Admittance-Controlled Teleoperation of a Pneumatic Actuator: Implementation and Stability Analysis

Abstract

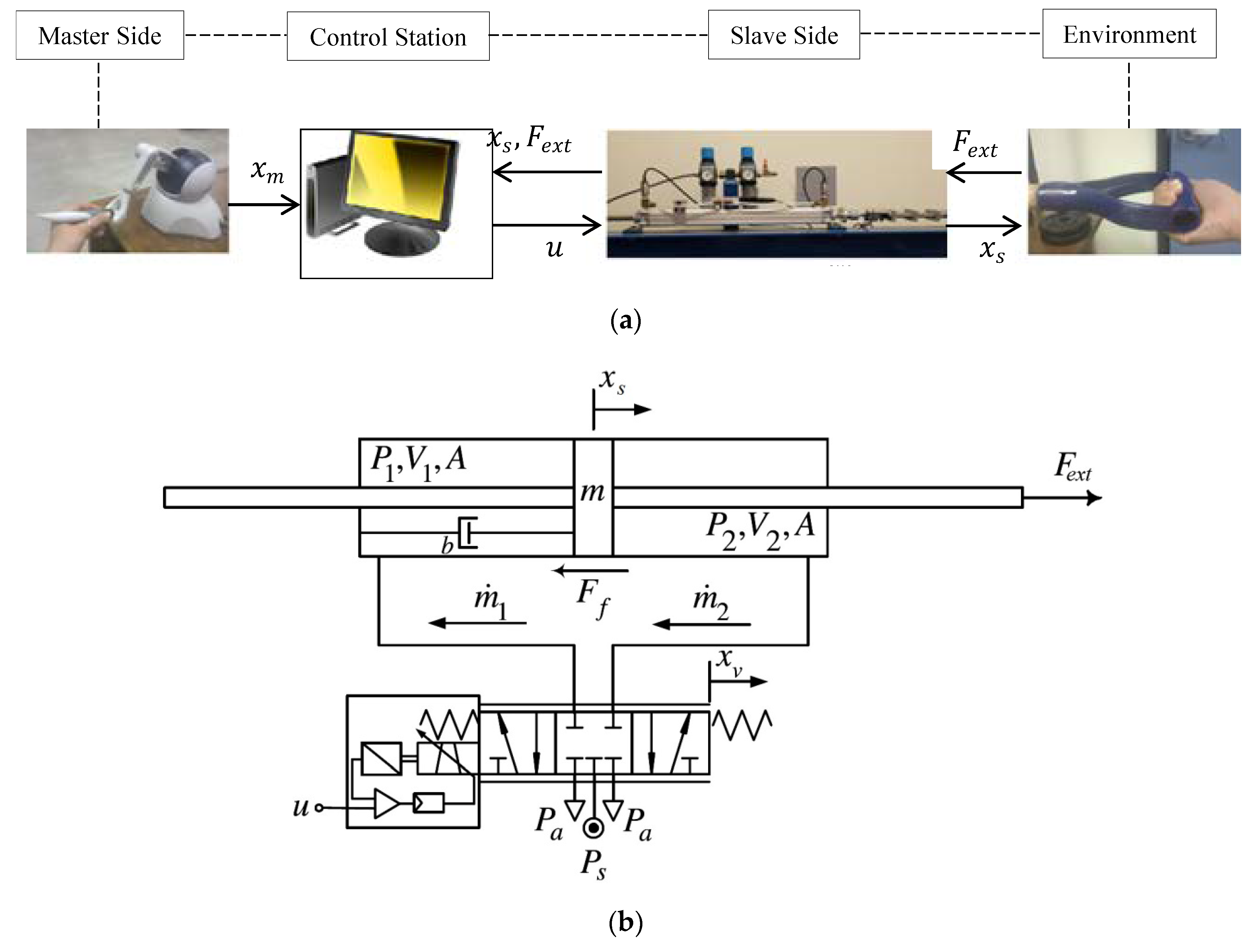

1. Introduction

2. Experimental Setup

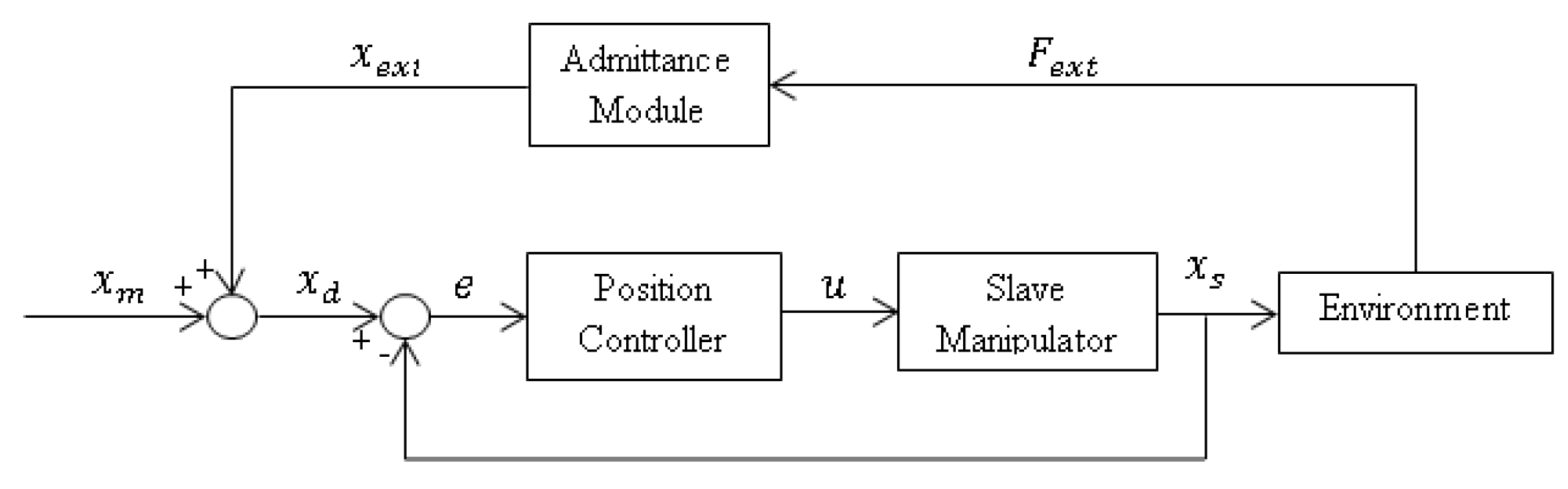

3. Control Architecture

3.1. Admittance Control

3.2. Position Controller

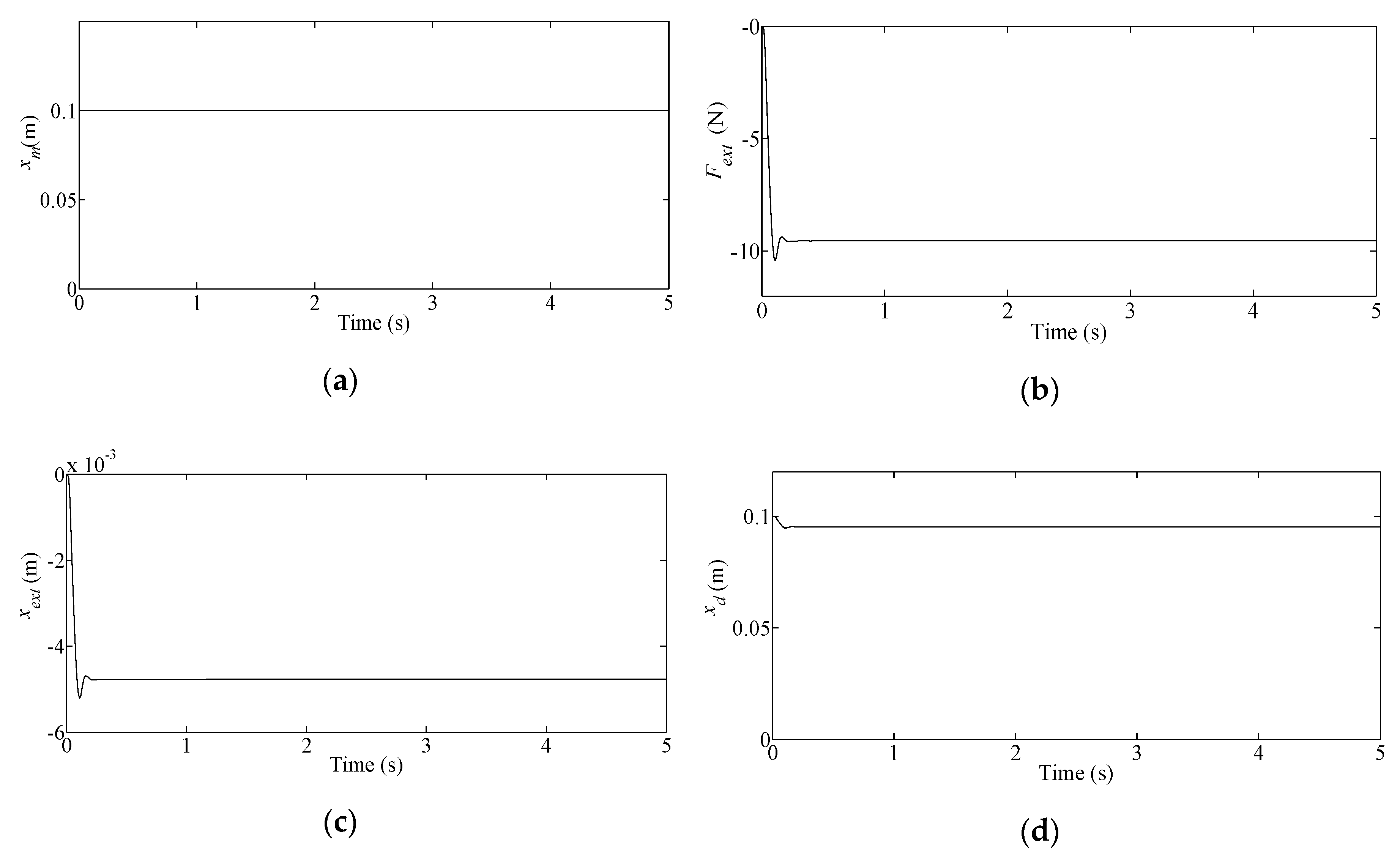

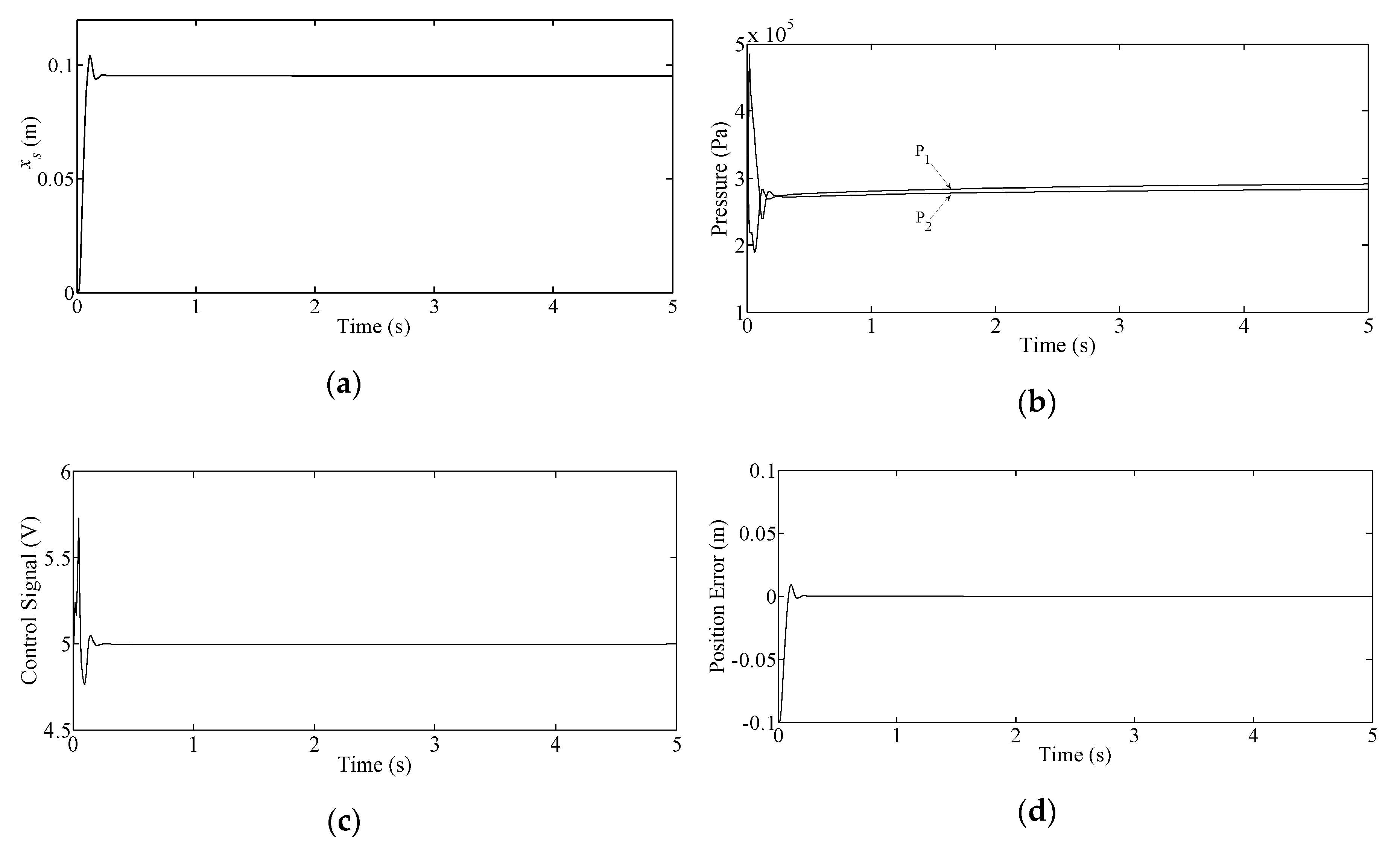

4. Simulation Studies

5. Stability Analysis

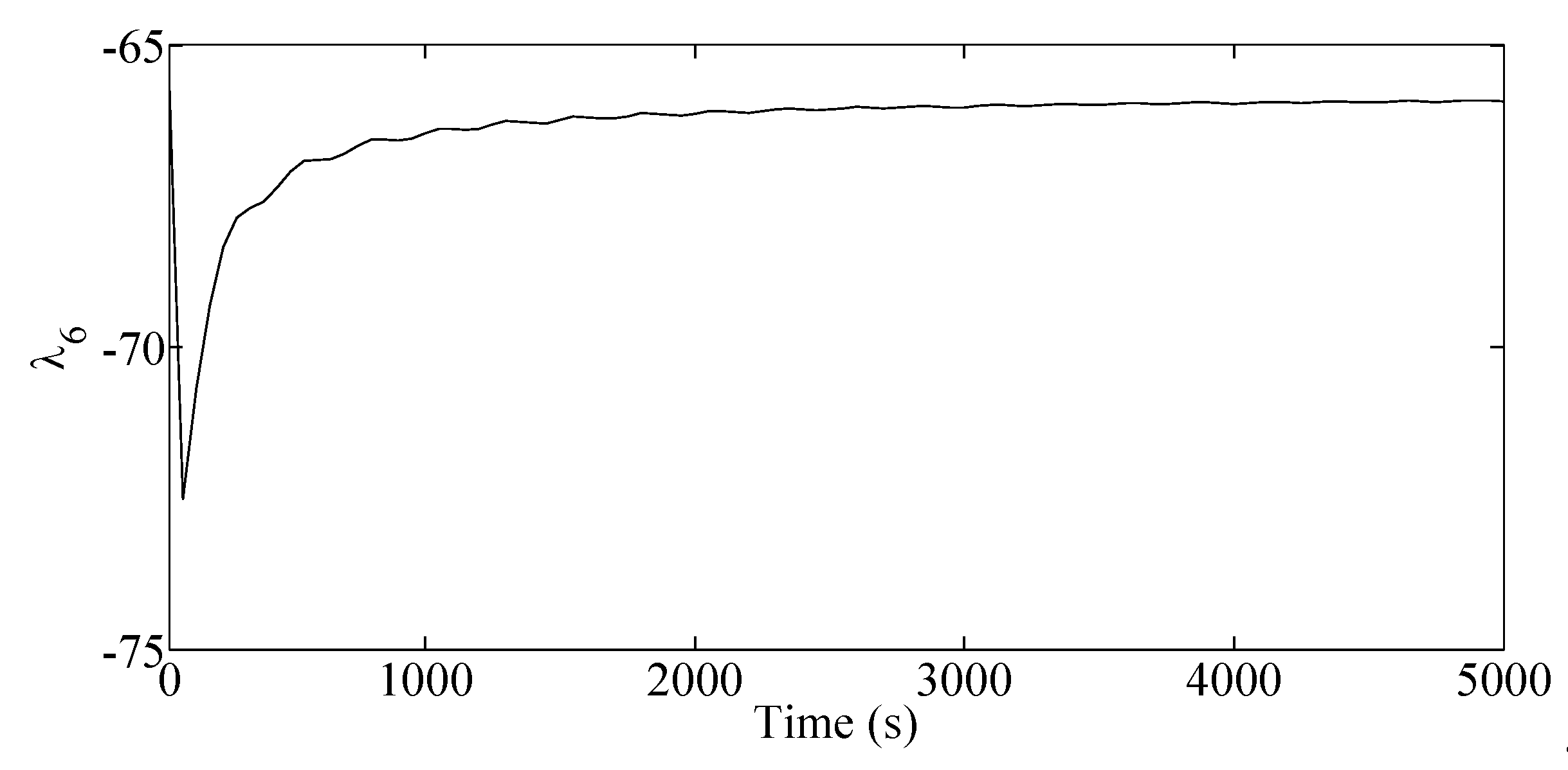

5.1. Calculation of Lyapunov Exponents

5.2. Stability Analysis of the Proposed Control System

5.3. Parametric Stability Analysis

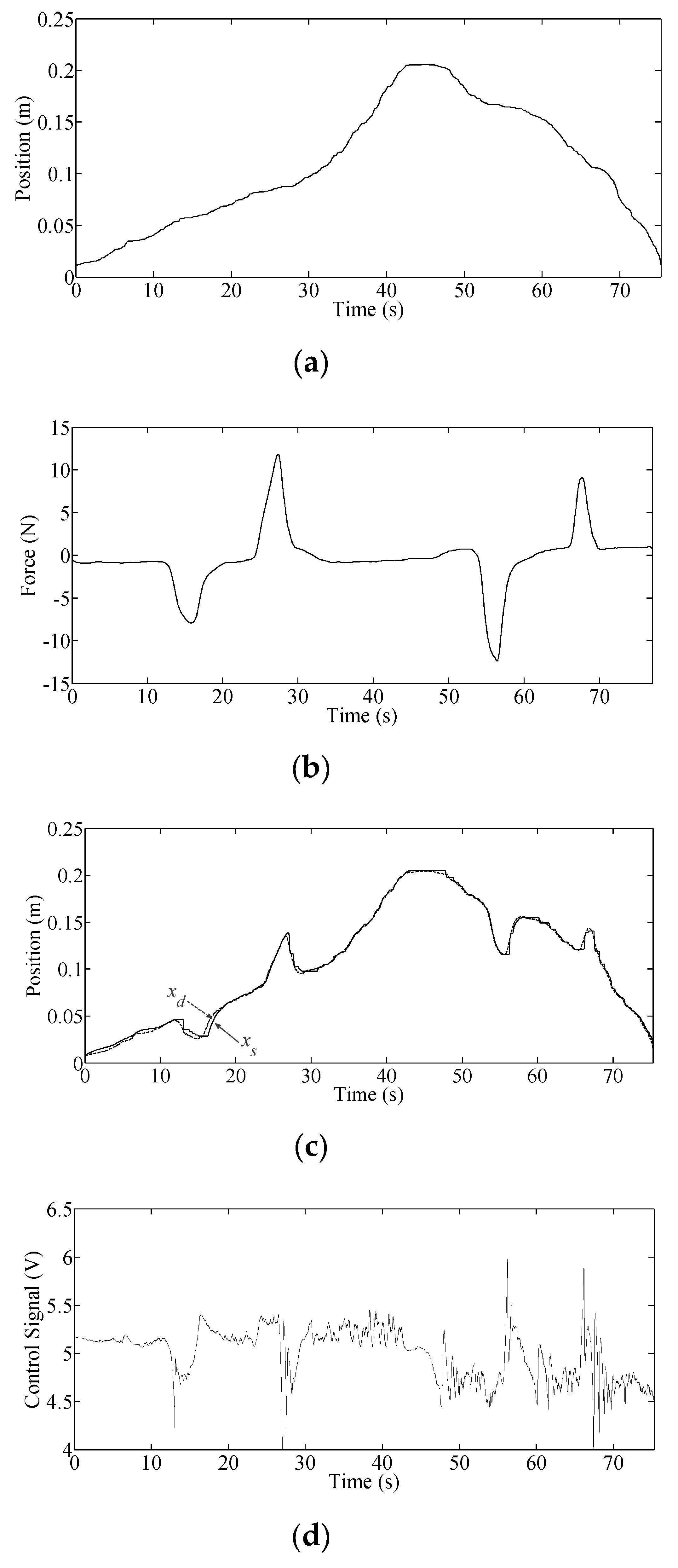

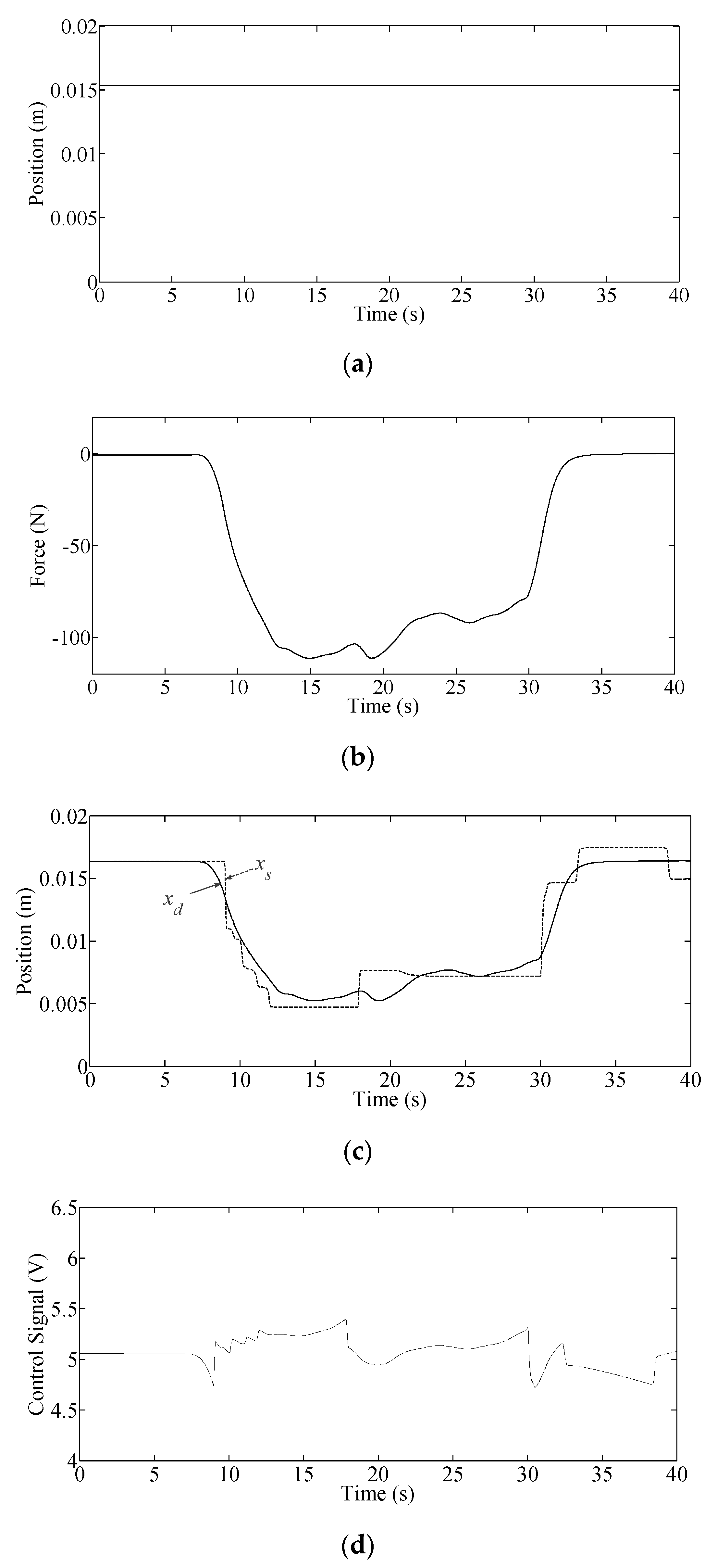

6. Experimental Results

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lawrence, P.; Salcudean, S.; Sepehri, N.; Chan, D.; Bachmann, S.; Parker, N.; Zhu, M.; Frenette, R. Coordinated and Force Feedback Control of Hydraulic Excavators. In Proceedings of the 4th International Symposium of Experimental Robotics, Stanford, CA, USA, 30 June–2 July 1995. [Google Scholar]

- Kontz, M.; Beckwith, J.; Book, W. Evaluation of a teleoperated haptic forklift. In Proceedings of the IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Monterey, CA, USA, 24–28 July 2005. [Google Scholar]

- Hokayem, P.F.; Spong, M.W. Bilateral teleoperation: An historical survey. Automatica 2006, 42, 2035–2057. [Google Scholar] [CrossRef]

- Le, M.; Pham, M.; Tavakoli, M.; Moreau, R. Sliding Mode Control of a Pneumatic Haptic Teleoperation System with on/off Solenoid Valves. In Proceedings of the IEEE International Conference on Robotics and Automation, Anchorage, AK, USA, 3–7 May 2010. [Google Scholar]

- Tadano, K.; Kawashima, K. Development of a Master–Slave System with Force-Sensing Abilities using Pneumatic Actuators for Laparoscopic Surgery. J. Adv. Robot. 2010, 24, 1763–1783. [Google Scholar] [CrossRef]

- Anderson, R.J. Bilateral control of teleoperators with time delay. IEEE Trans. Autom. Control 1989, 34, 494–501. [Google Scholar] [CrossRef]

- Dakkan, K.; Barth, E.; Goldfarb, M. Dynamic constraint based energy saving control of pneumatic servo systems. ASME J. Dyn. Syst. Meas. Control 2006, 128, 655–662. [Google Scholar] [CrossRef][Green Version]

- Zarei-nia, K.; Sepehri, N. Lyapunov stable displacement-mode haptic manipulation of hydraulic actuators: Theory and experiment. Int. J. Control 2012, 85, 1313–1326. [Google Scholar] [CrossRef]

- Yang, C.; Wu, Q.; Zhang, P. Estimation of Lyapunov exponents from a time series for N-dimensional state space using nonlinear mapping. Nonlinear Dyn. 2012, 69, 1493–1507. [Google Scholar] [CrossRef]

- Hannaford, B. A design framework for teleoperators with kinesthetic feedback. IEEE Trans. Robot. Autom. 1989, 5, 426–434. [Google Scholar] [CrossRef]

- Leleve, A.; Pham, M.; Tavakoli, M.; Moreau, R. Towards Delayed Teleoperation with Pneumatic Master and Slave for MRI. In Proceedings of the ASME Biennial Conference on Engineering Systems Design and Analysis, Nantes, France, 2 July 2012. [Google Scholar]

- Hodgson, S.; Le, M.; Tavakoli, M.; Pham, M. Improved tracking and switching performance of an electro-pneumatic positioning system. J. Mechatron. 2012, 22, 1–12. [Google Scholar] [CrossRef]

- Hogan, N.; Buerger, S. Impedance and Interaction Control. In Robotics and Automation Handbook; CRC Press: Boca Raton, FL, USA, 2004; Chapter 19; p. 24. [Google Scholar]

- Durbha, V.; Li, P. Passive Bilateral Teleoperation and Human Power Amplification with Pneumatic Actuators. In Proceedings of the ASME Dynamic Systems and Control Conference, Hollywood, CA, USA, 12–14 October 2009. [Google Scholar]

- Khalil, H. Nonlinear Systems; Prentice Hall: Upper Saddle River, NJ, USA, 1995. [Google Scholar]

- Hogan, N. Controlling impedance at the man/machine interface. In Proceedings of the IEEE International Conference on Robotics and Automation, Scottsdale, AZ, USA, 14–19 May 1989. [Google Scholar]

- Durbha, V.; Li, P. Passive Tele-Operation of Pneumatic Powered Robotic Rescue Crawler. In Proceedings of the 6th FPNI-PhD Symposium, West Lafayette, IN, USA, 15–19 June 2010. [Google Scholar]

- Li, H.; Tadano, K.; Kawashima, K. Achieving Force Perception in Master-Slave Manipulators Using Pneumatic Artificial Muscles. In Proceedings of the Society of Instrument & Control Engineers (SICE) Annual Conference, Akita, Japan, 20–23 August 2012. [Google Scholar]

- Hogan, N. Impedance control: An approach to manipulation part I,II,III. J. Dyn. Syst. Meas. Control 1985, 107, 1–24. [Google Scholar] [CrossRef]

- Sekhavat, P.; Sepehri, N.; Wu, C. Overall Stability Analysis of Hydraulic Actuator’s Switching Contact Control Using the Concept of Lyapunov Exponents. In Proceedings of the International Conference on Robotics and Automation, Barcelona, Spain, 18–22 April 2005. [Google Scholar]

- Garmsiri, N.; Sun, Y.; Yang, C.; Sepehri, N. Bilateral teleoperation of a pneumatic actuator: Experiment and stability analysis. Int. J. Fluid Power 2015, 16, 99–110. [Google Scholar] [CrossRef]

- De Wit, C.C.; Olsson, H.; Astrom, K.; Lischinsky, P. A new model for control of systems with friction. IEEE Trans. Autom. Control 1995, 40, 419–425. [Google Scholar] [CrossRef]

- Liu, S.; Bobrow, J. An analysis of a pneumatic servo system. Trans. ASME J. Dyn. Syst. Meas. Control 1988, 110, 228–235. [Google Scholar] [CrossRef]

- Richer, E.; Hurmuzlu, Y. A High Performance Pneumatic Force Actuator System: Part II—Nonlinear Controller Design. J. Dyn. Syst. Meas. Control 2000, 122, 426–434. [Google Scholar] [CrossRef]

- Sanville, F. A new method of specifying the flow capacity of pneumatic fluid power valves. BHRA 2nd Int. Fluid Power Symp. 1971, D337–D347. [Google Scholar]

- Karpenko, M.; Sepehri, N. Development and Experimental Evaluation of a Fixed-Gain Nonlinear Control for a Low-Cost Pneumatic Actuator. IEEE Proc. Control Theory Appl. 2006, 153, 629–640. [Google Scholar] [CrossRef]

- Richardson, R.; Brown, M.; Bhakta, B.; Levesley, M. Impedance control for a pneumatic robot-based around pole-placement, joint space controllers. J. Control Eng. Pract. 2005, 13, 291–303. [Google Scholar] [CrossRef]

- Shen, X. Nonlinear model-based control of pneumatic artificial muscle servo systems. J. Control Eng. Pract. 2010, 18, 311–317. [Google Scholar] [CrossRef]

- Gulati, N.; Barth, E. A Globally Stable, Load-Independent Pressure Observer for the Servo Control of Pneumatic Actuators. IEEE ASME Trans. Mechatron. 2009, 14, 295–306. [Google Scholar] [CrossRef]

- Sadri, S.; Wu, C. Stability analysis of a nonlinear vehicle model in plane motion using the concept of Lyapunov exponents. Int. J. Veh. Mech. Mobil. 2013, 51, 906–924. [Google Scholar] [CrossRef]

- Wolf, A.; Swift, J.; Swinney, H.; Vastano, J. Determining Lyapunov Exponents from a Time Series. J. Phys. 1985, 16, 285–317. [Google Scholar] [CrossRef]

- Garmsiri, N.; Sun, Y.; Sepehri, N. Impedance Control of a Teleoperated Pneumatic Actuator: Implementation and Stability Analysis. ACTA Control Intell. Syst. 2017, 45, 19–30. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

| Parameter | Symbol (Unit) | Value |

|---|---|---|

| Actuator stroke | ||

| Piston annulus area | () | |

| Valve time constant | ||

| Valve orifice area gradient | ||

| Supply pressure | () | 5 |

| Valve coefficient of discharge | ||

| Static friction | 38.5 | |

| Coulomb friction | 32.9 | |

| Ratio of specific heats | ||

| Ideal gas constant | ||

| Valve critical pressure ratio | ||

| Valve spool gain | ||

| Damping coefficient of bristle | 93.13 | |

| Spring constant of bristle | 4500 | |

| Mass of moving parts | () | |

| Compressibility correction factor | ||

| Temperature of air | ||

| Atmospheric pressure | 1 | |

| Viscous damping coefficient | b (Ns/m) | 70 |

| Stribeck velocity | 0.02 | |

| Cylinder inactive volume |

| 0.0 | 0.0 | −0.1 | −17.8 | −18.0 |

| 10 | 0.0 | 0.0 | −0.1 | −17.7 | −18.0 | −75.7 | −229.3 |

| 50 | 0.0 | 0.0 | −0.1 | −17.8 | −18.0 | −75.7 | −229.3 |

| 100 | 0.0 | 0.0 | −0.1 | −17.8 | −18.0 | −75.5 | −229.4 |

| 150 | 0.0 | 0.0 | −0.1 | −17.8 | −18.1 | −75.5 | −229.5 |

| 200 | 0.0 | 0.0 | −0.1 | −17.9 | −18.1 | −75.4 | −229.6 |

| 300 | 0.0 | 0.0 | −0.1 | −17.9 | −18.1 | −75.3 | −229.7 |

| 600 | 0.0 | 0.0 | −0.1 | −18.1 | −18.6 | −74.8 | −230.1 |

| 20 | 0.0 | 0.0 | −0.1 | −19.8 | −64.6 | −64.7 | −191.4 |

| 30 | 0.0 | 0.0 | −0.1 | −26.0 | −56.1 | −56.1 | −202.3 |

| 40 | 0.0 | 0.0 | −0.1 | −34.3 | −47.8 | −47.8 | −210.7 |

| 60 | 0.0 | 0.0 | −0.1 | −31.7 | −31.9 | −55.0 | −222.2 |

| 80 | 0.0 | 0.0 | −0.1 | −17.8 | −18.1 | −75.5 | −229.4 |

| 100 | 0.0 | 0.0 | −0.4 | −13.2 | −14.5 | −83.2 | −230.0 |

| 120 | 0.0 | 0.0 | −0.7 | −7.5 | −34.4 | −70.9 | −228.0 |

| 140 | 56.6 | - | - | - | - | - | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garmsiri, N.; Sun, Y.; Sekhavat, P.; Yang, C.X.; Sepehri, N. Admittance-Controlled Teleoperation of a Pneumatic Actuator: Implementation and Stability Analysis. Actuators 2020, 9, 103. https://doi.org/10.3390/act9040103

Garmsiri N, Sun Y, Sekhavat P, Yang CX, Sepehri N. Admittance-Controlled Teleoperation of a Pneumatic Actuator: Implementation and Stability Analysis. Actuators. 2020; 9(4):103. https://doi.org/10.3390/act9040103

Chicago/Turabian StyleGarmsiri, Naghmeh, Yuming Sun, Pooya Sekhavat, Cai Xia Yang, and Nariman Sepehri. 2020. "Admittance-Controlled Teleoperation of a Pneumatic Actuator: Implementation and Stability Analysis" Actuators 9, no. 4: 103. https://doi.org/10.3390/act9040103

APA StyleGarmsiri, N., Sun, Y., Sekhavat, P., Yang, C. X., & Sepehri, N. (2020). Admittance-Controlled Teleoperation of a Pneumatic Actuator: Implementation and Stability Analysis. Actuators, 9(4), 103. https://doi.org/10.3390/act9040103