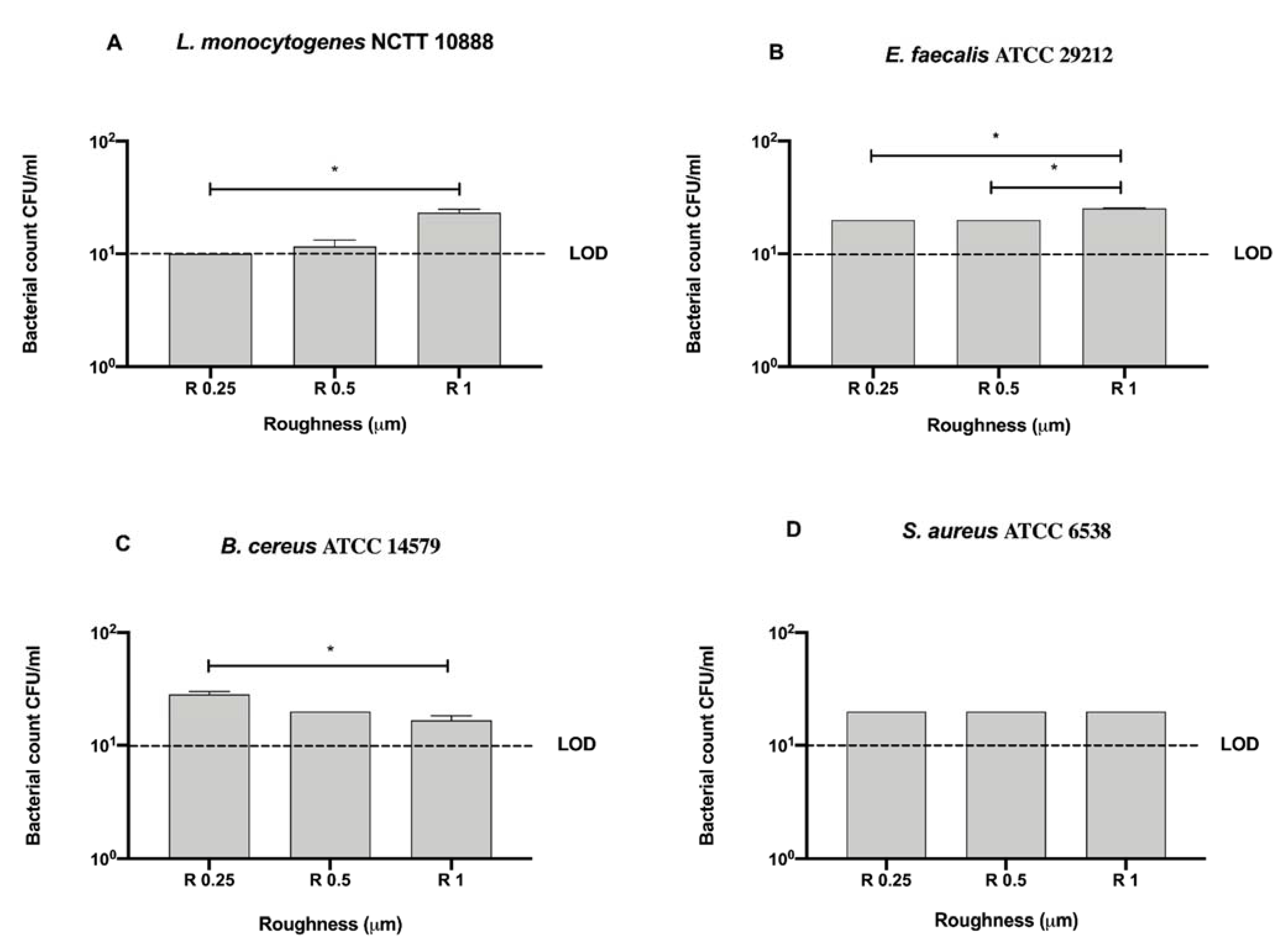

3.1. Untreated Stainless steel Samples

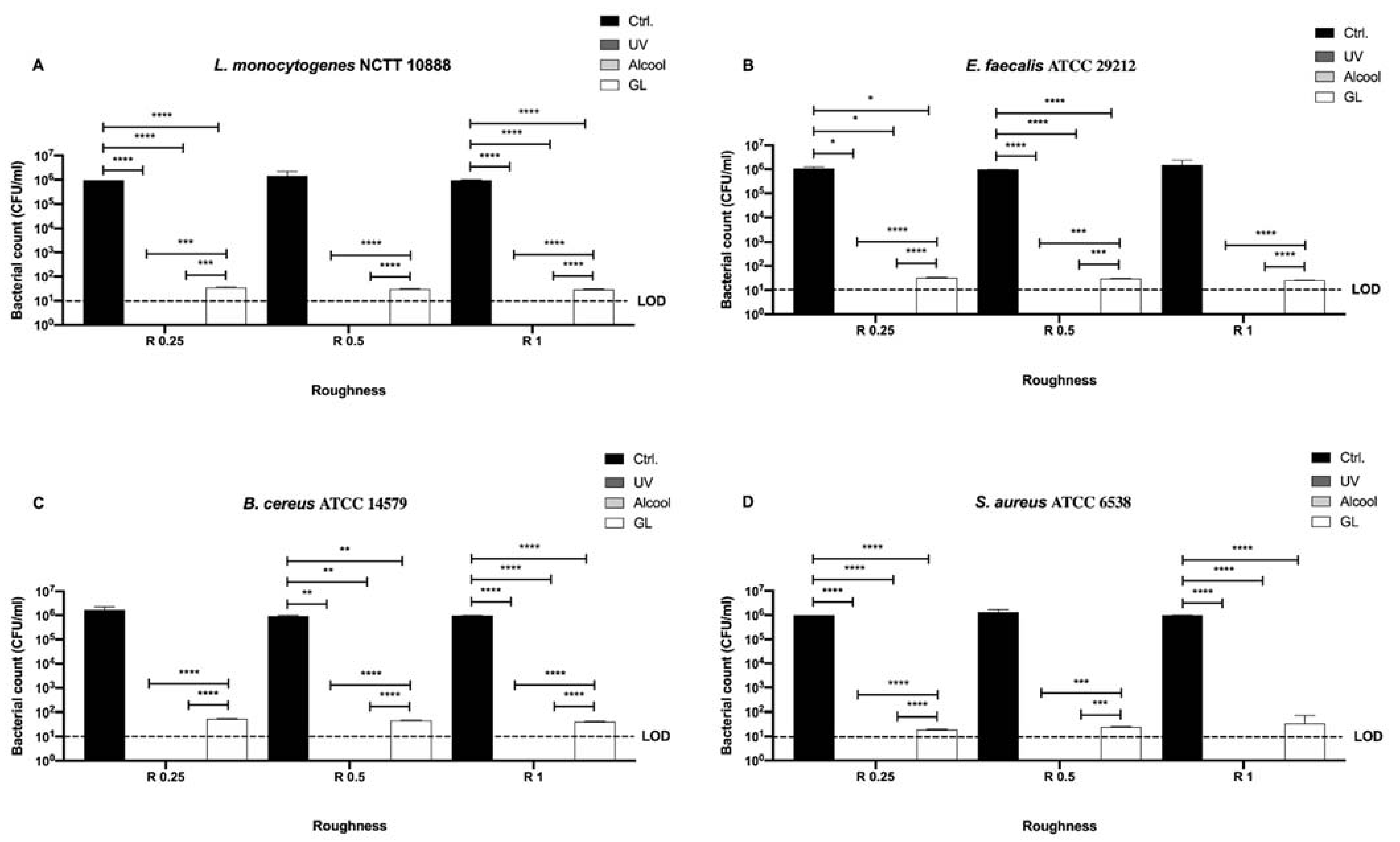

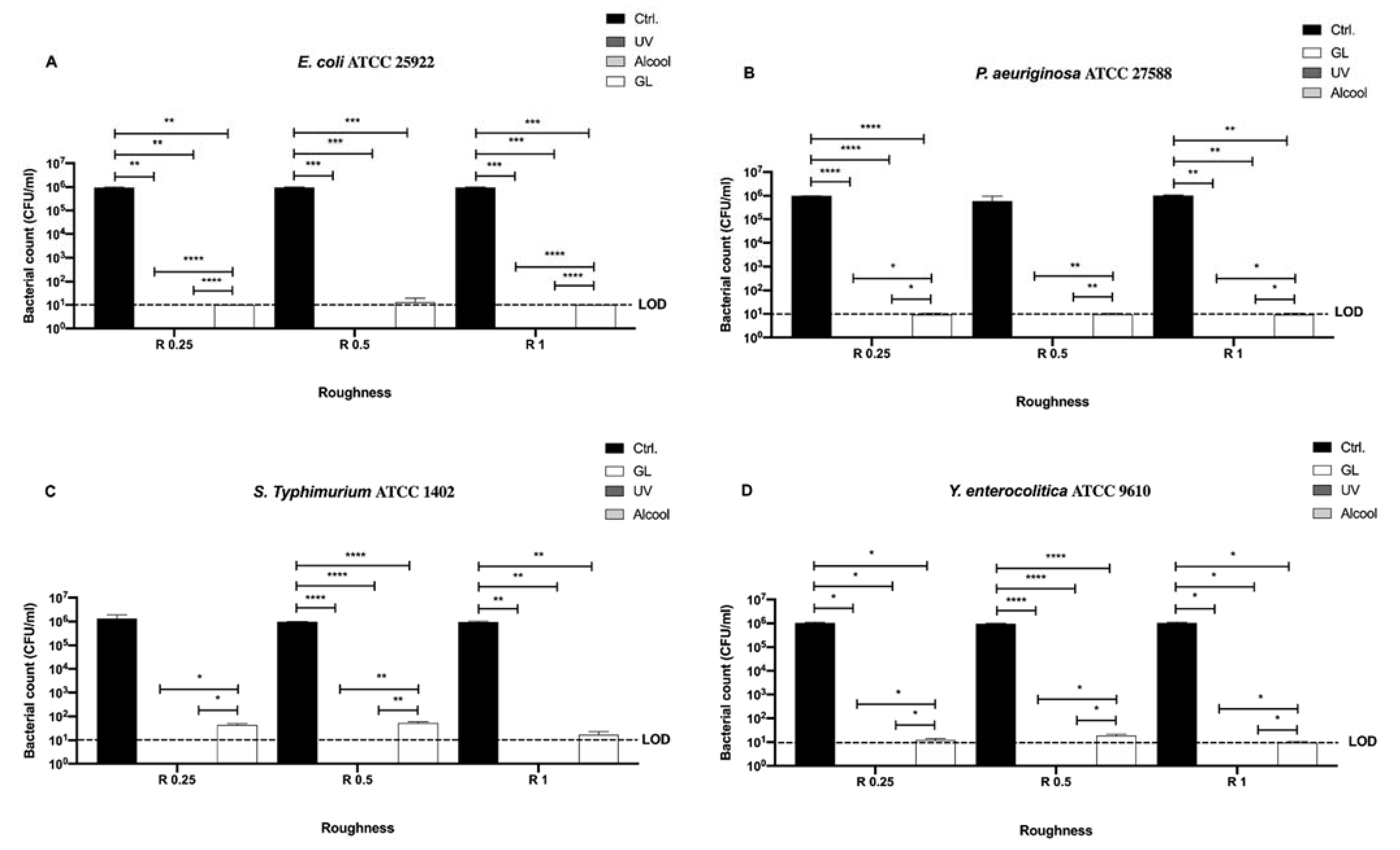

3.2. NanoXHAM® D-Coated Stainless steel Samples

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kuligowski, J.; Halperin, K.M. Stainless steel cookware as a significant source of nickel, chromium, and iron. Arch. Environ. Contam. Toxicol. 1992, 23, 211–215. [Google Scholar] [CrossRef]

- Francis, F.J. Wiley Encyclopedia of Food Science and Technology, 2nd ed.; Wiley: Hoboken, NJ, USA, 1999; Volume 4, p. 2816. [Google Scholar]

- Verran, J.; Airey, P.; Packer, A.; Whitehead, K.A. Microbial retention on open food contact surfaces and implications for food contamination. Adv. Appl. Microbiol. 2008, 64, 223–246. [Google Scholar] [CrossRef]

- Dewangan, A.K.; Patel, A.D.; Bhadania, A.G. Stainless Steel for Dairy and Food Industry: A Review. J. Mater. Sci. Eng. 2015, 4, 1–4. [Google Scholar] [CrossRef]

- Tuthill, A.H.; Brunkow, R. Stainless steels for bio-processing. Bioprocessing 2004, 2, 46–53. [Google Scholar]

- Hilbert, L.R.; Bagge-Ravn, D.; Kold, J.; Gram, L. Influence of surface roughness of stainless steel on microbial adhesion and corrosion resistance. Int. Biodeterior. Biodegrad. 2003, 52, 175–185. [Google Scholar] [CrossRef]

- Awad, T.S.; Asker, D.; Hatton, B.D. Food-Safe Modification of Stainless Steel Food-Processing Surfaces to Reduce Bacterial Biofilms. ACS Appl. Mater. Interfaces 2018, 10, 22902–22912. [Google Scholar] [CrossRef] [PubMed]

- Airey, P.; Verran, J. Potential use of copper as a hygienic surface; problems associated with cumulative soiling and cleaning. J. Hosp. Infect. 2007, 67, 271–277. [Google Scholar] [CrossRef]

- Arnold, J.W.; Boothe, D.H.; Suzuki, O.; Bailey, G.W. Multiple imaging techniques demonstrate the manipulation of surfaces to reduce bacterial contamination and corrosion. J. Microsc. 2004, 216, 215–221. [Google Scholar] [CrossRef]

- Verran, J.; Boyd, R.D.; Whitehead, K.A.; Hall, K. Surface Topography and the Retention of Organic Soil and Microorganisms on Hygienic Surfaces. In Proceedings of the 2nd Hygienic Coatings and Surfaces Conference, Orlando, FL, USA, 26–28 January 2004. [Google Scholar]

- Boulangé-Petermann, L.; Rault, J.; Bellon-Fontaine, M.N. Adhesion of streptococcus thermophilus to stainless steel with different surface topography and roughness. Biofouling 1997, 11, 201–216. [Google Scholar] [CrossRef]

- Flint, S.H.; Brooks, J.D.; Bremer, P.J. Properties of the stainless steel substrate, influencing the adhesion of thermo-resistant streptococci. J. Food Eng. 2000, 43, 235–242. [Google Scholar] [CrossRef]

- Holah, J.T.; Thorpe, R.H. Cleanability in relation to bacterial retention on unused and abraded domestic sink materials. J. Appl. Bacteriol. 1990, 69, 599–608. [Google Scholar] [CrossRef] [PubMed]

- Tide, C.; Harkin, S.R.; Geesey, G.G.; Bremer, P.J.; Scholz, W. The influence of welding procedures on bacterial colonization of stainless steel weldments. J. Food Eng. 1999, 42, 85–96. [Google Scholar] [CrossRef]

- Verran, J.; Boyd, R.D. The relationship between substratum surface roughness and microbiological and organic soiling: A review. Biofouling 2001, 17, 59–71. [Google Scholar] [CrossRef]

- Maller, R.R. Passivation of stainless steel. Trends Food Sci. Technol. 1998, 9, 28–32. [Google Scholar] [CrossRef]

- Verran, J.; Whitehead, K. Factors affecting microbial adhesion to stainless steel and other materials used in medical devices. Int. J. Artif. Organs 2005, 28, 1138–1145. [Google Scholar] [CrossRef]

- Verran, J.; Rowe, D.L.; Boyd, R.D. Visualization and measurement of nanometer dimension surface features using dental impression materials and atomic force microscopy. Int. Biodeterior. Biodegrad. 2003, 51, 221–228. [Google Scholar] [CrossRef]

- Cunliffe, D.; Smart, C.A.; Alexander, C.; Vulfson, E.N. Bacterial adhesion at synthetic surfaces. Appl. Environ. Microbiol. 1999, 65, 4995–5002. [Google Scholar] [CrossRef]

- Teughels, W.; Van Assche, N.; Sliepen, I.; Quirynen, M. Effect of material characteristics and/or surface topography on biofilm development. Clin. Oral Implant. Res. 2006, 17 (Suppl. 2), 68–81. [Google Scholar] [CrossRef]

- Wilks, S.A.; Michels, H.; Keevil, C.W. The survival of Escherichia coli O157 on a range of metal surfaces. Int. J. Food Microbiol. 2005, 105, 445–454. [Google Scholar] [CrossRef]

- Di Cerbo, A.; Pezzuto, F.; Scarano, A. Cytotoxic and Bacteriostatic Activity of Nanostructured TiO2 Coatings. Pol. J. Microbiol. 2016, 65, 225–229. [Google Scholar] [CrossRef]

- Wu, L.-Y.; Kuo, Y.-L.; Chang, K.-H.; Chen, T.-H.; Cheng, C.-Y.; Liu, Y.-S.; Huang, C. Effects of cyclonic plasma deposited organosilicon nano-coating on 316 stainless steel and its surface characterization. Surf. Interface Anal. 2019, 51, 993–1000. [Google Scholar] [CrossRef]

- Barreiros, F.M.; Vieira, M.T.; Castanho, J.M. Fine tuning injection feedstock by nano coating SS powder. Metal. Powder Rep. 2009, 64, 18–21. [Google Scholar] [CrossRef]

- Yun, H.; Li, J.; Chen, H.-B.; Lin, C.-J. A study on the N-, S- and Cl-modified nano-TiO2 coatings for corrosion protection of stainless steel. Electrochim. Acta 2007, 52, 6679–6685. [Google Scholar] [CrossRef]

- Rosace, G.; Canton, R.; Colleoni, C. Plasma enhanced CVD of SiOxCyHz thin film on different textile fabrics: Influence of exposure time on the abrasion resistance and mechanical properties. Appl. Surf. Sci. 2010, 256, 2509–2516. [Google Scholar] [CrossRef]

- Stoica, M.; Alexe, P.; Carac, G.; Nicolau, A. Importance of Finishing for the Integrity of Stainless Steel Surfaces during Sanitation Treatments. J. Environ. Prot. Ecol. 2011, 12, 1669–1679. [Google Scholar]

- Iannitti, T.; Di Cerbo, A.; Loschi, A.R.; Rea, S.; Suzawa, M.; Morales-Medina, J.C. Repeated administration of a flavonoid-based formulated extract from citrus peels significantly reduces peripheral inflammation-induced pain in the rat. Food Sci. Nutr. 2020, 8, 3173–3180. [Google Scholar] [CrossRef]

- Di Cerbo, A.; Mescola, A.; Iseppi, R.; Canton, R.; Rossi, G.; Stocchi, R.; Loschi, A.R.; Alessandrini, A.; Rea, S.; Sabia, C. Antibacterial Effect of Aluminum Surfaces Untreated and Treated with a Special Anodizing Based on Titanium Oxide Approved for Food Contact. Biology 2020, 9, 456. [Google Scholar] [CrossRef] [PubMed]

- MOMA Nanotech SRL. nanoXHAM® D. Available online: https://www.nanotech.it/bundles/datadeo/images/materiale/4183/nanoXham%20D_ita_2018.pdf (accessed on 19 December 2020).

- Moretti, G.; Guidi, F.; Canton, R.; Battagliarin, M.; Rossetto, G. Corrosion protection and mechanical performance of SiO2 films deposited via PECVD on OT59 brass. Anti-Corros. Methods Mater. 2005, 52, 266–275. [Google Scholar] [CrossRef]

- Lai, C.S.; Li, S.; Liu, C.B.; Miyauchi, Y.; Suzawa, M.; Ho, C.T.; Pan, M.H. Effective suppression of azoxymethane-induced aberrant crypt foci formation in mice with citrus peel flavonoids. Mol. Nutr. Food Res. 2013, 57, 551–555. [Google Scholar] [CrossRef]

- Plutino, M.R.; Colleoni, C.; Donelli, I.; Freddi, G.; Guido, E.; Maschi, O.; Mezzi, A.; Rosace, G. Sol-gel 3-glycidoxypropyltriethoxysilane finishing on different fabrics: The role of precursor concentration and catalyst on the textile performances and cytotoxic activity. J. Colloid Interface Sci. 2017, 506, 504–517. [Google Scholar] [CrossRef]

- Long, D.A. Infrared and Raman characteristic group frequencies. Tables and charts George Socrates John Wiley and Sons, Ltd., Chichester, Third Edition, 2001. Price £135. J. Raman Spectrosc. 2004, 35, 905. [Google Scholar] [CrossRef]

- Patel, R.P.; Wolden, C.A. Plasma-enhanced chemical vapor deposition synthesis of silica-silicone nanolaminates using a single precursor. J. Vac. Sci. Technol. A 2011, 29, 021012. [Google Scholar] [CrossRef]

- Theil, J.A.; Tsu, D.V.; Watkins, M.W.; Kim, S.S.; Lucovsky, G. Local bonding environments of Si–OH groups in SiO2 deposited by remote plasma-enhanced chemical vapor deposition and incorporated by postdeposition exposure to water vapor. J. Vac. Sci. Technol. A 1990, 8, 1374–1381. [Google Scholar] [CrossRef]

- Rodriguez, A.; Autio, W.R.; McLandsborough, L.A. Effect of surface roughness and stainless steel finish on Listeria monocytogenes attachment and biofilm formation. J. Food Prot. 2008, 71, 170–175. [Google Scholar] [CrossRef]

- Guobjrnsdottir, B.; Einarsson, H.; Thorkelsson, G. Microbial Adhesion to Processing Lines for Fish Fillets and Cooked Shrimp: Influence of Stainless Steel Surface Finish and Presence of Gram-Negative Bacteria on the Attachment of Listeria monocytogenes**. Food Technol. Biotechnol. 2005, 43, 55–61. [Google Scholar]

- Alessandrini, A.; Seeger, H.M.; Di Cerbo, A.; Caramaschi, T.; Facci, P. What do we really measure in AFM punch-through experiments on supported lipid bilayers? Soft Matter 2011, 7, 7054–7064. [Google Scholar] [CrossRef]

- Seeger, H.M.; Di Cerbo, A.; Alessandrini, A.; Facci, P. Supported lipid bilayers on mica and silicon oxide: Comparison of the main phase transition behavior. J. Phys. Chem. B 2010, 114, 8926–8933. [Google Scholar] [CrossRef]

- Whitehead, K.A.; Rogers, D.; Colligon, J.; Wright, C.; Verran, J. Use of the atomic force microscope to determine the effect of substratum surface topography on the ease of bacterial removal. Colloids Surf. B Biointerfaces 2006, 51, 44–53. [Google Scholar] [CrossRef]

- Rio, L.; Kusiak-Nejman, E.; Kiwi, J.; Bétrisey, B.; Pulgarin, C.; Trampuz, A.; Bizzini, A. Comparison of Methods for Evaluation of the Bactericidal Activity of Copper-Sputtered Surfaces against Methicillin-Resistant Staphylococcus aureus. Appl. Environ. Microbiol. 2012, 78, 8176–8182. [Google Scholar] [CrossRef]

- Lin, C.C.; Wu, J.J.; Pan, Y.G.; Chao, Y.H.; Lin, F.C.; Lee, Y.R.; Chu, C.L. Gold lotion from citrus peel extract ameliorates imiquimod-induced psoriasis-like dermatitis in murine. J. Sci. Food Agric. 2018, 98, 5509–5517. [Google Scholar] [CrossRef]

- Li, S.; Lin, Y.C.; Ho, C.T.; Lin, P.Y.; Suzawa, M.; Wang, H.C.; Chu, C.L.; Chen, D.Y.; Lin, C.C. Formulated extract from multiple citrus peels impairs dendritic cell functions and attenuates allergic contact hypersensitivity. Int. Immunopharmacol. 2014, 20, 12–23. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.; Yang, W.; Tang, F.; Chen, X.; Ren, L. Antibacterial activities of flavonoids: Structure-activity relationship and mechanism. Curr. Med. Chem. 2015, 22, 132–149. [Google Scholar] [CrossRef] [PubMed]

- Cabeca, T.K.; Pizzolitto, A.C.; Pizzolitto, E.L. Activity of disinfectants against foodborne pathogens in suspension and adhered to stainless steel surfaces. Braz. J. Microbiol. 2012, 43, 1112–1119. [Google Scholar] [CrossRef] [PubMed][Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Cerbo, A.; Mescola, A.; Rosace, G.; Stocchi, R.; Rossi, G.; Alessandrini, A.; Preziuso, S.; Scarano, A.; Rea, S.; Loschi, A.R.; et al. Antibacterial Effect of Stainless Steel Surfaces Treated with a Nanotechnological Coating Approved for Food Contact. Microorganisms 2021, 9, 248. https://doi.org/10.3390/microorganisms9020248

Di Cerbo A, Mescola A, Rosace G, Stocchi R, Rossi G, Alessandrini A, Preziuso S, Scarano A, Rea S, Loschi AR, et al. Antibacterial Effect of Stainless Steel Surfaces Treated with a Nanotechnological Coating Approved for Food Contact. Microorganisms. 2021; 9(2):248. https://doi.org/10.3390/microorganisms9020248

Chicago/Turabian StyleDi Cerbo, Alessandro, Andrea Mescola, Giuseppe Rosace, Roberta Stocchi, Giacomo Rossi, Andrea Alessandrini, Silvia Preziuso, Antonio Scarano, Stefano Rea, Anna Rita Loschi, and et al. 2021. "Antibacterial Effect of Stainless Steel Surfaces Treated with a Nanotechnological Coating Approved for Food Contact" Microorganisms 9, no. 2: 248. https://doi.org/10.3390/microorganisms9020248

APA StyleDi Cerbo, A., Mescola, A., Rosace, G., Stocchi, R., Rossi, G., Alessandrini, A., Preziuso, S., Scarano, A., Rea, S., Loschi, A. R., & Sabia, C. (2021). Antibacterial Effect of Stainless Steel Surfaces Treated with a Nanotechnological Coating Approved for Food Contact. Microorganisms, 9(2), 248. https://doi.org/10.3390/microorganisms9020248