Abstract

Adaptive vehicle control systems are crucial for enhancing safety, performance, and efficiency in modern transportation, particularly as vehicles become increasingly automated and responsive to dynamic environments. This review explores the advancements in bio-inspired actuators and their potential applications in adaptive vehicle control systems. Bio-inspired actuators, which mimic natural mechanisms such as muscle movement and plant tropism, offer unique advantages, including flexibility, adaptability, and energy efficiency. This paper categorizes these actuators based on their mechanisms, focusing on shape memory alloys, dielectric elastomers, ionic polymer–metal composites, polyvinylidene fluoride-based electrostrictive actuators, and soft pneumatic actuators. The review highlights the properties, operating principles, and potential applications for each mechanism in automotive systems. Additionally, it investigates the current uses of these actuators in adaptive suspension, active steering, braking systems, and human–machine interfaces for autonomous vehicles. The review further outlines the advantages of bio-inspired actuators, including their energy efficiency and adaptability to road conditions, while addressing key challenges like material limitations, response times, and integration with existing automotive control systems. Finally, this paper discusses future directions, including the integration of bio-inspired actuators with machine learning and advancements in material science, to enable more efficient and responsive adaptive vehicle control systems.

1. Introduction

Adaptive vehicle control systems are essential in advancing the safety, efficiency, and responsiveness of modern transportation, particularly as vehicles transition toward electrification and autonomy. These systems require actuators capable of continuous, precise, and responsive behavior in dynamic environments. Traditional rigid actuators, though effective in fixed mechanical systems, often lack the compliance, adaptability, and integration required for next-generation automotive technologies. Bio-inspired actuators—engineered to mimic the mechanisms found in muscles, tendrils, and other biological structures—offer promising alternatives due to their inherent flexibility, energy efficiency, and ability to deform safely and reversibly under external stimuli [1,2].

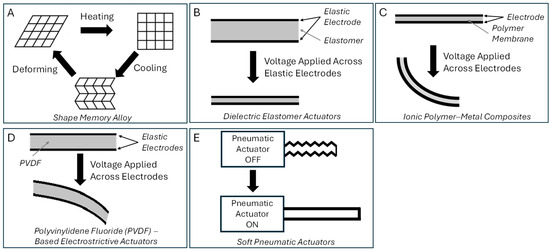

Soft robotics, a domain closely aligned with bio-inspiration, has demonstrated the value of compliant actuators in systems requiring high degrees of adaptability and physical interaction. These actuators rely on unconventional mechanisms like thermomechanical phase transitions (shape memory alloys), electrostatic deformation (dielectric elastomers), ion-driven bending (ionic polymer–metal composites), electrostrictive mechanisms (polyvinylidene fluoride (PVDF)-based electrostrictive actuators), and pressurized expansion (soft pneumatic actuators) to generate movement [2,3]. Their ability to undergo large strains while maintaining structural integrity makes them especially suited for automotive applications where a variable geometry, passive compliance, and multifunctional integration are critical, particularly in reconfigurable interiors, active suspensions, morphing aerodynamic surfaces, and soft human–machine interfaces. Figure 1 shows a schematic of each of these five categories of bio-inspired actuators.

Figure 1.

Schematic illustration of representative actuation principles in major classes of bio-inspired actuators. (A) Shape memory alloys undergo thermally induced phase transitions between the martensite and austenite phases, enabling deformation recovery upon heating. (B) Dielectric elastomer actuators expand laterally and compress in thickness when voltage is applied across the elastic electrodes. (C) Ionic polymer–metal composites bend due to asymmetric ion migration within a hydrated polymer membrane under an applied electric field. (D) PVDF-based electrostrictive actuators nonlinearly deform in the presence of electric fields due to dipole alignment in ferroelectric domains. (E) Soft pneumatic actuators deform by pressurizing internal chambers, producing linear or bending motion when activated.

From a design perspective, the biological analogs of these actuators inform both their function and control architecture. Natural muscles, for instance, exhibit properties that include distributed actuation, embedded sensing, and energy-efficient cyclic operation. These principles are reflected in the development of artificial muscle systems that integrate actuation and sensing within the same material domain, enabling closed-loop feedback without the need for external sensors or rigid linkages [1]. In the automotive context, these characteristics offer distinct advantages in weight reduction, component modularity, and real-time responsiveness, which are essential for implementing control systems capable of adapting to terrain variability, vehicle loading conditions, and driver or passenger behavior.

This review explored bio-inspired actuators through a technical lens, categorizing them by actuation mechanism and assessing their performance parameters—strain range, actuation force, response time, energy density, and durability—within the context of adaptive vehicle control. It further evaluated the current and emerging applications in automotive systems, including compliant suspensions, steering and braking modules, and responsive human–machine interfaces. This paper also discusses the integration challenges associated with these actuators, including material fatigue, nonlinear behavior, and control complexity, before outlining future directions that involve hybrid actuator systems, embedded sensing, and machine learning-driven control strategies to meet the demands of intelligent, adaptive mobility.

2. Types of Bio-Inspired Actuators

Table 1 provides a summary of the four technologies discussed in this section along with their typical actuation uses. The five technologies include shape memory alloys (SMAs), dielectric elastomer actuators (DEAs), ionic polymer–metal composites (IPMCs), polyvinylidene fluoride (PVDF)-based electrostrictive actuators, and soft pneumatic actuators (SPAs).

Table 1.

Summary of the five categories of bio-inspired actuators discussed in this paper.

2.1. Shape Memory Alloys (SMAs)

Shape memory alloys (SMAs) are smart materials capable of undergoing reversible solid-state phase transformations between the martensitic and austenitic phases, enabling them to recover a predefined shape upon heating. In the low-temperature martensitic phase, the crystal structure of the material is relatively soft and can accommodate significant deformation. When stress is applied, the material undergoes a twinning process, allowing it to change shape without permanent damage. Upon heating, the material transitions to the high-temperature austenitic phase, which has a more ordered and symmetrical crystal structure. This structural change drives the material to return to its original, pre-deformed shape, a process known as the shape memory effect.

This thermally induced transformation allows SMAs to function as compact, silent actuators with a high energy density and an excellent strain recovery, often exceeding 8 percent in nickel–titanium (NiTi) alloys [4,5]. Because their actuation mechanism relies on a temperature change rather than complex mechanical systems, SMAs are particularly well suited for applications that require precise movement, minimal mechanical complexity, and low noise. Their combination of a high actuation strain, a compact form factor, and relatively simple control makes them a compelling candidate for adaptive systems across a range of fields, including aerospace, biomedical devices, and robotics.

Despite their versatility, SMAs face notable challenges. Their limitations include thermal hysteresis, slow cooling rates, and a reduced fatigue life under high-cycle actuation [6,7]. Hu et al. [8] highlighted the need for improved bidirectional actuation architectures, particularly for systems requiring rotational or antagonistic motion, like origami-inspired mechanisms or adaptive valve control. Lee et al. [9] proposed a reactive tubular SMA brake with fast thermal recovery and an energy-efficient design, demonstrating SMA viability in high-frequency wearable robotics, which may translate to automotive actuation domains. Earlier research by Turner et al. [10] also demonstrated the potential of SMA-hybrid composites to enhance the mechanical robustness and response control. Ongoing efforts in materials engineering aim to improve the SMA actuator bandwidth, fatigue resistance, and multifunctionality through alloy tuning, embedded sensing, and integration with advanced composite structures [4,7,11].

2.2. Dielectric Elastomer Actuators (DEAs)

Dielectric elastomer actuators (DEAs) are soft, compliant electroactive devices that mimic the behavior of biological muscle. They consist of a thin, flexible dielectric elastomer film positioned between two stretchable electrodes. When a high voltage is applied across the electrodes, the resulting electrostatic forces compress the elastomer in thickness and cause it to expand in the planar directions. This deformation can produce large, muscle-like strains that often exceed 100 percent [12]. The actuation mechanism of DEAs is based on the Maxwell stress effect, where the applied electric field induces attractive forces between the electrodes, leading to a reduction in the film thickness and a simultaneous lateral expansion. This ability to undergo large, reversible strains makes DEAs well suited for dynamic applications that require a high flexibility and adaptability.

DEAs offer several notable advantages, including a high energy density, a low weight, and response times on the order of milliseconds [13,14]. These properties make them particularly attractive for lightweight robotic systems, haptic interfaces, and adaptive structures where rapid and tunable motion is essential. Moreover, their simple structure, lack of rigid components, and potential for miniaturization position DEAs as a promising class of actuators for future soft and wearable technologies.

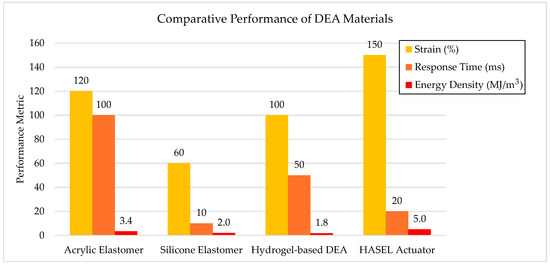

Material innovations have significantly expanded the functional scope of DEAs. Feng et al. [15] developed ultrahigh energy density elastomers with an improved dielectric strength, enabling high-speed deformation for soft robotics. Kellaris et al. [16] introduced Peano-HASEL actuators, electrohydraulic variants that combine the compliance of DEAs with the amplification benefits of hydraulic systems, achieving linear contraction and mimicking the performance of biological muscles. Rothermund et al. [17] and Perera et al. [18] highlighted HASEL actuators’ unique self-healing and strain-adaptive capabilities, positioning them as robust candidates for safety-critical systems such as impact-mitigating vehicle panels. A comparative overview of key DEA material characteristics, including the energy density, strain range, and response time, is provided in Figure 2, illustrating how materials selection directly affects the performance outcomes.

Figure 2.

Comparative performance metrics of various DEA materials used in soft actuator systems. HASEL actuators exhibited the highest strain and energy density, while silicone elastomers offered a rapid response. The data were adapted from [15,16,18,19,20].

As emphasized by Youn et al. [14], improvements in the electromechanical efficiency and reliability remain essential for translating DEA technology from laboratory settings to in-vehicle systems. Despite these hurdles, the scalability, speed, and compliance of DEAs continue to support their integration into morphing surfaces, adaptive interfaces, and other automotive subsystems.

2.3. Ionic Polymer–Metal Composites (IPMCs)

Ionic polymer–metal composites (IPMCs) are a class of soft electroactive polymers that exhibit bending motion in response to low-voltage electrical stimulation. These materials consist of a hydrated ionomer membrane, typically Nafion, coated with thin layers of conductive metal electrodes [21]. When a small voltage is applied (typically between 1 and 5 volts), mobile cations within the polymer migrate toward the cathode, dragging water molecules along with them [22]. This ionic redistribution causes differential swelling across the membrane, leading to smooth and controllable bending that closely resembles natural muscle movement [23].

The actuation behavior of IPMCs is highly efficient and silent, with the added benefit of continuous deformation under steady-state excitation. These materials are lightweight, operate under safe voltage levels, and produce biologically relevant motion, making them ideal for compact and biomimetic systems. Their low power requirements and precise movement profile allow for integration into environments where precision and quiet operation are paramount.

Despite their functional advantages, IPMCs face challenges related to a low force output, a limited displacement compared to other soft actuators, and sensitivity to moisture loss. These limitations are exacerbated under dry operating conditions, where dehydration leads to performance degradation over time. Bhandari et al. [24] reviewed fabrication improvements, including advanced electrode coatings and surface treatments that enhance adhesion and reduce solvent evaporation. Nemat-Nasser and Wu [25] provided comparative assessments of different ionomer backbones and cation types, showing how an ionic composition significantly affects the blocking force, response time, and durability. To improve long-term functionality, Kim and Shahinpoor [26] investigated surface roughening and electroless plating techniques to strengthen the metal–polymer interface and maintain conductivity under repeated cycling.

2.4. Polyvinylidene Fluoride (PVDF)-Based Electrostrictive Actuators

Polyvinylidene fluoride (PVDF)-based copolymers, particularly polyvinylidene fluoride–trifluoroethylene (PVDF–TrFE), represent a highly promising class of electroactive polymers for bio-inspired actuator applications. Unlike DEAs, which rely on Maxwell stress for actuation, or IPMCs, which function through ionic transport, PVDF-based copolymers operate via an electrostrictive mechanism in which electric fields induce nonlinear deformation through dipole alignment in ferroelectric domains. These materials exhibit high dielectric constants (ε_r ~ 40–50), a low mechanical impedance, and transverse strain responses of up to 7% under relatively modest electric fields (~50–100 V/μm), enabling compact actuation without the need for bulky pre-stretch or fluidic components [27]. Their ability to generate strain with a high precision and at low voltages makes them ideal candidates for lightweight, embedded actuation in space-constrained vehicular environments such as haptic interfaces, aerodynamic morphing skins, and adaptive seat structures.

Key advances in actuator design have emerged through the integration of PVDF–TrFE materials into micromachined unimorph and bridge-type actuator architectures. Cheng et al. demonstrated that unimorph actuators incorporating electrostrictive PVDF copolymers could achieve significant vertical displacement with minimal power consumption and fast transient responses, owing to the large electromechanical coupling and elastic compliance of the polymer layer [28]. Building on this, Zhang et al. developed a bridge-type actuator topology using the same copolymer, which enabled bidirectional lateral displacement and an enhanced blocking force in a compact micromachined format [29]. These devices exhibited high energy densities and operational bandwidths well suited for feedback-intensive, dynamic applications in automotive systems, such as vibration-damping panels or intelligent flow control surfaces. Additionally, the micromachining compatibility of these polymers allows for direct integration with MEMS-based sensing and control units, simplifying actuator feedback loops and reducing the overall subsystem complexity.

Further performance gains have been achieved through hybridization and functionalization strategies. Zhang and Cheng introduced an actuator system that combined electrostrictive PVDF copolymers with piezoelectric ceramics, enhancing electromechanical coupling and allowing for a tailored mechanical output across frequency ranges [30]. Such hybrid systems leverage the fast response of PVDF materials and the high stiffness of ceramics to enable variable actuation modes, from coarse positioning to fine-tuned control, in a single device. Moreover, Zhang et al. developed an electroactive micropump diaphragm using P(VDF–TrFE) films, demonstrating stable and repeatable flow generation suitable for microscale fuel delivery and thermal regulation subsystems in electric vehicles [31]. These developments suggest that PVDF-based actuators not only rival more established soft actuator technologies, but also offer distinct advantages in terms of power efficiency, integrability, and mechanical versatility. Their ability to support miniaturized, distributed, and multifunctional actuation makes them a critical addition to the portfolio of bio-inspired actuators with potential for adaptive vehicle control.

2.5. Soft Pneumatic Actuators (SPAs)

Soft pneumatic actuators (SPAs) are compliant systems that use air or fluid pressure to drive motion by inflating internal chambers embedded within elastomeric structures. When pressurized, these cavities expand in carefully controlled ways, allowing the actuator to bend, twist, or extend linearly depending on its internal geometry. The motion results from the deformation of soft, stretchable materials and is governed by the shape and placement of internal chambers, the thickness and stiffness of the surrounding walls, and the overall material composition. This design flexibility makes soft pneumatic actuators highly tunable. Engineers can tailor their response characteristics by adjusting the chamber layouts, adding asymmetries in wall construction, or varying the stiffness of different material layers. As a result, they can produce a wide range of motion types with large, controllable deformations and relatively simple fabrication methods.

These actuators offer several practical advantages. They are inherently safe for human interaction due to their softness and low stiffness, which reduces the risk of injury. They also offer a high force-to-weight ratio and are capable of adapting to irregular or dynamic surfaces. These features have made them indispensable in soft robotics and wearable devices.

In the context of adaptive vehicle systems, soft pneumatic actuators are increasingly valuable for applications requiring gentle contact, quiet operation, and robust compliance. Their modularity and tunability allow for creative integration into components such as adaptive seating, variable stiffness mounts, or soft interfaces for human–machine interaction. As interest grows in biomimetic and flexible systems, soft pneumatic actuators are likely to play a key role in the evolution of intelligent vehicle interiors and reconfigurable structures [32]. Recent developments have expanded the SPA applicability across wearable, structural, and interior vehicular interfaces.

Despite these advantages, SPA integration in high-speed automotive systems is limited by external compressor requirements, relatively slow actuation dynamics, and air leakage concerns. To address this, Chen et al. [33] proposed hybrid actuation systems that combine dielectric elastomers and SPAs to achieve faster, multimodal responses. Progress in compact fluidic control units, low-latency valve systems, and onboard pressure generation remains critical for advancing SPA deployment in real-time vehicle control architectures.

3. Current Applications in Vehicle Control Systems

3.1. Adaptive Suspension Systems

Bio-inspired actuators, especially those based on SMAs, are being adopted in adaptive suspension systems to dynamically modulate vehicle response based on the terrain and load conditions. SMAs enable compact and noise-free actuation by exploiting reversible phase transformations between the martensitic and austenitic phases. These properties are particularly advantageous in off-road or rugged environments, where the active control of ride dynamics is critical.

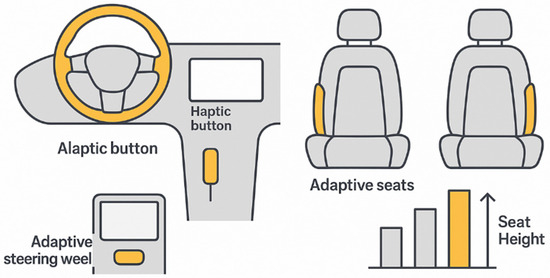

Sellitto et al. [34] demonstrated a numerically simulated SMA-based active suspension system for off-road vehicles, employing thermally activated NiTi elements integrated into a suspension linkage. The system allowed for the real-time tuning of the suspension stiffness and damping by adjusting the SMA state through Joule heating. The simulation results indicated a reduction in vertical displacement and improved vibration attenuation, supporting SMAs’ suitability for terrain-adaptive suspension designs. Figure 3 illustrates the conceptual architecture of such a suspension system, showing how SMA elements are embedded within the vehicle’s suspension arms to achieve vertical compliance and a terrain-adaptive performance.

Figure 3.

Adaptive interior components incorporating SPAs in human–machine interfaces. SPAs enable dynamic adjustments for steering wheels, tactile feedback for haptic buttons, and an adaptable seat height.

Supporting this automotive application, Colorado et al. [35] developed a morphing wing for a bat-inspired robot using SMA-driven skeletal mechanisms. The design permitted the in-flight adjustment of the wing geometry, improving the aerodynamic efficiency in a variable airflow. These concepts extend to vehicle suspension by illustrating how compliant structures and localized actuation can produce performance-optimized responses to dynamic environments. Similarly, Lazos [36] explored bio-inspired wing configurations based on bird and insect morphology, underscoring the value of flexible structures in distributing and adapting to external loads—an approach that can inform next-generation chassis or suspension systems designed to adapt geometry in real time.

The fast response rates and compact nature of IPMCs also make them potential candidates to support adaptive suspension. Yang et al. [37] provided a comprehensive review of theoretical and computational models that describe IPMC dynamics, with particular attention to data-driven control strategies that improve the actuation accuracy in adaptive systems. Hao et al. [36] further emphasized the multifunctionality of IPMCs, highlighting their ability to act as both actuators and sensors. This dual capability enables real-time feedback and closed-loop control, which are particularly advantageous in soft robotics and human–machine interfaces.

In adaptive suspension systems, SPAs have also been utilized for vibration control and ergonomic enhancement. Pan et al. [38] and Li and Lee [39] developed SPA-based suspension architectures capable of tuning the stiffness in real time in response to road conditions. Maciejewski et al. [40] showed that pneumatic muscles embedded in seating systems reduce vibration exposure, thereby improving driver comfort and reducing fatigue over long durations.

3.2. Active Steering and Braking Systems

Bio-inspired actuators also show promise in steering and braking systems, where a rapid responsiveness and fine control are essential. Unlike conventional actuators that rely on centralized servomechanisms, soft robotic principles enable distributed, compliant actuation that can enhance the safety, redundancy, and control precision under nonlinear loading conditions.

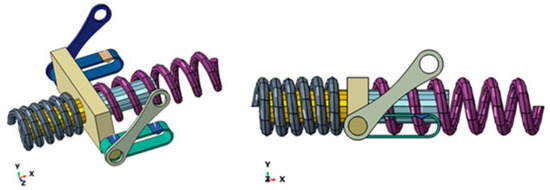

SMAs are particularly prominent in adaptive aerodynamic systems that support steering and braking. Battaglia et al. [5] demonstrated a skid plate mechanism that uses SMA springs to reconfigure airflow paths around the vehicle, thereby reducing drag. Riccio et al. [41] further developed a bistable morphing spoiler utilizing antagonistic SMA wires to toggle between aerodynamic states without requiring a continuous energy input. As illustrated in Figure 4, these compact designs achieve large deformations and maintain shape stability, even under varying thermal loads. The use of bistable mechanisms leverages SMA’s intrinsic hysteresis, allowing stable transitions between states without feedback-intensive control schemes.

Figure 4.

Isometric view (left) and lateral view (right) of a bistable morphing spoiler actuated by antagonistic SMA wires, allowing for a shape change between the aerodynamic configurations without a continuous power input [41].

SMA applications have also been extended to aerospace-inspired morphing components such as smart flaps and adaptive airfoils. Kim et al. [42] integrated SMA wires into a hybrid composite flap actuator capable of retaining the shape without sustained power, improving the energy efficiency. Hajarian et al. [43] experimentally validated a morphing airfoil using SMA wires for real-time aerodynamic control. Costanza and Tata [11] provided a broader review of similar aerospace applications and emphasized the potential for the cross-sector transfer of SMA-based morphing technologies into automotive and robotic systems.

In the robotics domain, bio-inspired actuators continue to evolve, with several developments directly relevant to vehicle control. Plum et al. [44] introduced a soft autonomous underwater vehicle powered by electroactive actuators embedded in fin structures, enabling smooth and controllable propulsion with a low mechanical complexity. Though aquatic in design, the principle of compliant actuation translates well to terrestrial systems—for instance, in adaptive brake pads that conform to rotor surfaces or steering mechanisms that accommodate terrain-induced forces. Chu et al. [45] surveyed various biomimetic underwater robots driven by smart actuators, including SMAs and dielectric elastomers, highlighting their advantages in high-cycle operation and responsive deformation—key traits for robust, adaptive steering systems.

DEAs have similarly demonstrated strong potential in propulsion and wearable robotics. Berlinger et al. [46] showed that DEA-driven flapping fins can achieve efficient, quiet propulsion in modular underwater vehicles. Hines et al. [19] emphasized the suitability of DEAs in untethered micro-robots, where a low weight and a compact form factor are essential. Jung et al. [47] advanced this line of research by integrating electronics directly into DEA modules, enabling autonomous function without bulky external controllers—an important consideration for future vehicle-integrated components.

IPMCs have proven useful in confined or aquatic environments due to their compactness and responsiveness. Zhou and Low [48] employed IPMC-driven fins in a small biomimetic underwater vehicle, achieving agile maneuverability in tight operational channels. Jung et al. [49] characterized IPMC behavior across varying humidity and frequency conditions, highlighting the role of environmental tuning in maximizing the performance. Shahinpoor et al. [22] noted that further advances in material encapsulation, ionomer chemistry, and hybrid architectures are expected to expand IPMC applicability in adaptive vehicle systems and beyond.

These actuator technologies are further supported by broader studies of morphing structures. Barbarino et al. [50], in their review of morphing aircraft, described how embedded actuators can dynamically reshape structural profiles. These techniques can be adapted for terrestrial vehicles to modulate the brake caliper spacing and tire contact patches, or even make real-time adjustments to the toe and camber angles—offering an improved handling and braking efficiency through adaptive structural control.

3.3. Autonomous Vehicle Interfaces

Human–machine interaction (HMI) in autonomous vehicles is transitioning from static interfaces to adaptive, context-aware systems. Bio-inspired soft actuators are central to this evolution, enabling reconfigurable and tactile surfaces that respond to both user input and the vehicle context. These actuators can be embedded throughout the cabin, within steering wheels, seats, and dashboard surfaces, to deliver physical cues, adjust the form factor, and modulate surface compliance to enhance comfort and safety.

DEAs have been actively investigated for morphing haptic interfaces and adaptive cabin components. Depari et al. [51] and Boys et al. [52] demonstrated DEA-based tactile displays and feedback rotors that offer promising concepts for future touch interfaces and dynamic control panels. However, Zhang et al. [53] and Bernat et al. [54] identified key limitations of DEAs, including their high driving voltage requirements, mechanical fragility, and low blocking force. To address these issues, solutions such as multilayer stacking, a bistable design, and stretchable encapsulants have been proposed to improve their durability and functionality [55,56].

IPMCs have also been explored for a range of compact, low-voltage applications such as smart air vents, active tactile controls, and miniature valve actuators. Their ability to function as both actuators and sensors enables closed-loop control within soft robotic interfaces, as demonstrated by Hao et al. [37]. Yang et al. [23] further emphasized the role of data-driven control strategies in mitigating nonlinear behavior and improving the real-time actuation accuracy in adaptive systems.

SPAs also show strong promise for HMI applications involving safety and adaptability. Xavier et al. [57] cataloged material developments and fabrication techniques supporting SPA use in morphing surfaces and safe human interaction. Li et al. [32] demonstrated customizable, 3D-printed SPA architectures with embedded sensing, which are well suited to adaptive dashboards, seat structures, and tactile user interfaces. Polygerinos et al. [58] extended this concept through a wearable pneumatic glove with precise deformation control, pointing to future driver-assist haptics or vehicle-mounted robotic aids.

Additional inspiration comes from biologically derived systems. Laschi et al. [59] introduced an octopus-inspired robotic arm with embedded soft actuators capable of continuous deformation across multiple degrees of freedom. This architecture informs the design of reconfigurable seating, tactile dashboards, and surface morphing systems that adjust in response to user presence, posture, or environmental context. Such adaptability enhances the comfort and passive safety, particularly in Level 3 and 4 autonomous driving, where systems must dynamically respond to real-time conditions.

Finally, bio-inspired proprioceptive systems further enrich HMI design. Plum et al. [44] highlighted soft underwater fins capable of adjusting their actuation based on external stimuli, an approach transferable to steering wheels or seats that respond to driver engagement, alertness, or collision conditions. Chu et al. [45] reinforced the importance of actuator–sensor hybrids and resilient control architectures, especially in systems requiring fault tolerance under variable stimuli. These features align closely with the demands of autonomous HMI systems, which must offer fail-safe tactile alerts and adaptive ergonomics under both routine and emergency scenarios.

4. Discussion

Each of the bio-inspired actuators discussed in the previous sections have a series of advantages as well as challenges. The characteristics and limitations of each mechanism are described in Table 2 and discussed in the subsequent sections.

Table 2.

Table outlining limitations, challenges, and important characteristics of the five actuator technologies discussed in this paper.

4.1. Advantages of Bio-Inspired Actuators for Vehicle Control

Bio-inspired actuators present numerous advantages over traditional rigid systems, particularly in adaptive and human-centered vehicle applications. Their compliant nature, multifunctionality, and ability to mimic muscle-like behavior position them as transformative components in the evolution of intelligent mobility systems. However, real-world deployment requires a clear understanding of the trade-offs between performance, integration complexity, and durability. These factors still limit widespread automotive adoption.

A core strength of soft and bio-inspired actuators is their mechanical compliance and morphological adaptability. Unlike traditional motor-driven linkages, actuators such as DEAs, IPMCs, and hydrogels exhibit continuous deformation in response to external stimuli, allowing them to emulate biological muscle function. This enables distributed actuation, where multiple small actuators embedded within surfaces or interfaces coordinate localized shape changes. Applications benefiting from this capability include dynamic aerodynamic skins, reconfigurable seats, and haptic touch panels [60,61,62].

Energy efficiency and a reduced mechanical complexity are additional advantages. Many bio-inspired actuators operate without gears, belts, or rigid frames, allowing for lighter subsystems and reduced energy demands. As Sitti and Peña-Francesch [60] emphasize, these actuators often exhibit favorable strain energy densities. For example, IPMCs operate at low voltages (<5 V), offering smooth, analog-like motion ideal for distributed applications such as active vents, adaptive tactile controls, or low-power haptic feedback [63].

Another critical dimension is safety and enhanced HMI. Soft actuators inherently minimize injury risks due to their low mechanical impedance, a crucial feature in driver-assist exosystems, wearable feedback loops, and occupant safety structures [64]. Their silent, analog behavior also enables intuitive control interfaces, in contrast to traditional ON/OFF rigid-state mechanisms—an asset in autonomous or semi-autonomous vehicles, where human input is increasingly multimodal [61,62].

Despite these advantages, several challenges hinder large-scale deployment across automotive and mobility platforms. First, material and environmental limitations—such as elastomer degradation in DEAs, water loss in IPMCs, or fatigue in SMAs—affect the long-term durability, especially under thermal cycling, humidity, or continuous strain. These issues raise concerns about the reliability and maintenance overhead in mission-critical automotive systems, such as adaptive suspension or braking.

Second, many soft actuators, particularly DEAs, require high activation voltages (often in the kilovolt range), demanding robust encapsulation, safety insulation, and voltage step-up systems that complicate integration and raise the cost. Conversely, SPAs and SMAs, while low-voltage or thermally driven, exhibit slower response times, posing limits on the actuation bandwidth in real-time applications.

Moreover, control complexity and modeling challenges persist. Many soft actuators have nonlinear, time-dependent responses requiring sophisticated feedback loops, adaptive control algorithms, and real-time sensor fusion. The difficulty of achieving high-precision, repeatable control has limited their transition from lab prototypes to robust in-vehicle systems. This issue is compounded by a lack of standardized modeling frameworks across actuator types. Looking forward, several emerging trends point to more feasible implementation:

Hybrid actuation architectures, which combine the strengths of multiple actuator types (e.g., SMA-DEAs for a high force and a fast response), are being explored to enable multimodal motion control, particularly in dynamic vehicle body panels or robotic control arms.

Functional integration with embedded sensors, especially MEMS-compatible materials like PVDF-based copolymers, promises real-time self-sensing and closed-loop control without added hardware.

Advances in materials science, such as an improved elastomer stability, novel nanocomposite electrodes, and ionogel matrices for IPMCs, are pushing the envelope of the actuator lifespan and environmental robustness.

The miniaturization and 3D printing of SPAs and DEAs have made custom geometries and conformal surfaces more practical, opening the doors for interior morphing structures and personalized control layouts.

The path to real-world automotive implementation lies in combining material innovation, modular hybrid designs, and embedded intelligence. Future work should prioritize scalable actuator platforms with a validated performance across thermal, mechanical, and electrical domains relevant to vehicular conditions. Furthermore, collaboration between materials scientists, control engineers, and automotive OEMs will be essential to translating laboratory successes into road-ready systems. These directions will be elaborated upon in Section 5, focusing on design frameworks that leverage hybridization and real-time control for multifunctional adaptive components.

4.2. Challenges and Limitations

Despite their advantages, bio-inspired actuators face significant technical and system-level barriers that limit their integration into advanced vehicle control systems. These challenges span material performance, actuation dynamics, reliability, control strategies, and interfacing with existing automotive infrastructure.

Material degradation and operational consistency remain major obstacles. Many soft actuators degrade under cyclic loading due to mechanical fatigue, dielectric breakdown, or dehydration. For instance, dielectric elastomers often suffer from dielectric fatigue, pre-strain loss, and electrical aging [60], while IPMCs are prone to water loss, electrode delamination, and inconsistent actuation in low-humidity environments [63,65]. Achieving the durability standards required for automotive deployment, where the components are exposed to temperature swings, vibration, and a long service cycle, remains a key issue. Techniques such as encapsulation, hybrid electrode layering, and ionomer surface treatment have improved the performance [65,66], but long-term aging under field conditions remains insufficiently validated.

The response time and control latency of certain actuators further restrict their application in high-speed or safety-critical subsystems. Thermal actuators, particularly SMAs, rely on heat transfer for actuation, resulting in inherently slow cycling and thermal hysteresis [60,67]. While effective in morphing structures or idle-positioning systems, they struggle with tasks requiring a millisecond responsiveness. Turabimana et al. [68] demonstrated a successful SMA-based idle air control actuator in a commercial vehicle, but acknowledged response speed limitations that constrained broader drivetrain integration. Similarly, IPMCs and hydrogel-based actuators operate via electrochemical diffusion, introducing nonlinearity and actuation lag [65,67]. This limits their use in fast feedback loops such as emergency braking or steering correction, unless paired with faster hybrid components [69].

Nonlinear control dynamics also present a formidable challenge. Soft actuators often exhibit hysteresis, creep, and time-dependent behavior that is difficult to model using linear or classical control theory. Although machine learning-based strategies such as deep neural networks and reinforcement learning have shown promise [66], their deployment in automotive environments is constrained by the need for extensive validation, safety certification, and explainability. Bio-inspired adaptive control frameworks, such as those proposed by Riazi et al. [70] and García-Córdova et al. [71], offer robust solutions through distributed sensing and fault-tolerant architectures, but full-scale integration into automotive electronic control units (ECUs) remains in the early research stages.

Electrical and mechanical interfacing with existing vehicle systems is another limitation. Many bio-inspired actuators require nonstandard voltage or power conditioning hardware. For instance, dielectric elastomers often demand kilovolt-scale driving voltages that pose insulation, safety, and EMI challenges [60,72]. HASEL actuators, a subclass of electrohydraulic devices, have improved voltage requirements, as shown by Lodh and Le [72], who developed an ultrahigh-gain converter enabling compact, low-voltage operation. Nonetheless, integrating such devices alongside conventional 12V or 48V vehicle electrical systems requires novel isolation, shielding, and energy management solutions.

Mechanically, soft actuators may demand compliant anchoring, strain isolation, or hybrid linkage mechanisms to transmit force without compromising their deformation profiles. Lai et al. [69] highlighted the difficulty of reconciling soft actuator flexibility with the mechanical demands of bidirectional motion and force output in their glove-based hybrid system. This illustrates the broader challenge of embedding soft components within rigid, load-bearing automotive subsystems.

Collectively, these challenges demonstrate the need for actuator-specific durability studies, faster hybrid designs, improved control theory, and dedicated hardware–software integration platforms. Continued interdisciplinary efforts will be essential to transition bio-inspired actuators from proof-of-concept to road-ready technologies.

5. Future Research Directions

The future development of bio-inspired actuators for vehicle control will likely advance along three major axes: hybrid actuator architectures, intelligent control frameworks, and next-generation multifunctional materials and interfaces. These directions reflect a shift from single-function proof-of-concept devices to highly integrated, adaptive subsystems suitable for real-world deployment in intelligent transportation systems.

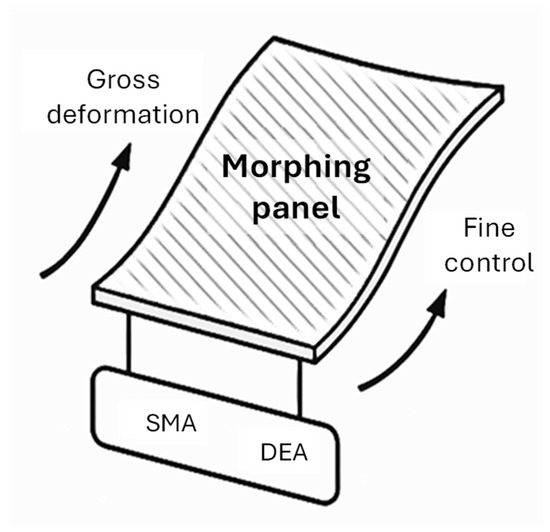

Hybrid actuator systems continue to gain momentum as a strategy for overcoming the limitations of individual actuator technologies. Combining materials with complementary mechanical and electromechanical properties allows for the design of actuators that can deliver both a high force and a fast response across a wide frequency spectrum. Cheng et al. [73] demonstrated this principle in the context of a smart SMA actuator for UAV tail wings, where the integration of thermally-driven SMA wires yielded the controlled morphing of aerodynamic surfaces—a paradigm that can readily extend to adaptive spoilers or cooling flaps in ground vehicles. Kashef Tabrizian et al. [74] proposed hybrid actuators that embed SMA wire helices into pneumatic rubber matrices, enabling multimodal deformation such as twisting, bending, and axial extension. These complex motions are especially relevant for bio-inspired surfaces that must adapt spatially to a shifting airflow or load conditions. A conceptual example of such integration, combining DEAs for fine control with SMA coils for gross deformation, is presented in Figure 5, illustrating how hybrid material strategies can enable real-time shape morphing across multiple scales.

Figure 5.

Example of a hybrid actuation architecture combining SMA-based gross deformation with DEA-based fine control to enable real-time shape changes across multiple spatial and temporal scales.

Resonant designs also offer promising energy-efficient actuation. Du et al. [75] reported a high-speed rotary motor powered by resonant dielectric elastomer actuators, delivering rapid bidirectional motion suitable for compact vehicular subsystems such as camera gimbals or airflow redirectors. Hybridizing these soft dielectric components with shape-memory or electrohydraulic elements could provide both agility and holding force, especially where sustained position locking is needed.

Advances in control systems and autonomy are essential for managing the nonlinear and time-varying behavior of soft materials. Machine learning tools, especially deep reinforcement learning and adaptive observers, have already demonstrated effectiveness in navigating soft actuator hysteresis and environmental coupling [67]. However, integration with real-time vehicular control units requires further progress in algorithm robustness and energy efficiency. Liu et al. [76] introduced a light-controlled IPMC actuator driven via PLZT ceramics, demonstrating a novel control pathway that reduces electromagnetic interference—a significant consideration in automotive sensor-dense environments. Similarly, Wang et al. [77] utilized a bionic muscle configuration to actuate a soft robotic fish, achieving the efficient control of a complex, rhythmic motion. These experimental platforms show promise for developing distributed actuator systems that autonomously adapt to terrain or load conditions in real-time, leveraging both embedded sensing and intelligent feedback architectures.

Control fusion also remains a major research priority. Soft robotic interfaces will require the seamless integration of sensory input, actuator responses, and high-level control logic. Projects like those of García-Córdova et al. [71] and Riazi et al. [70] propose frameworks with hierarchical bio-inspired control layers for fault tolerance and resilience—ideally suited for vehicle safety applications such as seatbelt tensioners, adaptive headrests, or active suspension arms.

Material and interface innovations are equally critical to expanding application domains. Transparent and flexible materials allow actuators to be co-integrated with user-facing surfaces. Ege and Balikci [78] developed PVDF-film-based actuators that provide localized haptic feedback on transparent touchscreens, which could directly enhance in-vehicle infotainment systems with tactile cues. As vehicles grow increasingly reliant on screen-based controls, haptic feedback could enhance their usability and safety by minimizing driver distraction.

Meanwhile, soft actuator arrays embedded in surfaces could enable whole-body gesture recognition, postural adjustments, or distributed thermal management. The actuation systems described in Wang et al. [77] and Jafferis et al. [79] suggest paths toward fully untethered, modular designs, features that are desirable in vehicle interiors that must reconfigure dynamically. Future research could explore integration with automotive-grade flexible electronics and conformal sensors [62], enabling multi-sensory feedback and user-aware adaptation.

The trajectory of bio-inspired actuator research points toward modular, intelligent, and human-centered vehicle systems. Progress in hybrid materials, robust control, and tactile interfacing will enable actuation technologies to evolve from niche applications to embedded infrastructure within next-generation mobility platforms. Actuators will no longer serve only as force generators, but as cognitively integrated components that respond to both the environment and the user, forming the muscle of truly adaptive vehicles.

6. Conclusions

Bio-inspired actuators offer a promising avenue for advancing adaptive vehicle control by mimicking natural mechanisms such as muscle contractions, ion transport, and fluid-driven deformation to enable compliant, efficient, and responsive actuation. This review examined key actuator types, including shape memory alloys, dielectric elastomers, ionic polymer–metal composites, polyvinylidene fluoride-based electrostrictive actuators, and soft pneumatic actuators. The review highlighted their operating principles, material characteristics, and suitability for adaptive systems. Case studies in suspension modulation, active steering and braking, and autonomous vehicle interfaces demonstrate a growing feasibility, though challenges in material durability, actuation speed, and system integration persist. Emerging research into hybrid actuation systems, machine learning-based control strategies, and multifunctional material development shows strong potential to overcome these limitations. Ultimately, continued interdisciplinary innovation will be necessary to improve actuator reliability, streamline integration into automotive architectures, and support the scalable implementation of bio-inspired technologies across intelligent mobility platforms.

Author Contributions

Conceptualization, V.M. and R.S.; data gathering, M.L. and R.S.; formal analysis, V.M., M.L. and R.S.; writing—original draft preparation, M.L.; writing—review and editing, V.M. and R.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No new data were created in this study.

Conflicts of Interest

Rajesh Shah was employed by the Koehler Instrument Company. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| SMA | Shape memory alloys |

| DEA | Dielectric elastomer actuators |

| IPMC | Ionic polymer–metal composites |

| PVDF | Polyvinylidene fluoride |

| SPA | Soft pneumatic actuators |

References

- Sarker, A.; Islam, T.U.; Islam, M.R. A Review on Recent Trends of Bioinspired Soft Robotics: Actuators, Control Methods, Materials Selection, Sensors, Challenges, and Future Prospects. Adv. Intell. Syst. 2024, 7, 2400414. [Google Scholar] [CrossRef]

- Ren, L.; Li, B.; Wei, G.; Wang, K.; Song, Z.; Wei, Y.; Ren, L.; Liu, Q. Biology and Bioinspiration of Soft Robotics: Actuation, Sensing, and System Integration. iScience 2021, 24, 103075. [Google Scholar] [CrossRef]

- Rus, D.; Tolley, M.T. Design, Fabrication and Control of Soft Robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef] [PubMed]

- Shreekrishna, S.; Nachimuthu, R.; Nair, V.S. A Review on Shape Memory Alloys and Their Prominence in Automotive Technology. J. Intell. Mater. Syst. Struct. 2023, 34, 499–524. [Google Scholar] [CrossRef]

- Battaglia, M.; Sellitto, A.; Giamundo, A.; Visone, M.; Riccio, A. Shape Memory Alloys Applied to Automotive Adaptive Aerodynamics. Materials 2023, 16, 4832. [Google Scholar] [CrossRef] [PubMed]

- Sofla, A.Y.N.; Meguid, S.A.; Tan, K.T.; Yeo, W.K. Shape Morphing of Aircraft Wing: Status and Challenges. Mater. Des. 2010, 31, 1284–1292. [Google Scholar] [CrossRef]

- Jani, J.; Leary, M.; Subic, A.; Gibson, M.A. A Review of Shape Memory Alloy Research, Applications and Opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Hu, K.; Rabenorosoa, K.; Ouisse, M. A review of SMA-based actuators for bidirectional rotational motion: Application to origami robots. Front. Robot. AI 2021, 8, 698427. [Google Scholar] [CrossRef]

- Lee, K.; Kim, Y.; Park, H. Shape memory alloy-based reactive tubular (SMART) brake for compact and energy-efficient wearable robot design. ACS Appl. Mater. Interfaces 2024, 16, 8974–8983. [Google Scholar] [CrossRef]

- Turner, T.L.; Lach, C.L.; Cano, R.J. Fabrication and characterization of SMA hybrid composites. In Proceedings of the SPIE—The International Society for Optical Engineering, Newport Beach, CA, USA, 5 March 2001; Volume 4333, pp. 343–353. [Google Scholar]

- Costanza, G.; Tata, M.E. Shape memory alloys for aerospace, recent developments, and new applications: A short review. Materials 2020, 13, 1856. [Google Scholar] [CrossRef]

- Pelrine, R.; Kornbluh, R.; Pei, Q.; Joseph, J. High-speed electrically actuated elastomers with strain greater than 100%. Science 2000, 287, 836–839. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Wang, Z.; Chen, Y.; Liu, H. Review of dielectric elastomer actuators and their applications in soft robots. Adv. Intell. Syst. 2021, 3, 2000282. [Google Scholar] [CrossRef]

- Youn, J.; Jeong, S.M.; Hwang, G.; Kim, H.; Hyeon, K.; Park, J.; Kyung, K. Dielectric elastomer actuator for soft robotics applications and challenges. Appl. Sci. 2020, 10, 640. [Google Scholar] [CrossRef]

- Feng, W.; Wang, J.; Xiao, S.; Ma, X.; Sun, Y.; Li, Y.; Liao, G.; Zhang, D. A large-strain and ultrahigh energy density dielectric elastomer for fast moving soft robot. Nat. Commun. 2024, 15, 48243. [Google Scholar] [CrossRef]

- Kellaris, N.; Helgeson, M.E.; Smith, G.M.; Mitchell, S.K.; Keplinger, C. Peano-HASEL actuators: Muscle-mimetic, electrohydraulic transducers that linearly contract on activation. Sci. Robot. 2018, 3, eaar3276. [Google Scholar] [CrossRef] [PubMed]

- Rothemund, P.; Kellaris, N.; Mitchell, S.; Acome, E.; Keplinger, C. HASEL artificial muscles for a new generation of lifelike robots—recent progress and future opportunities. Adv. Mater. 2021, 33, 2003375. [Google Scholar] [CrossRef]

- Perera, O.; Zhang, L.; Sharma, Y.; Elgeneidy, K. A review of soft robotic actuators and their applications in bioengineering, with an emphasis on HASEL actuators’ future potential. Actuators 2024, 13, 524. [Google Scholar] [CrossRef]

- Hines, L.; Petersen, K.; Lum, G.Z.; Sitti, M. Soft actuators for small-scale robotics. Adv. Mater. 2016, 29, 1603483. [Google Scholar] [CrossRef]

- Acome, E.; Mitchell, S.K.; Morrissey, T.G.; Emmett, M.B.; Benjamin, C.; King, M.; Radakovitz, M.; Keplinger, C. Hydraulically amplified self-healing electrostatic actuators (HASEL). Science 2018, 359, 61–65. [Google Scholar] [CrossRef]

- Shahinpoor, M.; Kim, K.J. Ionic polymer-metal composites: I. Fundamentals. Smart Mater. Struct. 2001, 10, 819–833. [Google Scholar] [CrossRef]

- Shahinpoor, M.; Bar-Cohen, Y.; Simpson, J.O.; Smith, J. Ionic polymer-metal composites (IPMCs) as biomimetic sensors, actuators, and artificial muscles—A review. Smart Mater. Struct. 1998, 7, R15–R30. [Google Scholar] [CrossRef]

- Yang, L.; Wang, H.; Yang, Y. Modeling and control of ionic polymer metal composite actuators: A review. Eur. Polym. J. 2023, 186, 111821. [Google Scholar] [CrossRef]

- Bhandari, B.; Lee, G.-Y.; Ahn, S.-H. A review on IPMC material as actuators and sensors: Fabrications, characteristics and applications. Int. J. Precis. Eng. Manuf. 2012, 13, 141–163. [Google Scholar] [CrossRef]

- Nemat-Nasser, S.; Wu, Y. Comparative experimental study of ionic polymer–metal composites with different backbone ionomers and in various cation forms. J. Appl. Phys. 2003, 93, 5255–5267. [Google Scholar] [CrossRef]

- Kim, K.J.; Shahinpoor, M. Ionic polymer metal composites: II. Manufacturing techniques. Smart Mater. Struct. 2003, 12, 65–79. [Google Scholar] [CrossRef]

- Xavier, M.S.; Tawk, C.D.; Zolfagharian, A.; Pinskier, J.; Howard, D.; Young, T.; Lai, J.; Harrison, S.M.; Yong, Y.K.; Bodaghi, M.; et al. Soft pneumatic actuators: A review of design, fabrication, modeling, sensing, control, and applications. IEEE Access 2022, 10, 59442–59485. [Google Scholar] [CrossRef]

- Tawk, C.; Alici, G. A review of 3D-printable soft pneumatic actuators and sensors: Research challenges and opportunities. Adv. Mater. Technol. 2021, 3, 2000223. [Google Scholar] [CrossRef]

- Polygerinos, P.; Wang, Z.; Galloway, K.C.; Wood, R.J.; Walsh, C.J. Soft pneumatic glove for hand rehabilitation. Robot. Auton. Syst. 2015, 73, 135–146. [Google Scholar] [CrossRef]

- Pan, K.; Hsu, L.; Lee, L.; Chiang, H.; Li, I.; Wang, W. Development and control of active vehicle suspension systems using pneumatic muscle actuator. In Proceedings of the 2017 IEEE International Conference on Real-time Computing and Robotics (RCAR), Okinawa, Japan, 14–18 July 2017; pp. 617–622. [Google Scholar] [CrossRef]

- Li, I.; Lee, L. Design and development of an active suspension system using pneumatic-muscle actuator and intelligent control. Appl. Sci. 2019, 9, 4453. [Google Scholar] [CrossRef]

- Maciejewski, I.; Pecolt, S.; Błażejewski, A.; Krzyzynski, T.; Glowinski, S. Controller of pneumatic muscles implemented in active seat suspension. Appl. Sci. 2024, 14, 6385. [Google Scholar] [CrossRef]

- Zhang, Q.M.; Cheng, Z.-Y.; Bharti, V. Development, characterization, and theoretical evaluation of electroactive polymer-based micropump diaphragm. Sens. Actuators A Phys. 2005, 121, 267–274. [Google Scholar] [CrossRef]

- Sellitto, A.; Pappalettera, G. Numerical simulation of a shape memory alloy–based active suspension for off-road vehicles. Materials 2023, 16, 2123. [Google Scholar] [CrossRef]

- Colorado, J.; Barrientos, A.; Rossi, C.; Breuer, K.S. Biomechanics of Smart Wings in a Bat Robot: Morphing Wings Using SMA Actuators. Bioinspiration Biomim. 2012, 7, 036006. [Google Scholar] [CrossRef]

- Lazos, B.S. Biologically inspired fixed-wing configuration studies. J. Aircr. 2005, 42, 1089–1098. [Google Scholar] [CrossRef]

- Hao, M.; Wang, Y.; Zhu, Z.; He, Q.; Zhu, D.; Luo, M. A compact review of IPMC as soft actuator and sensor: Current trends, challenges, and potential solutions. Front. Robot. AI 2019, 6, 129. [Google Scholar] [CrossRef]

- Cheng, Z.-Y.; Xu, H.S.; Zhang, Q.M. High-performance micromachined unimorph actuators based on electrostrictive poly (vinylidene fluoride–trifluoroethylene) copolymer. Appl. Phys. Lett. 2002, 80, 1082–1084. [Google Scholar] [CrossRef]

- Zhang, Q.M.; Cheng, Z.-Y.; Li, J.Y. Design, modeling, fabrication, and performances of bridge-type high-performance electroactive polymer micromachined actuators. J. Microelectromech. Syst. 2005, 14, 464–471. [Google Scholar] [CrossRef]

- Zhang, Q.M.; Cheng, Z.-Y.; Xu, H.S. An electroactive polymer–ceramic hybrid actuation system for enhanced electromechanical performance. Appl. Phys. Lett. 2004, 85, 1045–1047. [Google Scholar] [CrossRef]

- Riccio, A.; Sellitto, A.; Battaglia, M. Morphing Spoiler for Adaptive Aerodynamics by Shape Memory Alloys. Actuators 2024, 13, 330. [Google Scholar] [CrossRef]

- Kim, N.-G.; Han, M.-W.; Iakovleva, A.; Park, H.-B.; Chu, W.-S.; Ahn, S.-H. Hybrid Composite Actuator with Shape Retention Capability for Morphing Flap of UAV. Compos. Struct. 2020, 243, 112227. [Google Scholar] [CrossRef]

- Hajarian, A.; Zakerzadeh, M.R.; Baghani, M. Design, Analysis and Testing of a Smart Morphing Airfoil Actuated by SMA Wires. Smart Mater. Struct. 2019, 28, 115043. [Google Scholar] [CrossRef]

- Plum, F.; Labisch, S.; Dirks, J.-H. SAUV—A Bio-Inspired Soft-Robotic Autonomous Underwater Vehicle. Front. Neurorobotics 2020, 14, 8. [Google Scholar] [CrossRef] [PubMed]

- Chu, W.-S.; Lee, K.-T.; Song, S.-H.; Han, M.-W.; Lee, J.-Y.; Kim, H.-S.; Kim, M.-S.; Park, Y.-J.; Cho, K.-J.; Ahn, S.-H. Review of Biomimetic Underwater Robots Using Smart Actuators. Int. J. Precis. Eng. Manuf. 2012, 13, 1281–1292. [Google Scholar] [CrossRef]

- Berlinger, F.; Duduta, M.; Nagpal, R.; Wood, R.J. A modular dielectric elastomer actuator to drive miniature autonomous underwater vehicles. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Brisbane, Australia, 21–25 May 2018; pp. 3429–3435. [Google Scholar]

- Jung, Y.; Kwon, K.; Ko, S.H. Untethered soft actuators for soft standalone robotics. Nat. Commun. 2024, 15, 5197. [Google Scholar] [CrossRef] [PubMed]

- Jung, K.; Nam, J.; Choi, H. Investigations on actuation characteristics of IPMC artificial muscle actuator. Sens. Actuators A Phys. 2003, 107, 183–192. [Google Scholar] [CrossRef]

- Zhou, C.; Low, K.H. Design and locomotion control of a biomimetic underwater vehicle with fin propulsion. IEEE/ASME Trans. Mechatron. 2011, 17, 25–35. [Google Scholar] [CrossRef]

- Barbarino, S.; Bilgen, O.; Ajaj, R.M.; Friswell, M.I.; Inman, D.J. A review of morphing aircraft. J. Intell. Mater. Syst. Struct. 2011, 22, 823–877. [Google Scholar] [CrossRef]

- Depari, L.; Shrestha, M.; Teo, E.H.T. Rotary haptic device solutions using a conical dielectric elastomer actuator. In Proceedings of the SPIE—The International Society for Optical Engineering, Long Beach, CA, USA, 9 May 2024; Volume 10. [Google Scholar] [CrossRef]

- Boys, H.; Frediani, G.; Poslad, S.; Busfield, J.; Carpi, F. A dielectric elastomer actuator-based tactile display for multiple fingertip interaction with virtual soft bodies. In Proceedings of the SPIE—The International Society for Optical Engineering, Portland, OR, USA, 17 April 2017; Volume 10163. [Google Scholar]

- Zhang, Q.; Yu, W.; Zhao, J.; Meng, C.; Guo, S. A review of the applications and challenges of dielectric elastomer actuators in soft robotics. Machines 2025, 13, 101. [Google Scholar] [CrossRef]

- Bernat, J.; Bojar, P.; Kula, K.; Krajnik, M.; Krysicki, T. Review of soft actuators controlled with electrical stimuli: IPMC, DEAP, and MRE. Appl. Sci. 2023, 13, 1651. [Google Scholar] [CrossRef]

- Kovacs, G.; Düring, L.; Michel, S.; Terrasi, G. Stacked dielectric elastomer actuator for tensile force transmission. Sens. Actuators A Phys. 2009, 155, 299–307. [Google Scholar] [CrossRef]

- Wingert, A.; Lichter, M.D.; Dubowsky, S. On the design of large degree-of-freedom digital mechatronic devices based on bistable dielectric elastomer actuators. IEEE/ASME Trans. Mechatron. 2006, 11, 448–456. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, H.; Mao, J.; Chirarattananon, P.; Helbling, E.F.; Hyun, N.-S.P.; Clarke, D.R.; Wood, R.J. Controlled flight of a microrobot powered by soft artificial muscles. Nature 2019, 575, 324–329. [Google Scholar] [CrossRef]

- Cheng, Z.-Y.; Zhang, Q.M.; Bharti, V.; Xu, H.S.; Xia, F. Electrostrictive poly (vinylidene fluoride-trifluoroethylene) copolymers. Sens. Actuators A Phys. 2001, 90, 138–147. [Google Scholar] [CrossRef]

- Mazzolai, B.; Margheri, L.; Cianchetti, M.; Dario, P.; Laschi, C. Soft-robotic arm inspired by the octopus: II. From artificial requirements to innovative technological solutions. Bioinspir. Biomim. 2012, 7, 025005. [Google Scholar] [CrossRef]

- Li, M.; Pal, A.; Aghakhani, A.; Pena-Francesch, A.; Sitti, M. Soft actuators for real-world applications. Nat. Rev. Mater. 2022, 7, 235–249. [Google Scholar] [CrossRef]

- Ankit, N.; Ho, T.Y.K.; Nirmal, A.; Kulkarni, M.R.; Accoto, D.; Mathews, N. Soft actuator materials for electrically driven haptic interfaces. Adv. Intell. Syst. 2021, 4, 2100061. [Google Scholar] [CrossRef]

- Park, J.; Lee, Y.; Cho, S.; Choe, A.; Yeom, J.; Ro, Y.G.; Kim, J.; Kang, D.; Lee, S.; Ko, H. Soft sensors and actuators for wearable Human–Machine interfaces. Chem. Rev. 2024, 124, 1464–1534. [Google Scholar] [CrossRef]

- Gupta, A.; Mukherjee, S. 10 - Ionic polymer–metal composites: Smart multifunctional properties and applications in an underwater environment. Nanocomposite Manufacturing Technologies 2025, 227–241. [Google Scholar] [CrossRef]

- Thalman, C.; Artemiadis, P. A review of soft wearable robots that provide active assistance: Trends, common actuation methods, fabrication, and applications. Wearable Technol. 2020, 1, e3. [Google Scholar] [CrossRef]

- Wang, Y. A Comprehensive Survey of Ionic Polymer–Metal Composite Transducers: Preparation, Performance Optimization and Applications. Soft Sci. 2023, 3, 9. [Google Scholar] [CrossRef]

- Majidi, C. Soft Robotics: A Perspective—Current Trends and Prospects for the Future. Soft Robot. 2014, 1, 5–11. [Google Scholar] [CrossRef]

- Kim, D.; Kim, S.-H.; Kim, T.; Kang, B.B.; Lee, M.; Park, W.; Ku, S.; Kim, D.; Kwon, J.; Lee, H.; et al. Review of machine learning methods in soft robotics. PLoS ONE 2021, 16, e0246102. [Google Scholar] [CrossRef]

- Turabimana, P.; Sohn, J.W.; Choi, S.-B. Design and Control of a Shape Memory Alloy-Based Idle Air Control Actuator for a Mid-Size Passenger Vehicle Application. Appl. Sci. 2024, 14, 4784. [Google Scholar] [CrossRef]

- Lai, J.; Song, A.; Shi, K.; Ji, Q.; Lu, Y.; Li, H. Design and Evaluation of a Bidirectional Soft Glove for Hand Rehabilitation-Assistance Tasks. IEEE Trans. Med. Robot. Bionics 2023, 5, 730–740. [Google Scholar] [CrossRef]

- Sun, B.; Li, W.; Wang, Z.; Zhu, Y.; He, Q.; Guan, X.; Dai, G.; Yuan, D.; Li, A.; Cui, W.; et al. Recent Progress in Modeling and Control of Bio-Inspired Fish Robots. J. Mar. Sci. Eng. 2022, 10, 773. [Google Scholar] [CrossRef]

- García-Córdova, F.; Guerrero-González, A.; Hidalgo-Castelo, F. Bioinspired control architecture for adaptive and resilient navigation of unmanned underwater vehicle in monitoring missions of submerged aquatic vegetation meadows. Biomimetics 2024, 9, 329. [Google Scholar] [CrossRef]

- Lodh, T.; Le, H. An Ultra High Gain Converter for Driving HASEL Actuator Used in Soft Mobile Robots. Biomimetics 2023, 8, 53. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, J.; Li, R.; Gu, X.; Zhang, Y.; Zhu, J.; Zhang, W. Design and Prototype Testing of a Smart SMA Actuator for UAV Foldable Tail Wings. Actuators 2024, 13, 499. [Google Scholar] [CrossRef]

- Kashef Tabrizian, S.; Cedric, F.; Terryn, S.; Vanderborght, B. SMA Wire Use in Hybrid Twisting and Bending/Extending Soft Fiber-Reinforced Actuators. Actuators 2024, 13, 125. [Google Scholar] [CrossRef]

- Du, B.; Tang, C.; Jiang, S.; Wang, Y.; Liu, X.-J.; Zhao, H. High-Speed Rotary Motor for Multidomain Operations Driven by Resonant Dielectric Elastomer Actuators. Adv. Intell. Syst. 2023, 5, 2300243. [Google Scholar] [CrossRef]

- Liu, Y.; Ming, P.; Chen, J.; Jing, C. Experimental Analysis of IPMC Optical-Controlled Flexible Driving Performance under PLZT Ceramic Configuration. Sensors 2024, 24, 5650. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Zhang, C.; Zhang, Y.; Yang, L.; Tan, W.; Qin, H.; Wang, F.; Liu, L. Fast-Swimming Soft Robotic Fish Actuated by Bionic Muscle. Soft Robot. 2024, 11, 845–856. [Google Scholar] [CrossRef] [PubMed]

- Ege, E.S.; Balikci, A. Transparent Localized Haptics: Utilization of PVDF Actuators on Touch Displays. Actuators 2023, 12, 289. [Google Scholar] [CrossRef]

- Jafferis, N.T.; Helbling, E.F.; Karpelson, M.; Wood, R.J. Untethered flight of an insect-sized robot with flapping wings. Nature 2019, 570, 491–495. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).