Micromanipulation: A Challenge for Actuation

Abstract

1. Introduction

- how could these micro devices be fabricated and operated?

- how could they improve certain aspects of our lives?

1.1. Downsizing Effects

1.2. Design, Fabrication, and Control

- theoretical modeling,

- numerical simulation, and

- experimental testing.

- design,

- fabrication,

- fabrication constrained design rules,

- packaging and

- biocompatibility.

- electrostatic,

- electrothermal,

- electromagnetic,

- piezoelectric.

- Micro-electro-mechanical system (MEMS) integration:

- automatic regulation and control of microsystems,

- operational aspects of micromanipulation,

- measurements.

1.3. Applications

1.4. Forthcoming or Emerging Issues

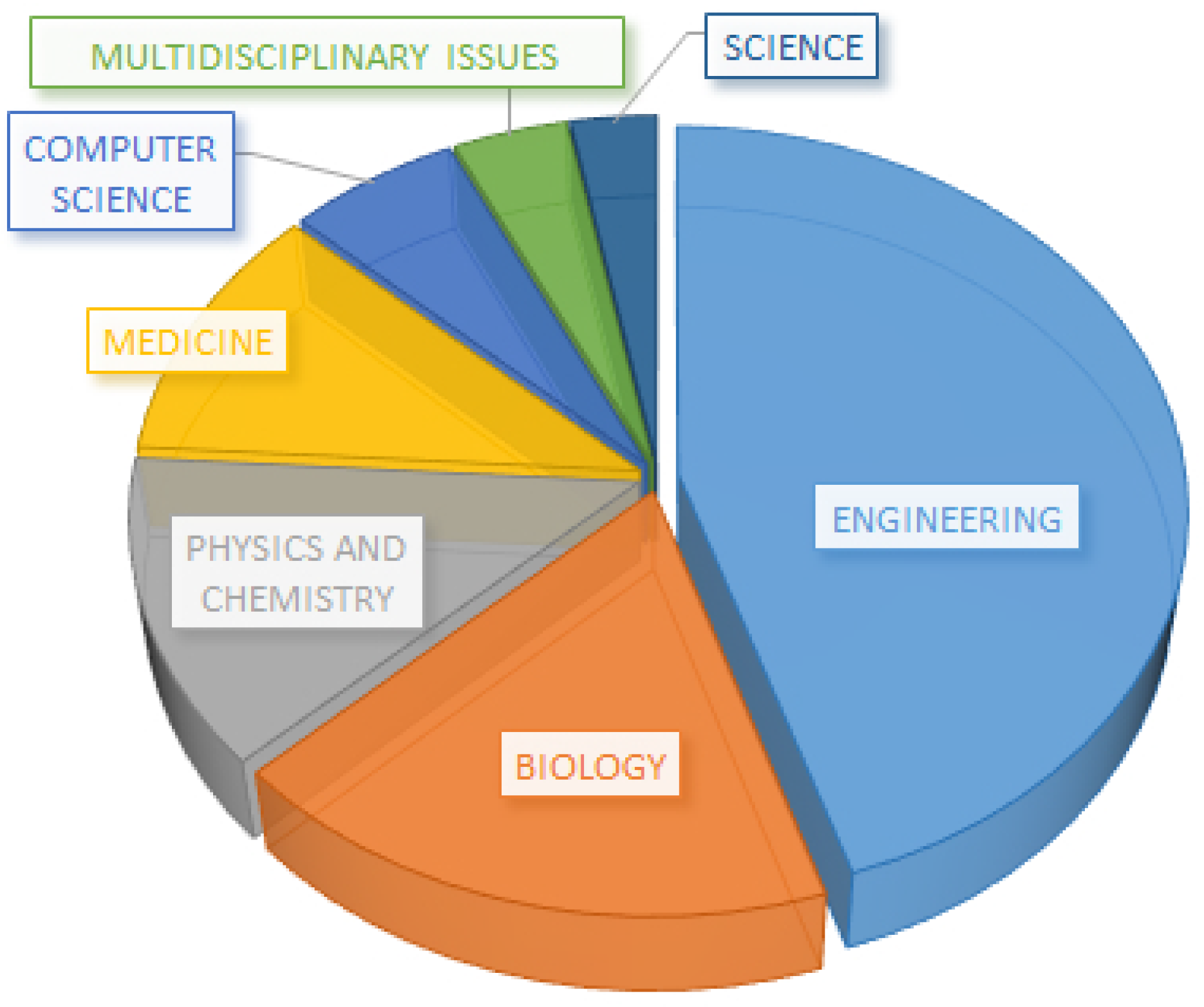

2. On the Variety of Demand vs. the Supplying Capability

- Engineering,

- Biology,

- Physics and Chemistry,

- Medicine,

- Computer Science,

- Multidisciplinary issues, and

- Science.

3. Tools for the Observation

4. Micro- or Nano-Manipulators vs. Micro- or Nano-Robots

5. Conclusions

Conflicts of Interest

References

- Galilei, G. Discourses and Mathematical Demonstrations Relating to Two New Sciences [In Italian: Discorsi e Dimostrazioni Matematiche Intorno a Due Nuove Scienze Attenenti Alla Meccanica E I Movimenti Locali]; Lodewijk Elzevir: Leiden, The Netherlands, 1638. [Google Scholar]

- Swift, J. Travels into Several Remote Nations of the World. In Four Parts. By Lemuel Gulliver, First a Surgeon, and then a Captain of Several Ships; Benjamin Motte: London, UK, 1726. [Google Scholar]

- Bhushan, B.E. (Ed.) Springer Handbook of Nanotechnology; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Feynman, R.P. There’s plenty of room at the bottom [data storage]. J. Microelectromech. Syst. 1992, 1, 60–66. [Google Scholar] [CrossRef]

- Huang, H.; Kamm, R.D.; Lee, R.T. Cell mechanics and mechanotransduction: Pathways, probes, and physiology. Am. J. Physiol. Cell Physiol. 2004, 287, C1–C11. [Google Scholar] [CrossRef] [PubMed]

- Swaminathan, V.; Mythreye, K.; Tim O’Brien, E.; Berchuck, A.; Blobe, G.; Superfine, R. Mechanical Stiffness grades metastatic potential in patient tumor cells and in cancer cell lines. Cancer Res. 2011, 71, 5075–5080. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Liu, K.K. Optical tweezers for single cells. J. R. Soc. Interface 2008, 5, 671–690. [Google Scholar] [CrossRef]

- Potrich, C.; Lunelli, L.; Bagolini, A.; Bellutti, P.; Pederzolli, C.; Verotti, M.; Belfiore, N.P. Innovative silicon microgrippers for biomedical applications: Design, mechanical simulation and evaluation of protein fouling. Actuators 2018, 7, 12. [Google Scholar] [CrossRef]

- Huesgen, T.; Woias, P.; Kockmann, N. Design and fabrication of MEMS thermoelectric generators with high temperature efficiency. Sens. Actuators A Phys. 2008, 145–146, 423–429. [Google Scholar] [CrossRef]

- Judy, J.W. Microelectromechanical systems (MEMS): Fabrication, design and applications. Smart Mater. Struct. 2001, 10, 1115–1134. [Google Scholar] [CrossRef]

- Shen, D.; Park, J.H.; Ajitsaria, J.; Choe, S.Y.; Wikle, H.C.; Kim, D.J. The design, fabrication and evaluation of a MEMS PZT cantilever with an integrated Si proof mass for vibration energy harvesting. J. Micromech. Microeng. 2008, 18, 055017. [Google Scholar] [CrossRef]

- Bagolini, A.; Ronchin, S.; Bellutti, P.; Chistè, M.; Verotti, M.; Belfiore, N.P. Fabrication of Novel MEMS Microgrippers by Deep Reactive Ion Etching with Metal Hard Mask. J. Microelectromech. Syst. 2017, 26, 926–934. [Google Scholar] [CrossRef]

- Rezazadeh, G.; Tahmasebi, A.; Zubstov, M. Application of piezoelectric layers in electrostatic MEM actuators: Controlling of pull-in voltage. Microsyst. Technol. 2006, 12, 1163–1170. [Google Scholar] [CrossRef]

- Pacheco, S.P.; Katehi, L.P.B.; Nguyen, C.T.C. Design of low actuation voltage RF MEMS switch. In Proceedings of the 2000 IEEE MTT-S International Microwave Symposium Digest, Boston, MA, USA, 11–16 June 2000; pp. 165–168. [Google Scholar]

- Bell, D.J.; Lu, T.J.; Fleck, N.A.; Spearing, S.M. MEMS actuators and sensors: Observations on their performance and selection for purpose. J. Micromech. Microeng. 2005, 15, S153–S164. [Google Scholar] [CrossRef]

- Donald, B.R.; Levey, C.G.; Paprotny, I. Planar microassembly by parallel actuation of MEMS microrobots. J. Microelectromech. Syst. 2008, 17, 789–808. [Google Scholar] [CrossRef]

- Andrieux, G.; Eloy, J.C.; Mounier, E. Technologies and market trends for polymer MEMS in microfluidics and lab-on-chip. In Proceedings of the SPIE, Progress in Biomedical Optics and Imaging, San Jose, CA, USA, 22–27 January 2005; pp. 60–64. [Google Scholar]

- De Pasquale, G.; Bertana, V.; Scaltrito, L. Experimental evaluation of mechanical properties repeatability of SLA polymers for labs-on-chip and bio-MEMS. Microsyst. Technol. 2018, 24, 3487–3497. [Google Scholar] [CrossRef]

- Palmieri, M. DNA lab on chip rests on MEMS foundation. EDN 2004, 49, 24–28. [Google Scholar]

- Takahashi, K.; Kwon, H.N.; Mita, M.; Fujita, H.; Toshiyoshi, H.; Suzuki, K.; Funaki, H. Monolithic integration of high voltage driver circuits and MEMS actuators by ASIC-like postprocess. In Proceedings of the International Conference on Solid State Sensors and Actuators and Microsystems, Digest of Technical Papers, TRANSDUCERS ’05, Seoul, Korea, 5–9 June 2005; Volume 1, pp. 417–420. [Google Scholar]

- Grayver, E.; M’Closkey, R.T. Automatic gain control ASIC for MEMS gyro applications. In Proceedings of the American Control Conference, Arlington, VA, USA, 25–27 June 2001; Volume 2, pp. 1219–1222. [Google Scholar]

- Borovic, B.; Liu, A.Q.; Popa, D.; Cai, H.; Lewis, F.L. Open-loop versus closed-loop control of MEMS devices: Choices and issues. J. Micromech. Microeng. 2005, 15, 1917–1924. [Google Scholar] [CrossRef]

- Park, S.; Horowitz, R. Adaptive control for the conventional mode of operation of MEMS gyroscopes. J. Microelectromech. Syst. 2003, 12, 101–108. [Google Scholar] [CrossRef]

- Zheng, Q.; Dong, L.; Lee, D.H.; Gao, Z. Active disturbance rejection control for MEMS gyroscopes. IEEE Trans. Control Syst. Technol. 2009, 17, 1432–1438. [Google Scholar] [CrossRef]

- Gad-el Hak, M.E. (Ed.) The MEMS Handbook, 2nd ed.; Mechanical and Aerospace Engineering Series; CRC Press, Tayor and Francis Group: Boca Raton, FL, USA, 2005. [Google Scholar]

- Dochshanov, A.; Verotti, M.; Belfiore, N.P. A Comprehensive Survey on Microgrippers Design: Operational Strategy. J. Mech. Des. Trans. ASME 2017, 139, 070801. [Google Scholar] [CrossRef]

- Belfiore, N.P.; Broggiato, G.; Verotti, M.; Balucani, M.; Crescenzi, R.; Bagolini, A.; Bellutti, P.; Boscardin, M. Simulation and construction of a MEMS CSFH based microgripper. Int. J. Mech. Control 2015, 16, 21–30. [Google Scholar]

- Belfiore, N.P.; Verotti, M.; Crescenzi, R.; Balucani, M. Design, optimization and construction of MEMS-based micro grippers for cell manipulation. In Proceedings of the ICSSE 2013 IEEE International Conference on System Science and Engineering, Budapest, Hungary, 4–6 July 2013; pp. 105–110. [Google Scholar]

- Marano, D.; Cammarata, A.; Fichera, G.; Sinatra, R.; Prati, D. Modeling of a Three-Axes MEMS Gyroscope with Feedforward PI Quadrature Compensation. In Advances on Mechanics, Design Engineering and Manufacturing; Eynardetal, B., Ed.; Springer: Cham, Switzerland, 2017; pp. 71–80. [Google Scholar]

- Sanò, P.; Verotti, M.; Bosetti, P.; Belfiore, N.P. Kinematic Synthesis of a D-Drive MEMS Device with Rigid-Body Replacement Method. J. Mech. Des. Trans. ASME 2018, 140, 075001. [Google Scholar] [CrossRef]

- Belfiore, N.P. Distributed Databases for the development of Mechanisms Topology. Mech. Mach. Theory 2000, 35, 1727–1744. [Google Scholar] [CrossRef]

- Belfiore, N.P. Brief note on the concept of planarity for kinematic chains. Mech. Mach. Theory 2000, 35, 1745–1750. [Google Scholar] [CrossRef]

- Pennestrì, E.; Belfiore, N.P. On the numerical computation of Generalized Burmester Points. Meccanica 1995, 30, 147–153. [Google Scholar] [CrossRef]

- Pennestrì, E.; Belfiore, N.P. Modular third-order analysis of planar linkages with applications. In ASME Design Technical Conference, Mechanism Synthesis and Analysis; ASME: New York, NY, USA, 1994; Volume 70, pp. 99–103. [Google Scholar]

- Pennestrì, E.; Belfiore, N.P. On Crossley’s contribution to the development of graph based algorithms for the analysis of mechanisms and gear trains. Mech. Mach. Theory 2015, 89, 92–106. [Google Scholar] [CrossRef]

- Sinatra, R.; Cammarata, A.; Angeles, J. Kinetostatic and inertial conditioning of the McGill schnflies-motion generator. Adv. Mech. Eng. 2010, 2, 186203. [Google Scholar]

- Verotti, M.; Belfiore, N.P. Isotropic compliance in E(3): Feasibility and workspace mapping. J. Mech. Rob. 2016, 8, 061005. [Google Scholar] [CrossRef]

- Verotti, M.; Masarati, P.; Morandini, M.; Belfiore, N.P. Isotropic compliance in the Special Euclidean Group SE(3). Mech. Mach. Theory 2016, 98, 263–281. [Google Scholar] [CrossRef]

- Kwak, B.M.; Haug, E.J. Optimal synthesis of planar mechanisms by parametric design techniques. Eng. Optim. 1976, 2, 55–63. [Google Scholar] [CrossRef]

- Lu, Q.; Huang, W.; Sun, M. Parametric design of flexible amplification mechanism based on flexure hinge. J. Vib. Meas. Diagn. 2016, 36, 935–941. [Google Scholar]

- Paul, S.R.; Nayak, S.K.; Anis, A.; Pal, K. MEMS-Based Controlled Drug Delivery Systems: A Short Review. Polym. Plast. Technol. Eng. 2016, 55, 965–975. [Google Scholar] [CrossRef]

- Lee, H.J.; Choi, N.; Yoon, E.S.; Cho, I.J. MEMS devices for drug delivery. Adv. Drug Deliv. Rev. 2018, 128, 132–147. [Google Scholar] [CrossRef] [PubMed]

- Rebello, K.J. Applications of MEMS in surgery. Proc. IEEE 2004, 92, 43–55. [Google Scholar] [CrossRef]

- Park, Y.S.; Gopalsami, N.; Gundeti, M.S. Tactile MEMS-based sensor element for robotic surgery. In Proceedings of the American Nuclear Society 2014 Annual Meeting, Reno, NV, USA, 15–19 June 2014; pp. 43–44. [Google Scholar]

- Chronis, N.; Lee, L.P. Polymer mems-based microgripper for single cell manipulation. In Proceedings of the Seventeenth IEEE International Conference on Micro Electro Mechanical Systems, Maastricht, The Netherlands, 25–29 January 2004; pp. 17–20. [Google Scholar]

- Pan, P.; Wang, W.; Ru, C.; Sun, Y.; Liu, X. MEMS-based platforms for mechanical manipulation and characterization of cells. J. Micromech. Microeng. 2017, 27, 123003. [Google Scholar] [CrossRef]

- Di Giamberardino, P.; Bagolini, A.; Bellutti, P.; Rudas, I.J.; Verotti, M.; Botta, F.; Belfiore, N.P. New MEMS tweezers for the viscoelastic characterization of soft materials at the microscale. Micromachines 2017, 9, 15. [Google Scholar] [CrossRef] [PubMed]

- Polla, D.L.; Krulevitch, P.; Wang, A.; Smith, G.; Diaz, J.; Mantell, S.; Zhou, J.; Zurn, S.; Nam, Y.; Cao, L.; Hamilton, J.; Fuller, C.; Gascoyne, P. MEMS-based diagnostic microsystems. In Proceedings of the 1st Annual International IEEE-EMBS Special Topic Conference on Microtechnologies in Medicine and Biology, Lyon, France, 12–14 October 2000; pp. 41–44. [Google Scholar]

- Huang, Y.; Mather, E.L.; Bell, J.L.; Madou, M. MEMS-based sample preparation for molecular diagnostics. Fresenius’ J. Anal. Chem. 2002, 372, 49–65. [Google Scholar] [CrossRef] [PubMed]

- Gnerlich, M.; Perry, S.F.; Tatic-Lucic, S. A submersible piezoresistive MEMS lateral force sensor for a diagnostic biomechanics platform. Sens. Actuators A Phys. 2012, 188, 111–119. [Google Scholar] [CrossRef]

- Pandya, H.J.; Park, K.; Chen, W.; Goodell, L.A.; Foran, D.J.; Desai, J.P. Toward a Portable Cancer Diagnostic Tool Using a Disposable MEMS-Based Biochip. IEEE Trans. Biomed. Eng. 2016, 63, 1347–1353. [Google Scholar] [CrossRef]

- Ho, C.M.; Tung, S.; Lee, G.B.; Tai, Y.C.; Jiang, F.; Tsao, T. MEMS—A technology for advancements in aerospace engineering. In Proceedings of the 35th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 6–9 January 1997. [Google Scholar]

- Kraft, M.; White, N.M. MEMS for Automotive and Aerospace Applications; Woodhead Publishing Series in Electronic and Optical Materials; Elsevier Ltd.: Amsterdam, The Netherlands, 2013; pp. 1–342. [Google Scholar]

- Bhat, K.N.; Nayak, M.M.; Kumar, V.; Thomas, L.; Manish, S.; Thyagarajan, V.; Gaurav, S.; Bhat, N.; Pratap, R. Design, development, fabrication, packaging, and testing of MEMS pressure sensors for aerospace applications. In Micro and Smart Devices and Systems; Vinoy, K.J., Ananthasuresh, G.K., Pratap, R., Krupanidhi, S.B., Eds.; Springer: New Delhi, India, 2014; Volume 14, pp. 3–17. [Google Scholar]

- Nelson, B.J.; Zhou, Y.; Vikramaditya, B. Sensor-Based Microassembly of Hybrid MEMS Devices. IEEE Control Syst. 1998, 18, 35–45. [Google Scholar]

- Tsui, K.; Geisberger, A.; Ellis, M.; Skidmore, G. Micromachined end-effector and techniques for directed MEMS assembly. J. Micromech. Microeng. 2004, 14, 542–549. [Google Scholar] [CrossRef]

- Wei, Y.; Xu, Q. An overview of micro-force sensing techniques. Sens. Actuators A Phys. 2015, 234, 359–374. [Google Scholar] [CrossRef]

- Lin, L. MEMS post-packaging by localized heating and bonding. IEEE Trans. Adv. Packag. 2000, 23, 608–616. [Google Scholar] [CrossRef]

- Howlader, M.M.R.; Okada, H.; Kim, T.H.; Itoh, T.; Suga, T. Wafer level surface activated bonding tool for MEMS packaging. J. Electrochem. Soc. 2004, 151, G461–G467. [Google Scholar] [CrossRef]

- May, G. Intelligent SOP manufacturing. IEEE Trans. Adv. Packag. 2004, 27, 426–437. [Google Scholar] [CrossRef]

- Belfiore, N.P.; Rudas, I. Applications of computational intelligence to mechanical engineering. In Proceedings of the 15th IEEE International Symposium on Computational Intelligence and Informatics, Budapest, Hungary, 19–21 November 2014; pp. 351–368. [Google Scholar]

- Delsing, J.; Lindgren, P. Sensor communication technology towards ambient intelligence. Meas. Sci. Technol. 2005, 16, R37. [Google Scholar] [CrossRef]

- Gammaitoni, L.; Neri, I.; Vocca, H. The benefits of noise and nonlinearity: Extracting energy from random vibrations. Chem. Phys. 2010, 375, 435–438. [Google Scholar] [CrossRef]

- Green, P.; Worden, K.; Atallah, K.; Sims, N. The benefits of Duffing-type nonlinearities and electrical optimisation of a mono-stable energy harvester under white Gaussian excitations. J. Sound Vib. 2012, 331, 4504–4517. [Google Scholar] [CrossRef]

- Puik, E.; Gielen, P.; Telgen, D.; van Moergestel, L.; Ceglarek, D. A generic systems engineering method for concurrent development of products and manufacturing equipment. IFIP Adv. Inf. Commun. Technol. 2014, 435, 139–146. [Google Scholar]

- Ailinger, R.L.; Black, P.L.; Lima-Garcia, N. Use of electronic monitoring in clinical nursing research. Clin. Nurs. Res. 2008, 17, 89–97. [Google Scholar] [CrossRef]

- Morgan, D. Respect for autonomy: Is it always paramount? Nurs. Ethics 1996, 3, 118–125. [Google Scholar] [CrossRef]

- Tuma, J.R. Nanoethics in a Nanolab: Ethics via Participation. Sci. Eng. Ethics 2013, 19, 983–1005. [Google Scholar] [CrossRef]

- Makarczuk, T.; Matin, T.R.; Karman, S.B.; Diah, S.Z.M.; Davaji, B.; MacQueen, M.O.; Mueller, J.; Schmid, U.; Gebeshuber, I.C. Biomimetic MEMS to assist, enhance and expand human sensory perceptions—A survey on state-of-the art developments. In Smart Sensors, Actuators, and MEMS V; Schmid, A., Sánchez-Rojas, J.L., Leester-Schaedel, M., Eds.; SPIE Digital Library: Bellingham, WA, USA, 2011; Volume 8066. [Google Scholar]

- Simou, P.; Alexiou, A.; Tiligadis, K. Artificial humanoid for the elderly people. Adv. Exp. Med. Biol. 2015, 821, 19–27. [Google Scholar] [PubMed]

- Bonciani, G.; Biancucci, G.; Fioravanti, S.; Valiyev, V.; Binni, A. Learning micromanipulation, Part 2: Term projects in practice. Actuators 2018, 7, 56. [Google Scholar] [CrossRef]

- Biancucci, G.; Bonciani, G.; Fioravanti, S.; Binni, A.; Lucchese, F.; Matrisciano, A. Learning micromanipulation, Part 1: An approach based on multidimensional ability inventories and text mining. Actuators 2018, 7, 55. [Google Scholar] [CrossRef]

- Web of Science by Clarivate Analytics. 2018. Available online: https://clarivate.com/products/web-of-science/ (accessed on 18 September 2018).

- Technology Readiness Levels (TRL), Horizon 2020—Work Programme 2018–2020 General Annexes, Extract from Part 19—Commission Decision C(2017)7124. 2017. Available online: http://ec.europa.eu/research/participants/data/ref/h2020/other/wp/2018-2020/annexes/h2020-wp1820-annex-g-trl%5C_en.pdf (accessed on 16 September 2018).

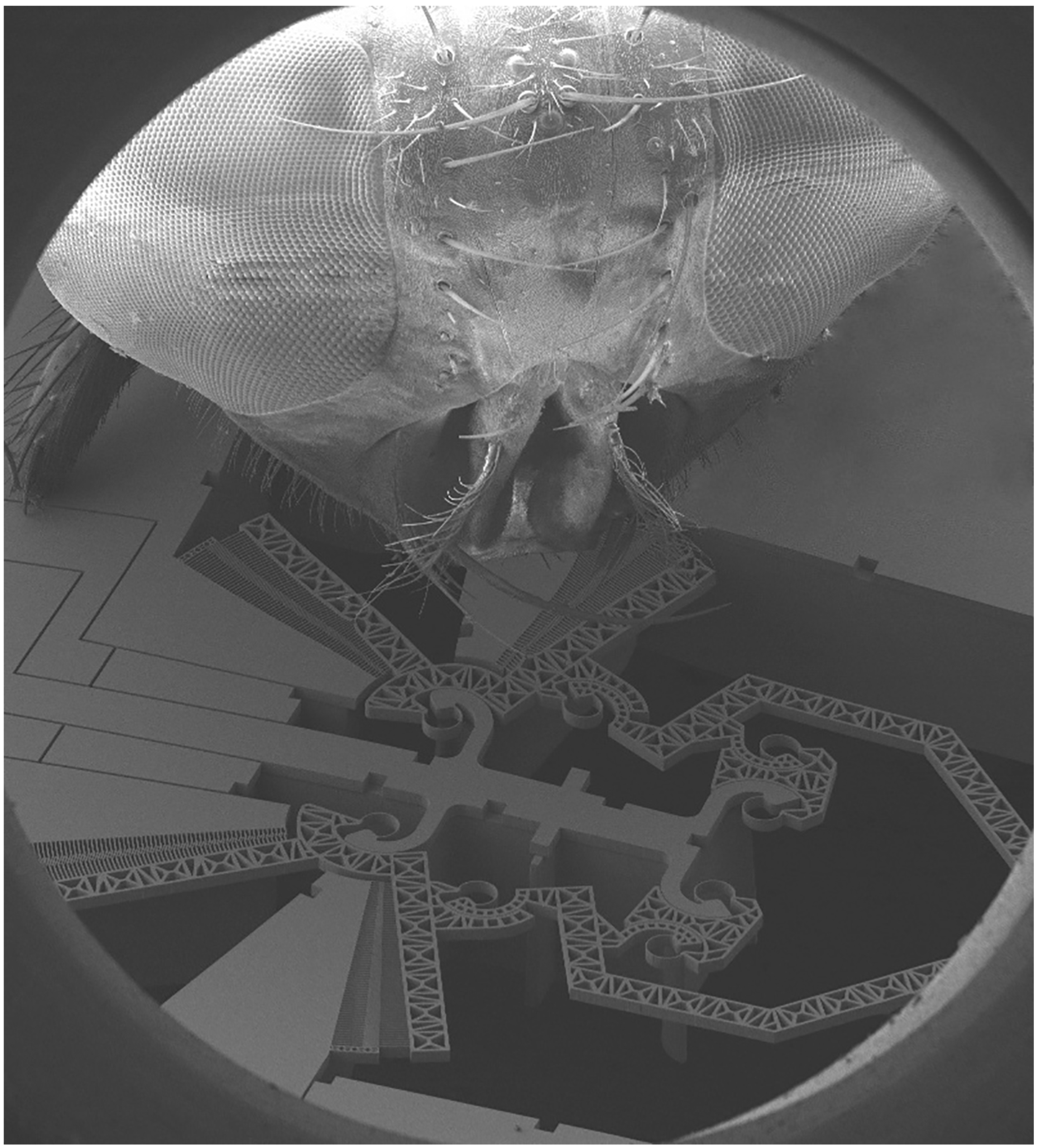

- Sukontason, K.L.; Chaiwong, T.; Piangjai, S.; Upakut, S.; Moophayak, K.; Sukontason, K. Ommatidia of blow fly, house fly, and flesh fly: Implication of their vision efficiency. Parasitol. Res. 2008, 103, 123–131. [Google Scholar] [CrossRef] [PubMed]

- Barlow, H.B. The Size of Ommatidia in Apposition Eyes. J. Exp. Biol. 1952, 29, 667–674. [Google Scholar]

- Kleindiek Nanotechnik GmbH. MM3A-EM Micromanipulator, Version 10.01. © Kleindiek Nanotechnik GmbH. 2018. Available online: https://www.nanotechnik.com/fileadmin/public/brochures/mm3a-em.pdf (accessed on 4 September 2018).

- Belfiore, N.P.; Simeone, P. Inverse kinetostatic analysis of compliant four-bar linkages. Mech. Mach. Theory 2013, 69, 350–372. [Google Scholar] [CrossRef]

- Belfiore, N.P.; Emamimeibodi, M.; Verotti, M.; Crescenzi, R.; Balucani, M.; Nenzi, P. Kinetostatic optimization of a MEMS-based compliant 3 DOF plane parallel platform. In Proceedings of the ICCC 2013 IEEE 9th International Conference on Computational Cybernetics, Tihany, Hungary, 8–10 July 2013; pp. 261–266. [Google Scholar]

- Balucani, M.; Belfiore, N.P.; Crescenzi, R.; Verotti, M. The development of a MEMS/NEMS-based 3 D.O.F. compliant micro robot. Int. J. Mech. Control 2011, 12, 3–10. [Google Scholar]

- Verotti, M.; Dochshanov, A.; Belfiore, N.P. Compliance Synthesis of CSFH MEMS-Based Microgrippers. J. Mech. Des. Trans. ASME 2017, 139, 022301. [Google Scholar] [CrossRef]

- Verotti, M.; Dochshanov, A.; Belfiore, N.P. A Comprehensive Survey on Microgrippers Design: Mechanical Structure. J. Mech. Des. Trans. ASME 2017, 139, 060801. [Google Scholar] [CrossRef]

- Belfiore, N.P.; Prosperi, G.; Crescenzi, R. A simple application of conjugate profile theory to the development of a silicon micro tribometer. In Proceedings of the ASME 2014 12th Biennial Conference on Engineering Systems Design and Analysis, Copenhagen, Denmark, 25–27 June 2014; Volume 2. [Google Scholar]

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Belfiore, N.P. Micromanipulation: A Challenge for Actuation. Actuators 2018, 7, 85. https://doi.org/10.3390/act7040085

Belfiore NP. Micromanipulation: A Challenge for Actuation. Actuators. 2018; 7(4):85. https://doi.org/10.3390/act7040085

Chicago/Turabian StyleBelfiore, Nicola Pio. 2018. "Micromanipulation: A Challenge for Actuation" Actuators 7, no. 4: 85. https://doi.org/10.3390/act7040085

APA StyleBelfiore, N. P. (2018). Micromanipulation: A Challenge for Actuation. Actuators, 7(4), 85. https://doi.org/10.3390/act7040085