Design for Disassembly and Augmented Reality Applied to a Tailstock

Abstract

1. Introduction

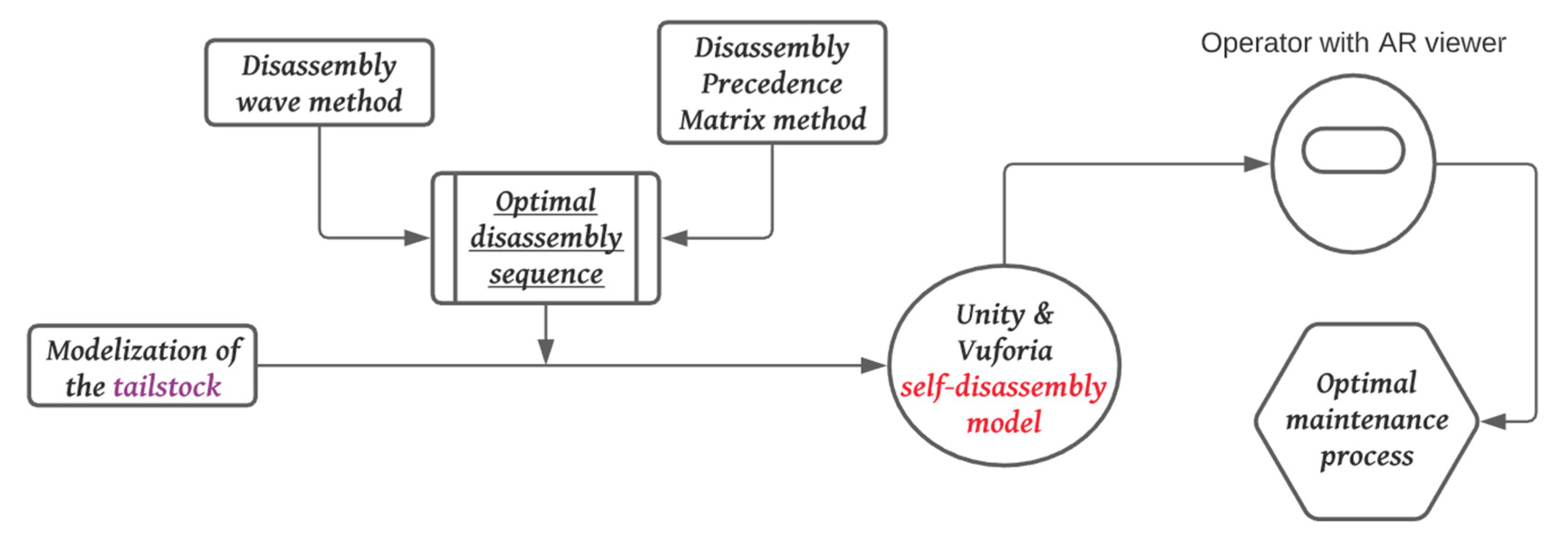

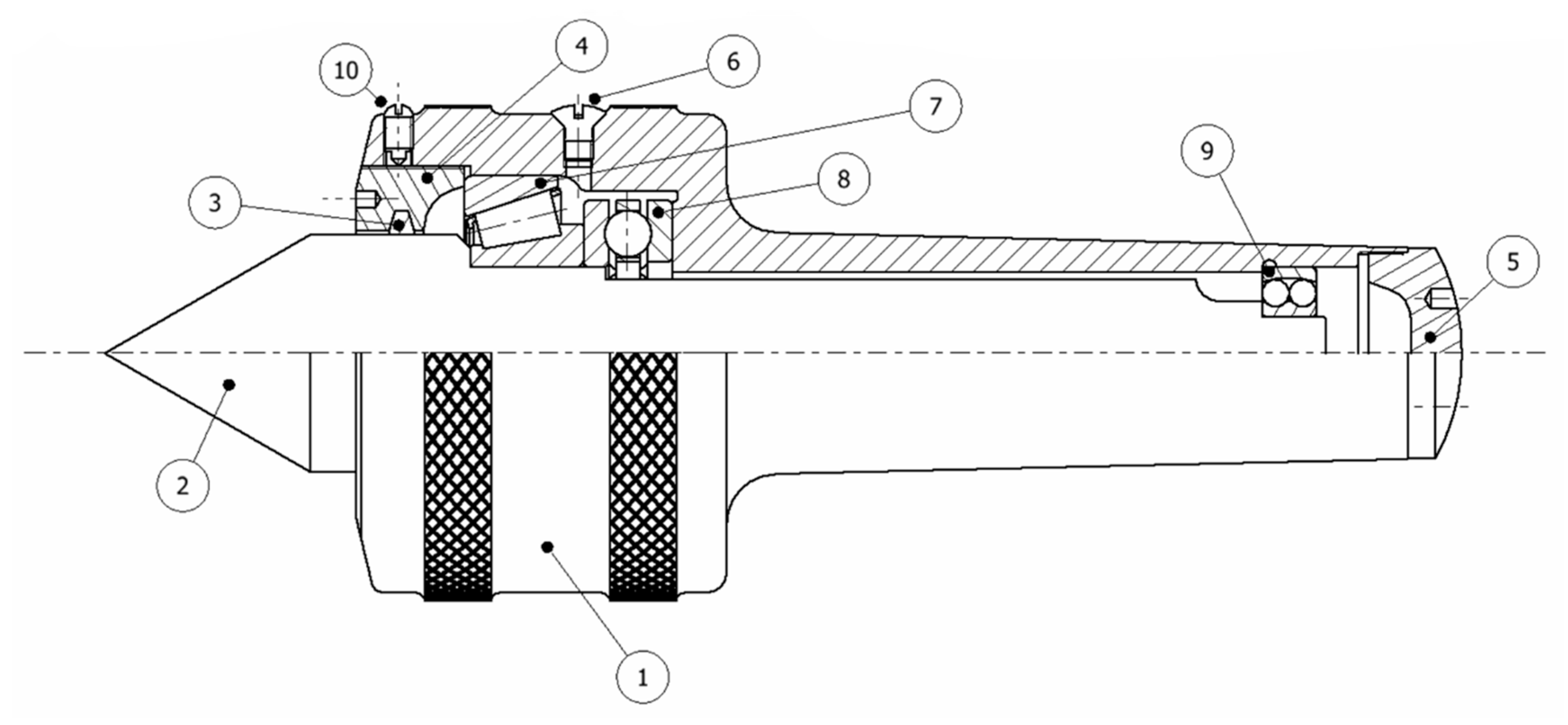

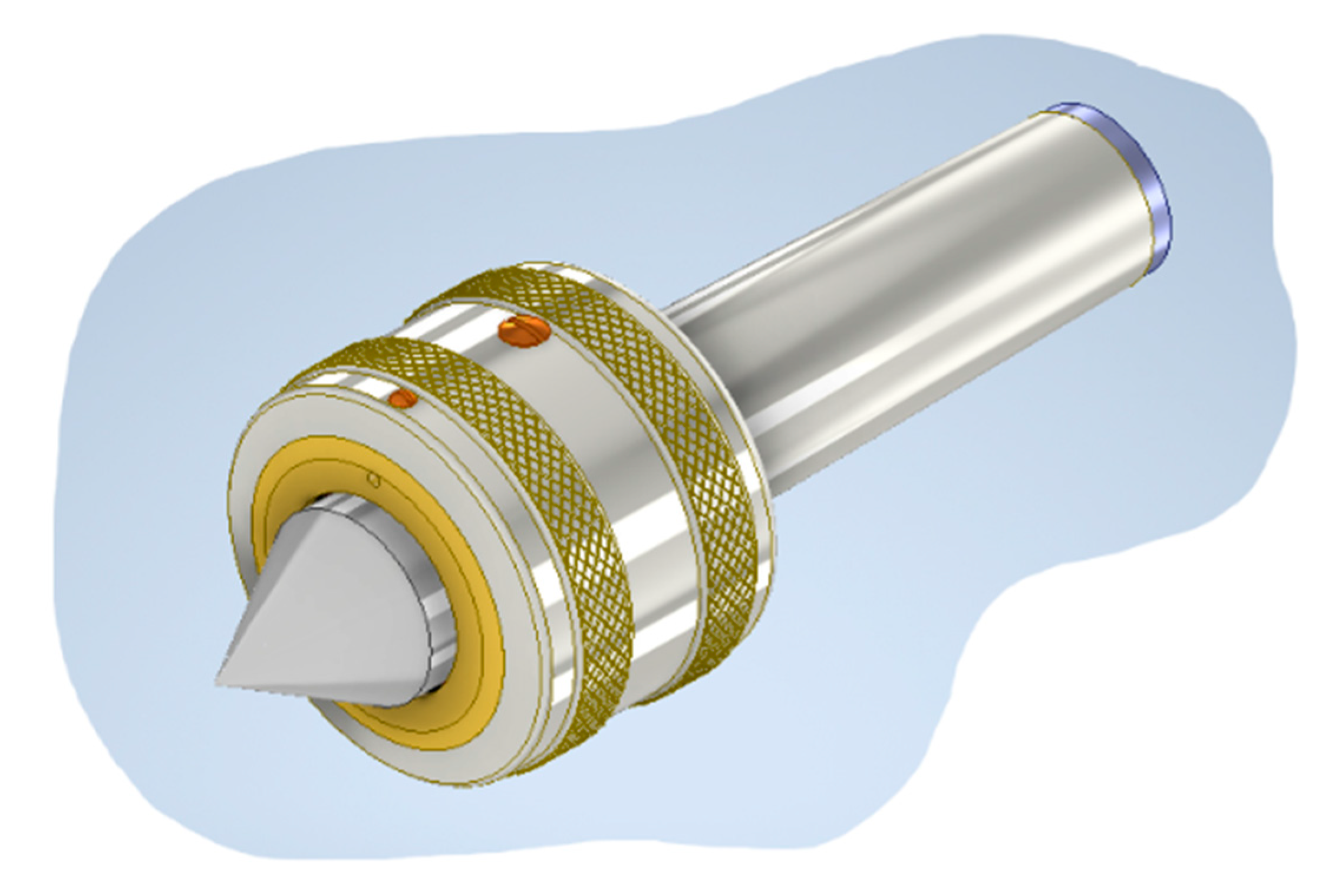

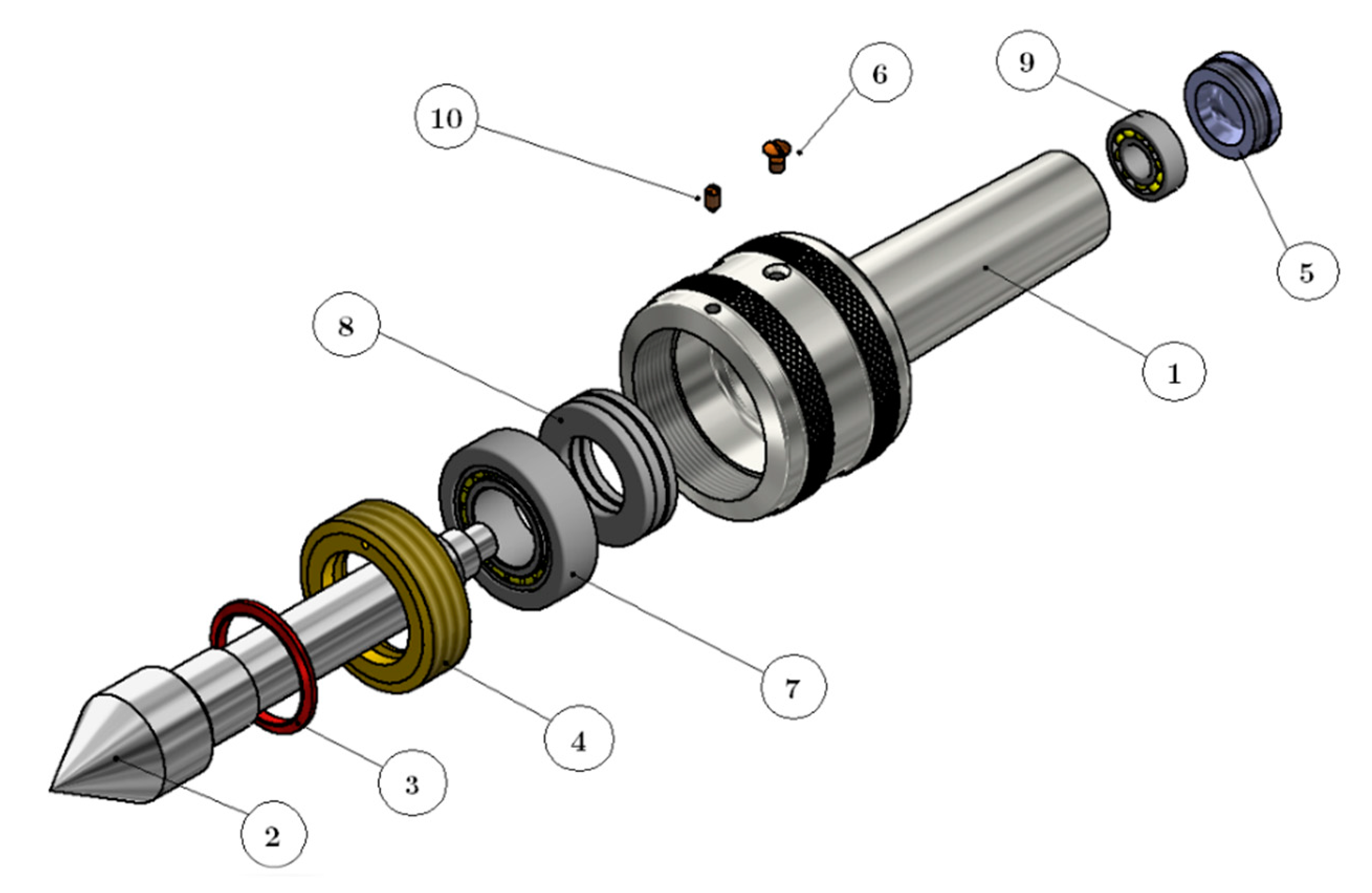

2. Case Study: The Tailstock

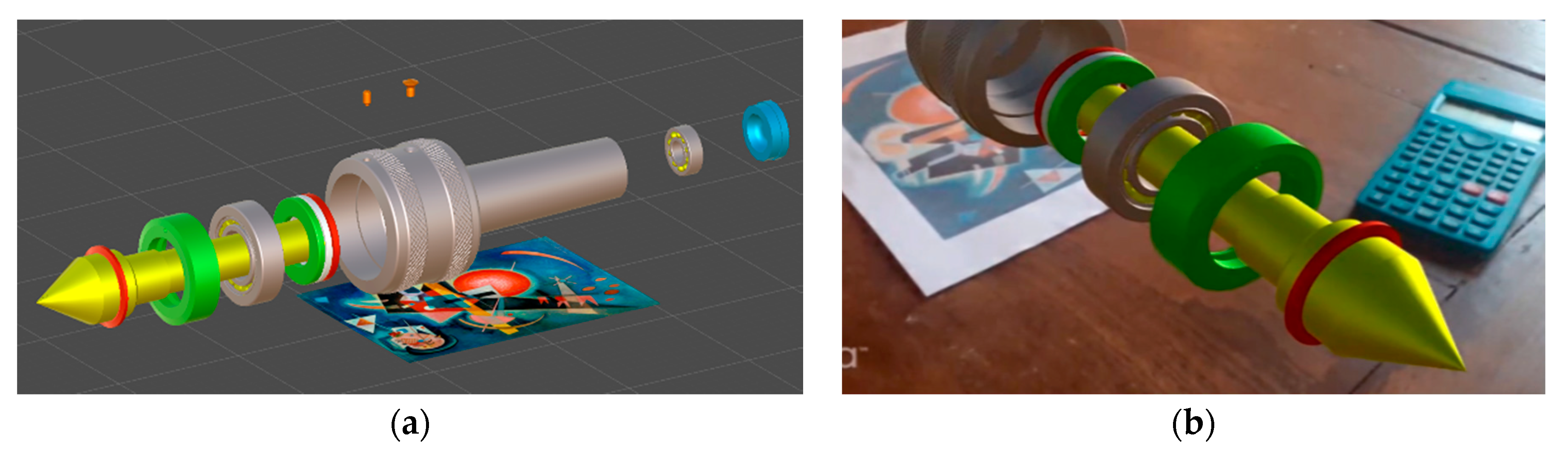

2.1. Industrial Use

2.2. CAD Modeling

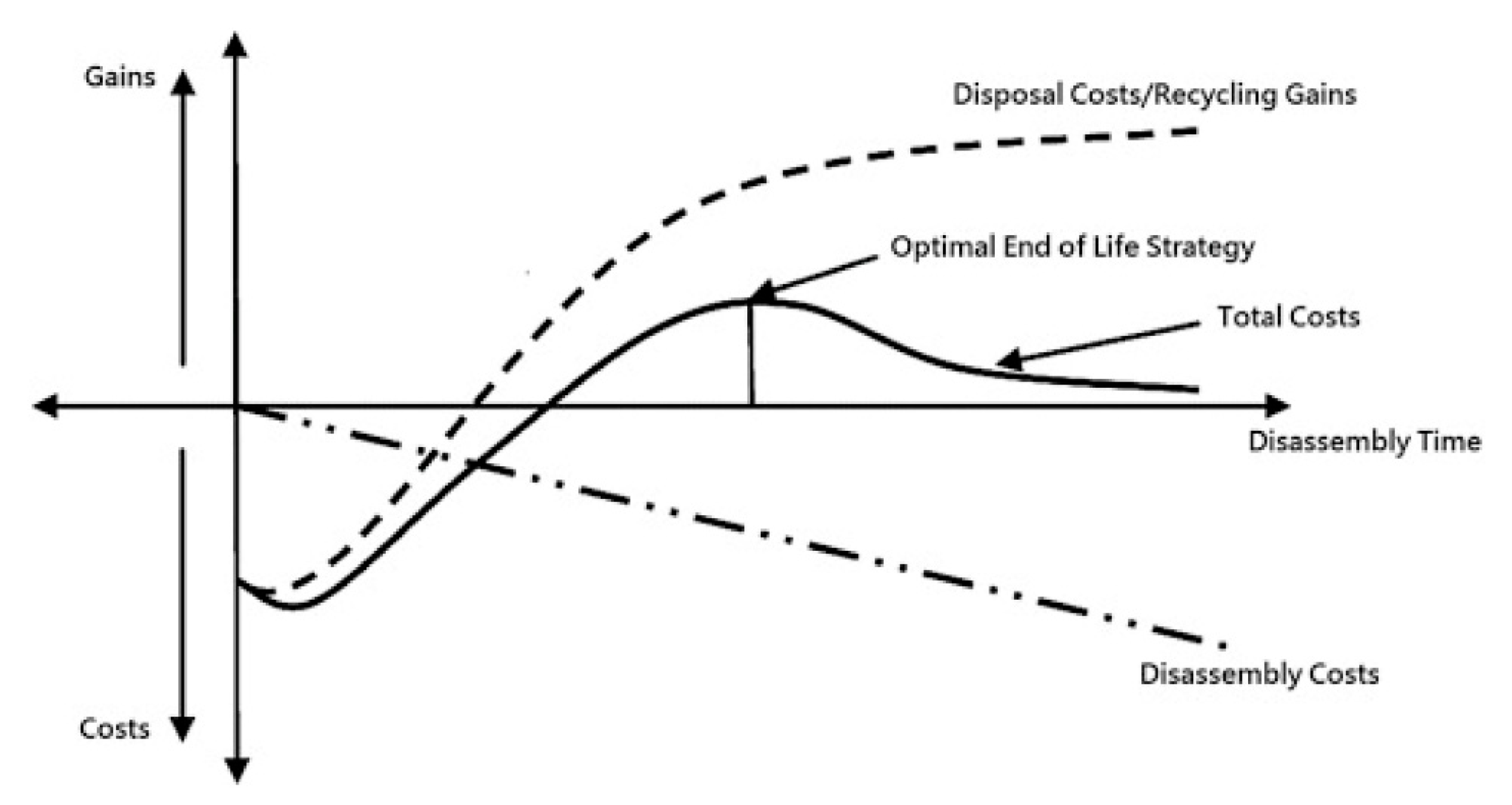

3. Methods for Analyzing the Disassembly Process

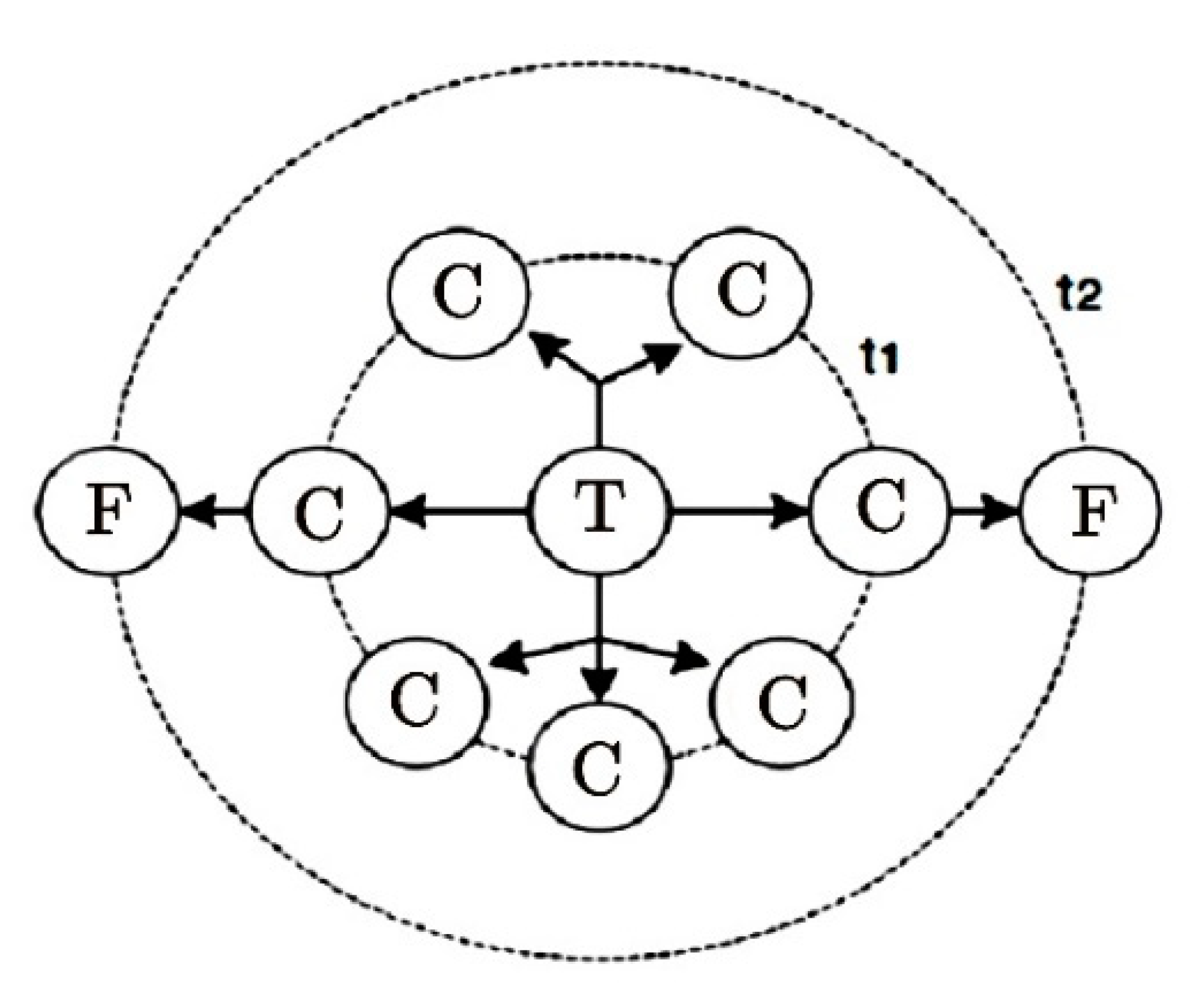

3.1. 1st Method

Application of the 1st Method

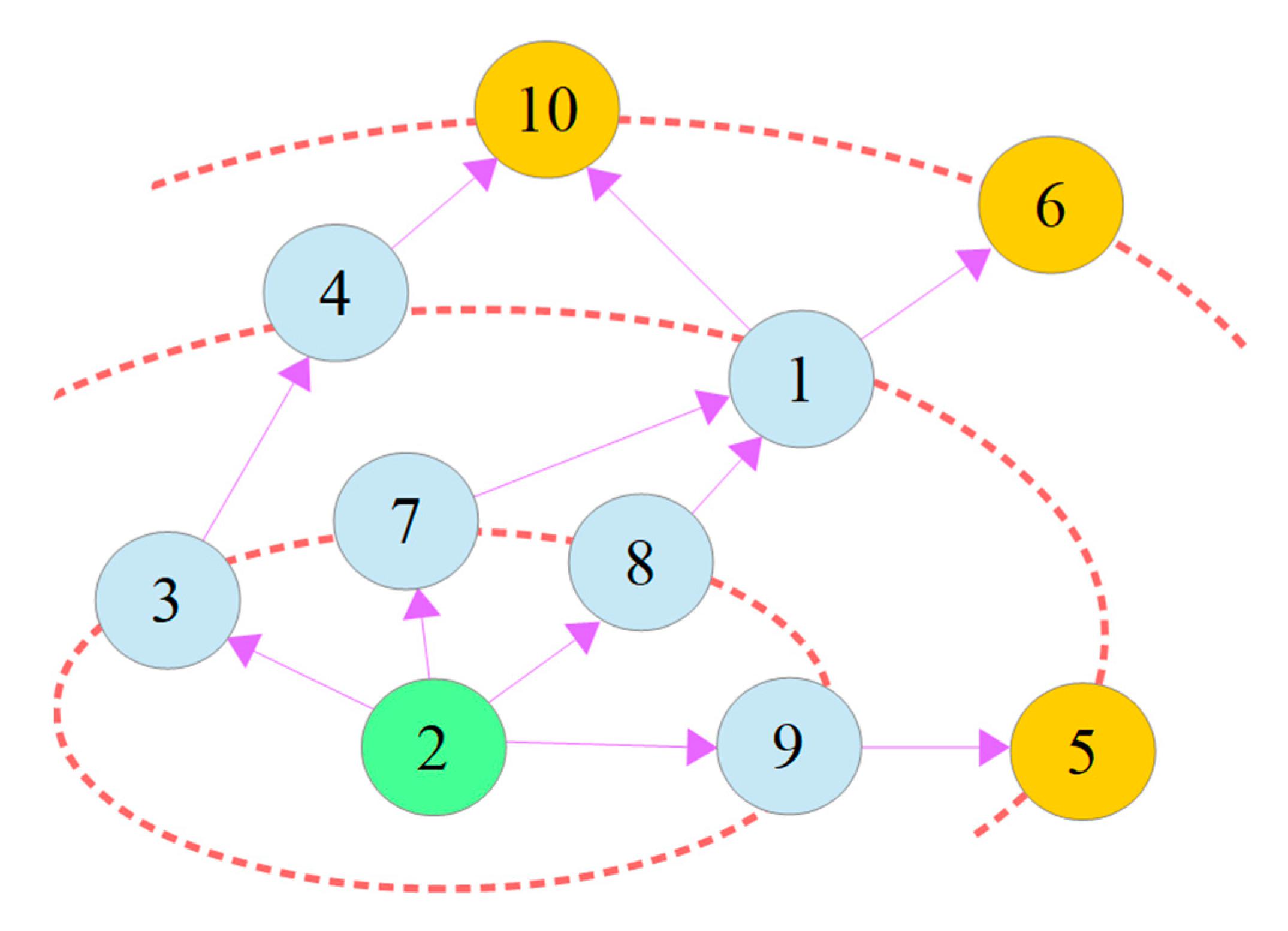

3.2. 2nd Method

Application of the 2nd Method

- (a)

- 6, 5, 9, 10, 4 and 3, 2

- (b)

- 6, 10, 4 and 3, 2

3.3. Estimation of Disassembly Time

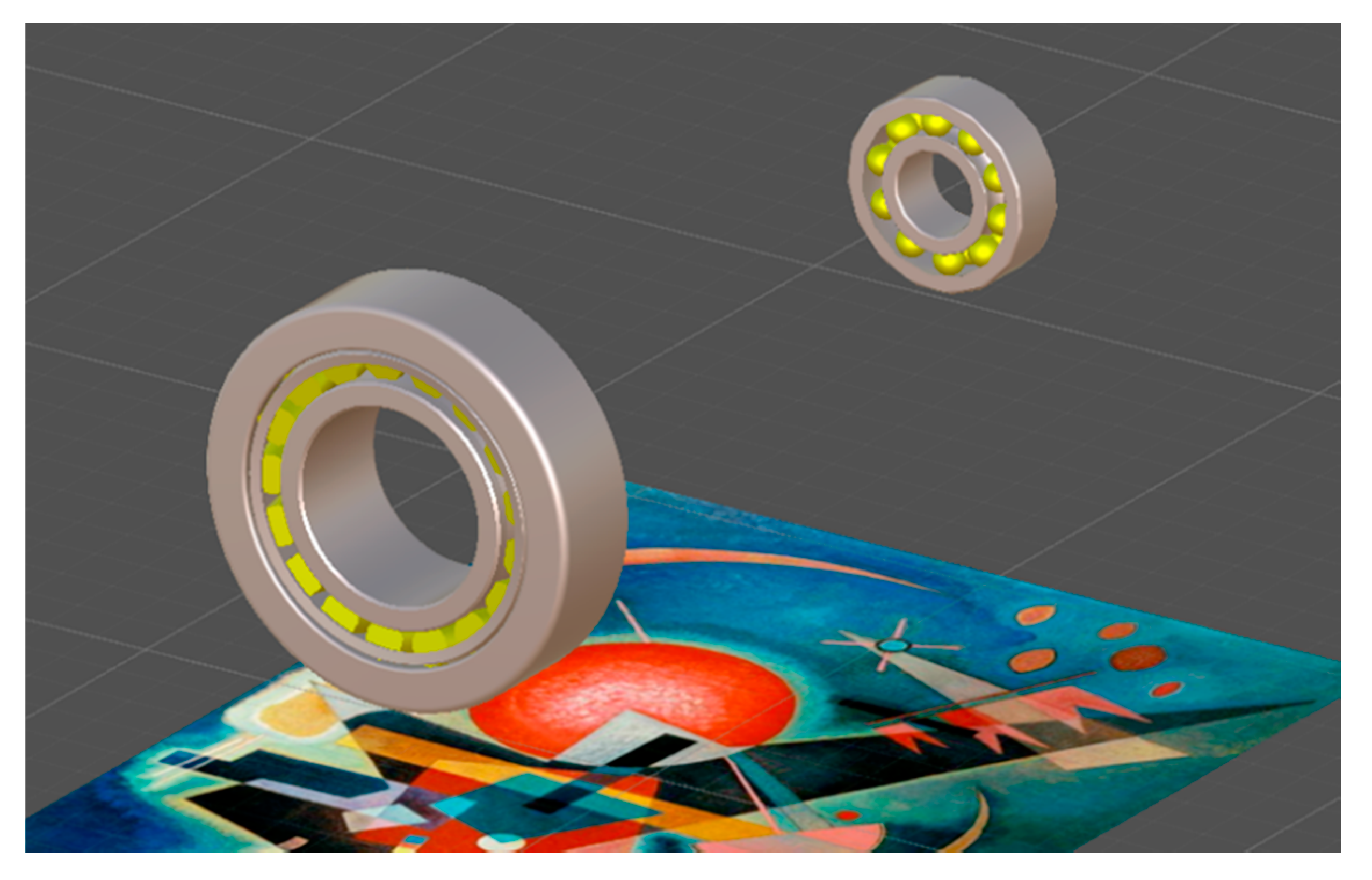

4. Augmented Reality

4.1. Key Features of the AR

4.2. Case Study of the Tailstock with Unity and Vuforia

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kalpakjian, S.; Schmid, S.R. Manufacturing Engineering and Technology; Prentice Hall: A Pearson Education Company: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- Feldmann, K.; Trautner, S.; Lohrmann, H.; Melzer, K. Computer based product structure analysis for technical goods regarding optimal end-of-life strategies. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2001, 215, 684–693. [Google Scholar] [CrossRef]

- Gonza’lez, B.; Adenso-Dı´az, B. A scatter search approach to the optimum disassembly sequence problem. Comp. Oper. Res. 2006, 33, 1776–1793. [Google Scholar] [CrossRef]

- Tian, G.; Liu, Y.; Tian, Q.; Chu, J. Evaluation model and algorithm of product disassembly process with stochastic feature. Clean Technol. Environ. Policy 2012, 14, 345–356. [Google Scholar] [CrossRef]

- Kroll, E.; Carver, B. Disassembly analysis through time estimation and other metrics. Robot. Comput. Integr. Manuf. 1999, 15, 191–200. [Google Scholar] [CrossRef]

- Frizziero, L.; Liverani, A.; Caligiana, G.; Donnici, G.; Chinaglia, L. Design for Disassembly (DfD) and Augmented Reality (AR): Case Study Applied to a Gearbox. Machines 2019, 7, 29. [Google Scholar] [CrossRef]

- Grandi, A. Gestione dei Progetti d’Innovazione; McGraw Hill Education: Bologna, Italy, 2017. [Google Scholar]

- Manfè, G.; Pozza, R.; Scarato, G. Disegno Meccanico; Principato Editore: Bologna, Italy, 2013. [Google Scholar]

- Funaioli, E.; Maggiore, A.; Meneghetti, U. Lezioni di Meccanica Applicata Alle Macchine; Pitagora Editore: Bologna, Italy, 2006. [Google Scholar]

- Raja, V.; Fernandes, K. Reverse Engineering: A Industrial Perspective; Springer Science & Business Media: Berlin, Germany, 2008. [Google Scholar] [CrossRef]

- Soh, S.; Ong, S.K.; Nee, A. Application of Design for Disassembly from Remanufacturing Perspective. Procedia CIRP 2015, 26, 577–582. [Google Scholar] [CrossRef]

- Yi, J.; Yu, B.; Du, L.; Li, C.; Hu, D. Research on the selectable disassembly strategy of mechanical parts based on the generalized CAD model. Int. J. Adv. Manuf. Technol. 2008, 37, 599–604. [Google Scholar] [CrossRef]

- Tao, F.; Luning, B.; Zuo, Y.; Nee, A. Partial/Parallel Disassembly Sequence Planning for Complex Products. J. Manuf. Sci. Eng. 2017, 140. [Google Scholar] [CrossRef]

- Desai, A.; Mital, A. Evaluation of disassemblability to enable design for disassembly in mass production. Int. J. Ind. Ergon. 2003, 32, 265–281. [Google Scholar] [CrossRef]

- Alkhamisi, A.; Monowar, M.M. Rise of Augmented Reality: Current and Future Application Areas. Int. J. Internet Distrib. Syst. 2013, 1, 25–34. [Google Scholar] [CrossRef]

- Vuforia. Available online: https://developer.vuforia.com/ (accessed on 1 July 2020).

- Unity. Available online: https://unity3d.com/get-unity/download (accessed on 1 July 2020).

- Piancastelli, L.; Frizziero, L.; Bombardi, T. Bézier based shape parameterization in high speed mandrel design. Int. J. Heat Technol. 2014, 32, 57–63. [Google Scholar]

- Frizziero, L.; Liverani, A. Disassembly sequence planning (DSP) applied to a gear box: Comparison between two literature studies. Appl. Sci. 2020, 10, 4591. [Google Scholar] [CrossRef]

- Francia, D.; Seminerio, D.; Caligiana, G.; Frizziero, L.; Liverani, A.; Donnici, G. Virtual Design for Assembly Improving the Product Design of a Two-Way Relief Valve, Lecture Notes in Mechanical Engineering 2020. In Proceedings of the International Conference on Design Tools and Methods in Industrial Engineering, ADM 2019, Modena, Italy, 9–10 September 2019; pp. 304–314. [Google Scholar]

- Francia, D.; Ponti, S.; Frizziero, L.; Liverani, A. Virtual mechanical product disassembly sequences based on disassembly order graphs and time measurement units. Appl. Sci. 2019, 9, 3638. [Google Scholar] [CrossRef]

- Donnici, G.; Frizziero, L.; Francia, D.; Liverani, A.; Caligiana, G. A preliminary evaluation to support DFD of handcrafted products. Int. J. Mech. Prod. Eng. Res. Dev. 2019, 9, 1033–1050. [Google Scholar]

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|

| Casing | Rotating tip | Rubber gasket | Ring nut | Cover | Screw | Tapered rolling bearing | Thrust bearing | Oscillating bearing | Fixing screw |

| DPM | F5 | F6 | F10 | C1 | C2 | C4,3 | C7 | C8 | C9 |

|---|---|---|---|---|---|---|---|---|---|

| F5 | 0 | 0 | 0 | 101111 | 0 | 0 | 0 | 0 | 0 |

| F6 | 0 | 0 | 0 | 111011 | 0 | 0 | 0 | 0 | 0 |

| F10 | 0 | 0 | 0 | 111011 | 0 | 110000 | 0 | 0 | 0 |

| C1 | 011111 | 110111 | 110111 | 0 | 101111 | 101111 | 101111 | 101111 | 011111 |

| C2 | 0 | 0 | 0 | 011111 | 0 | 001111 | 011111 | 011111 | 011111 |

| C4,3 | 0 | 0 | 110000 | 011111 | 001111 | 0 | 010000 | 010000 | 0 |

| C7 | 0 | 0 | 0 | 011111 | 101111 | 100000 | 0 | 010000 | 0 |

| C8 | 0 | 0 | 0 | 011111 | 101111 | 100000 | 100000 | 0 | 0 |

| C9 | 0 | 0 | 0 | 101111 | 101111 | 0 | 0 | 0 | 0 |

| BOM | Force | Grasp | Weight | Sim | Tools | Dim | Location | Tool Accuracy | TMU | s |

|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 5.5 | 2 | 2 | 0.8 | 1-1 | 1 | 2 | 1.2 | 42.24 | 1.52 |

| 4 | 3 | 4 | 2 | 0.8 | 1-3 | 1.6 | 2 | 2 | 368.64 | 13.3 |

| 5 | 3 | 2 | 2 | 0.8 | 1-1 | 1 | 2 | 1.2 | 23.04 | 0.83 |

| 6 | 1 | 4 | 2 | 1.2 | 1-2 | 1 | 2 | 2 | 76.8 | 2.76 |

| 7 | 5.5 | 4 | 2 | 0.8 | 3-3 | 1.6 | 2 | 2 | 2027.5 | 73 |

| 8 | 0.5 | 3.5 | 2 | 0.8 | 2-2 | 2 | 2 | 2 | 89.6 | 3.2 |

| 9 | 3.5 | 4 | 2 | 0.8 | 3-3 | 1.6 | 2 | 2 | 1290.2 | 46.5 |

| 10 | 1 | 4 | 2 | 1.2 | 1-2 | 1 | 2 | 2 | 76.8 | 2.76 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Freddi, M.; Frizziero, L. Design for Disassembly and Augmented Reality Applied to a Tailstock. Actuators 2020, 9, 102. https://doi.org/10.3390/act9040102

Freddi M, Frizziero L. Design for Disassembly and Augmented Reality Applied to a Tailstock. Actuators. 2020; 9(4):102. https://doi.org/10.3390/act9040102

Chicago/Turabian StyleFreddi, Marco, and Leonardo Frizziero. 2020. "Design for Disassembly and Augmented Reality Applied to a Tailstock" Actuators 9, no. 4: 102. https://doi.org/10.3390/act9040102

APA StyleFreddi, M., & Frizziero, L. (2020). Design for Disassembly and Augmented Reality Applied to a Tailstock. Actuators, 9(4), 102. https://doi.org/10.3390/act9040102